Patents

Literature

36results about How to "Good anti-sagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

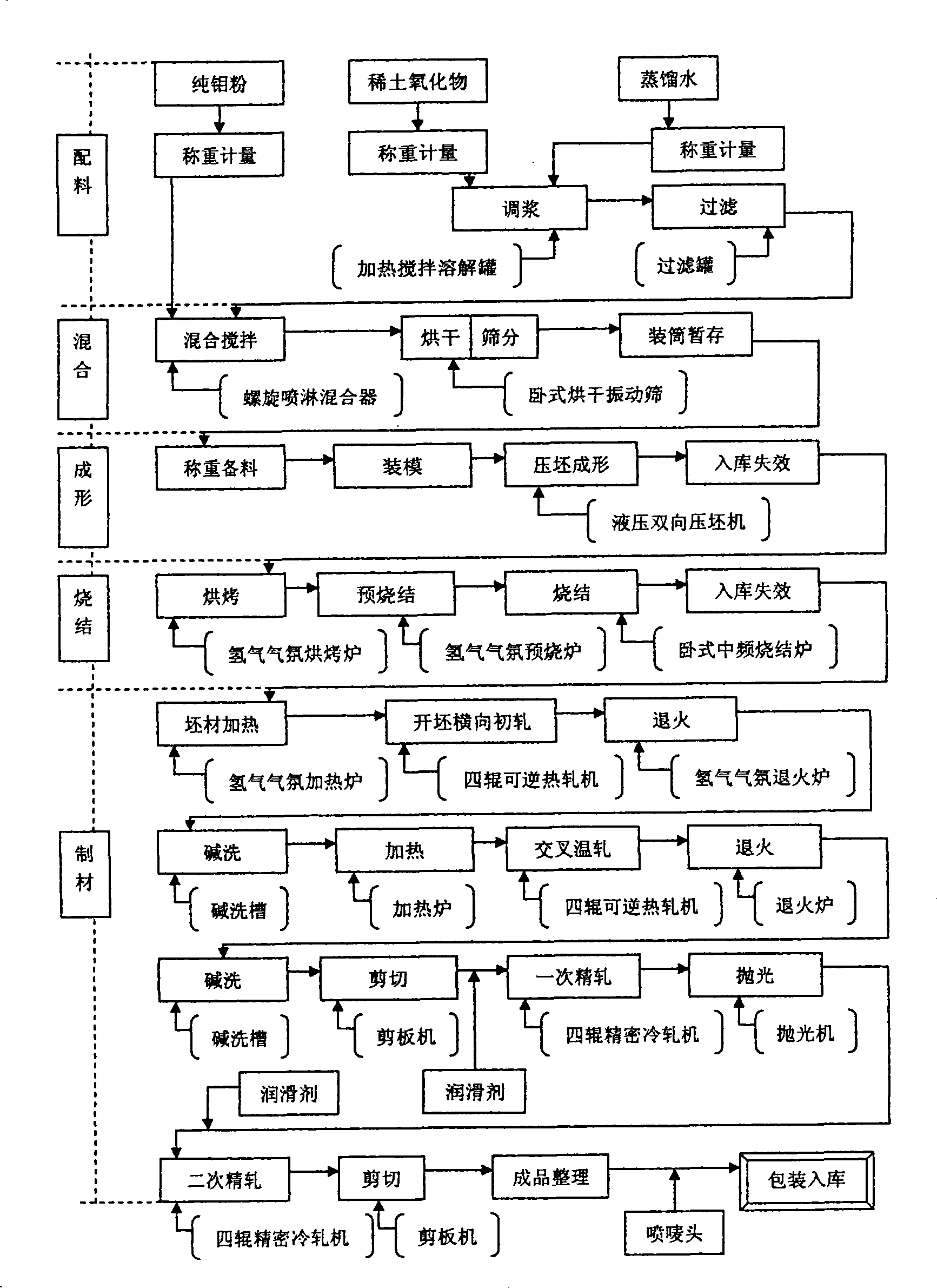

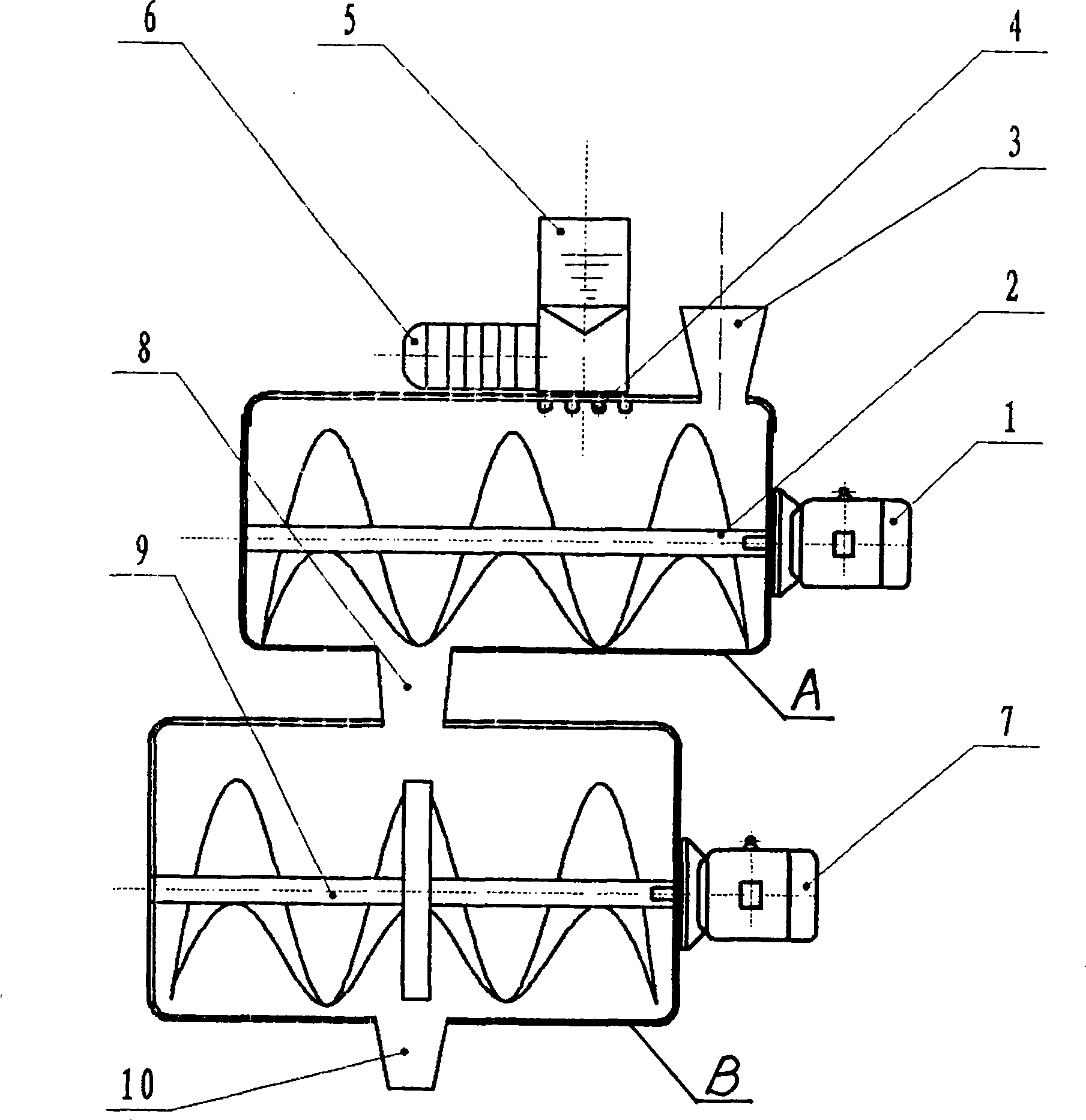

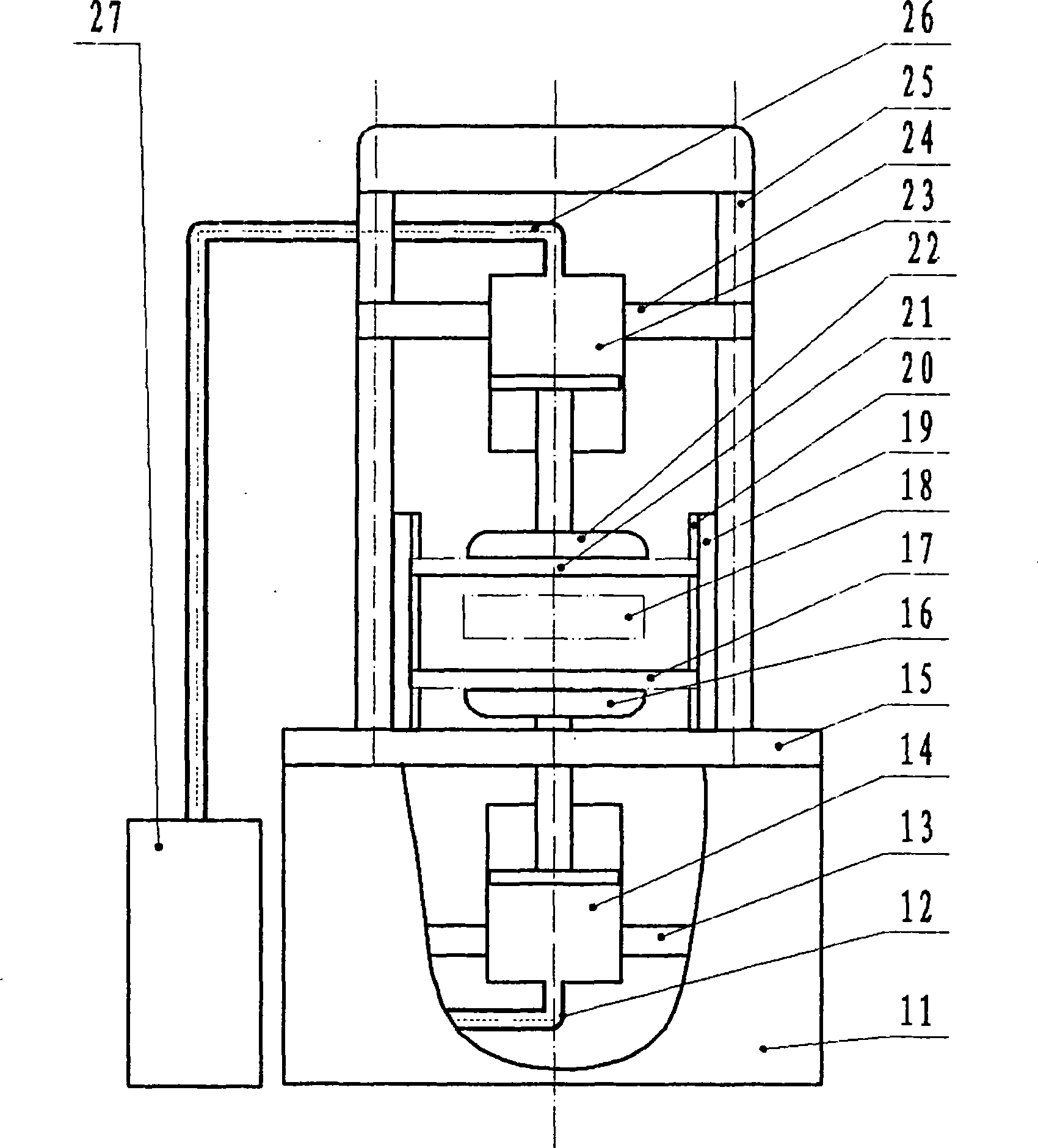

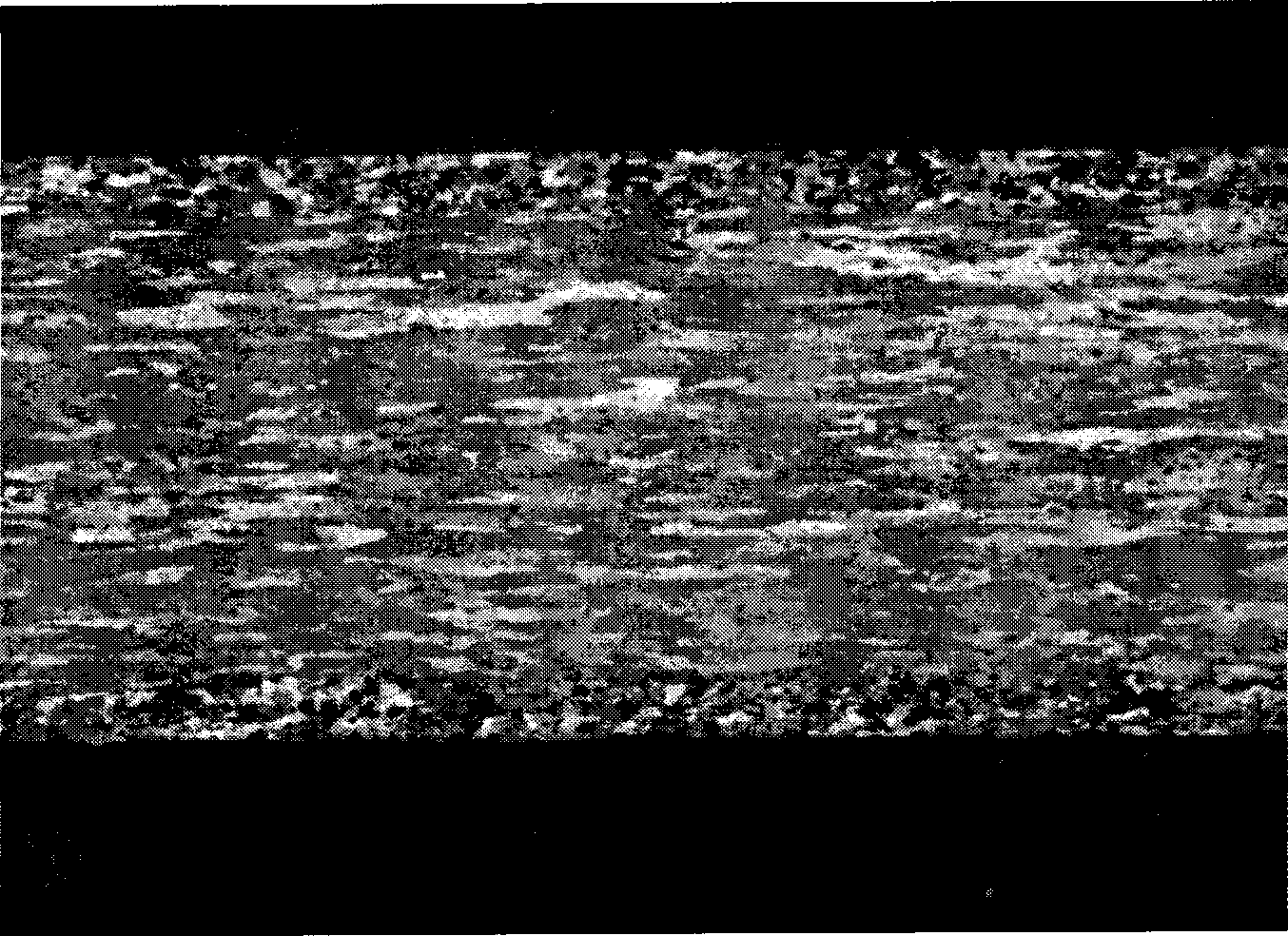

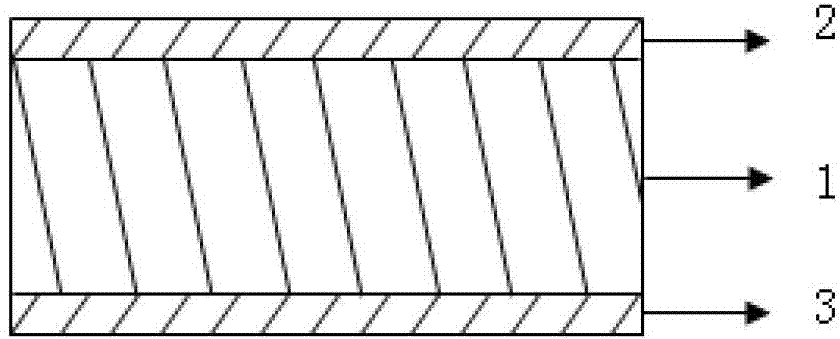

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

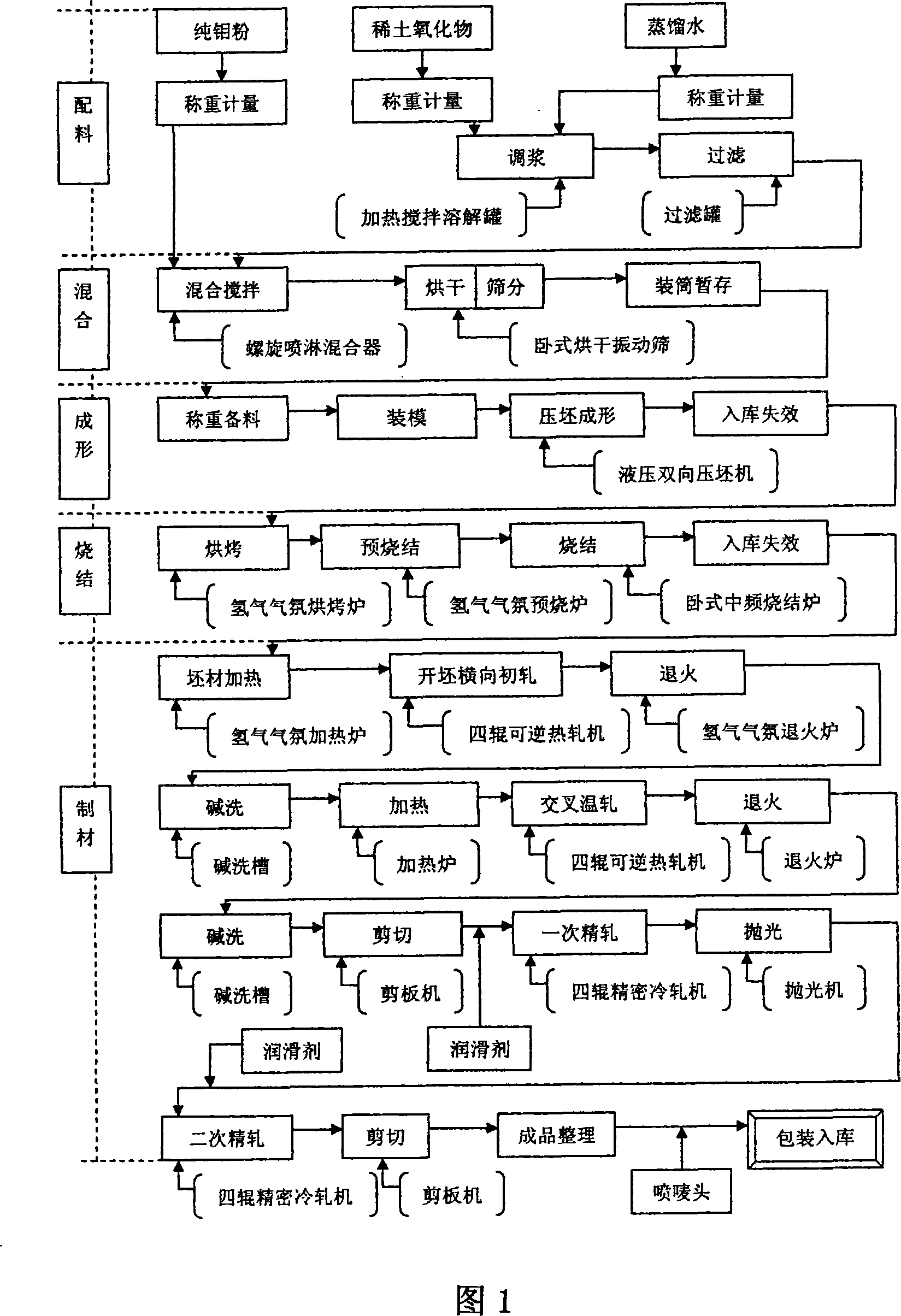

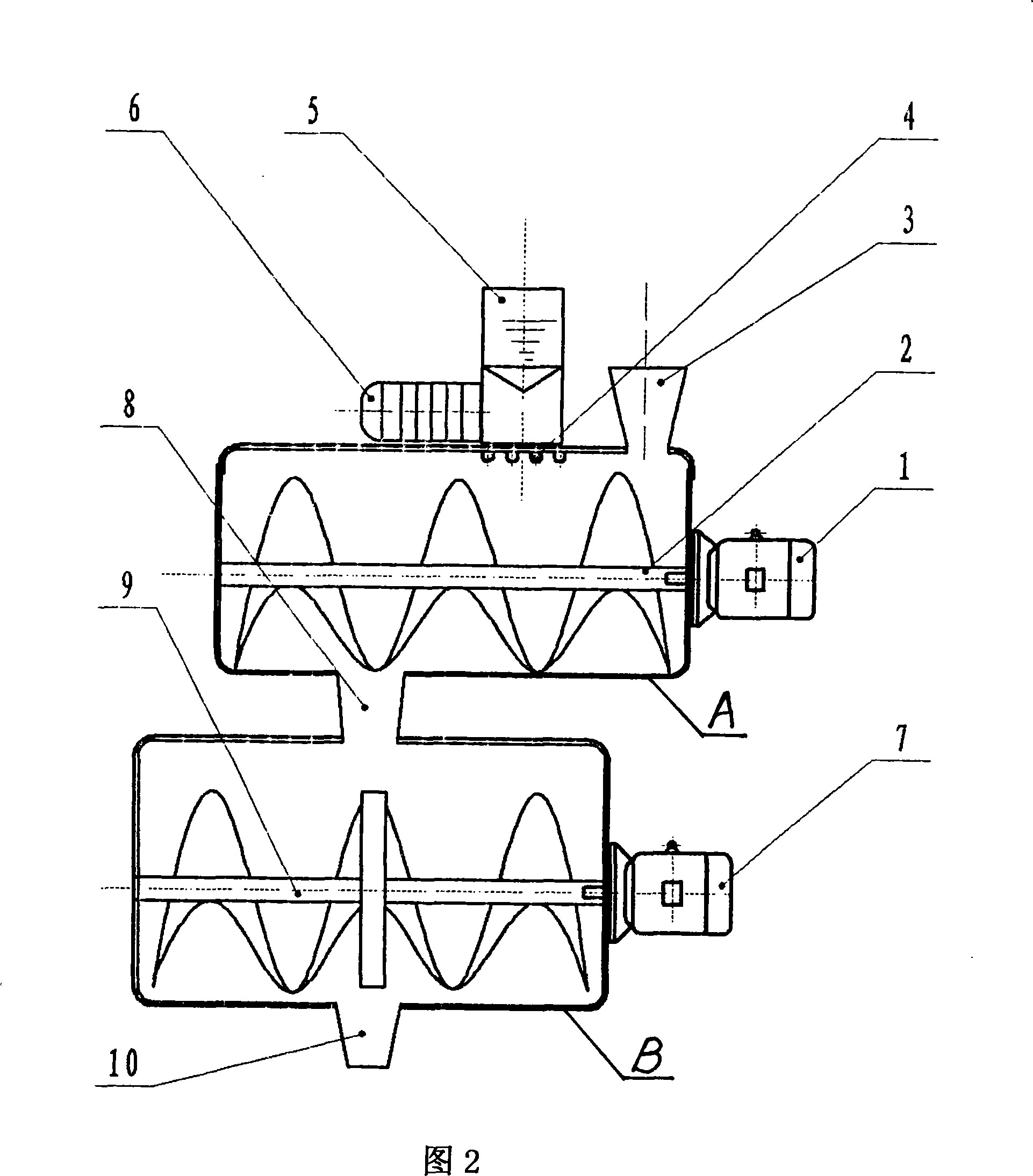

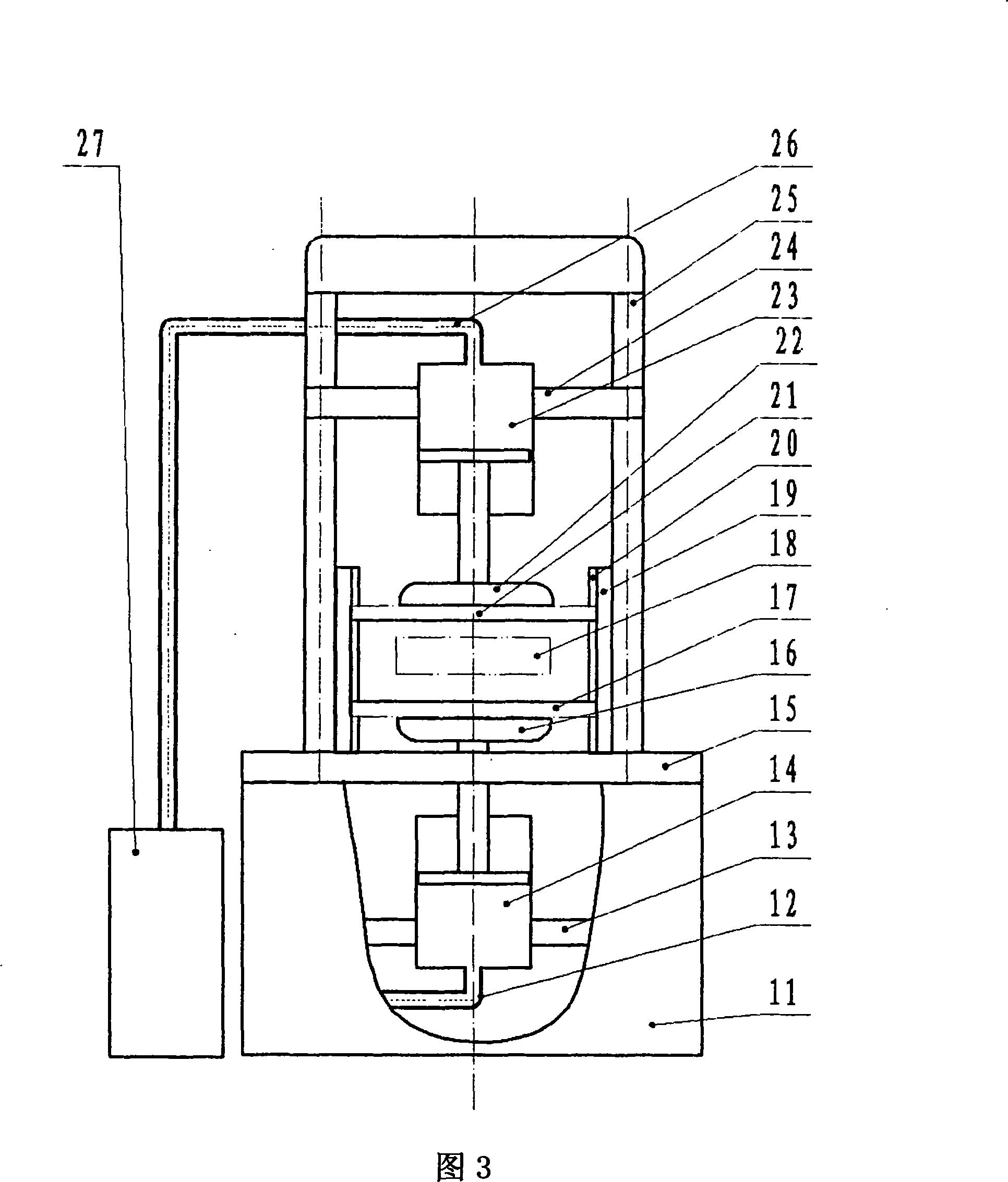

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

Aluminium alloy foil for founding and rolling automotive heat radiator fin billet and manufacturing method thereof

