Patents

Literature

140results about How to "Fast cross-linking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

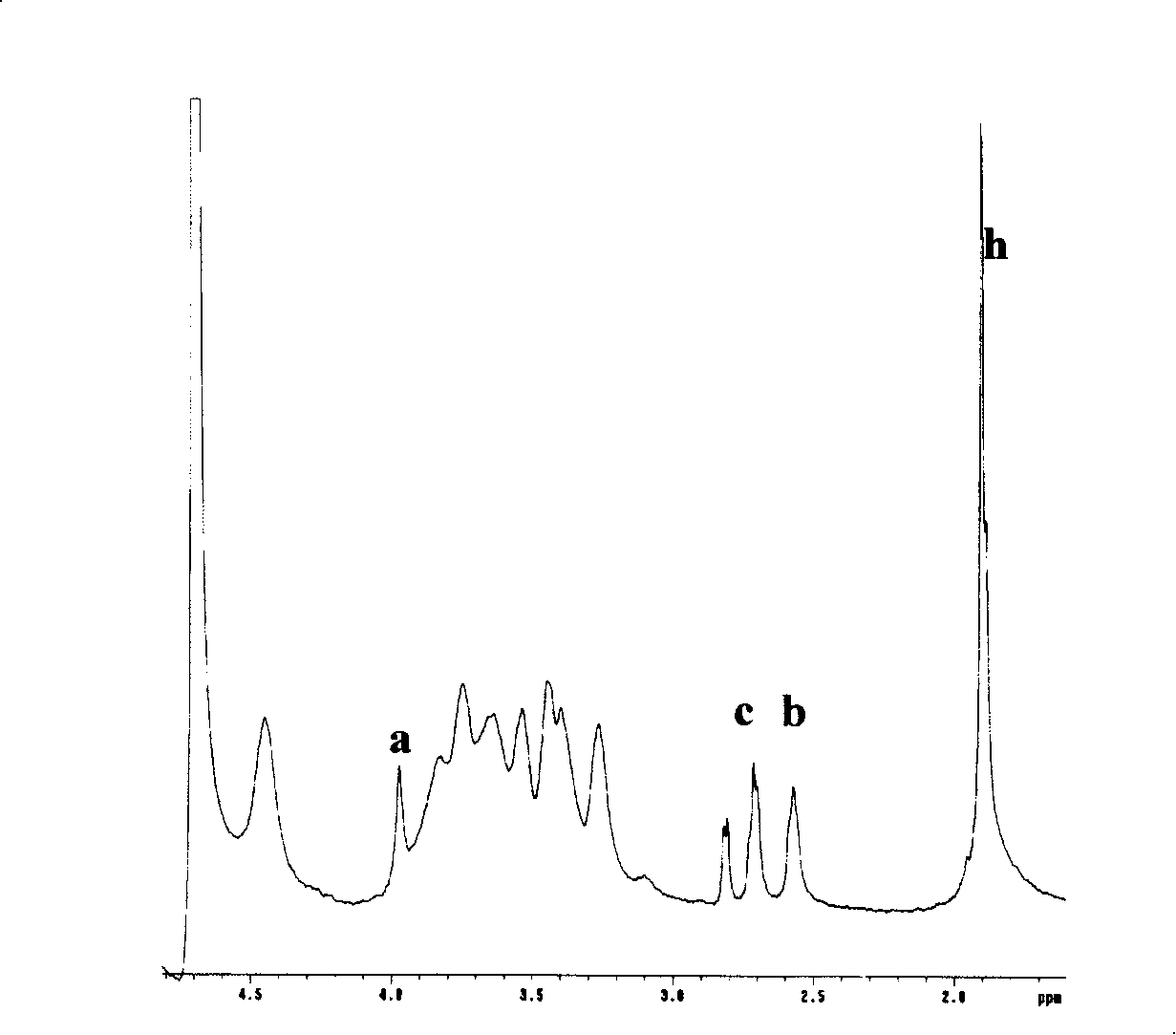

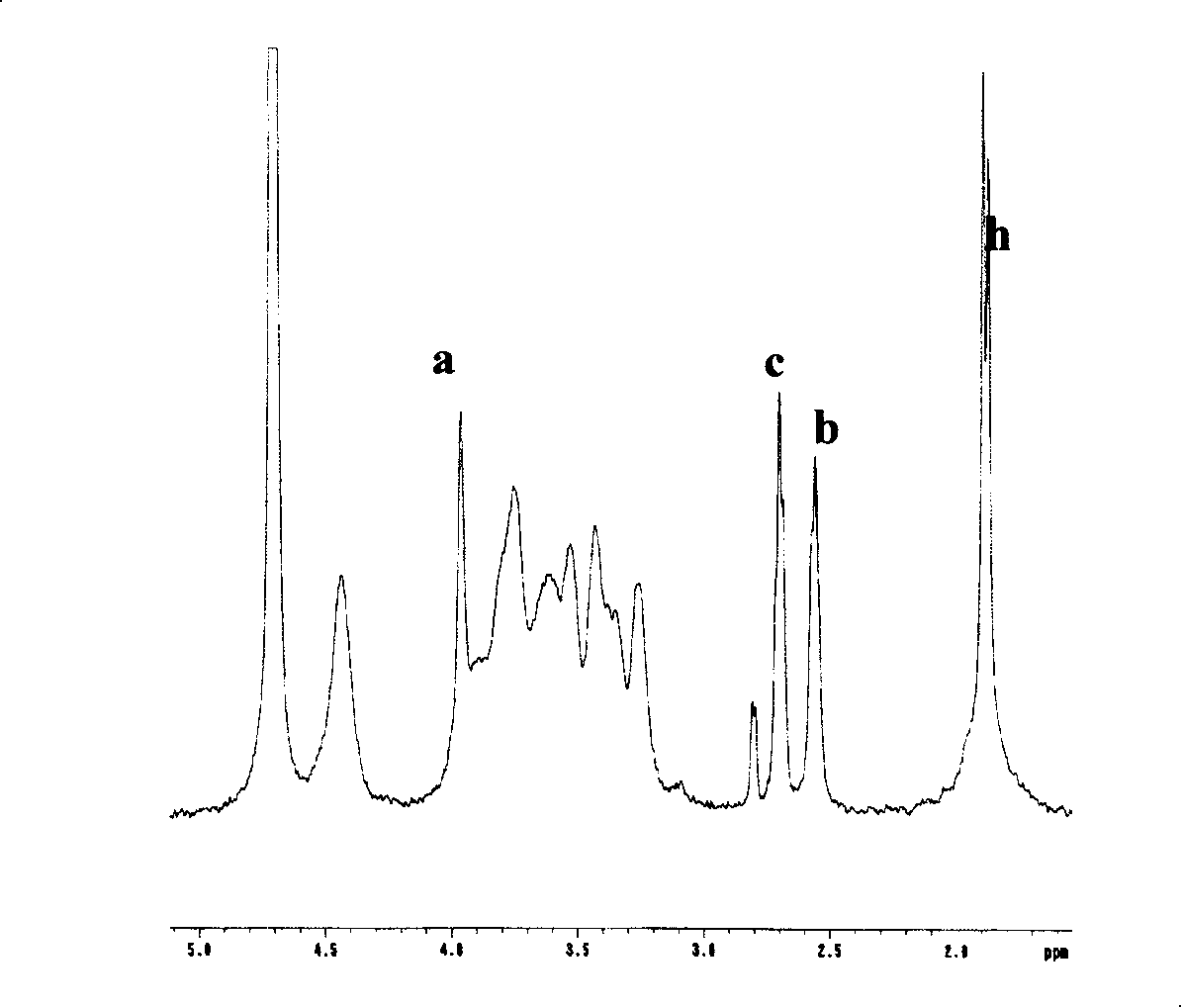

Macromolecule thiolated modified derivatives and cross-linking material thereof

ActiveCN101200504AAvoid stickingEasy to manufacturePeptide preparation methodsAmide group formation/introductionChemical structureProduction rate

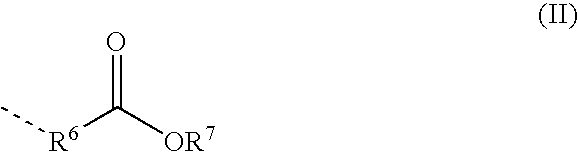

The present invention discloses a macromolecular sulfydryl modified derivative with general formula (I) or (II) as well as corresponding dithio-bond cross-linking material and corresponding cross-linking material of sulfydryl reaction active cross linker. Wherein, R1 and R2 include alkylidene, substituted alkylidene, aromatic base, polyether polyols, etc. and R1 and R2 can have the same or different chemical structure; P refers to macromolecular compound residue including carboxyl in the side chain and the molecular weight of the macromolecular sulfydryl modified derivative is 10 to 5 million. The side-chain chemical structure of the macromolecular sulfydryl modified derivative with general formula (I) or (II) is flexible and changeable with notable advantages of adjustable performance, mild preparation conditions, high production rate, high modification and controllability. The cross-linking material of the macromolecular sulfydryl modified derivative provided by the present invention can be used to inhibit the attachment of cells and used as the matrix for cell adhesion and growth.

