Patents

Literature

141results about How to "Enough contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

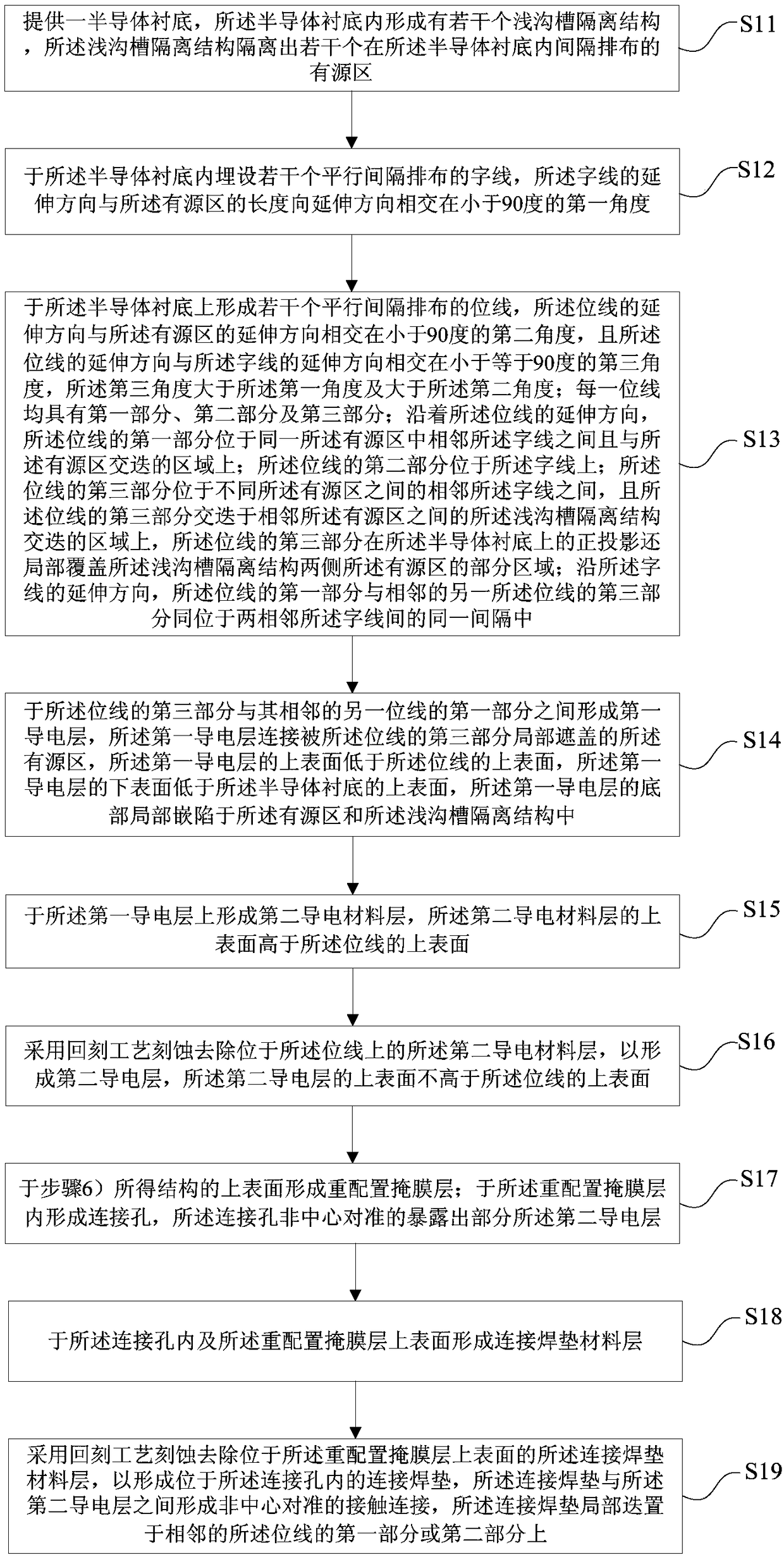

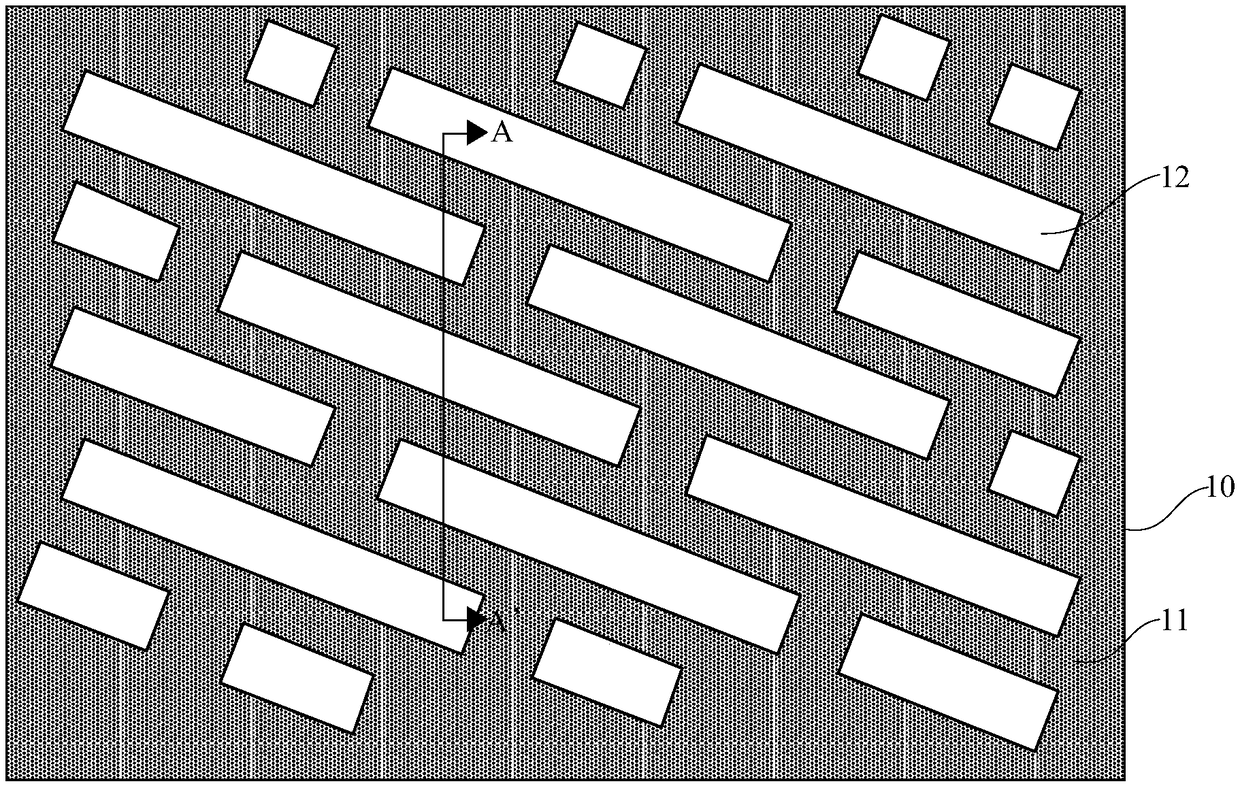

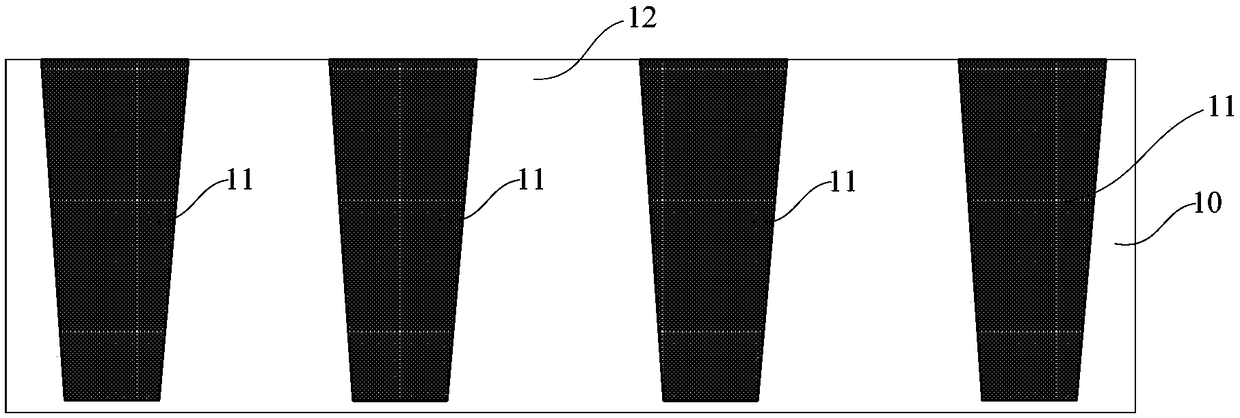

Semiconductor contact structure, memory structure and preparation method

PendingCN109003938AImproved Bridging ToleranceEnough contact areaTransistorSemiconductor/solid-state device manufacturingConductive materialsSemiconductor

The invention provides a semiconductor contact structure, a memory structure and a preparation method thereof. The preparation method of the memory structure comprises the following steps: 1) providing a semiconductor substrate; 2) a plurality of word lines are formed at parallel intervals in that semiconductor substrate; 3) bury a plurality of bit lines arrange at parallel intervals on that semiconductor substrate; 4) for a first conductive layer on that bit line; 5) for a second conductive material layer on that first conductive lay; 6) etch that second conductive material layer to form a second conductive lay by adopting a back etching process; 7) for a reconfiguration mask layer on that upper surface of the structure obtain in the step 6); Forming connection holes in the reconfigured mask layer; 8) for a connection pad material layer in that connection via hole and on the upper surface of the reconfigured mask layer; 9) etching the connection pad material lay to form a connection pad by adopting a etching-back process. The invention can improve the contact resistance of the connection pad and the bridging tolerance between the connection pads.

Owner:CHANGXIN MEMORY TECH INC

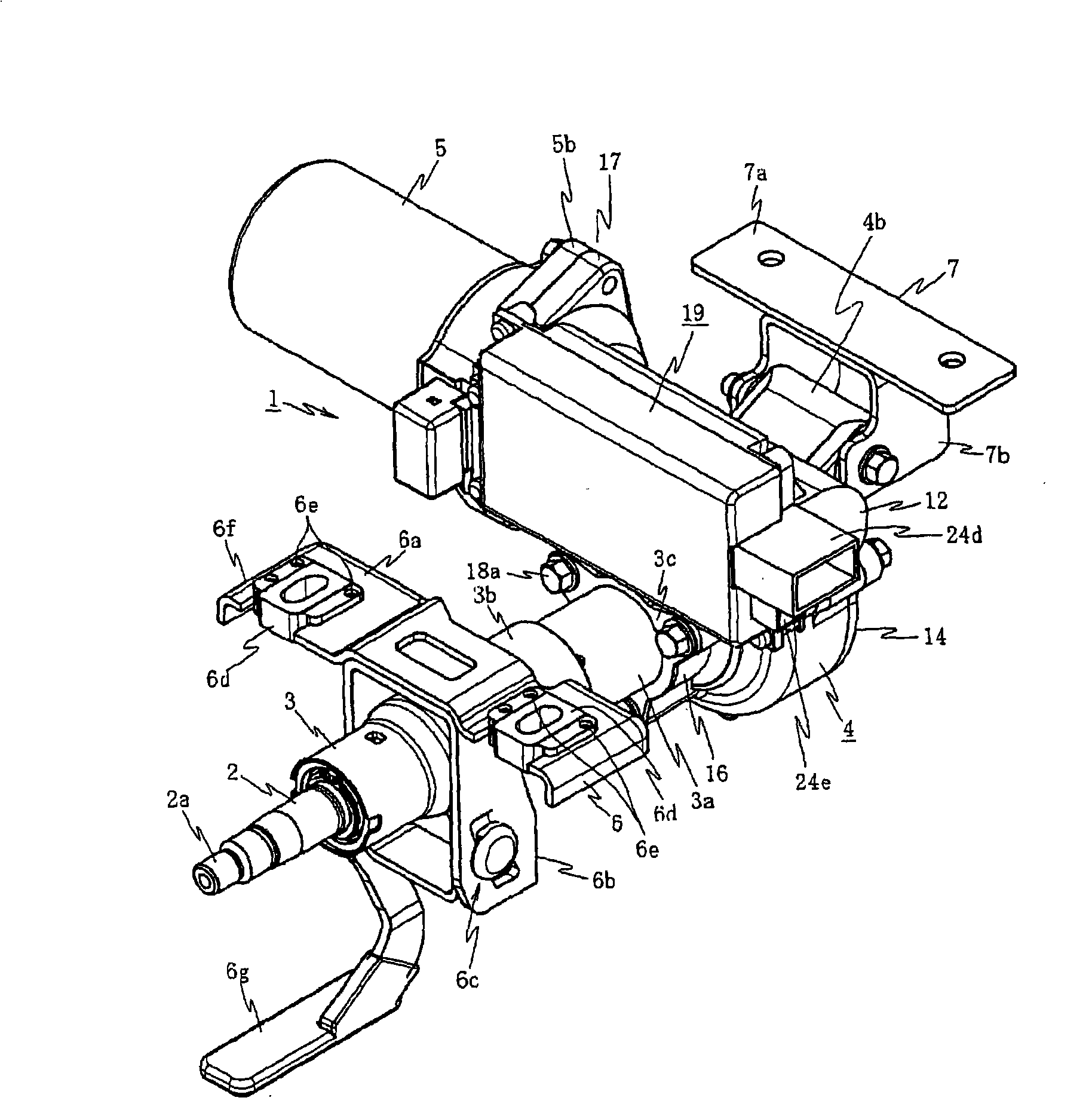

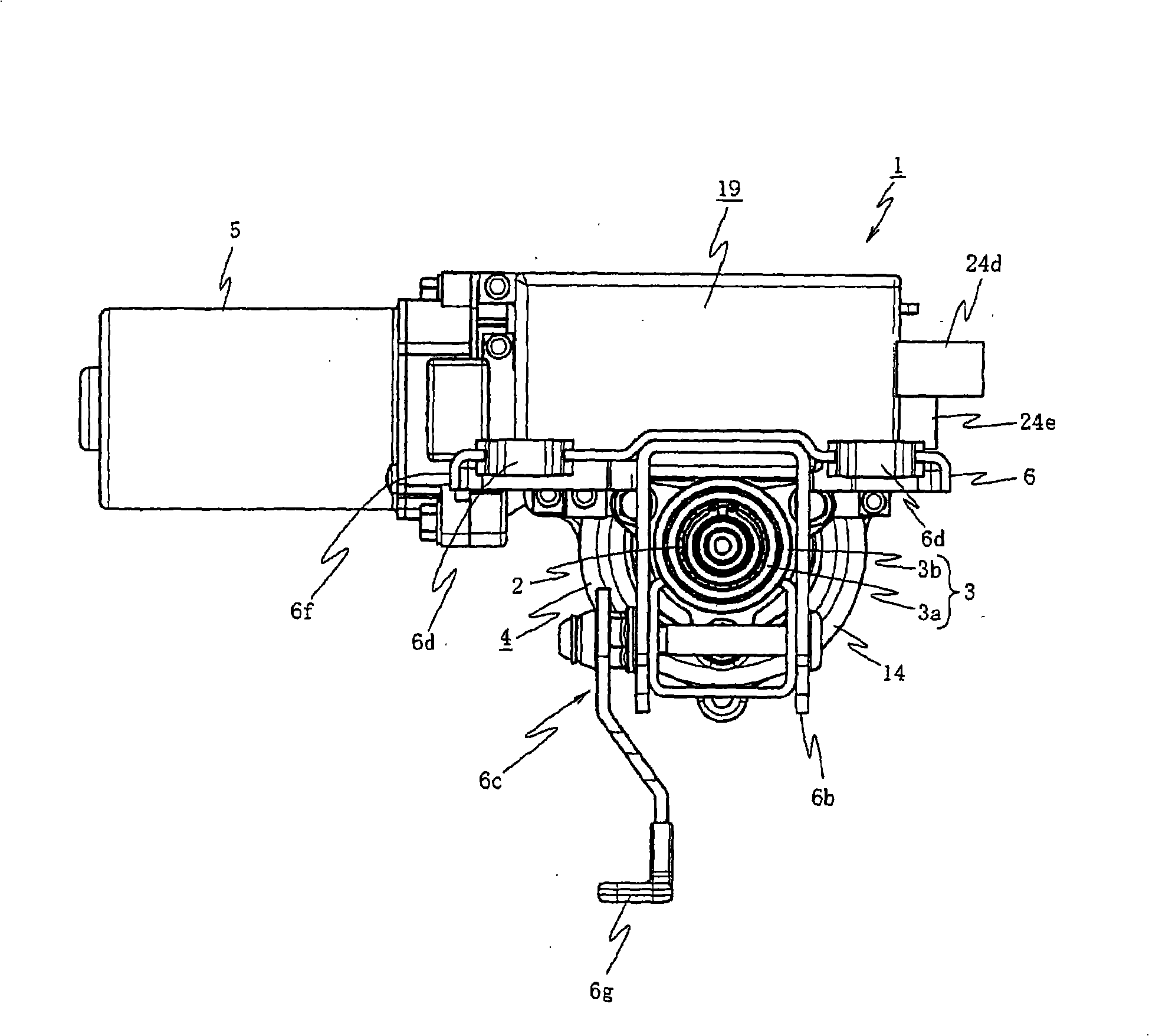

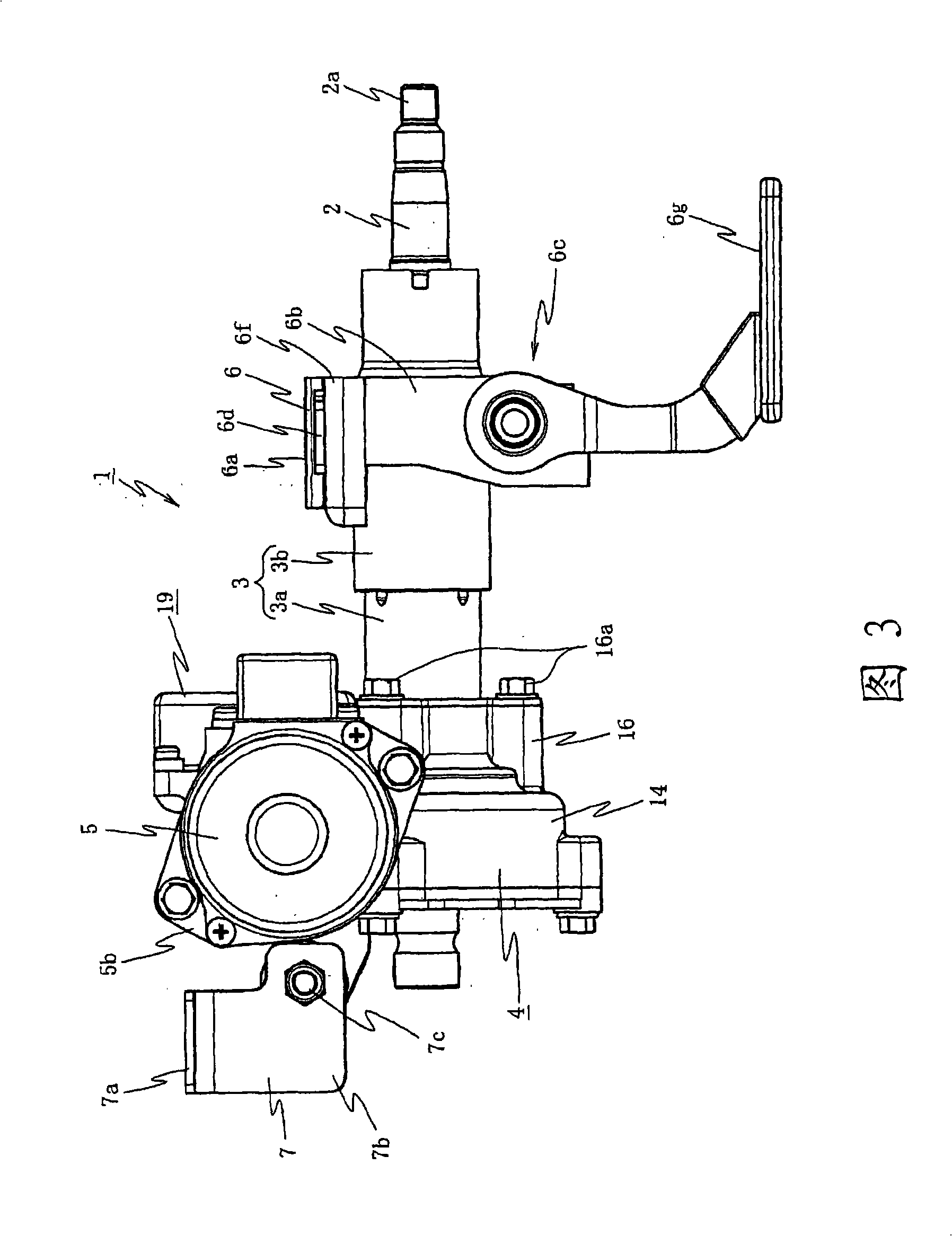

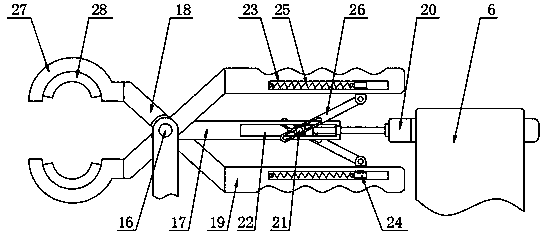

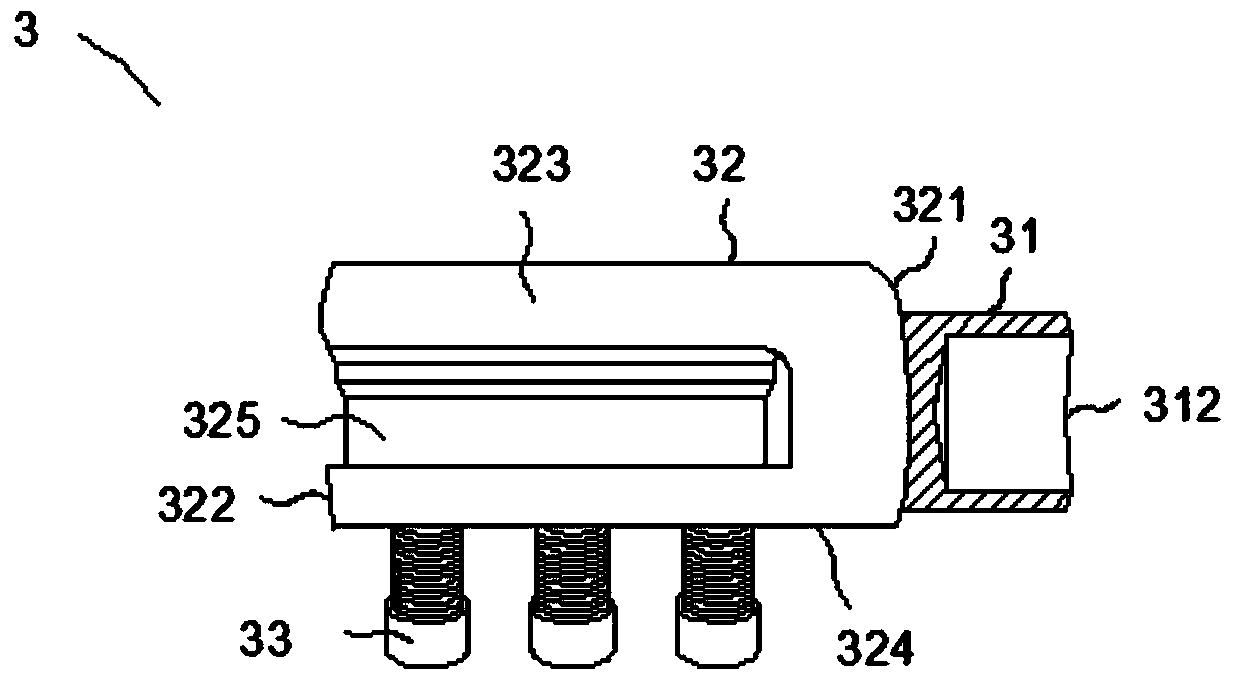

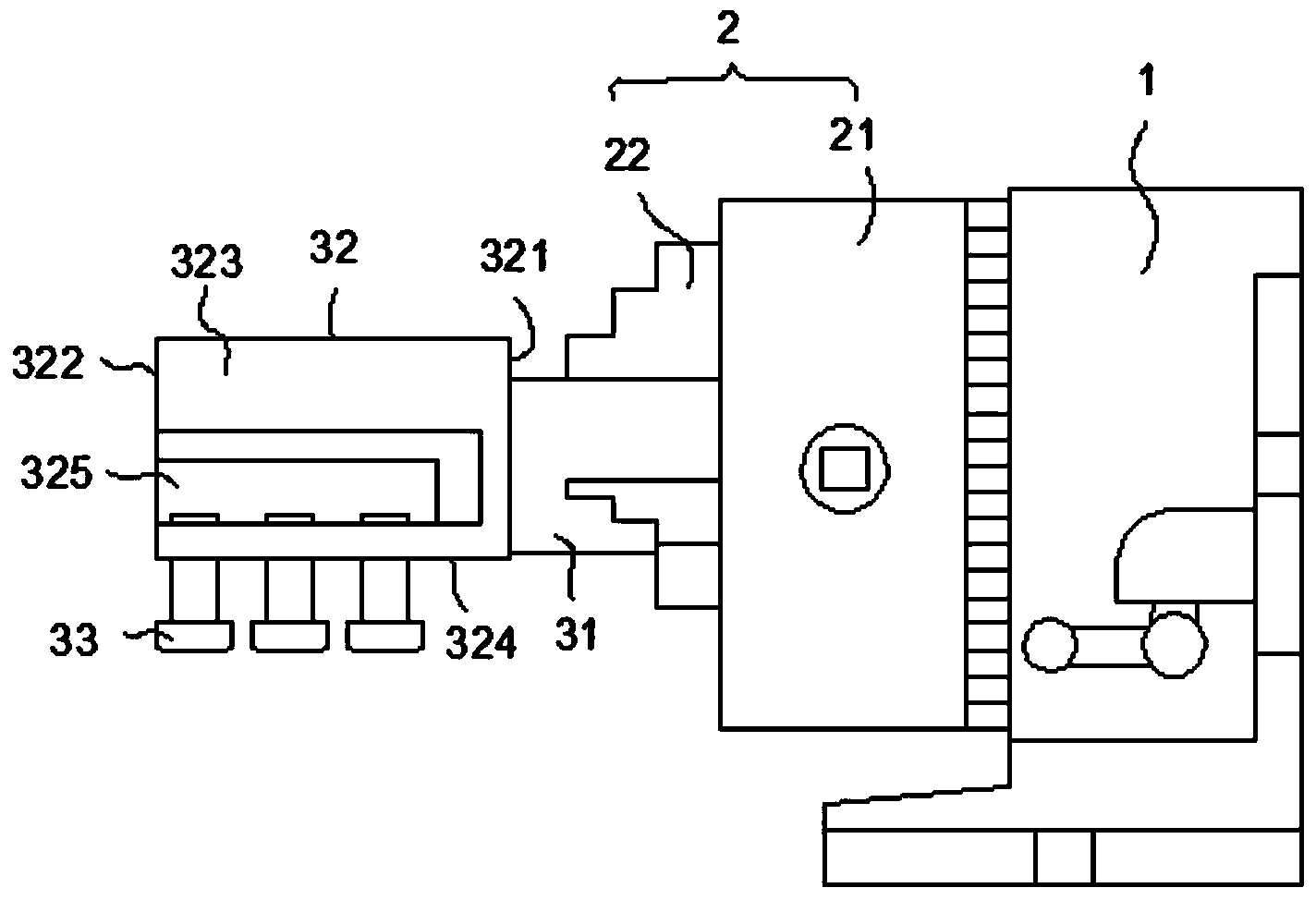

Electric power steering device and method of assembling the same

InactiveCN101410289AAvoid mixingShort electrical connection lengthToothed gearingsSteering columnsElectrical resistance and conductanceElectric power steering

To provide an electric power steering apparatus in which it is possible to minimize a connection distance between a control unit and an electric motor and surely prevent electric noise from mixing between the control unit and the electric motor as well as to minimize electric resistance and minimize an electric loss by directly connecting the control unit and connection terminals of the electric motor and a torque sensor. A motor control apparatus includes a steering column 3 having inserted therein a steering shaft 2 to which steering torque is transmitted, a reduction gear box 4 coupled to the steering shaft 2, and an electric motor 5 that transmits a steering assisting force to the steering shaft 2 via a reduction mechanism in the reduction gear box 4. The electric motor 5 and a control unit 19 including a control board mounted with a control circuit that controls to drive the electric motor 5 are provided side by side in the reduction gear box 4 and a connection terminal of the electric motor 5 is electrically connected to the control unit 19 directly.

