Patents

Literature

101results about How to "Natural luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wax-containing composition for leather and its product surface coating

ActiveCN1611560AGood miscibilityHigh affinityLiquid surface applicatorsCoatingsSolubilityCarbon chain

The invention relates to a kind of waxy combination for surface coating of leather and its products, which is mainly composed with wax, high molecular polymer cream, long carbon-chain fatty alcohol, fatty amide, surface-active agent, and water, but its components doesn't contain organic solvent, water solubility organic alcohol, and mineral oil. Use fatty amide as cosolvent of coating combination system; fatty amide has fine intersolubility with wax, fatty alcohol, high molecular polymer, and other solid constituents; so it can improve stability of coating combination system, can guarantee continuation and compactness of coating film, and also can avoid the disadvantages of containing mineral oil and low molecular water solubility alcohol in the components. When using for surface coating of leather and its products, it has natural gloss, excellent abilities of water-resistant, antidusting, drying proof, and wet proof, and fine frictional property. So it has convenient usage that is safe, and can decline pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

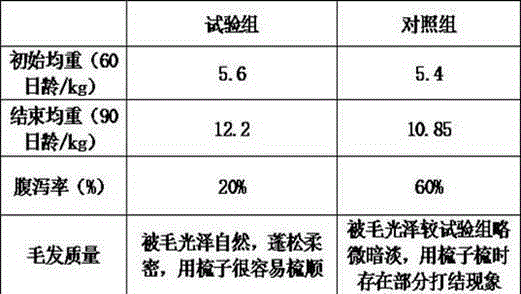

Healthcare agent for pet puppies

InactiveCN105230987AMake up for nutritional imbalancesIncrease nutritionAnimal feeding stuffBiotechnologyVitamin C

The invention discloses a healthcare agent for pet puppies. The healthcare agent for pet puppies comprises the following ingredients in parts by mass: 5-10 parts of egg micro-capsule powder, 5-15 parts of hydrolyzed wheat protein, 0.5-1.5 parts of vitamin A, 3-10 parts of glucose, 2-5 parts of chicken liver powder, 0.3-1 part of vitamin D3, 15-25 parts of puffed oat flour, 15-25 parts of puffed corn flour, 5-8 parts of vitamin C and 30-50 parts of skimmed milk powder. The healthcare agent for pet puppies of the invention is capable of supplementing nutrients required puppy growth and development, increasing pet appetite, reinforcing body immunity, preventing and treating intestinal inflammation, improving pet physique as well as improving hair quality. The healthcare agent for pet puppies is obvious in effect, safe and free of toxic and side effects.

Owner:山东贝瑞康生物科技有限公司

Manufacturing method of edible lipstick

The invention discloses an edible lipstick. The edible lipstick is prepared by the following components in proportion: 100-500 parts of carnauba wax, 200-300 parts of candelila wax, 50-100 parts of peanut oil, 50-100 parts of colza oil, 50-100 parts of citrus honey, 50-100 parts of linseed oil, 50-100 parts of sunflower oil, 800 parts of red sorghum pigment and 600-1000 parts of 95% ethyl alcohol. A manufacturing method comprises the following steps of dissolving the carnauba wax; filtering through a polymer dialysis membrane; grinding by a grinding miller; stirring by a stirrer; and carrying out cooling solidification to obtain the edible lipstick.

