Patents

Literature

64results about How to "Unique feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

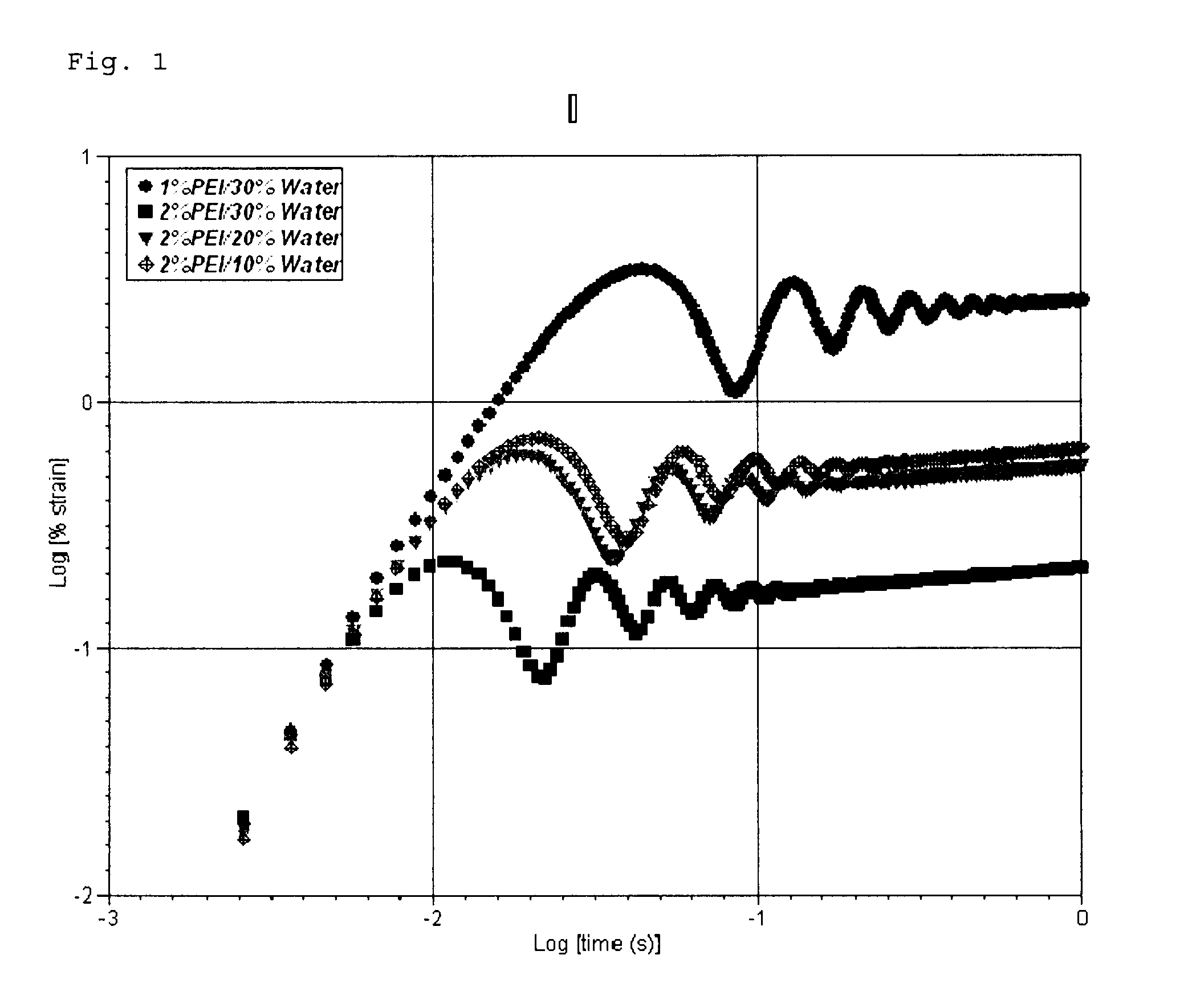

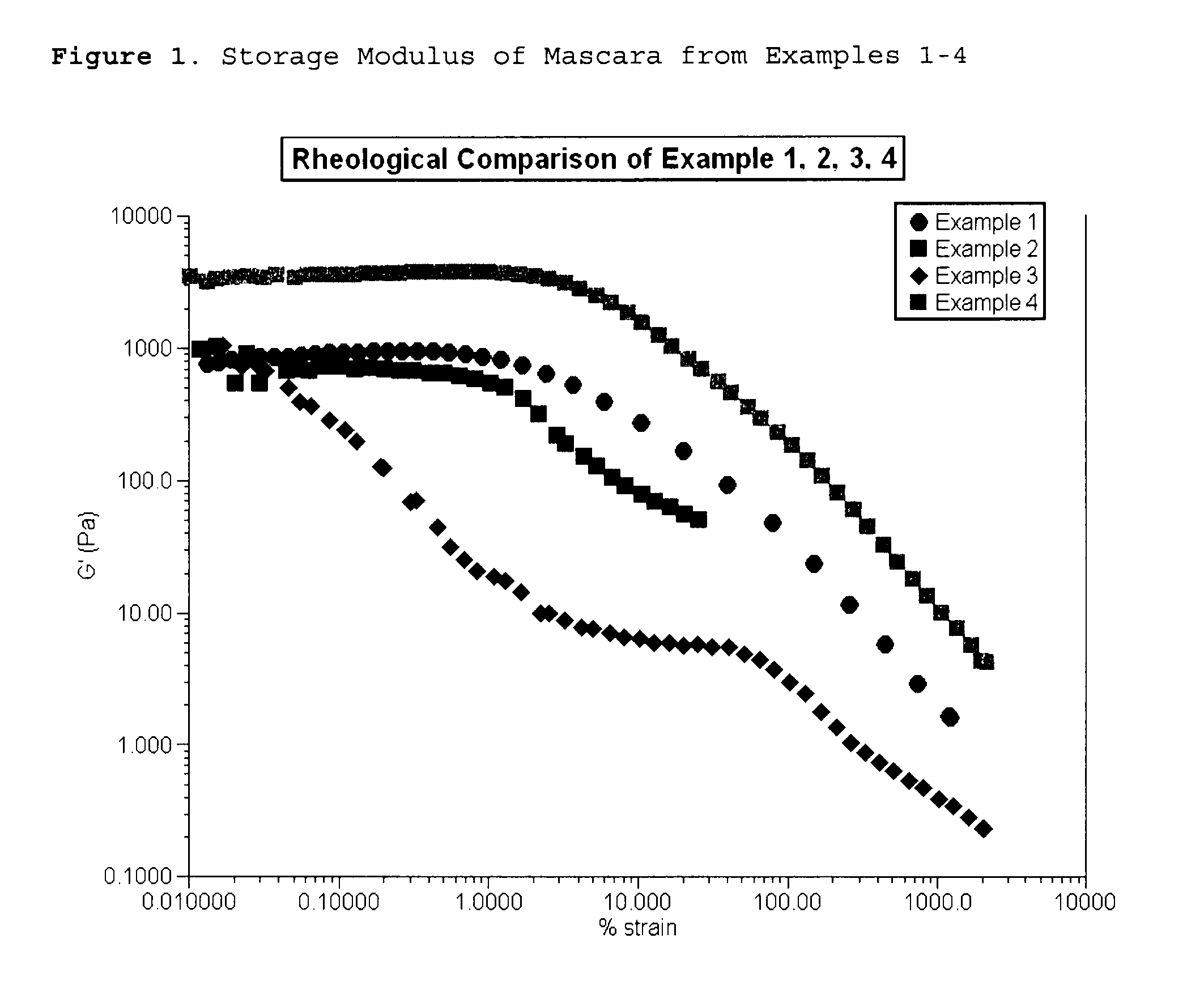

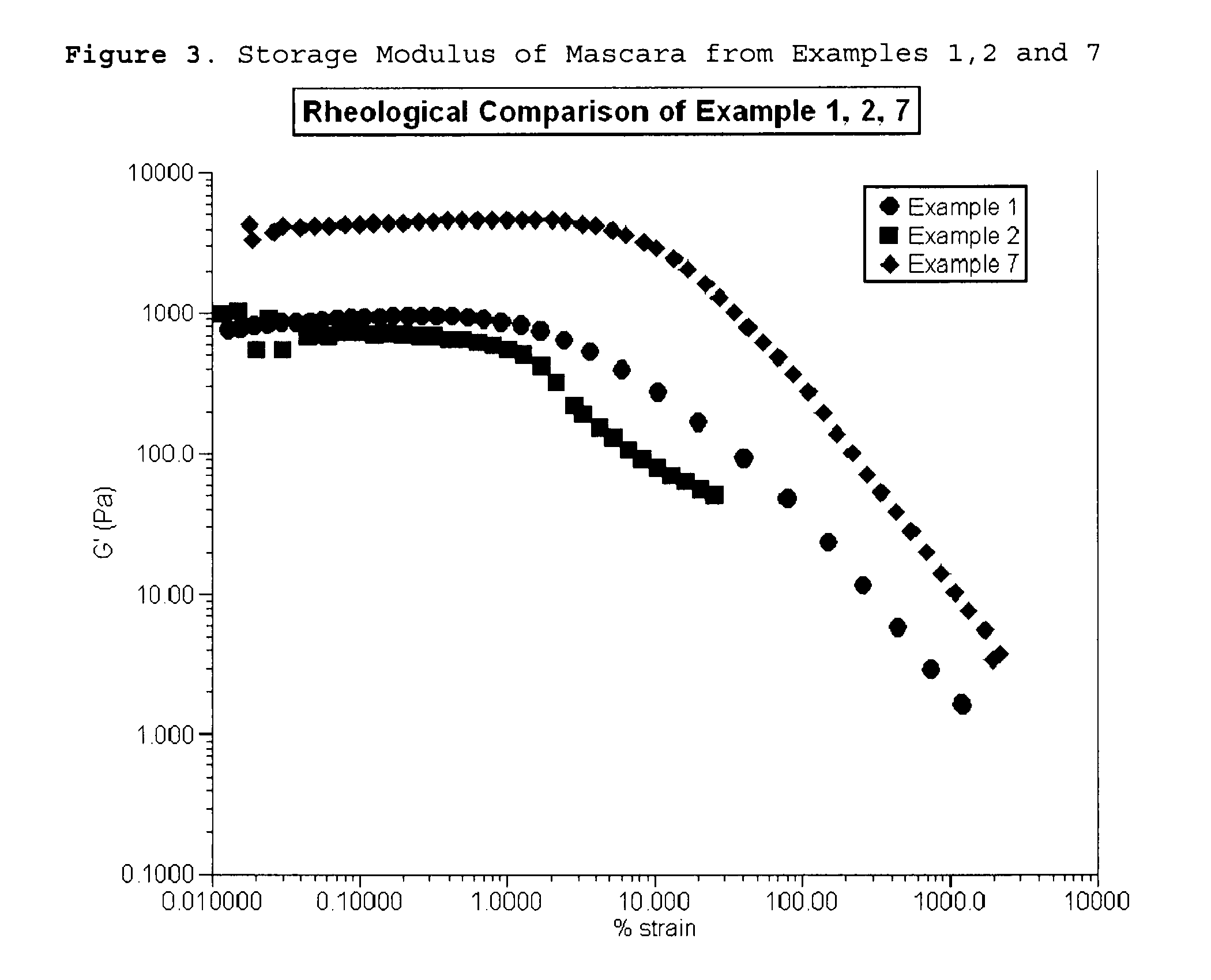

Cosmetic compositions of varying viscoelasticity

InactiveUS20110286950A1Stable textureUnique textureCosmetic preparationsHair cosmeticsViscoelasticityPolyamine

The present invention is directed to stable cosmetic composition which is waterproof, comfortable and has a unique cushiony / bouncy texture and feel containing: (a) a reaction product of (i) at least one polyamine and (ii) at least one oil soluble high carbon polar modified polymer; (b) water; (c) at least one non-volatile solvent capable of solubilizing the polar modified polymer; and (d) optionally, at least one volatile solvent other than water,—and (e) optionally, at least one colorant.