Owner:NSK LTD

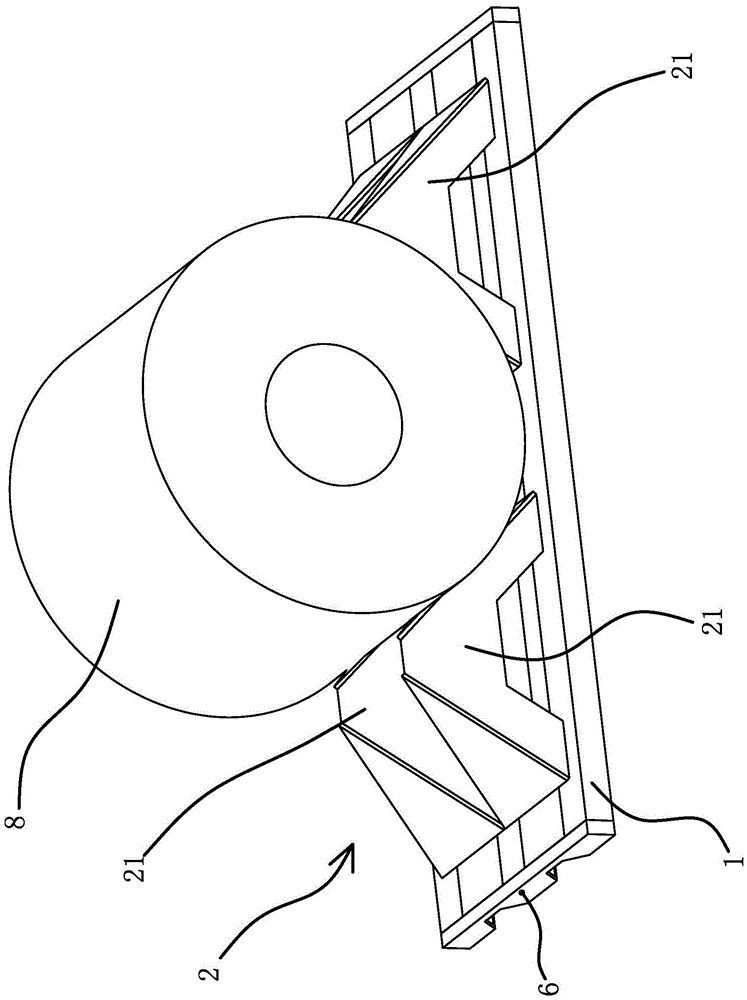

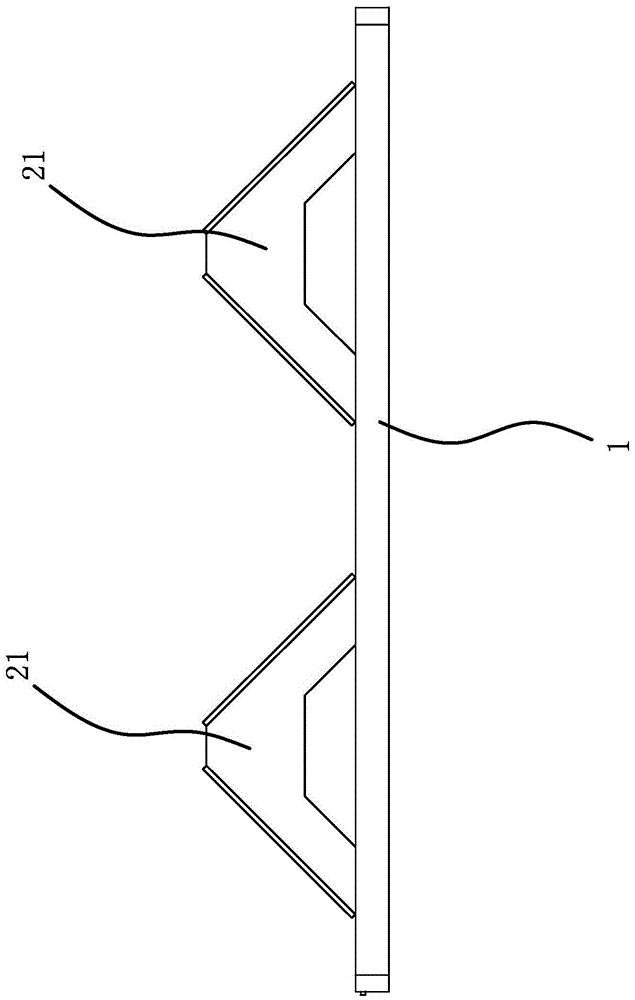

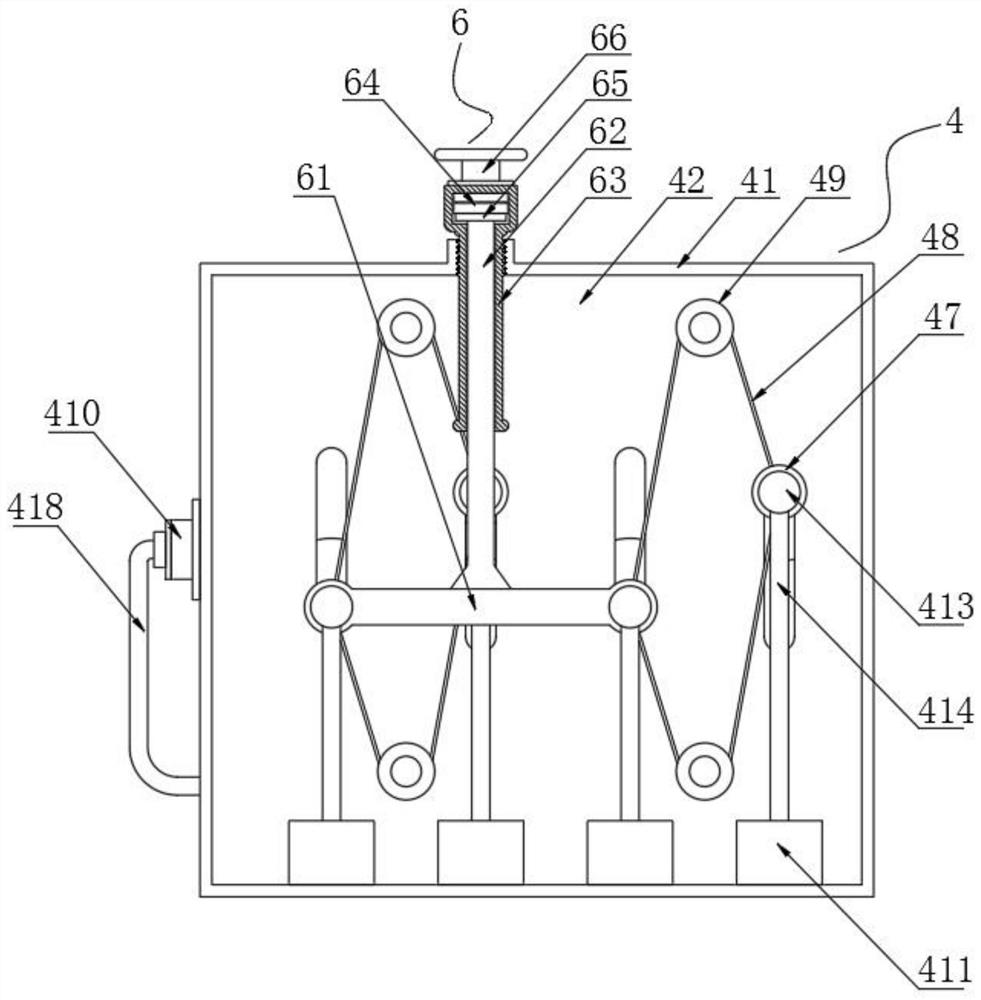

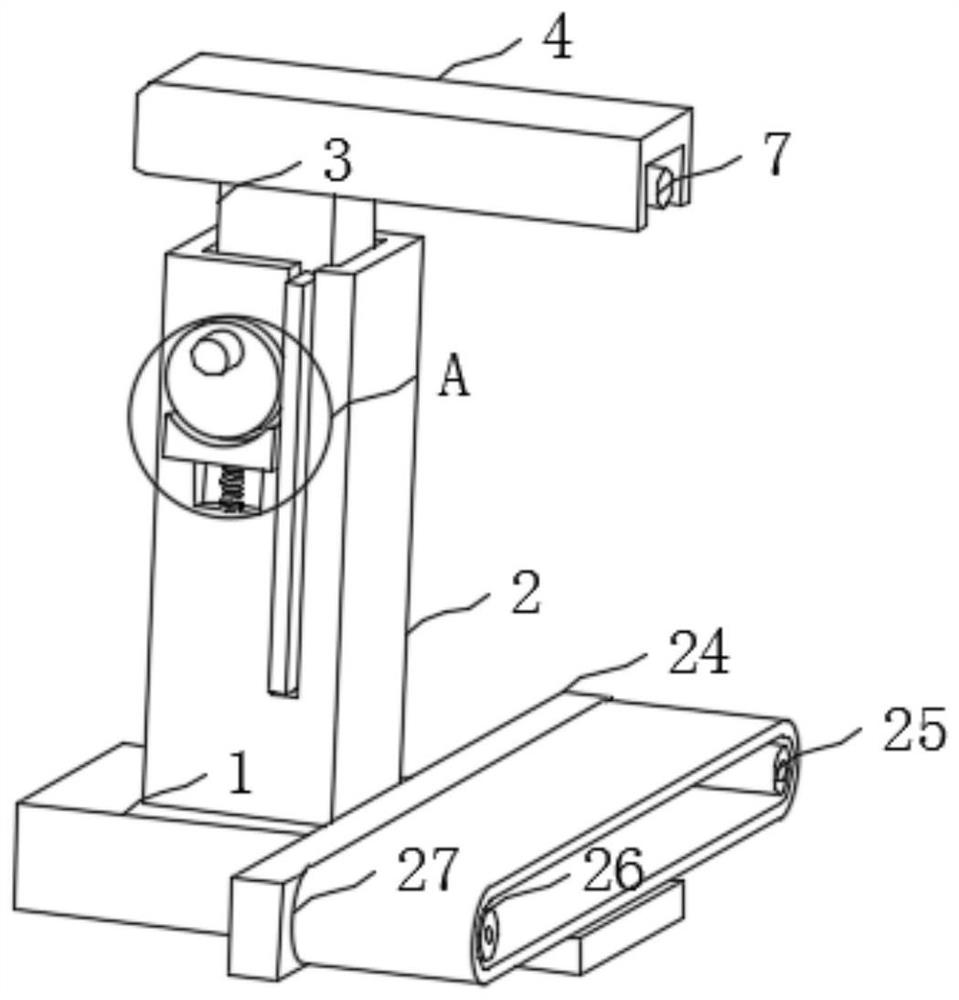

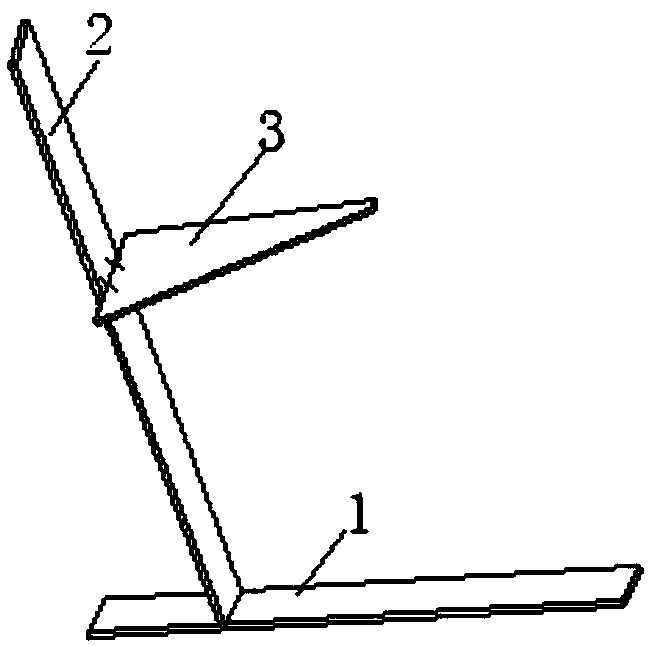

Tray used for steel coil transportation

ActiveCN105600134AEasy to transfer and transportEasy to transportExternal framesRigid containersEngineeringMechanical engineering

The invention provides a tray used for steel coil transportation, and belongs to the technical field of transportation. The tray solves the technical problem that an existing movable tray is not suitable for bearing steel coils. The tray comprises a tray frame and a limiting frame arranged on the tray frame and used for positioning a steel coil. At least two long-strip-shaped installation grooves are formed in the bottom of the tray frame. Long-strip-shaped rolling wheel frames are arranged in the installation grooves. A plurality of rolling wheels are connected to the rolling wheel frames in the length direction of the rolling wheel frame. Guide structures capable of guiding the rolling wheel frames to move up and down relative to the tray frame and limiting structures capable of preventing the rolling wheel frames from being disengaged from the installation grooves are arranged on the portions, located in the installation grooves, on the tray frame. Gas bags are arranged in the installation grooves and located above the rolling wheel frames. The whole rolling wheels can be located in the installation grooves when the gas bags are not inflated. The gas bags can act on the rolling wheel frames to make the rolling wheels stretch out of the installation grooves when the gas bags are inflated and expanded. The tray has the advantage that the steel coil can be stably transported.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

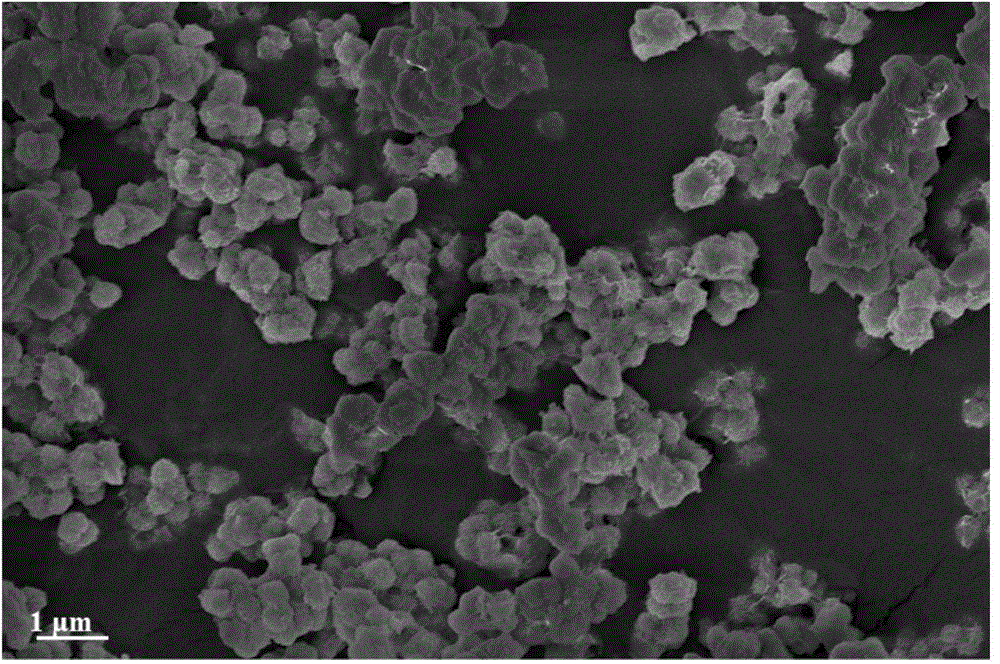

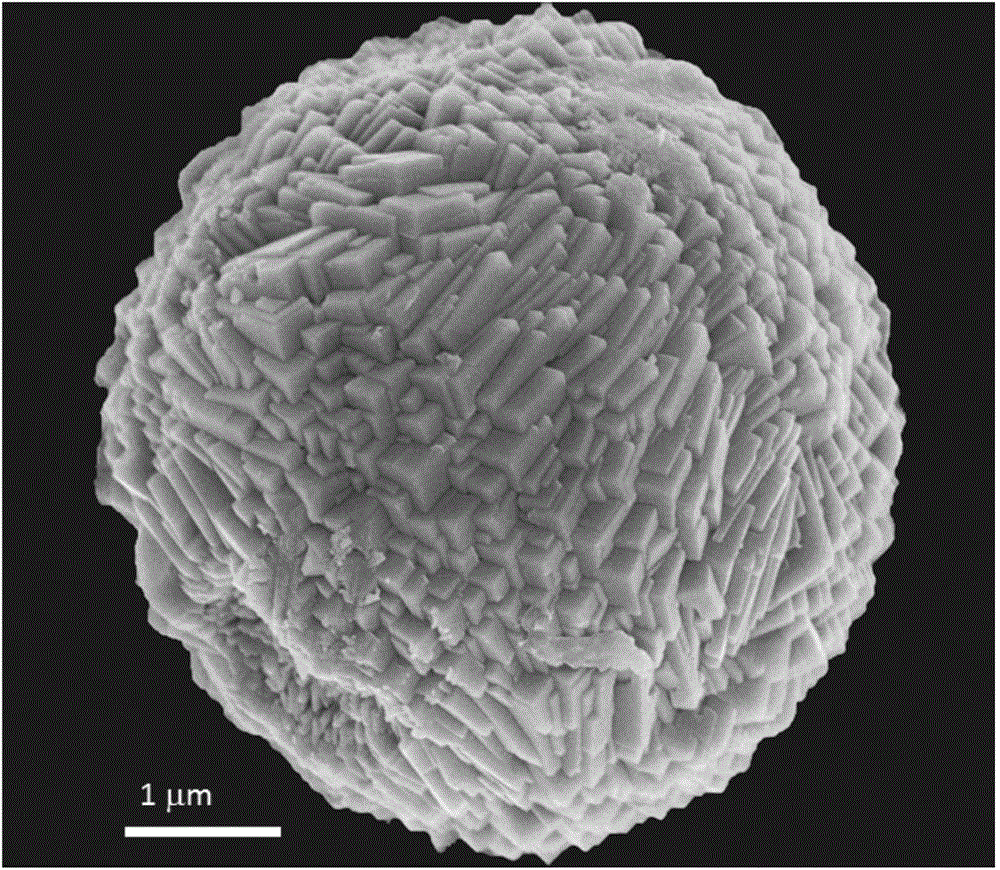

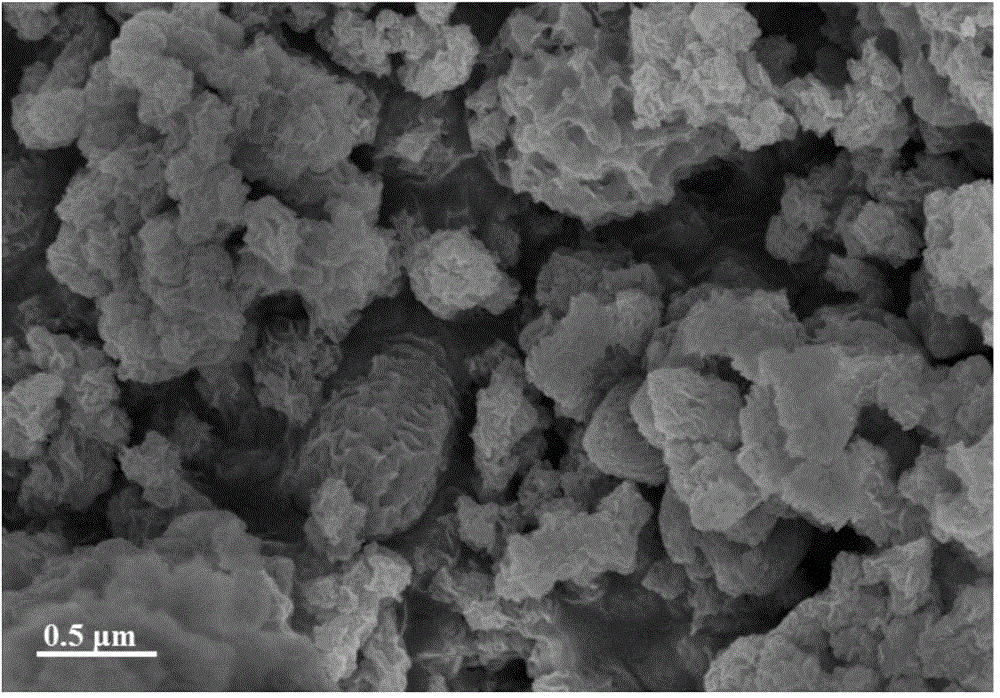

Hollow porous spherical mixed oxide for lithium ion battery negative electrode and preparation method of hollow porous spherical mixed oxide

ActiveCN104466108AEasy to prepareConducive to industrial mass productionCell electrodesNanotechnologyManganeseSpherical shaped

The invention relates to hollow porous spherical mixed oxide for a lithium ion battery negative electrode and a preparation method of the hollow porous spherical mixed oxide. The material is a uniform nano-mixture of Mn2O3 and NiMn2O4, and a specific chemical formula is NixMn<1-x>O<1.5-0.5x> (x is more than 0 and less than 1 / 3). The preparation method of the hollow porous spherical mixed oxide comprises the steps that based on complexing action of ammonia water and nickel ions, the precipitation speed of nickel carbonate is reduced, so that a spherical structure of the manganese carbonate cannot be destroyed by the nickel carbonate and has a certain modification function on a spherical structure of the manganese carbonate to form a uniform spherical mixture (NixMn<1-x>CO3, x is more than 0 and less than 1 / 3) of the nickel carbonate and the manganese carbonate; the prepared hollow porous spherical mixed oxide for the lithium ion battery negative electrode is obtained by using a high-temperature segmental roasting process. Compared with the prior art, the method is easy to operate and suitable for industrial large batch production; by utilizing the hollow porous spherical mixed oxide, the large-current charging / discharging performance of the lithium ion battery negative electrode can be effectively improved, and the and the cycle life of the lithium ion battery negative electrode can be effectively prolonged.