Owner:BIOREGEN BIOMEDICAL (CHANGZHOU) CO LTD

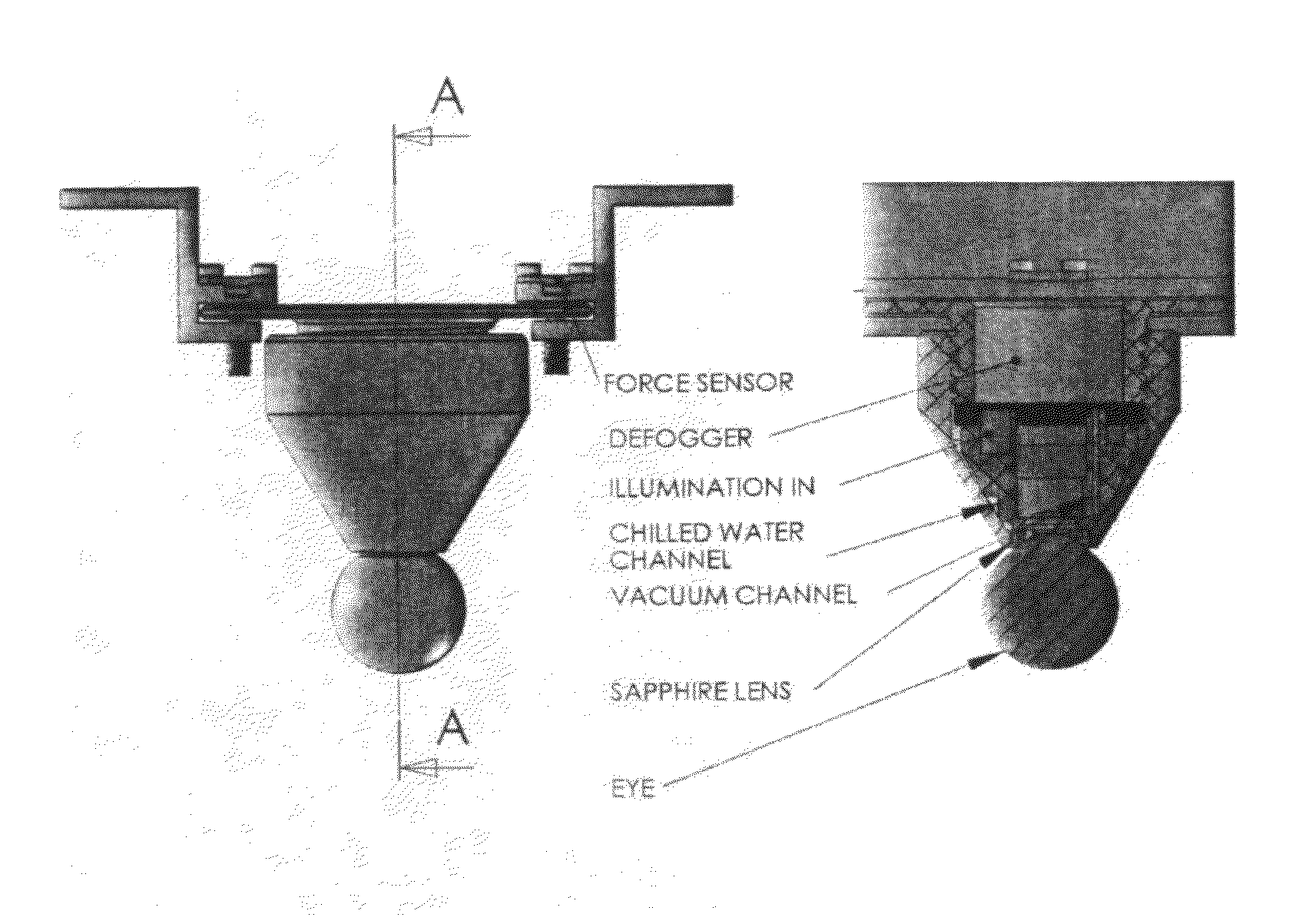

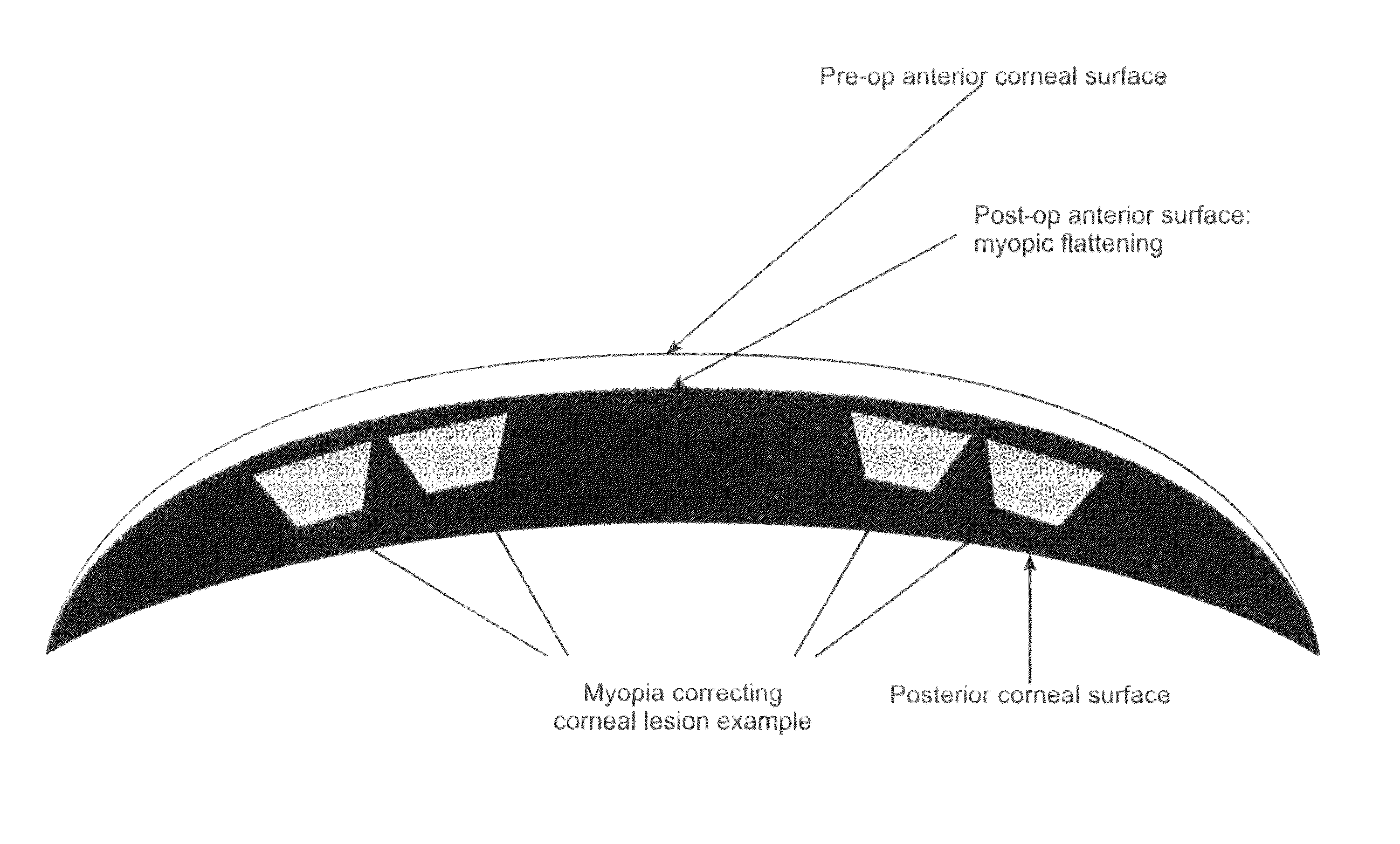

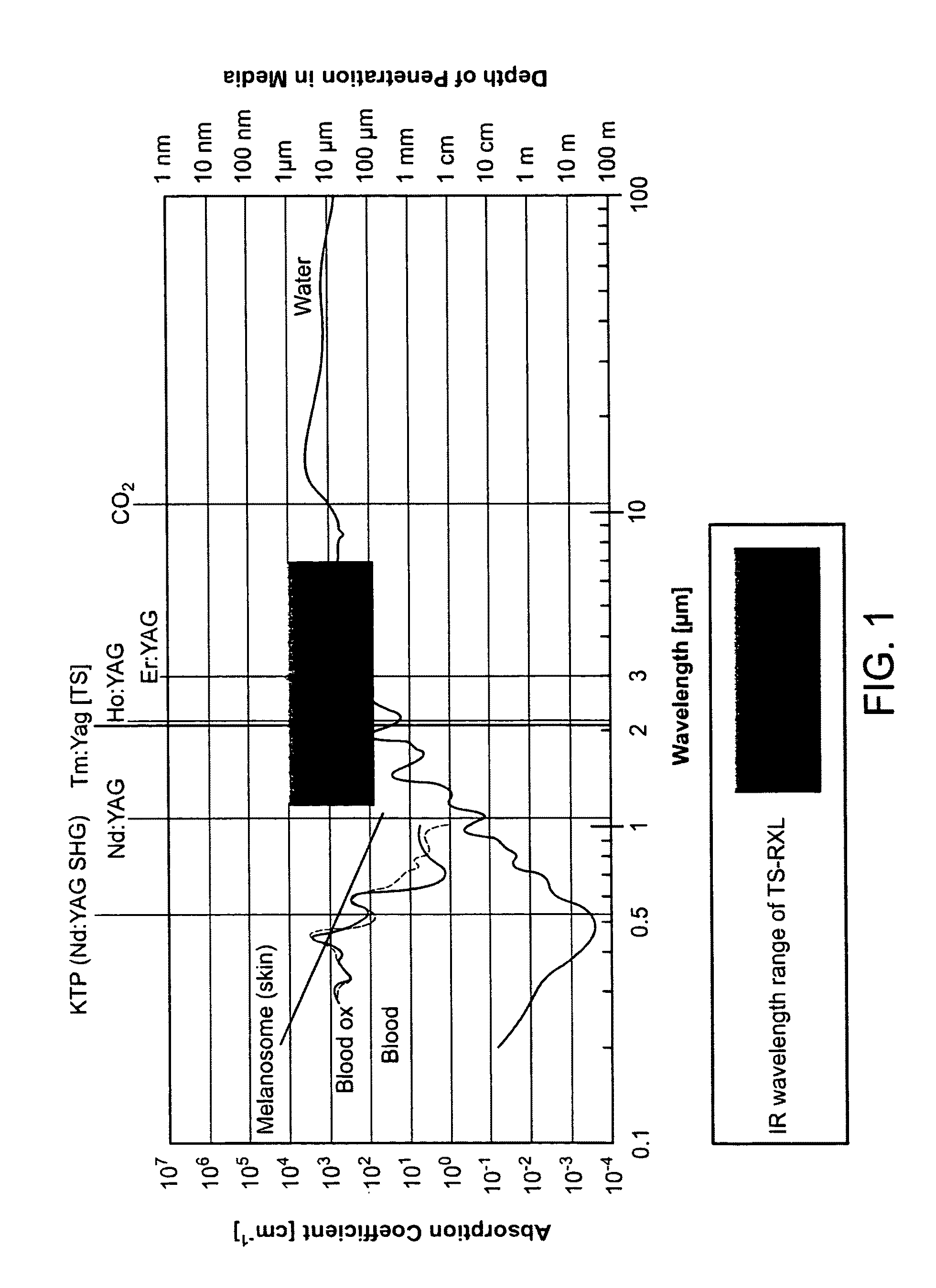

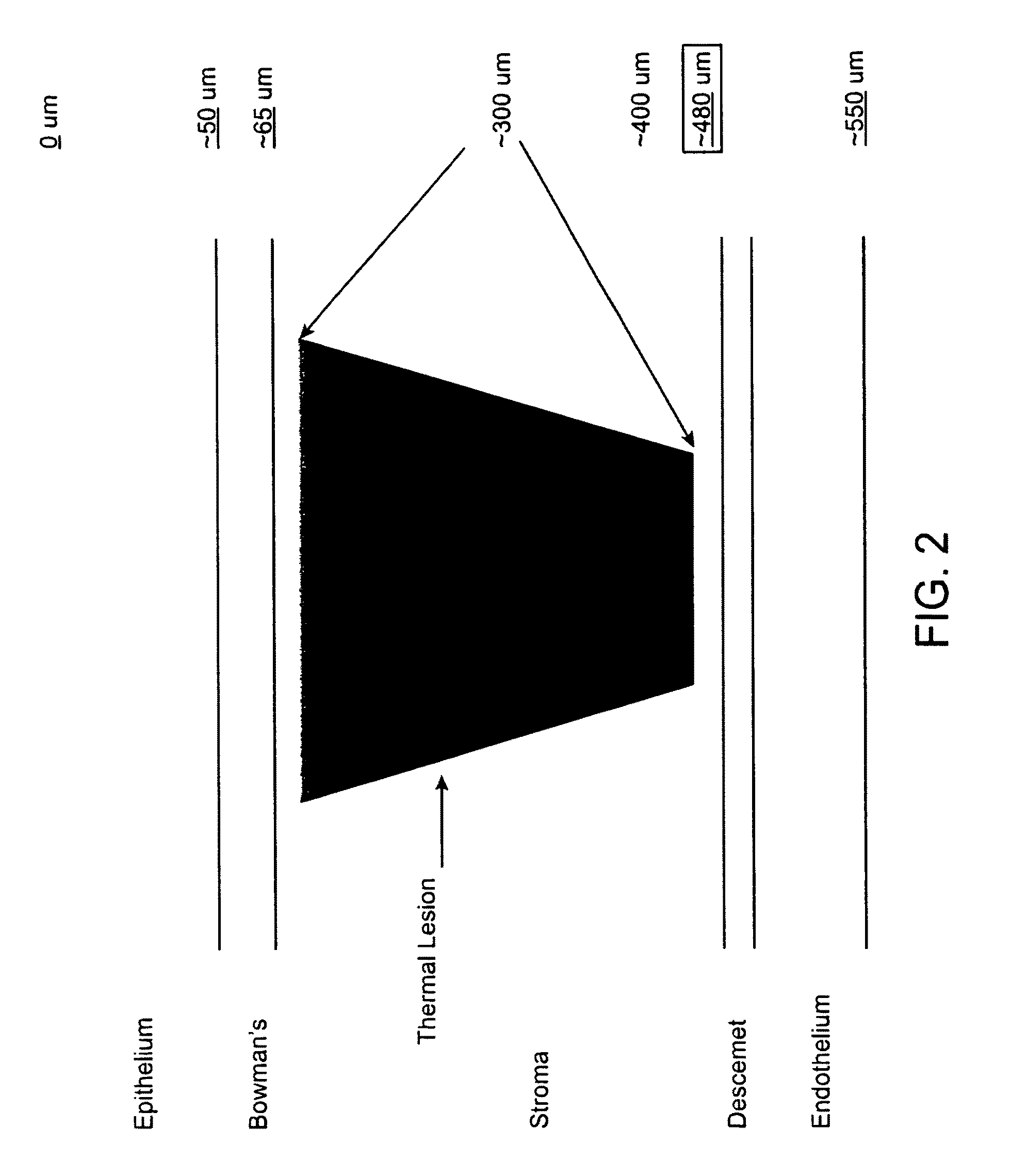

Method and apparatus for treatment of ocular tissue using combined modalities

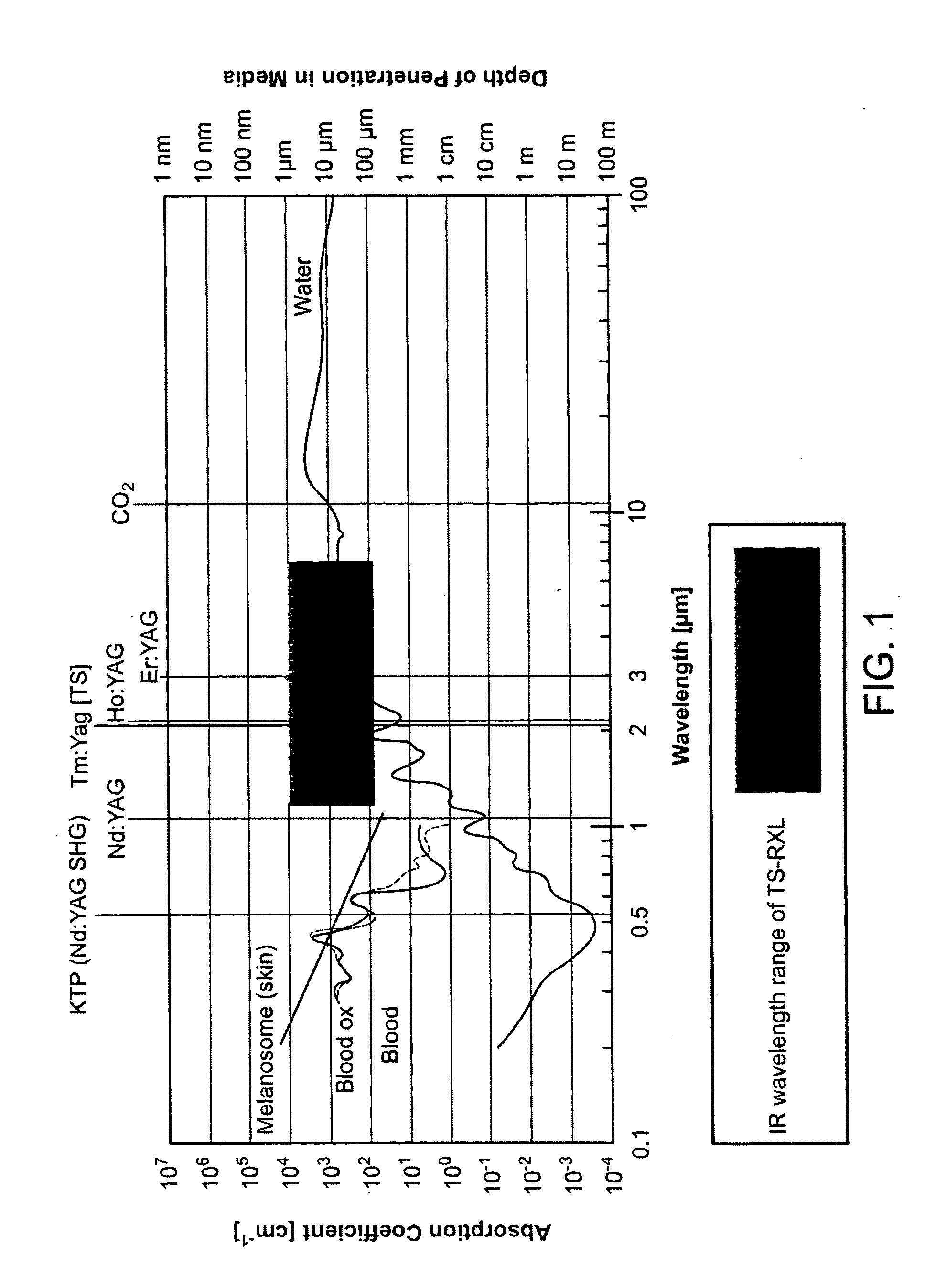

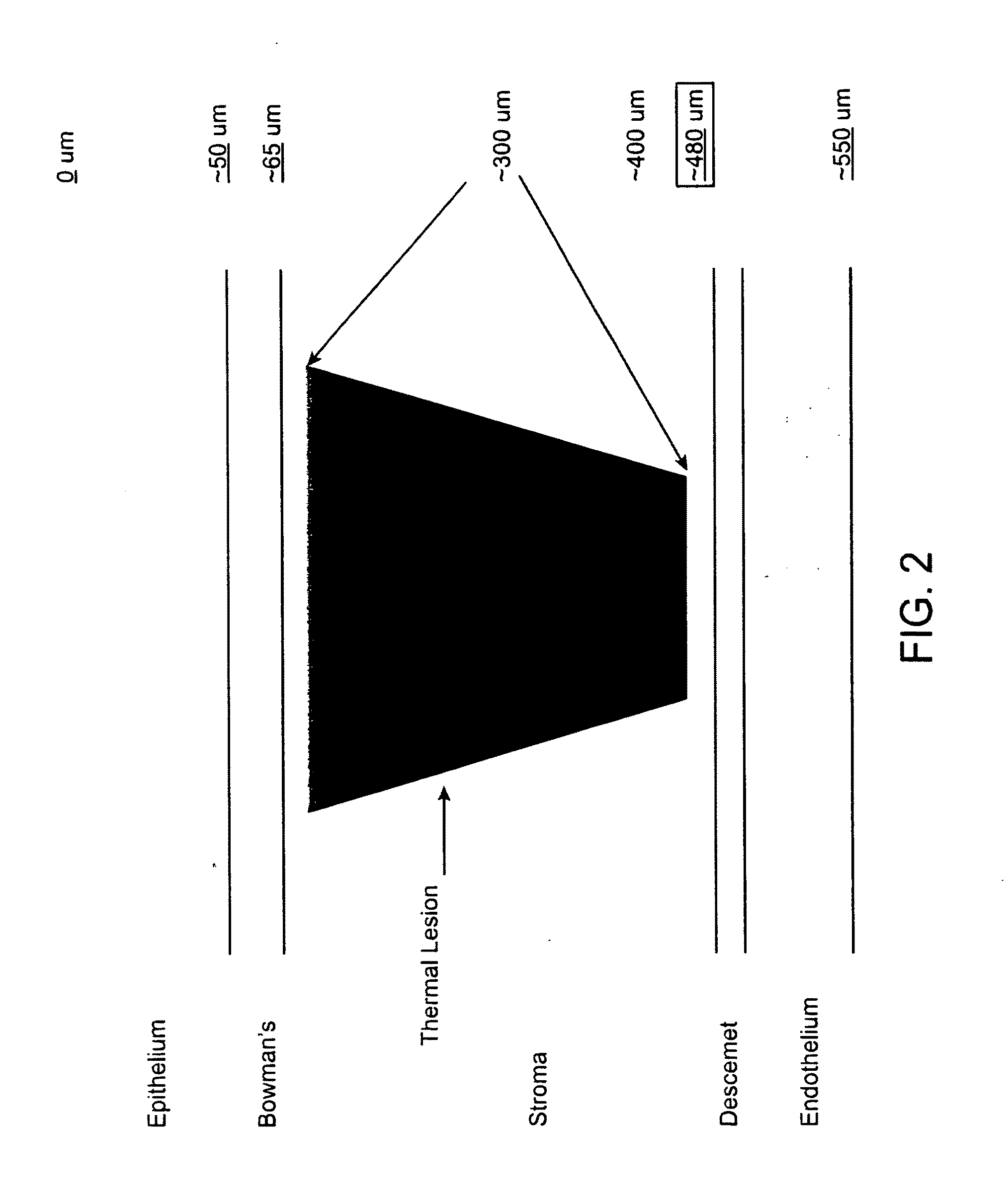

ActiveUS20110282333A1Promote cornealFast cross-linkingLaser surgerySurgical instrument detailsHigh absorptionCollagen cross linking

An apparatus and a method are provided for treating a targeted area of ocular tissue in a tissue-sparing manner comprising use of two or more therapeutic modalities, including thermal radiation source (such as an CW infrared fiber laser), operative in a wavelength range that has a high absorption in water, and photochemical collagen cross-linking (CXL), together with one or more specific system improvements, such as peri-operative feedback measurements for tailoring of the therapeutic modalities, an ocular tissue surface thermal control / cooling mechanism and a source of deuterated water / riboflavin solution in a delivery system targeting ocular tissue in the presence of the ultraviolet radiation. Additional methods of rapid cross-linking (RXL), are provided that further enables cross-linking (CXL) therapy to be combined with thermal therapy.

Owner:ALEYEGN TECH LLC

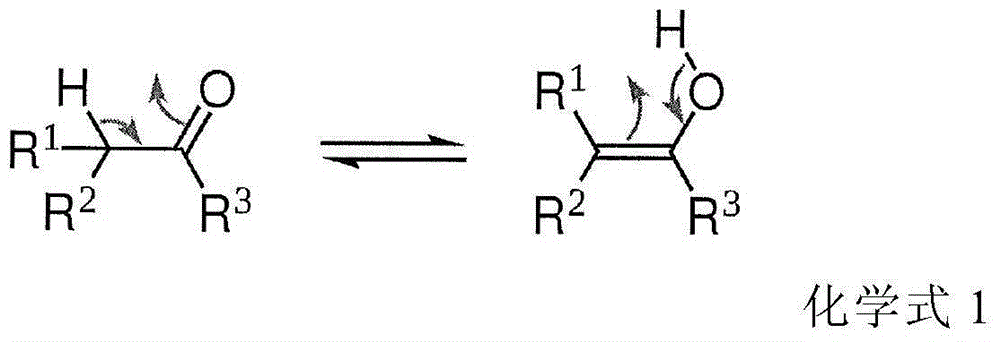

Crosslinkable composition crosslinkable with a latent base catalyst

ActiveUS8962725B2Reduce environmental burdenEffective use timeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemistryPolymer chemistry

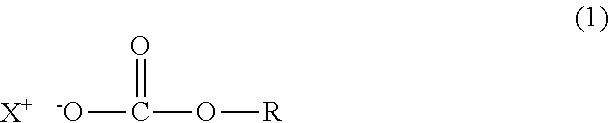

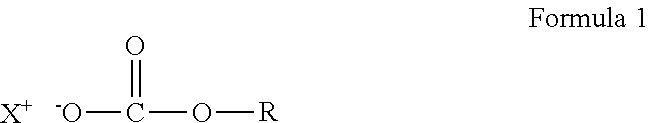

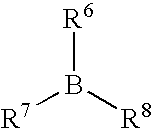

The present invention relates to a crosslinkable composition comprising at least one crosslinkable component crosslinkable by a latent base crosslinking catalyst comprising a substituted carbonate salt according to formula 1 wherein X+ represents a cation and wherein R is hydrogen, alkyl, aryl or aralkyl group, and wherein the crosslinkable composition comprises 0.1-10 wt %, preferably 0.1-5, more preferably 0.2-3 and most preferably 0.5-1.5 wt % water (relative to total weight of the crosslinkable composition). The invention further relates to a coating composition comprising the crosslinkable composition according to the invention, a novel catalyst composition and to the use of said catalyst composition according to the invention as a latent base crosslinking catalyst in coating compositions, preferably in RMA crosslinkable compositions.

Owner:ALLNEX NETHERLANDS BV

Solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging

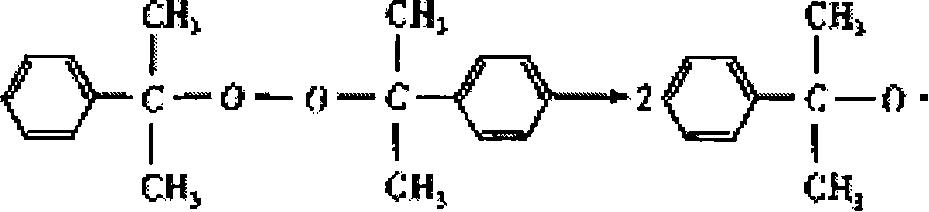

InactiveCN101626039AIncrease crosslink densityModerate reaction temperatureElectrical equipmentGlass/slag layered productsAntioxidantPhosphate

The invention relates to a solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging, which comprises the following materials by weight portions: 100 portions of copolymer of ethylene vinyl acetate, 0.8-1.4 portions of crosslink curing agent, 0.05-0.15 portion of crosslink curing accelerator, 0.2-0.6 portion of tackifier, 0.1-0.5 portion of antioxidant, 0.05-0.25 portion of ultraviolet light stabilizer and 0.1-0.3 portion of ultraviolet light absorbent, wherein the crosslink curing agent is tert butyl peroxy 2-ethyl hexyl carbonate; the crosslink curing accelerator is triallyl isocyanurate; the tackifier is r-glycidyl ether oxy-propylltrimethoxysilane; the antioxidant is one or two selected from the group consisting of bis(2,4-dicumylphenyl)pentaerythritol diphosphite, distearyl pentaerythritol diphosphite, tris(nonyl phenyl)phosphate and tris(2,4-butylphenyl)phosphate; and ultraviolet light absorbent is gas phase silicon dioxide. The solar cell packaging EVA adhesive film can resist high temperature of 85 DEG C, humidity of 85 percent, ultraviolet light and thermal oxidative aging.