Owner:LOREAL SA

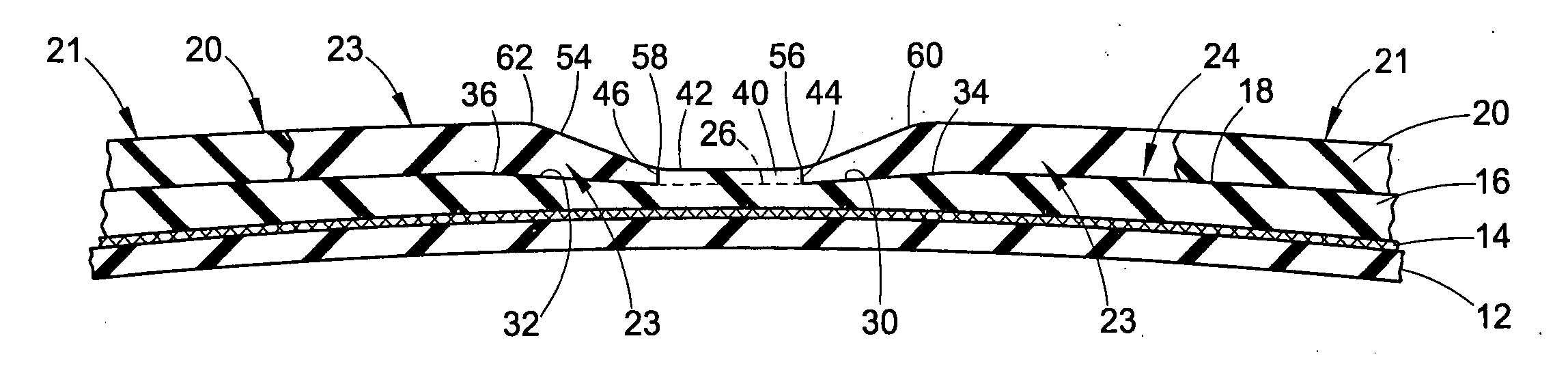

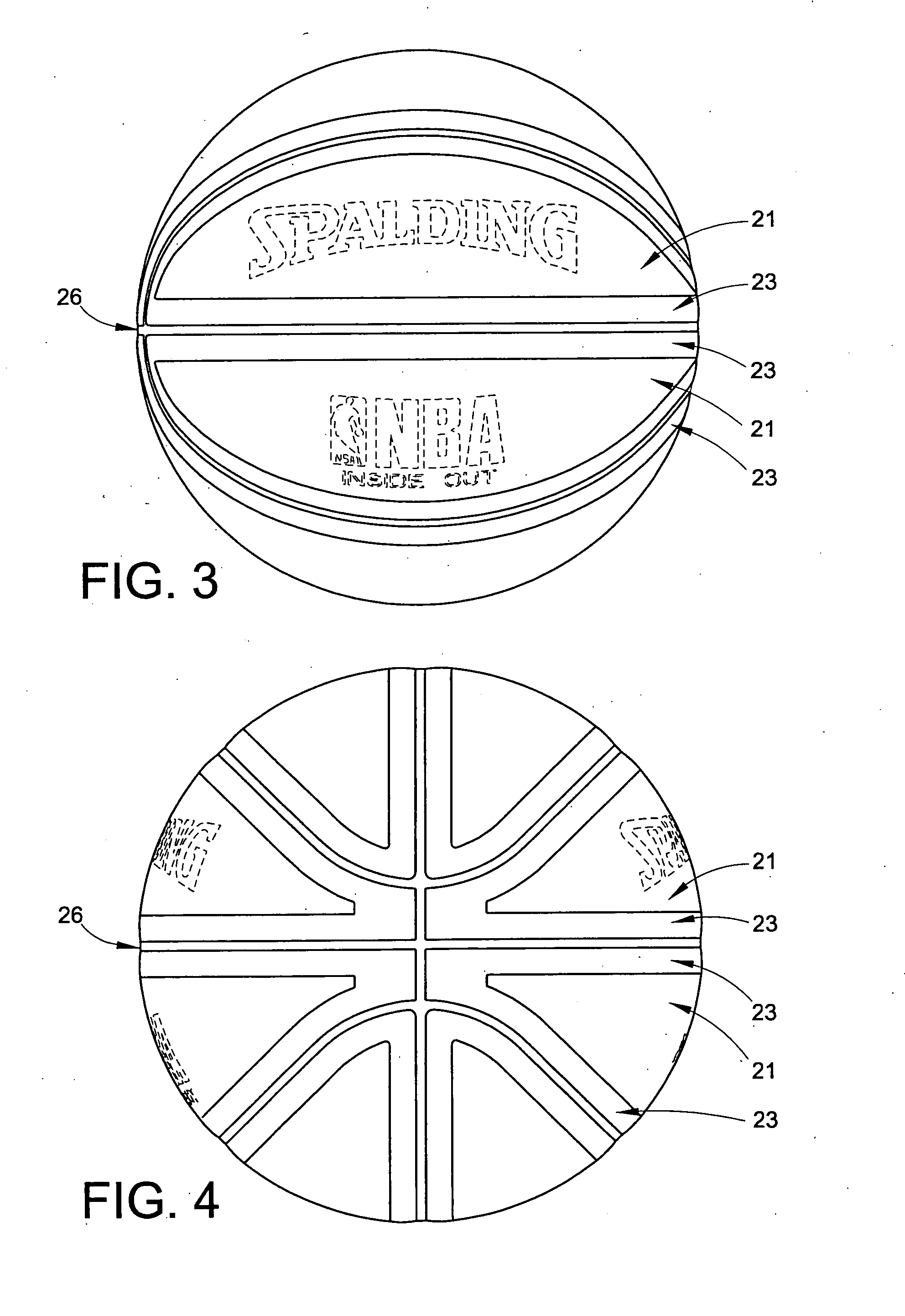

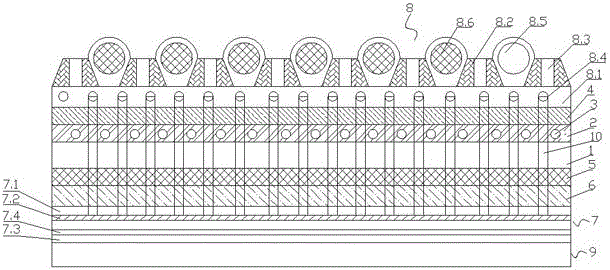

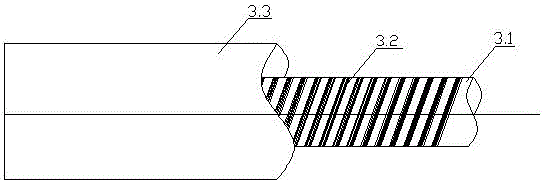

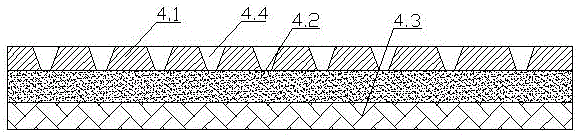

Sportsball and method of manufacturing same

ActiveUS20050153803A1Variable gripVariable feel propertyHollow inflatable ballsHollow non-inflatable ballsEngineeringBuilding construction

The present development is directed to sportsballs or gameballs and to methods for producing the same. More particularly, the disclosure is directed to inflatable sportsballs or gameballs, such as basketballs, having a laminated construction, and to process for fabricating the same.

