Preparation method and packaging method of a metal airgel-based solder preform

A solder preform and airgel-based technology, applied in airgel preparation, metal processing equipment, welding equipment, etc., can solve problems such as insufficient strength, difficult coating, holes, etc., and achieve stable welding quality and low cost , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A silver nanowire airgel-based solder preform and packaging method thereof, the specific method comprising:

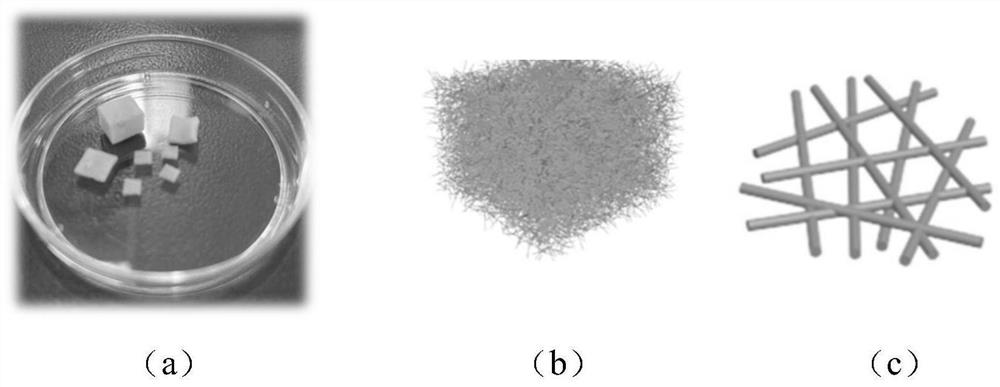

[0046] (1) Use lignin and amino acid hydrolysis monomers to prepare three-dimensional growth active agents, and mix them with metal precursors (AgNO 3 ), surfactant (PVP), oxidizing agent (FeCl 3 ), etc., and stir evenly; put it into a closed reaction mold for heating, and react to obtain a silver nanowire airgel-based tissue containing a solvent inside, and use a sodium chloride solution (1M) to clean the obtained silver nanowire gel tissue to remove its The remaining reaction reagents and free nanowire monomers in the interior are dried again, and the surface is cut with a low-voltage electron beam to remove the uneven area, and a silver nanowire aerogel with a thickness of about 5 mm is obtained; the obtained silver nanowire aerogel The schematic diagram of the structure of the glue is shown in figure 1 shown.