ActiveCN1876868AHigh strengthGood anti-saggingRoll mill control devicesMetal rolling arrangementsManganeseTitanium

The invention discloses an aluminum alloy foil used in strand car radiator fin and its manufacturing process, in which the component and the proportion by weight of the foil are: 0.50-0.70 % iron, 0.26-0.54% silicon, 0-0.05 % copper, 1.0-1.3% manganese, 1.4-1.8% zinc, 0.01-0.03% titanium and the other is aluminum. The manufacturing process consists of first casting bar plate, then performing cold reducing working for casting bar plate to prepare foil finished articles. Compared with the current invention, with the same thickness, the product has higher intensity and fine sag resistance under an elevated temperature, by which the fin can not collapse when the car radiator welds under an elevated temperature.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

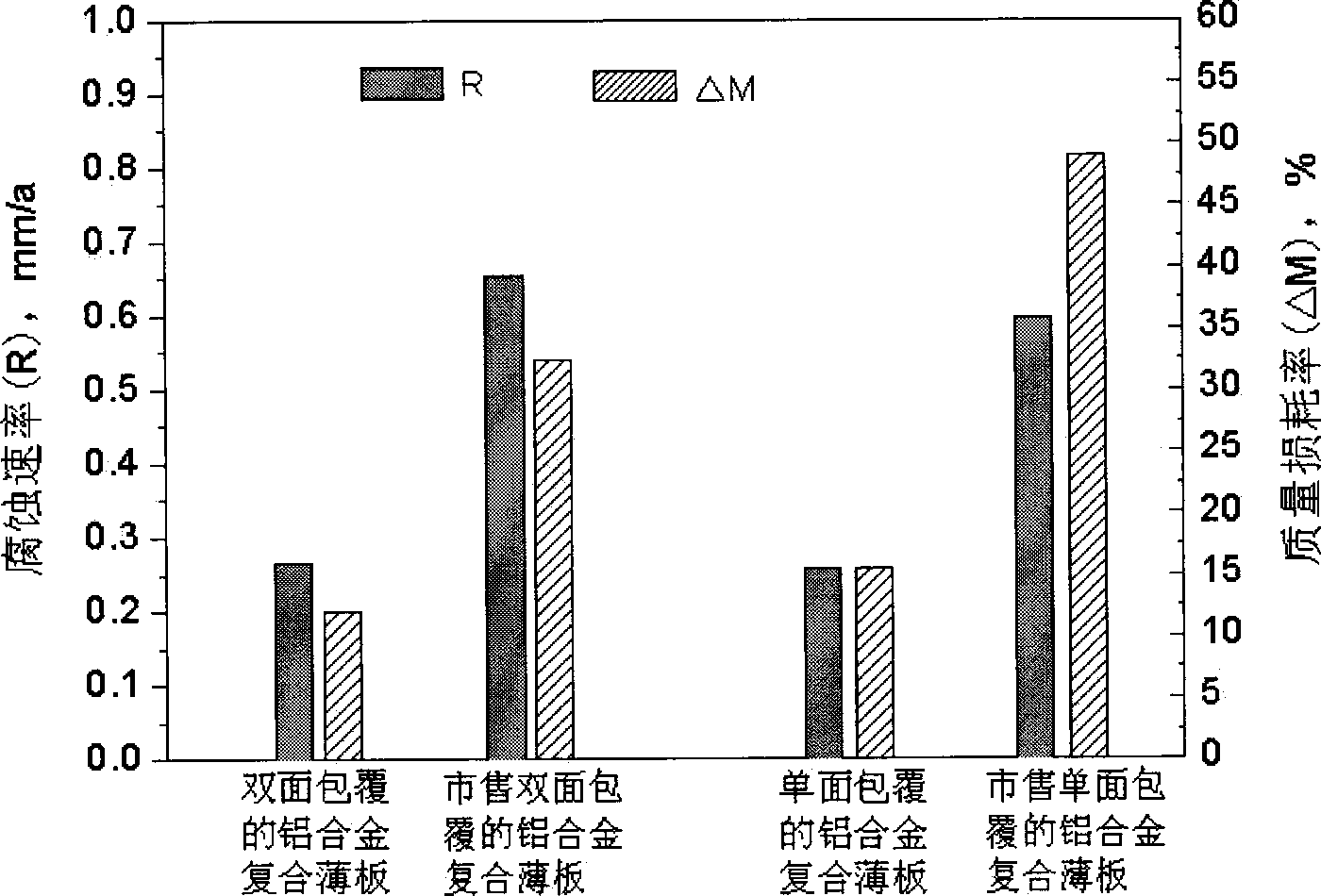

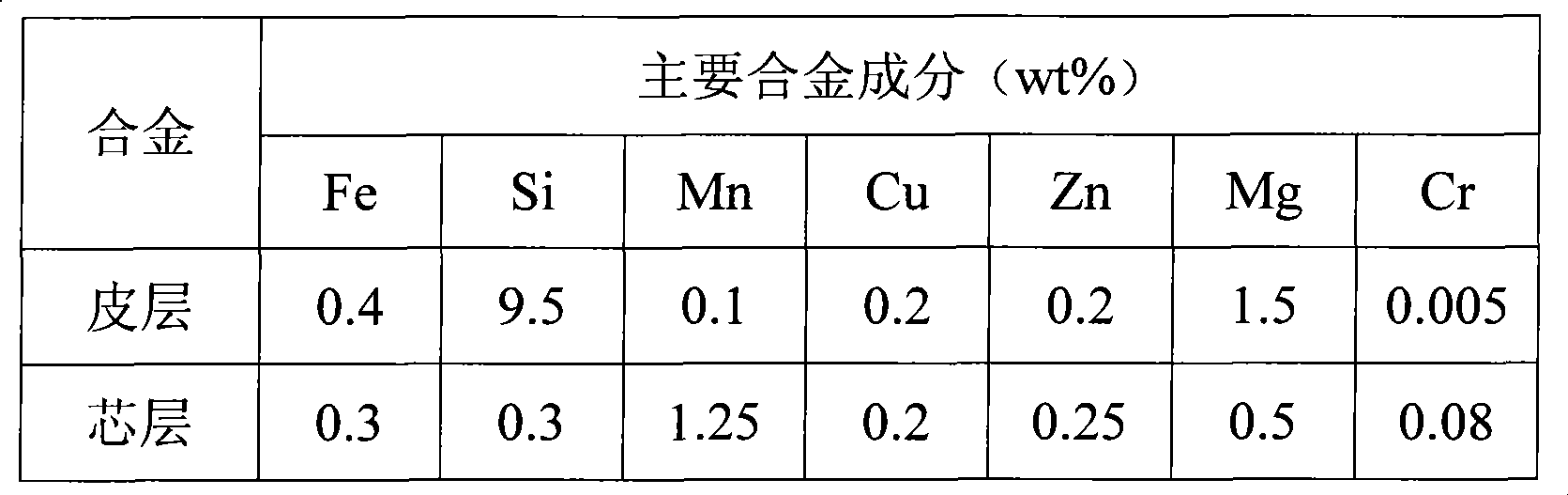

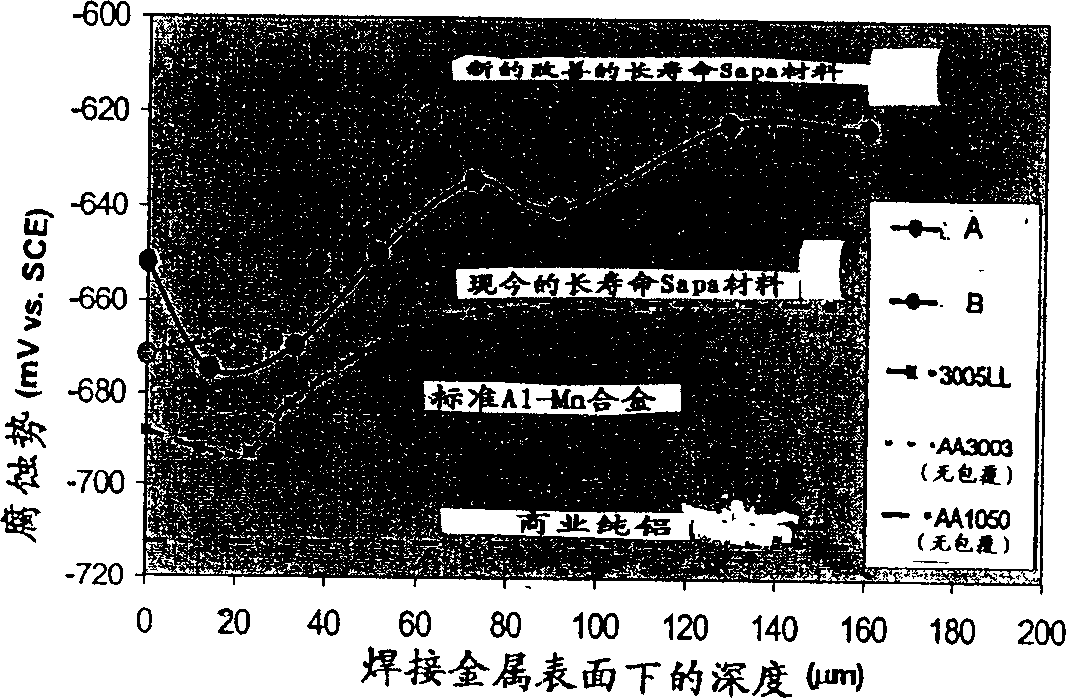

Aluminum alloy composite sheet having long service life

InactiveCN101412299AImprove mechanical propertiesGood anti-saggingMetal layered productsSurface layerAlloy composite