Owner:RUSSELL BRANDS +1

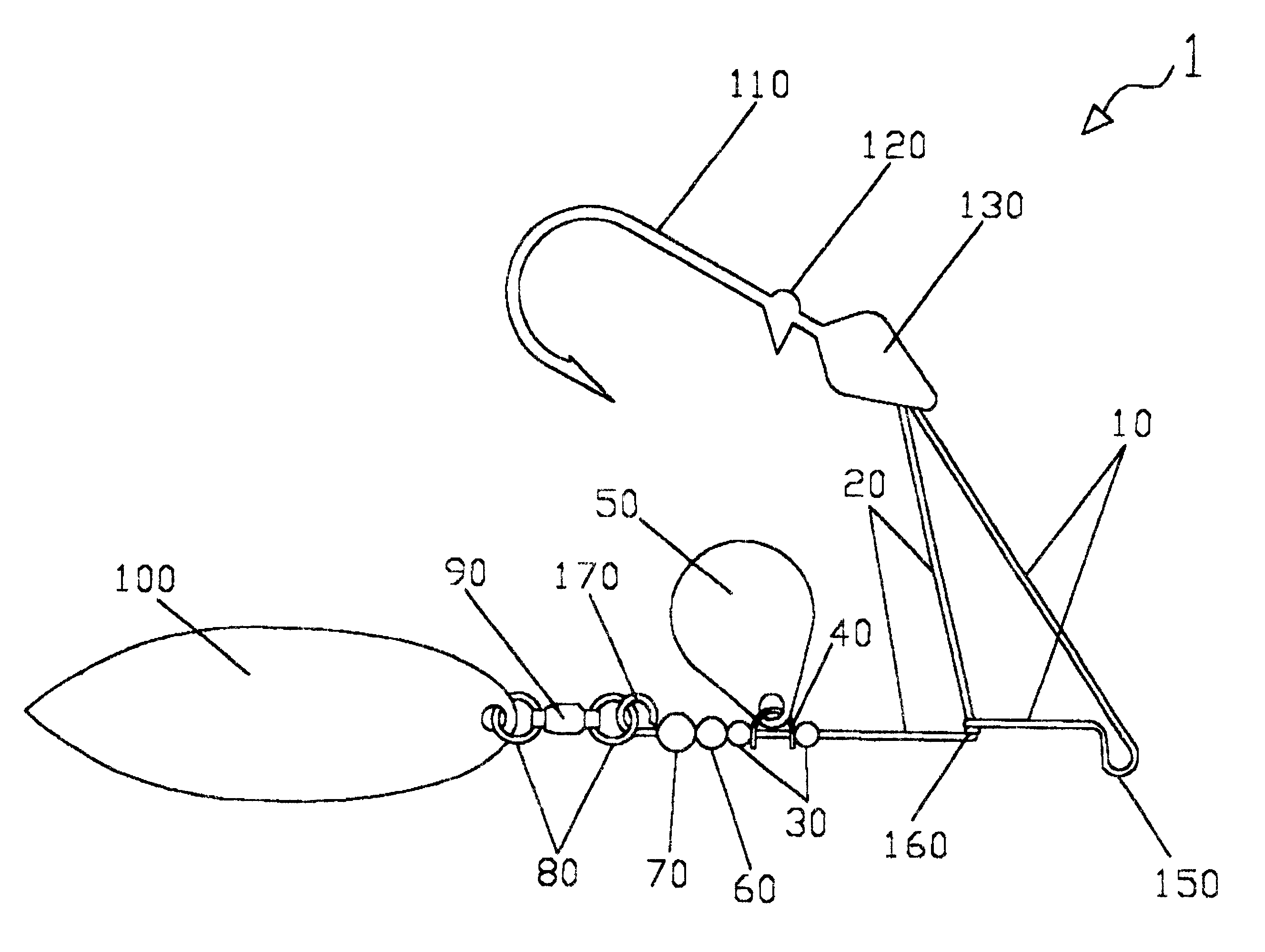

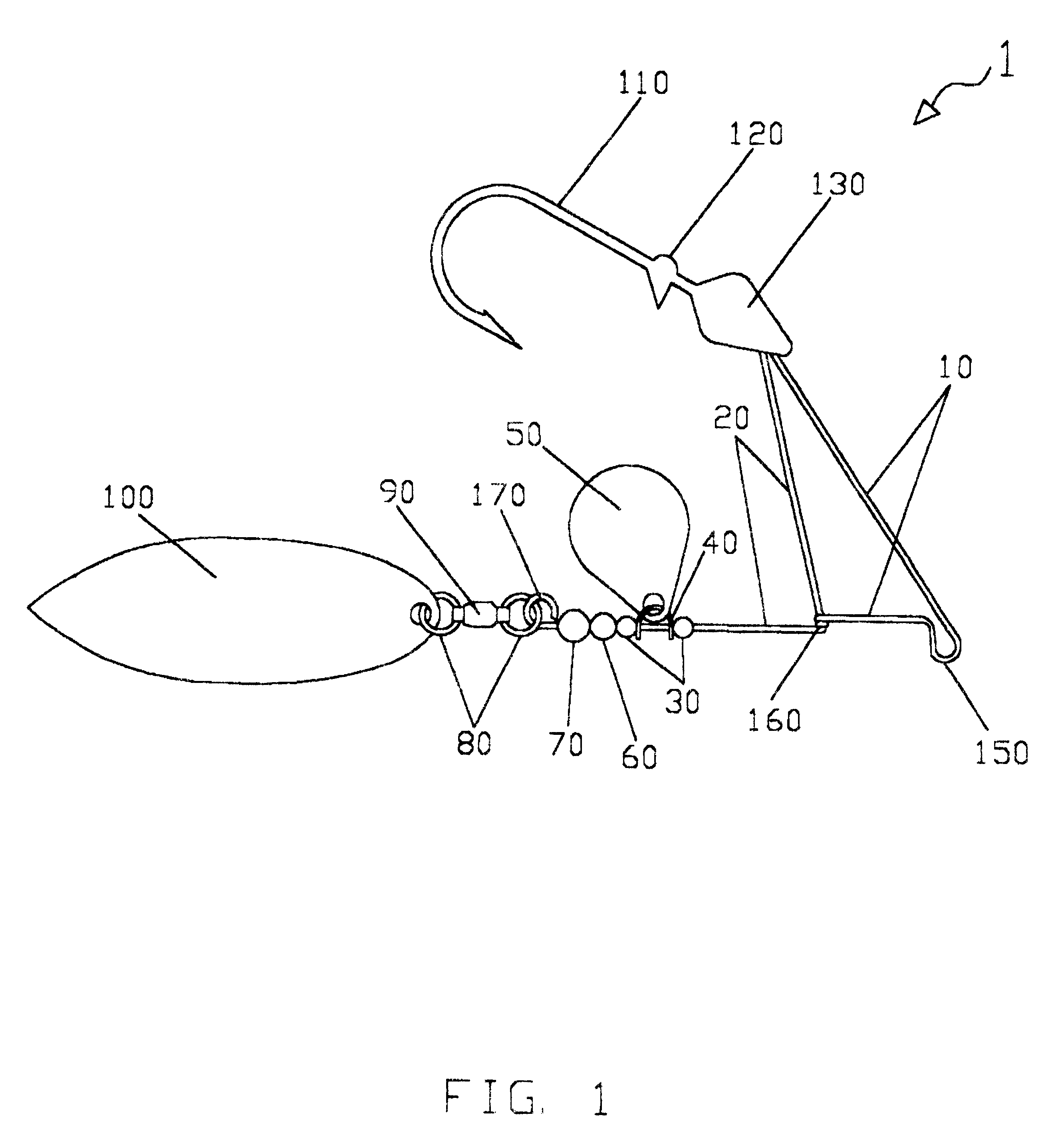

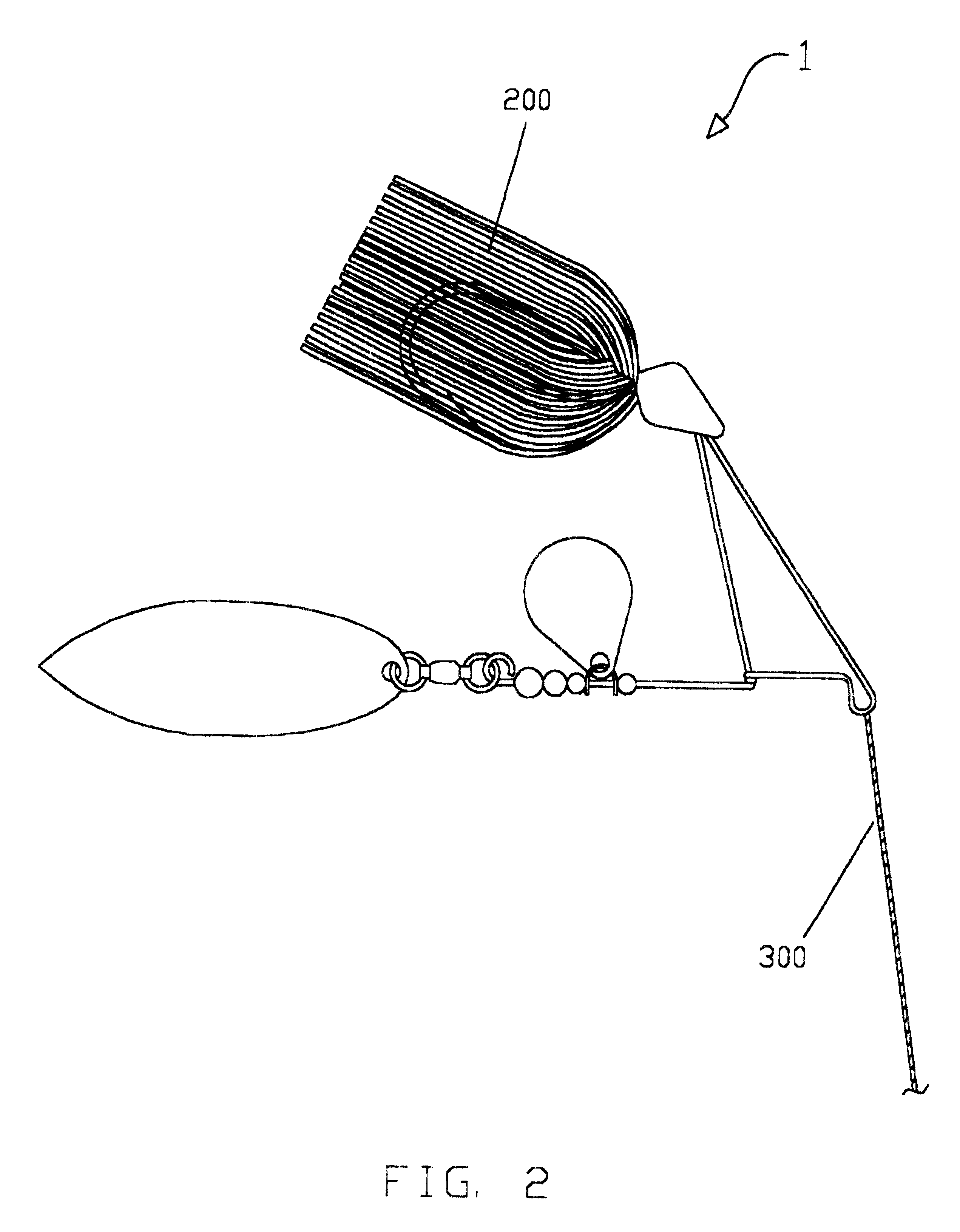

Double wire spinner bait

Disclosed is a double wire spinning bait lure. The lure preferably comprises a multi-piece construction, in particular, a hook, a molded lead head, two stainless steel wires connected to form a frame, and two spinning blades. The design of the lure is able to retain its original form and functionality after repeated use and provides a spinning effect that is capable of maintaining