Wear-resistant tear-resistant ethylene propylene diene monomer rubber material

A EPDM rubber and tear-resistant technology, applied in the field of rubber materials, can solve the problems of unsatisfactory wear and tear resistance of EPDM rubber, reduce vulcanization reversion, improve strength and hardness, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

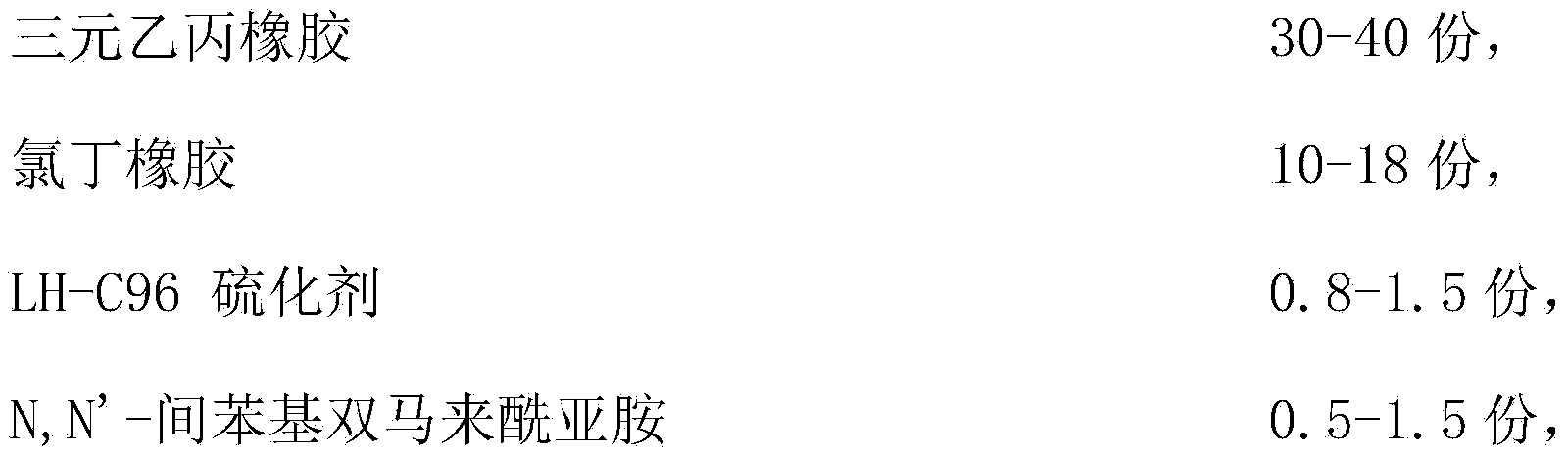

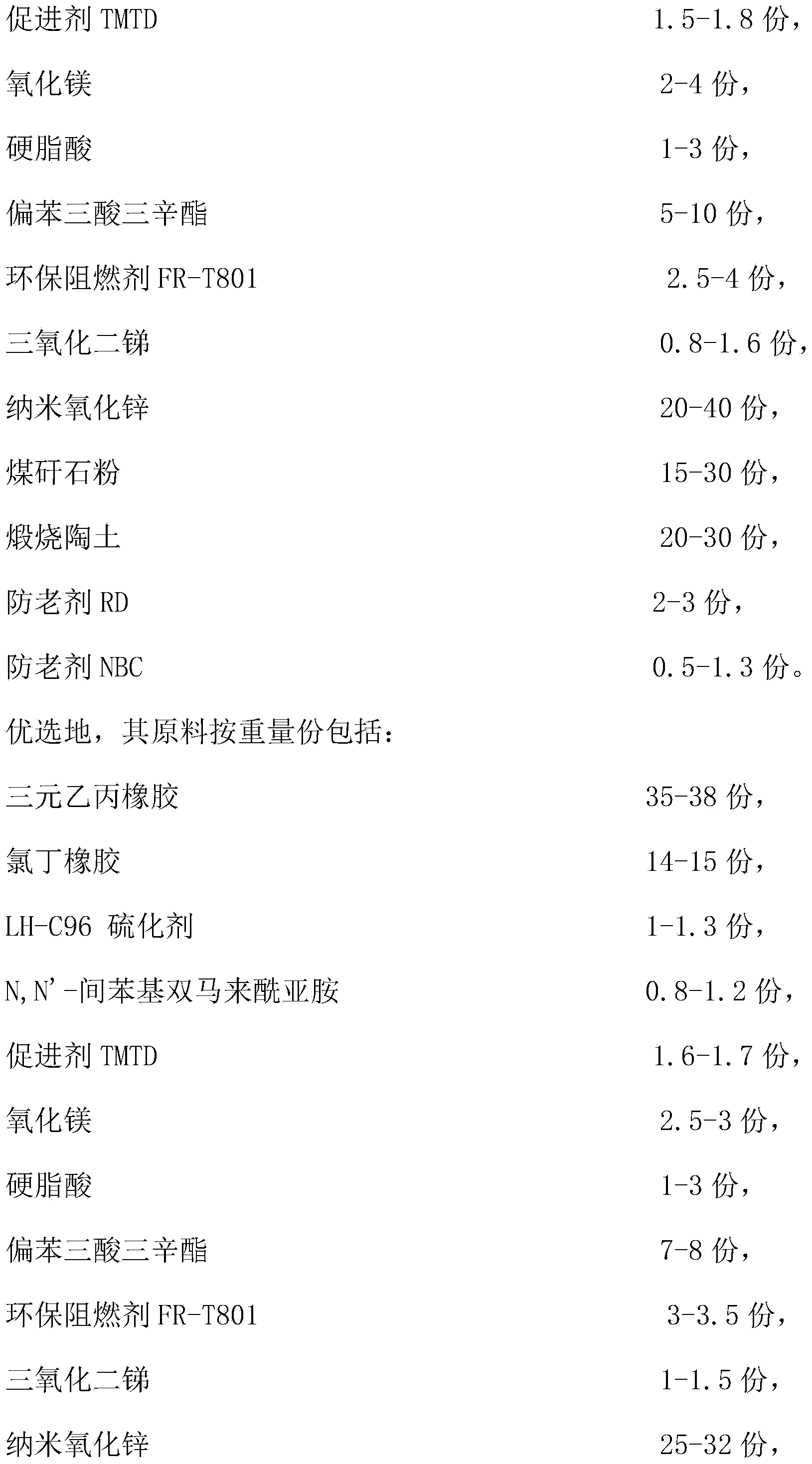

Method used

Image

Examples

Embodiment 1

[0015] Among the zinc oxide nanoparticles in Example 1, those with a particle diameter of 10-20nm accounted for 60wt%, those with a particle diameter of 50-60nm accounted for 10wt%, and those with a particle diameter of 70-100nm accounted for 30wt%.

Embodiment 2

[0016] Among the zinc oxide nanoparticles in Example 2, those with a particle diameter of 10-20nm accounted for 40wt%, those with a particle diameter of 50-60nm accounted for 30wt%, and those with a particle diameter of 70-100nm accounted for 30wt%.

Embodiment 4

[0017] Among the zinc oxide nanoparticles in Example 4, those with a particle diameter of 10-20nm accounted for 60wt%, those with a particle diameter of 50-60nm accounted for 30wt%, and those with a particle diameter of 70-100nm accounted for 10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com