Owner:苏州爱康商务咨询服务有限公司

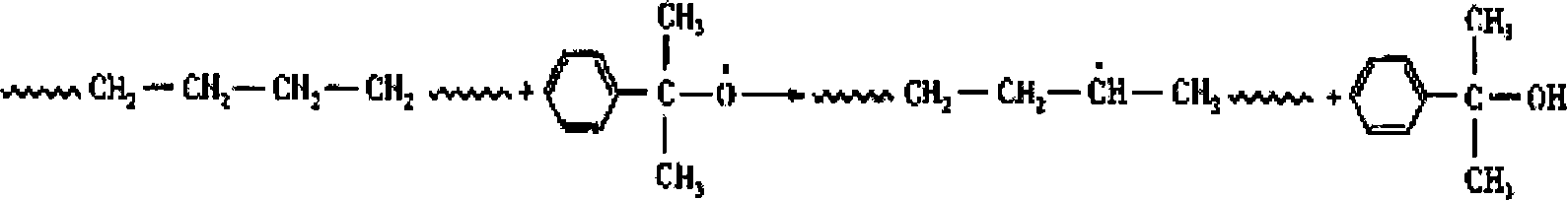

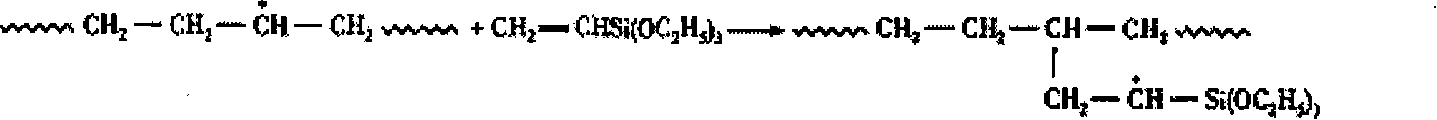

Technique for manufacturing natural crosslinking polyethylene-insulated cable material

InactiveCN101148522AShort crosslinking timeShorten the production cyclePlastic/resin/waxes insulatorsCross-linked polyethyleneSilane coupling

The present invention relates to technological process of making cable insulating polyethylene material with cross-linking completed at natural condition, fast reaction speed, simple production process and easy operation. The making process includes the following steps: 1. melting, mixing and pelletizing two groups of material in a double screw extruder separately to obtain material A comprising polyethylene 100 weight portions, initiator 0.05-0.2 weight portions, silane coupler 0.5-5.0 weight portions and pre-cross linking resisting agent 0.1-0.5 weight portions; and material B comprising polyethylene 100 weight portions, catalyst 0.5-5 weight portions, antioxidant 1-10 weight portions, machining assistant 1-10 weight portions and pre-cross linking resisting agent 0.5-5 weight portions; and 2. mixing the material A and the material B in the weight ratio of 18-20 to 1, and melting and extruding in a double screw extruder to form the cable insulating layer.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

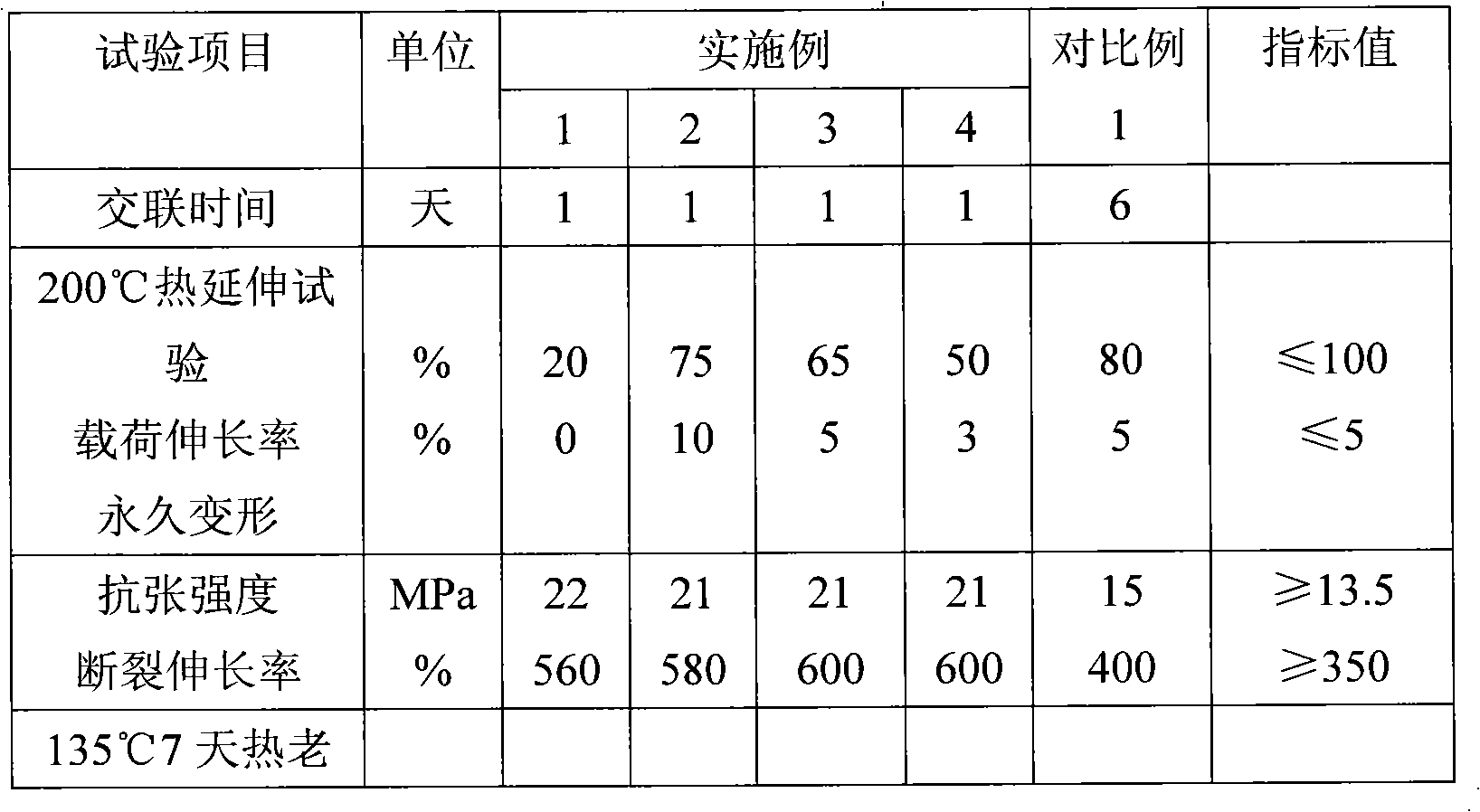

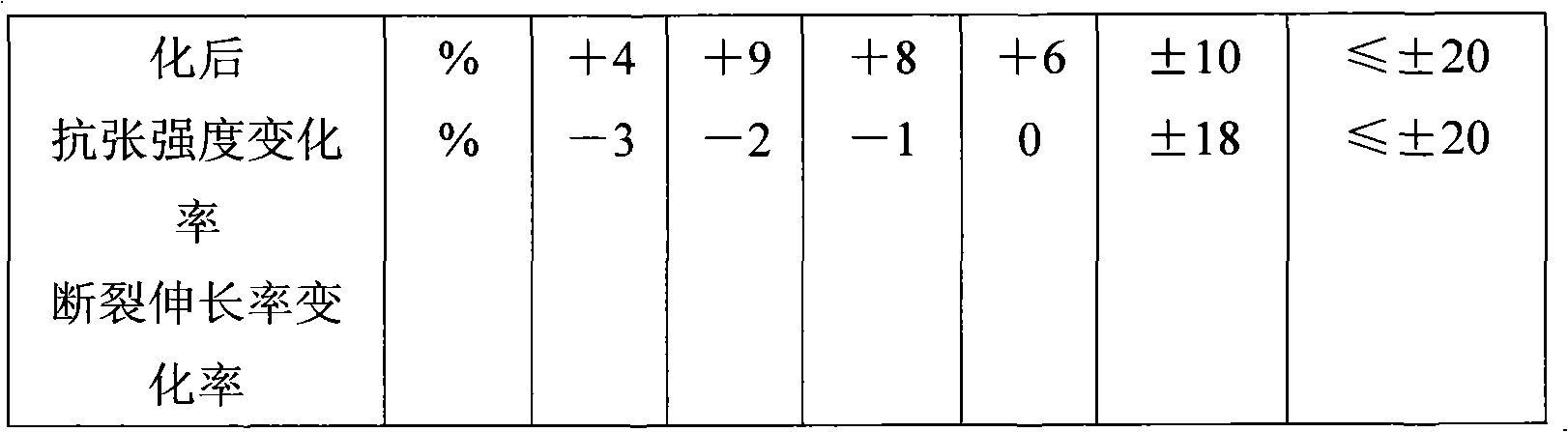

Method for preparing crosslinkable polyethylene cable material

The invention discloses a preparation method of crosslinkable polyethylene cable material, which includes the steps and the following components are represented in proportion by weight: throwing polyethylene 75-95 proportion by weight, ethylene-vinyl acetate copolymer 0-20 proportion by weight, unsaturated silicone hydride 1.0-5 proportion by weight, free radical evocating agent 0.1-0.5 proportion by weight, organotin catalyst 0.1-1 proportion by weight, organic acid compound 0.1-1 proportion by weight, anti-oxidant 0.1-0.5 proportion by weight, anti-copper agent 0.1-0.5 proportion by weight, and lubricant 0.5-2 proportion by weight into the high speed mixing machine with rotary speed at 80-120 rpm for mixing 15-25 minutes, and then adding the mixture into the double-screw extruder, melting and prilling for obtaining crosslinkable polyethylene cable material. The method provided by the invention mixes all the material and dispersing uniformly, and then executes grafting reaction, thereby realizing more uniform grafting reaction and guaranteeing homogeneity of the crosslinking process, in addition, the invention uses organic acid compound which remarkably improves catalysis function of organotin catalyst, and improves crosslinking speed of silicone hydride, and overcomes the defect that the conventional silicone hydride crosslinked plastic can be linked only in warm water or steam environment with long time cooking, thereby saving production cost for manufacturer considerably. The crosslinkable polyethylene cable material obtained according to the invention is extruded by plastic cable extrusion machine unit for obtaining cable insulation layer, and is placed under the condition of 23 DEG C. with 50% humidity for one day naturally, then the crosslinking process is finished, moreover the product can pass performance indexes of hot extension performance test, dynamics test and aging characteristic test according to the national standard request.

Owner:SHANGHAI JIAO TONG UNIV

Crosslinkable composition crosslinkable with a latent base catalyst

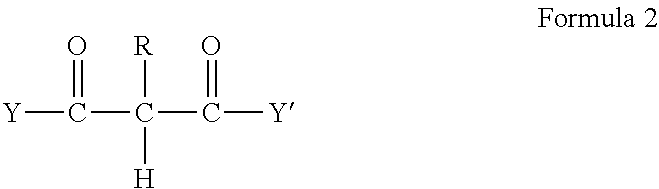

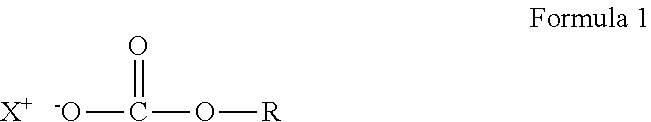

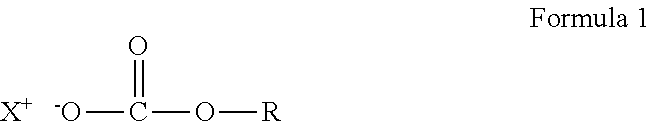

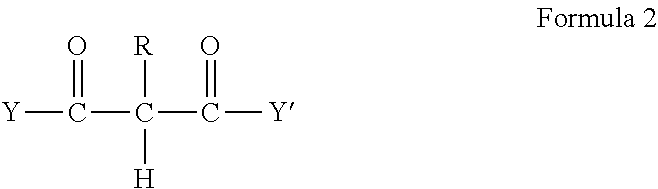

ActiveUS9534081B2Effective use timeExtended validity periodOrganic-compounds/hydrides/coordination-complexes catalystsPolyester coatingsArylHydrogen

The present invention relates to a crosslinkable composition comprising at least one crosslinkable component and a latent base crosslinking catalyst, which crosslinkable composition has a solids content of typically at least 55 wt (dry weight after crosslinking relative to the total weight of the crosslinking composition) wherein the latent base catalyst is a substituted carbonate salt according to formula 1wherein X+ represents a non acidic cation, preferably a quaternary ammonium or phosphonium, and wherein R is hydrogen, alkyl, aryl or aralkyl group.

Owner:ALLNEX NETHERLANDS BV

Crosslinkable composition crosslinkable with a latent base catalyst

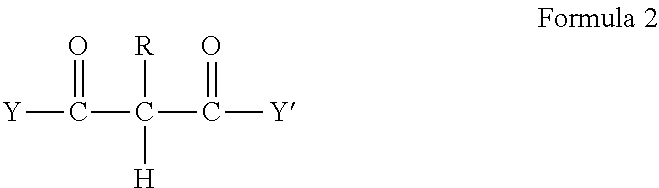

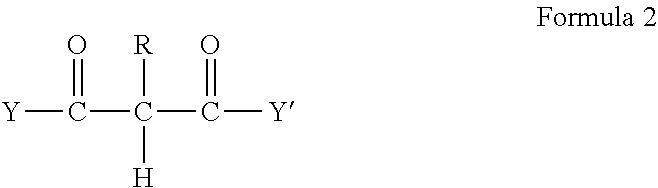

ActiveUS9181453B2Effective use timeExtended validity periodOrganic-compounds/hydrides/coordination-complexes catalystsInksHydrogenEvaporation

The present invention relates to a crosslinkable polymer composition comprising reactive components A and B each comprising at least 2 reactive groups wherein the at least 2 reactive groups of component A are acidic protons (C—H) in activated methylene or methine groups and the at least 2 reactive groups of component B are activated unsaturated groups (C═C) to achieve crosslinking by Real Michael Addition (RMA), wherein the component A is a malonate containing component and wherein components A and B react on drying of the crosslinkable polymer composition by deblocking of latent base catalyst C by evaporation of carbon dioxide, which latent base crosslinking catalyst, is a substituted carbonate salt according to formula 1wherein X+ represents a non acidic cation and wherein R is hydrogen, alkyl, aryl or aralkyl group.

Owner:ALLNEX NETHERLANDS BV

Crosslinkable composition crosslinkable with a latent base catalyst

ActiveUS9181452B2Effective use timeExtended validity periodOrganic-compounds/hydrides/coordination-complexes catalystsPolyester coatingsArylPhosphonium

The present invention relates to a crosslinkable composition comprising at least one crosslinkable component and a latent base crosslinking catalyst, which crosslinkable composition has a solids content of typically at least 55 wt (dry weight after crosslinking relative to the total weight of the crosslinking composition) wherein the latent base catalyst is a substituted carbonate salt according to formula 1wherein X+represents a non acidic cation, preferably a quaternary ammonium or phosphonium, and wherein R is hydrogen, alkyl, aryl or aralkyl group.

Owner:ALLNEX NETHERLANDS BV

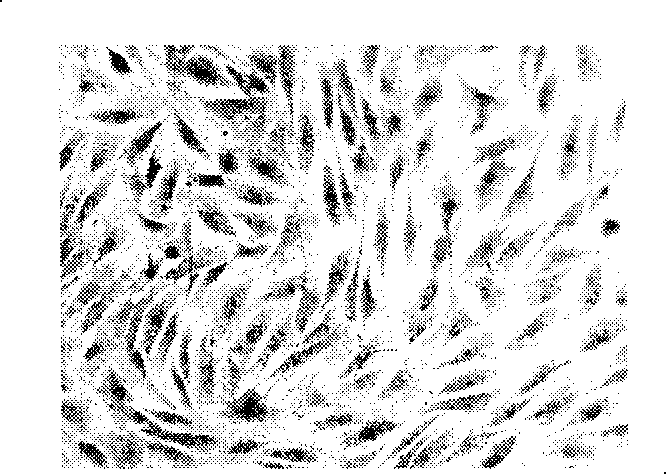

Injected chemical crosslinking protein/polypeptide hydrogel and preparation method thereof

InactiveCN101864178AStable structureMechanical Strength AdjustmentMacromolecular non-active ingredientsProsthesisHuman bodyCell-Extracellular Matrix

The invention belongs to the technical fields of biotechnology, biological medical materials and tissue engineering, in particular to injected chemical crosslinking protein / polypeptide hydrogel and a preparation method thereof. The injected chemical crosslinking protein / polypeptide hydrogel consists of natural or synthesized protein / polypeptide with a crosslinking phenolic hydroxyl group, horse radish peroxidase and hydrogen peroxide which quickly form the chemical crosslinking hydrogel under physiological condition. The protein / polypeptide hydrogel has good biocompatibility and easily regulated mechanical strength, and is degradable, and the degraded product is amino acids capable of being absorbed by a human body. In addition, the framework of the protein / polypeptide hydrogel very approaches a protein three-dimensional network which supports the cell growth in extracellular matrix, and the invention can be widely applied to multiple biological and medical fields such as drug controlled-release carriers, cell culture supports and the like.

Owner:FUDAN UNIV

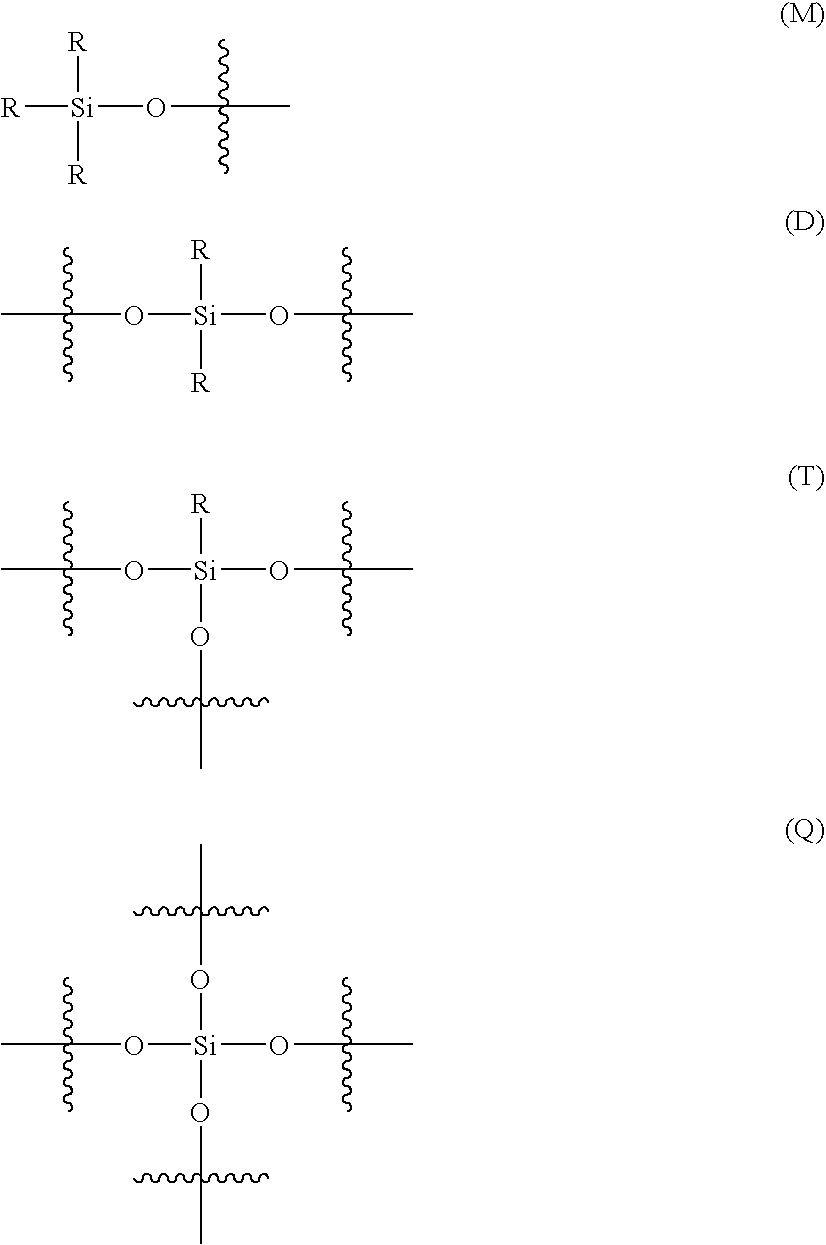

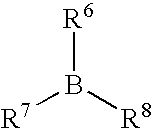

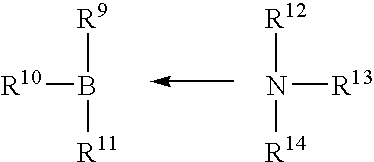

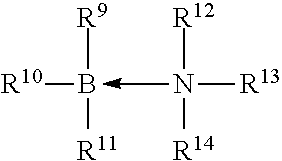

Curable Organosilicon Composition

ActiveUS20090306307A1Reduce the temperatureLow production costOrganic non-macromolecular adhesiveInksPolymer scienceOrganic chemistry