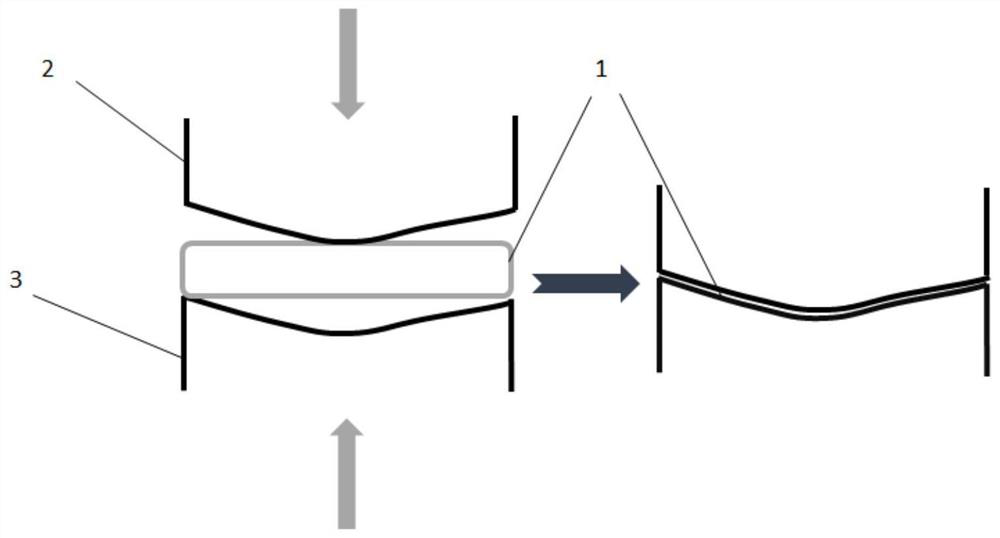

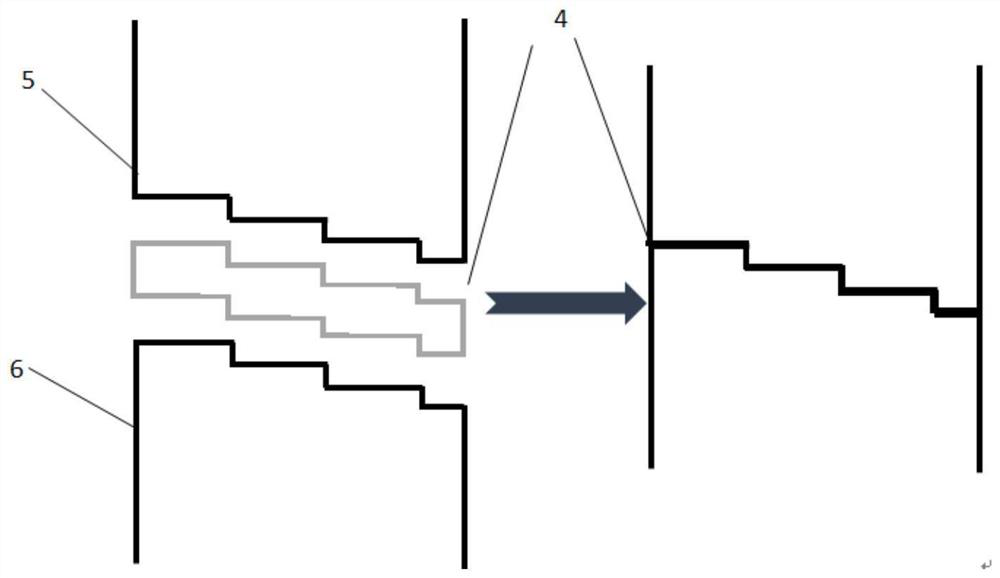

[0047] (2) Hot-press the obtained clean silv...

Embodiment 2

[0051] An application of a method for encapsulating a nano-copper wire airgel-based solder preform doped with nano-silver, the specific method comprising:

[0052] (1) Using silver nitrate as a precursor, PVP as a surfactant, ferric chloride as an oxidant, and ethylene glycol as a solvent, nano-silver particles were prepared by liquid phase reduction method, with an average particle size of 30-50 nm; The obtained nano-silver particles were repeatedly washed with ionized water and alcohol, and dried at 50°C to obtain clean nano-silver particles;

[0053] (2) Using copper sulfate pentahydrate as the precursor, sodium hypophosphite monohydrate as the reducing agent, diethylene glycol as the solvent, and PVP as the surface active agent as the reducing agent, copper nanowires were prepared by the liquid phase reduction method, using Repeated washing and centrifugation of the obtained copper nanowires with ethanol and deionized water solution to remove residual reagents; and using a...

Embodiment 3

[0060] A silver nanowire airgel preform and packaging method for depositing a Sn coating on the surface, the specific method comprising:

[0061] (1) The silver nanowire aerogel was prepared by liquid-phase induced reduction reaction and supercritical drying, and the obtained silver nanowire gel was washed with sodium chloride solution (1M), and the silver nanowire aerogel was aerosolized by electroless plating method. A Sn coating of about 20 nm was deposited on the surface of the gel, and a low-power laser was used for cutting to obtain a silver nanowire aerogel with a thickness of about 50 mm containing the Sn coating.

[0062] (2) The obtained silver nanowire airgel matrix with Sn coating was hot-pressed at low temperature, and then cut into preformed sheets with an average thickness of 50 μm, the hot-pressing temperature was 100 ℃, and the hot-pressing time was 10 min .

[0063] (3) Place the obtained silver nanowire airgel containing Sn coating between ceramic materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com