Anchor-free EPS decorative component system

A technology of decorative components and anchors, which is applied in the direction of building construction, construction, covering/lining, etc., can solve the problems of easy rusting of anchors, reduced thermal insulation effect, and reduced service life of decorative components, and achieves high early strength and water retention Sexual reduction, surface tension reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

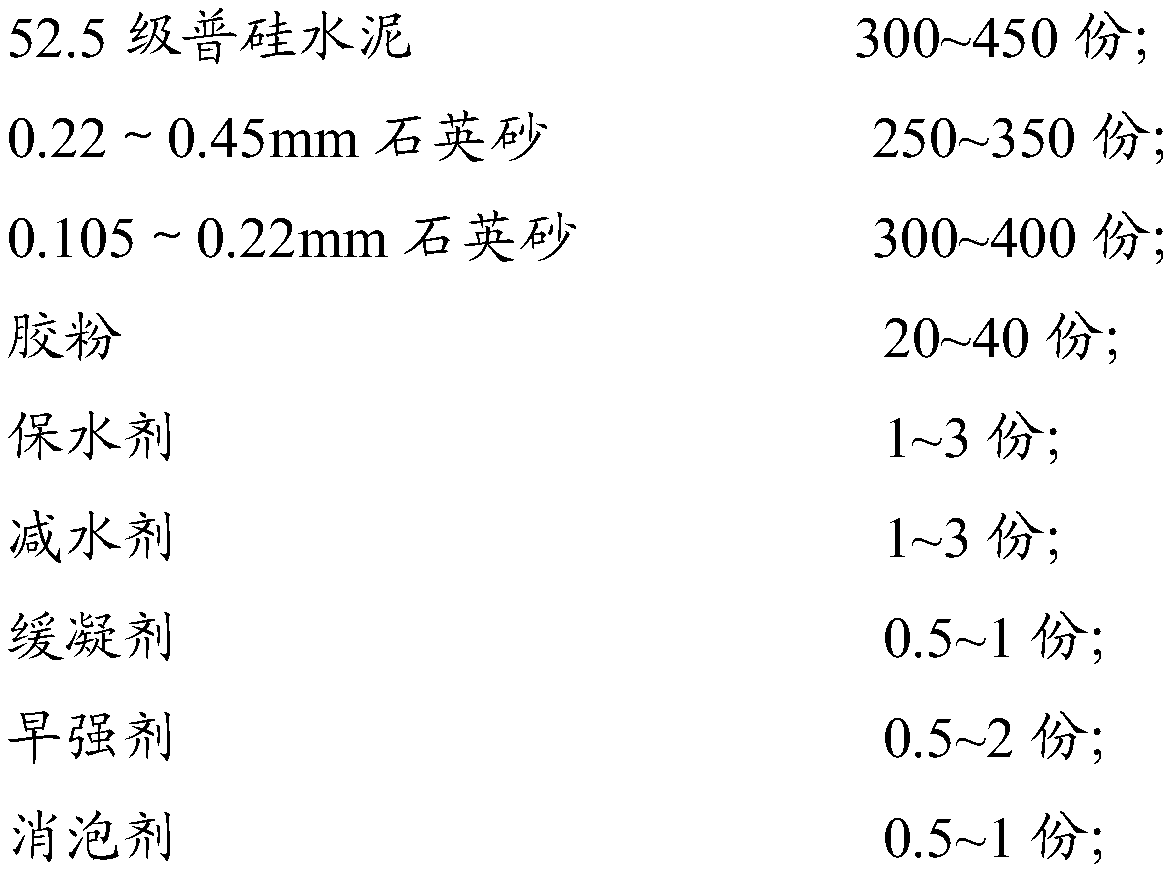

[0054] The bonding mortar includes 300 parts of 52.5 grade ordinary silicon cement, 310 parts of 0.22-0.45mm quartz sand, 364 parts of 0.105-0.22mm quartz sand, 20 parts of vinyl acetate-ethylene copolymerized redispersible latex powder, and 2 parts of viscosity 60000mPa·s Hydroxypropyl methyl modified cellulose ether, 1 part of polycarboxylate water reducer, 0.5 part of citric acid, 1.2 parts of lithium carbonate, 0.5 part of silicone defoamer, 0.4 part of sodium dodecylbenzenesulfonate, 0.5 parts of starch ether, 0.5 parts of polyacrylic acid shrinkage reducer. Water content in the bonding mortar: 20wt%.

Embodiment 2

[0056] The bonding mortar includes 350 parts of 52.5 grade ordinary silicon cement, 280 parts of 0.22-0.45mm quartz sand, 340 parts of 0.105-0.22mm quartz sand, 23 parts of vinyl acetate-ethylene copolymerized redispersible latex powder, and 2 parts of viscosity 75000mPa·s Hydroxypropyl methyl modified cellulose ether, 1.2 parts of polycarboxylate water reducer, 0.7 parts of citric acid, 1 part of lithium carbonate, 0.5 parts of silicone defoamer, 0.5 parts of sodium dodecylbenzenesulfonate, 0.5 parts of starch ether, 0.7 parts of polyacrylic acid shrinkage reducer. Water content in the bonding mortar: 20.5wt%.

Embodiment 3

[0058] The bonding mortar in Example 3 includes 380 parts of 52.5 grade ordinary silicon cement, 270 parts of 0.22-0.45mm quartz sand, 320 parts of 0.105-0.22mm quartz sand, 25 parts of vinyl acetate-ethylene copolymerized redispersible latex powder, 2.2 parts Viscosity 70000mPa·s hydroxypropyl methyl modified cellulose ether, 1.5 parts of polycarboxylate water reducer, 0.8 parts of citric acid, 1 part of lithium carbonate, 0.7 parts of silicone defoamer, 0.7 parts of dodecylbenzene Sodium sulfonate, 0.6 part of starch ether, 0.9 part of polyacrylic shrinkage reducer. Water content in the bonding mortar: 21wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com