Cloudy surface polishing agent realizing strong suede waxy feel and preparation method thereof

A technology of treatment agent and waxy feeling, which is applied in the field of matte surface cleaning treatment agent and its preparation, can solve the problems of single variety and function, low simulation degree of leather feeling, and weak oily waxy feeling, etc., to achieve natural luster and smooth skin. High sense of simulation and good blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

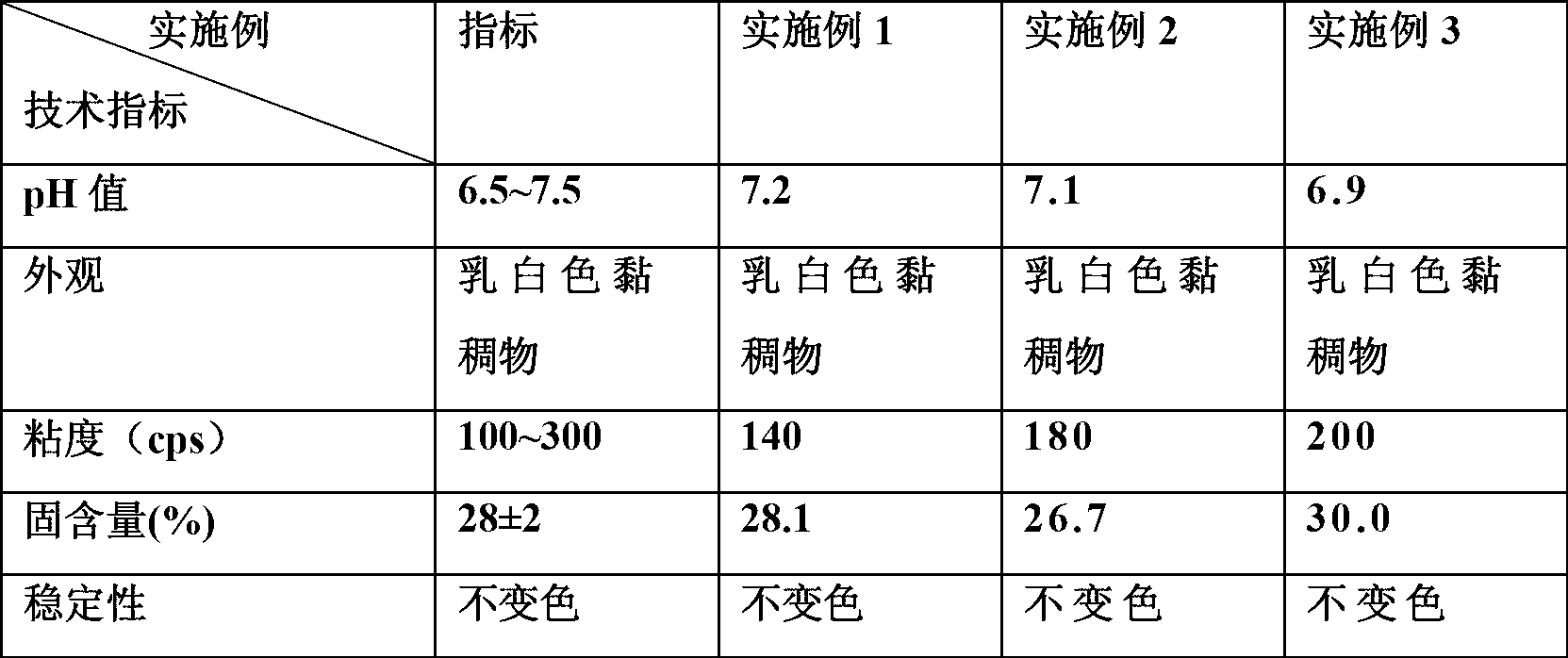

Embodiment 1

[0019] This example provides a kind of suede wax feeling strong matt surface cleaning and brightening treatment agent, in parts by weight, its raw material formula is as follows: 40 parts of acrylic resin; 18 parts of ethylene glycol monobutyl ether; 55 parts of ethyl acetate; Butyl acetate 50 parts; 15 parts of hydrophilic silicone oil; 9 parts of silica matting powder; 2 parts of dimethyl silicone oil; 2 parts of alkylamine salt copolymer; 3 parts of oxidized castor oil; 3 parts of polyurethane elastic microspheres; 2 parts of wax.

[0020] According to the above components and proportions, after adding ethylene glycol monobutyl ether, ethyl acetate, butyl acetate, hydrophilic silicone oil, dimethyl silicone oil, oxidized castor oil, and alkylamine salt copolymer to the acrylic resin, the Stir at a stirring speed of 1800r / min at room temperature until the dispersion is uniform, then add silica matting powder, wax and polyurethane elastic microspheres while stirring, and after...

Embodiment 2

[0022] This example provides a kind of suede surface wax feeling strong matt surface cleaning and brightening treatment agent, in parts by weight, its raw material formula is as follows: 38 parts of acrylic resin; 16 parts of monobutyl ether; 56 parts of ethyl acetate; 52 parts of butyl acetate; 12 parts of hydrophilic silicone oil; 9 parts of silica matting powder; 1 part of dimethyl silicone oil; 1 part of alkylamine salt copolymer; 4 parts of oxidized castor oil; 4 parts of polyurethane elastic microspheres; 2 parts of wax.

[0023] According to the above components and proportions, after adding ethylene glycol monobutyl ether, ethyl acetate, butyl acetate, hydrophilic silicone oil, dimethyl silicone oil, oxidized castor oil, and alkylamine salt copolymer to the acrylic resin, the Stir at a stirring speed of 1500r / min at room temperature until it is uniformly dispersed, then add silica matting powder, wax and polyurethane elastic microspheres while stirring, and after the di...

Embodiment 3

[0025] This example provides a kind of suede surface wax feeling strong matt surface cleaning and brightening treatment agent, and its raw material formula is as follows in parts by weight: 50 parts of acrylic resin; 20 parts of ethylene glycol monobutyl ether; 55 parts of ethyl acetate; Butyl acetate 60 parts; 11 parts of hydrophilic silicone oil; 13 parts of silica matting powder; 5 parts of dimethyl silicone oil; 4 parts of alkylamine salt copolymer; 2 parts of oxidized castor oil; 3 parts of polyurethane elastic microspheres; 3 parts of wax.

[0026] According to the above components and proportions, after adding ethylene glycol monobutyl ether, ethyl acetate, butyl acetate, hydrophilic silicone oil, dimethyl silicone oil, oxidized castor oil, and alkylamine salt copolymer to the acrylic resin, the Stir at a stirring speed of 2000r / min at room temperature until the dispersion is uniform, then add silica matting powder, wax and polyurethane elastic microspheres while stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com