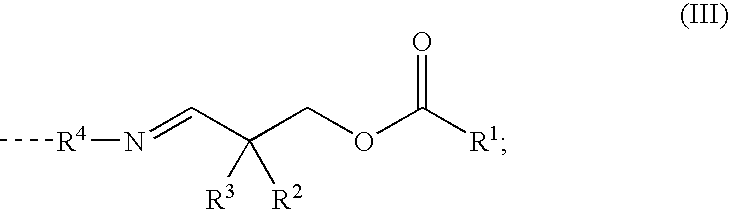

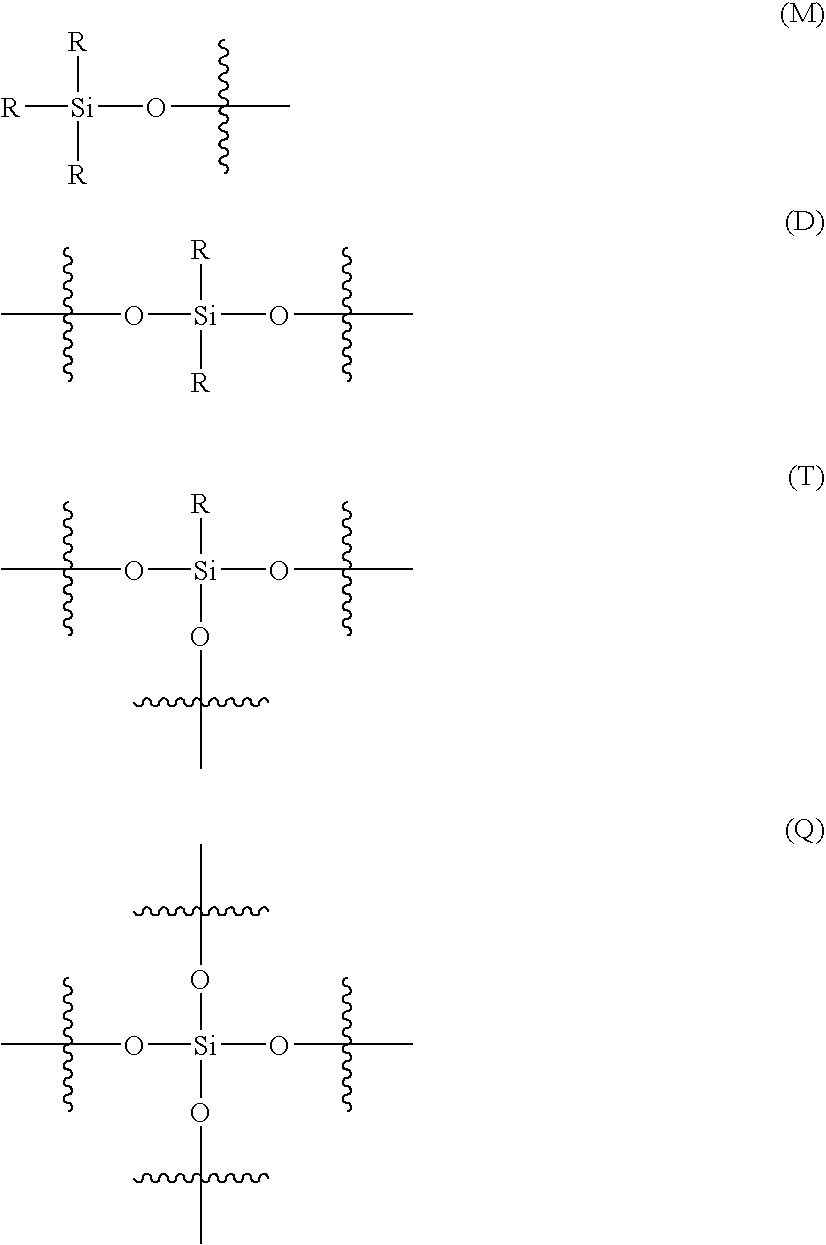

A curable organosilicon composition includes a radical curable organosilicon compound, an organoborane amine complex, a condensation curable organosilicon compound, a condensation cure catalyst, and a condensation-reactive cross-linking compound. The curable organosilicon composition may further include an amine-reactive compound. A method of forming the curable organosilicon composition introduces the organoborane-amine complex and the amine-reactive compound into separate reaction vessels. The curable organosilicon composition is used to form various articles.

Owner:DOW SILICONES CORP

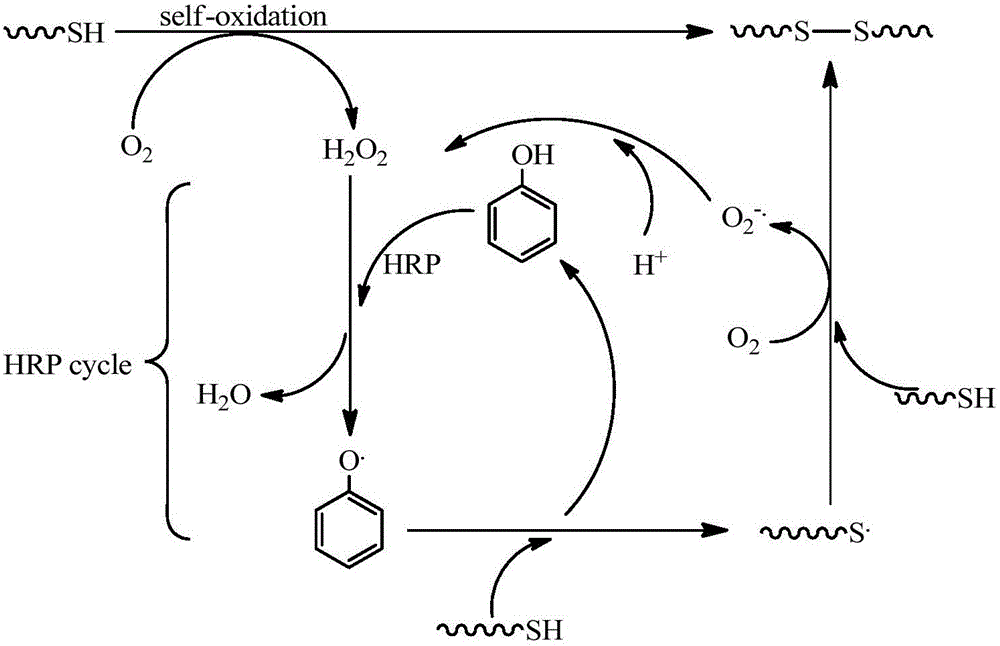

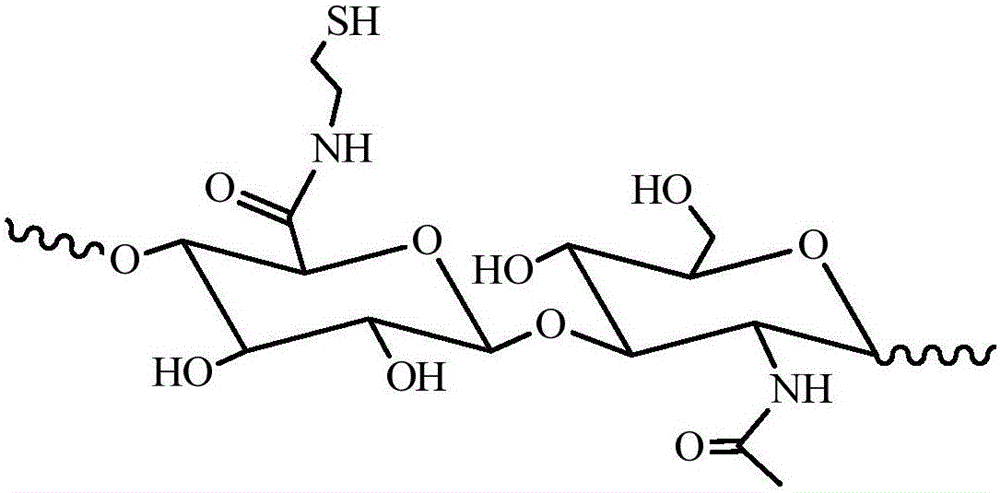

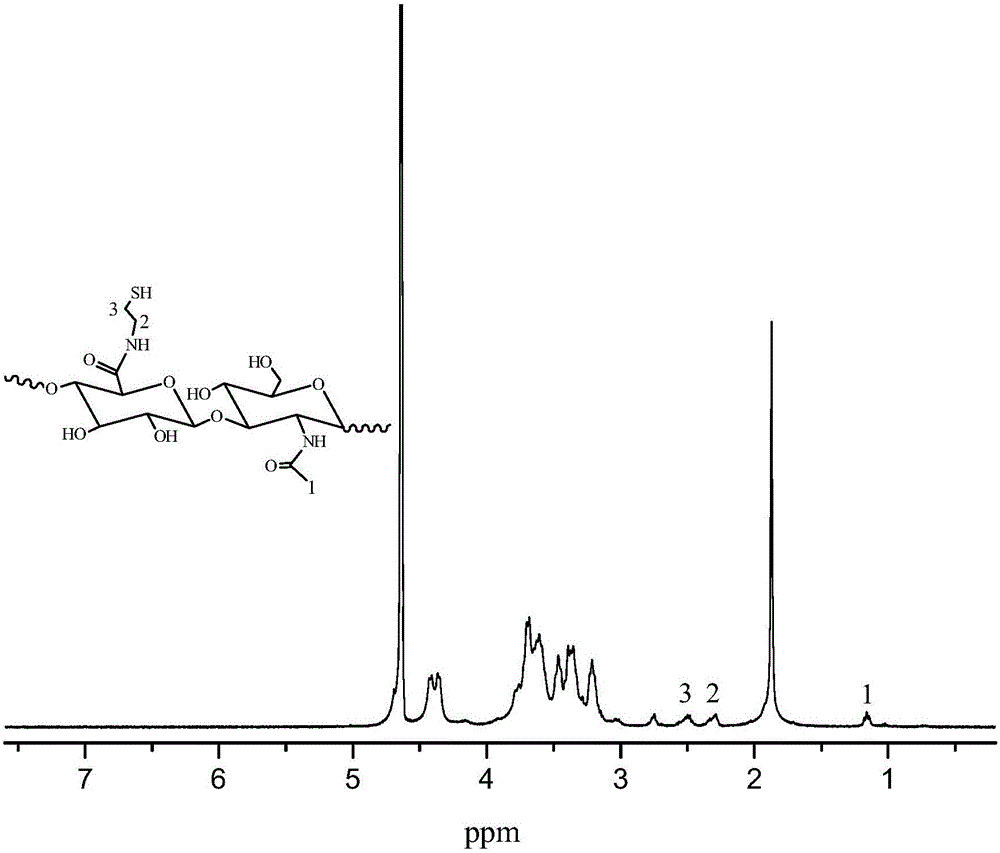

Enzyme-catalyzed disulfide bond-crosslinked natural polymer hydrogel and preparation method thereof

ActiveCN105039465AMild reaction conditionsEasy to operateFermentationBiocompatibility TestingDisulfide bond

The invention provides enzyme-catalyzed disulfide bond-crosslinked natural polymer hydrogel and a preparation method thereof. The hydrogel comprises a three-dimensional net structure composed of crosslink bonds of cystamine or N,N-diacetyl-L-cystine; under the conditions that horseradish peroxidase is used as a catalyst and a phenol compound is used as an enzyme substrate, sulfydryl-grafted natural polymers are rapidly oxidized to form disulfide bonds, so that the hydrogel is obtained. According to the invention, raw materials are safe in source and environment-friendly, the product has excellent biocompatibility; reaction conditions are mild, and the operation is simple; the system is not required to be additionally added with hydrogen peroxide, and physiological activity of a loaded drug or cells is completely guaranteed.