Owner:SHANGHAI JIAO TONG UNIV

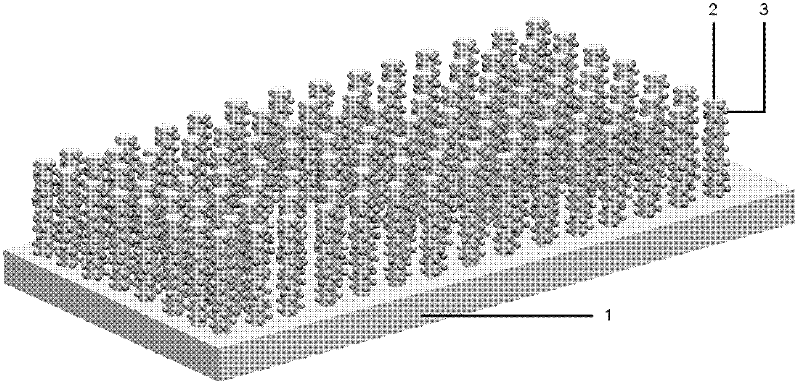

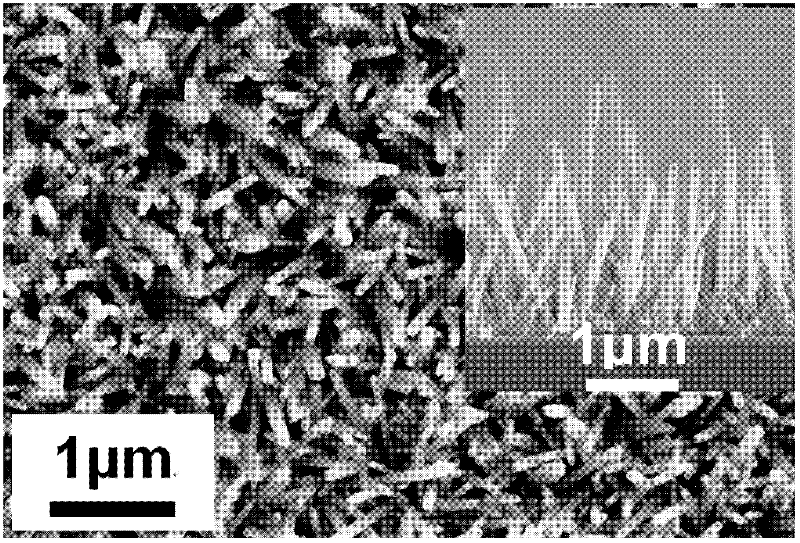

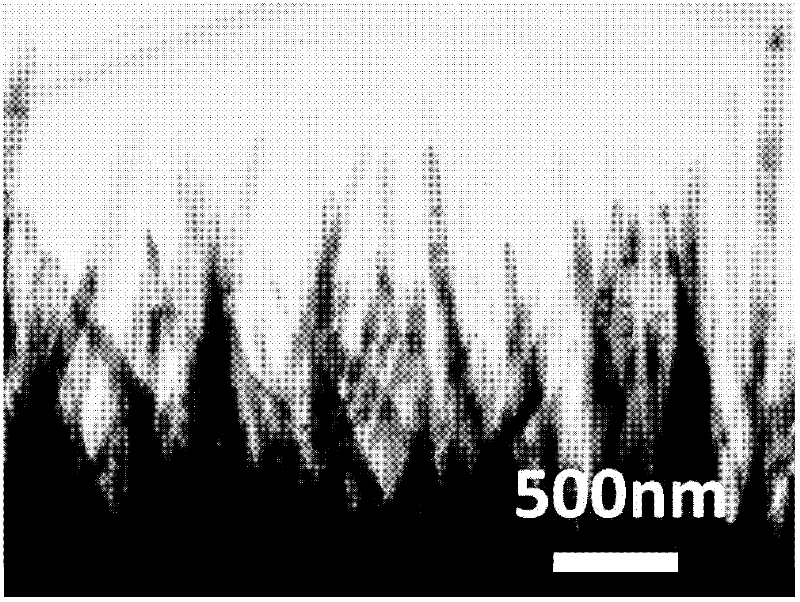

Zinc oxide nanowire array photocatalytic material based on cuprous oxide quantum dot modification and its preparation method and application

InactiveCN102266775AGuaranteed contactEasy to recycleBiocideWater/sewage treatment by irradiationCopper nitrateOxygen

The invention belongs to the technical field of nanometer material application, and specifically relates to a photo-catalytic material based on a zinc oxide nanometer linear array modified with cuprous oxide quantum dots, and a preparation method and application thereof. According to the invention, the zinc oxide nanometer linear array which firmly grows on a conductive substrate is used as a working electrode, a platinum electrode is used as a counter electrode, a saturated calomel electrode is used as a reference electrode, and the dimethyl sulfoxide solution of copper nitrate is used as electrolyte; and an electrochemical cyclic voltammetry method is performed to obtain the photo-catalytic material based on the zinc oxide nanometer linear array modified with the cuprous oxide quantum dots. The photo-catalytic material of the invention is placed in the water solution to be treated; zinc oxide and cuprous copper produce photoelectrons and holes respectively under the irradiation of sunlight; and the photoelectrons and holes can react with dissolved oxygen and hydroxyl ions in water respectively to generate derivatives with strong oxidizability for killing bacteria.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

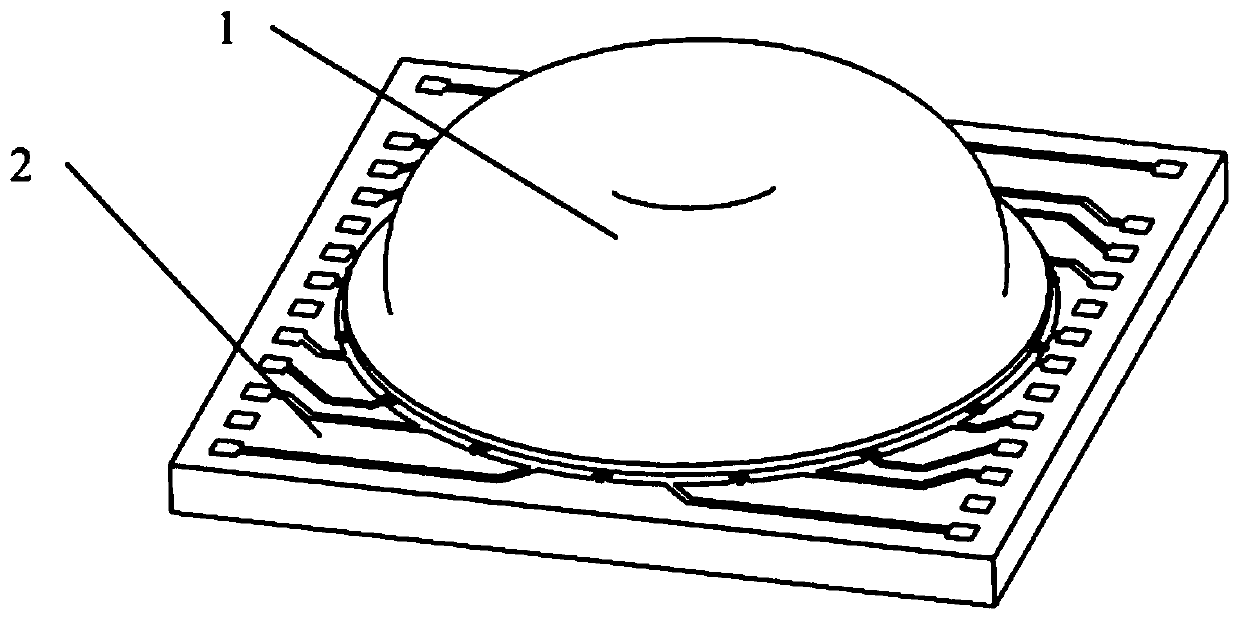

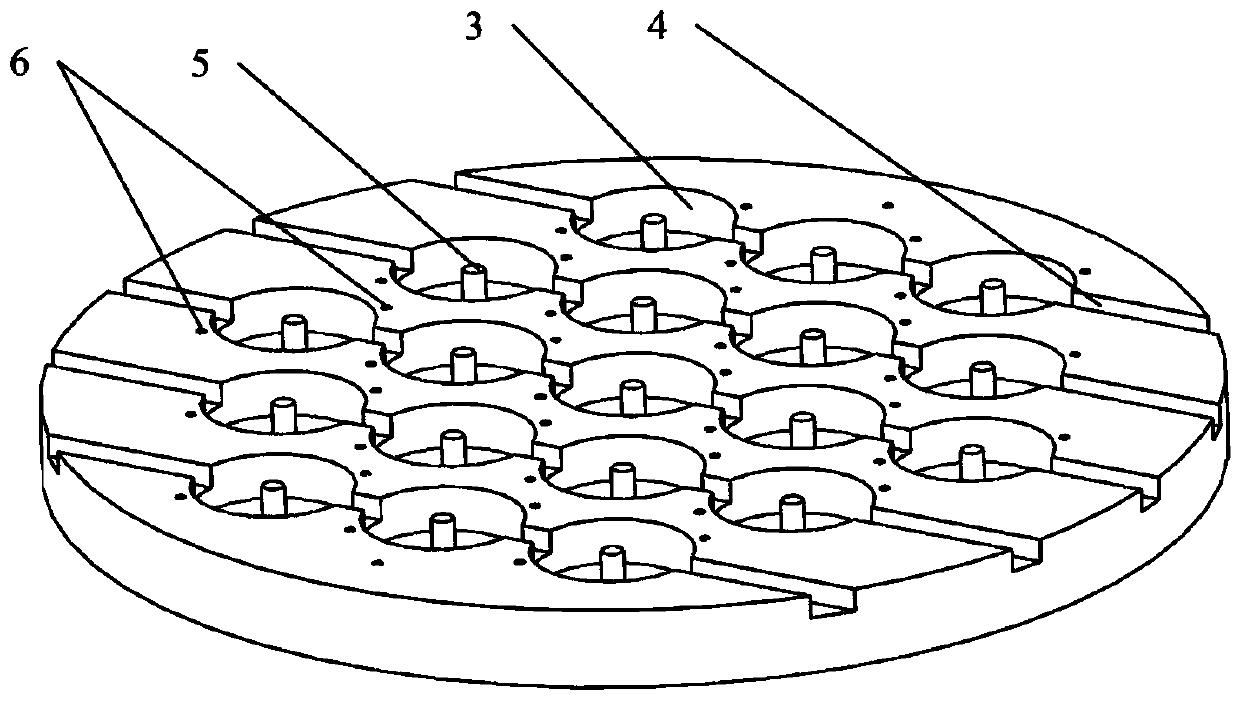

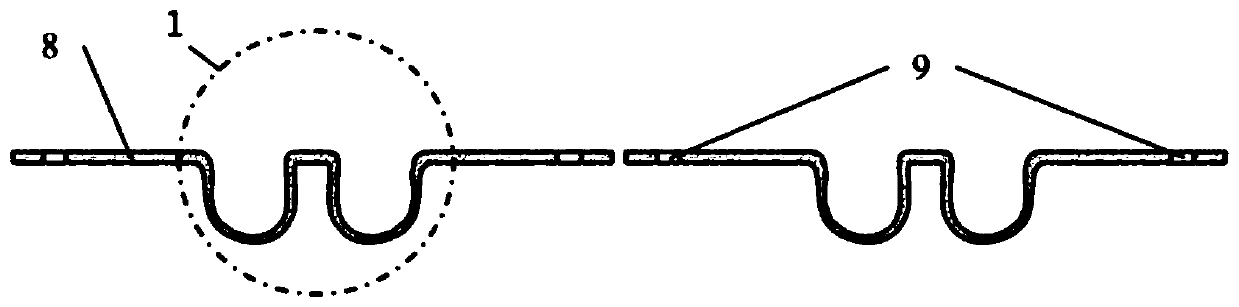

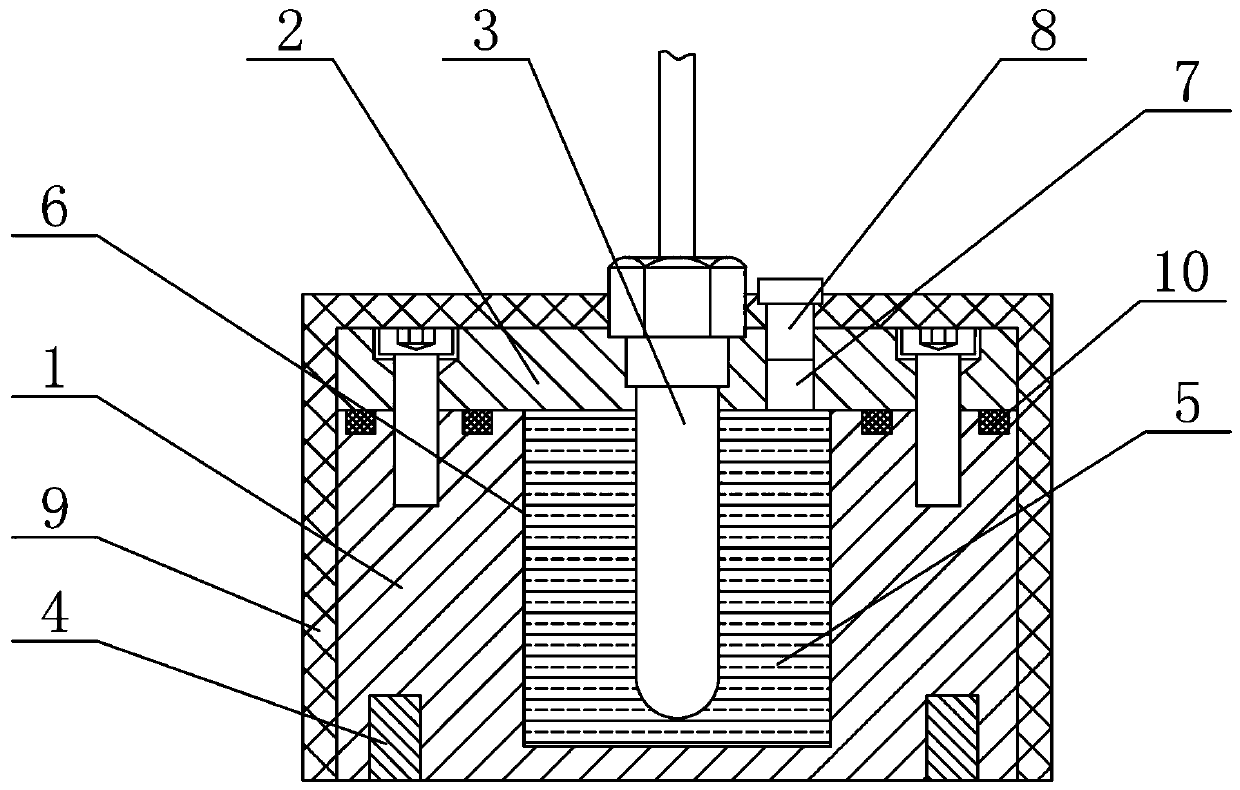

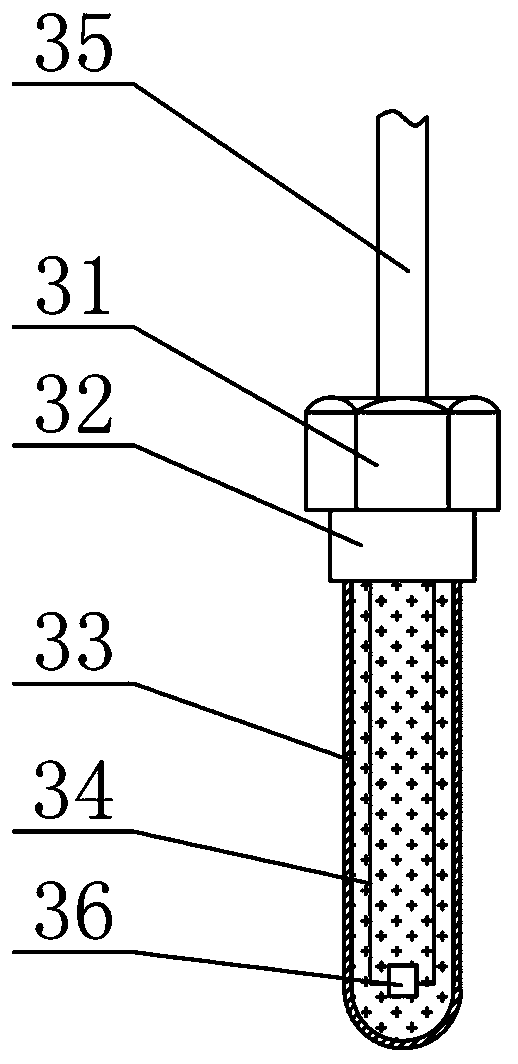

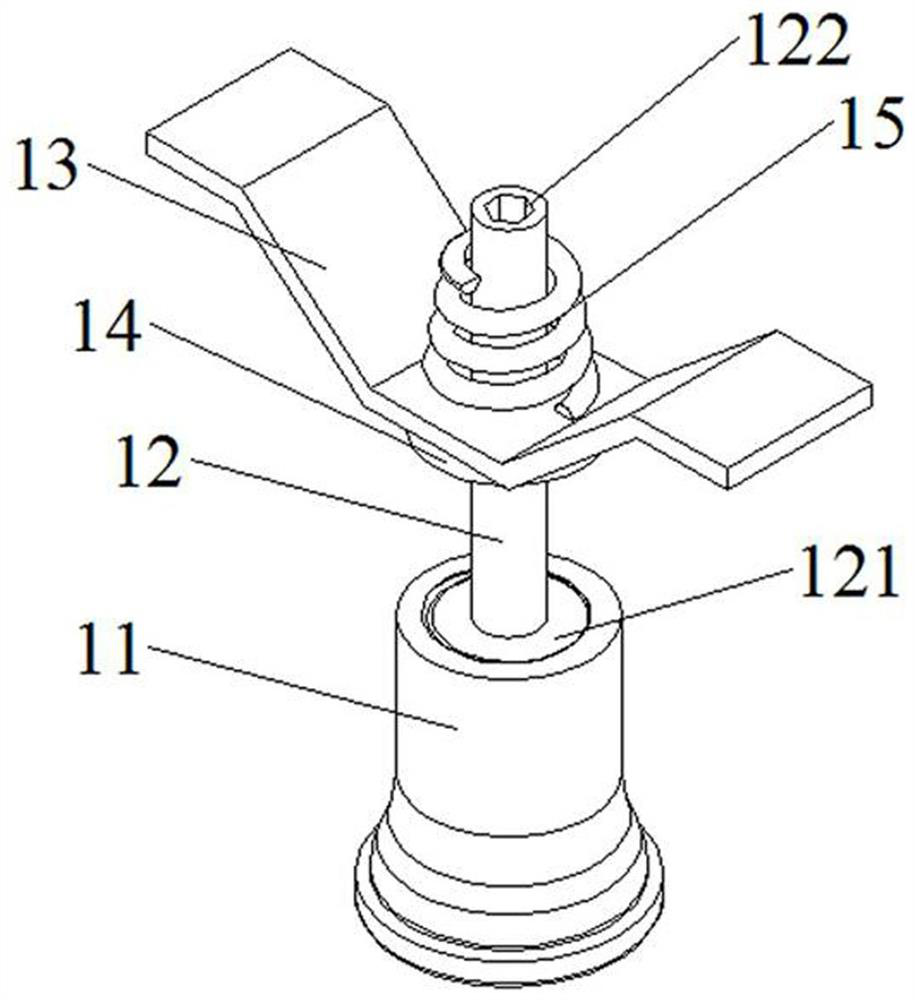

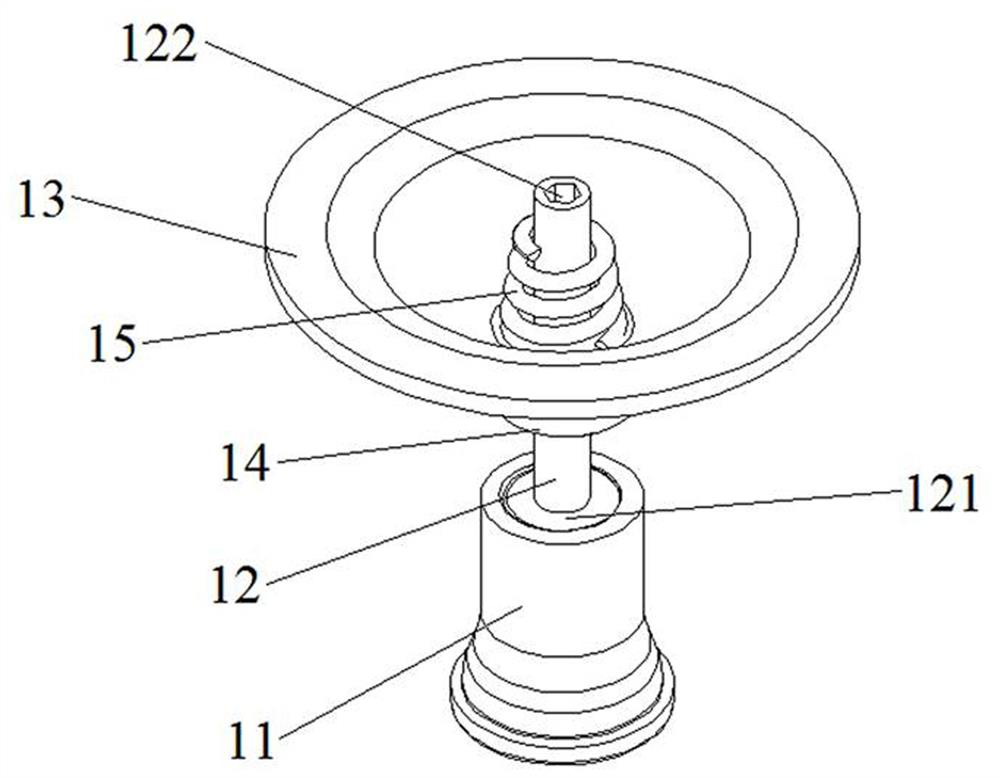

Micro-hemispherical resonator gyro structure, assembly method and wafer fixture

InactiveCN110749315AReduce assembly errorsImprove stabilitySpeed measurement using gyroscopic effectsMicrostructural device assemblyPhysicsResonator

The invention relates to a micro-hemispherical resonator gyro structure, an assembly method and a wafer fixture. The invention discloses a micro-hemispherical resonator gyro structure wafer level assembly method, comprising the following steps: performing high temperature softening deformation machining and forming on independently manufactured glass sheets, then forming a micro-hemispherical resonant structures in the middle of each glass sheet, cutting glass sheet locating holes at the two ends of each glass sheet by adopting laser cutting, and by taking the locating holes as a benchmark, aligning multiple micro-hemispherical resonant structures which are the same and fixing the same micro-hemispherical resonant structures on the wafer fixture; and then performing operations by taking the wafer fixture as a unit, and completing subsequent processes, namely micro-hemispherical resonant structure releasing, surface metallization, fixation with a planar electrode, separation from the wafer fixture as well as cleaning, thus the micro-hemispherical resonator gyro structure driven by the planar electrode at the bottom is obtained. The micro-hemispherical resonator gyro structure waferlevel assembly method disclosed by the invention fixes and mounts multiple independently manufactured micro-hemispherical resonant structures on the same wafer fixture, a wafer level mounting operation is realized, an assembly error of the micro-hemispherical resonator gyro structure can be obviously reduced, stability and consistency of the processes as well as assembly efficiency are improved.

Owner:NAT UNIV OF DEFENSE TECH

Wire and cable processing equipment

ActiveCN110867285AFast processingImprove processing efficiencyFilament handlingCleaning using gasesDust controlElectric machinery

The invention discloses wire and cable processing equipment. The surface of a bottom plate is fixedly connected with a cooling frame, a dust removal box, a power assisting wheel, a first fixing frame,a second fixing frame and a motor fixing frame from left to right. The top of the first fixing frame is fixedly connected with a telescopic air cylinder through a supporting frame; the bottom end ofa piston rod of the telescopic air cylinder penetrates through the top of the first fixing frame and extends to an inner cavity of the first fixing frame; and the inner cavity of the first fixing frame is movably connected with the surface of the piston rod of the telescopic air cylinder. The invention relates to the technical field of cable processing. According to the wire and cable processing equipment, all the structures are matched to carry out cooling, dust removal, cutting and take-up operation on the processed and formed cable in sequence; a plurality of processing flows are integratedand synchronously carried out, so that the processing efficiency is higher, and time required for transportation in each processing procedure is effectively saved; and the wire and cable processing equipment is suitable for processing of large-batch cables, and the processing speed of the processing equipment is increased.

Owner:泰宇电缆实业有限公司

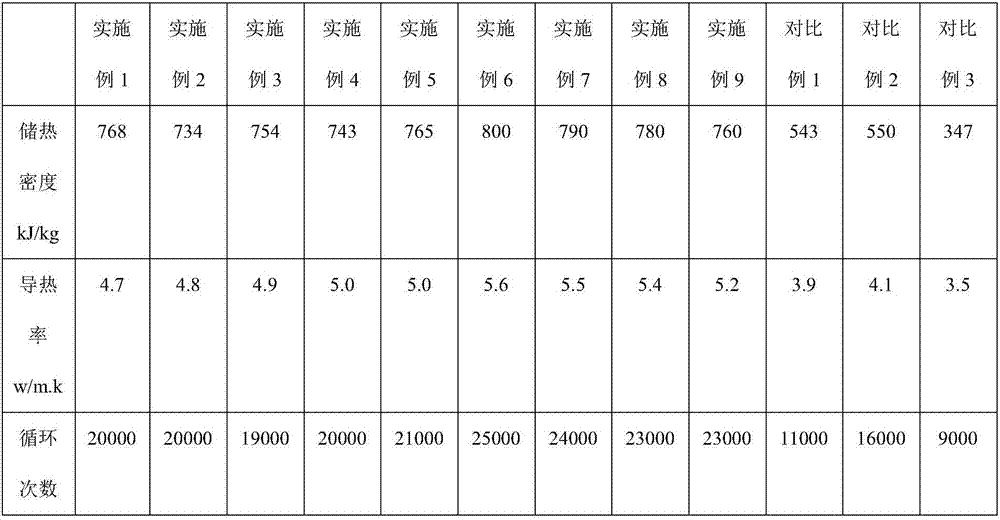

A phase-change heat storage material and a preparing method thereof

ActiveCN107337436AHigh heat storage densityImprove thermal conductivityGranularityHeat storage material

A phase-change heat storage material is provided. The phase-change heat storage material includes carbonate and a ceramic matrix. The granularity of the carbonate is 2-10 [mu]m, and the granularity of the ceramic matrix is 1-10 [mu]m. The phase-change heat storage material has a high heat storage density and high thermal conductivity, the heat storage density of the material can be 700 kJ / kg or above, and the thermal conductivity of the material can be 4.5 w / m.k or above. The number of times of cyclic use of the material is greatly increased and can be 19000 or above.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Antibacterial 3D printing material for medical products

InactiveCN107118502AImprove antibacterial propertiesWell mixedAdditive manufacturing apparatusMedical productAntimony trioxide

The invention discloses an antibacterial 3D printing material for medical products, which comprises the following raw materials: ABS resin, organic fluorinated epoxy, acrylic resin, urea-formaldehyde resin, polyhydroxybutyrate, antibacterial reinforcer, modified zeolite, calcium molybdate, calcined whiting powder, zeolite powder, nitrocotton, zinc phosphate, bentonite, antimony trioxide, zinc oxide, seaweed meal, diatomite, antimony trioxide, zirconium oxide, aluminum sulfate, aluminum oxide, hydroxyethyl cellulose (HEC), lauryl acrylate, trimethyl phosphate, acrylonitrile, silane coupling agent KH-560, sulfonated oil, an antifoamer, and a modifying additive. The antibacterial 3D printing material disclosed by the invention has excellent antibacterial property.