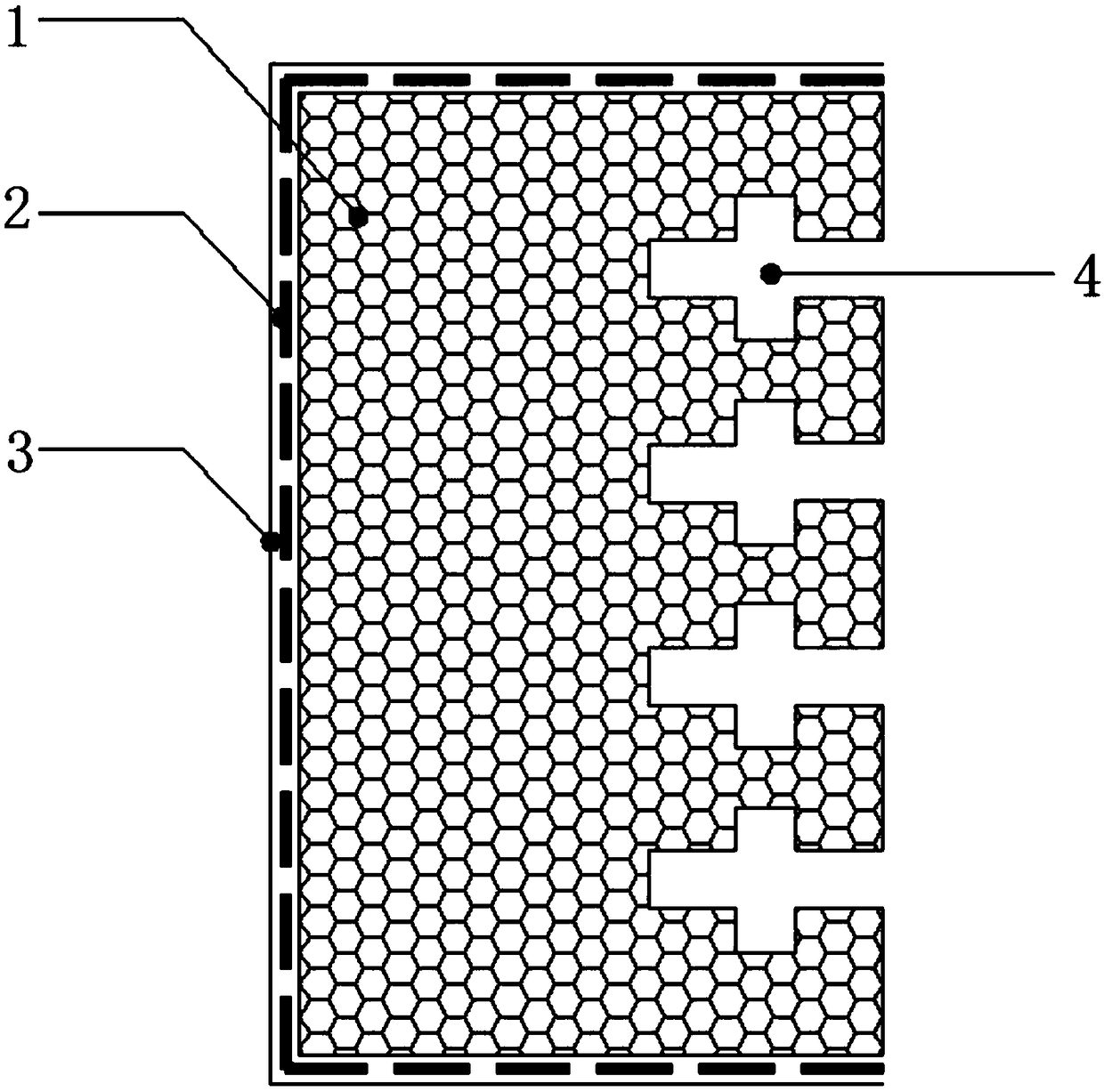

The invention provides a long-life aluminum alloy composite thin plate, which at least comprises a core layer and a surface layer, wherein the core layer comprises Al-Mn alloy, and one side or two sides of the core layer are coated with the Al-Si alloy; the Al-Mn alloy of the core layer comprises the components by the following mass percentages: 0.05 to 0.5 weight percent of Si, 0.05 to 0.5 weight percent of Fe, 0.05 to 0.3 weight percent of Cu, 1.0 to 1.6 weight percent of Mn, 0.3 to 0.7 weight percent of Mg, 0.05 to 0.3 weight percent of Zn, and 0.05 to 0.15 weight percent of Cr, and the balance components being Al and inevitable impurities. Through selecting alloy elements preferably and controlling the texture, the prepared aluminum alloy composite thin plate has excellent corrosion resistance on the basis of keeping the alloy to have good mechanical performance, anti-sagging performance and brazing performance, thus the aluminum alloy composite thin plate is very advantageous to production and manufacturing and is a perfect material for producing heat exchanger parts.

Owner:苏州有色金属研究院有限公司

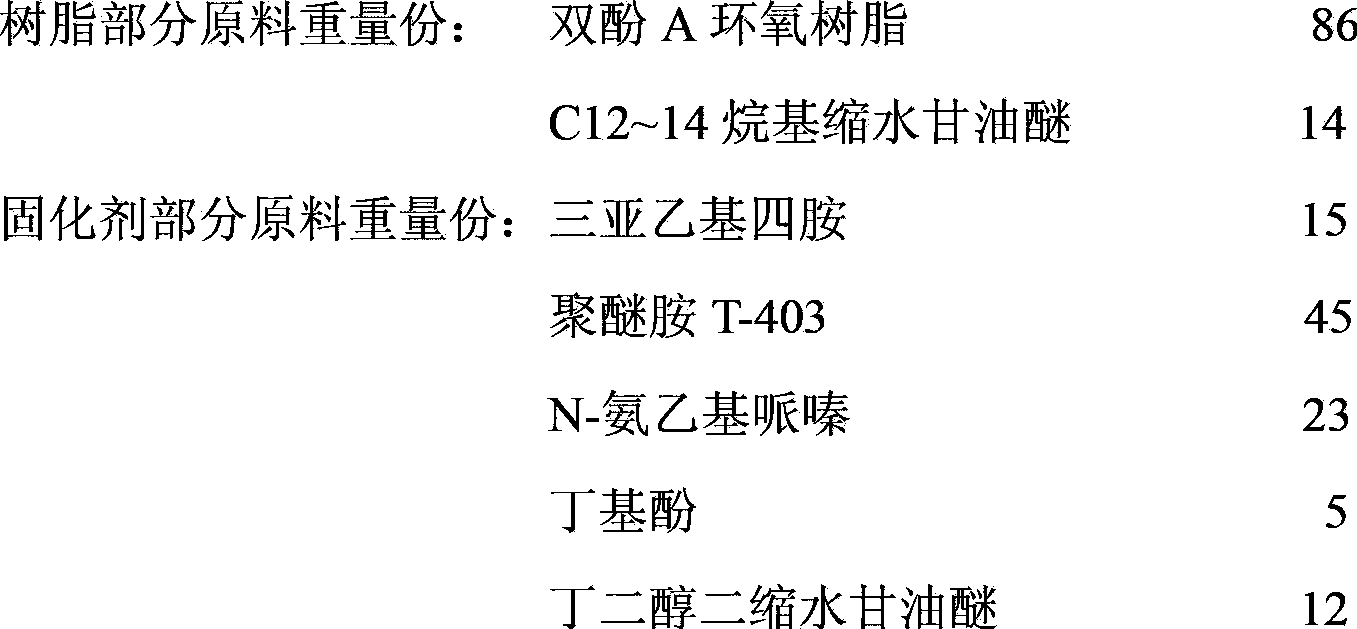

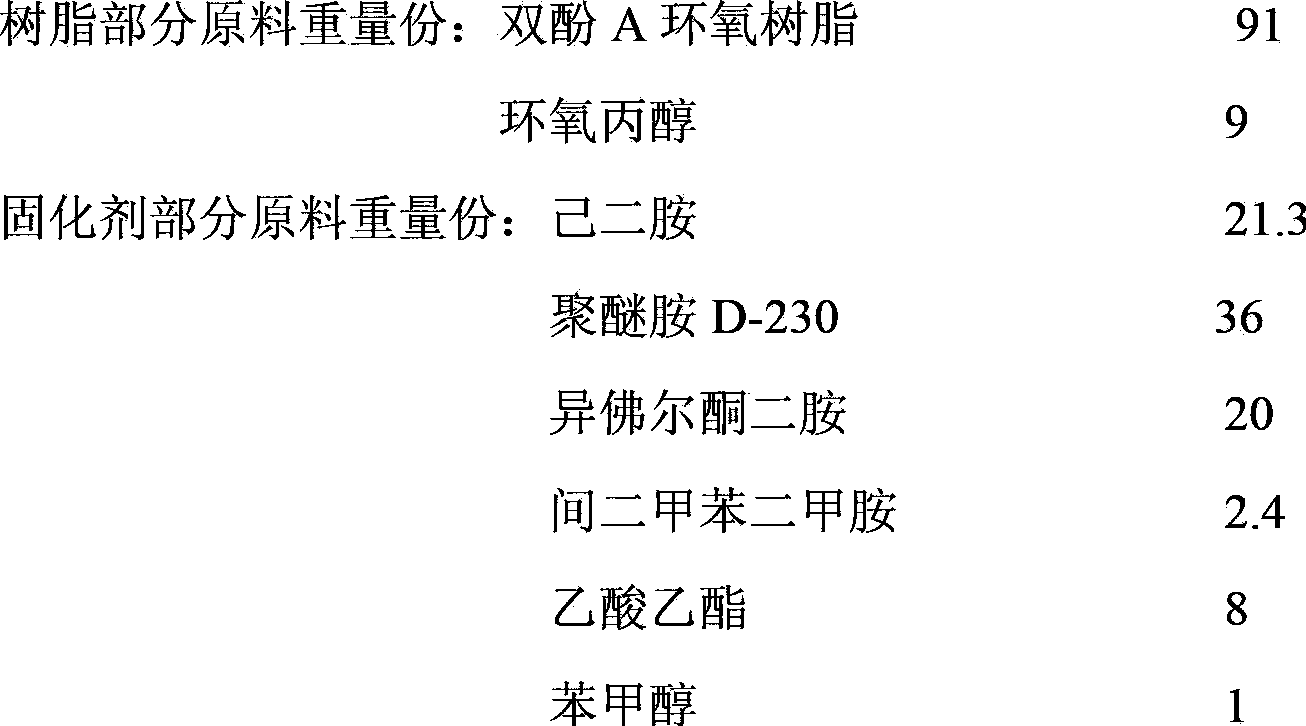

Epoxy resin system for wind blade hand lay-up repair and preparation method thereof

The invention discloses an epoxy resin system for wind blade hand lay-up repair and a preparation method thereof. The epoxy resin system is formed by mixing of a resin part and a curing agent part that are prepared respectively and are in a weight ratio of 100:28-32. Specifically, the resin part is formed by mixing 85-95 parts by weight of one of or a mixture of bisphenol A epoxy resin and bisphenol F epoxy resin, and 5-15 parts by weight of a diluents; and the curing agent part is prepared by modification of, by weight, 40-70 parts of fatty amine, 0-30 parts of alicyclic amine, 0-10 parts of aromatic amine, 0-35 parts of an assistant, and 5-15 parts of an epoxy compound. The epoxy resin system for wind blade hand lay-up repair provided by the invention is accord with the medium viscosity requirement of hand lay-up molding, and has the characteristics of good sagging resistance, low operating environment requirement, and excellent fiber material infiltration. After curing, the product has excellent toughness, mechanical properties, heat resistance, water resistance and other comprehensive performance, and can meet the requirements of hand lay-up molding epoxy resin used for wind blade matched repair.