Owner:NANCHANG UNIV

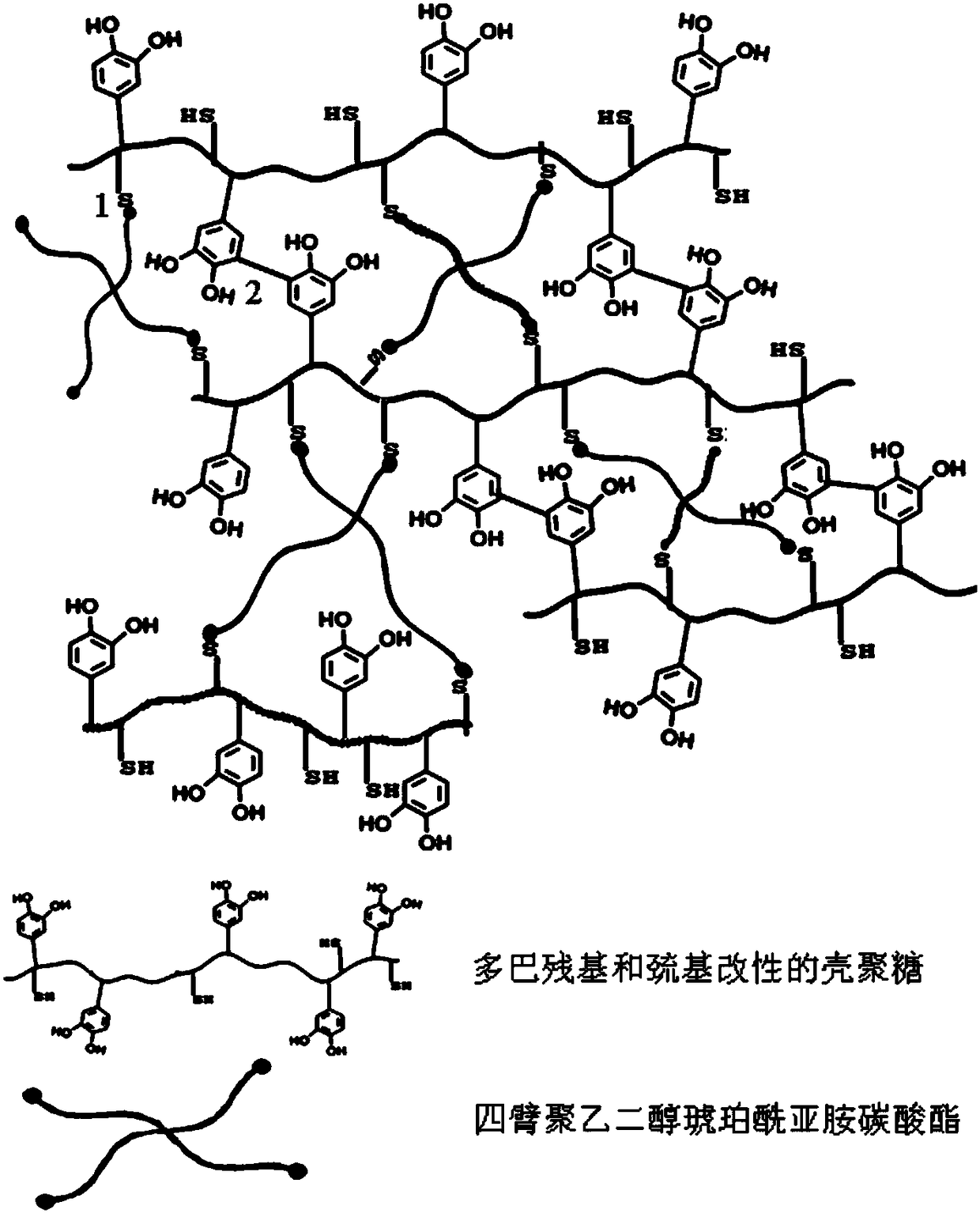

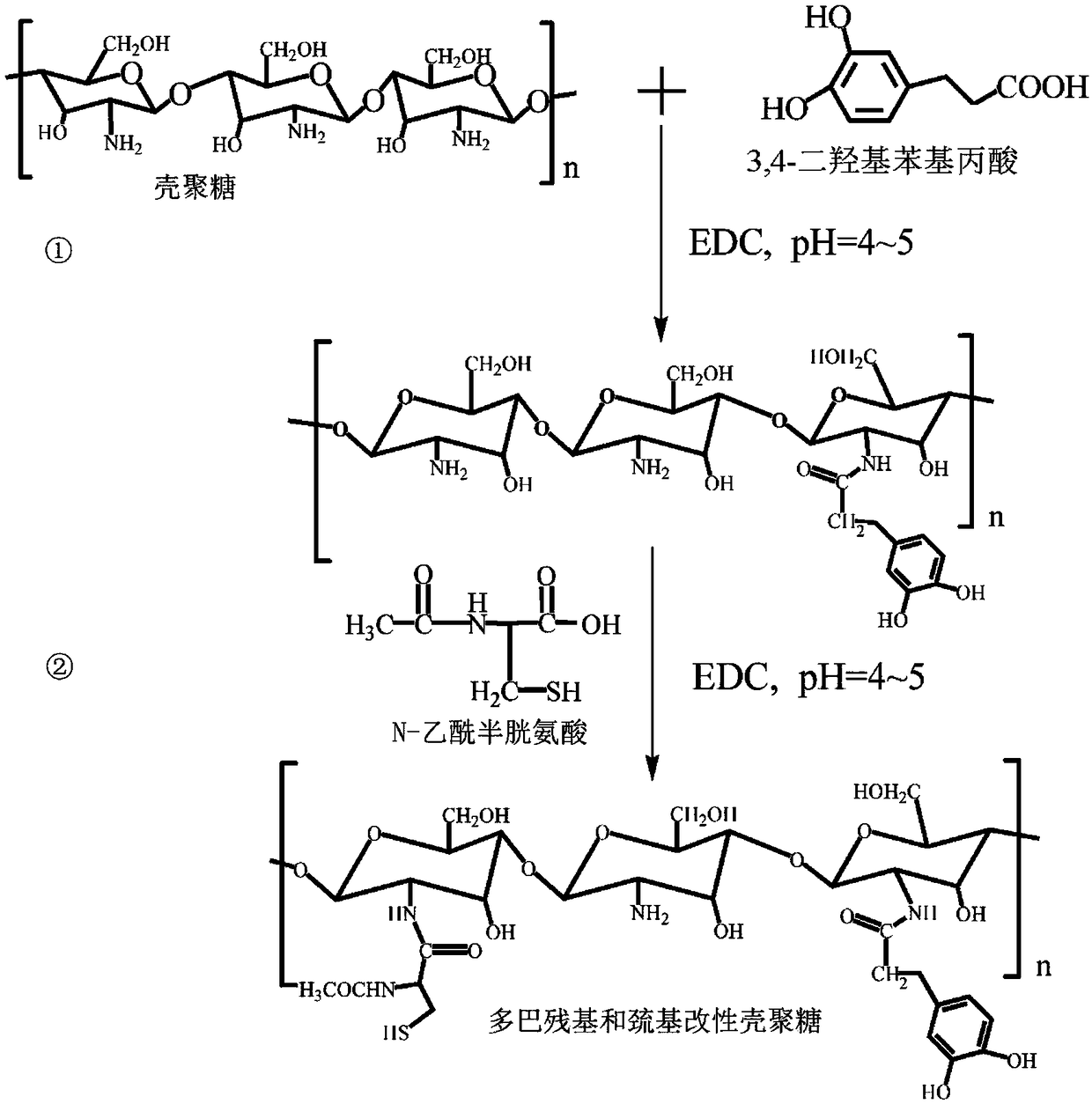

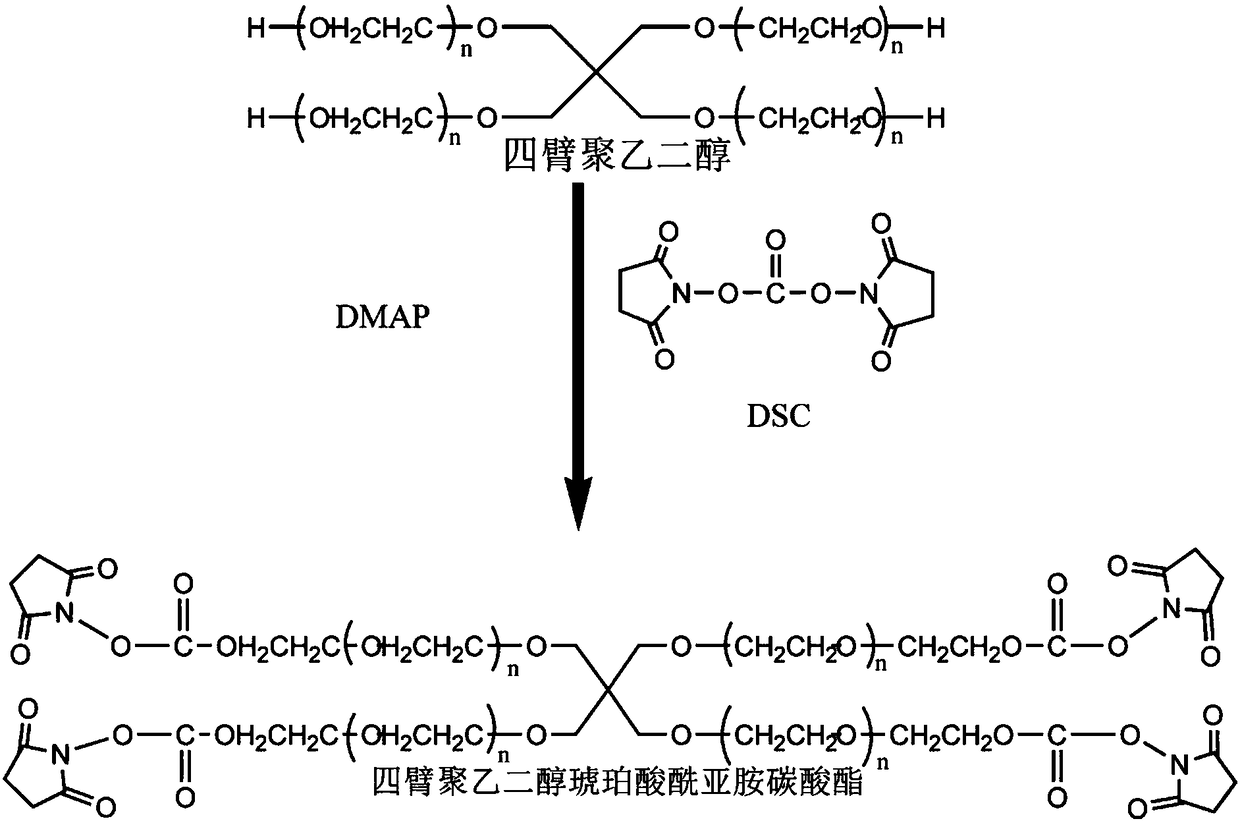

Bi-crosslinking mussel binding protein bionic hydrogel for tissue adhesive and preparation method of bi-crosslinking mussel binding protein bionic hydrogel

InactiveCN108503857AFast cross-linkingGood adhesionSurgical adhesivesTissue adhesivesBiocompatibility Testing

The invention relates to a bi-crosslinking mussel binding protein bionic hydrogel for a tissue adhesive and a preparation method of the bi-crosslinking mussel binding protein bionic hydrogel. The hydrogel is obtained by taking mercapto group modified chitosan containing dopa residues as a matrix and performing bi-crosslinking under the condition of four-arm polyethyleneglycol succinimidyl carbonate and sodium periodate. The preparation method comprises the following steps of preparation of dopa residue modified chitosan, preparation of dopa residue and mercapto group modified chitosan, preparation of four-arm polyethyleneglycol succinimidyl carbonate and preparation of the bi-crosslinking mussel binding protein bionic hydrogel. In the preparation method provided by the invention, by takingthe sodium periodate as a crosslinking agent which performs rapid crosslinking and the four-arm polyethyleneglycol succinimidyl carbonate as a crosslinking agent which is relatively slow in reaction,the hydrogel is prepared by bi-crosslinking, the crosslinking speed is rapid, and the prepared hydrogel has very good adhesion performance, biocompatibility and mechanical strength and is hydrogel which can be used for the tissue adhesive.

Owner:DONGHUA UNIV

Condensation-Crosslinking Silicone Materials

Materials crosslinkable at room temperature by condensation are based on organosilicon compounds which cure to give permanently resilient materials, and which employ one or more compounds of the metals Li, Na, K, Mg, Ca, or Sr as catalyst.

Owner:WACKER CHEM GMBH

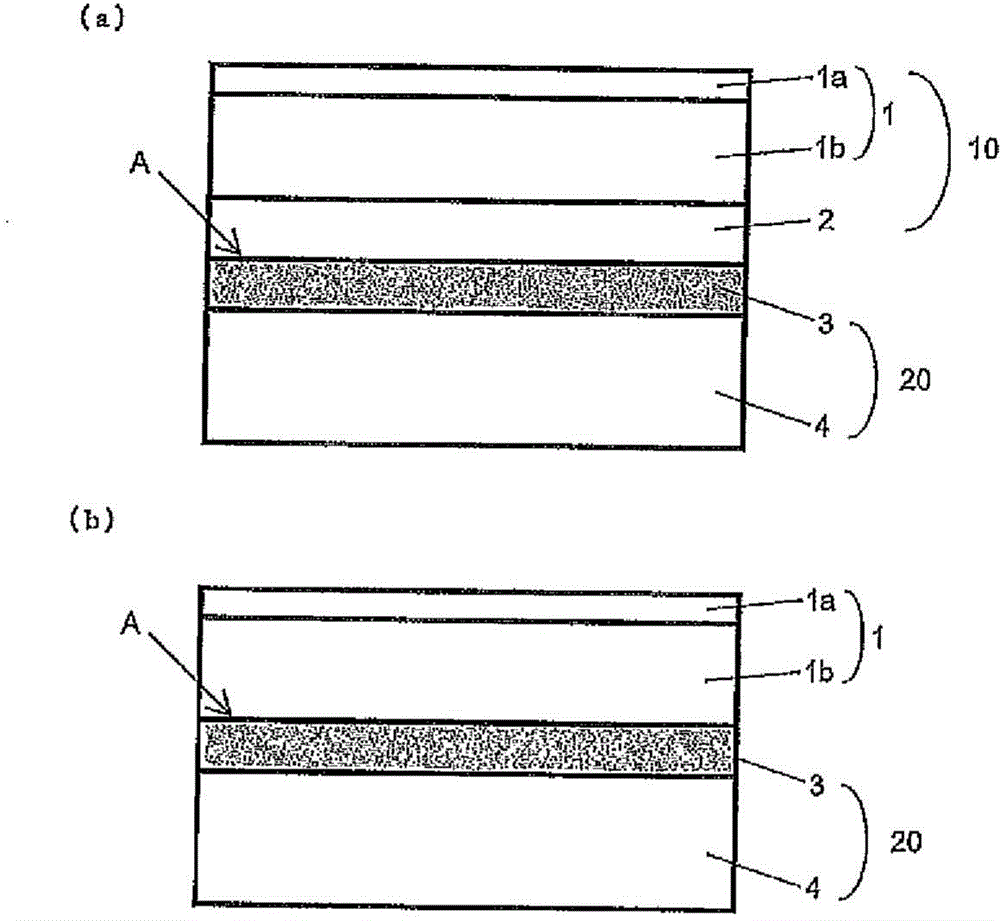

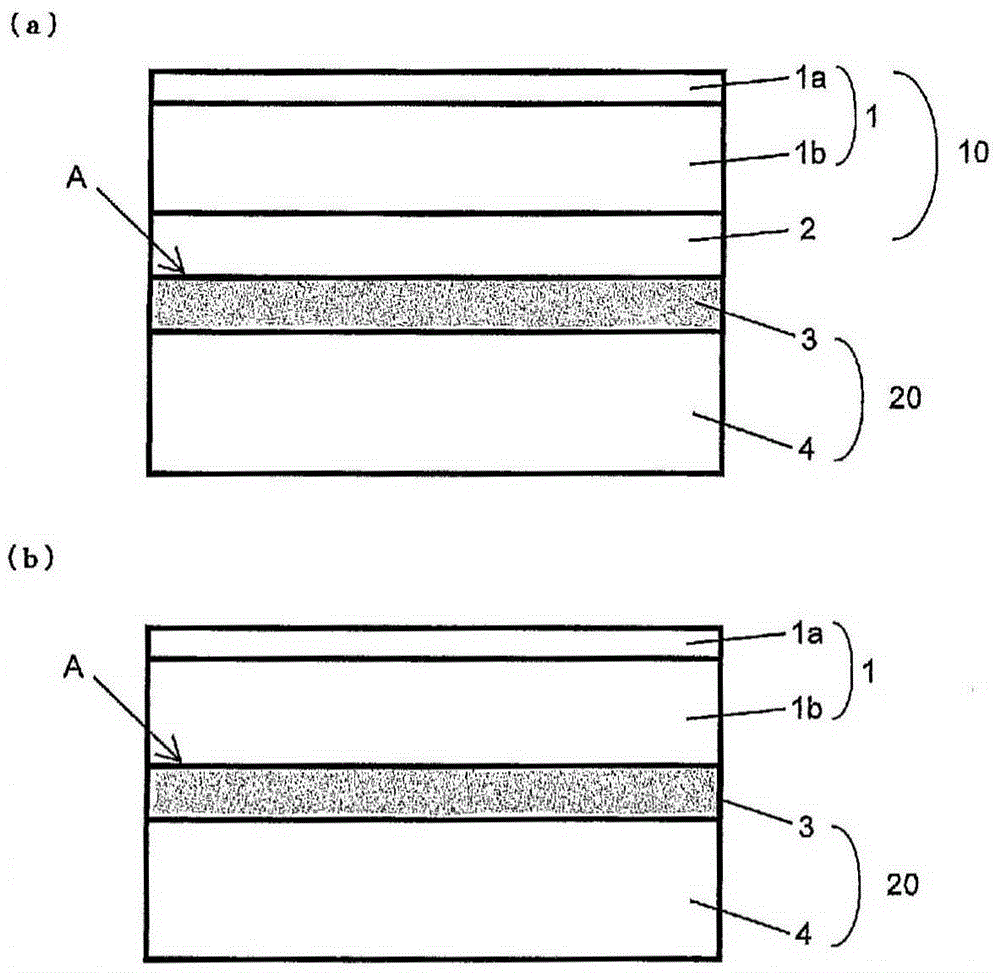

Carrier film for transparent conductive films and laminate

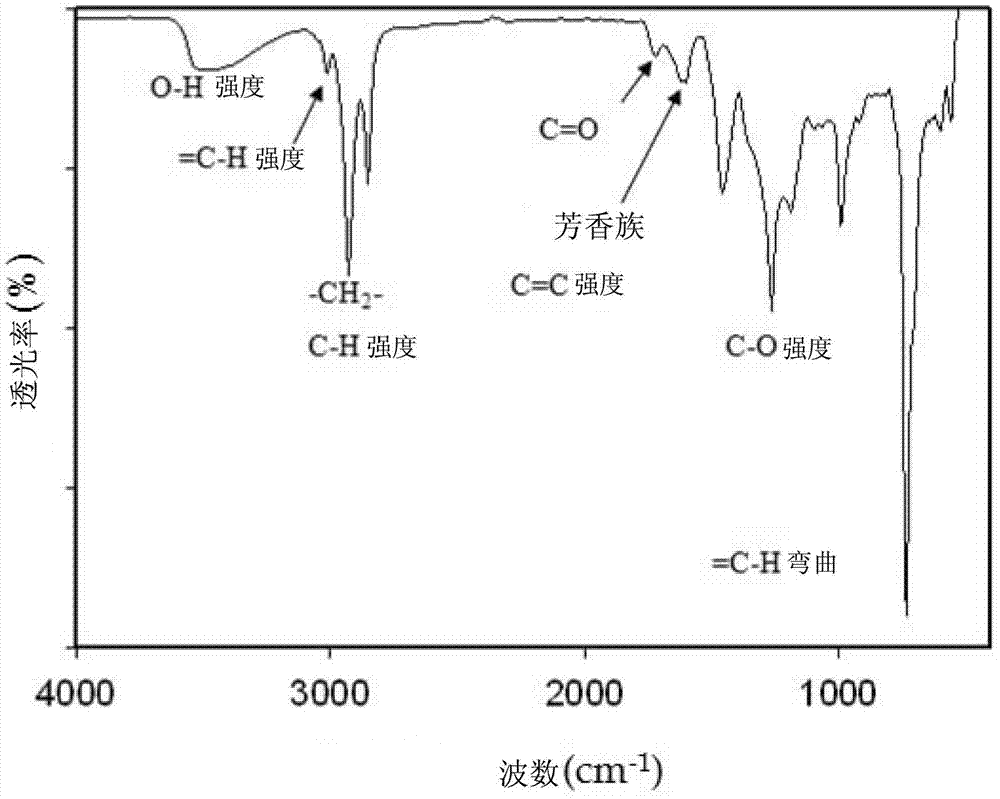

ActiveCN104419342AReduce crosslink densityInhibit the zipper phenomenonConductive layers on insulating-supportsFilm/foil adhesivesTransparent conducting filmGlass transition

Owner:NITTO DENKO CORP

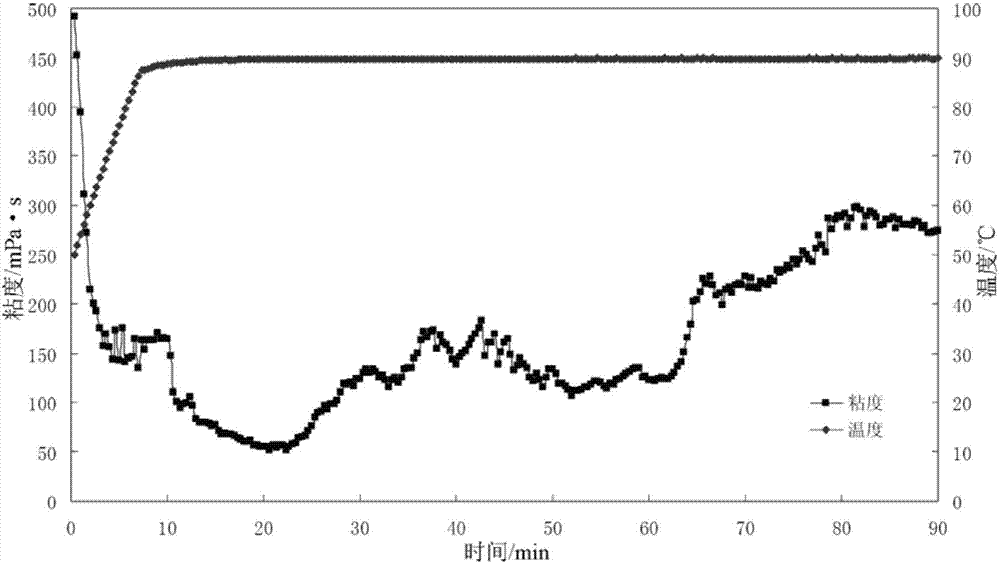

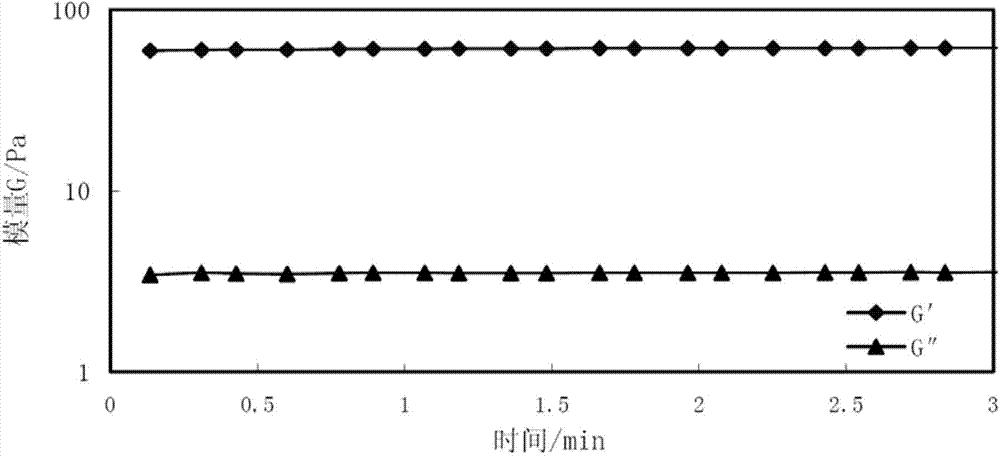

Fracturing fluid cross-linking agent and preparation method and application thereof

The invention relates to a fracturing fluid cross-linking agent and a preparation method and application thereof. The cross-linking agent prepared by the invention can rapidly react with dialkyl phosphate, so that gelled fracturing fluid is formed by lower alkanes. The preparation method of the cross-linking agent comprises the following steps: (1) preparing a complex solvent, namely mixing an alcohol and water according to the mass ratio of 1:2-1:4, stirring uniformly, thereby obtaining the complex solvent; (2) sequentially adding the following components in parts by mass into a reaction container: 40-70 parts of the complex solvent, 30-60 parts of a trivalent iron salt and 6-25 parts of a complexing agent, and stirring and reacting at the temperature of 50-70 DEG C for 3-4 hours; and (3) cooling the reaction solution to the temperature of 30 DEG C, adding 2-8 parts of a cross-linking accelerator, uniformly stirring, thereby obtaining the lower alkane anhydrous fracturing fluid cross-linking agent.

