A phase-change heat storage material and a preparing method thereof

A technology of phase-change heat storage materials and mixtures, which is applied in the field of new energy and energy-saving materials, can solve the problems that the performance expectations of inorganic salt phase-change heat storage materials cannot be met, and achieve stable overall shape, high heat storage density, shape retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

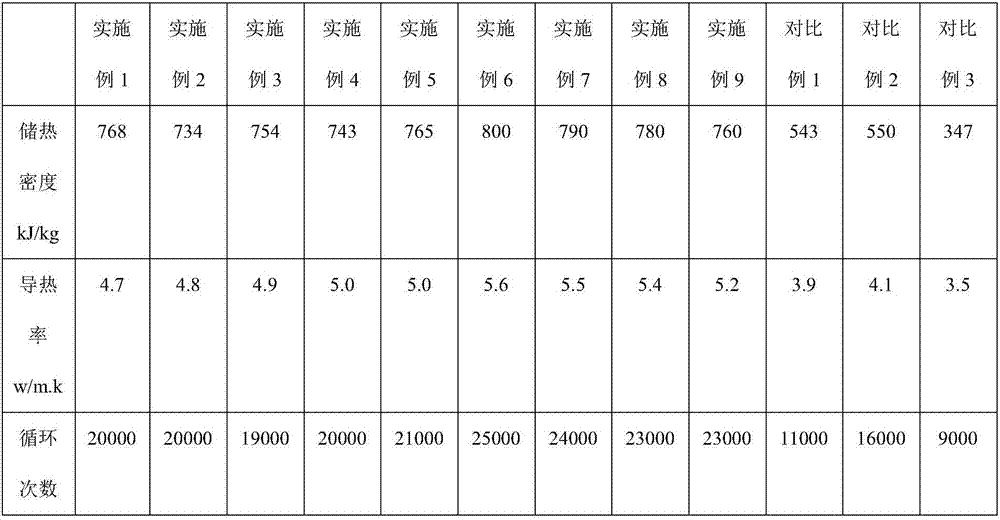

Examples

Embodiment 1

[0031] This embodiment provides a phase change heat storage material, which includes the following raw materials:

[0032] Sodium carbonate 25g, lithium carbonate 30g and magnesium oxide 30g.

[0033] A method for preparing a phase change heat storage material, comprising the steps of:

[0034] (1) sodium carbonate, lithium carbonate and magnesium oxide are dried at 90°C;

[0035] (2) Use a ball mill to crush sodium carbonate and lithium carbonate to a particle size of 3 μm, mix evenly, use a ball mill to crush magnesium oxide to a particle size of 10 μm, and mix the mixture of magnesium oxide, sodium carbonate and lithium carbonate at a pressure of 15Mpa Next, press for 60s to form;

[0036] (3) Sintering at 750° C. for 0.5 h to obtain a phase change heat storage material.

Embodiment 2

[0038] This embodiment provides a phase change heat storage material, which includes the following raw materials:

[0039] Sodium carbonate 22g, barium carbonate 20g and magnesium oxide 48g.

[0040] A method for preparing a phase change heat storage material, comprising the steps of:

[0041] (1) drying sodium carbonate, barium carbonate and magnesium oxide at 130°C;

[0042] (2) Use a ball mill to crush sodium carbonate and barium carbonate to a particle size of 5 μm, mix evenly, use a ball mill to crush magnesium oxide to a particle size of 5 μm, and mix the mixture of magnesium oxide, sodium carbonate and barium carbonate at a pressure of 20 MPa Next, press for 50s to form;

[0043] (3) Sintering at 750° C. for 1 hour to obtain a phase change heat storage material.

Embodiment 3

[0045] This embodiment provides a phase change heat storage material, which includes the following raw materials:

[0046] 65g of carbonate, 48g of magnesium oxide and 3g of kaolin; wherein the carbonate includes potassium carbonate and sodium carbonate with a mass ratio of 50:50.

[0047] A method for preparing a phase change heat storage material, comprising the steps of:

[0048] (1) drying sodium carbonate, potassium carbonate and magnesium oxide at 100°C;

[0049] (2) Sodium carbonate and potassium carbonate were pulverized to a particle size of 2 μm by a ball mill, and ground and mixed to form eutectics, and magnesium oxide was pulverized to a particle size of 7 μm by a ball mill, and the co-crystal of magnesium oxide and kaolin with sodium carbonate and potassium carbonate was The crystals are mixed and pressed for 50 seconds under a pressure of 30Mpa;

[0050](3) Sintering at 730° C. for 2 hours to obtain a phase change heat storage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com