Owner:HEFEI SKE INTELLIGENT TECH

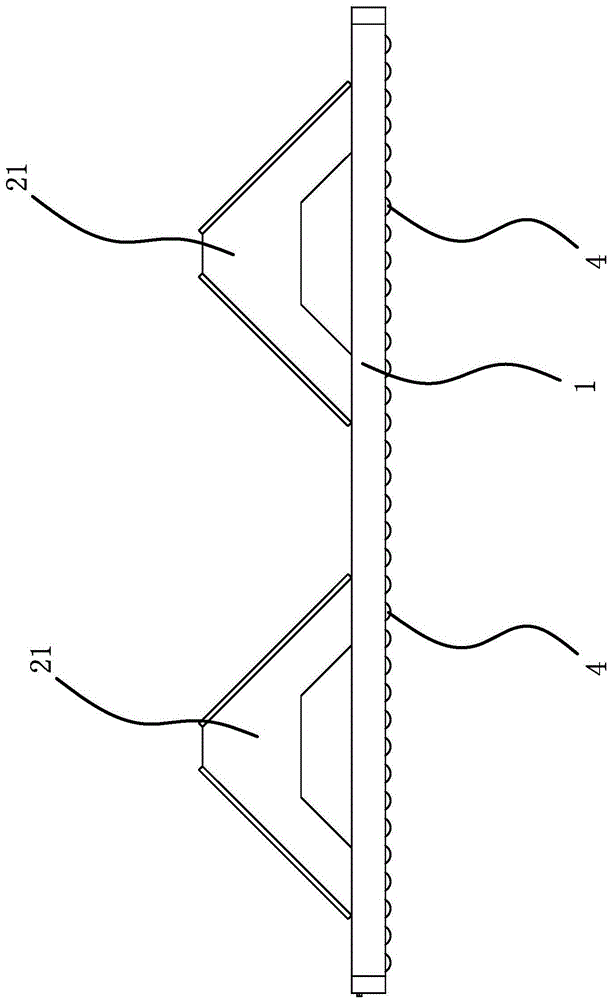

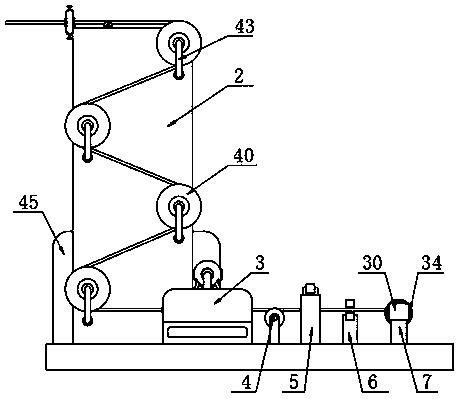

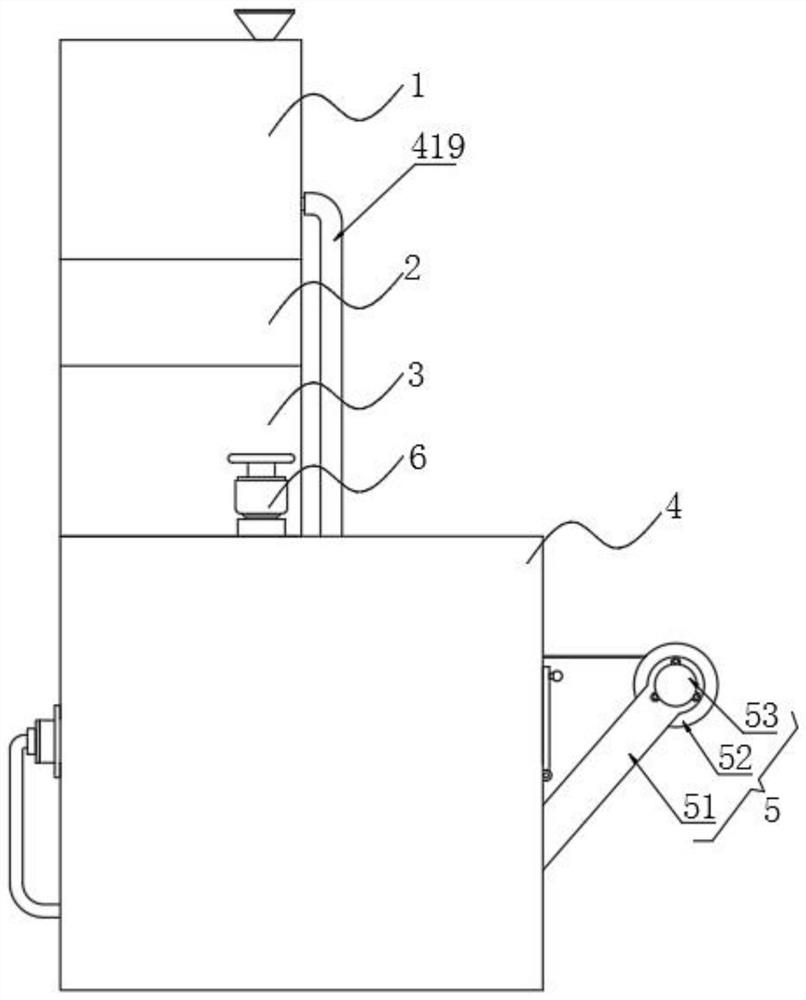

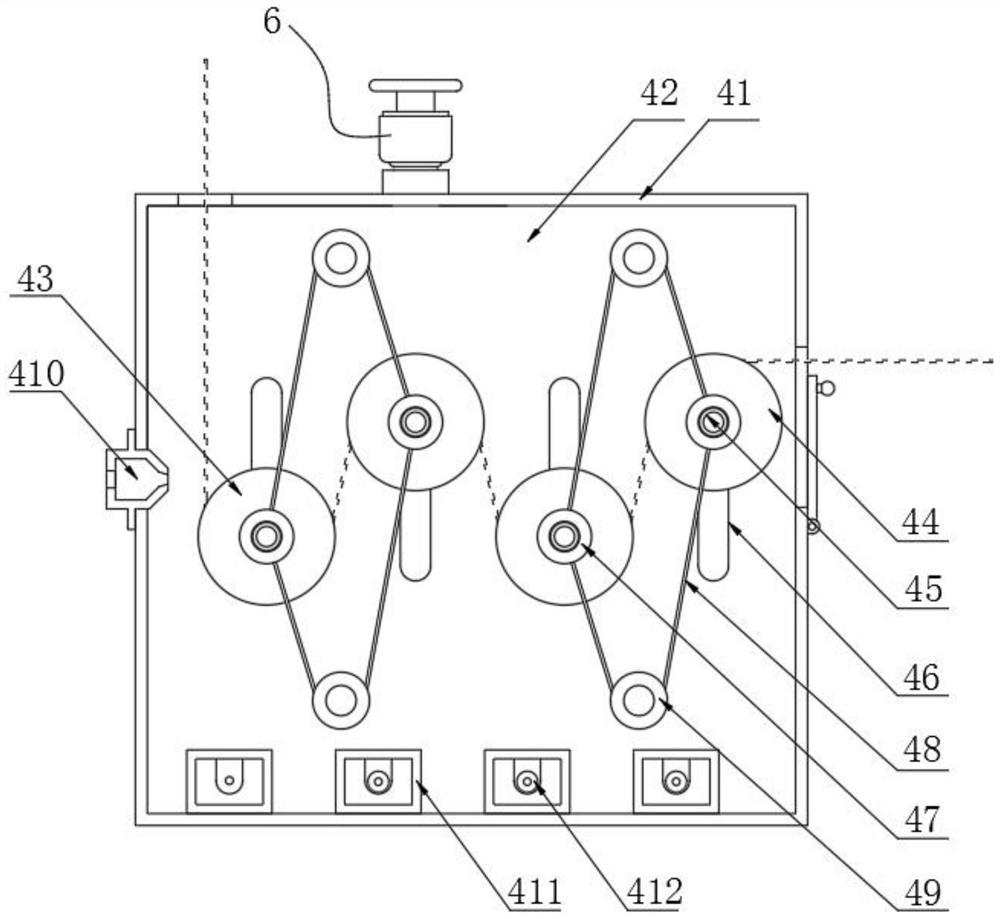

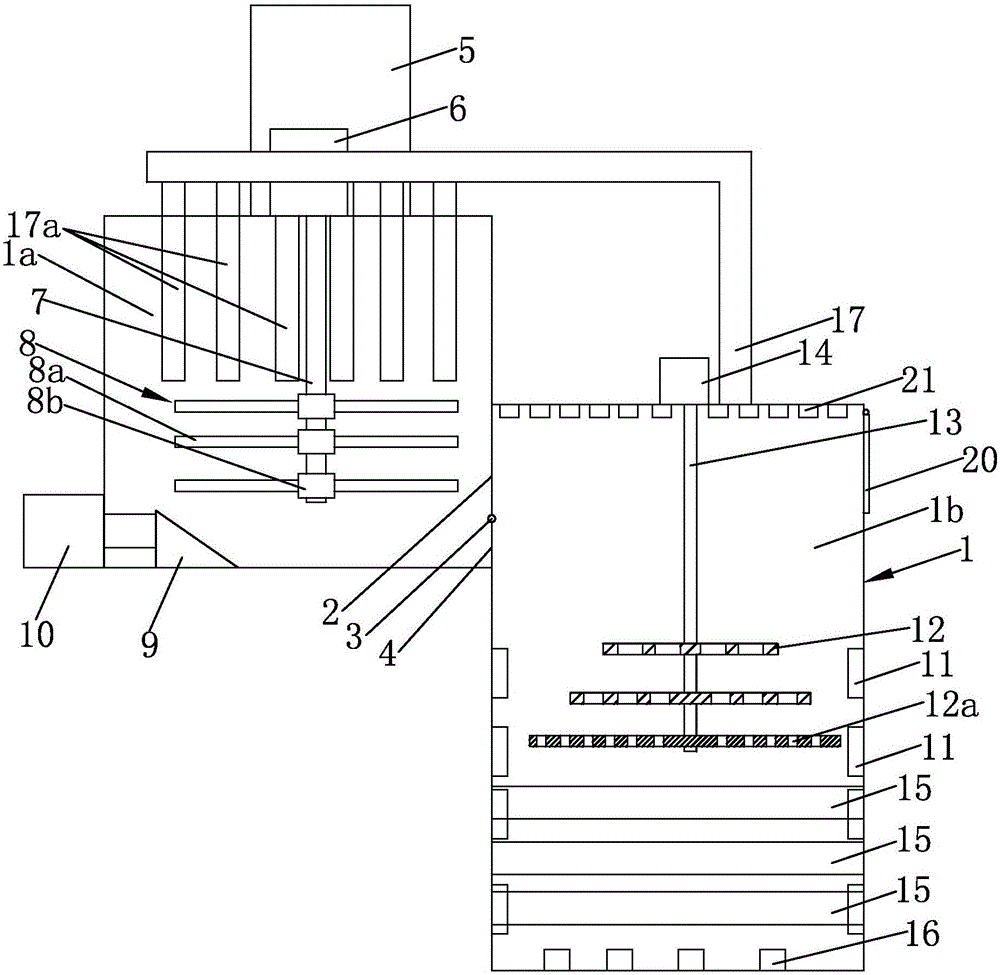

Production system of ultra-low shrinkage bright FDY and operation method thereof

ActiveCN111926403AHeight adjustableControl tensionNew-spun product collectionArtificial thread manufacturing machinesFiberIndustrial engineering

The invention discloses a production system of ultra-low shrinkage bright FDY and an operation method thereof. The production system comprises a spinneret box, an oil rolling tank, a network box, a heating shaping box and a package mechanism, wherein the spinneret box is fixedly connected to the top of the oil rolling tank. The invention relates to the technical field of textile equipment. According to the production system of the ultra-low shrinkage bright FDY and the operation method thereof, pulleys are arranged to be matched with digging ropes to connect two heating rollers and two shapingrollers correspondingly, when switching to a working mode, fiber filaments move in an S shape between the heating rollers and the shaping rollers, contact area is enough for heating shaping, before processing, a group of heating rollers and shaping rollers are pulled up by a lifting device, and a horizontal gap can be formed between the upper and lower two groups of heating rollers and shaping rollers, under the blowing of airflow, the fiber filaments can quickly pass through the heating rollers and the shaping rollers to extend to the right side, and traction and limit of the filaments are quick and convenient without the need of turning on equipment, the chance of dust pollution is reduced, and the efficiency is improved.

Owner:杭州辰泽新材料有限公司

Environment-friendly life, medical and construction solid trash incinerator

The invention discloses an environment-friendly life, medical and construction solid trash incinerator. A fixed smoke baffle is vertically arranged at the connection joint of an upper cavity and a lower cavity. The upper end of the fixed smoke baffle is fixed to the inner top face of the lower cavity. A trash passing opening for trash to pass through is reserved between the lower end of the fixed smoke baffle and the bottom face of the upper cavity. A trash inlet pipe is arranged on the top of the upper cavity. A discharge port of the trash inlet pipe communicates with a feed port in the top of the upper cavity. A set of combustion spray nozzles are densely distributed on the inner wall of the lower cavity. The uppermost combustion spray nozzle is close to the lower end of the movable smoke baffle, and the lowest combustion spray nozzle is located at the bottom of the lower cavity. Gas spray nozzles are densely distributed on the inner bottom face of the lower cavity, are vertically arranged and spray gas upwards. Gas is supplied to all the gas spray nozzles by the same gas pump through external pipelines. The gas pump is arranged outside a furnace body. It is ensured that the trash incineration is sufficient, meanwhile, the effect that the trash is pre-dried through high-temperature hot gas is improved, and the environmental protection performance is good.

Owner:吉林省拓维环保集团股份有限公司

Antibacterial synthetic resin, and preparation method thereof

The invention discloses an antibacterial synthetic resin, and belongs to the technical field of resin preparation. The antibacterial synthetic resin comprises polylactic acid, organic fluorine epoxy resin, polyphenylene sulfide, polycarbonate, polyhydroxybutyrate, hydrogenated p-phenylenediamine, urea-formaldehyde resin, polypropylene resin, polyhydroxybutyrate, lauryl acrylate, calcium molybdate,trimethyl phosphate, polycaprolactone, fluorine micro powder, nanometer montmorillonite, zinc borate, chlorinated paraffin, dispersant CNF, single-walled carbon nanotube, chitosan, zinc oxide, silanecoupling agent KH-560, an antibacterial modifying auxiliary agent. A preparation method comprises following steps: preparation of a base material; preparation of a modifying material; and mixing of the base material and the modifying material. The antibacterial synthetic resin possesses excellent antibacterial properties.

Owner:安徽高盛化工股份有限公司

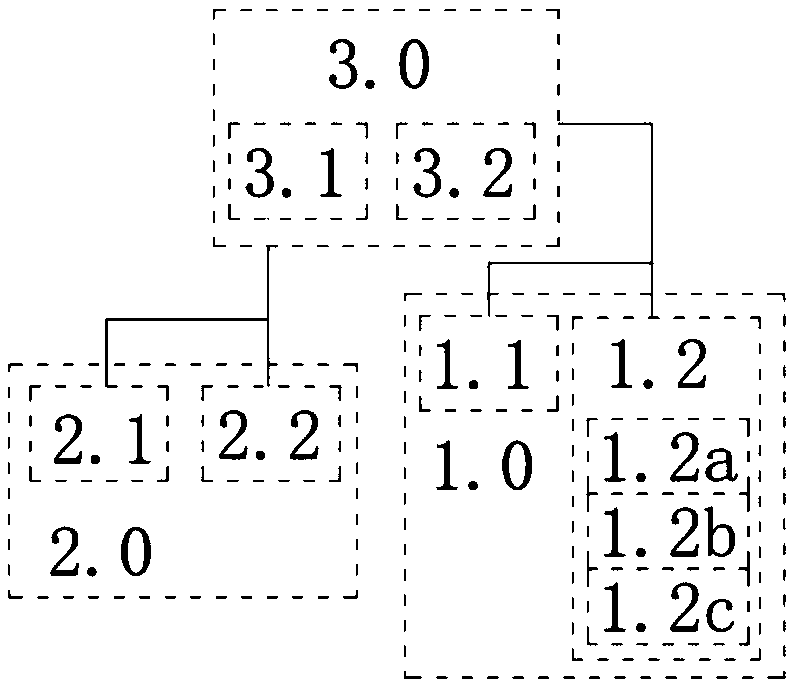

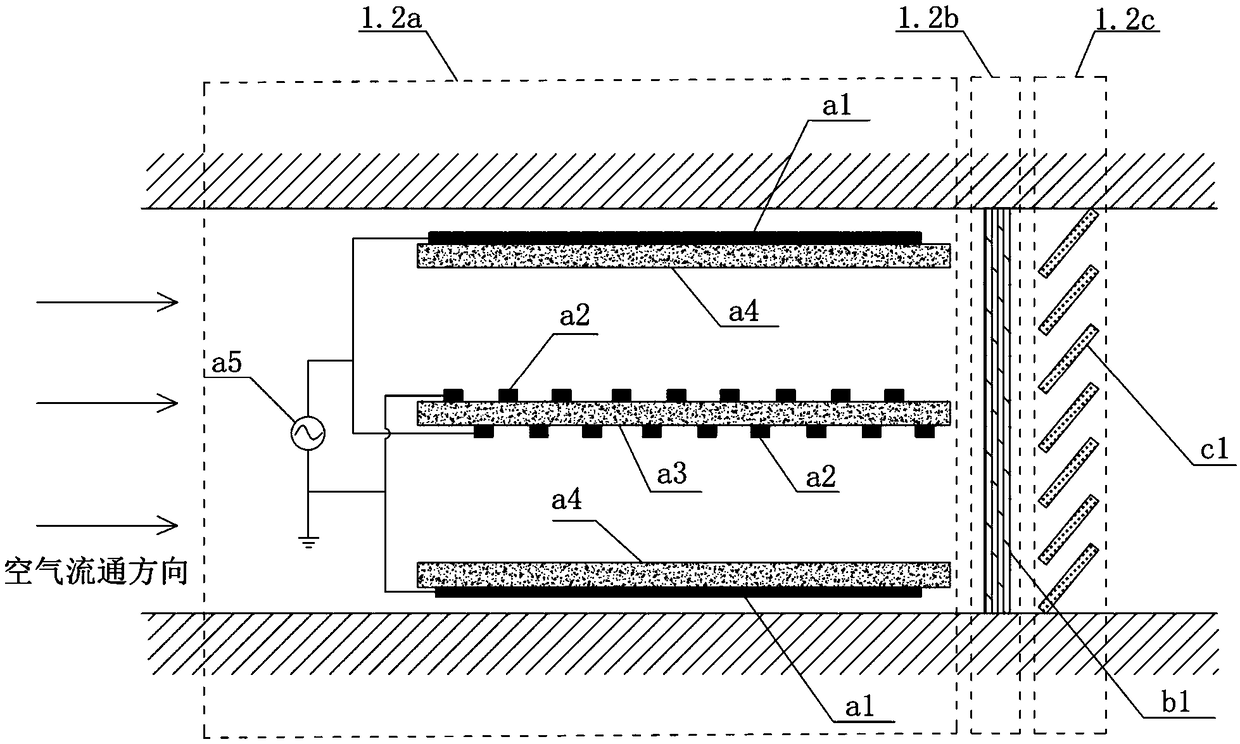

Air purification system of rail vehicle

InactiveCN108715169AImprove purification efficiencyImprove purification effectGas treatmentRailway heating/coolingAir monitoringIn vehicle

Disclosed is an air purification system of a rail vehicle. The system comprises a purification unit, a monitoring unit and a control unit; the purification unit comprises an ordinary purification device and a reinforcement purification device which are located in a container ventilation system; the monitoring unit comprises an in-vehicle air monitoring device and an out-vehicle air monitoring device; the control unit includes a fresh air inflow controller and a return air inflow controller; the fresh air inflow controller can control the flow rate of inflow of fresh air in the container ventilation system and the purification device which the inflow fresh air is about to pass through, and the return air inflow controller can control the flow rate of inflow of return air in the container ventilation system and the purification device which the inflow return air is about to pass through; the control unit controls mediums of the fresh air inflow controller, the return air inflow controller and the reinforcement purification device to prevent the work of a discharger according to monitoring results of the in-vehicle air monitoring device and the out-vehicle air monitoring device. The air purification system can select the amount of fresh air and return air according to the air quality inside and outside the vehicle and targetedly and efficiently purify the air in a vehicle body.