Owner:PETROCHINA CO LTD

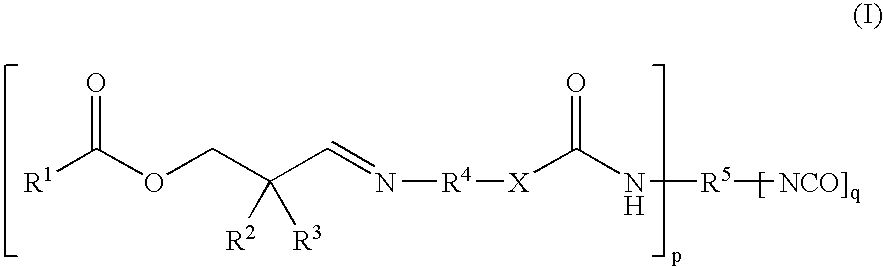

Reactive Polyurethane-Hot Melt Adhesive Having a Low Isocyanate-Monomer Content

InactiveUS20080251204A1Reduce contentFast cross-linkingOther chemical processesPolyureas/polyurethane adhesivesPolymer scienceRoom temperature

The invention relates to relates to moisture-hardened hot melt adhesive which contains at least one polyurethane polymer of formula (I) which comprises aldimine groups and which is solid at room temperature, in addition to at least one polyurethane polymer P which comprises isocyanate groups, if q in formula (I) represents zero, or if X in formula (I) represents N—R8 with R8 as a substituent of formula (III). The compositions are characterised in that contain visibly less isocyanate monomers and are therefor particularly advantageous from a work-hygiene point of view.

Owner:SIKA TECH AG

Curable organosilicon composition

ActiveUS8097689B2Reduce the temperatureReduce surface humidityOrganic non-macromolecular adhesivePhotochemistryOrganosilicon

Owner:DOW SILICONES CORP

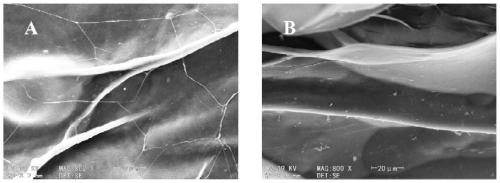

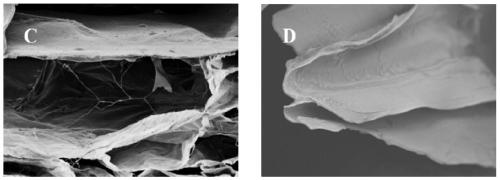

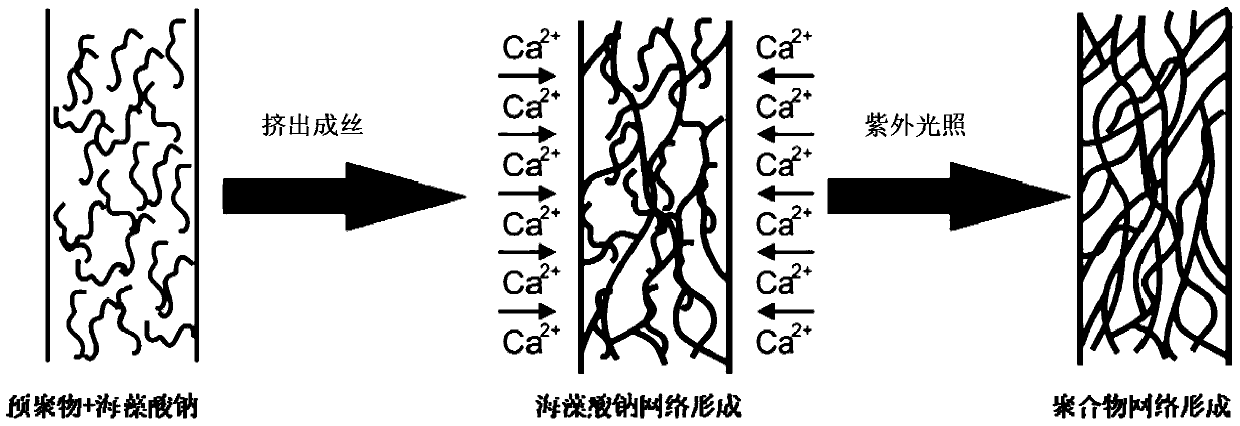

Konjac glucomannan glycosyl antibacterial hydrogel fiber and preparation method thereof

ActiveCN110067042AUniform structureStrong water absorptionConjugated artificial filamentsArtifical filament manufactureFiberBiocompatibility Testing

The invention discloses a konjac glucomannan glycosyl antibacterial hydrogel fiber and a preparation method thereof. The fiber comprises the following raw material components in parts by weight: 50-100 parts of konjac glucomannan polymerizable monomers, 100-800 parts of alginate, 10-20 parts of organic guanidine salt polymerizable monomers, 10000-40000 parts of deionized water and 0.1-5 parts of an initiator. The preparation method comprises the following steps: (1) preparing modified konjac glucomannan with double bonds on side groups and the organic guanidine salt polymerizable monomer; (2)preparing a spinning liquid; and (3) preparing a hydrogel fiber by using a two-step crosslinking method. The preparation method disclosed by the invention is simple and safe, low in cost, rich in material and good in experiment repeatability; no high-voltage electric field is used in the preparation process, no organic solvent is used, no pollution can be caused, cell damage can be avoided, and cell packaging can be achieved; the prepared hydrogel is not only uniform, controllable in size, high in mechanical property and good in water absorption performance, but also good in biocompatibility,and has an excellent antibacterial property and a wide application prospect, particularly in the field of sanitary materials.

Owner:DONGHUA UNIV

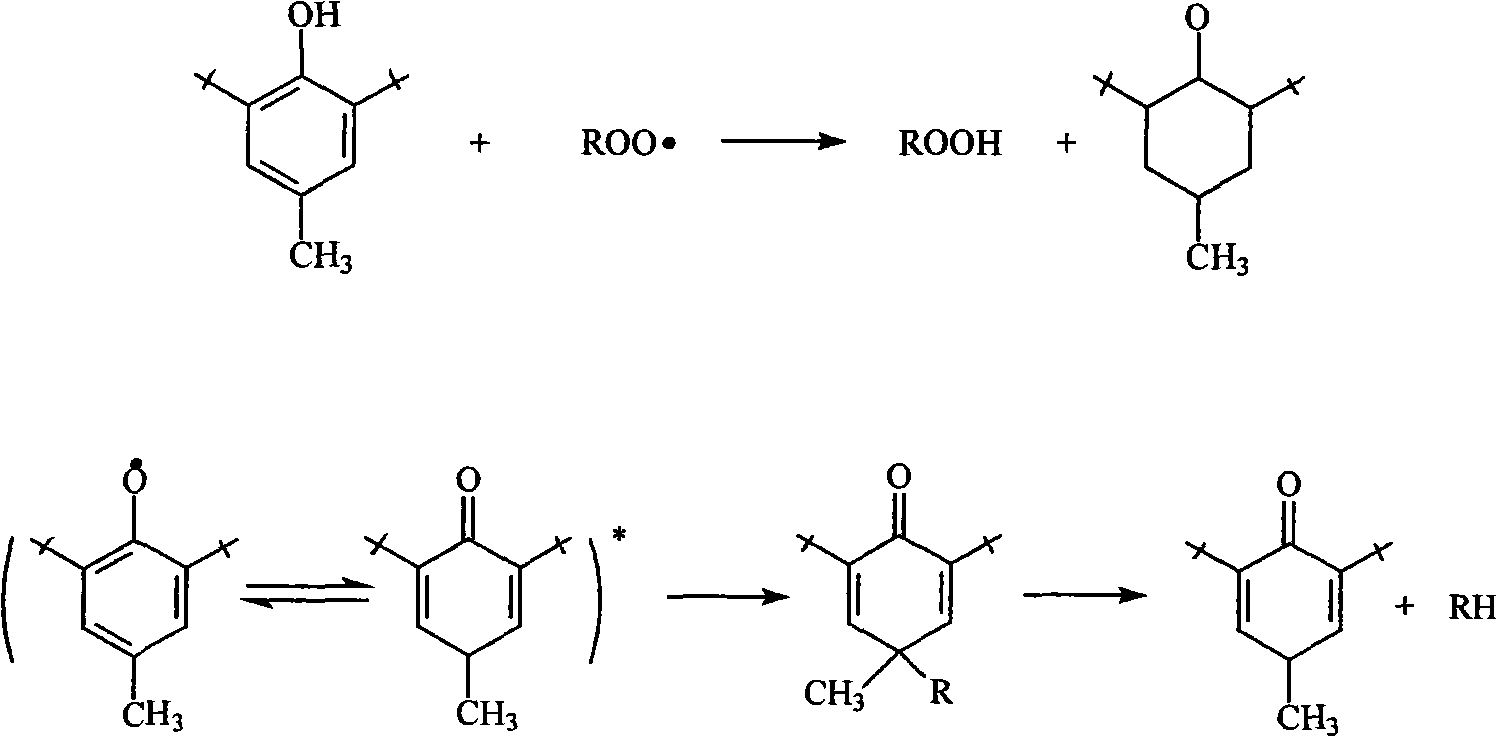

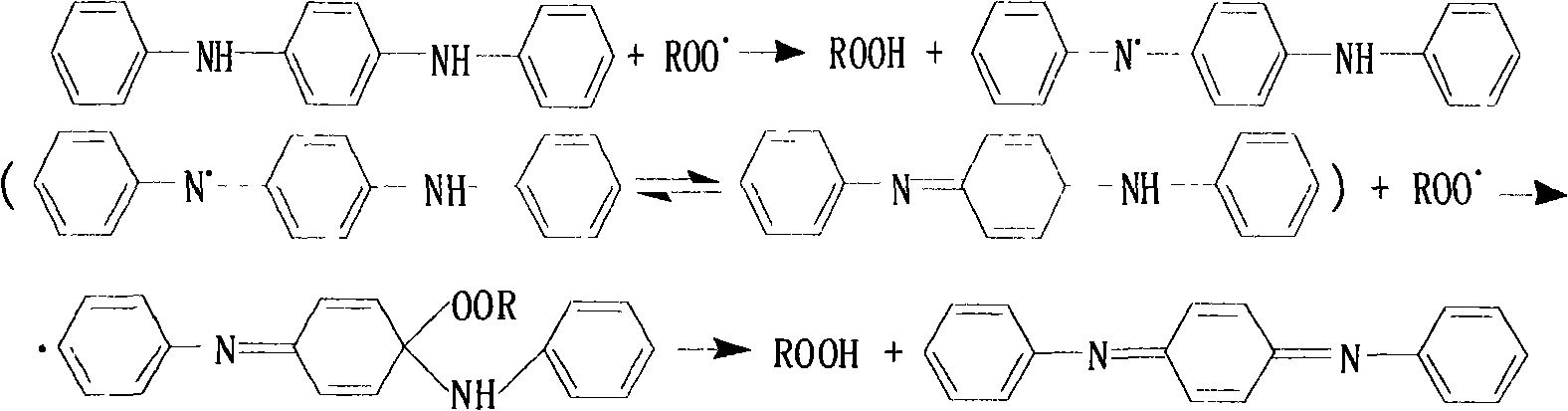

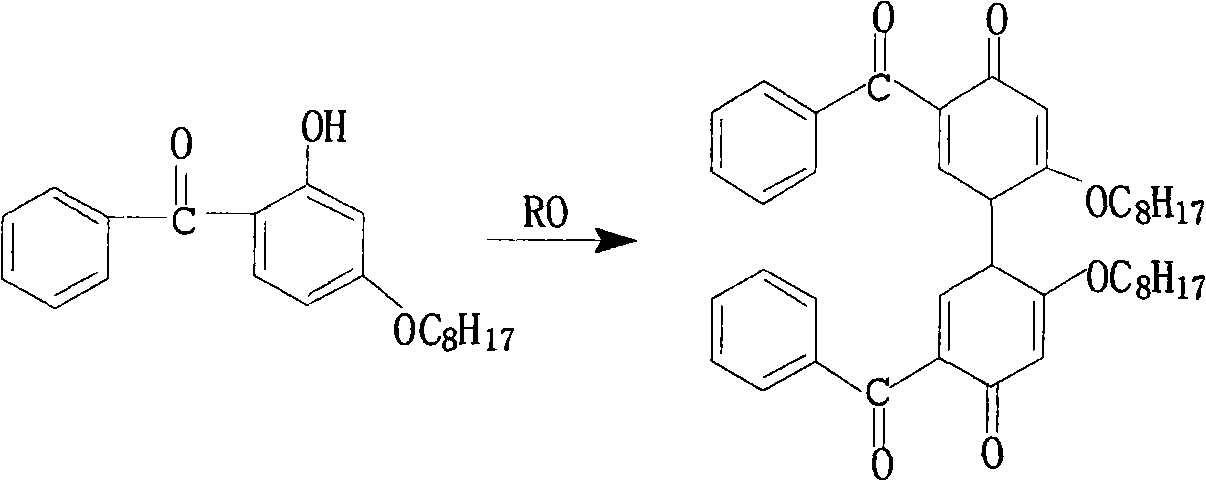

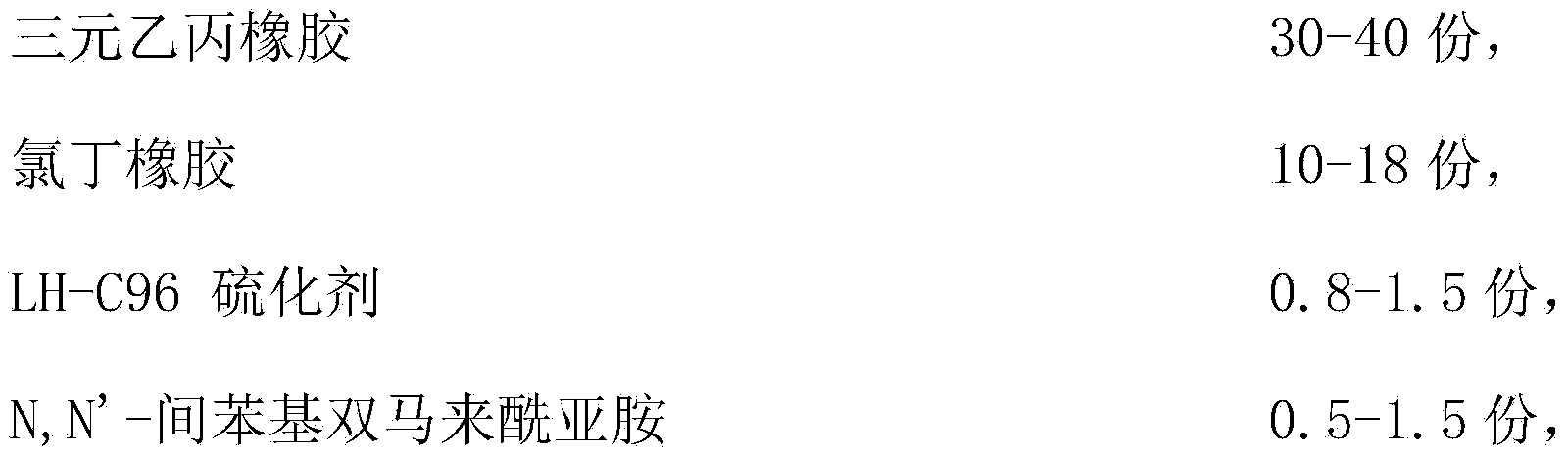

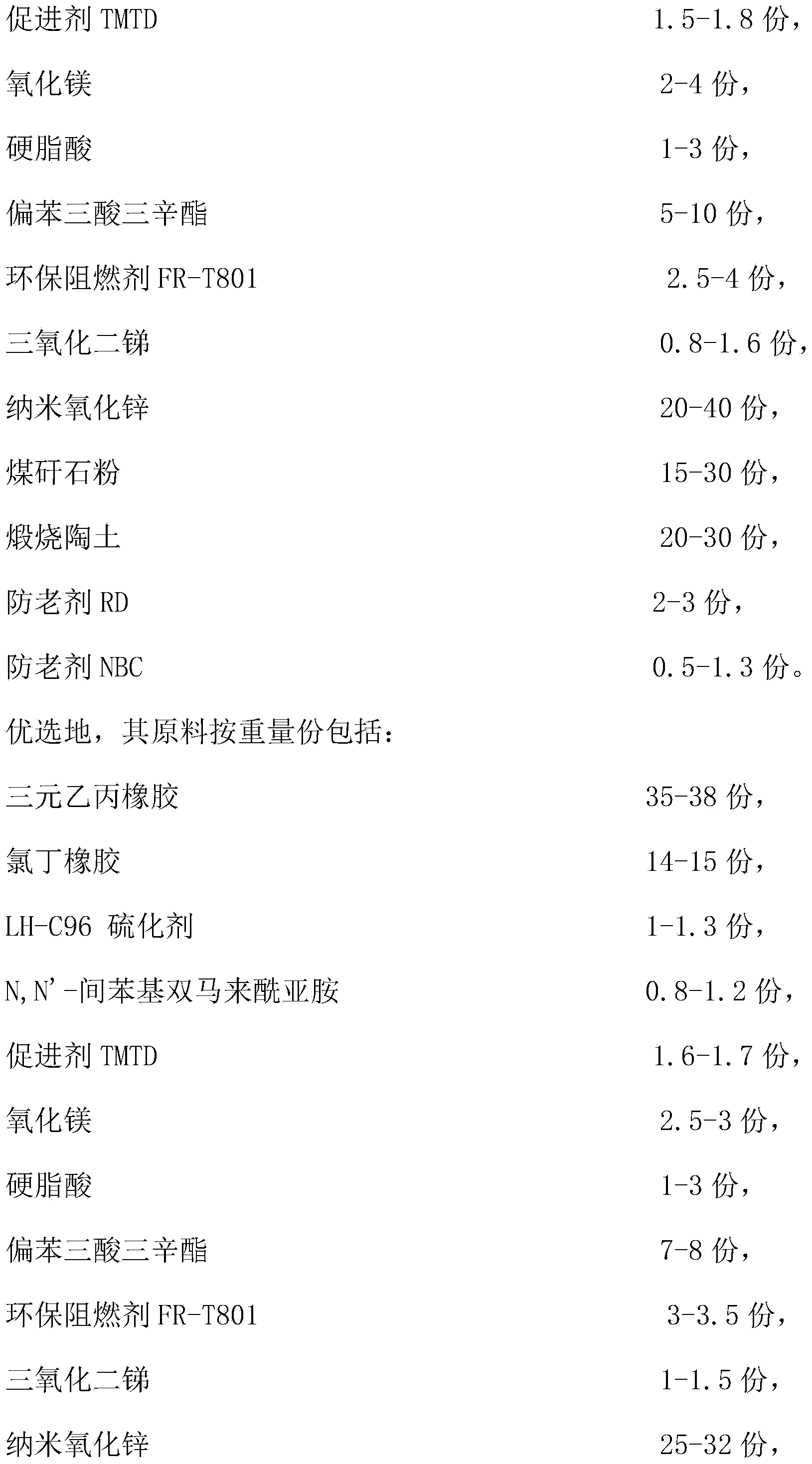

Wear-resistant tear-resistant ethylene propylene diene monomer rubber material

The invention discloses a wear-resistant tear-resistant ethylene propylene diene monomer rubber material which is prepared from the following raw materials in parts by weight: 30-40 parts of ethylene propylene diene monomer rubber, 10-18 parts of chloroprene rubber, 0.8-1.5 parts of LH-C96 vulcanizing agent, 0.5-1.5 parts of N,N'-m-phenyl bismaleimide, 1.5-1.8 parts of accelerator TMTD (tetramethyl thiuram disulfide), 2-4 parts of magnesium oxide, 1-3 parts of stearic acid, 5-10 parts of trioctyl trimellitate, 2.5-4 parts of environment-friendly flame retardant FR-T801, 0.8-1.6 parts of antimony trioxide, 20-40 parts of nano zinc oxide, 15-30 parts of coal gangue powder, 20-30 parts of calcined argil, 2-3 parts of anti-aging agent RD and 0.5-1.3 parts of anti-aging agent NBC. The material has the advantages of excellent wear resistance, excellent wear resistance and favorable aging resistance.

