Aluminum alloy composite sheet having long service life

A technology of composite sheet and aluminum alloy, which is applied in the field of aluminum alloy and long-life aluminum alloy composite sheet, can solve the problems of loss of heat dissipation effect of heat sink and reduced service life, and achieve significant economic and social effects, improved corrosion resistance, The effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

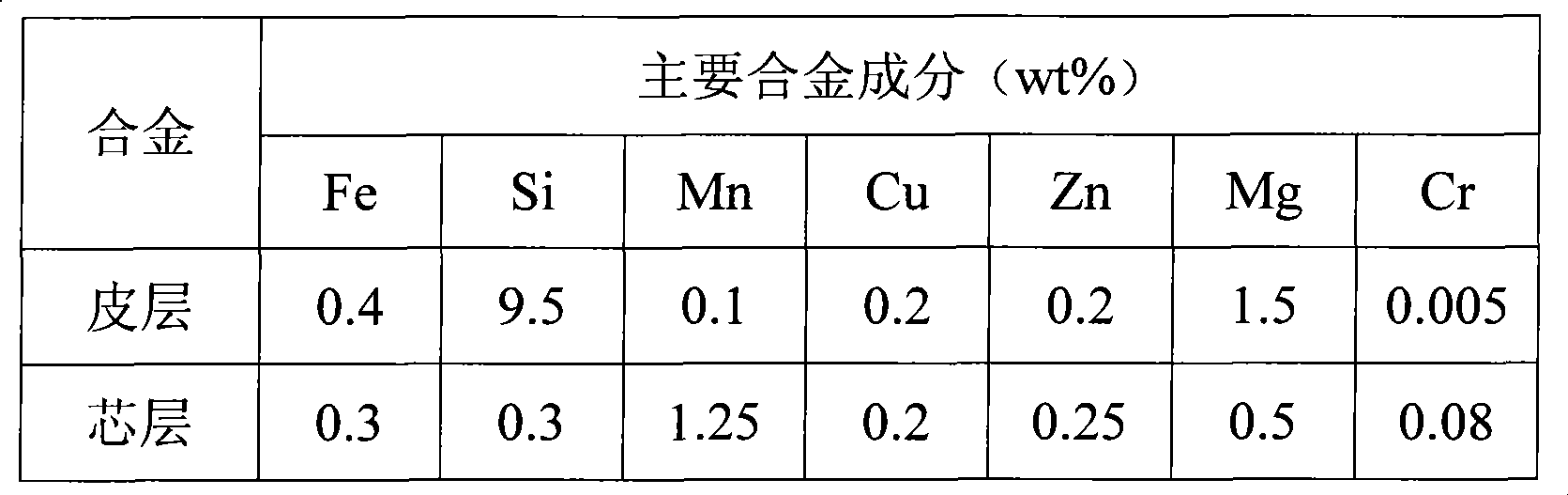

[0020] According to the present invention, one group of alloy components is selected for testing, and the chemical composition of the selected alloy is shown in Table 1.

[0021] Table 1

[0022]