Owner:陆飞

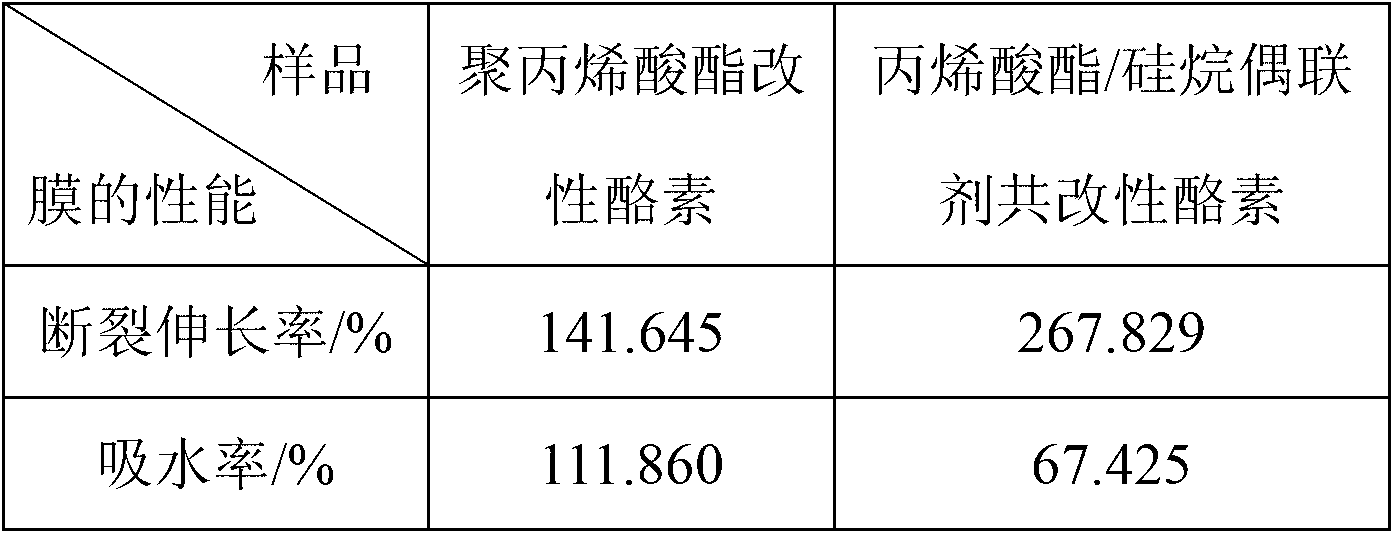

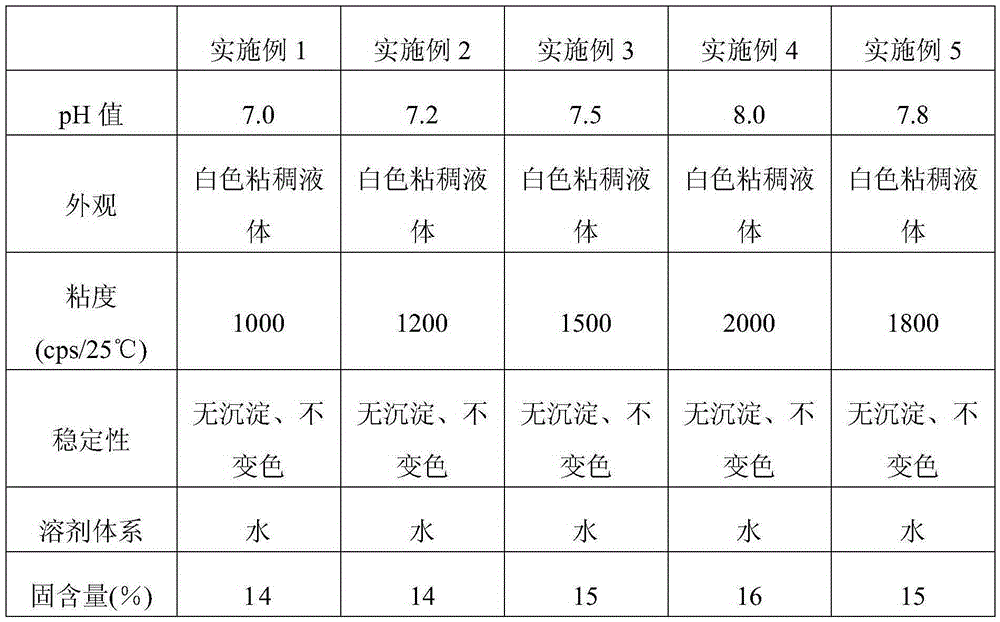

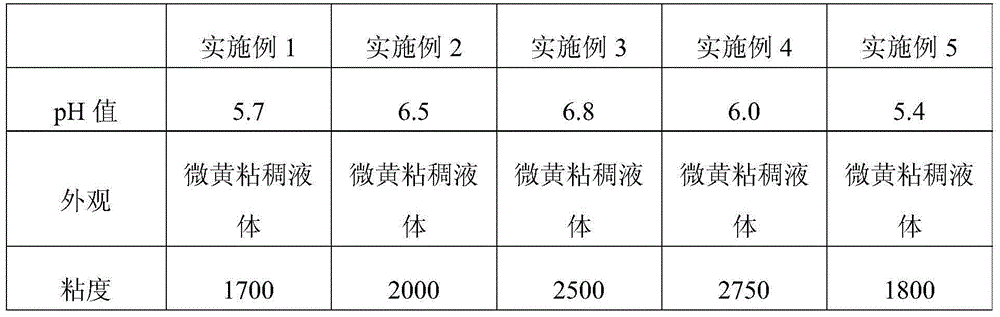

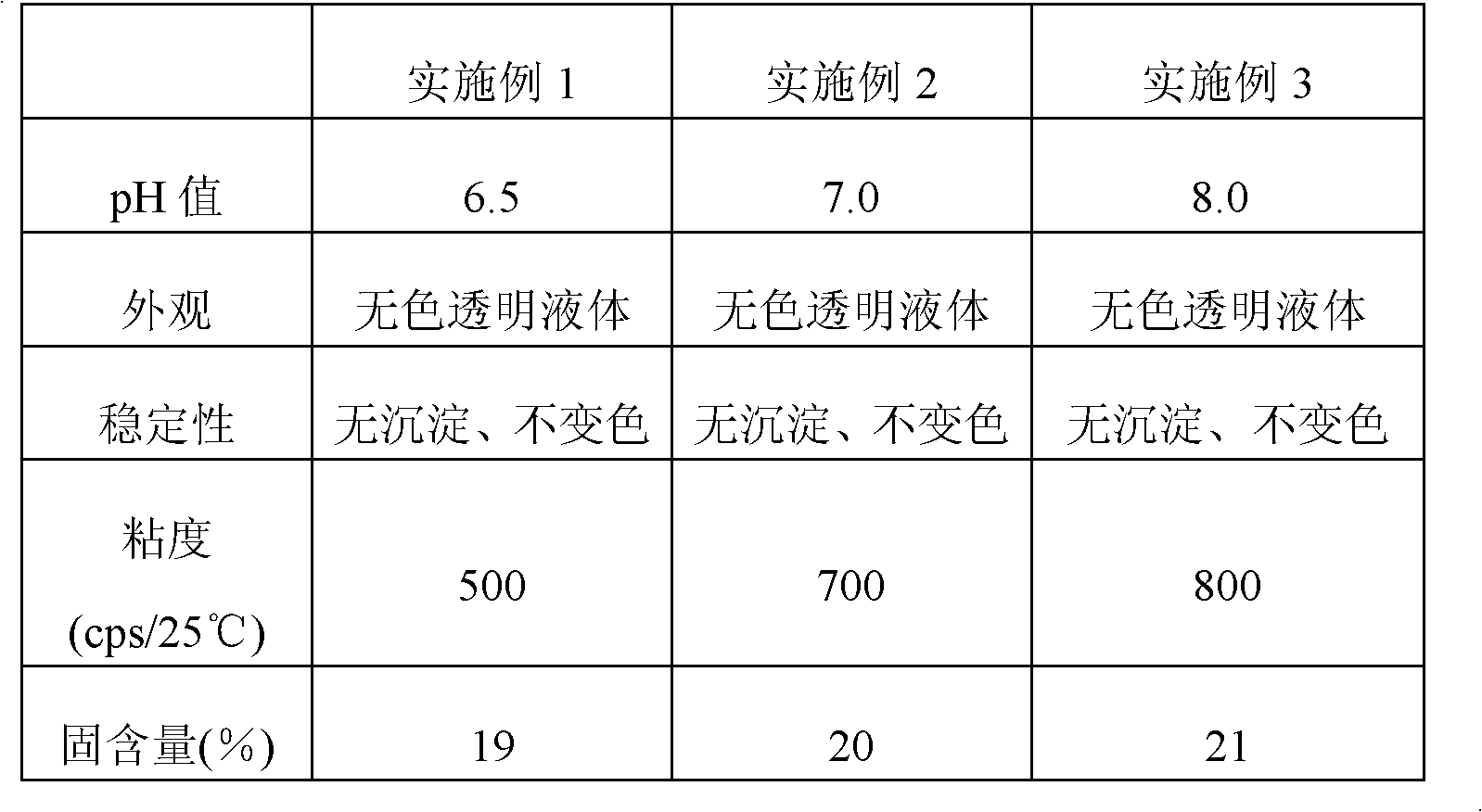

Method for preparing acrylate/ silane coupling agent shared modified casein leather finishing agent by adopting soap-free polymerization method

InactiveCN103059233AReduce adverse effectsHigh densityCoatingsLeather surface finishingPolymer scienceEmulsion

Provided is a method for preparing acrylate / silane coupling agent shared modified casein leather finishing agent by adopting a soap-free polymerization method. The method comprises the following steps: firstly, dissolving dry casein with triethanolamine and water, obtaining casein dissolved solution, adding dropwisely caprolactam solution into the casein dissolved solution, obtaining modified casein emulsion of caprolactam, then under the effect of persulfide initiator, adopting a semicontinuous seed emulsifier-free emulsion polymerization method, adding simultaneously methyl methacrylate, butyl acrylate and silane coupling agent to the modified casein emulsion of the caprolactam, and obtaining the acrylate / silane coupling agent shared modified casein leather finishing agent through free radical polymerization. According to the method for preparing the acrylate / silane coupling agent shared modified casein leather finishing agent by adopting the soap-free polymerization method, the casein is adopted to be as raw materials, health performance is good, gloss is natural, hand touch is comfortable and dry, emulgator is not added, adverse impact of the emulgator is eliminated, and the extensibility and a water resisting property of a film of the prepared acrylate / silane coupling agent shared modified casein leather finishing agent are remarkably improved.