Owner:安徽宁国尚鼎橡塑制品有限公司

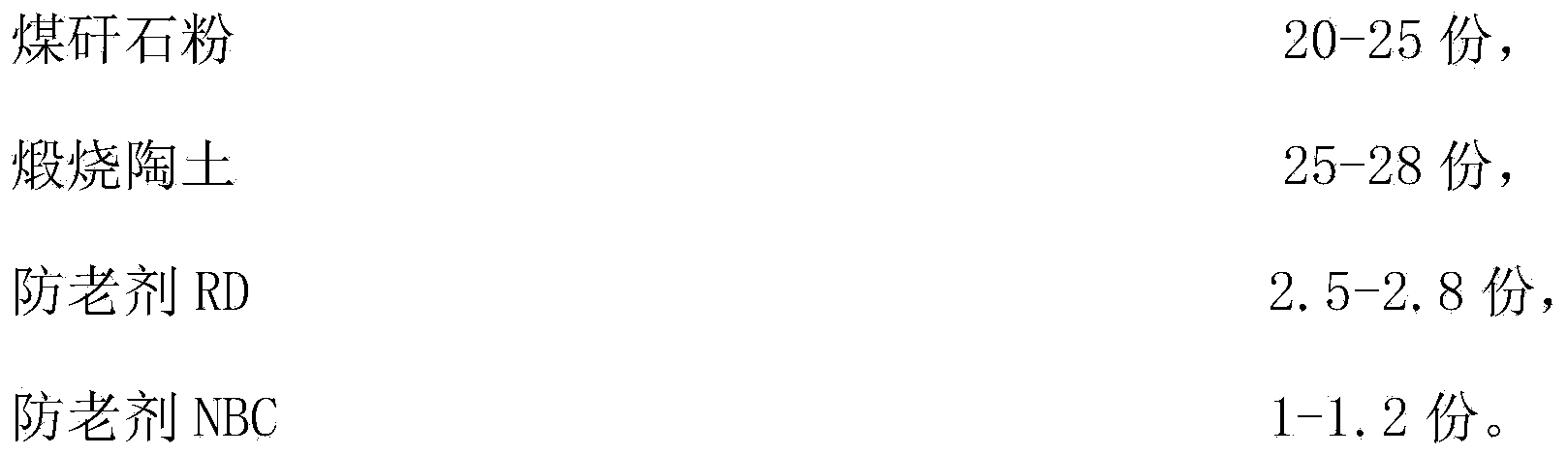

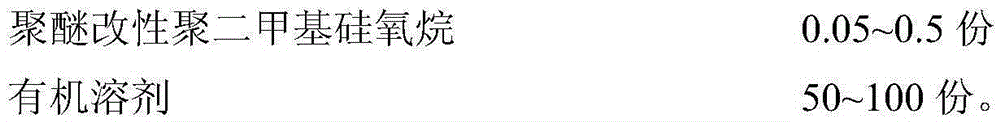

Silicone adhesive and optical double-sided tape employing silicone adhesive and used for toughened glass protection film

ActiveCN105400484AFast cross-linkingSolve the shrinkage cavityFilm/foil adhesivesMacromolecular adhesive additivesTectorial membraneOrganic solvent

The invention relates to a silicone adhesive composition. The silicone adhesive composition comprises, by mass, 100 parts of a low-viscosity silicone adhesive, 0.1 to 1 part of polydimethylsiloxane, 0.2 to 2 parts of a platinum catalyst, 0.05 to 0.5 part of polyether modified polydimethylsiloxane and 50 to 100 parts of an organic solvent. The invention also relates to an optical double-sided tape employing the silicone adhesive composition and used for a toughened glass protection film, and a preparation method thereof. Compared with the prior art, the optical double-sided tape provided by the invention can effectively overcome difficulty is bubble elimination during applying, enables an applied surface not to generate water ripple bubbles and snowflake bubbles and greatly improves the integral appearance and usage effect of the toughened glass protection film.

Owner:NINGBO SOKEN CHEM

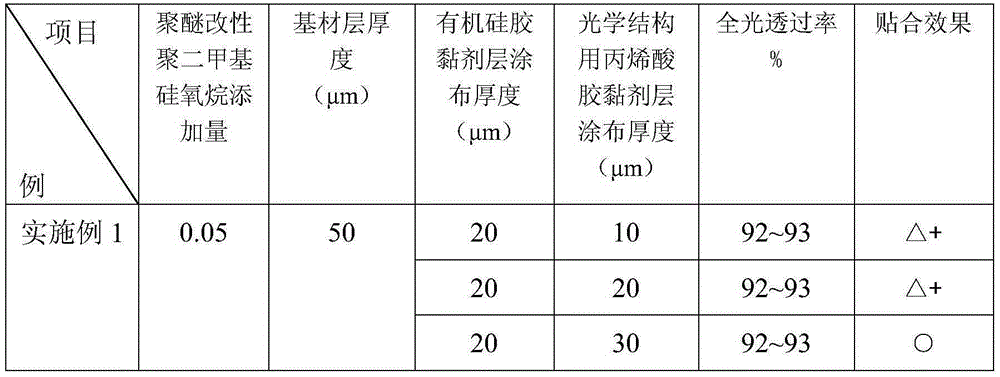

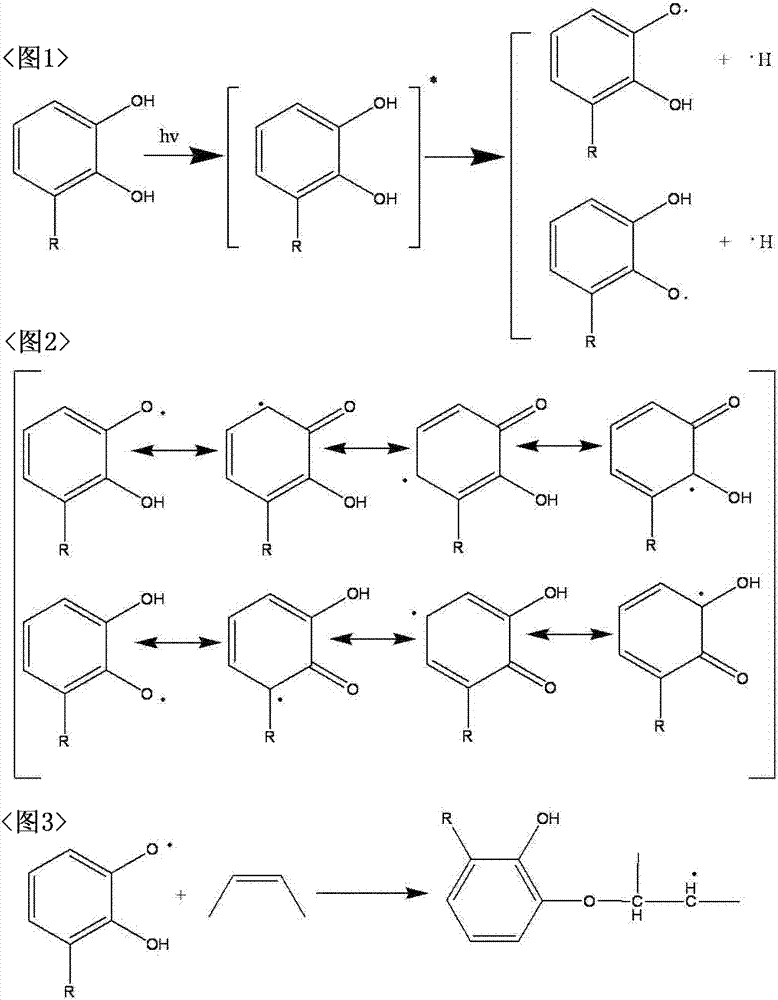

Surface treatment method for a substrate using denatured urushiol derived from Toxicodendron vernicifluum

InactiveCN102791809AImprove antibacterial propertiesStrong far infrared radiationAntifouling/underwater paintsNatural resin coatingsReaction rateFar infrared

Owner:POHANG IRON & STEEL CO LTD

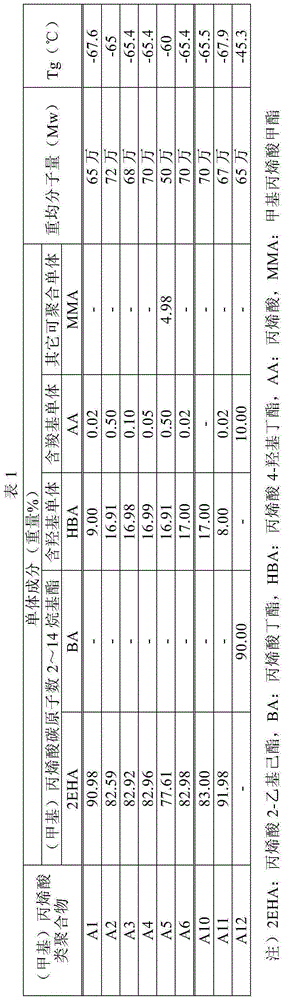

Carrier film for transparent conductive film and laminated body

ActiveCN105385371AModerate adhesionReduce crosslink densityFilm/foil adhesivesSynthetic resin layered productsMonomer compositionCross-link

The invention relates to a carrier film for a transparent conductive film and a laminated body. The invention provides the carrier film for the transparent conductive film. The carrier film for the transparent conductive film can maintain an appropriate adhesive force in a condition that changes occur to aging environments. According to the carrier film for the transparent conductive film, at least a single surface of a support body has an adhesive layer, wherein the adhesive layer is formed by adhesive composites. The adhesive composites contain (methyl) acrylic polymers (A) and aliphatic polyisocyanic acid ester cross-linking agents (B). A glass transition temperature of the (methyl) acrylic polymers (A) is below minus 50 DEG C. The (methyl) acrylic polymers (A) is obtained through polymerization of 59.5-91 % by weight of (meth) acrylic acid alkyl esters with a carbon atom number being 2-14, 8.5-40 % by weight of hydroxyl-containing monomers, 0.001-0.5 % by weight of carboxylic-containing monomers and 0-10 % by weight of other monomers and other copolymerization monomer composition relative to the amount of monomer composition total quantity.

Owner:NITTO DENKO CORP

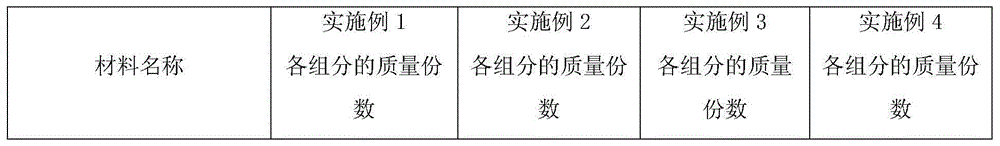

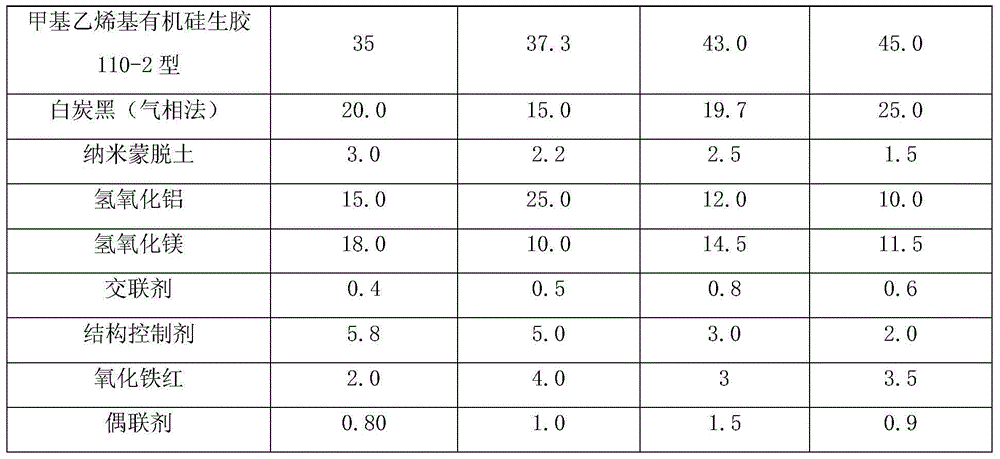

Intermediate pressure level low-smoke zero-halogen flame-retardant silicon rubber insulating material and manufacturing process thereof

ActiveCN104087001AIncrease elasticityImprove aging resistanceRubber insulatorsSilicone rubberIntermediate pressure

The invention discloses an intermediate pressure level low-smoke zero-halogen flame-retardant silicon rubber insulating material and a manufacturing process thereof. The material is characterized by being prepared from the following raw materials in parts by weight: 35-45 parts of methyl vinyl organic silicon rubber, 15-25 parts of white carbon black, 1.5-3 parts of nano-montmorillonite, 10-25 parts of aluminum hydroxide, 10-18 parts of magnesium hydroxide, 0.4-0.8 part of an across-linking agent, 2-5.8 parts of a structure control agent, 2-4 parts of iron oxide red and 0.80-1.5 parts of a coupling agent. The insulating material disclosed by the invention not only can satisfy the requirements on heat resistance, high electrical insulating performance and the like of an intermediate pressure level cable insulating material, a cable accessory and the like, but also has high mechanical strength, so that the novel application field of the silicon rubber material is opened up.