Owner:EPOXY BASE ELECTRONICS MATERIAL

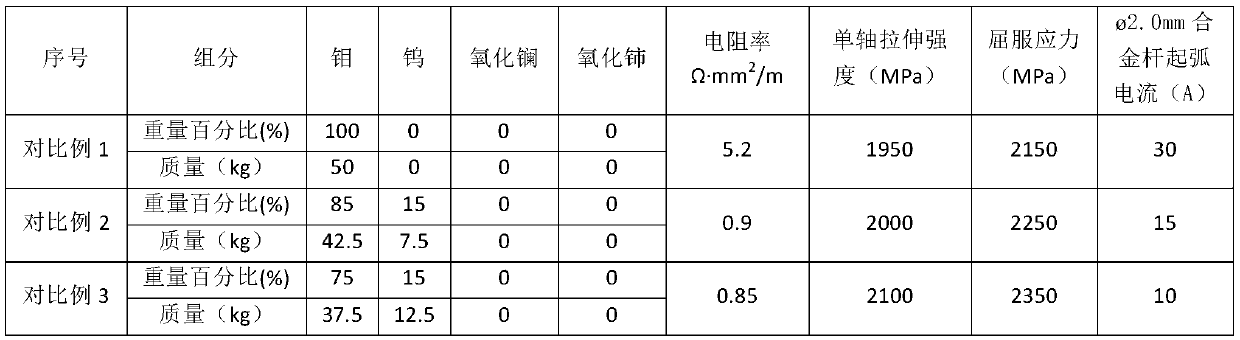

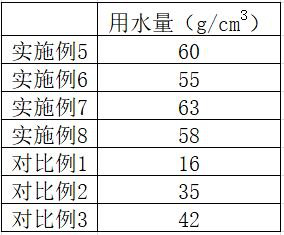

Building dry powder mortar

The invention relates to the technical field of building materials, in particular to a building dry powder mortar for building insulation board. The building plastering mortar is prepared from a mixture and water, wherein the mixture comprises the following components in portions by weight: 240-400 portions of ordinary portland cement, 30-100 portions of triple superphosphate, 500-680 portions of river sand, 20-50 portions of redispersable polymer gelatine powder, 1-3 portions of water-retaining agent and 0.2-3 portions of compound additive. The dosage of water is 4-20 times as much as the total weight portions of the mixture. The building dry powder mortar is used for construction of building external walls, and can enable the building external walls to have the advantages of favorable water retention, high binding strength, shedding resistance after moisture absorption, favorable water resistance, etc.

Owner:上海雅达特种涂料有限公司 +1

Automobile heat dissipation fin aluminum foil prepared from aluminum alloy XR348and preparation method of automobile heat dissipation fin aluminum foil

ActiveCN107299259AHigh strength after weldingImprove corrosion resistanceHeat exchange apparatusMetal rolling arrangementsManganeseImpurity

The invention relates to an automobile heat dissipation fin aluminum foil prepared from an aluminum alloy XR348. The aluminum alloy XR348 is prepared from the following components: 1.1 to 1.4 weight percent of manganese, 1.0 to 1.2 weight percent of silicon, 0.9 to 1.1 weight percent of iron, 0.8 to 1.0 weight percent of zinc, 0.21 to 0.30 weight percent of zirconium, 0 to 0.05 weight percent of titanium, 0 to 0.03 weight percent of copper, 0 to 0.01 weight percent of magnesium, 0 to 0.03 weight percent of a single unavoidable impurity, 0 to 0.10 weight percent of all unavoidable impurities and the balance of aluminum. The preparation method of the automobile heat dissipation fin aluminum foil comprises a step of performing continuous casting-rolling on the aluminum alloy XR348, so as to obtain the automobile heat dissipation fin aluminum foil. The preparation method disclosed by the invention is short in flow and high in quality; after being subjected to high-temperature soldering, the aluminum foil is extremely high in postwelding strength and high in corrosion resistance; diffusion of silicon atoms on a soldered layer can be prevented, so that the hang-down resistance property of a material is improved; therefore, the aluminum foil and the preparation method which are disclosed by the invention are extremely high in performance.

Owner:江阴新仁铝箔科技有限公司

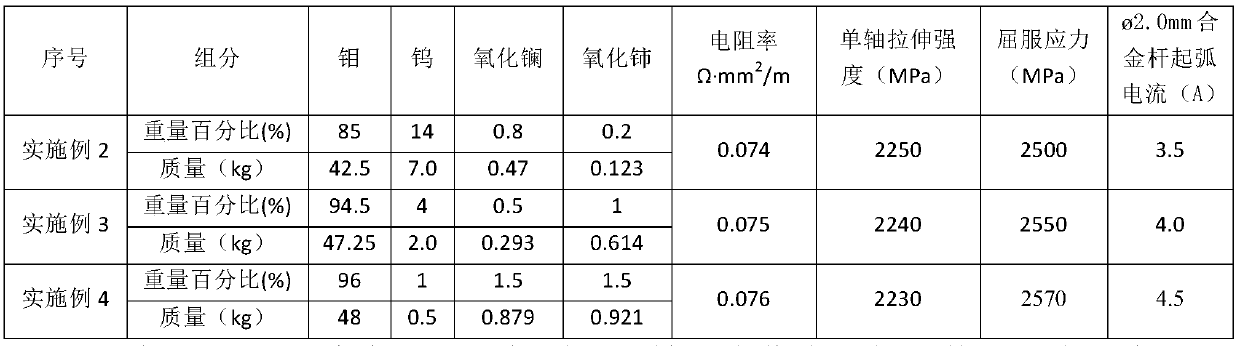

Rare earth, molybdenum and tungsten alloy used for cutting wires and preparing method thereof

ActiveCN110106418AImprove processing performanceImprove discharge performance and conductivityTemperature resistancePower flow

The invention provides a rare earth, molybdenum and tungsten alloy. The rare earth, molybdenum and tungsten alloy comprises, by weight, 74.8% to 98.5% of molybdenum, 0.5% to 25% of tungsten and 0.2% to 3% of rare earth. When the alloy is used for cutting wires, the advantages of small electrical resistivity, large cutting current, high cutting speed and long service life are achieved, and the goodtensile strength and high temperature resistance are achieved. The preparation process of the alloy can ensure uniform distribution of alloy compositions and the stable contents of all components, improves the product yield and has scale and commercial production prospects.

Owner:廊坊开发区阳雨钨业股份有限公司

Method for manufacturing improved vehicle radiator aluminum alloy foil material

InactiveCN103509982AHigh strengthGood collapse resistance and heat transfer capacityMetal rolling arrangementsTitaniumCopper

The invention provides a method for manufacturing an improved vehicle radiator aluminum alloy foil material, which contains the following components by weight: 0.03-0.30% of iron, 0.26-1.54% of silicon, 0-0.15% of copper, 1.3-2.8% of manganese, 1.4-1.8% of zinc, 0.10-0.25% of zirconium, 0.01-0.03% of titanium, and the balance aluminum.

Owner:王林海

Reclaimed surface plastering gypsum for building and preparation method thereof

The invention discloses reclaimed surface plastering gypsum for a building and a preparation method thereof. The plastering gypsum comprises the following components in parts by mass: 250-300 parts ofsalt gypsum, 10-20 parts of a solubilizing agent and 10-30 parts of a reinforcing admixture, and the solubilizing agent comprises DTPMP.Na7, potassium formate and zeolite powder according to a mass ratio of 1:2:1, and the reinforcing admixture comprises a retarder, a water-retaining agent, latex powder, desulfurized gypsum, zinc powder and hydrated iron oxide gel. The invention further disclosesa preparation method of the plastering gypsum, so that salt gypsum is recycled, and the plastering gypsum is high in operability and good in waterproof and moisture-proof performance.

Owner:浙江壮硕建材有限公司

High strength long-life aluminium tube material with high sagging resistance

ActiveCN1690237AImprove corrosion resistanceGood anti-saggingHeat exchange apparatusMetal rolling arrangementsAluminium alloy

Owner:SAPA HEAT TRANSFER AB

Long-acting anti-icing wind power blade coating and preparing method thereof

InactiveCN105111907AEvenly dispersedGuaranteed decentralizationPolyurea/polyurethane coatingsElectrical conductorDefoaming Agents

The invention discloses a long-acting anti-icing wind power blade coating and a preparing method thereof. According to a formula, the coating is prepared from a component A and a component B, wherein the component A is prepared from resin, dispersant, titanium dioxide, carbon black, a conducting material, a defoaming agent, a leveling agent, a rheological additive, a flatting agent, an adhesion promoter, an initiating agent, butyl acetate and propylene glycol monomethyl ether; the component B is prepared from an HDI tripolymer and a prepolymer made of HDI or IPDI, and the curing agent component with the -NCO content of 5-15%. The preparing method of the coating and a preparing method of the component A are provided. On the premise that a paint film has excellent performance for daily use, the film serves as a resistor while being changed into a conductor, the problem that blades ice during operation in snowy weather in winter is solved thoroughly, and long-term safe and stable operation and service life of a wind power unit are guaranteed.

Owner:文庆武

High-drooping-resistance high-strength composite aluminum foil core material alloy and preparation method thereof

InactiveCN107312954AGood anti-saggingAvoid erosionWelding/cutting media/materialsSoldering mediaManganeseCopper

The invention discloses a high-sagging-resistant high-strength composite aluminum foil core material alloy and a preparation method thereof. The core material alloy is composed of 0.15-0.40% iron, 0.05-0.25% silicon, 0.6-1.6% manganese, 0.4-0.8% copper, 0.1-0.4% chromium and the rest is aluminum. The preparation method of the core material alloy mainly includes: 1. Selecting an intermediate alloy (except Al-Cr alloy) for smelting, stirring, refining and standing; 2. Adding Cr agent, stirring and standing, and casting the molten aluminum 3. The core aluminum alloy plate is homogeneously treated, kept warm and then air-cooled, and then surface treated. The advantage of the present invention is that by optimizing the composition ratio of the composite aluminum foil core material alloy, combined with the above manufacturing method, casting rolling and heat treatment, a composite aluminum foil core material with excellent sag resistance and high tensile strength can be obtained; the method of the present invention is simple It is easy to implement and easy to implement, and is suitable for industrialized production.

Owner:SOUTHEAST UNIV

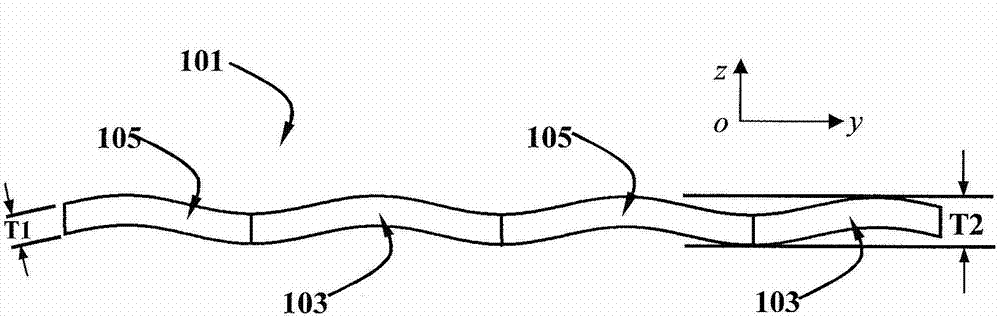

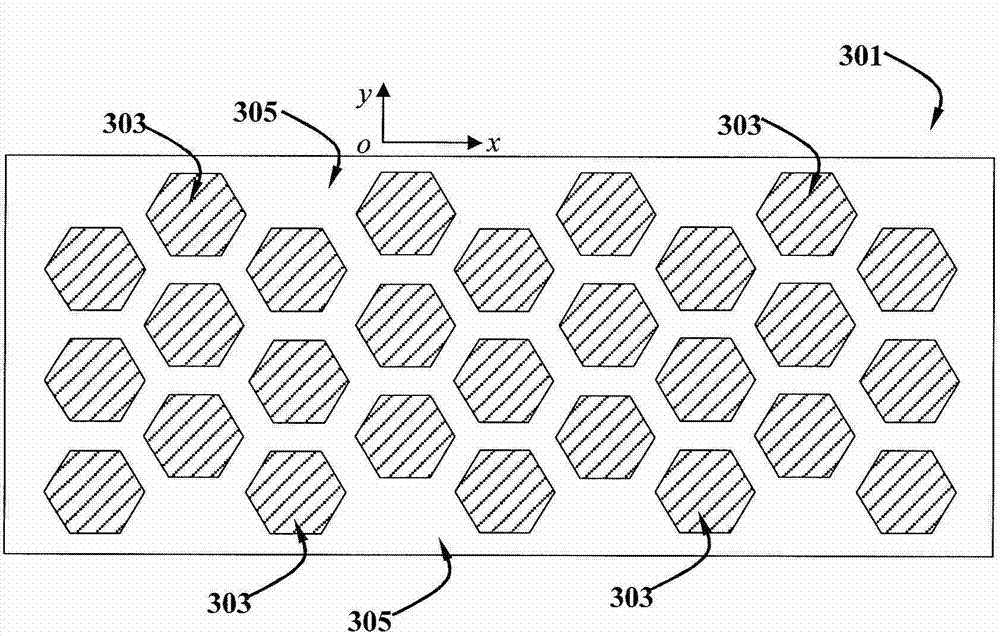

Method for making creep resistant refractory metal structures

InactiveCN102712078AImprove mechanical propertiesImproves sagging resistanceGlass furnace apparatusGlass drawing apparatusGrit blastingGlass melting

A method for making a metal structure comprising: (i) selectively grit-blasting a part of a major surface of the metal sheet at a temperature lower than the annealing temperature of the metal sheet to impart a stress in the metal sheet; and (ii) subjecting the metal sheet to a heat treatment at a temperature not lower than T(anneal) -400 DEG C so that the metal sheet deforms, such that the deformed metal sheet exhibits a higher strength in a desired direction, wherein T(anneal) is the annealing point of the metal. The invention is particularly advantageous for making thin Pt metal structures for glass melting, conditioning, delivery and forming operations.

