Carrier film for transparent conductive film and laminated body

A technology of transparent conductive film and transparent conductive layer, which is applied in the direction of layered products, synthetic resin layered products, film/sheet adhesives, etc., to achieve soft adhesive layers, reduce crosslinking density, and inhibit zipper phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175]

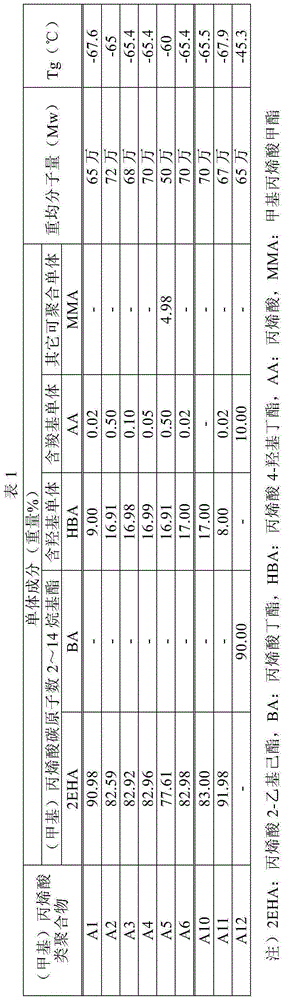

[0176] In a four-necked flask with a stirring blade, a thermometer, a nitrogen inlet tube and a condenser, 90.98% by weight of 2-ethylhexyl acrylate (2EHA), 9.00% by weight of 4-hydroxybutyl acrylate (HBA) and acrylic acid (AA ) 0.02% by weight of 100 parts by weight of monomer components, 0.2 parts by weight of 2,2'-azobisisobutyronitrile as a polymerization initiator, and 205 parts by weight of ethyl acetate. The liquid temperature of the solution was kept at about 63° C. and a polymerization reaction was performed for about 4 hours, thereby preparing an acrylic polymer (A1) solution (about 35% by weight). The acrylic polymer (A1) had a weight average molecular weight of 650,000 and a Tg of -67.6°C.

[0177]

[0178] The above-mentioned acrylic polymer (A1) solution (about 35% by weight) was diluted to 29% by weight with ethyl acetate, and 12 parts by weight of hexamethylene was added to 100 parts by weight (solid content) of the acrylic polymer in the solution....

Embodiment 2~10、 comparative example 1~4

[0182] As shown in Table 1 and Table 2, the monomer components constituting the (meth)acrylic polymer, the crosslinking agent constituting the adhesive composition, the catalyst, and the type or combination of the keto-enol tautomeric compound were changed. amount, except that, the carrier film for transparent conductive films was produced by the method similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com