Owner:ANHUI HANGTIAN CABLE GROUP

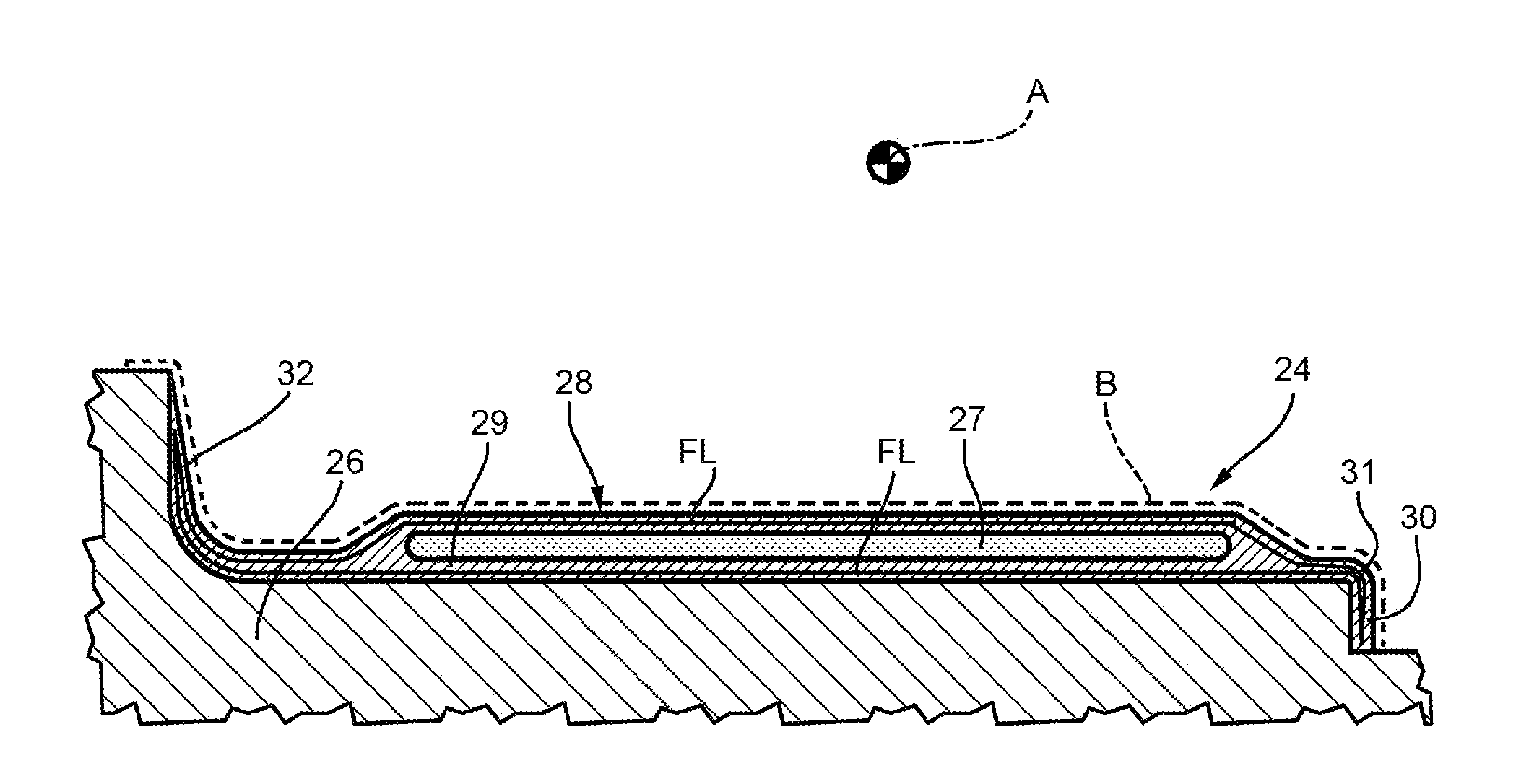

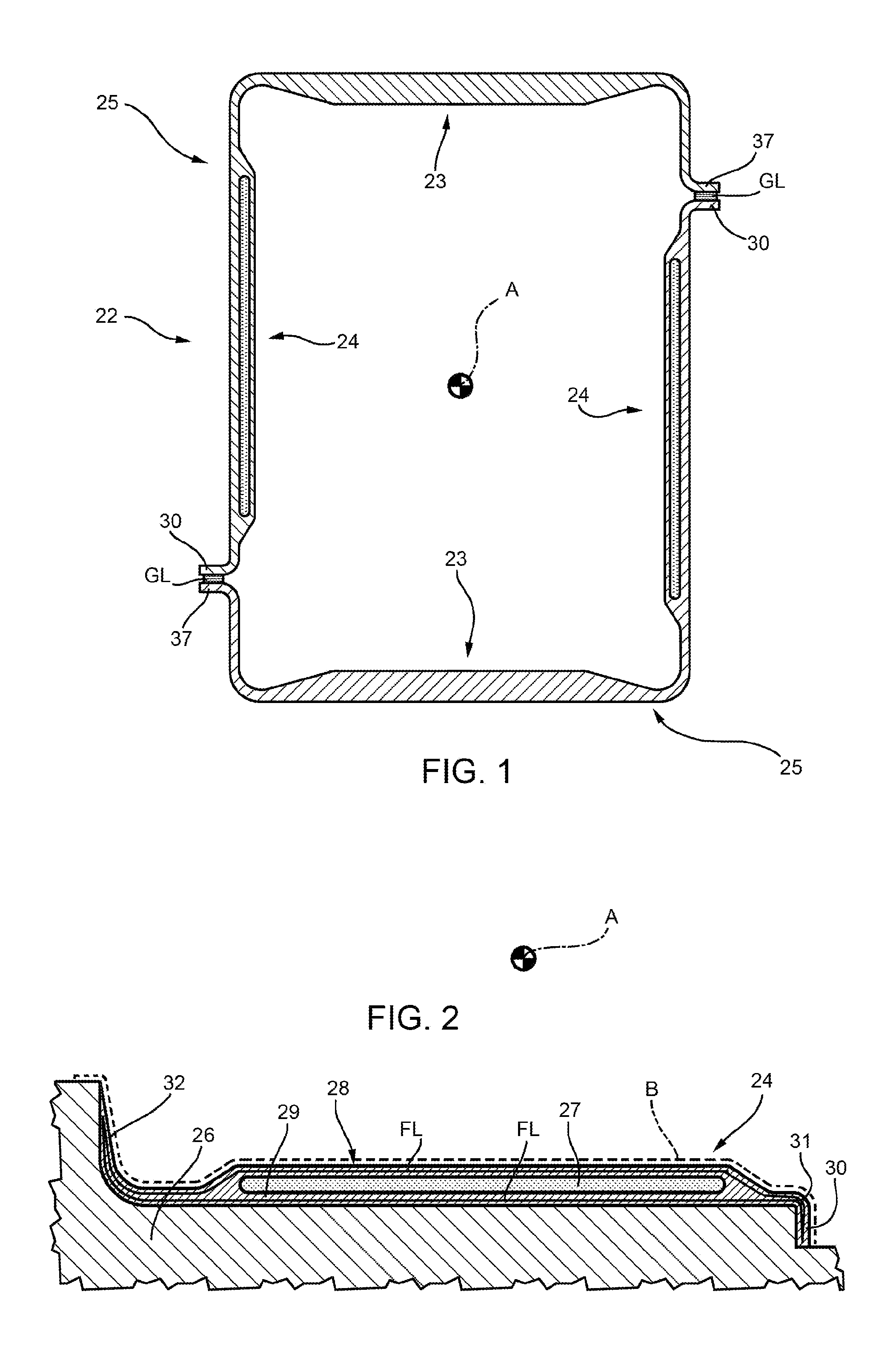

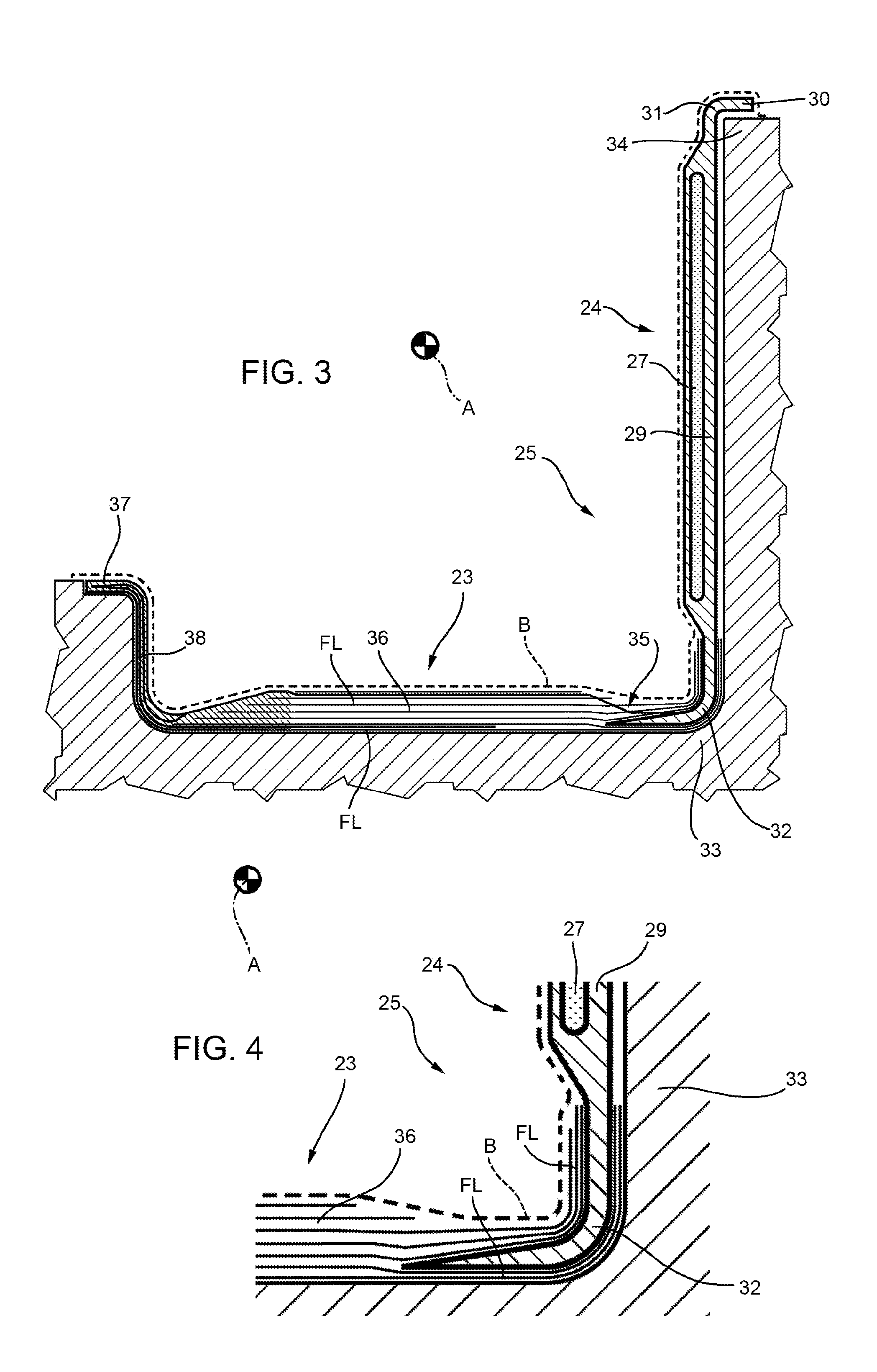

Method and apparatus for treatment of ocular tissue using combine modalities

ActiveUS8945101B2Promote corneal reshapingFast cross-linkingLaser surgerySurgical instrument detailsHigh absorptionCollagen cross linking

An apparatus and a method are provided for treating a targeted area of ocular tissue in a tissue-sparing manner comprising use of two or more therapeutic modalities, including thermal radiation source (such as an CW infrared fiber laser), operative in a wavelength range that has a high absorption in water, and photochemical collagen cross-linking (CXL), together with one or more specific system improvements, such as peri-operative feedback measurements for tailoring of the therapeutic modalities, an ocular tissue surface thermal control / cooling mechanism and a source of deuterated water / riboflavin solution in a delivery system targeting ocular tissue in the presence of the ultraviolet radiation. Additional methods of rapid cross-linking (RXL), are provided that further enables cross-linking (CXL) therapy to be combined with thermal therapy.

Owner:ALEYEGN TECH LLC

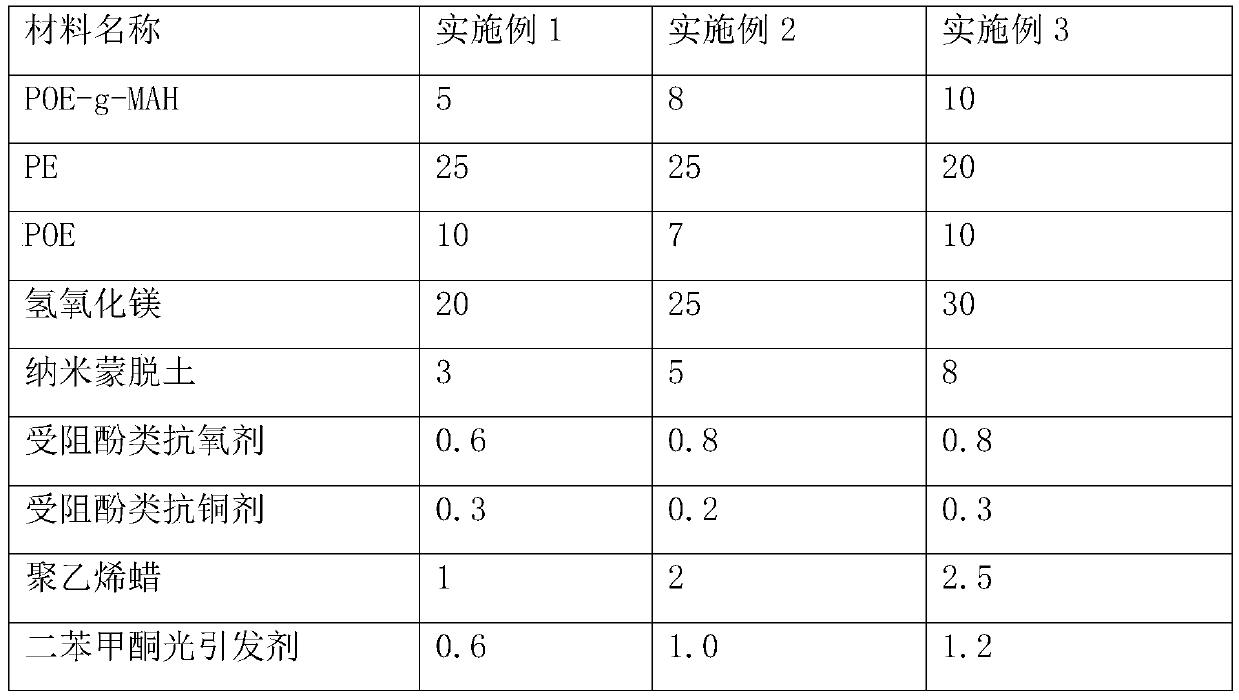

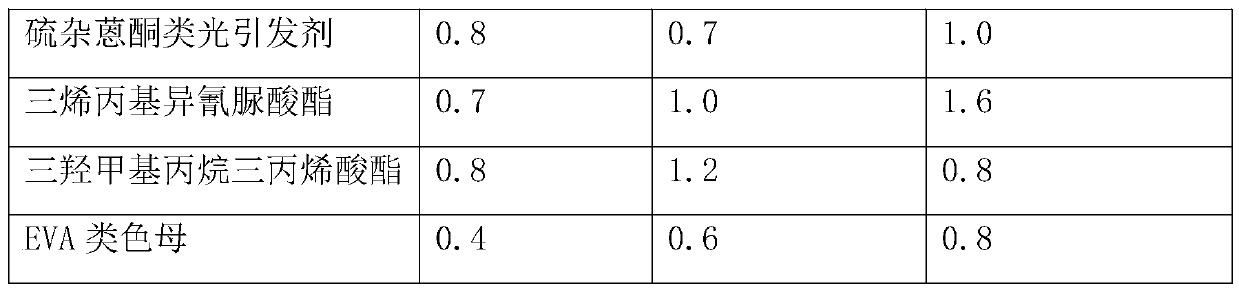

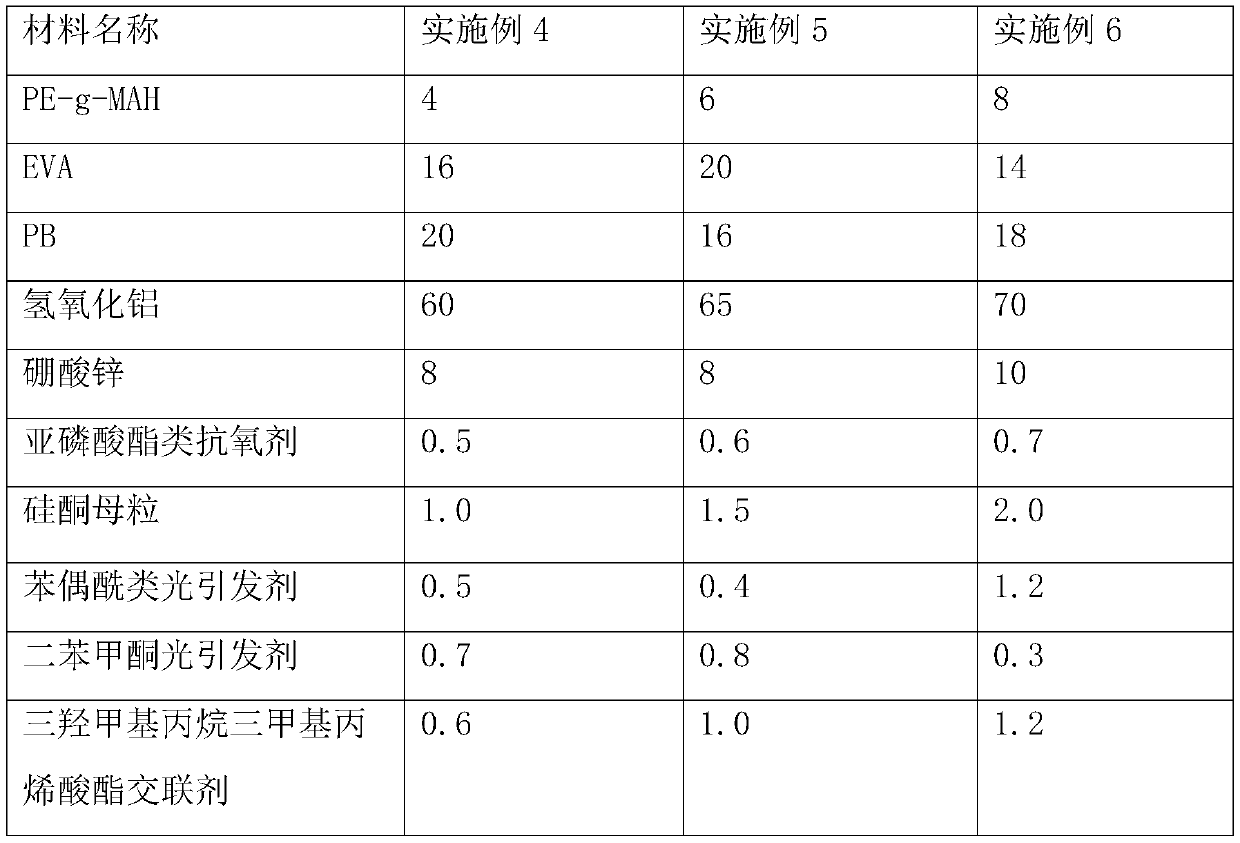

Double-layer coextruded insulation LED ultraviolet crosslinking colored low-smoke halogen-free flame-retardant cable material and preparation method thereof

ActiveCN110951141AGood flame retardant synergistic performanceGood copper aging resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer scienceAntioxidant

The invention discloses a double-layer coextruded insulation LED ultraviolet light crosslinking colored low-smoke halogen-free flame-retardant cable material. The cable material is composed of an inner-layer insulating material and an outer-layer insulating material, and the inner-layer insulating material is composed of a maleic anhydride grafted ethylene-octene copolymer, polyethylene, an ethylene-octene copolymer, a flame retardant, a flame retardant synergist, an antioxidant, a metal deactivator, a lubricant, a photoinitiator, a multifunctional group cross-linking agent and a color masterbatch; and the outer-layer insulating material is composed of maleic anhydride grafted polyethylene, an ethylene-vinyl acetate copolymer, syndiotactic 1,2-polybutadiene, the flame retardant, the flameretardant synergist, the antioxidant, the lubricant, the photoinitiator, the multifunctional crosslinking agent and the color master batch. The double-layer coextruded inner-layer insulating materialand the outer-layer insulating material are extruded, and then can be fast crosslinked online through LED irradiation equipment, various properties of cables can meet JG / T 441-2014, the mechanical properties and the electrical properties of the cable are excellent, the flame retardant property is good, and the service life of the cable can reach 70 years or longer.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Radiation Cross-Linkable Hot-Melt Contact Adhesives

InactiveUS20080039594A1Low viscosityImprove thermal stabilityLamination ancillary operationsSynthetic resin layered productsOligomerCrosslinked polymers

The invention relates to a radiation crosslinkable hot melt pressure sensitive adhesive comprised of a radiation crosslinkable polymer as component (A) based on epoxidized polyoflefins, wherein the epoxy groups are not consolidated in blocks; a tackifying resin possessing no epoxy groups as component (B); optionally a low molecular weight oligomer as component (C) that possesses reactive groups that can react with the epoxy groups of component (A); and an additive comprising a photo initiator as component (D).

Owner:HENKEL KGAA

Wind turbine blade tubular spar fabricating method

InactiveUS20130334735A1Drawback can be obviatedHighly precise dimensionFinal product manufactureLaminationTurbine bladeEngineering

A method of fabricating a wind turbine blade tubular spar, wherein the tubular spar extends along a designated axis, is made of reinforced polymer material having fibers arranged in at least two directions, and a polymer matrix incorporating the fibers, and has two caps and two webs; the method including the steps of: molding and cross-linking at least part of a cap or web in composite material; molding and cross-linking an L-shaped structure, which has two opposite parallel flanges, and at least partly incorporates the previously molded, cross-linked cap or web of composite material; repeating the above steps to mold and cross-link a further L-shaped structure; and joining the two cross-linked, L-shaped structures, with the flanges positioned facing in pairs.

Owner:WINDFIN

Silicone gel capable of removing scar and preparation method of silicone gel

ActiveCN106983784AImprove itchingIncrease relative volatilityOrganic active ingredientsInorganic active ingredientsCuticleDimethyl siloxane

The invention relates to the technical field of biological medicines and particularly relates to a silicone gel capable of removing a scar and a preparation method of the silicone gel. The silicone gel is prepared from the following raw materials in parts by weight: 1-10 parts of dimethyl silicone oil, 10-30 parts of hexamethyldisiloxane, 20-60 parts of a polydimethylsiloxane self-crosslinking polymer, 0-10 parts of a natural plant antimicrobial agent and 0-5 parts of an antipruritic agent. The dimethyl silicone oil and the polydimethylsiloxane self-crosslinking polymer can be quickly crosslinked and combined with other components under the action of the hexamethyldisiloxane and the hexamethyldisiloxane has high volatility, is capable of quickly promoting various substances to form a thin film after being crosslinked and combined, and is well tightly laminated with epidermis; hydration of skin is ensured; the silicone gel has the effects of smoothing and softening scars caused by various external causes; and meanwhile, various components work together, so that scar hyperpigmentation is significantly improved and the symptoms such as pruritus and erythema are improved.

Owner:HENAN HUIBO MEDICAL CO LTD

Natural silane cross-linked polyethylene cable material capable of resisting 110 DEG C

InactiveCN103102634AHigh silane graft contentHigh graft contentPlastic/resin/waxes insulatorsInsulated cablesCross-linkAntioxidant

The invention discloses a natural silane cross-linked polyethylene cable material capable of resisting 110 DEG C, which belongs to the technical field of insulating polymer materials for wires and cables. The material comprises a grafted component A and a catalytic component B according to the weight rate of (80-95): (5-20). The grafted component A comprises the following raw materials in parts by weight: 100 parts of polyethylene composite resin, 1.5-4 parts of silane coupling agent, 0.1-0.4 part of initiator, 0.1-0.5 part of anti-precrosslinker and 0.2-0.6 part of first antioxidant. The catalytic component B comprises the following raw materials in parts by weight: 100 parts of the polyethylene composite resin, 1-3 parts of organic sulfo-acid catalyst, 1-3 parts of organic bismuth catalyst, 0.5-2 parts of second antioxidant, 0.5-2 parts of copper inhibitor and 1-4 parts of lubricant. The natural silane cross-linked polyethylene cable material disclosed by the invention has the following advantages that the silane grafting content of the cable material is higher, the cross-linking speed under the natural condition is faster, the ageing resistance is better, and the application range can be widened.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com