Owner:CORNING INC

Method for preparing adhesive special for flexible veneers or bricks

InactiveCN101845283AHigh viscosityLight weightPolyureas/polyurethane adhesivesAcid polymer adhesivesAdhesive cementBrick

The invention relates to a method for preparing an adhesive special for flexible veneers or flexible bricks. In the method, acrylic acid aqueous latex is modified by using polyurethane aqueous latex to improve the low-temperature flexibility of the acrylic acid aqueous latex, so the acrylic acid aqueous latex is not hardened at a low temperature and is not softened at a high temperature, and the water resisting property and the binding strength are improved. The method for preparing the adhesive special for the flexible veneers or the flexible bricks has the advantages that: 1, the adhesive is ready for use after a can is opened, does not need field mixing, and is convenient and efficient; 2, a sizing process of the adhesive can adopt a spray coating method or a knife coating method, and has high construction efficiency; 3, the adhesive has high thixotropic property and sag resisting property, the bricks can be adsorbed by applying light pressure instead of kneading and pressing brick bodies, so time and labor are saved; and 4, as the adhesive is semitransparent after being sprayed on a wall body, no influence on observing a snapped control line is generated, the face bricks can be glued along the control line which is snapped on a wall in advance, and the operation is simple and convenient.

Owner:东营宜达新材料有限责任公司

Unsaturated polyester material with excellent covering power, black edge covering capacity and combination property and preparation method of unsaturated polyester material

InactiveCN109762450AImprove liquidityImprove the problem of poor flatnessPolyester coatingsPolyesterWax

The invention discloses an unsaturated polyester material with excellent covering power, black edge covering capacity and combination property. The unsaturated polyester material is prepared from components in parts by weight as follows: 35-45 parts of PE resin, 2-4 parts of a 20% CAB551-0.2 solution (CAB551-0.220: BAC80), 0.2-0.4 parts of a dispersant, 1-3 parts of a polishing aid, 2-5 parts of an active solvent, 45-55 parts of inorganic filler, 0.2-0.4 parts of fumed silica, 0.2-0.5 parts of a polyamide wax dispersion rheological aid, 0.5-1.5 parts of 40% active content rheological aid, 0.5-1 part of a thickening rheological agent, 0.1-0.3 parts of a defoaming agent and 0.2-0.5 parts of a leveling agent. The unsaturated polyester material with excellent covering power, black edge covering capacity and combination property has excellent covering power and black edge covering capacity for special-shaped parts, chamfered objects and molded carved plates and has the characteristics of good leveling performance, good fullness and good rubbing property and the like of the unsaturated polyester material.

Owner:CHENGDU ZHANCHEN PAINT

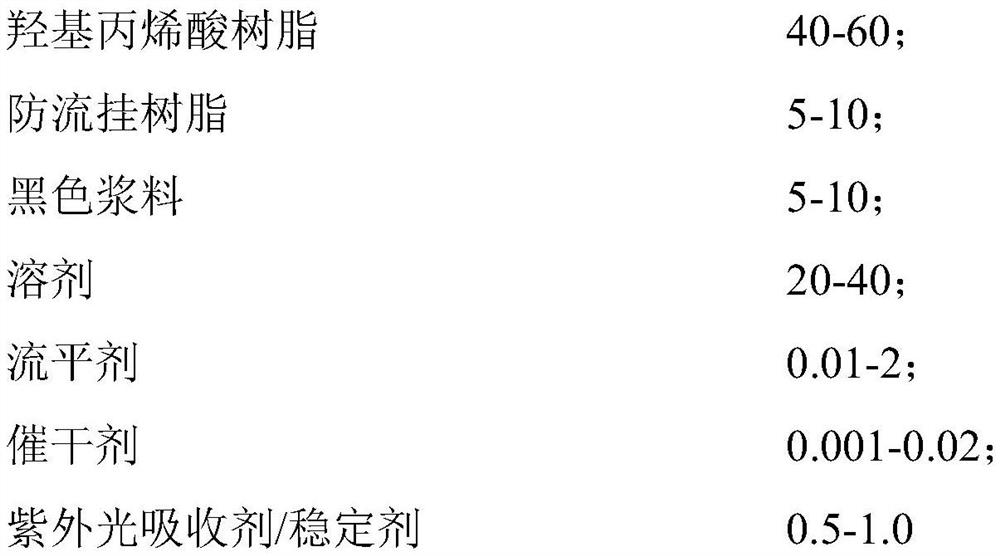

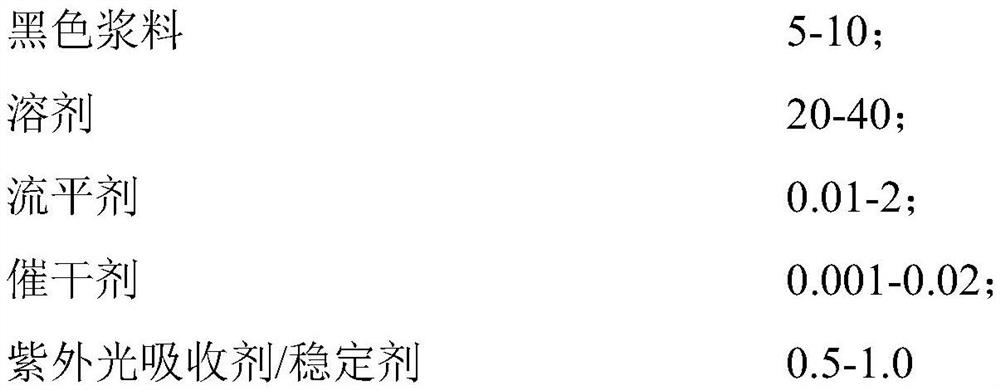

High-brightness black coating for automobile exterior decoration as well as preparation method and application of high-brightness black coating

PendingCN114381174AGood lookingExcellent physical and chemical resistanceSiccativesCoatingsAcrylic resinUltraviolet lights

The invention relates to an automobile exterior high-brightness black coating and a preparation method thereof. The preparation method comprises the step of mixing the following components in parts by weight: 40-60 parts of hydroxy acrylic resin; 5 to 10 parts of anti-sagging resin; 5-10 parts of black slurry; 20-40 parts of a solvent; 0.01-2 parts of a leveling agent; 0.001 to 0.02 part of a drier; and 0.5-1.0 part of an ultraviolet light absorber / stabilizer. Compared with the prior art, the high-brightness black coating disclosed by the invention is simple in preparation method, moderate in cost and easy to produce in batches, can be used for spraying automobile exterior trimming parts, has the characteristics of excellent constructability, sagging resistance, high hardness, difficulty in scratching, pure paint film color, partial blue phase, extremely high blackness, high gloss, high fullness and the like, and can be widely applied to automobile exterior trimming parts. Meanwhile, physical and chemical performance tests of hydrolysis resistance, fuel oil resistance, gravel impact resistance, illumination resistance, bird droppings resistance and the like are met.

Owner:DONGLAI COATING TECH SHANGHAI

High-sag-resistance composite brazing aluminum foil and preparation method thereof

ActiveCN103112211BGood anti-saggingGood anti-sag performanceMetal rolling arrangementsMetal layered productsManganeseCopper

The invention discloses a high-sag-resistance composite brazing aluminum foil. The high-sag-resistance composite brazing aluminum foil comprises an upper coating layer, a lower coating layer and a core material layer arranged between the upper and lower coating layers, wherein the core material layer comprises the following components in percentage by weight: 0.25-0.46% of iron, 0.01-0.25 % of silicon, 0.40-1.0% of manganese, 0.04-0.5% of copper, 0.01-0.4% of scandium, and the balance being aluminum, and the upper and lower coating layers are made of aluminum alloy. The invention also discloses a preparation method of the brazing aluminum foil. The high-sag-resistance composite brazing aluminum foil provided by the invention has the advantages that the composite aluminum foil with excellent sag resistance can be manufactured by optimizing the ratio of composite aluminum foil core material alloy and combining a casting, rolling and heating processing technology in a manufacturing method.

Owner:SOUTHEAST UNIV +1

A kind of xr348 aluminum alloy automobile cooling fin aluminum foil and preparation method thereof

ActiveCN107299259BHigh strength after weldingImprove corrosion resistanceHeat exchange apparatusMetal rolling arrangementsManganeseAlloy

The invention relates to an automobile heat dissipation fin aluminum foil prepared from an aluminum alloy XR348. The aluminum alloy XR348 is prepared from the following components: 1.1 to 1.4 weight percent of manganese, 1.0 to 1.2 weight percent of silicon, 0.9 to 1.1 weight percent of iron, 0.8 to 1.0 weight percent of zinc, 0.21 to 0.30 weight percent of zirconium, 0 to 0.05 weight percent of titanium, 0 to 0.03 weight percent of copper, 0 to 0.01 weight percent of magnesium, 0 to 0.03 weight percent of a single unavoidable impurity, 0 to 0.10 weight percent of all unavoidable impurities and the balance of aluminum. The preparation method of the automobile heat dissipation fin aluminum foil comprises a step of performing continuous casting-rolling on the aluminum alloy XR348, so as to obtain the automobile heat dissipation fin aluminum foil. The preparation method disclosed by the invention is short in flow and high in quality; after being subjected to high-temperature soldering, the aluminum foil is extremely high in postwelding strength and high in corrosion resistance; diffusion of silicon atoms on a soldered layer can be prevented, so that the hang-down resistance property of a material is improved; therefore, the aluminum foil and the preparation method which are disclosed by the invention are extremely high in performance.

Owner:江阴新仁铝箔科技有限公司

Porous granular instant building glue powder and preparation method thereof

ActiveCN102964091BRapid water absorption and dissolutionLow densityNon-macromolecular adhesive additivesStarch adhesivesCelluloseMeth-

A porous granular instant building rubber powder and a preparation method thereof. The porous granular instant building rubber powder is characterized by the following raw materials (parts by weight): 50-60 parts of starch, 20-30 parts of polyvinyl alcohol, 10-20 parts of release agent, 3-5 parts of vinyl ester polymer 2-3 parts of acrylate polymer, 1-2 parts of hydroxypropyl methyl cellulose ether, 0.2-0.5 parts of water resistance modifier, and 0.1-0.3 parts of nucleating agent. The invention adopts continuous and high-efficiency kneader pre-reaction and instantaneous graft modification of the rubber powder through a reduced-shrinkage screw compressor to obtain a highly water-absorbing porous granular building rubber powder. The rubber powder has fast water absorption and dissolution, water resistance, fast dispersion and good adhesion, and can be widely used in construction materials such as mortar, putty, tile adhesive, white latex, wallpaper adhesive, polypropylene waterproof membrane adhesive, etc. , can replace the traditional redispersible rubber powder.

Owner:广东顺德祁润化工有限公司

Preparation method for modified mixed cellulose ether and product obtained through method

The invention provides a preparation method for modified mixed cellulose ether. The preparation method comprises the steps of alkalization, etherification, desolventizing acid modulation and aftertreatment. According to alkalization, alkali liquor is adopted for carrying out alkali activation treatment on cellulose powder and starch; according to etherification, chloromethane, epoxypropane and ethylene oxide are adopted as an etherifying agent for etherifying the alkalified cellulose powder and starch for 90-120 minutes at the temperature of 30-54+ / -1 DEG C, 65-80+ / -1 DEG C and 85-95+ / -1 DEG C; according to desolventizing acid modulation, acid and hot water are added firstly, desolventizing is carried out, the desolventizing temperature ranges from 80 DEG C to 90 DEG C, and the pH value of the material obtained after desolventizing ranges from 5 to 7; the modified mixed cellulose ether is prepared from, by weight, 80-95 parts of cellulose powder, 1-3 parts of starch, 58-100 parts of chloromethane, 18-25 parts of epoxypropane and 8-10 parts of ethylene oxide. The preparation method is short in production period, and the obtained product has excellent water-retaining performance, dispersity, solubility, film-forming performance, stability, anti-mildew performance, ptosis resistance and high crushability. The invention further provides mixed modified mixed cellulose ether obtained through the preparation method.