Owner:SHAANXI UNIV OF SCI & TECH

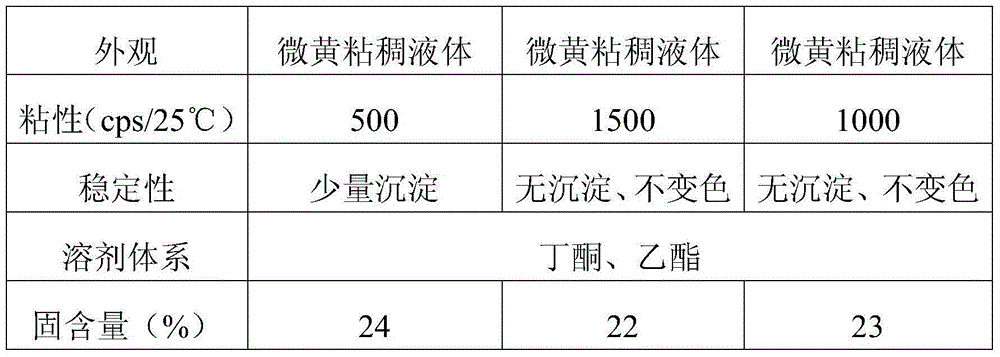

Water-based super-fogging super-blackening treating agent for synthetic leather and preparation method thereof

The invention relates to a water-based super-fogging super-blackening treating agent for synthetic leather, and the water-based super-fogging super-blackening treating agent is applied to a later period technology of the synthetic leather. The water-based super-fogging super-blackening treating agent is prepared from water-based resin, a water-based dispersing agent, a defoaming agent, silicon dioxide matting powder, a wetting agent, a Deuchem thickening agent and water. The invention further relates to a preparation method of the water-based super-fogging super-blackening treating agent for the synthetic leather. According to the water-based super-fogging super-blackening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster, better in color developing and excellent in comprehensive effect, meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based super-fogging super-blackening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

Discoloration polishing treatment agent for synthetic leather and preparation method thereof

ActiveCN104074057AComply with environmental standardsNatural lusterFibre treatmentWaxSilicon dioxide

The invention relates to discoloration polishing treatment agent for synthetic leather and a preparation method thereof. The treatment agent comprises the components of modified polyurethane, nitrocotton, dimethylformamide, butyl ester, silicon dioxide extinction powder, epoxidized soybean oil and organic silicone oil. The discoloration polishing treatment agent is a novel material of back-segment printing; all the components of the treatment agent are coordinated and coacted; a polished bright surface and oil wax have a good effect; the hand feeling is smooth; and the leather made of the treatment agent has the advantages of natural luster, clear color, strong dermis effect and excellent comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Preparation method of stereoscopic natural bright microfiber material and products thereof by lustring

InactiveCN106544883AStrong three-dimensional senseNatural lusterFibre typesPolyurethane dispersionPolymer science

The invention discloses a method for preparing a stereoscopic natural bright microfiber material by lustring, comprising the following steps: step one, preparing a fiber bat; step two, preparing base cloth; step three, carrying out impregnation via polyvinyl alcohol; step four, carrying out impregnation via PU by dipping an intermediate product prepared by the step three via wet polyurethane size, solidifying, washing at normal temperature, pre-drying for a second time, dipping via dispersoid, drying for a second time, washing with water at high temperature, drying and shaping to prepare a semi-finished product, wherein a solidification solution is dimethylformamide, and the dispersoid is water-soluble polyurethane dispersoid; step five, carrying out alkali minimization; and step six, carrying out leather facing effect treatment and treating via a functional agent. The invention also discloses a preparation method of the microfiber material and the products thereof. The prepared microfiber material and the products thereof are strong in texture stereoscopic feeling, natural in gloss and rich and full in hand feeling; various physical indexes such as peeling strength, abrasion resistance, tearing resistance, maximum tension force, yellowing resistance and breathability and the like are significantly higher than that of the similar products; the microfiber material and the products thereof can be widely applied to high-grade fashionable clothes, household articles and working articles.

Owner:泉州众信超纤科技股份有限公司

Chrome-tanned, water-dyed and polished leather manufacturing method

InactiveCN101914637AFine grainPlump and elasticTanning treatmentPre-tanning chemical treatmentHigh concentrationFolding endurance

The invention discloses a chrome-tanned, water-dyed and polished leather manufacturing method, which comprises the following steps of: 1, in an alkali coating step, liming the head, neck and back by using high-concentration sodium sulphide lime unhairing paste and liming the belly with low-concentration sodium sulphide lime unhairing paste; 2, performing softening with a high liquor ratio in a softening step; 3, after a pickling step is finished, pouring 1 / 3 of waste liquor out, supplementing 1 / 3 of normal-temperature water, performing chrome-tanning on naked leather in a slightly-swelling state, and performing uniform cutting after the chrome-tanning; 4, performing pre-dyeing in re-tanning; 5, performing re-dyeing with a low liquor ratio in a filling step; 6, performing oiling re-dyeing in an oiling step; and 7, finishing and flattening the leather and polishing the leather on a polishing machine after the oiling re-dyeing. The method of the invention has the advantages of endowing the leather product with softness, compact grain side, fullness, high elasticity, clear pores, high air permeability, folding endurance, tensile resistance, natural gloss and tight side ribs, along with fewer steps, cost reduction and no influence on surrounding atmosphere, and is widely applied to the production of soft upper leather and glove leather by using cow leather, pigskin and sheepskin, particularly goat skin.

Owner:HUIXIAN MINGDE LEATHER IND

Edible red cherry color-variable changeable lipstick and preparation method thereof

InactiveCN110354033AApply with confidenceGood edible moisturizing effectCosmetic preparationsMake-upEthylhexyl palmitateCrambe abyssinica

The invention relates to a lipstick, in particular to an edible red cherry color-variable changeable lipstick and a preparation method thereof. The color-variable changeable lipstick is prepared froma thickening agent, a moisturizing agent, a colorant, European sweet cherry seed oil, an European sweet cherry fruit extract, vegetable wool oil, ethylhexyl cocoate, macadamia ternifolia seed oil, simmondsia chinensis seed oil, crambe abyssinica seed oil, glycerol caprylate and ethylhexyl palmitate. The lipstick has the advantages of moisturizing, crack proofing and good use effects.

