Helical driving structure for gun barrel duct cleaning robot

A technology for cleaning robots and driving structures, which is applied to weapon cleaning devices, weapon accessories, offensive equipment, etc., can solve problems such as insufficient structure of variable-diameter pipes, and achieve the effects of simple structure, continuous movement and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

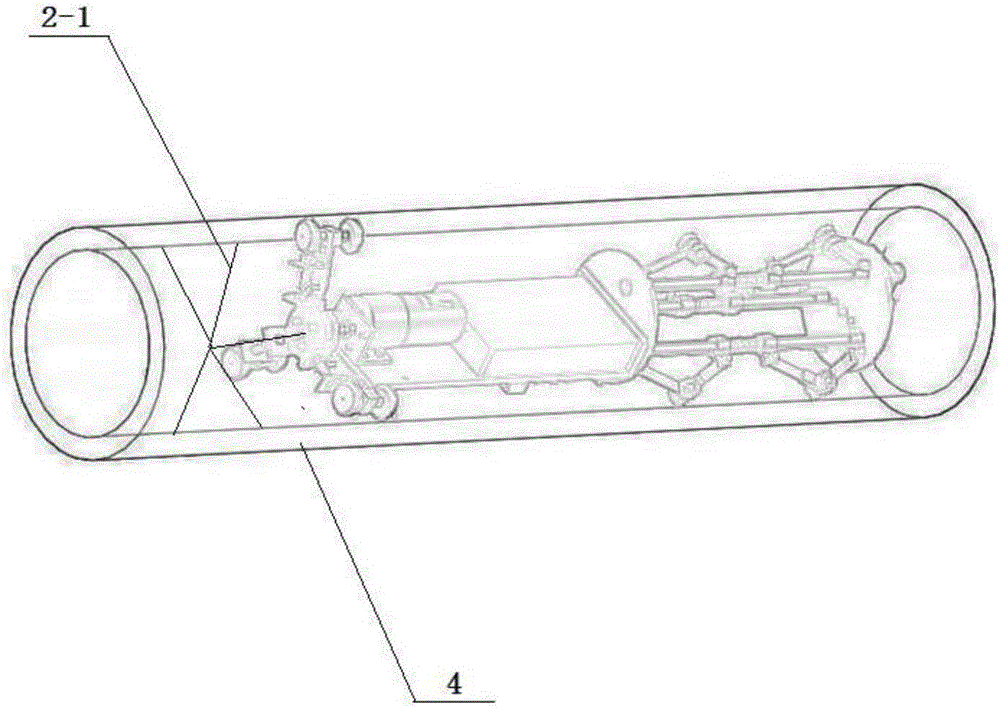

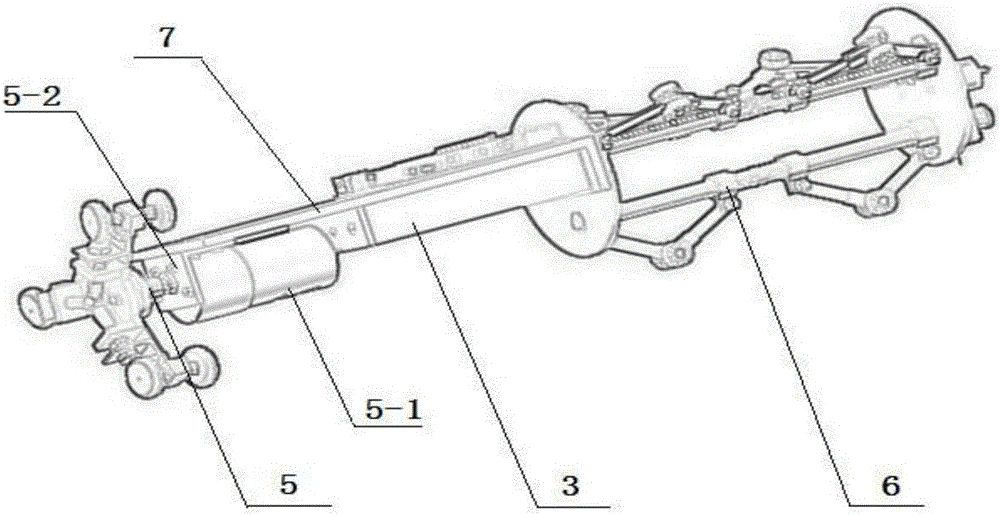

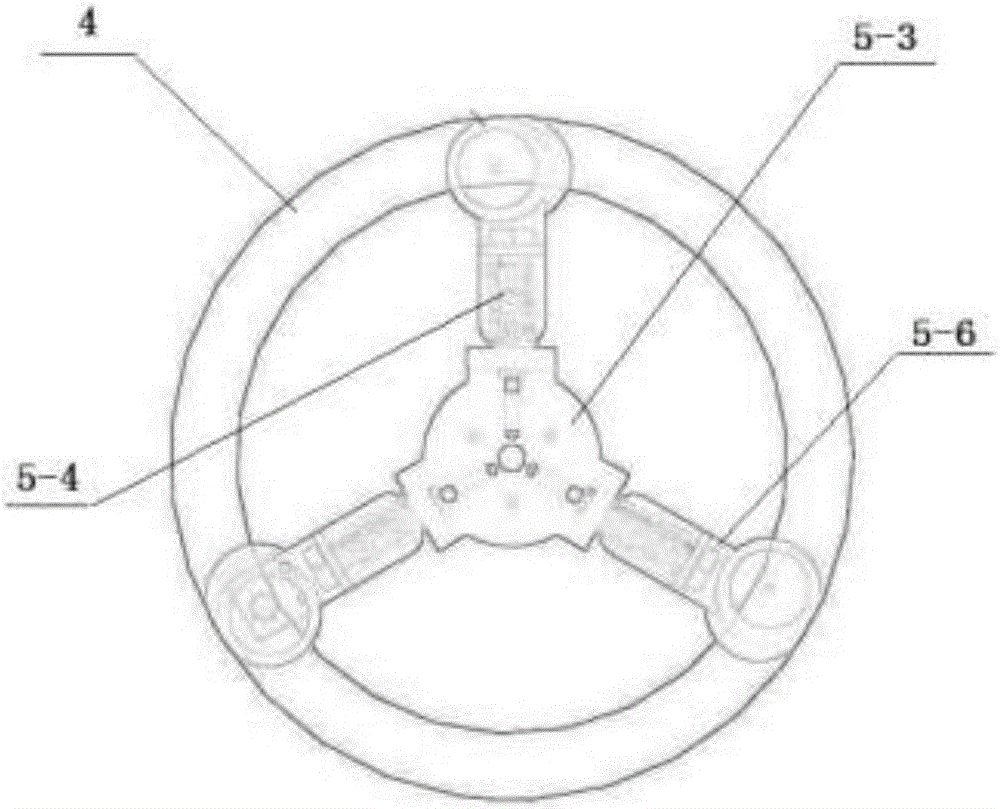

[0017] refer to Figure 1-5 , a spiral driving structure of a barrel pipe cleaning robot, the spiral driving structure is composed of a support plate 7, a driving motor 5-1, a spiral driving execution head 5, and a motion holder 6, and the driving motor passes through the motor The fixing seat 5-2 is installed on the support plate, and the helical drive execution head is fixed on the output shaft of the drive motor, and rotates under the action of the drive motor, and the helical drive execution head is driven by Three equal parts flange disc 5-3, L type drive wheel support 5-6, wheel group, compression spring 5-4 are formed, and described wheel group is rotatably fixed on the L type drive wheel support, and three groups of described L The L-shaped drive wheel bracket is slidably mounted on the third flange disc along the radial direction of the three equal flange dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com