Owner:SOUTHWEST JIAOTONG UNIV

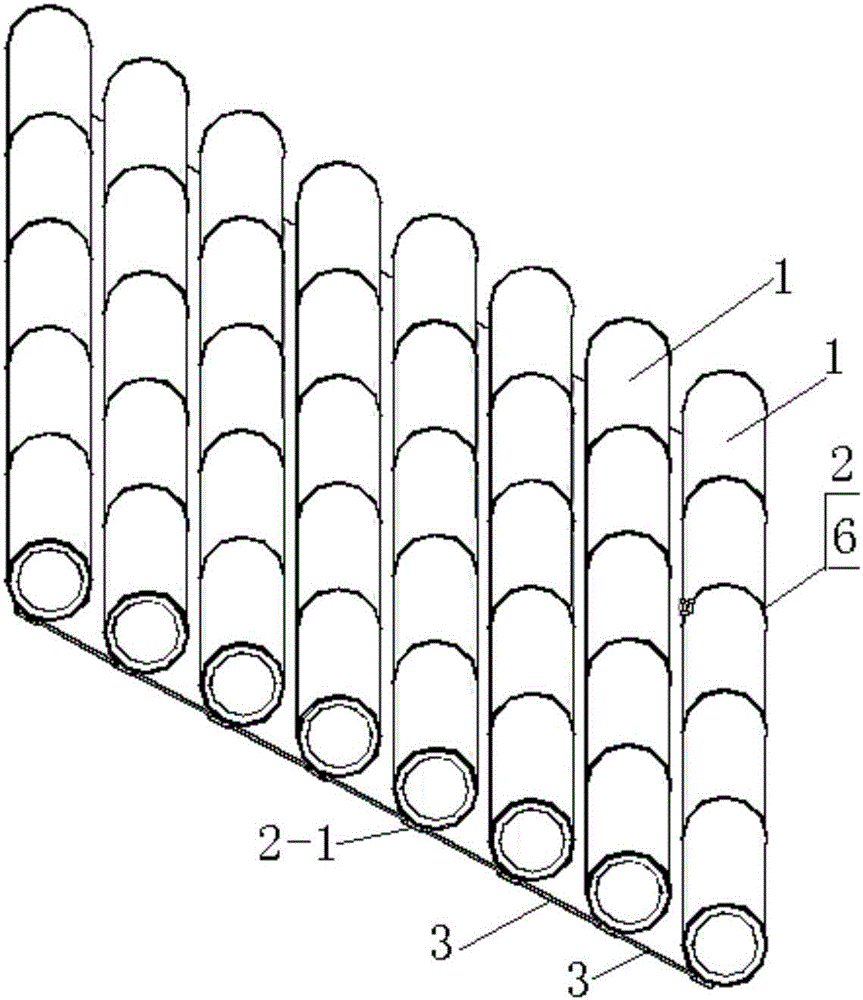

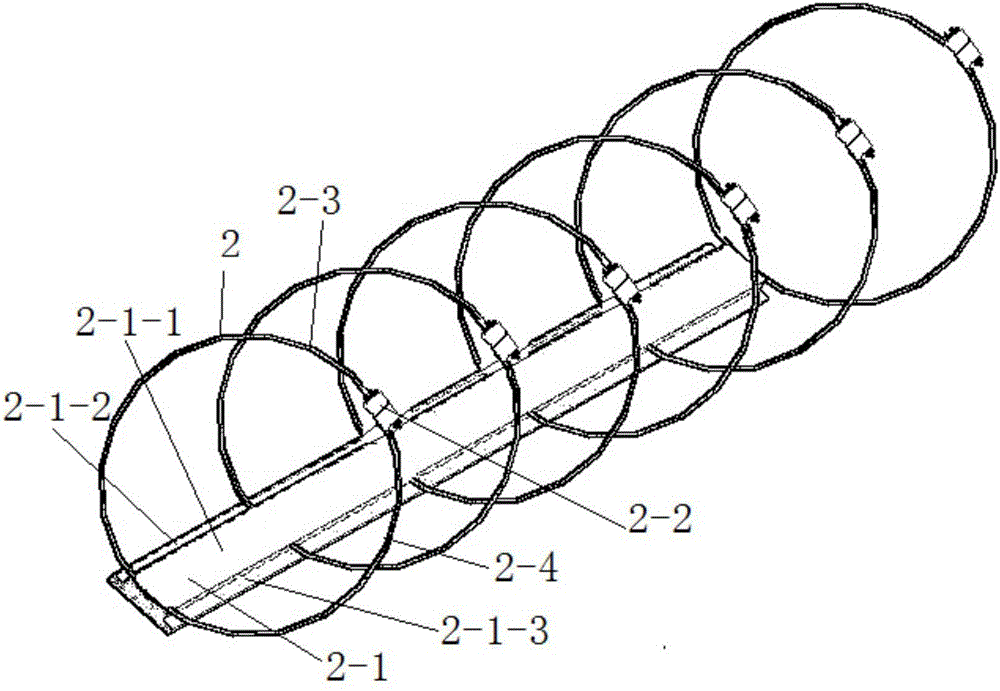

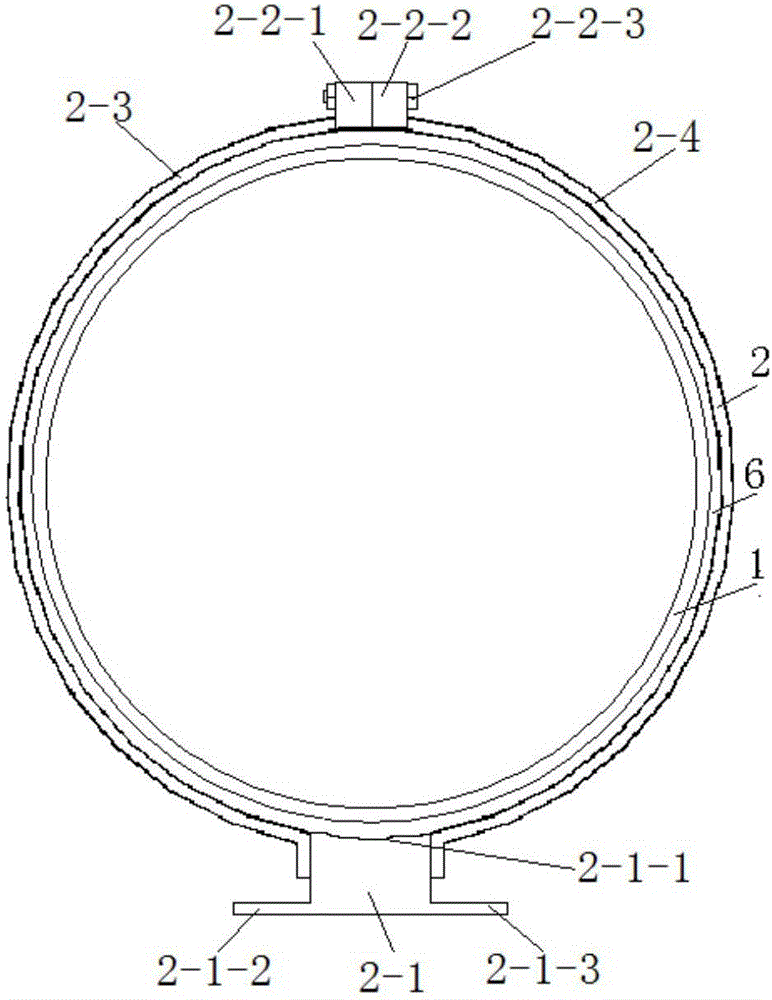

Steel strip reinforced original bamboo skeleton composite floor slab

The invention relates to a steel strip reinforced original bamboo skeleton composite floor slab. The steel strip reinforced original bamboo skeleton composite floor slab comprises a filling layer, a plurality of bottom plates and a plurality of original bamboos. All the original bamboos are arranged at intervals side by side. A steel supporting strip parallel to each original bamboo is arranged below the original bamboo. The upper top surface of each steel supporting strip makes contact with the lower bottom surface of the corresponding original bamboo. Each original bamboo is sleeved with a plurality of clamping hoops. Each clamping hoop comprises a left body and a right body. The lower end of each left body and the lower end of the corresponding right body are connected with the left side and the right side of the corresponding steel supporting strip. The other end of each left body and the other end of the corresponding right body are detachably connected through a connecting part. Each steel supporting strip is provided with a side plate in the horizontal direction. Each side plate comprises a left side plate body arranged on the left side of the corresponding steel supporting strip and a right side plate body arranged on the right side of the corresponding steel supporting strip. One bottom plate is arranged in the position between every two adjacent original bamboos. The left ends and the right ends of the bottom plates are overlapped on the side plates. The filling layer is arranged on the upper surfaces of the bottom plates and among all the original bamboos. The upper surface of the filling layer is higher than the tops of the clamping hoops. The steel strip reinforced original bamboo skeleton composite floor slab is light in weight, large in rigidity, savable in energy, environmentally friendly and low in manufacturing cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

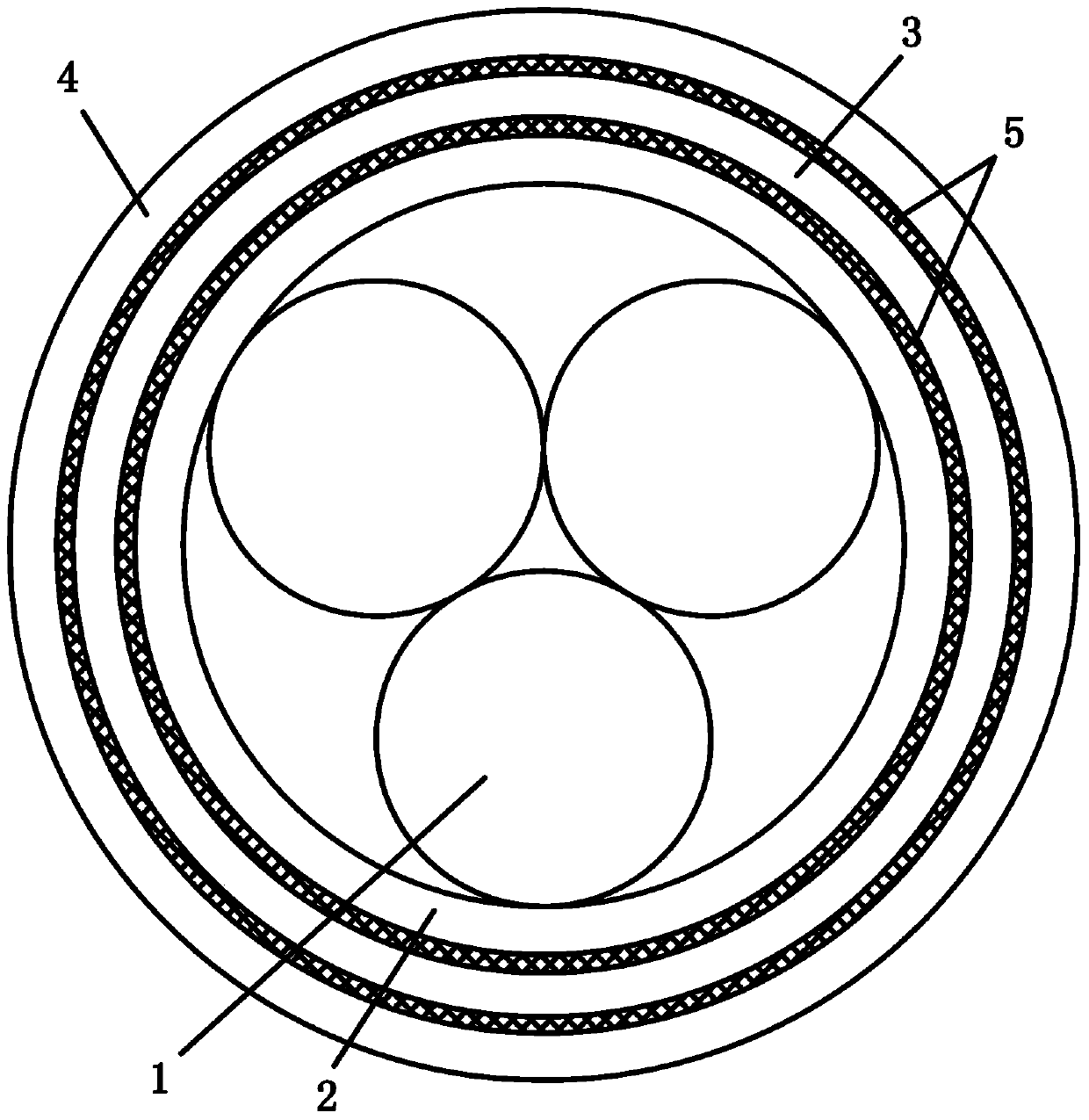

Low-smoke-zero-halogen high-flame-retardance power cable

ActiveCN103440921AStay resilientMaintain wear resistanceInsulated cablesPower cablesLow smoke zero halogenFiber

The invention discloses a low-smoke-zero-halogen high-flame-retardance power cable which structurally comprises a guiding wire. A flame retardant insulation layer is arranged on the outer side of the guiding wire. A carbon fiber flame retardant layer is arranged on the outer side of the flame retardant insulation layer. A foam flame retardant layer is arranged on the outer side of the carbon fiber flame retardant layer. The carbon fiber flame retardant layer is connected with the flame retardant insulation layer through a cross-linking layer, and the carbon fiber flame retardant layer is connected with the foam flame retardant layer through a cross-linking layer. According to the low-smoke-zero-halogen high-flame-retardance power cable, power cable flame retardant capacity is improved, and meanwhile release of toxic smoke is lowered during burning.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

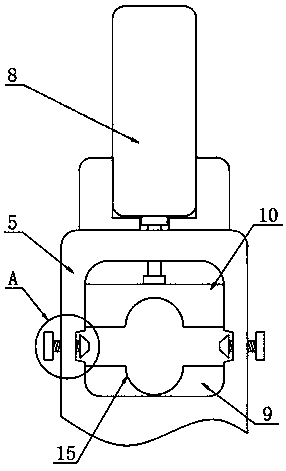

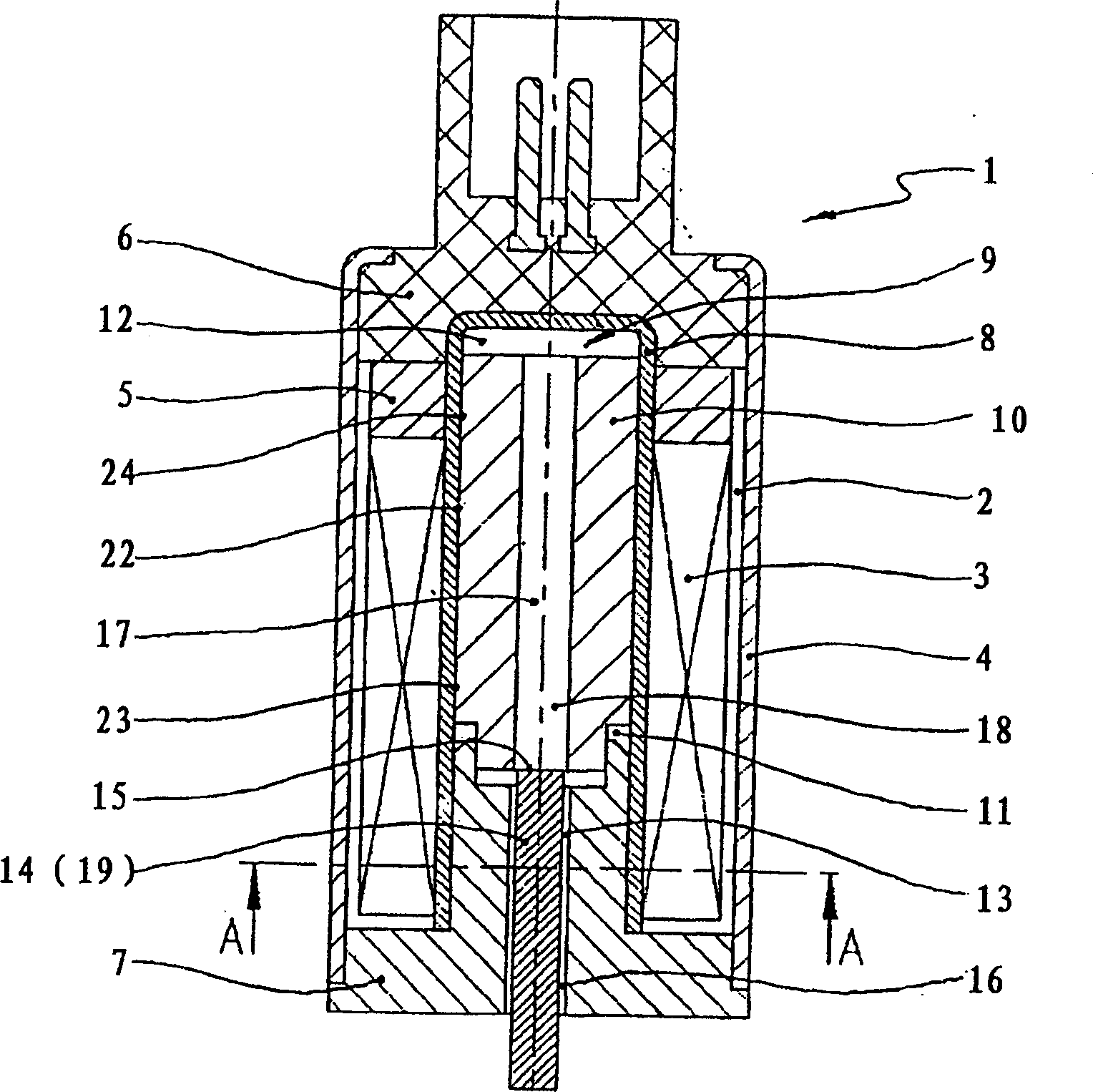

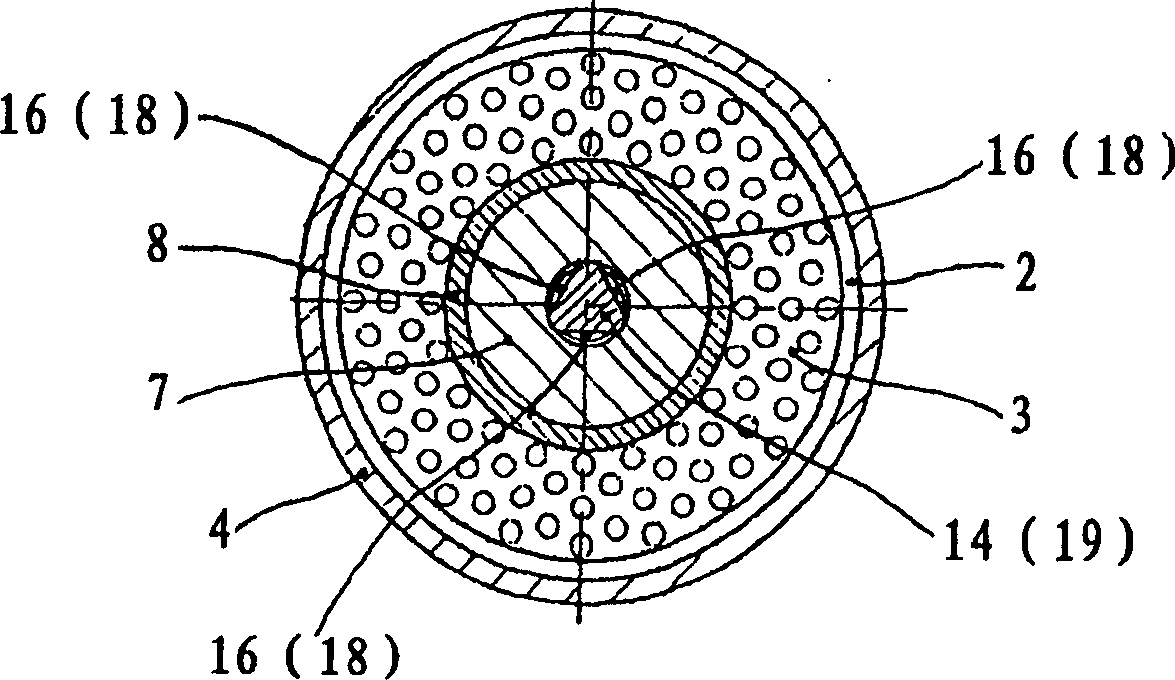

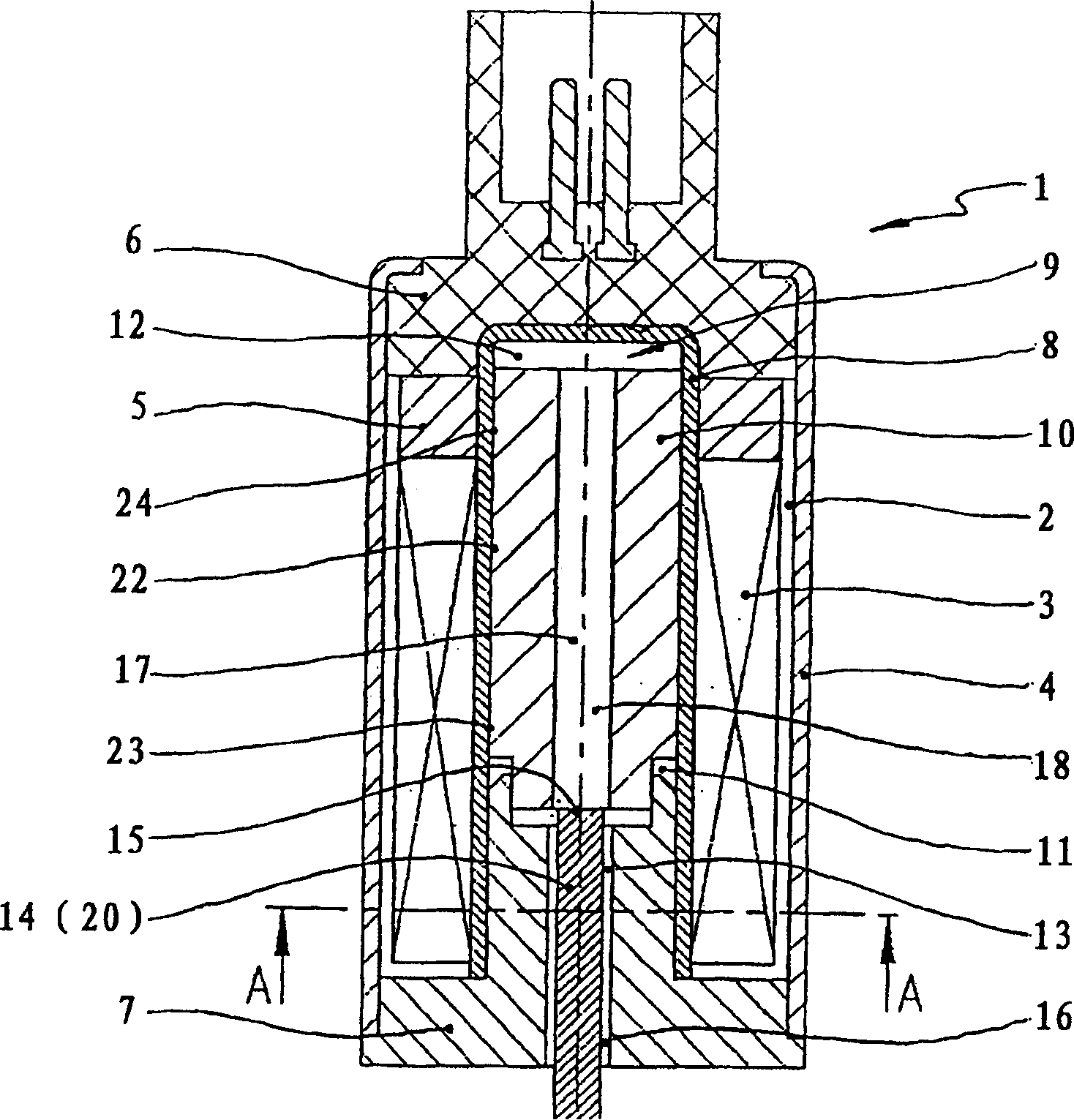

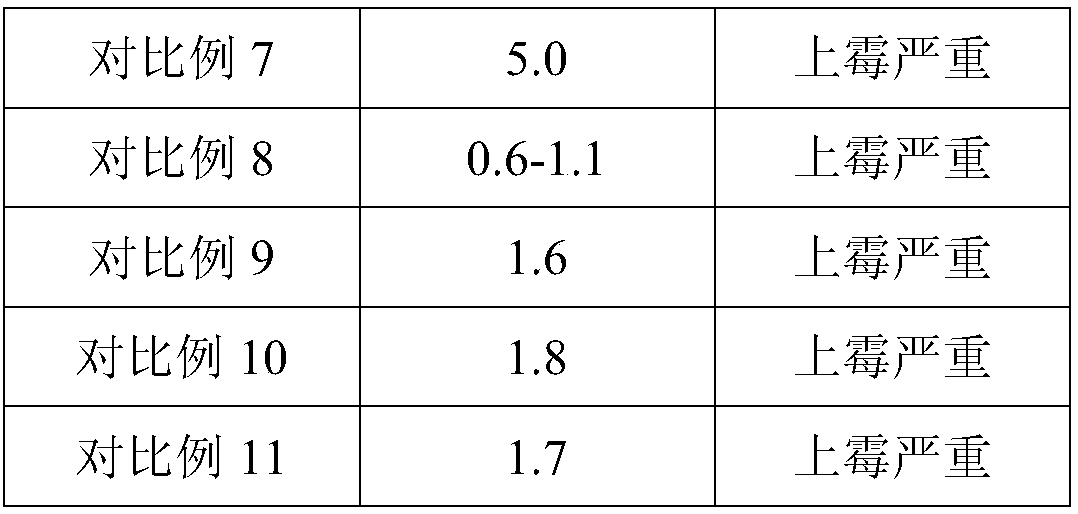

Electromagnet for controlling hydraulic valve

InactiveCN1272553CEnough contact areaSmall hysteresisOperating means/releasing devices for valvesServomotor componentsEngineeringLower pole

The present invention relates to an electromagnet (1) which includes a hollow, cylindrical coil body (2) that has at least one winding coil (3) and surrounded by a magnet housing (4). The coil body (2) is defined by an upper pole shoe (5) and a lower pole shoe (7). A nonmagnetic metal tube (8) is disposed in the hollow cylinder of the coil body and has an internal cavity which defines an armature chamber (9) for a cylindrical magnet armature (10). The magnet armature (10) divides the armature chamber (9) into a first chamber (11) and a second chamber (12) that interconnected by pressure equalizing channel in the magnet armature (10). The magnet armature (10) is connected to a control piston in a valve housing of a hydraulic valve through a tappet push rod (14) guided through an axial bore (13) formed to a lower pole shoe (7). The inner space of the valve housing is connected to the first chamber (11) of the armature chamber (9) by another pressure equalizing channel on the lower pole shoe (7). According to the present invention, the tappet push rod (14) is designed separating from the magnet armature (10) and is an independent profiles rod, and its section shape is different from the axial bore (13) and its section area is smaller than that of the axial bore (13). Furthermore, the magnet armature (10) has a central vertical bore (17) with diameter smaller than the maximum profiles width of the tappet push rod (14) and larger than the minimum profiles width of the tappet push rod.

Owner:SCHAEFFLER TECH AG & CO KG

Low-temperature contact type surface temperature sensor

PendingCN109253817AEasy to useGuaranteed accuracyThermometer detailsThermometers using electric/magnetic elementsEngineeringContact type

The invention relates to a low-temperature contact type surface temperature sensor, comprising a housing, an upper cover, a temperature sensor, a magnetic ring and a uniform temperature medium, wherein an annular clamping groove is formed in the lower end of the housing; the magnetic ring is mounted in the annular clamping groove; a uniform temperature tank is arranged in the housing; the upper cover is arranged on the upper end of the housing and seals the uniform temperature tank in the housing; the temperature sensor is arranged in the upper cover in a penetrating manner; the lower portionof the temperature sensor is inserted into the uniform temperature tank; the uniform temperature medium is accommodated in the uniform temperature tank, which is an antifreezing solution; a liquid injecting hole is formed in the upper cover and corresponds to the uniform temperature tank on the housing; and a plug is arranged in the liquid injecting hole. According to the invention, the low-temperature contact type surface temperature sensor is attached to the surface of an object to be detected in a magnetic attraction manner, and no damage to the object to be detected is caused, thus ensuring the normal safe use of the object to be detected; the liquid uniform temperature medium is arranged in the housing of the surface temperature sensor, and the temperature sensor is immersed in the uniform temperature medium, so that the influence of external environment temperature and humidity on the temperature sensor can be avoided, ensuring the accuracy of temperature measurement.