Owner:广东柏俐臣生物科技有限公司

Scraping-resistant polishing treating agent for synthetic leather and preparing method thereof

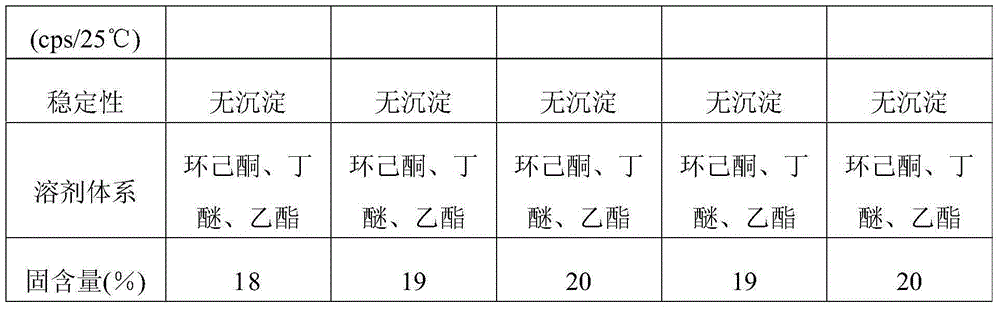

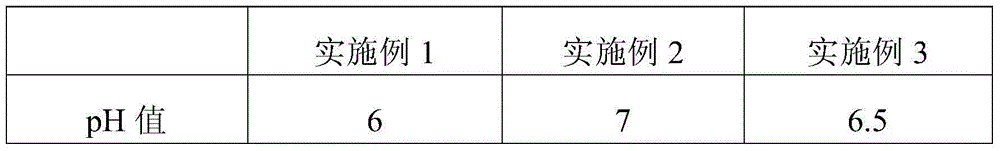

InactiveCN105220466AStrong sense of transparencyUnique feelFibre treatmentProduction lineCyclohexanone

The invention relates to a scraping-resistant polishing treating agent for synthetic leather. The scraping-resistant polishing treating agent is used for the later-stage printing technology for the synthetic leather. The scraping-resistant polishing treating agent is prepared from polyurethane resin, nitrocotton, ethyl ester, cyclohexanone, butyl ether, silicon dioxide matting agents, methyl-phenyl silicone oil, organic silicone oil and dispersing agents. The invention further relates to a preparing method of the scraping-resistant polishing treating agent for the synthetic leather. The components of the scraping-resistant polishing treating agent for the synthetic leather are coordinated and carry out combined action, the polished surface of the leather is high in lucent feeling and unique in hand feeling, the leather treated with the treating agent is natural in luster and clear in color, the polished surface of the leather is quite good in scraping resistance, and the comprehensive effect is good; the scraping-resistant polishing treating agent is a novel material for later-stage printing and can be used for an existing synthetic leather production line, the technology is simple, production devices do not need to be changed, production cost can not be increased, and the scraping-resistant polishing treating agent can also be used for pretreatment and is wide in application range.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Luster improving polishing treatment agent for synthetic leather and preparation method thereof

The invention relates to a luster improving polishing treatment agent for synthetic leather and a preparation method thereof. The treatment agent comprises alkyd resin, nitro-cotton, butanone, butyl ether, ethyl ester, silica extinction powder, organic modified methyl phenyl silicone oil and a dispersing agent. The luster improving polishing treatment agent for synthetic leather is a novel material for back-section printing of synthetic leather. By application of the treatment agent, the leather surface of synthetic leather is natural in gloss, clear in color and luster and high in temperature resistance and can be subjected to embossing, and polished synthetic leather has a good surface brightening effect, a good leather effect and excellent comprehensive effects.

Owner:浙江宝泽高分子材料有限公司

Mist-washing bright carbon black treatment agent special used for clothing leather and preparation method thereof

InactiveCN102535174AFog black effect is goodNatural lusterFibre treatmentButyl acetateNitrile rubber

The invention relates to a mist-washing bright carbon black treatment agent special used for clothing leather and a preparation method of the treatment agent. The mist-washing bright carbon black treatment agent consists of the following raw materials in parts by weight: 95-105 parts of anti-yellowing polyurethane resin with a modulus of 15-35MPa, 6-8 parts of matting agent, 2-4 parts of liquid nitrile rubber, 2-4 parts of phenyl methyl silicone oil, 1-3 parts of leveling / dispersing agent, 55-65 parts of dimethyl formamide, 45-55 parts of butyl acetate, 45-55 parts of propylene glycol methyl ether, 35-45 parts of isopropyl alcohol and 64-68 parts of aniline black pigment. Clothing leather treated by the mist-washing bright carbon black treatment agent provided by the invention not only has good mist black effect, but also has natural gloss and soft and comfortable handfeel. The mist-washing bright carbon black treatment agent is prepared by a manner of mixing first and then grinding, the operation is simple and the obtained treatment agent has good stability. Moreover, both the raw material cost and the production cost of the mist-washing bright carbon black treatment agent are lower than that of the existing similar products.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

Yangbuck matt surface unsmooth wax feeling treating agent for synthetic leather and preparation method thereof

ActiveCN104032583AStrong astringent and waxy leather surfaceNatural lusterFibre treatmentWaxPhenyl group

The invention relates to a Yangbuck matt surface unsmooth wax feeling treating agent for synthetic leather and a preparation method thereof. The treating agent comprises modified polyurethane resin, butanone, isopropanol, dichloroethane, silicon dioxide extinction powder, oleamide, wool fat and organic modification phenyl group silicone oil. The Yangbuck matt surface unsmooth wax feeling treating agent is a novel material used for later period printing of the synthetic leather, and by the aid of the treating agent, the synthetic leather is obviously and extremely high in unsmooth wax feeling, natural in gloss, clear in color and luster, splendid in color developing performance and excellent in comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Anti-yellowing matt surface brightening treating agent for synthetic leather and its preparation method

InactiveCN102851977AComply with environmental standardsNatural lusterFibre treatmentButyl acetateMedicine

The invention relates to an anti-yellowing matt surface brightening treating agent for synthetic leather and its preparation method. The treating agent is composed of modified anti-yellowing polyurethane resin, DMF, toluene, butyl acetate, silicon dioxide matting agent, amino silicone oil and castor oil. The treating agent meets EU environmental standard, and the synthetic leather treated by the treating agent has excellent comprehensive effects in the aspects of hand feeling, haze, color, etc.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Plukenetia volubilis oil helath-cared editable lipstick capable of moisturizing skin, and preparation method thereof

The invention belongs to the technical field of cosmetic, and more specifically relates to a plukenetia volubilis oil helath-cared editable lipstick capable of moisturizing skin, and a preparation method thereof. The plukenetia volubilis oil helath-cared editable lipstick capable of moisturizing skin is prepared from, by mass, 8 to 12% of carnauba wax, 5 to 10% of candelilla wax, 5 to 8% of soya lecithin, 5 to 8% of hydrogenated cocoa butter, 5 to 10% of shea butter, 30 to 50% of plukenetia volubilis oil, 10 to 20% of Argan nut oil, 5 to 10% of lanolin, 5 to 10% of rose hip oil, 0.1 to 0.5% ofa natural pigment, and 0.5 to 1% of glycerol caprylate. The luster of the plukenetia volubilis oil helath-cared editable lipstick is natural; the lip feel is soft; the moisture retention effect is excellent; the raw materials are pure natural products, no toxic chemical additive is added, so that the plukenetia volubilis oil helath-cared editable lipstick is editable, the mouthfeel is excellent,and health care effect, editable effect, and moisturizing effect are achieved.