Owner:广东龙湖科技股份有限公司

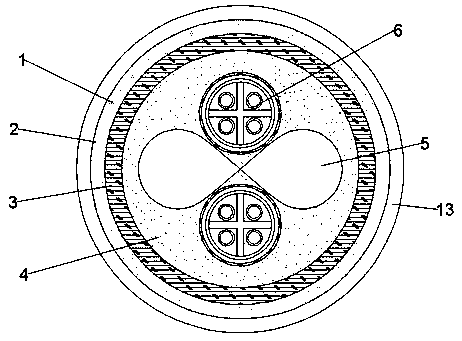

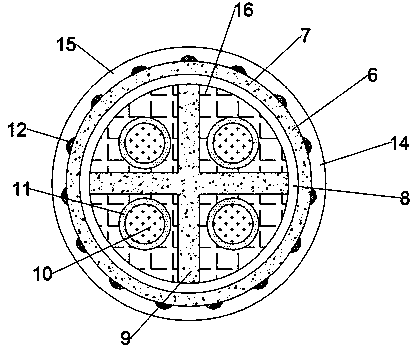

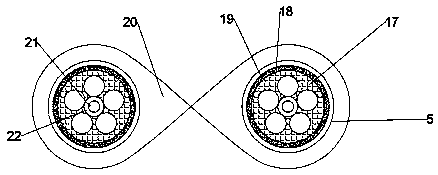

Anti-interference buffer type composite optical cable

InactiveCN108717880AAvoid mutual interferenceAvoid deformationQuad constructionsPower cables with screens/conductive layersControl lineTemperature resistance

The invention discloses an anti-interference buffer type composite optical cable, comprising a main body, a first insulation filling layer, a power line and a control line, wherein the power line is embedded in the main body and arranged at a middle position, the two control lines are arranged at the upper side and the lower side of the power line by taking the power line as a symmetry axis, and the first insulation filling layer fills a gap between the power line and the control lines; the power line is in a shape like a dumbbell, and a cavity is formed inside the power line; the shielding strip is arranged, so that mutual interference between the control line cores can be avoided; and the buffer convex body is arranged, so that better buffer protective effect is realized on the control lines, and the control lines are avoided from being deformed due to strong extrusion. The anti-interference buffer type composite optical cable disclosed by the invention is reasonable in layout and good in insulativity, high temperature resistance, corrosion resistance and flame resistance and also has good anti-pull, compression-resistant and sag-resistant capabilities, so that use security and reliability of the cable are greatly improved.

Owner:SHANDONG QUANXING YINQIAO OPTICAL & ELECTRIC CABLE SCI & TECH DEV

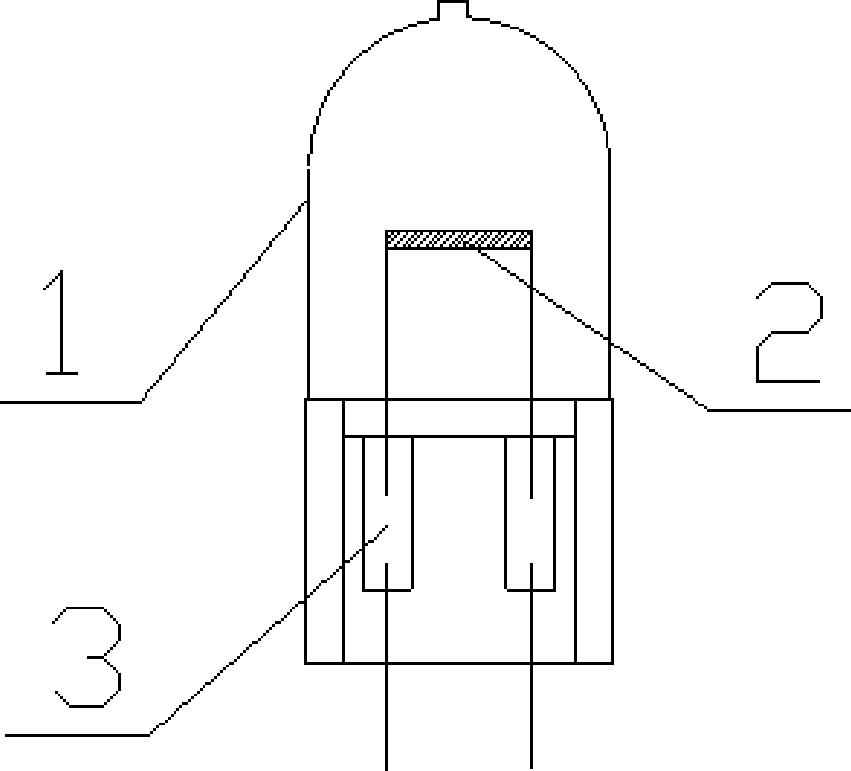

Manufacturing method for high brightness halogen lamp and high brightness halogen lamp thereof

InactiveCN101483132AReduce thermal conduction lossThermal loss reductionLamp incadescent bodiesWorking temperatureEngineering

The invention discloses a high-brightness halogen lamp and production method thereof. The halogen lamp includes a bulb and filament provided in the bulb. The method manufactures the filament in the light emitting regional section as three spiral filaments; and three spiral filaments has favorable anti-sag performance after adopting reasonable heat treating process, so that the filaments do no need any forms of support body, the cooling action of the existing halogen lamp support body to the filaments can be overcome, and the filament brightness can be further improved. The winding method is that the invention is produced by three times of winding of the straight tungsten wire; the filament adopting the structure can increase the working temperature of the filament under equal power to improve the brightness of the invention.

Owner:湖州和华科技有限公司

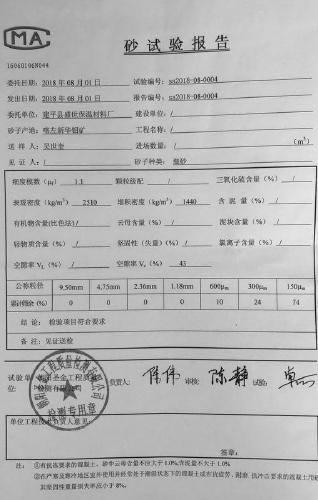

Method for preparing building mortar from tailings

InactiveCN109279825AHigh compressive strengthGood alkali resistanceSolid waste managementFiberEnvironmental resistance

The invention provides a method for preparing building mortar from tailings. The method comprises the following steps: directly injecting tailing slurry into a centrifugal dryer to remove water through spinning so as to obtain sand with a water content of 20%; then transferring the sand to a dryer for drying until the water content is 1%-2%; then conveying the sand to a cooling tower for cooling treatment and transferring the cooled sand to a vibration screening procedure to obtain qualified 120-to-300-mesh sand for subsequent usage; and preparing finished mortar by uniformly mixing, by mass,45-55 parts of the 120-to-300-mesh sand, 5 parts of 1-to-5-mm fly ash, 2 parts of fibers, 30 parts of cement, 3 parts of gypsum powder and 10 parts of rubber powder in a mixer under stirring, and thenpreparing bagged mortar by using a bagging machine. The method of the invention has the following advantages: waste produced in mining production is utilized, so the problem of environmental pollution is solved; and the building mortar has the advantages of high compressive strength, rapid curing speed, good water retention performance and crack resistance, and high alkali resistance and ultraviolet resistance, can be applied to a wet substrate, and is green and environmentally-friendly, and the performance indexes of the building mortar are in line with usage standards for sand.

Owner:吴世奎

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911BRaise the recrystallization temperatureImprove mechanical propertiesRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

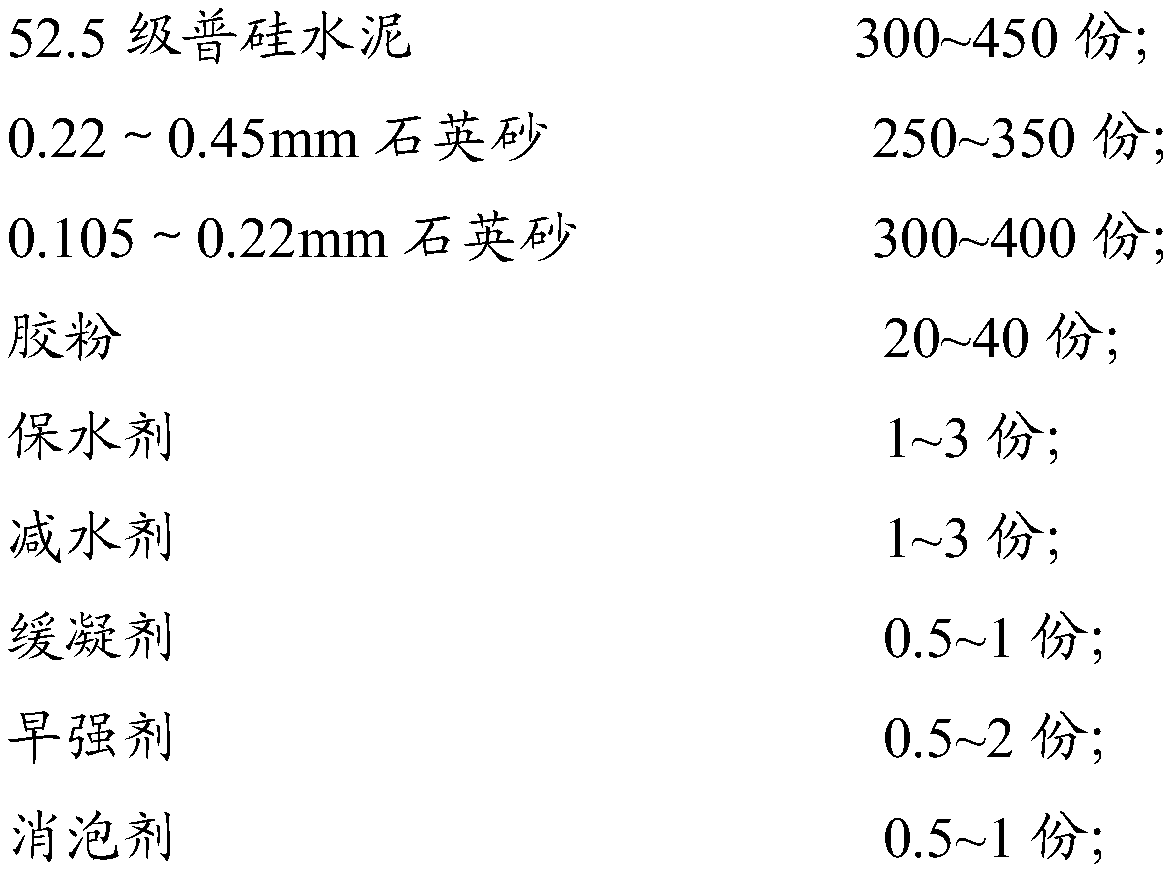

Anchor-free EPS decorative component system

The invention discloses an anchor-free EPS decorative component system. A groove is formed in the bottom surface of an EPS decorative component polystyrene board base body, during assembling, reinforcing anchors are not required, the working period is shortened, the cost is reduced, furthermore, a cold bridge formed by holes caused by nailing is avoided, and meanwhile, the quality problem caused by rusting of the anchors is avoided; a groove and a protrusion are arranged at the two ends of an EPS decorative component, firm attachment is implemented during lap joint, and cracks of a finish coatare avoided. Special binding mortar for the EPS decorative component has the characteristics of good initial mobility, high early strength, good permeability and high size stability, development of later strength is not affected while high early strength can be ensured, and by addition of a water retaining agent, the circumstance that the initial mobility of the mortar is reduced due to increasing of stickiness while full water-retaining property can be ensured; by addition of a surfactant, the surface tension of mortar is reduced, and permeability is enhanced; and by addition of a thixotropic lubricant, the mortar has a good application property and good sagging resistance.

