High-brightness black coating for automobile exterior decoration as well as preparation method and application of high-brightness black coating

A black paint and exterior decoration technology, applied in the paint field, can solve the problems of not pure enough paint film color, insufficient paint film hardness, insufficient blackness, etc., and achieve the effect of easy mass production, pure paint film color and high blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of automotive exterior high gloss black coating, its preparation method comprises the following steps:

[0027] 1) Add hydroxy acrylic resin to the mixing container, while stirring at a speed of 800.0-1200.0rpm, add anti-sag resin, black paste, solvent, leveling agent, drier, UV absorber / stabilizer in sequence ;

[0028] 2) After the feeding is completed, increase the speed to 1500.0-2000.0rpm, and stir and mix for 25-35min to obtain the high-gloss black paint for automobile exterior decoration.

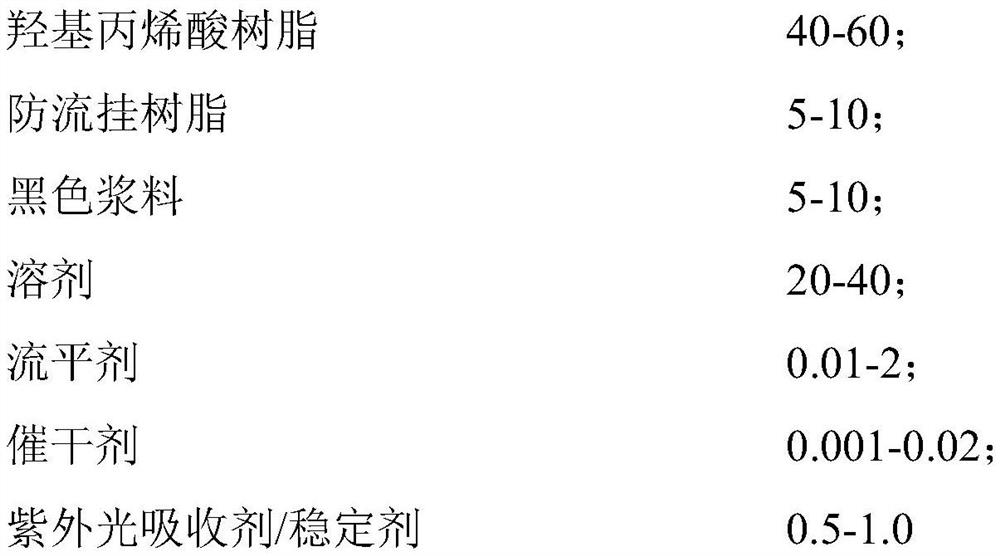

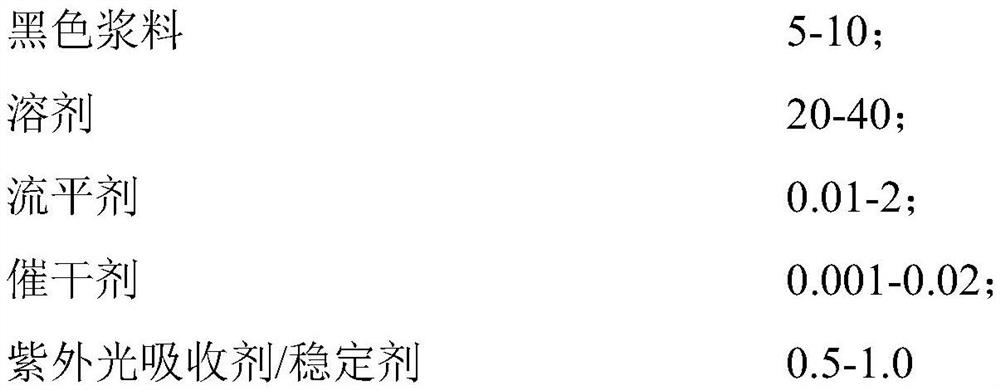

[0029] Wherein, each component and parts by weight content:

[0030]

[0031] Specifically, the hydroxy acrylic resin is preferably one or both of FS-4660P hydroxy acrylic resin from Deqian (Shanghai) Chemical Co., Ltd., or SETALUX-1279 hydroxy acrylic resin from Allnex Resin (China) Co., Ltd.

[0032] The anti-sagging resin is preferably SETALUX-81198 type hydroxy acrylic resin of Allnex Resin (China) Co., Ltd.

[0033] The black slurry is prepared by the followi...

Embodiment 1

[0042] A preparation method of high-gloss black paint for automobile exterior decoration, comprising the following steps:

[0043] 1) Adjust the speed of the mixer to 800.0-1200.0rpm, and then sequentially add hydroxyacrylic resin, anti-sag resin, black paste, solvent, leveling agent, drier, UV absorber / stabilizer; each component Consumption is as shown in table 1;

[0044] 2) After feeding, increase the rotation speed to 1500.0-2000.0 rpm, and stir and mix for 30 minutes to obtain high-gloss black paint for automobile exterior decoration.

[0045] Table 1 Types of Components Used and Quality and Dosage

[0046]

[0047]

[0048] Wherein, black slurry adopts following method to prepare:

[0049] Mix the first part of color paste solvent, dispersant, toner, and general-purpose resin evenly, grind to a fineness of ≤10 μm, and then add the second part of color paste solvent to adjust the viscosity to 80.0-100.0S (T4 cup) to obtain black paste material;

[0050] Wherein,...

Embodiment 2、 Embodiment 3

[0059] The types and mass dosages of the components in this example are shown in Table 3 and Table 4, respectively, and the rest, including the coating preparation method, coating preparation method, and coating testing standards, are the same as in Example 1. The test results are shown in Table 5.

[0060] Component type and quality consumption used in table 3 embodiment 2

[0061]

[0062] Component type and quality consumption used in the embodiment 3 of table 4

[0063]

[0064]

[0065] Table 5 Coating Test Standards and Test Results

[0066]

[0067]

[0068] According to embodiment 1, embodiment 2 and embodiment 3 contrast, the blackness of embodiment 1 is slightly lower than embodiment 2, embodiment 3; Embodiment column 2 is softer than actual case 1, embodiment 3 hardness slightly; Embodiment 3 black The degree and hardness are relatively good. Examples 1, 2, and 3 all have the characteristics of high gloss and high fullness, and at the same time mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com