Owner:HENAN PROVINCE INST OF METROLOGY

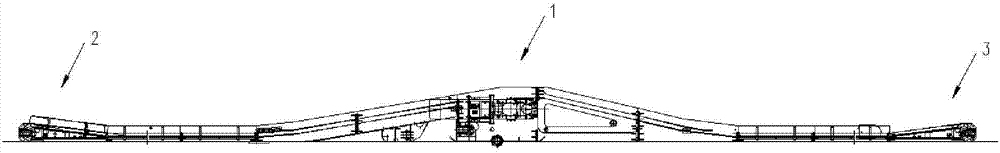

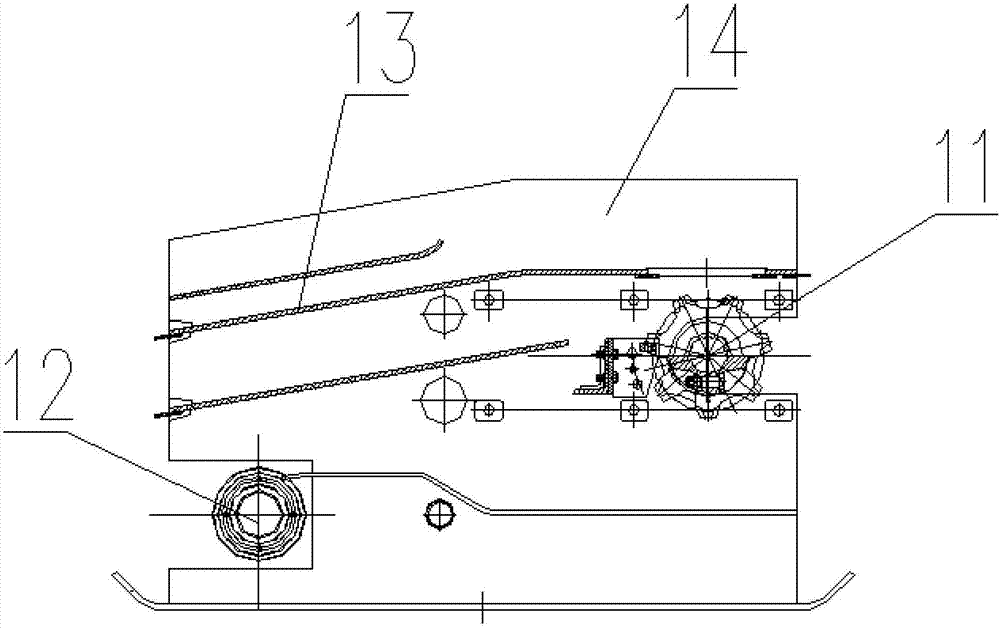

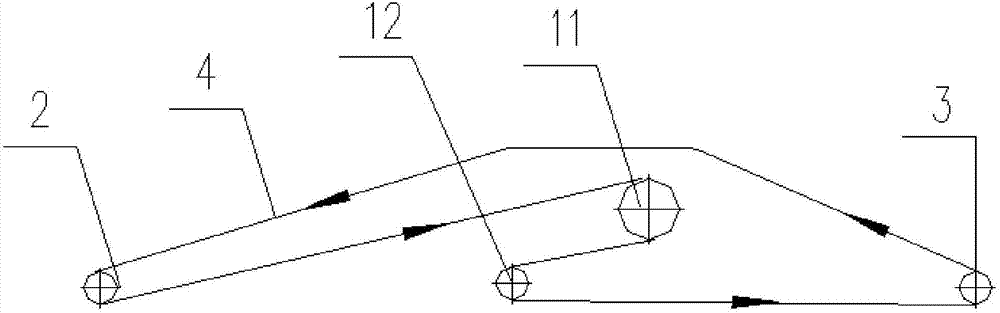

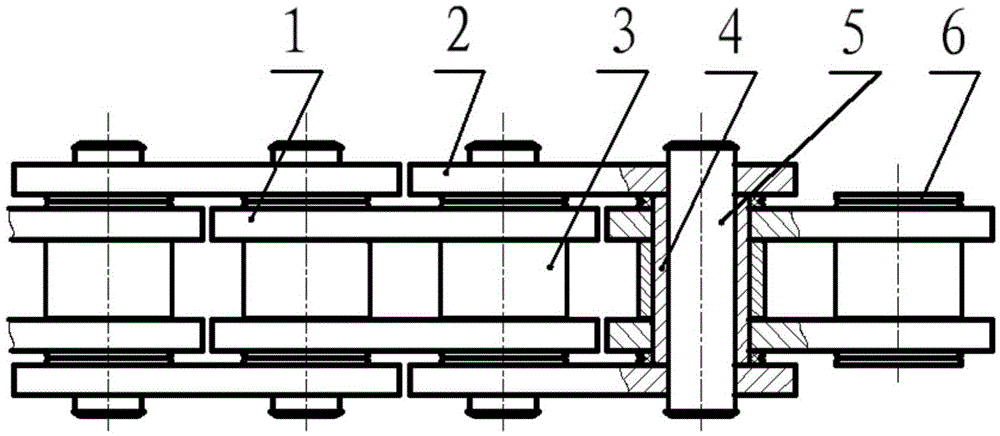

Scraper conveyor

PendingCN107215621AImprove mining efficiencySpace requirements are minimizedConveyorsControl engineeringStructural engineering

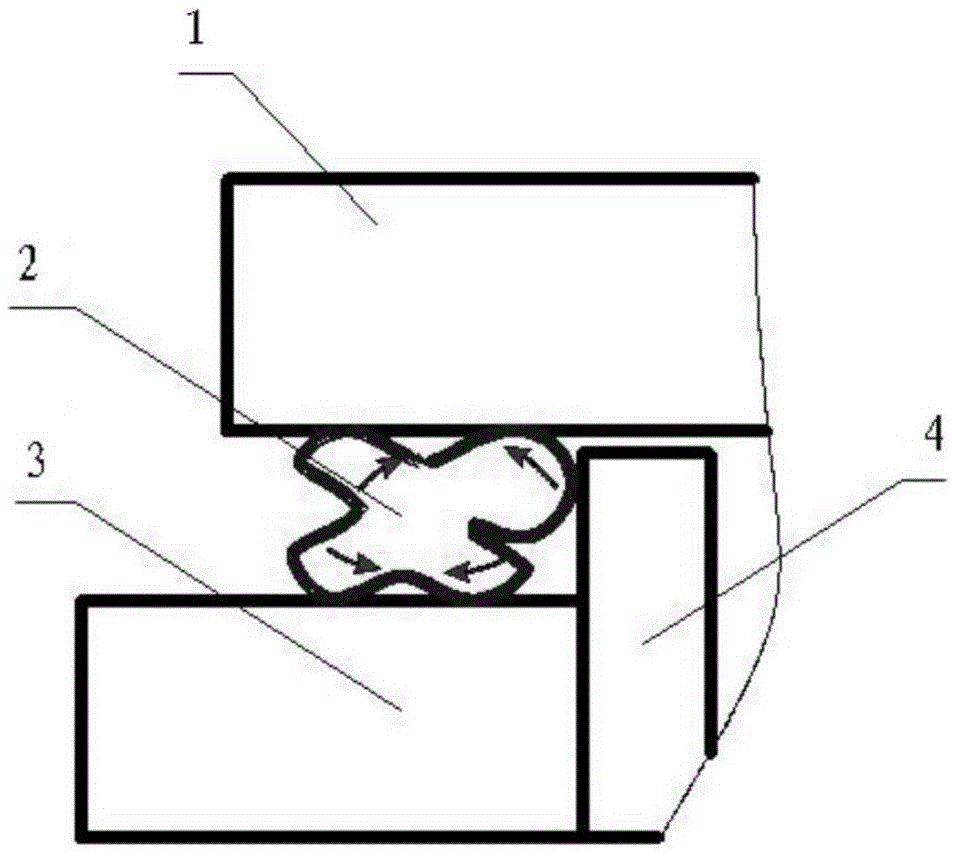

The invention provides a scraper conveyor. The scraper conveyor comprises a driving mechanism; the driving mechanism is located in the middle of the scraper conveyor and comprises a chain wheel, a transmission roller and a supporting plate; the supporting plate is located above the chain wheel; the transmission roller is located below the chain wheel; and a scraper chain is arranged to be laid from a loading end to an unloading end through the supporting plate, then be laid to the chain wheel after returning from the unloading end, then return from the chain wheel to be laid to the transmission roller and finally return from the transmission roller to be laid to the loading end so that the scraper chain can form a whole electrodeless closed chain. The scraper conveyor has the advantages that a transmission device is arranged in the middle so that the space requirements of the two ends can be reduced to the minimum, in addition, a driving part in the middle is not fixedly arranged at a certain position and can be arranged at any position in the middle along with increase and decrease of the number of groove bodies; and the multi-layer rotary arrangement of the scraper chain can be realized through the cooperation of the supporting plate and the transmission roller so that enough contact area between the scraper chain and the chain wheel can be guaranteed, and therefore the purpose of driving the scraper chain to operate can be achieved.

Owner:HUAINAN MINING IND GRP +1

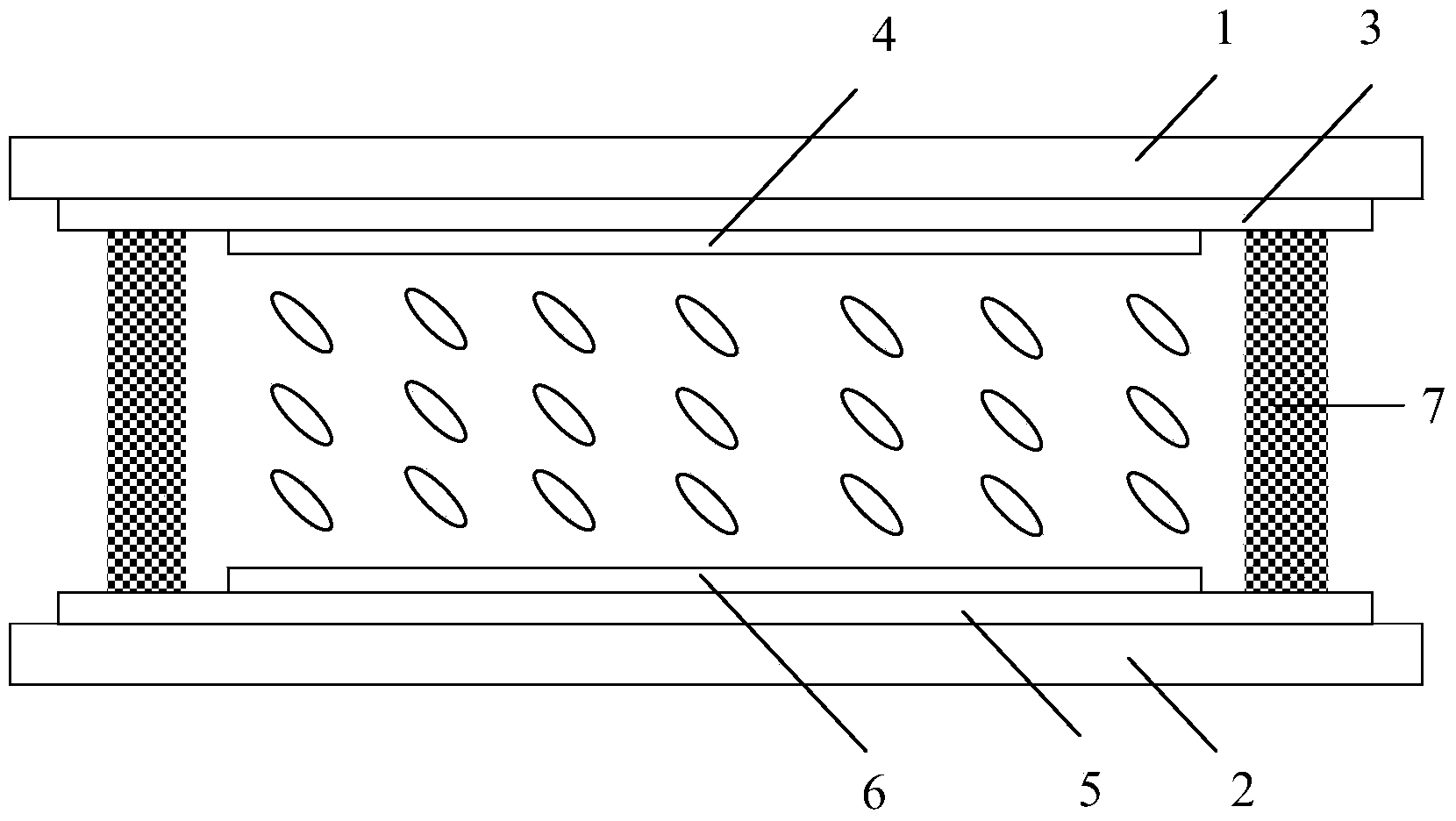

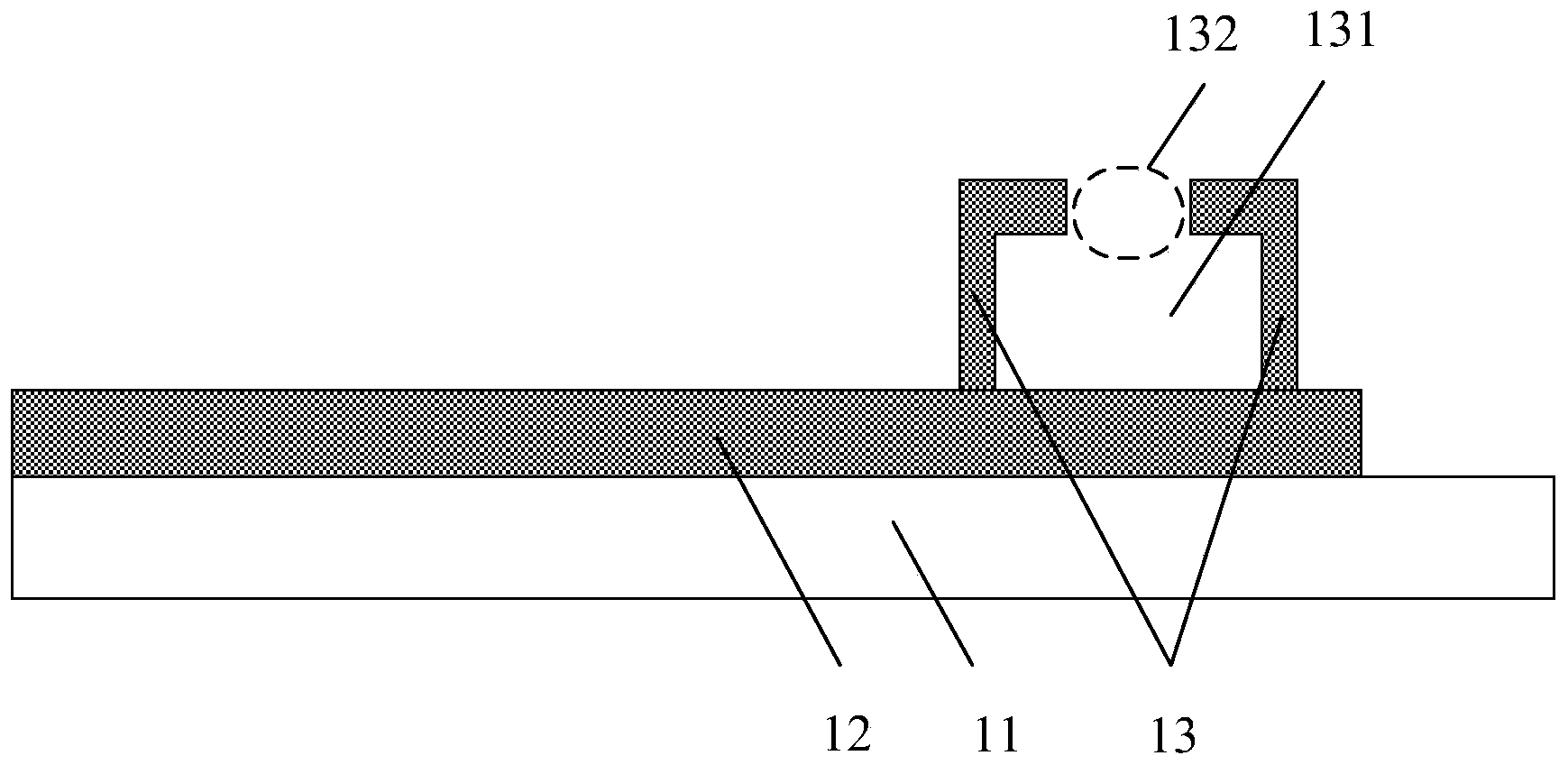

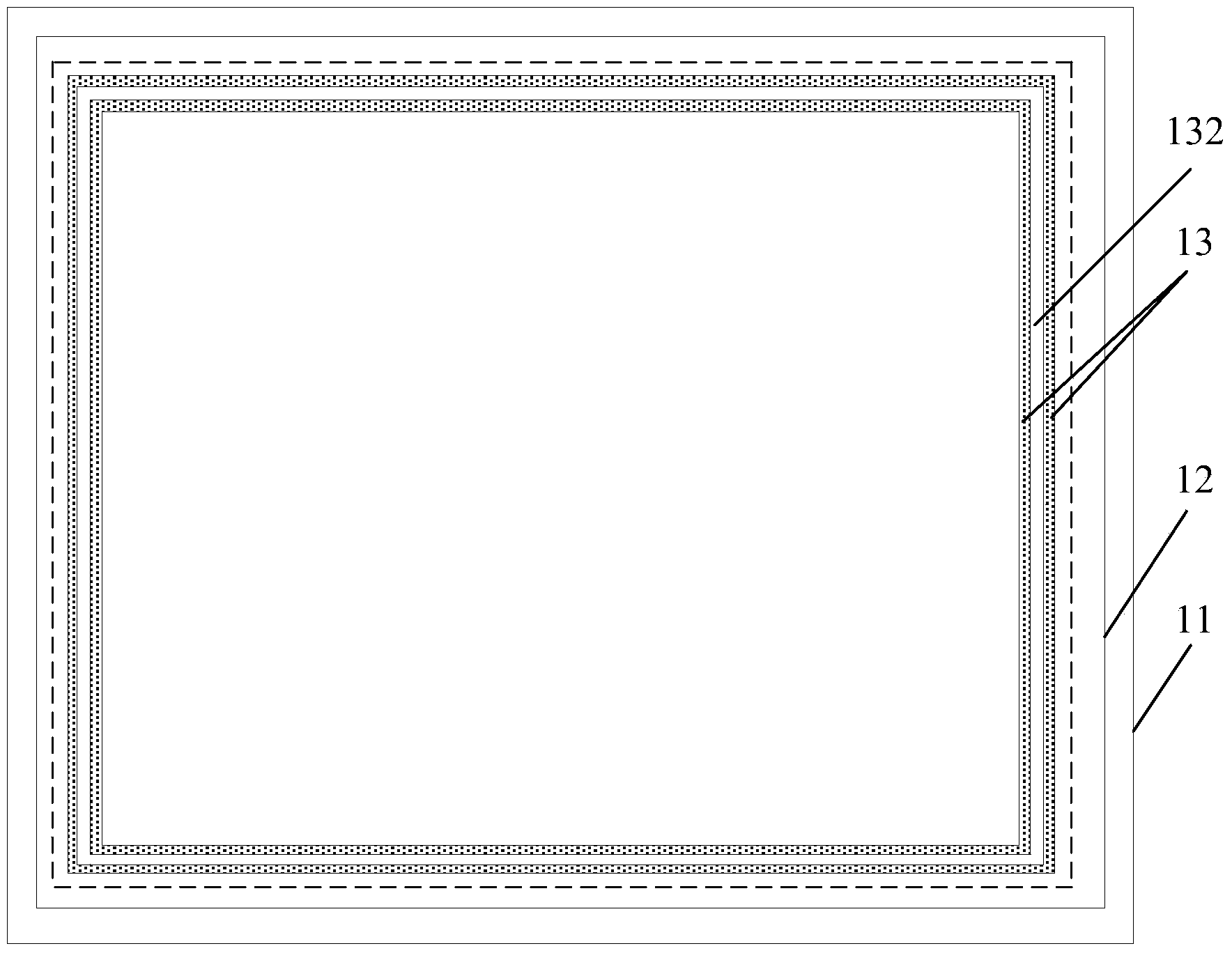

Liquid crystal display substrate and preparation method and display device thereof

ActiveCN103454797AEnough contact areaEasy to controlNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a liquid crystal display substrate and a preparation method and a display device thereof. The liquid crystal display substrate comprises a substrate and a thin film layer, wherein the thin film layer is formed on the substrate, the thin film layer is provided with a sealant blocking part, the sealant blocking part is arranged on the edge of a preset alignment film forming area, the sealant blocking part and the thin film layer form a cavity, the top of the sealant blocking part is provided with an opening, and the opening is communicated with the cavity. The liquid crystal display substrate has the advantages that the sealant blocking part is arranged on the edge of the preset alignment film forming area, and when the alignment film is formed, only a small part of the alignment film is coated into the cavity through the opening of the sealant blocking part, the enough contact area between the poured sealant and the cavity is ensured to provide adhesive force, and the position of the sealant is precisely controlled to reduce the distance with the display area, so the preparation of a narrow edge frame of the display device is realized.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

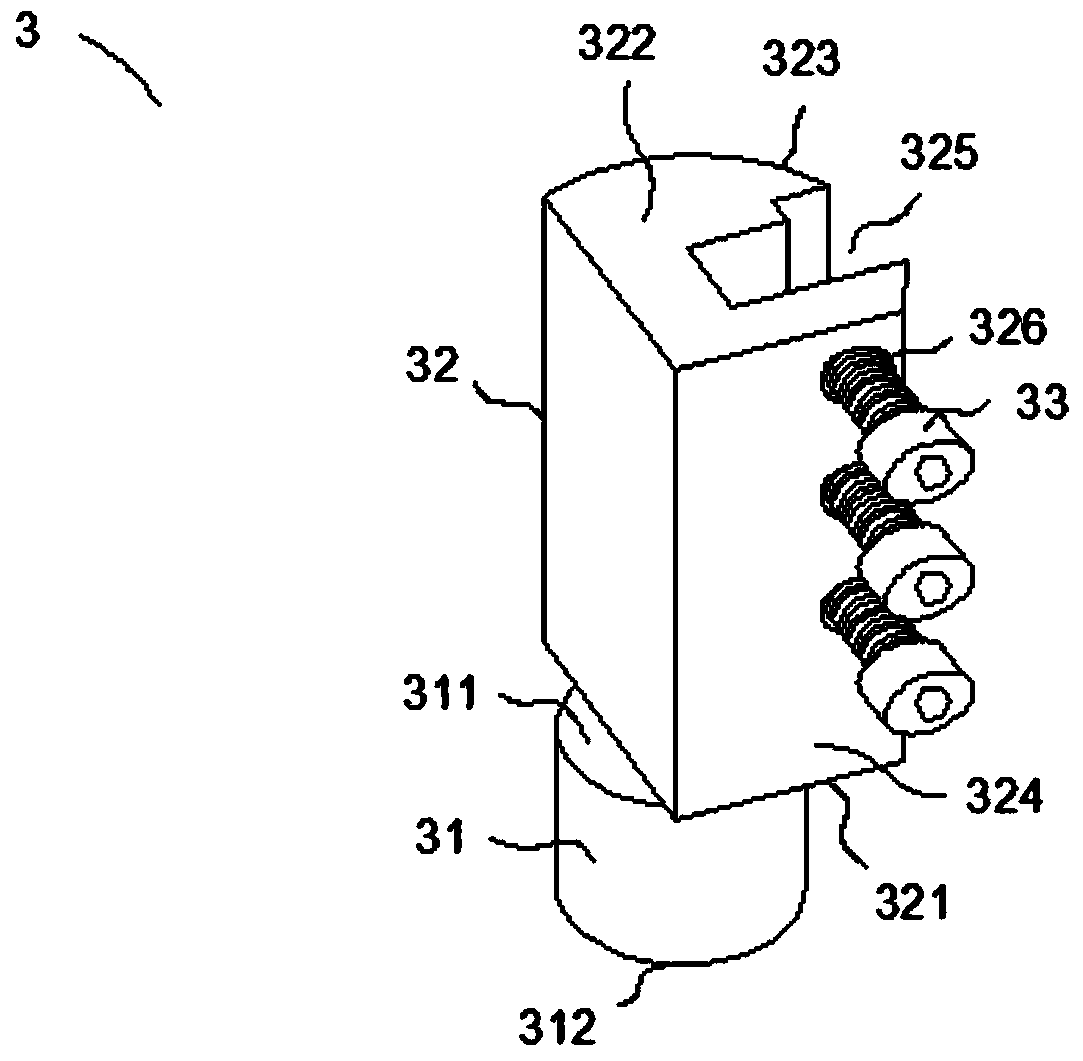

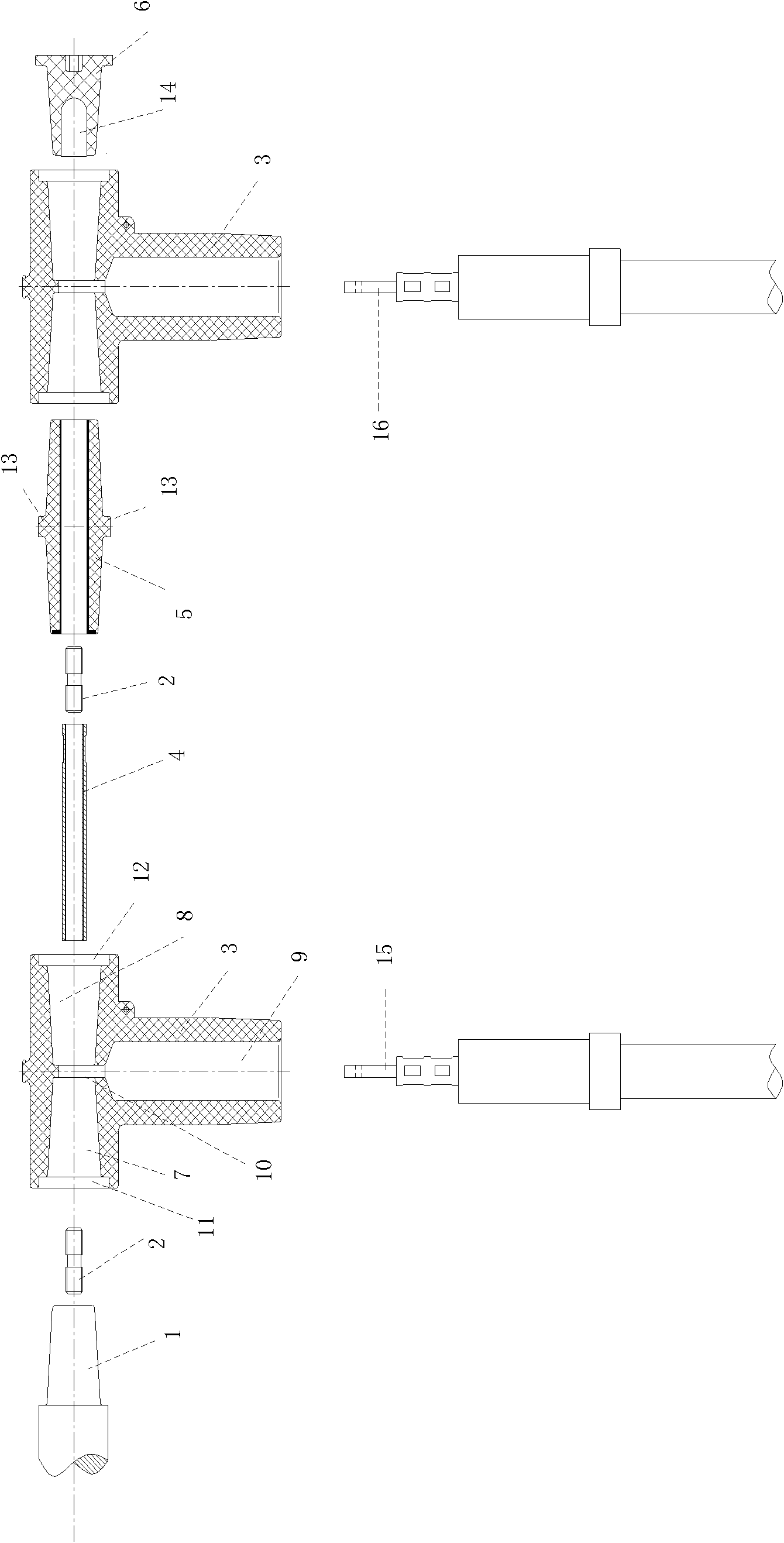

Multifunctional milling fixture and milling machine using multifunctional milling fixture

InactiveCN104227449AReduce manual labor intensityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringRadian

The invention provides a multifunctional milling fixture and a milling machine using the functional milling fixture. The milling fixture consists of a fixing part, a clamping part connected with one end of the fixing part and a screw rod screwed on the clamping part, wherein the fixing part is cylindrical and is provided with a connecting surface formed by a circumferential surface; the clamping part is shaped as a long strip and is provided with a jointing surface and an open surface which are located at the two ends of a longitudinal length direction, and a clamping surface and a locking surface which are located between the jointing surface and the open surface and are adjoined, wherein the jointing surface is fit and connected with the connecting surface, the clamping surface is depressed along the length direction of the clamping part to form a clamping groove, the upper part of the clamping groove is wide and the lower part of the clamping groove is narrow; the part, penetrating through the locking surface, of the screw rod stretches into the clamping groove. The multifunctional milling fixture and the milling machine using the multifunctional milling fixture have the beneficial effects that the machining efficiency is high, the structure is simple, the use is facilitated, the clamping reliability and stability are high, front and back surface machining can be conducted after only one step of clamping and radian needed by a workpiece can be machined. The milling fixture can satisfy the demand of 360-degree rotary machining of T-shaped, L-shaped, trapezoidal and flat parts.