Owner:广州丽彦妆生物科技有限公司

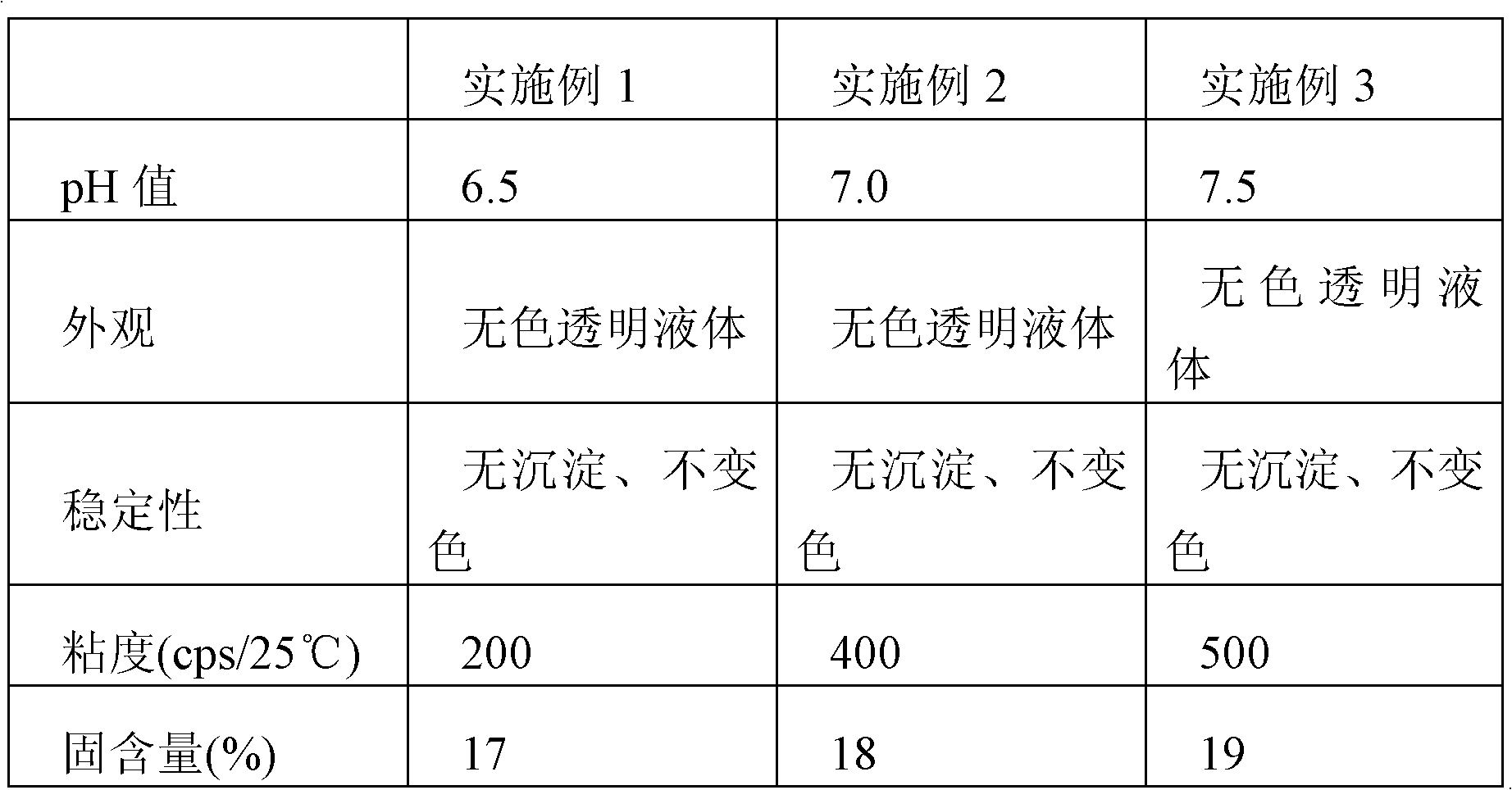

Eco-solvent silky waxy-feeling treatment agent for Yangbuck and its preparation method

InactiveCN102851984AComply with environmental standardsDoes not affect the effectFibre treatmentAfter treatmentSolvent

The invention relates to an eco-solvent silky waxy-feeling treatment agent for Yangbuck and its preparation method. The treatment agent consists of modified polyurethane resin, butyl acetate, isopropanol, silicon dioxide matting agent, modified siloxane, modified polyether silicone oil and polyethylene miropowder. The treatment agent is colorless transparent liquid, has good color development property and leveling property and no corrosivity on Yangbuck surface, and generates no influence on Yangbuck effect after treatment of Yangbuck surface via the treatment agent, and Yangbuck surface treated via the treatment agent is smooth and fine, and has unique silky hand feeling, unique and comfortable touch feeling, perfect durability, scratch resistance and hydrolysis resistance.

Preparation method of stereoscopic low-carbon fur spun wool

InactiveCN102808277ASuper three-dimensional senseUnique textureWeft knittingTextile treatment by pouringPre treatmentSizing

The invention discloses a preparation method of stereoscopic low-carbon fur spun wool. The preparation method comprises the following steps of: production of a finished color stripe, spinning of spun yarns, weaving and settling, wherein production of the finished color stripe comprises the following steps of: pre-treatment of wool and prolivon fiber Paster, respective dyeing of the wool and the prolivon fiber Paster, back washing, drying, silver mixing, first needle, second needle, recombing, can gilling and finisher gilling to obtain a finished stripe; spinning of the spun yarns comprises the following steps of: silver mixing, first needle, second needle, third needle, fourth needle, roving, combined spinning plus winding machines, doubling and two-for-one twisting; weaving comprises the following steps of production of a card, yarn drum placement and weaving with a circular knitting machine; and settling comprises the following steps of: wool washing with liquid flow, wet blank sizing, brushing and shearing, and burning and steaming. According to the method disclosed by the invention, the fur spun wool prepared by the method has the advantages of full bone feel, strong size stability, strong third dimension of a wool surface of a product, good glossiness, difficulty in deformation, strong recovery property, dual character of formal clothes and leisure fabric of the product, and wide application range.

Owner:JIANGSU LUGANG SCI & TECH

Process for producing Lyocell flame-retardant fiber Raschel blanket

ActiveCN106222871AHigh strengthLarge specific surface areaElectroconductive/antistatic filament manufactureBlanketYarnFiber

The invention relates to the field of blanket preparation and discloses a process for producing a Lyocell flame-retardant fiber Raschel blanket. The process comprises the following steps: 1) weaving, namely sequentially warping, weaving and cutting tufted yarns and base yarns, thereby obtaining a Lyocell flame-retardant fiber semi-finished Raschel blanket; 2) performing preliminary finish, namely setting, brushing, lustering and rolling the fabric; 3) dyeing and finishing, namely dyeing the fabric, performing reduction clearing on the fabric, neutralizing by acetic acid solution, washing and taking out of the jar, drying, steaming and color-fixing, softening and smoothing, and finally drying again; 4) performing after-finishing, namely drying and setting the fabric, performing front lustering, front brushing, front ironing and shearing, back fuzzing, back brushing, back lustering, back shearing, re-setting, front ironing and shearing, back ironing and shearing and slice stitching; and 5) inspecting the finished product, packaging and warehousing. The Lyocell flame-retardant fiber Raschel blanket disclosed by the invention is soft, stiff and elastic in fluff and skin-friendly, moisture-absorbing / desorbing and breathable in fabric and has the characteristics of being antibacterial, healthy, green and environmentally friendly.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Preparation technology of natural organism and vegetable fiber microfiber material, and preparation technology of product

