Method for constructing roadbed

A construction method and roadbed technology, applied in roads, roads, buildings, etc., can solve problems such as prolonging construction period, increasing project cost, and difficulty in taking soil, so as to improve consolidation strength, prolong service life, and improve overall stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

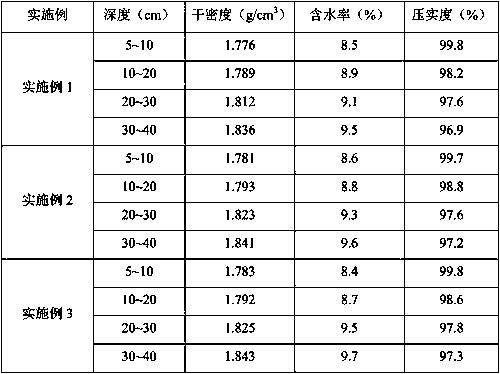

Embodiment 1

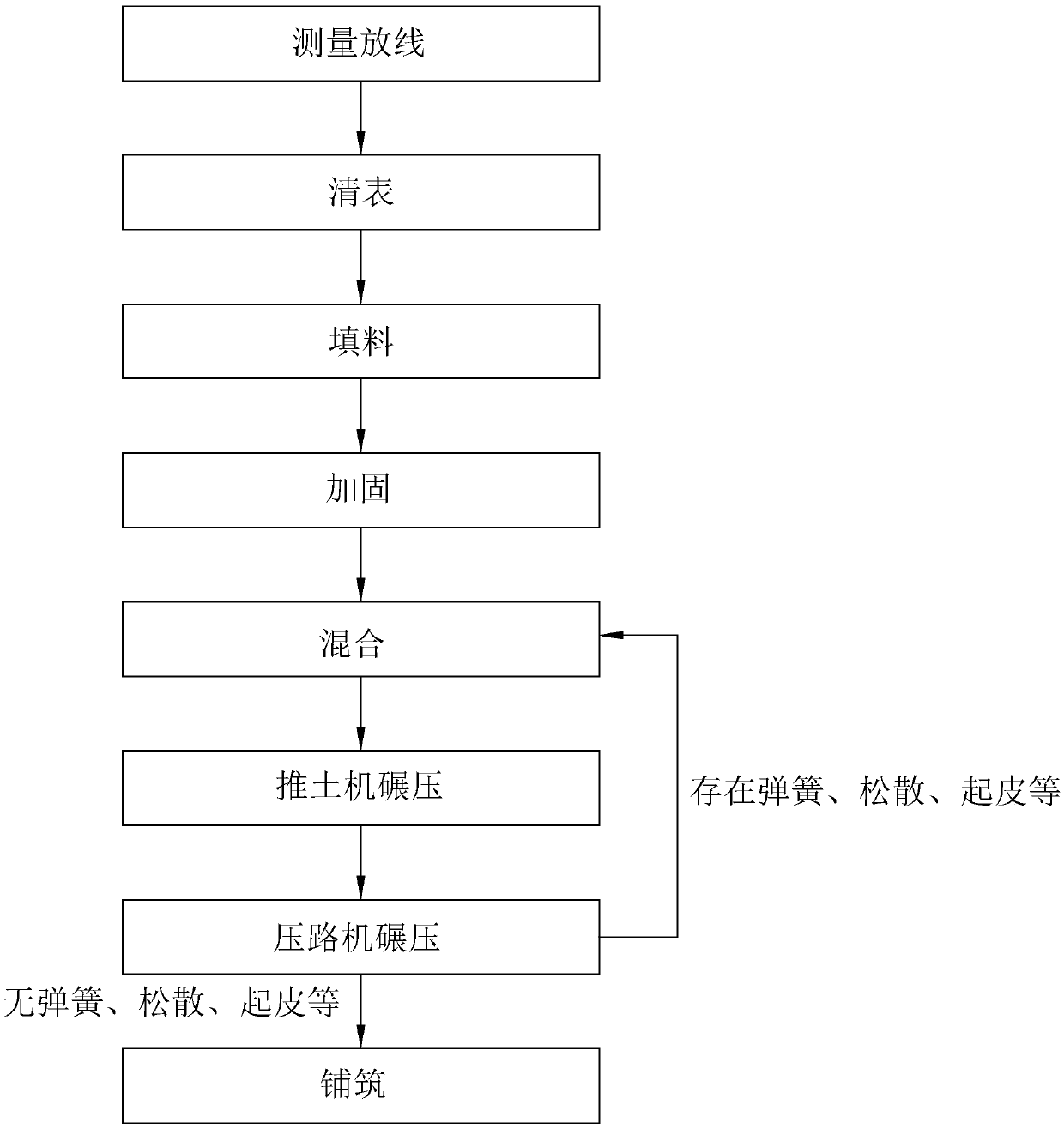

[0040] The specific construction method is as follows: a roadbed construction method is provided, including the following steps:

[0041] (1) Measurement and setting out: mark the area to be constructed, and the two sides of the roadbed need to exceed the design standard width of the roadbed by 0.5 meters.

[0042] (2) Lay the bottom layer: Remove the debris on the original road surface and level the surface; pave a 20cm gravel soil layer or gravel soil layer on the leveled surface, and roll it as the construction surface after leveling.

[0043] (3) Packing: Calculate the paving area of each vehicle according to the transportation volume of the dump truck and the loose paving thickness of the fine sand, use a ruler to draw the line, draw the network white grid of the paving area, and use the dump truck to press the fine sand according to the grid Reverse unloading, so that the dump truck always walks on the gravel soil layer or gravel soil layer; every time a truck of fine ...

Embodiment 2

[0055] The specific construction method is as follows: a roadbed construction method is provided, including the following steps:

[0056] (1) Measurement and setting out: mark the area to be constructed, and the two sides of the roadbed need to exceed the design standard width of the roadbed by 0.6 meters.

[0057] (2) Lay the bottom layer: Remove the debris on the original road surface and level the surface; pave a 30cm gravel soil layer or gravel soil layer on the leveled surface, and roll it as the construction surface after leveling.

[0058] (3) Packing: Calculate the paving area of each vehicle according to the transportation volume of the dump truck and the loose paving thickness of the fine sand, use a ruler to draw the line, draw the network white grid of the paving area, and use the dump truck to press the fine sand according to the grid Reverse unloading, so that the dump truck always walks on the gravel soil layer or gravel soil layer; every time a truck of fine ...

Embodiment 3

[0070] The specific construction method is as follows: a roadbed construction method is provided, including the following steps:

[0071] (1) Measurement and setting out: mark the area to be constructed, and the two sides of the roadbed need to exceed the design standard width of the roadbed by 0.8 meters.

[0072] (2) Lay the bottom layer: Remove the debris on the original road surface and level the surface; pave a 30cm gravel soil layer or gravel soil layer on the leveled surface, and roll it as the construction surface after leveling.

[0073] (3) Packing: Calculate the paving area of each vehicle according to the transportation volume of the dump truck and the loose paving thickness of the fine sand, use a ruler to draw the line, draw the network white grid of the paving area, and use the dump truck to press the fine sand according to the grid Reverse unloading, so that the dump truck always walks on the gravel soil layer or gravel soil layer; every time a truck of fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com