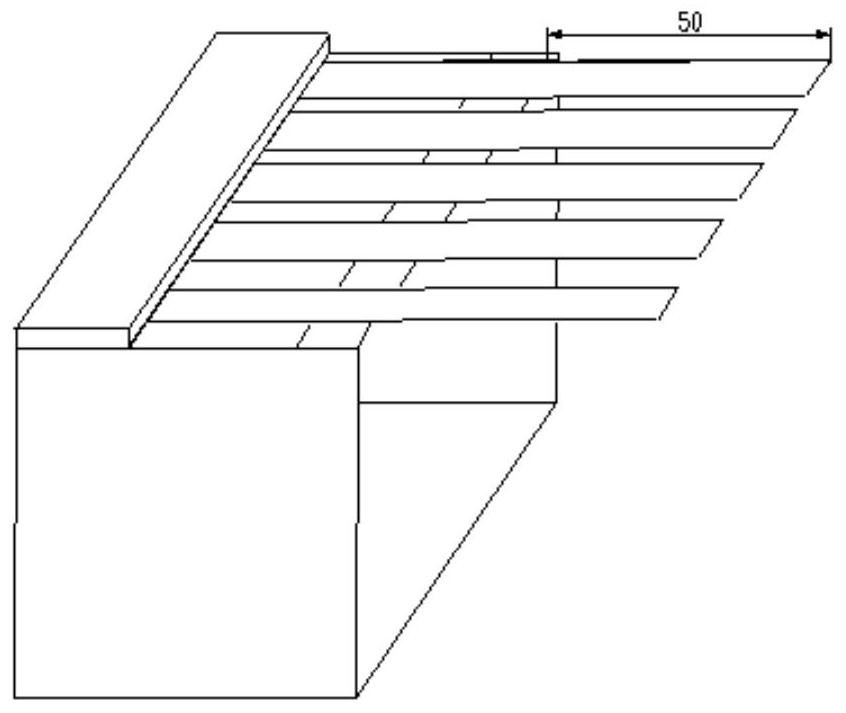

A kind of aluminum foil material for producing automobile heat dissipation composite fins and its preparation method

A composite fin and aluminum foil technology, applied in welding equipment, manufacturing tools, metal rolling, etc., can solve the complex production process of hot-rolled composite heat dissipation composite fins, achieve excellent anti-sag performance, reduce production costs, The effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

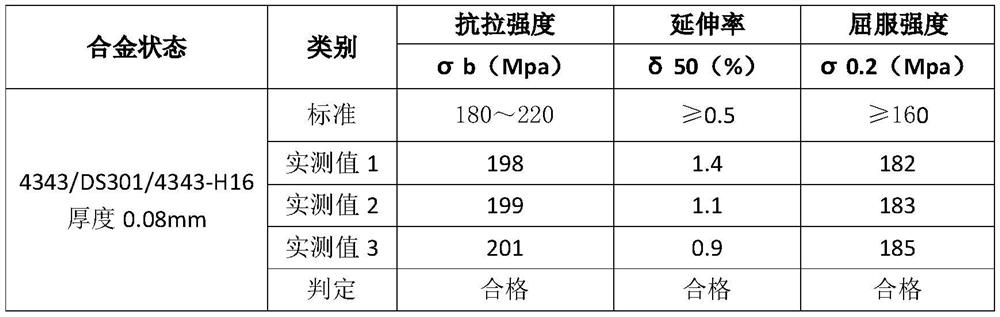

Examples

Embodiment 1

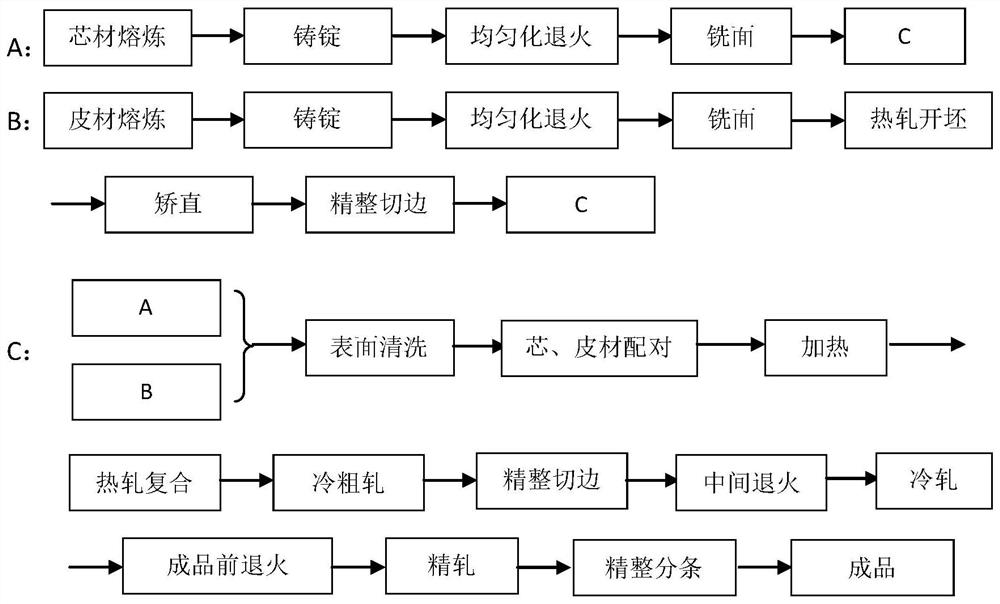

[0030] 1. According to the alloy ratio: silicon 0.6wt%, iron 0.2wt%, copper 0.05wt%, manganese 1.0wt%, magnesium 0.05wt%, zinc 1.1wt%, zirconium 0.1wt%, titanium 0-0.05wt%, smelting Finally, the core material cast-rolled plate is prepared by continuous casting and rolling; according to the alloy ratio: 6.8wt% silicon, 0.2wt% iron, 0.05wt% copper, 0.05wt% manganese, 0.02wt% zinc, and the remaining components are aluminum. After smelting Prepare cast-rolled sheet of leather material by continuous casting-rolling method;

[0031] 2. Core material preparation: cold-roll the core material cast-rolled plate to 4.0mm, weld the outer ring, tighten the steel strip on the plate surface, anneal in a high-temperature annealing furnace, heat up to the target heating temperature of 550°C within 3 hours and keep it for 26 hours. 530°C heat preservation for 5h, then air cooling out of the furnace to obtain the core material blank;

[0032] 3. Leather material preparation: Heat treatment of t...

Embodiment 2

[0058] 1. According to the alloy ratio: 0.95wt% silicon, 0.68wt% iron, 0.15wt% copper, 1.7wt% manganese, 0.08wt% magnesium, 1.8wt% zinc, 0.18wt% zirconium, the rest is aluminum, used after smelting The continuous casting and rolling method prepares the core cast rolling plate; according to the alloy ratio: 8.1wt% silicon, 0.8wt% iron, 0.2wt% copper, 0.1wt% manganese, 0.2wt% zinc, and the rest of the ingredients are aluminum. Cast-rolling method to prepare cast-rolled sheet of leather material;

[0059] 2. Core material preparation: core material cast-rolled plate is cold-rolled to 5.0mm, the outer ring is welded, the steel strip is tightened on the plate surface, annealed in a high-temperature annealing furnace, the temperature is raised to the target heating temperature of 580°C within 3 hours and kept for 22 hours, and the temperature is turned to 550°C ℃ for 3 hours, and then air-cooled after taking out the furnace to obtain a core material blank;

[0060] 3. Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com