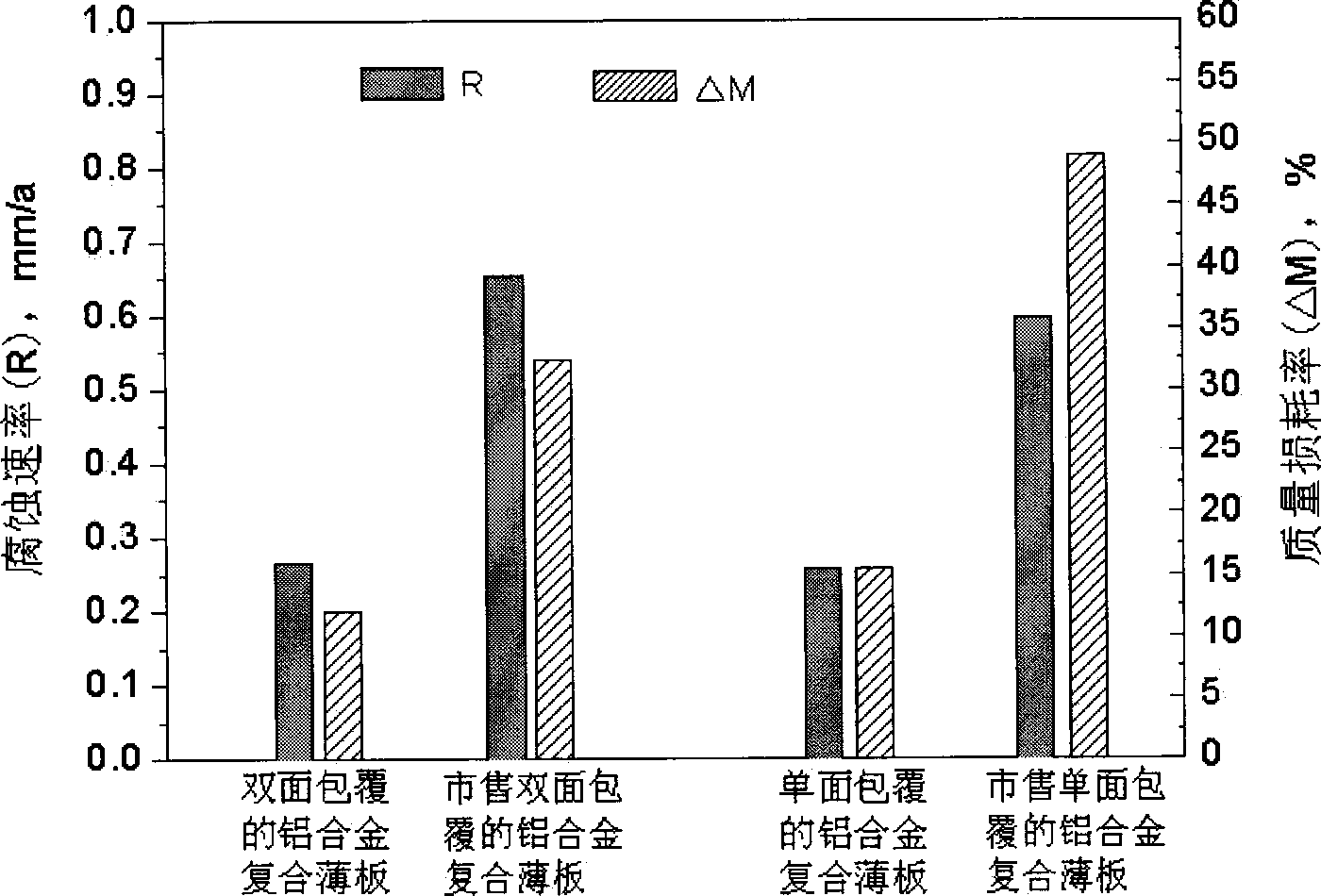

[0023] Manufacture and obtain double-sided coated aluminum alloy composite sheet, the structural characteristics of the composite sheet after annealing are as follows: figure 1 . According to GB 10124-88, the corrosion resistance test is carried out, and the comparison results with similar alloy products on the market are used to evaluate the corrosion resistance of the alloy. The comparison results are shown in figure 2 shown.

Embodiment 2

[0025] The composition of the alloy in this embodiment is the same as in Table 1.

[0026] The aluminum alloy composite sheet coated on one side is manufactured, and its structure characteristics after annealing are similar to the aluminum alloy composite sheet coated on both sides. Evaluate the advantages and disadvantages of its corrosion resistance by the method of Example 1, and the obtained comparison results are shown in figure 2 .

[0027] In summary, the present invention improves the corrosion resistance of the alloy on the basis of maintaining good mechanical properties, sag resistance and brazing properties of the alloy through the optimization of alloy elements. Through the control of the organization, the corrosion resistance is improved by using the characteristics of elongated grains, and its corrosion resistance is better than that of similar products in the existing market. The aluminum alloy composite thin plate not only has an excellent service life, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com