Owner:君旺节能科技股份有限公司

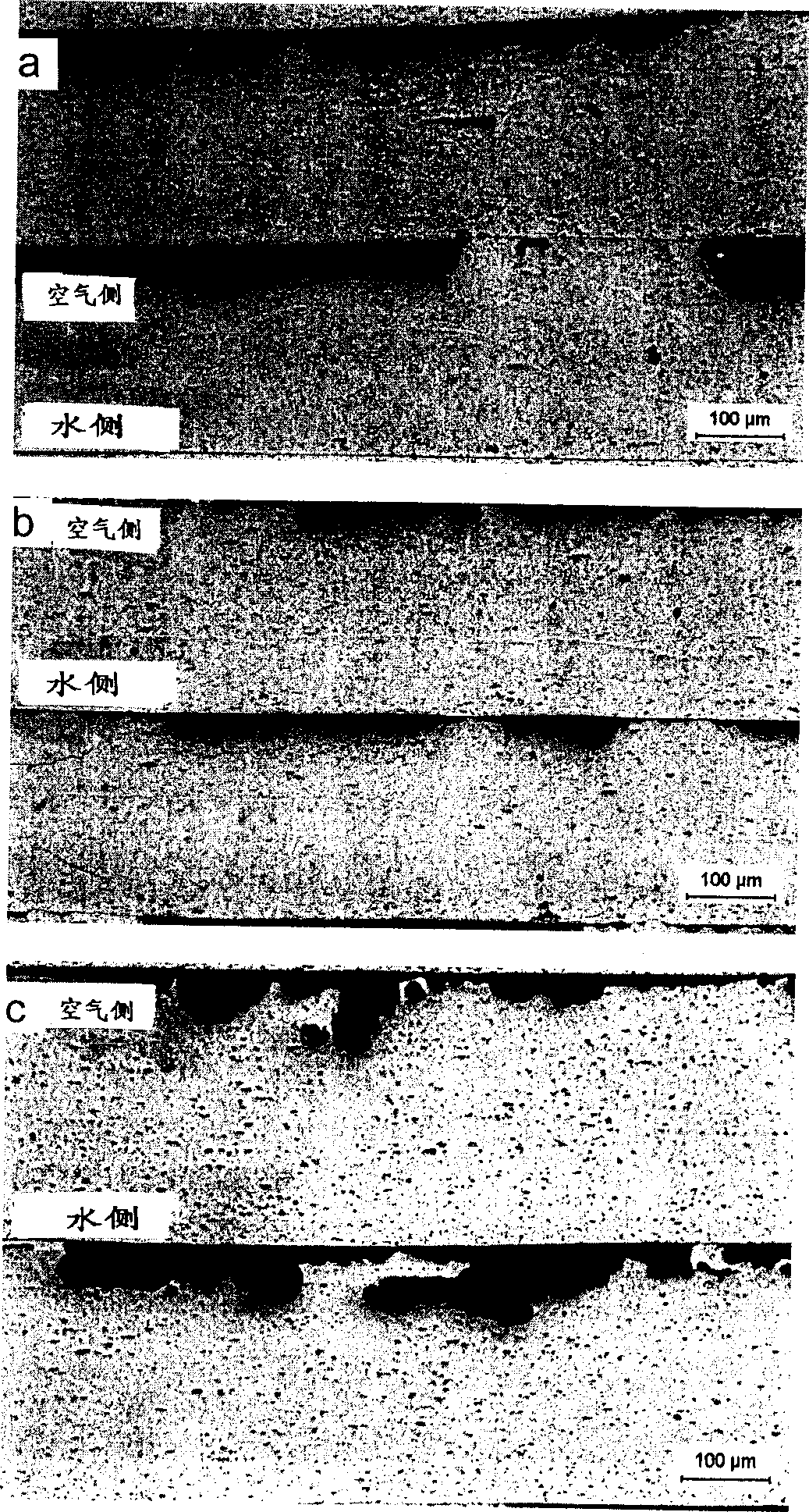

Anti-sagging plasterboard and method for producing same

ActiveCN101747014BSolve accompanying problemsGood anti-saggingSolid waste managementCeramicwareGlass fiberFoaming agent

The invention discloses an anti-sagging plasterboard comprising the following components by weight percent: 0.02-0.25 percent of boric acid, 0.4-1.2 percent of starch, 0.2-1.0 percent of glass fiber, 0.04-0.15 percent of foaming agent, 0.01-0.08 percent of borax, 0.05-0.5 percent of paper and the balance of the gypsum. The invention also discloses a method for producing the anti-sagging plasterboard, comprising the following steps: a, making paper into paper pulp solution, dissolving boric acid and borax into the paper pulp solution, and adding glass fiber to the paper pulp solution to form paper pulp mixture; and b, stirring the paper pulp mixture to crushed plaster powder, the starch and the foaming agent, and forming the mixture on a forming platform. The anti-sagging plasterboard has good anti-sagging performance, and the deformation amount of the anti-sagging plasterboard can be controlled between 1.6 mm and 8 mm. In addition, the method for producing the anti-sagging plasterboard well solves the problem that the boric acid, the borax and the glass fiber are associated with plaster crystal, which can not be solved by the dry adding in the prior art.

Owner:NINGBO BEIXIN BUILDING MATERIAL

Preparation method for transparent thixotropic unsaturated polyester resin

The invention relates to a preparation method for a transparent thixotropic unsaturated polyester resin and belongs to the technical field of organic high molecule compound preparation. The preparation method includes the following steps that (1) dihydric alcohol, saturated dicarboxylic acid or acid anhydride and unsaturated dicarboxylic acid or acid anhydride are added in a container, and a polycondensation dehydration reaction is performed to obtain a resin A; (2) acrylic ester or a methacrylic ester crosslinking monomer is added in the resin A; (3) after uniformly mixing, fumed silica is added, and a high-speed dispersion is performed; and styrene can be added in the resin A in the step (2). The transparent thixotropic unsaturated polyester resin has the advantages that the thixotropy and sag resistance are good, the appearance transparency of the resin and cured substances with any thickness is high, substrates can be fully protected, and patterns of the substrates can be clearly presented.

Owner:CHANGZHOU HUARI NEW MATERIAL

Method for manufacturing vehicle radiator aluminum foil material

InactiveCN103509976AHigh strengthGood collapse resistance and heat transfer capacityHeat exchange apparatusSlagAluminium alloy

The invention provides a method for manufacturing a vehicle radiator aluminum foil material, and provides an aluminum alloy key material core layer, which is formed after fusing, stirring, mixing, removing gas, removing slag, etc.

Owner:孙建良

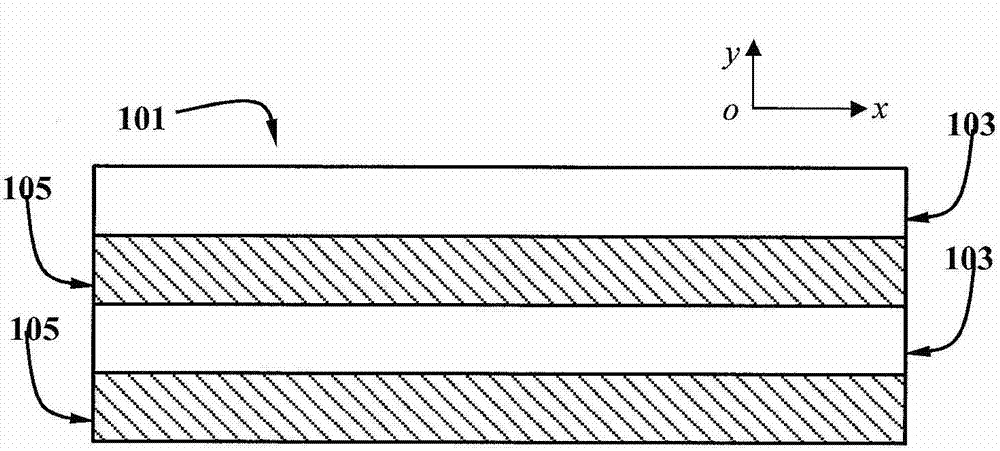

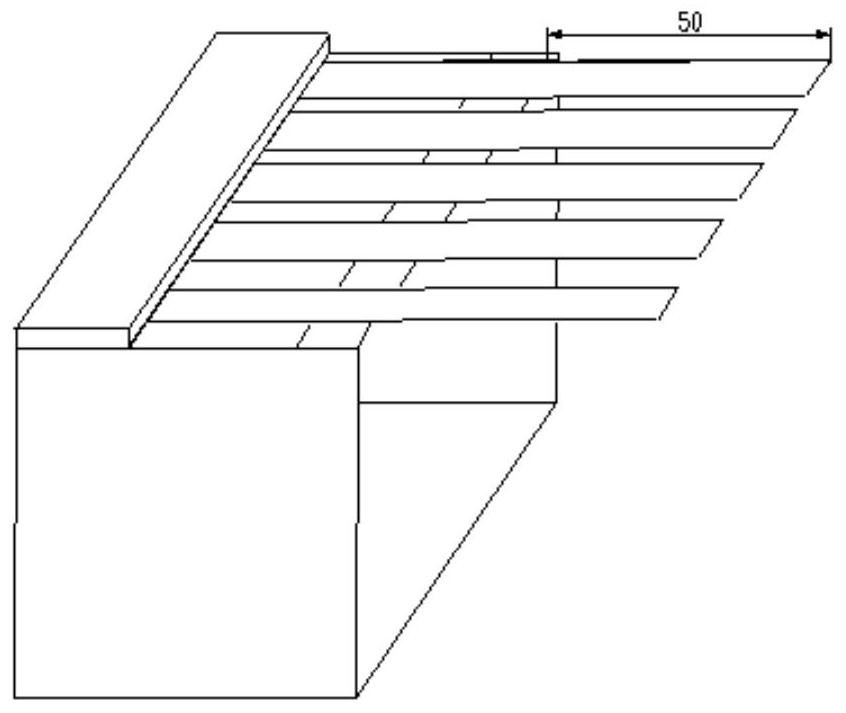

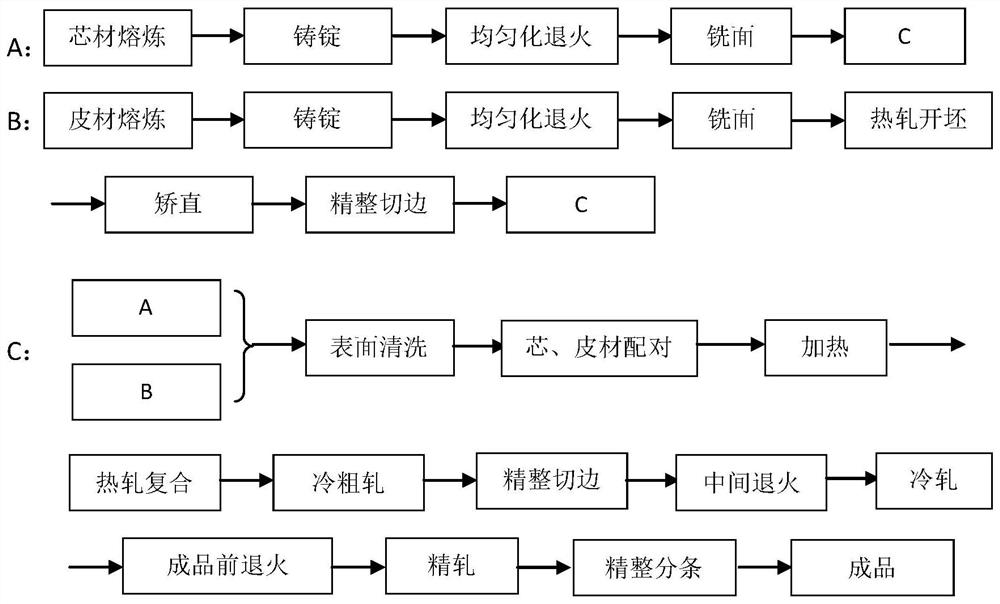

A kind of aluminum foil material for producing automobile heat dissipation composite fins and its preparation method

ActiveCN110257673BReduce thicknessImprove thickness control accuracySoldering apparatusMetal rolling arrangementsAluminum foilCorrosion resistant

The invention relates to an aluminum foil for producing a heat dissipating composite fin for an automobile and a preparation method thereof. The material comprises a core material and leather materials on the upper and lower layers; the aluminum foil for the composite fin is a part of an automobile heat exchanger, the leather materials of the aluminum foil for the composite fin have a lower melting point, the characteristic that the leather materials of the aluminum foil have the lower melting point is adopted for brazing at a certain high temperature, and the the leather materials of the aluminum foil melt when the melting point is reached so as to realize combination of the core material of fin and other components of the heat exchanger. The leather materials are compounded on the upper and lower surfaces of the core material, the core material and the leather materials are continuously cast and rolled to obtain a cast-rolled billet, and compounding is achieved after cold rolling compounding. The preparation method has high production efficiency, high flexibility and high quality, the aluminum foil material coating rate is more stable, and the aluminum foil has the high strength after welding, the excellent corrosion resistance and excellent anti-sagging performance after high temperature brazing; and to sum up, the performance of the prepared aluminum foil for the heat dissipating composite fin for the automobile is excellent.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com