Owner:GUANGXI HUAYIN ALUMINUM

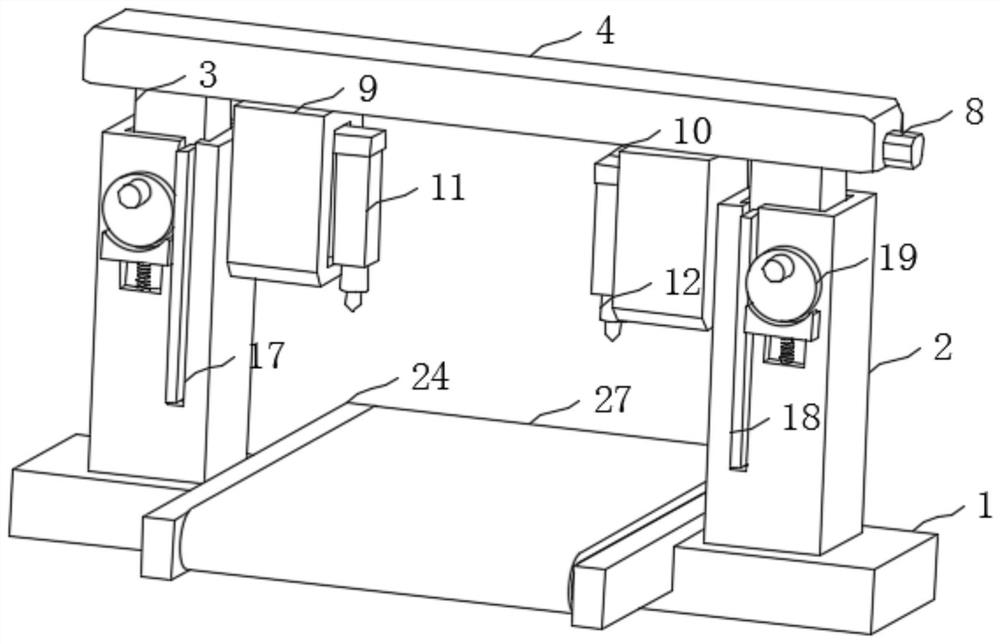

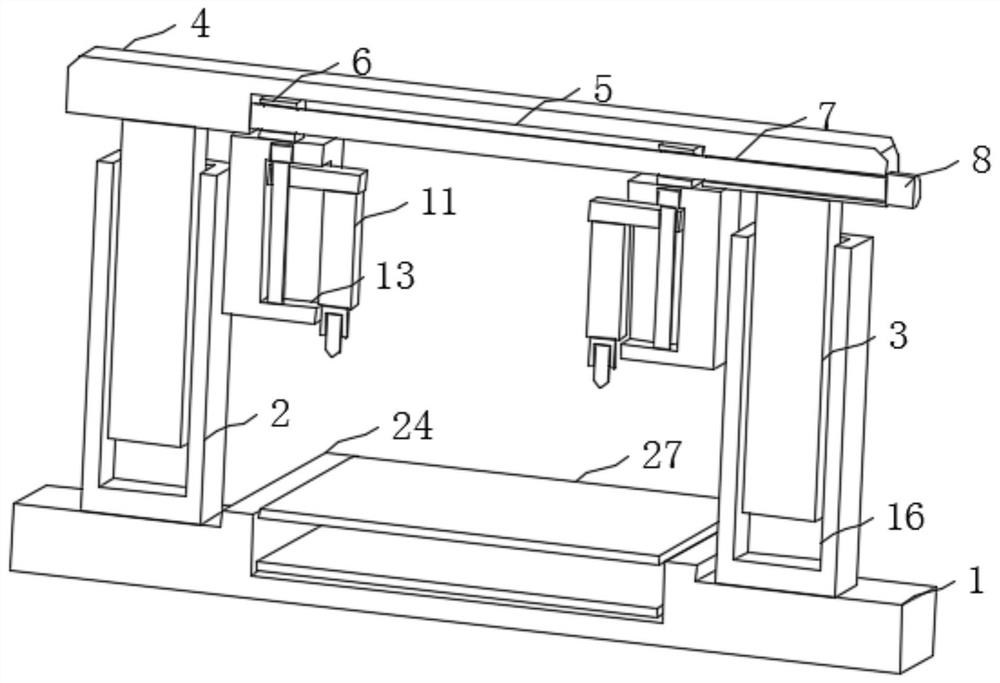

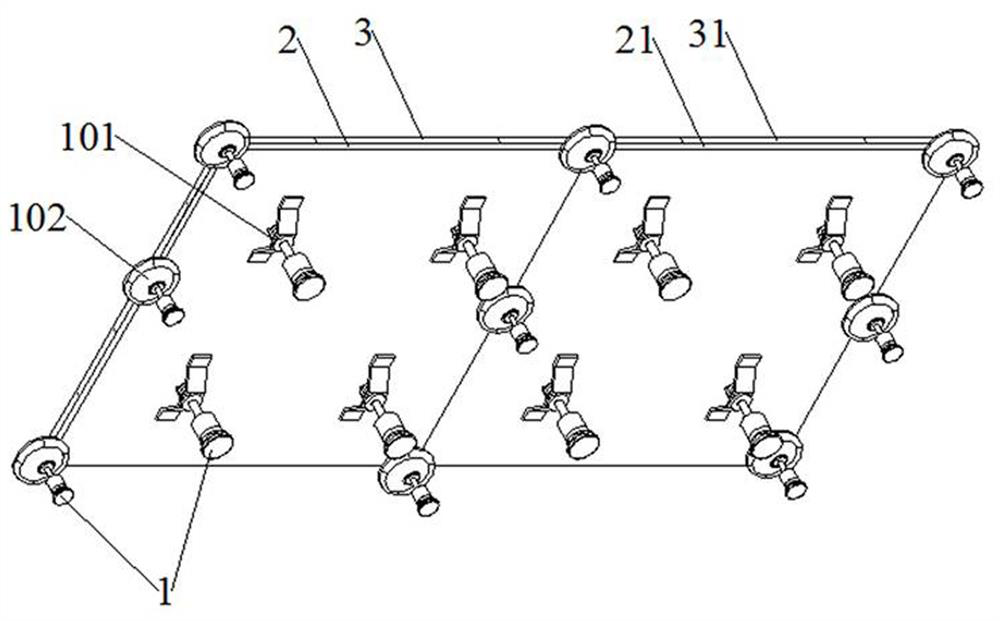

Gantry welding robot

PendingCN113319486AExpand the adjustment rangeReduce usage limitationsWelding/cutting auxillary devicesAuxillary welding devicesSupport planeSoldering gun

The invention discloses a gantry welding robot. The gantry welding robot comprises two fixing rods fixedly installed on a base, supporting rods are installed on the two fixing rods correspondingly, lifting mechanisms are installed between the two supporting rods and the two fixing rods correspondingly, a supporting frame is installed between the two supporting rods in a matched mode, the supporting frame is slidably connected with two sliding blocks, sliding mechanisms matched with the two sliding blocks are arranged on the supporting frame, installation blocks are fixedly installed at the lower ends of the two sliding blocks, and moving blocks are installed on the two installation blocks through moving mechanisms. The gantry welding robot has the advantages that welding operation can be carried out on two different positions on a workpiece at the same time, and the working efficiency is effectively improved; and meanwhile, besides the height of a welding gun can be adjusted, the installation height of the supporting frame can further be adjusted according to needs, so that the height adjusting range of the device can be widened, the gantry welding robot is suitable for welding workpieces with different heights, and the use limitation of the device is effectively reduced.

Owner:SANCHU OF CHINA RAILWAY TUNNEL GROUP

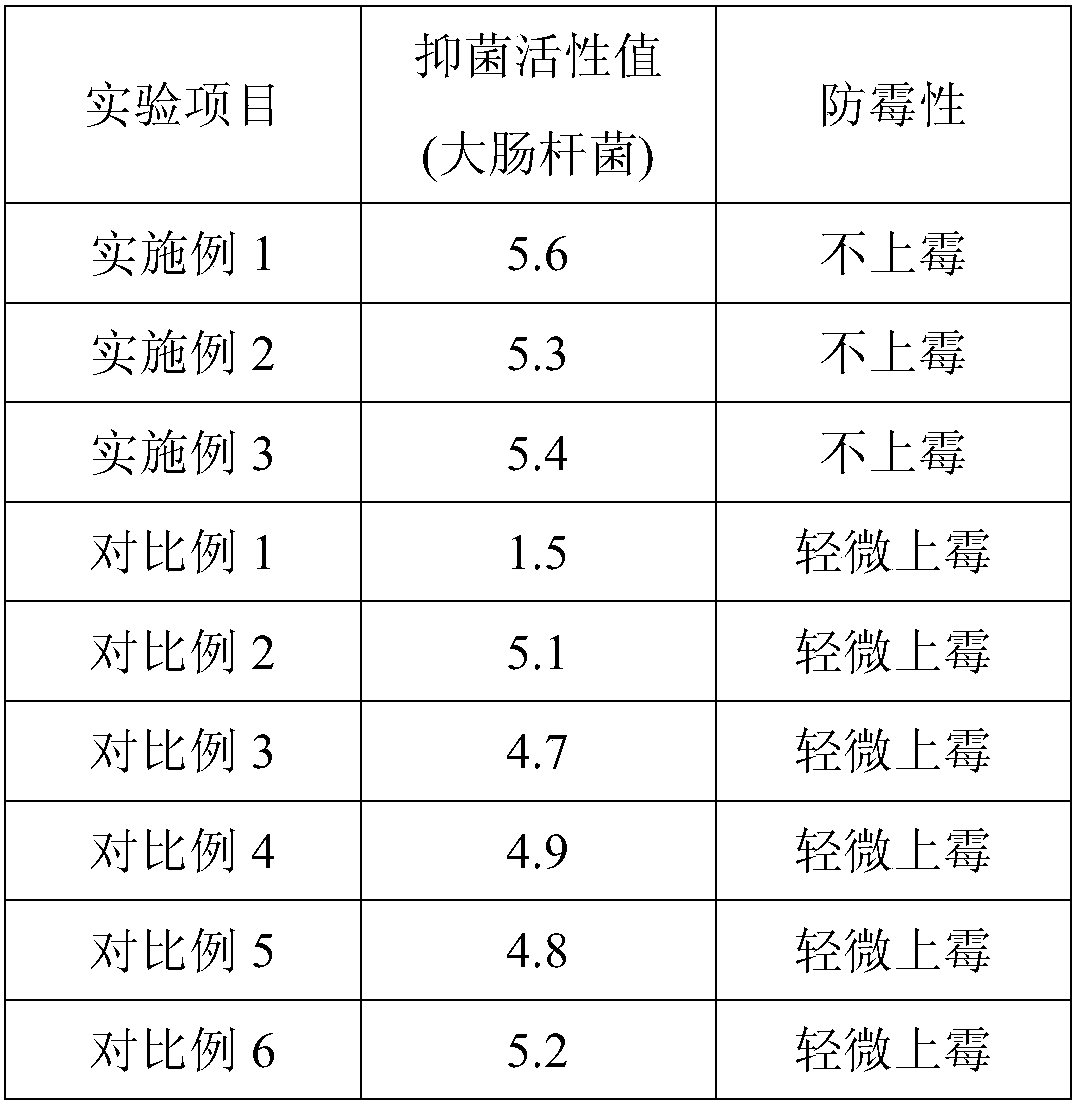

Toilet paper and preparation method thereof

InactiveCN108532354AImprove antibacterial propertiesImprove mildew resistanceNon-macromolecular organic additionVegetable material additionFiberCarbon fibers

The invention discloses toilet paper and a preparation method thereof, and belongs to the technical field of toilet paper preparation. The toilet paper comprises tree peony roots and barks, potato extracts, lemon extracts, argy wormwood leaf oil, heartleaf houttuynia herbs, polyethyleneimine, balsam pear fruit juice, polylactic acid, bamboo carbon fibers, antimicrobial modified additives, mold-proof modified additives, melamine resin and 1, 3-butylene glycol. The toilet paper includes the steps: preparing modified materials; adding the tree peony roots and barks, the potato extracts, the lemonextracts, the argy wormwood leaf oil and the heartleaf houttuynia herbs into straw pulp to stir mixture; adding the modified materials, the polyethyleneimine and the balsam pear fruit juice to uniformly stir mixture; producing big-roll toilet paper by a conventional method; enabling the water content of the toilet paper to be 8% or more; performing cutting, sealing and packaging to obtain the toilet paper. The toilet paper prepared by the method has excellent antibacterial and mold-proof performances.

Owner:长沙小新新能源科技有限公司

35kV shielding type separable connector and expansion method thereof

ActiveCN102142623AGood electrical conductivityCompact assemblyLine/current collector detailsCoupling contact membersEngineeringElectrical and Electronics engineering

The invention relates to a 35kV shielding type separable connector, comprising at least two same T-shaped separable connectors and at least one middle connector, wherein horizontal parts of the T-shaped separable connectors are provided with first cavity bodies and second cavity bodies which are mutually communicated, and vertical parts of the T-shaped separable connectors are provided with third cavity bodies along the vertical direction; the T-shaped separable connectors are in bilateral symmetry relative to the longitudinal axes of the third cavity bodies; conducting units are prefabricated in the T-shaped separable connectors, are arranged among the first cavity bodies and the second cavity bodies and are communicated with the third cavity bodies; the middle connector comprises insulating jackets and a hollow conducting rod sheathed in the insulating jackets; the insulating jackets are in bilateral symmetry, and the left half part and the right half part are respectively adaptive to the first cavity bodies and the second cavity bodies; and the two ends of the conducting rod are respectively and fixedly connected with a connecting piece. In the 35kV shielding type separable connector, the electric performance effect is good, the multi-stage expansion can be realized, and the expansion method is used for connecting the plurality of T-shaped separable connectors in series.

Owner:GCA CO LTD

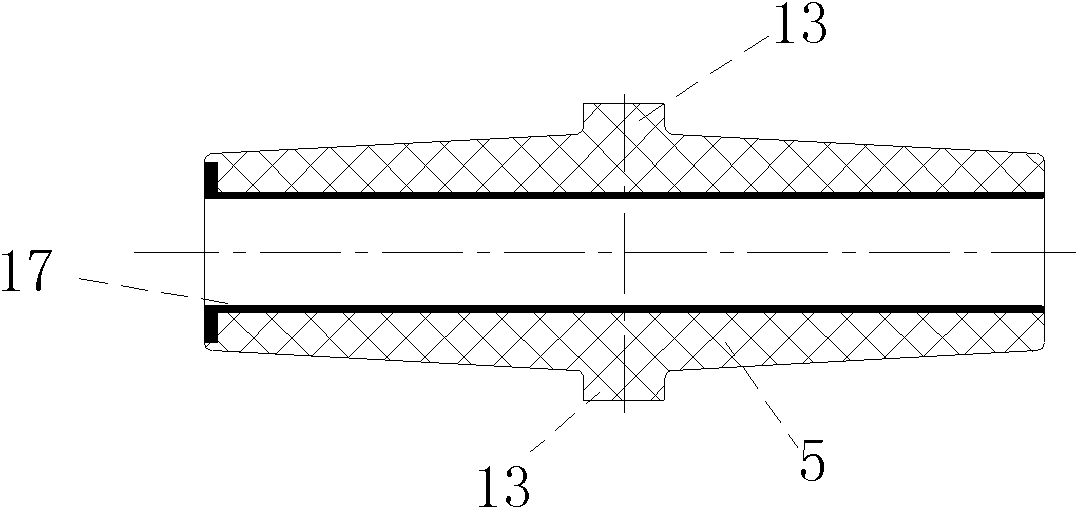

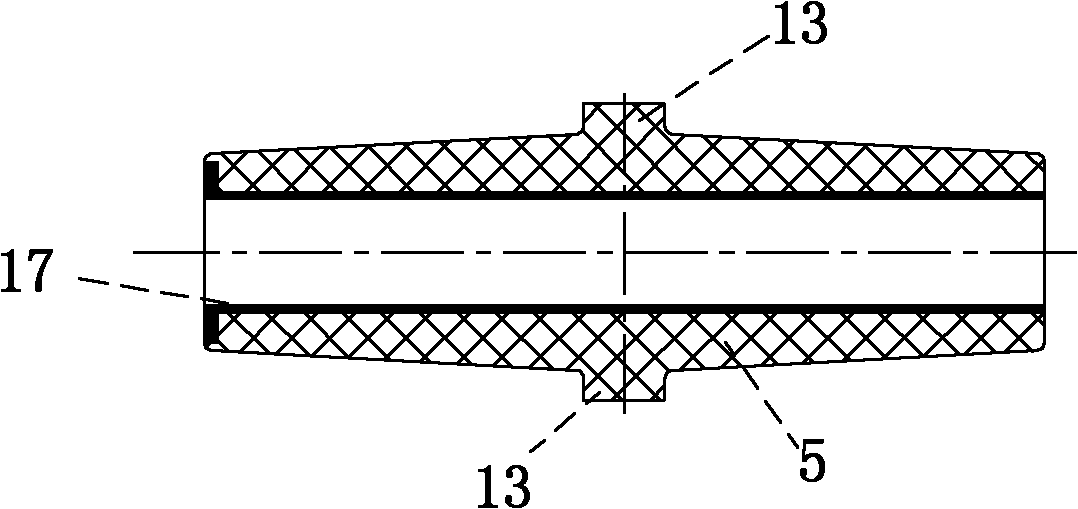

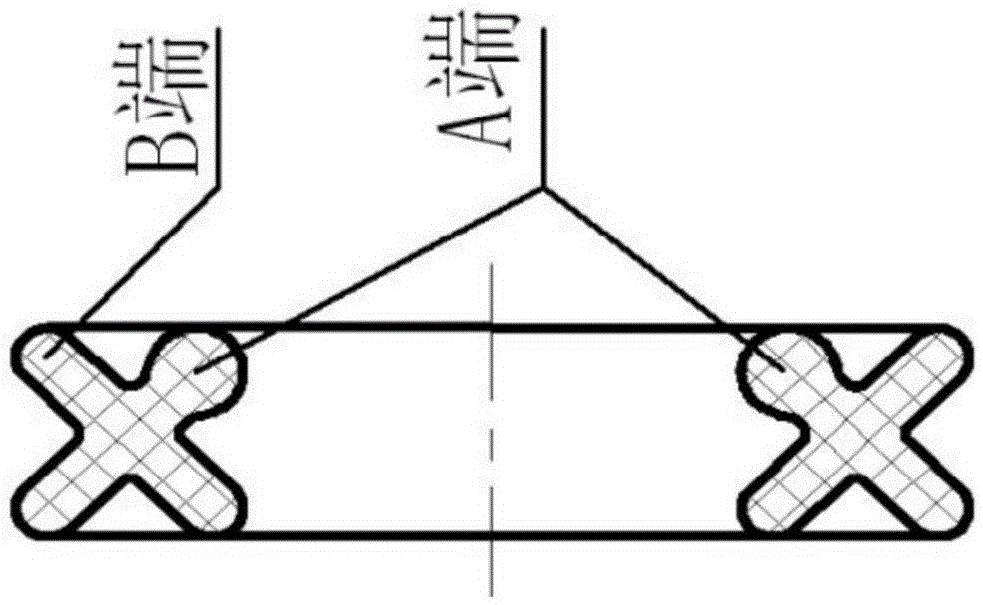

Large-displacement oil seal chain

InactiveCN106065922AImprove oil sealing abilityStrong resistanceEngine sealsDriving chainsInterference fitEngineering

The invention provides a large-displacement oil seal chain which comprises an outer single joint, an inner single joint and a sealing ring, which are matched, wherein the sealing ring is positioned between contact surfaces of the inner single joint and the outer single joint; the inner single joint comprises a sleeve, inner chain plates and rollers, which are assembled and matched; the outer single joint comprises a pin roll sleeved by the sleeve and outer chain plates, which are arranged in an interference fit manner; the sealing ring is X-shaped, and four end parts of the X-shaped sealing ring adopt circular-arc-shaped structures; and the circular-arc diameter of the end part, which is in contact with one outer chain plate, of the sleeve is 1.4 times that of other three end parts of the sleeve. The chain has high tensile strength, high fatigue strength and high wear resistance.