The invention discloses a preparation technology of a natural organism and vegetable fiber microfiber material. The technology comprises the following steps: 1, preparing fiber batting composed of dermal fiber-containing composite fibers, modified high-shrinkage polyester fibers and vegetable fibers; 2, preparing a base cloth; 3, carrying out polyvinyl alcohol impregnation treatment; 4, carrying out PU impregnation treatment; 5, carrying out alkali decrement treatment; and 6, carrying out surface effect and function agent treatment: coating the surface of a semi-finished product to form a surface layer, and preparing the microfiber material from the surface layer according to a needed surface effect, wherein the surface layer is coated through the following steps: coating an air-permeable lining film, coating a surface slurry, drying the slurry, coating the surface slurry, and drying the slurry to obtain the finished microfiber material. The invention also discloses the microfiber material prepared through adopting the above technology, and a preparation technology of a product. The microfiber material and the product produced through the above technologies are comparable to derma in physical properties, and has the appearance, quality, strength, softness, air permeability and other physical properties of the derma.

Owner:泉州众信超纤科技股份有限公司

Manufacturing method of ceramic substrate lacquerware

InactiveCN110893737AColorful and reservedSolve the problem of easy falling offOrnamental structuresSpecial ornamental structuresLacquerwareVarnish

The invention discloses a manufacturing method of a ceramic substrate lacquerware. The method comprises the following steps of (1) manufacturing a ceramic substrate green body; (2) polishing; (3) coating a raw lacquer; (4) baking a varnish; (5) coating colored paint; (6) carrying out graining modification on a surface; (7) grinding: a, coating a first black refined Chinese lacquer; b, grinding paint; (8) brightening; and (9) wiping. In the invention, a problem that the raw lacquer is easy to fall off when be coated on a ceramic surface is solved. The raw lacquer can be firmly attached to the surface of a ceramic substrate through a scientific baking process, preferably baking is performed at a temperature of 130 DEG C for 40-45 min, and a bright color of the raw lacquer is still kept. Crafts ceramics and arts and crafts are ingeniously combined, a novel and unique ceramic utensil which is not easy to damage, is resistant to a high temperature and moisture, and is easy to store is manufactured, gloss is natural, a texture is clear, soft and beautiful, transparency and brightness are achieved, an artistic ornamental value and a collection value are achieved too, and the manufacturingmethod is scientific in procedure design and is practical.

Owner:程凌云

Anti-glare wet-wax-feeling treating agent for synthetic leather and preparation method thereof

InactiveCN106519943AStrong wet wax feeling on the matte surfaceNatural lusterPolyurea/polyurethane coatingsTextiles and paperWaxEthyl ester

The invention relates to an anti-glare wet-wax-feeling treating agent for synthetic leather and a preparation method thereof. The anti-glare wet-wax-feeling treating agent for the synthetic leather is prepared from the following components: polyurethane, dimethylformamide, ethyl ester, methylbenzene, silicon dioxide matting powder, oleamide, a dispersing agent and organic silicone oil. The components of the anti-glare wet-wax-feeling treating agent for the synthetic leather provided by the invention are coordinated mutually and acted jointly, the anti-glare wet-wax-feeling treating agent for the synthetic leather is applied in surface treatment of sheep pakistani leather or other leather, and a leather surface treated through the treating agent is higher in wet-wax-feeling, natural in gloss, clear in color and lustre, excellent in scuff resistance, and good in comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Weight-losing tablet and preparation method thereof

ActiveCN107307406AReduce synthesisReduce intakeFood shapingFood ingredient functionsWeight decreasingNutrient

The invention discloses a weight-losing tablet and a preparation method thereof, and belongs to the field of weight-losing medicines. The weight-losing tablet is prepared from the following components in parts by mass: 20 to 25 parts of white kidney bean, 30 to 35 parts of tangerine, 20 to 25 parts of raspberry fruit, 5 to 8 parts of opuntia ficus, 5 to 8 parts of folium nelumbinis, 1 to 2 parts of xylitol, 1 to 2 parts of sorbitol, 1 to 2 parts of sucralose, 2 to 5 parts of microcrystalline cellulose, 1 to 2 parts of magnesium stearate, and 0.3 to 0.5 part of edible essence. The preparation method is characterized in that in the granulating process, a granulating device by using edible vinegar as a huddling liquid is adopted. The weight-losing tablet has the advantages that the functions of controlling body weight, decreasing body lipid and reducing weight are realized; the intestine functions are regulated; the functions of resisting oxidizing and delaying aging are realized; the glycemic index of foods is reduced, and the blood glucose value is balanced; the heat absorbing is controlled; the blood lipid is regulated, the fat settling of artery is inhibited, the multiple functions of improving the health of cardiovascular vessels and the like are realized, the health and safety effects are realized, the nutrients required by a human body are maintained, and the red-face, luster-skin, health and nature effects are realized.

