Side welding method of deformable metal foil structure with small initial inclined angle

A technology of initial angle and welding method, applied in welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult welding of deformable metal foil structures, achieve good sealing, increase post-weld strength, and structural sealing strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

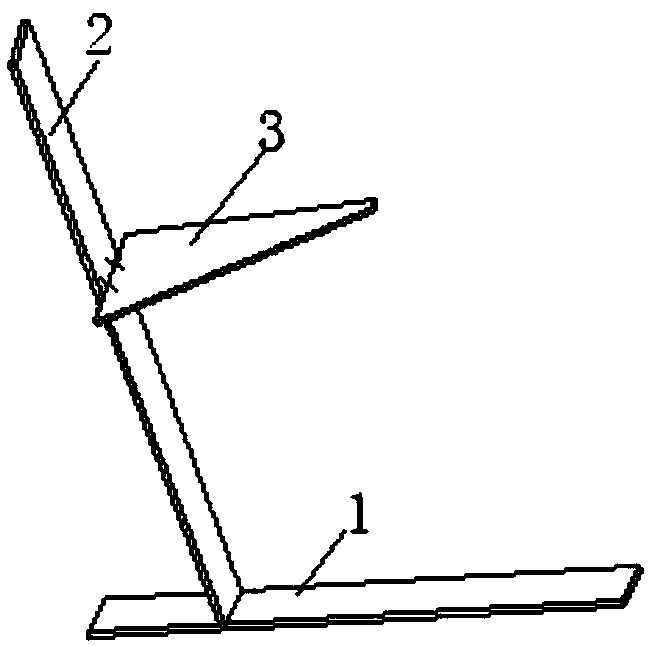

[0020] Specific implementation mode 1: This implementation mode is a side welding method of a deformable metal foil structure with a small initial angle, which is specifically completed according to the following steps:

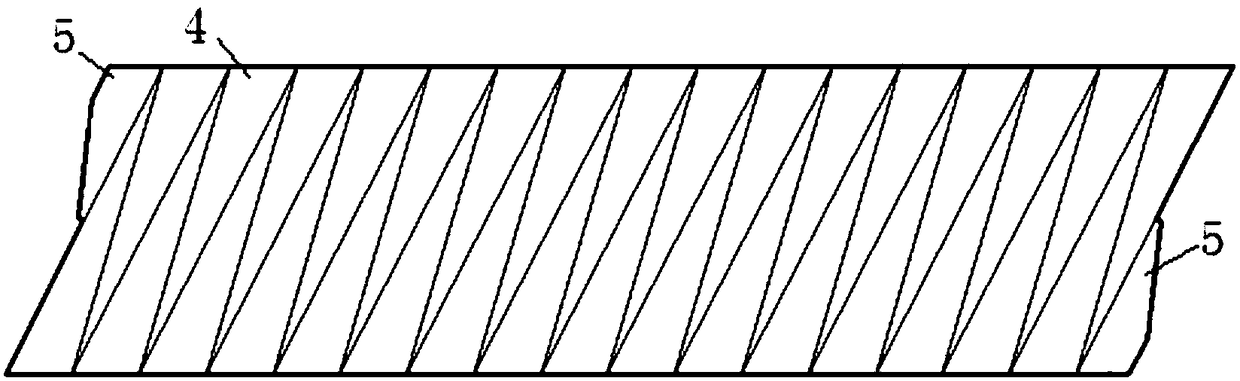

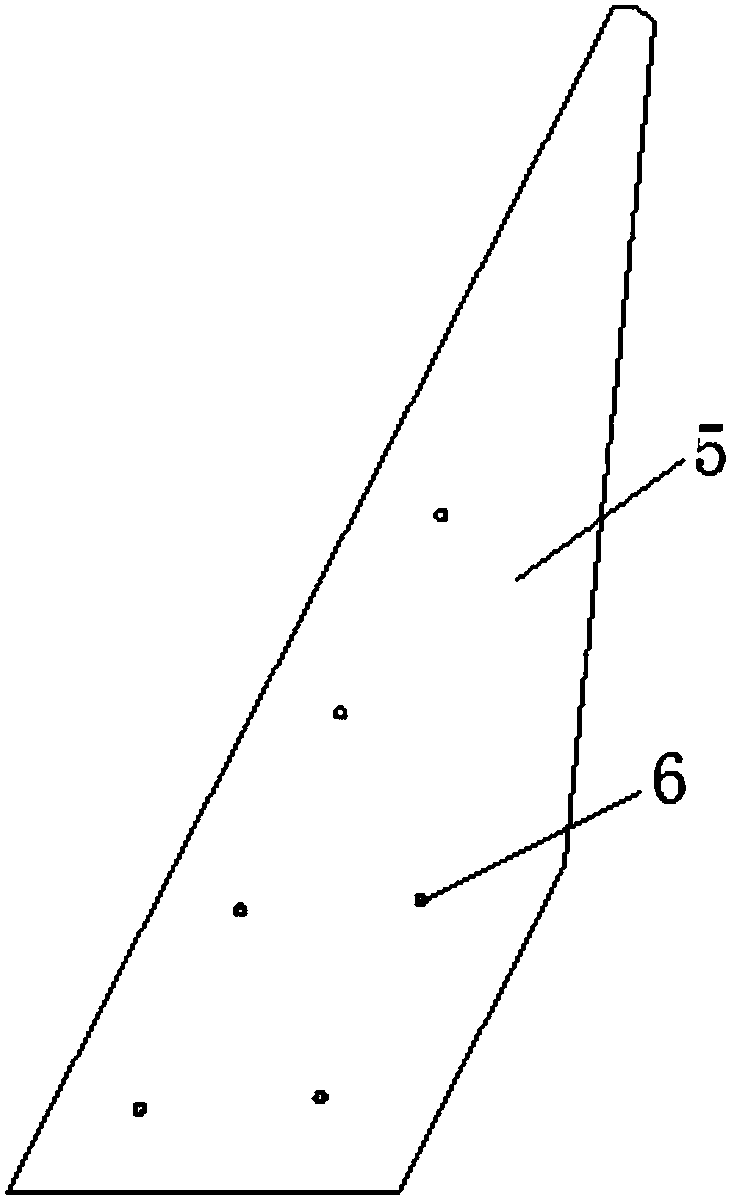

[0021] 1. Joints are arranged on both sides of the deformable metal foil structure foil sheet, the deformable metal foil structure foil sheet is parallelogram, and the deformable metal foil structure foil sheet is composed of multiple identical triangular blades Composition, the plane shape formed by two adjacent triangular blades is a parallelogram, the outermost two triangular blades of the deformable metal foil structure foil sheet are the blades to be welded, and the joint is set at the minimum of the longest hypotenuse of the blade to be welded Acute angle end, and the joint set on the blade to be welded is lap-welded with the blade to be welded on the other side. During lap welding, the joint will not interfere with other parts except the blade to be wel...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the deformable metal foil structure foil sheet in step 1 is composed of a plurality of identical triangular blades, and the longest hypotenuse of the triangular blades is The length is 207mm, the length of the shortest side is 40mm, and the angle of the smallest acute angle corresponding to the shortest side is 11°. Others are the same as the first embodiment.

[0028] The included angle of the deformable metal foil structure with a small initial angle made of the deformable metal foil structure foil sheet provided in this embodiment is 35°.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the joint described in step one is hexagonal ABCDLK, the side AB of the hexagonal ABCDLK is on the extension line of the shortest side of the blade to be welded, and the side AK Coincident with the longest hypotenuse of the blade to be welded, the length of side AB is 30mm, the length of side BC is 28mm, the length of side CD is 65mm, the angle between side AB and side BC is 117°, the length of side BC and side CD The included angle is 159°, the side DL is a 45° chamfered side, and the length of the side DL is 2mm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com