Owner:青岛征和链传动有限公司

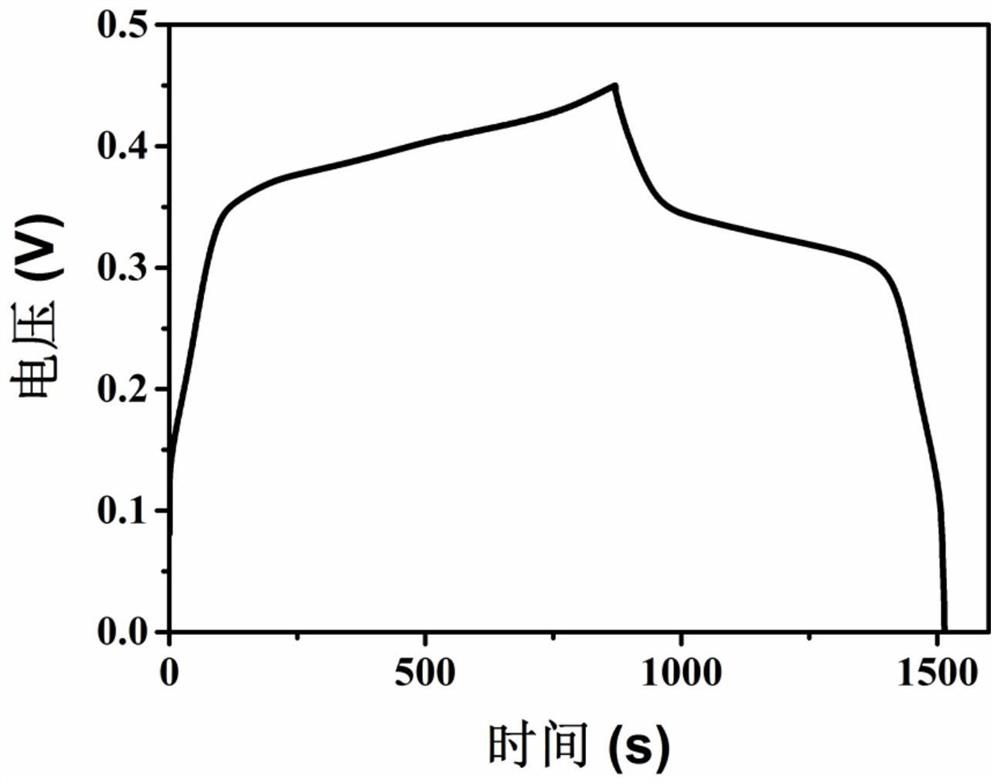

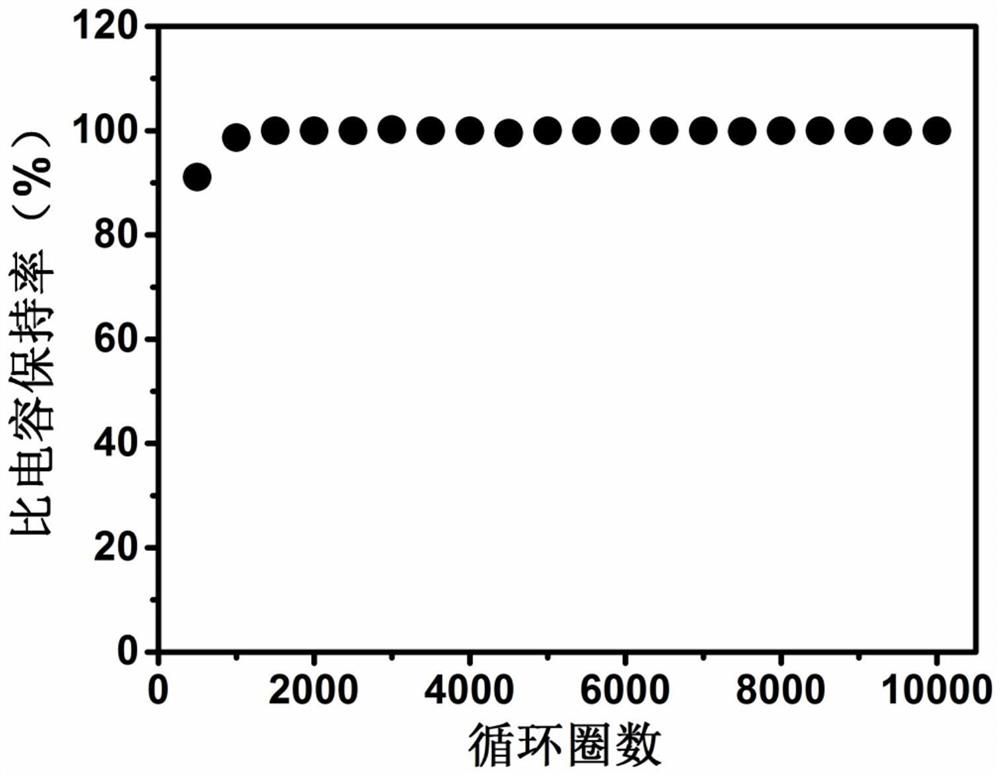

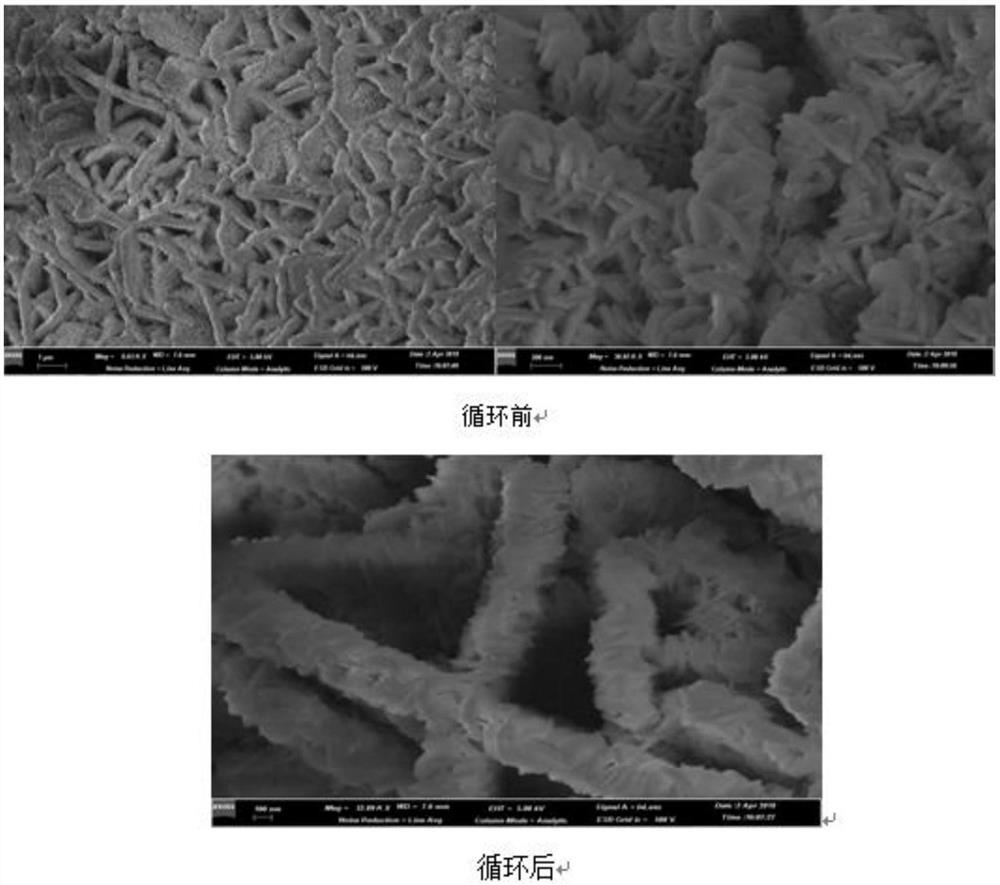

Preparation method of NiO@CoMoO4/NF capacitor electrode

ActiveCN113421775AImprove conductivityFacilitated DiffusionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrolytic agent

The invention discloses a preparation method of a NiO@CoMoO4 / NF capacitor electrode. The NiO@CoMoO4 / NF capacitor electrode is prepared by taking NF, COCl2.6H2O, Na2MOO4.2H2O, glucose and a tough material as raw materials through the steps of preparation of NiO@CoMoO4 / NF, loading of NiO@CoMoO4 / NF carbon quantum dots, coating of the NiO@CoMoO4 / NF tough material loaded with the carbon quantum dots and the like. The NiO@CoMoO4 / NF has a higher specific capacitance value, meanwhile, the conductivity of the electrode can be greatly improved, on the other hand, the NiO@CoMoO4 / NF electrode is treated by a ductile material, so that the NiO@CoMoO4 / NF electrode can adapt to volume change in the charging and discharging process, meanwhile, the corrosion effect of an electrolyte can be prevented, finally, the product is good in cycling stability, and after 10000 times of charging and discharging cycles, the capacity is not attenuated, 100% of the maximum capacity is still kept, the mass specific capacitance is greatly increased, the mass specific capacitance of the electrode at 1 A / g can reach 1457 F / g, the electrochemical energy storage is excellent, and the electrode is worthy of market popularization.

Owner:CHONGQING UNIV OF ARTS & SCI

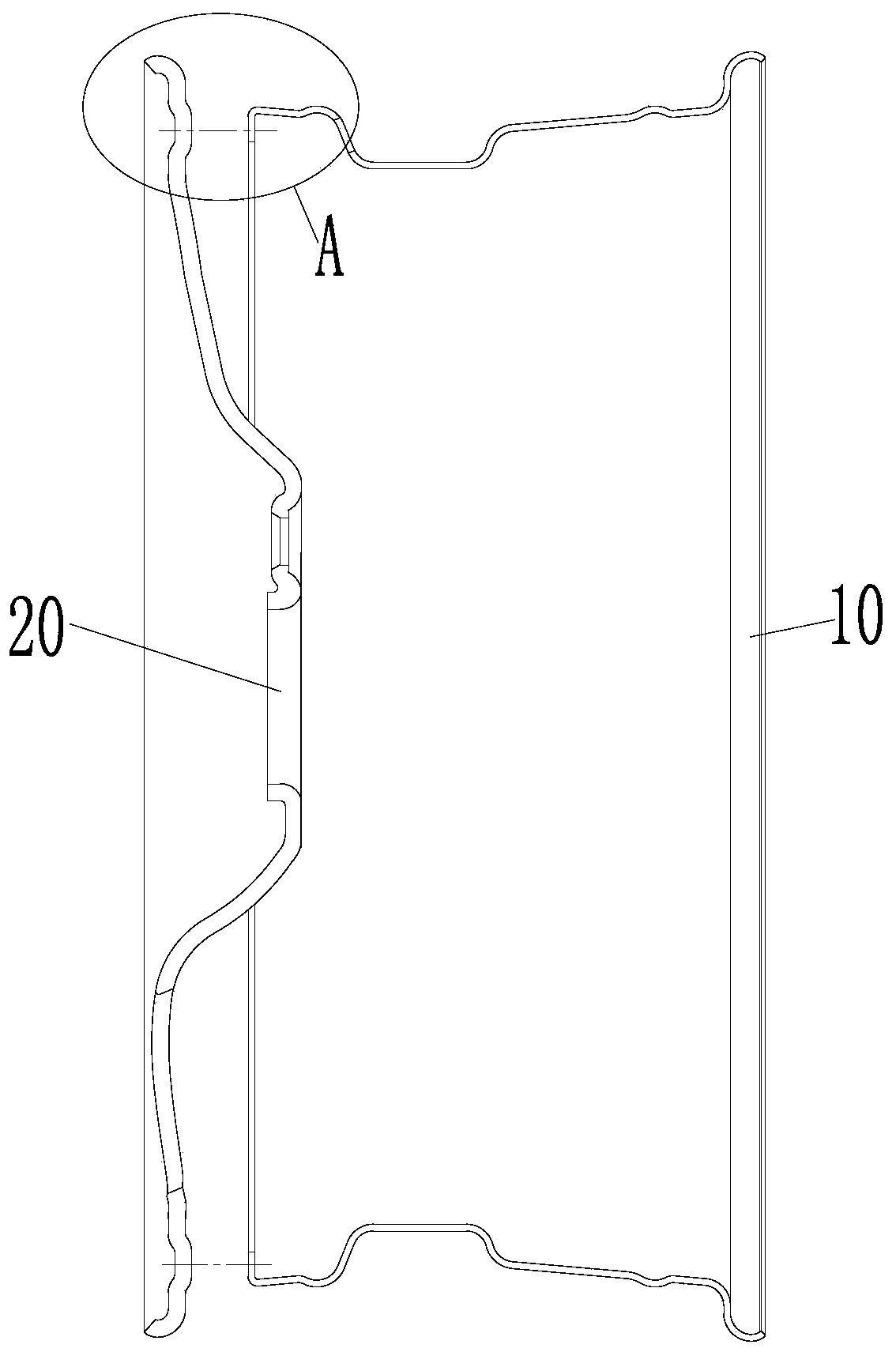

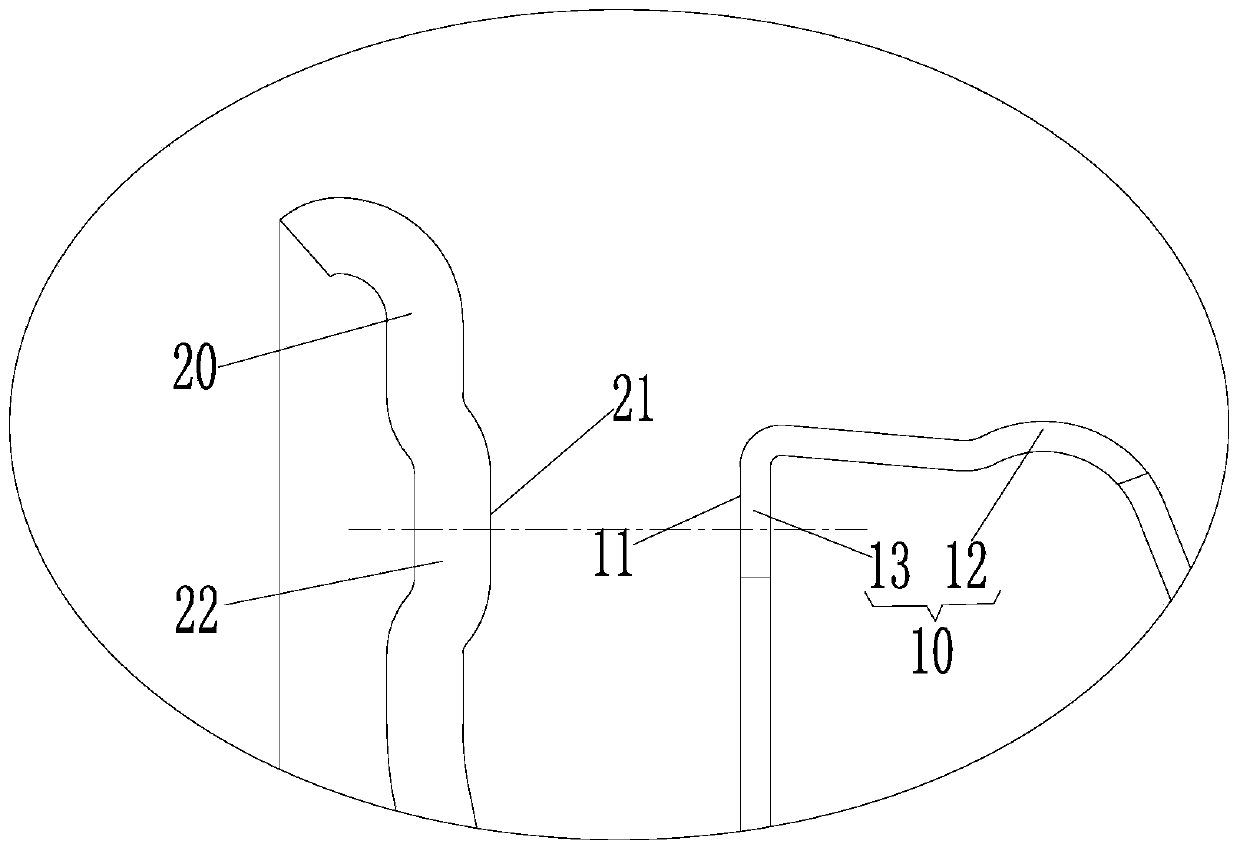

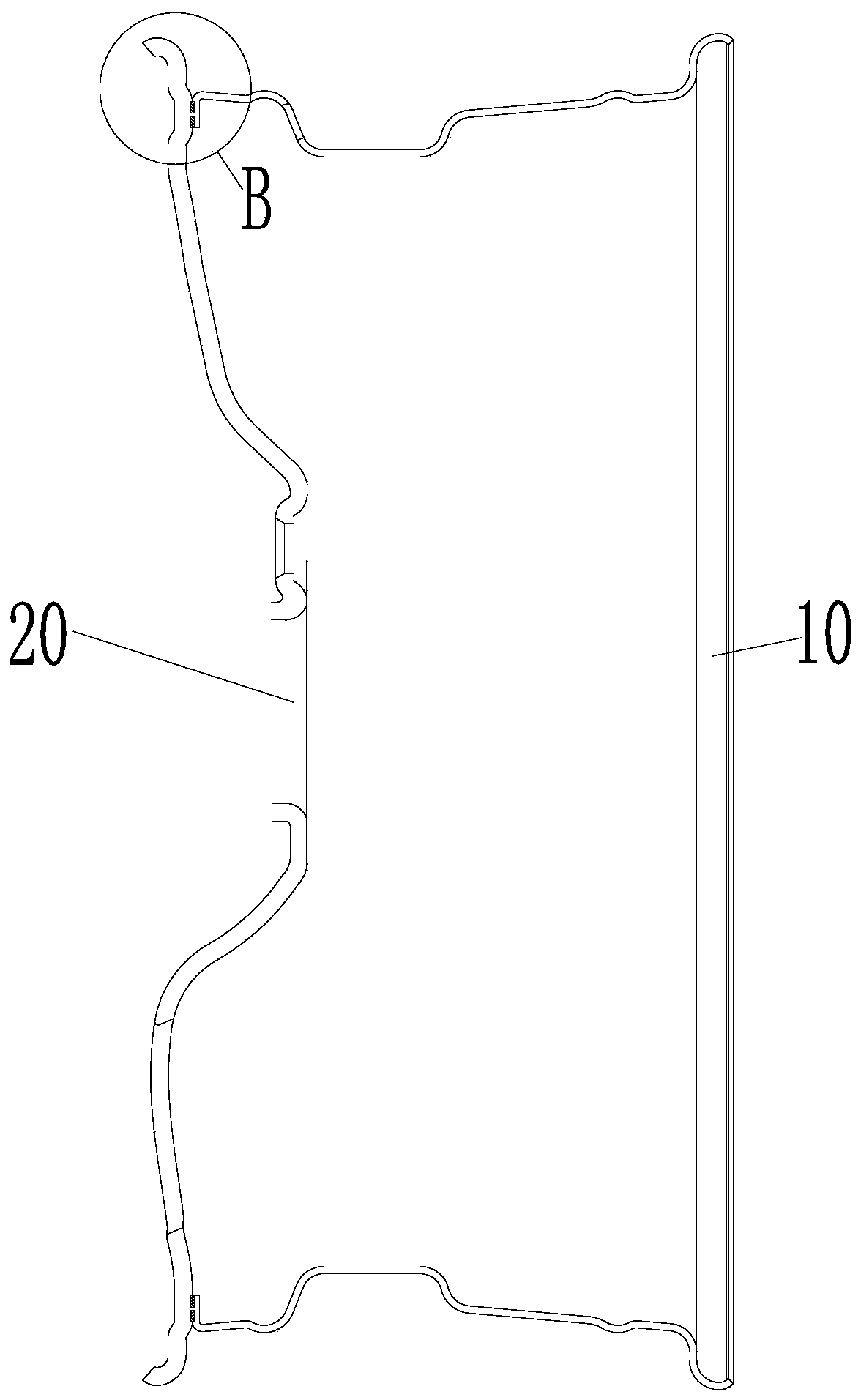

Wheel

InactiveCN110303817AImprove connection stabilityImprove structural strengthDisc wheelsLaser beam welding apparatusEngineeringContact position

The invention provides a wheel. The wheel comprises a rim and a spoke, wherein the rim comprises a rim body and a bent flange, the bent flange is connected with the edge of the rim body, and a first connecting surface is formed on the end surface, facing away from the rim body, of the bent flange; the part of the surface of the axial end of the spoke forms a second connecting surface, the spoke issubjected to laser welding with the first connecting surface through the second connecting surface, welding bead structures used for fixedly connecting the rim and the spoke are formed, the number ofthe welding bead structures is two, the one welding bead structure is located at the radial outer side of the contact position between the first connection surface and the second connection surface,and the other welding bead structure is located at the radial inner side of the contact position between the first connecting surface and the second connecting surface. The wheel solves the problem that the welding mode and the welding position of the wheel in the prior art are not reasonable, the structure of the wheel manufactured by machining is not stable, is poor in strength and cannot meet the use requirement of a wheel with a relatively long service life.

Owner:ZHEJIANG JINGU CO LTD

Fabricated shock absorption and impact resistance ground and mounting method thereof

PendingCN113417432AEasy to laySave time waiting for dryingCovering/liningsFlooring insulationsClassical mechanicsEngineering

The invention discloses a fabricated shock absorption and impact resistance ground. The fabricated shock absorption and impact resistance ground comprises an overhead mechanism (1) arranged on an original ground, a moisture-proof base plate (2) arranged on the overhead mechanism and a floor surface layer (3) arranged above the moisture-proof base plate; the moisture-proof base plate comprises base plate units which are spliced with one another, and the floor surface layer comprises panel units which are spliced with one another; the overhead mechanism comprises a first overhead assembly and a second overhead assembly; and the overhead assembly comprises a leveling base, a leveling screw rod arranged on the leveling base, a base plate supporting seat arranged on the leveling screw rod, a supporting piece arranged below the base plate supporting seat and used for bearing the base plate supporting seat, a supporting spring arranged on the leveling screw rod above the base plate supporting seat in a sleeving mode and a limiting spring. The fabricated shock absorption and impact resistance ground has shock-resisting and shock-absorbing functions, facilitates pipeline laying, shortens the construction period and has certain sound insulation performance.

Owner:ZHEJIANG YASHA DECORATION

Herba dendrobii officinale healthcare soap and preparation method thereof

InactiveCN108865526AGood antibacterial propertiesGood biocompatibilitySoap detergents with organic compounding agentsDetergent compounding agentsBorneolPolylactic acid

The invention discloses herba dendrobii officinale healthcare soap. The herba dendrobii officinale healthcare soap is prepared from the following raw materials: blend oil, alcohol, glycerinum, EDTA, white sugar, water, herba dendrobii officinale, flos lonicerae, radix scutellariae, cortex cinnamomi, cortex moutan, folium artemisiae argyi, clove, radix angelicae, borneol, fructus gleditsiae, licorice root, antibacterial additive, polylactic acid, zeolite, zinc oxide, and silane coupling agent KH-560. The invention also provides a preparation method of the herba dendrobii officinale healthcare soap. The prepared soap is excellent in antibacterial performance.

Owner:安徽皖斛堂生物科技有限公司

Antibacterial polyvinyl chloride resin and preparation method thereof

The invention discloses antibacterial polyvinyl chloride resin, and belongs to the technical field of resin preparation. The antibacterial polyvinyl chloride resin is prepared from polyvinyl chlorideresin, polylactic acid, organic fluorine epoxy resin, polyphenylene sulfide, polycarbonate, polyhydroxybutyrate, vinyl acetate, calcium molybdate, chitosan, zinc borate, kieselguhr, wood fiber powder,chlorinated paraffin, polyethylene glycol, trioctyl trimellitate, polycaprolactone, trimethyl phosphate, tributyl citrate, adipic dihydrazide, tartaric acid, potassium peroxodisulfate, zinc phosphate, fluorine micro powder, nanometer titania, a silane coupling agent KH-560 and antibacterial performance additives. The antibacterial polyvinyl chloride resin is prepared through the steps of preparing a base material, preparing a modified material, mixing the base material, the modified material and other materials and the like. The prepared polyvinyl chloride resin has the excellent antibacterial performance.

Owner:HWASU

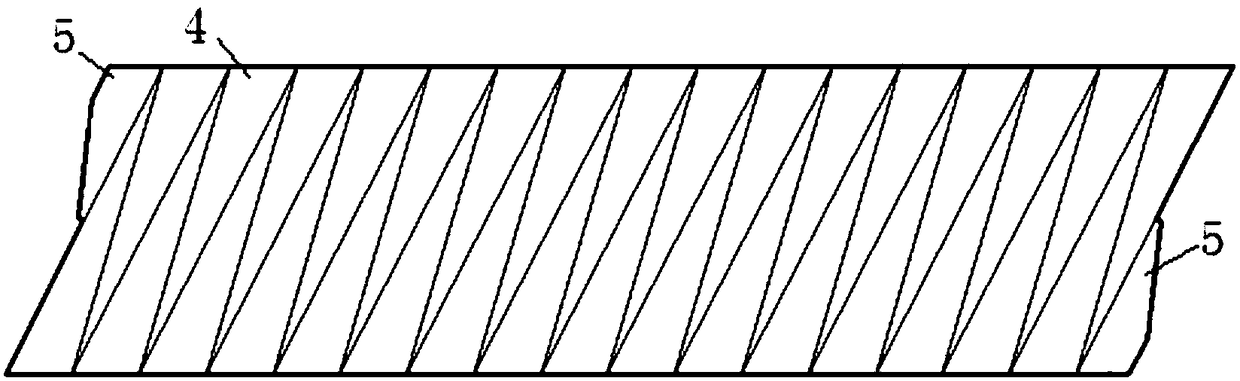

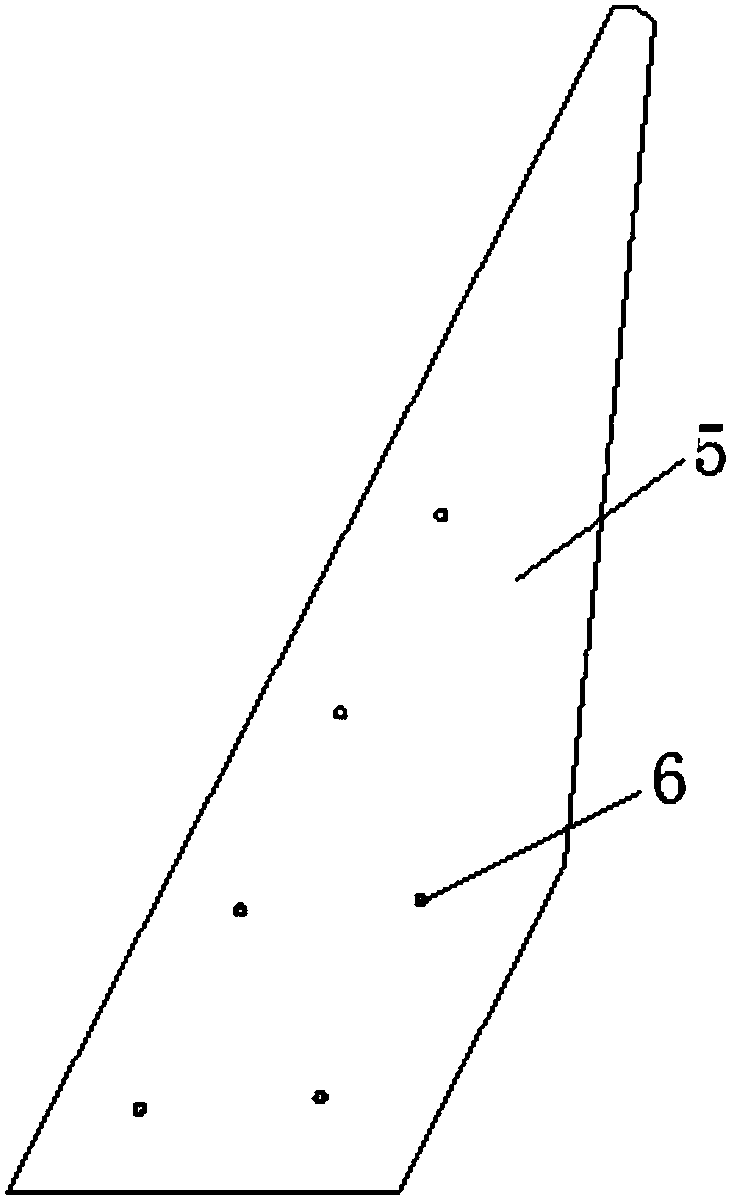

Side welding method of deformable metal foil structure with small initial inclined angle

InactiveCN108723621AHigh strength after weldingHigh strengthSoldering apparatusWelding apparatusCompression moldingMetal foil

The invention particularly relates to a side welding method of a deformable metal foil structure with a small initial inclined angle, and belongs to the field of special welding and connecting of deformable metal foil structures. The invention aims to solve the problem that the side of a deformable metal foil structure with a small initial inclined angle is difficult to weld. The side welding method comprises the following steps: first, the arrangement of a connector; second, the arrangement of six spot welding positions; third, compression molding to obtain a before-brazing deformable metal foil structure ; fourth, spot welding to obtain an after-spot welding structure; and fifth, the adoption of a heat treatment furnace to complete the side welding of the deformable metal foil structurewith the small initial inclined angle. The side welding method has the advantage of being capable of bearing 1.2 atm pressure difference. The side welding method is mainly used for side welding of thedeformable metal foil structure with the small initial inclined angle.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com