Owner:HUNAN KANG QI YI BAI BIOLOGICAL TECH CO LTD

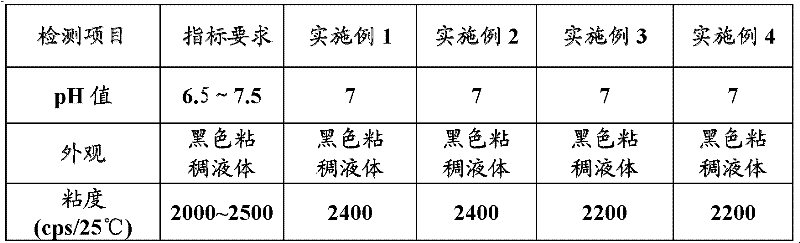

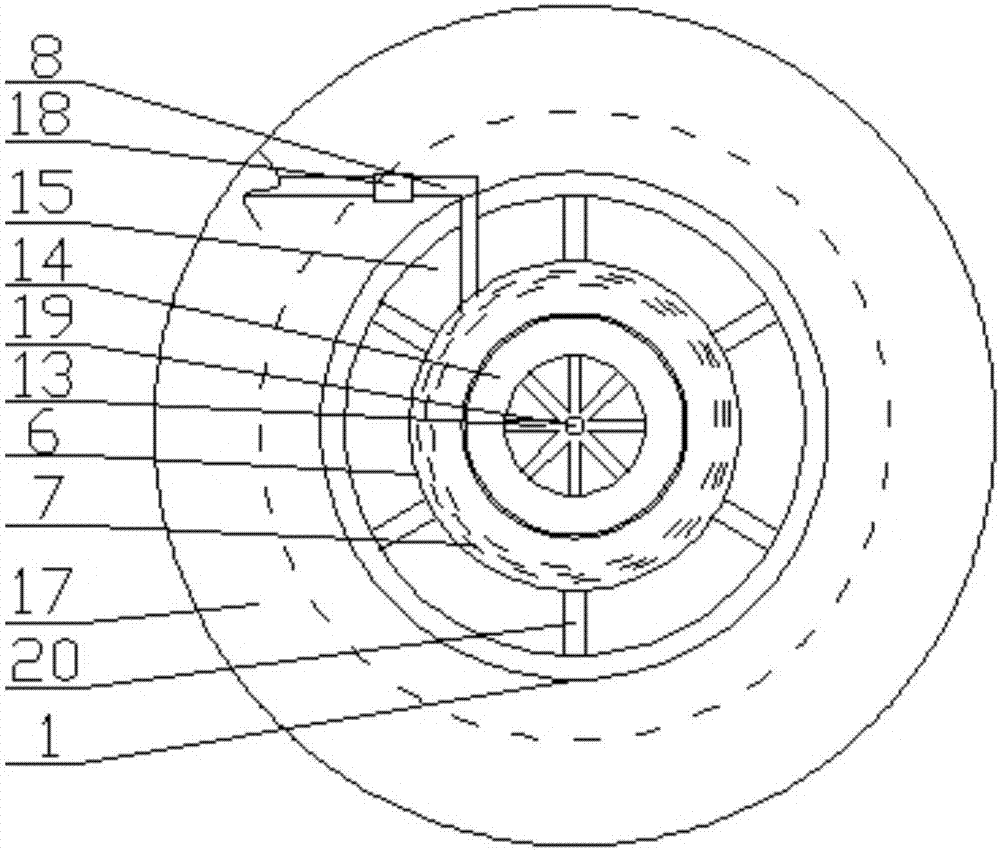

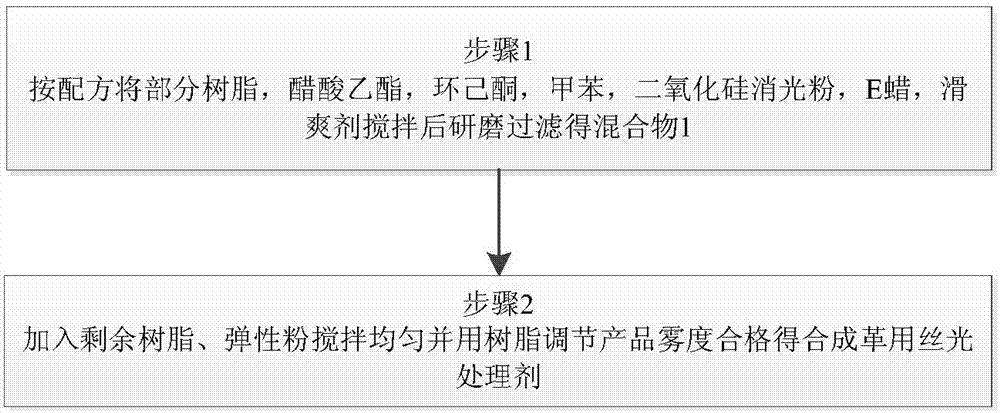

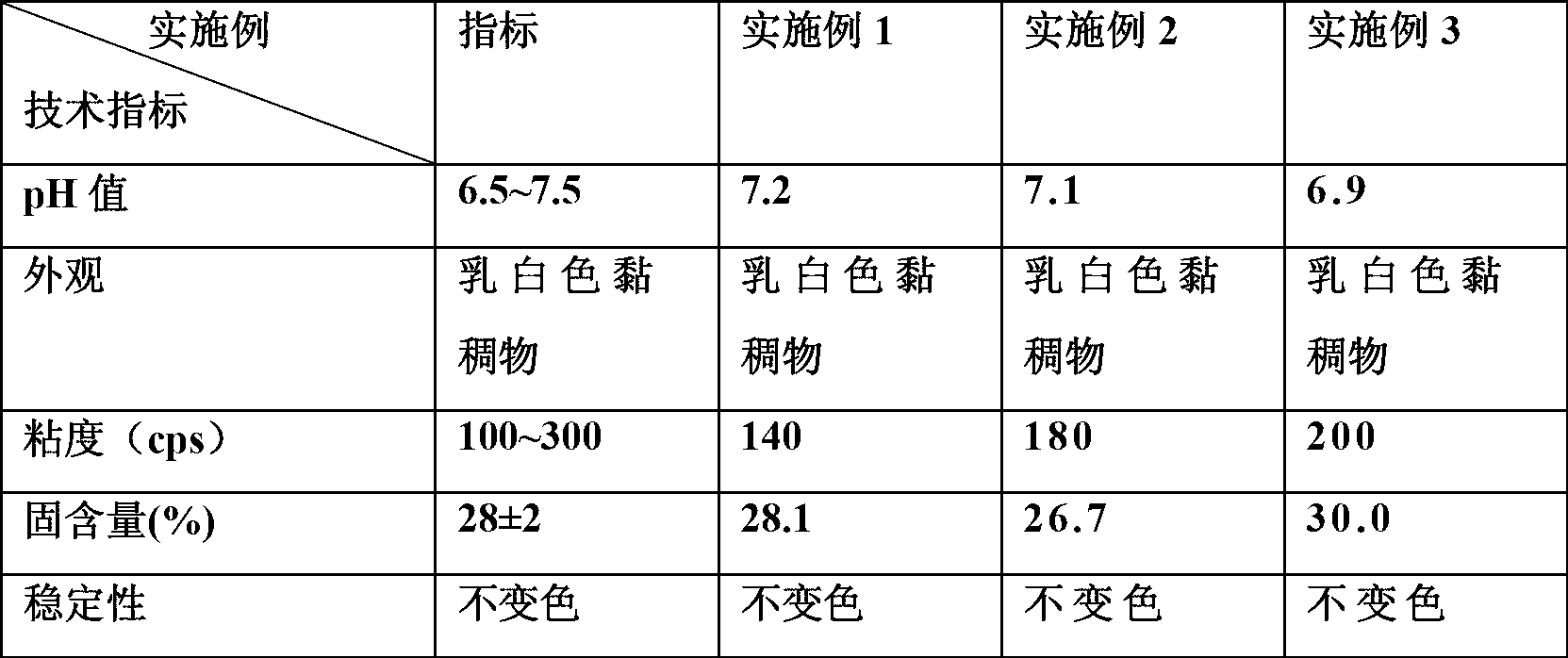

Mercerizing agent for synthetic leather and preparation method thereof

The invention relates to a mercerizing agent for synthetic leather. The mercerizing agent comprises the following components in parts by mass: 30-35 parts of resin, 5-7 parts of acetic ester, 35-37 parts of toluene, 13-17 parts of cyclohexanone, 0.4-0.8 parts of silica matting powder, 0.6-1 part of E wax, 5-10 parts of elastic powder, and 0.1-0.3 parts of a smoothing agent. The invention also discloses a preparation method of the mercerizing agent for synthetic leather. Partial resin, acetic ester, cyclohexanone, toluene, silica matting powder, E wax, and the smoothing agent are stirred according to the formula, grinding and filtering are carried out in order to obtain a mixture 1, residual resin and the elastic powder are added into the mixture 1 with uniform stirring, resin is used for adjusting haze of a product, after the product is qualified, the mercerizing agent for synthetic leather is obtained; after treatment, the leather surface has good layering, unique hand feeling and good haze; leather prepared by using the mercerizing agent has natural luster, clear color, good mercerizing effects, good scraping resistance, and good integrative effects.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Spraying type ceramic surface-sintered silver paste and preparation method thereof

