Modified resin sand consolidation agent as well as preparation method and application thereof

A technology of modified resin and sand-fixing agent, applied in chemical instruments and methods, earth-moving drilling, and fluid production, etc., can solve the problems of oil well sand production affecting production, downhole screen blockage, pump stuck, etc., and the initial solidification time can be reached. Controllable, high consolidation strength, small formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Composition and preparation of the modified resin sand consolidation agent of the present embodiment:

[0052] Main agent: E-51 epoxy resin produced by Hangzhou Wuhuigang Adhesive Co., Ltd. (epoxy equivalent 185-200g / eq; epoxy value 0.48-0.54eq / mg; viscosity 10000-25000Pa·S / 25℃), 100 parts by weight;

[0053] Curing agent: ethylenediamine, 6.4 parts by weight;

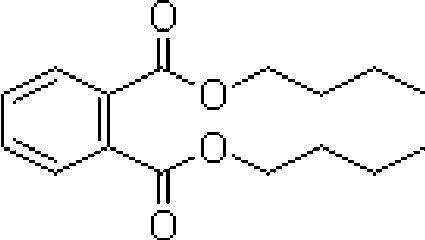

[0054] Softening agent: dibutyl ester, 15 parts by weight;

[0055] Diluent: acetone, 22 parts by weight;

[0056] Silane coupling agent: γ-(2,3-glycidoxy)propyltrimethoxysilane, 2 parts by weight.

[0057] Glass fiber: 2-3 mm in length, about 20 μm in diameter, 10 parts by weight;

[0058] Heat the above main agent epoxy resin until the fluidity becomes better, add diluent, and stir fully; then add softener and coupling agent in turn, stir fully; add curing agent, stir rapidly; and add glass fiber under stirring, Stir evenly to obtain the modified resin sand consolidation agent of the present invention.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com