The invention discloses a spraying type ceramic surface-sintered silver paste which contains the following components: 50-60 parts of nanometer silver powder, 1-3 parts of glass powder, 5-10 parts of twain, 5-10 parts of polyvinylpyrrolidone, 5-10 parts of dimeticone, 3-5 parts of sweet almond oil and 15-20 parts of water. A preparation method comprises the following steps: adding water into a container; adding polyvinylpyrrolidone and stirring till dissolving; adding twain, dimeticone and sweet almond oil and stirring for 0.5-1 hour at 500-600rpm; lastly, adding the nanometer silver powder and the glass powder and stirring for 20-30min at 500-600rpm. According to the invention, the preparation process of the silver paste is simple, the silver layer is firm after the sintering and is difficult to fall off; the silver paste is nontoxic and harmless and contains no other heavy metal; when the silver paste is applied to the food container, the silver paste has disinfecting and bactericidal effects; the silver paste is wide in application prospect.

Owner:河北银瓷天成文化传播有限公司

Method for manufacturing color paint coated artistic bottle

InactiveCN101407152ANot easy to saveEasy to storeDecorative surface effectsSpecial ornamental structuresLacquerMetallurgy

The invention provides a method for manufacturing a lacquer-casting handicraft bottle, which comprises the following steps: the outer surface of a real blank of the handicraft bottle is subjected to polishing treatment; base color layer lacquer is cast on the outer surface of the polished handicraft bottle to prepare a base color layer of the handicraft bottle; an artistic handicraft is adhered to the base color layer of the handicraft bottle; the handicraft bottle and the artistic handicraft are subjected to spray painting and sealing to prepare a transparent paint layer of the handicraft bottle; UV lacquer is sprayed on the transparent paint layer of the handicraft bottle, and ultraviolet rays between 2,000 and 3,000 watts are used for illumination and solidification when the UV lacquer is sprayed simultaneously; and the lacquer-casting handicraft bottle is formed after cooling and waxy luster packaging. The method aims to the technical blank of the lacquer-casting handicraft bottle and skillfully combines the handicraft bottle and the artistic handicraft to manufacture the novel handicraft bottle having the advantages of novelty and specialty, difficult damage, high-temperature resistance, moisture resistance and easy storage. The handicraft bottle has natural luster, clear grain, soft texture and artistic aesthetic feeling, and is transparent and bright; and the manufacturing method has scientific process design and is suitable for practicality.

Owner:张洪帆

Production method for Flycool fiber Raschel blanket

The invention relates to a production method for a Flycool fiber Raschel blanket. The production method includes the following steps: 1) yarn selection; 2) weaving; 3) scouring; 4) dyeing; 5) reduction clearing; and 6) finishing. The production method adopts Flycool fiber as tufted yarns of the Raschel blanket; nanometer-scale complex ore ingredients are added into the Flycool fiber, and then the Flycool fiber has excellent pulling and cool feeling performance, the obtained fabric can decrease the temperature of the surface of a human body so as to improve the temperature of an air conditioning device in summer, and the pulling and cool feeling performance of the Flycool fiber is permanent and meets the high standard demands of energy conservation and emission reduction. The Flycool fiber Raschel blanket has the characters of natural gloss, excellent air permeability and improved skin care performance in comparison with the like products, can generate momentary cool feeling of 1-2 DEG C after contacting skins, and has a moisture-absorption, sweat-releasing and anti-ultraviolet effect.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Special inhibition type leather stain remover for bacterial

InactiveCN104928087AGood decontamination effectGood antibacterial effectSurface-active non-soap compounds and soap mixture detergentsPolishing compositionsPolymer sciencePropanoic acid

The invention discloses a special bacterial inhibition type stain remover for leather. The special bacterial inhibition type stain remover is prepared from the following raw materials in parts by weight: 7-12 parts of birch tar oil, 4-7 parts of rosewood oil, 3-5 parts of iso-octyl acetate, 7-12 parts of sodium lauraminopropionate, 5-6 parts of modified polyurethane emulsion, 4-8 parts of isocyanate, 10-18 parts of ethyl acrylate, 6-11 parts of acrylic acid, 10-15 parts of isopropyl alcohol, 5-8 parts of N-alkyl stearamide, 6-12 parts of montan wax emulsion, 5-9 parts of amino silicon oil, 3-7 parts of ethyl acetate, 5-7 parts of dicyclohexyl methane diisocyanate, and 4-8 parts of palm wax. The special bacterial inhibition type stain remover has the beneficial effects that: the special bacterial inhibition type stain remover for leather has good stain removing property and bacterial inhibition, so that the leather is soft and natural in gloss, and ageing oxidization of the leather can be delayed.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

Cloudy surface polishing agent realizing strong suede waxy feel and preparation method thereof

The invention relates to a cloudy surface polishing agent realizing a strong suede waxy feel and a preparation method thereof. The cloudy surface polishing agent realizing a strong suede waxy feel comprises, by weight, 35 to 50 parts of acrylic resin, 10 to 25 parts of monobutyl ether, 40 to 60 parts of ethyl acetate, 40 to 65 parts of butyl acetate, 10 to 20 parts of hydrophilic silicone oil, 8 to 15 parts of silica extinction powder, 1 to 5 parts of dimethicone, 1 to 4 parts of a wetting dispersant, 1 to 4 parts of oxidized castor oil, 2 to 4 parts of polyurethane elastic microspheres and 2 to 4 parts of wax. The cloudy surface polishing agent realizing a strong suede waxy feel has a reasonable formula, an oil feel and a waxy feel and realizes cloudy surface polishing. After water washing, the cloudy surface polishing agent has good blackening, a strong trench bottom suede feel, a strong surface waxy feel and natural gloss, turns white difficultly, and has a good handle and a high leather simulation degree.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

Post-finishing auxiliary agent for processing human hair fibers

A post-finishing auxiliary agent for processing human hair fibers is characterized by including the following components by mass: 1-5% of dodecyl glycoside, 1-5% of dilaurinol maleate, 1-5% of quaternary ammonium salt, 10-20% of a dimethyl silicone oil emulsion, 5-10% of an amino silicone oil emulsion, and 60-80% of deionized water. The post-finishing auxiliary agent is easy to dilute, low in cost and simple in use process, and the human hair fibers after treatment has the advantages of excellent smooth, gentle and agreeable and antistatic properties, strong toughness and natural luster.

Owner:SHAOYANG SUNSHINE HAIR PROD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com