produces greater vibrations, thus, making the lure more attractive to fish and increasing the odds for catching more fish.

Owner:MOORE CHESTER C

Cosmetic composition containing hydrophilic spherical polymethylsilsesquioxane powder

InactiveUS20080118537A1Narrowing particleFeel smoothCosmetic preparationsImpression capsSuspending AgentsAqueous solution

A cosmetic composition is disclosed containing hydrophilic, spherical powder of polymethylsilsesquioxane having a particle size ranged from 1-20 microns with a narrow particle size distribution. The hydrophilic, spherical powder in the composition is prepared by a process comprising (1) hydrolyzing and condensing methyltrimethoxysilane in water in the presence of a thickener as suspending agent, an oil as surface tension modifier and an acid or base as catalyst to form spherical particles, (2) post-hydrolyzing the spherical particles in an aqueous NaOH solution and (3) purifying the spherical particles by repeated washing and vacuum stripping.

Owner:GRANT INDS

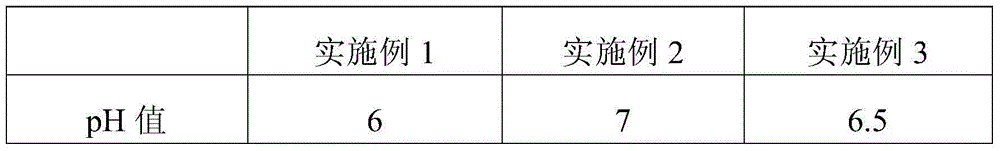

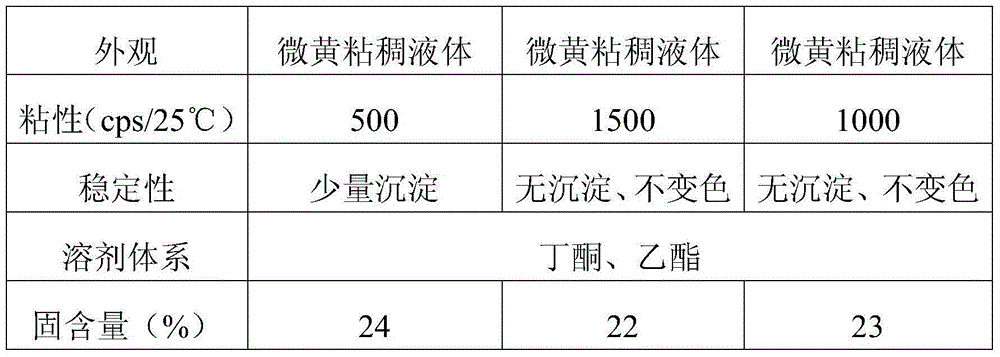

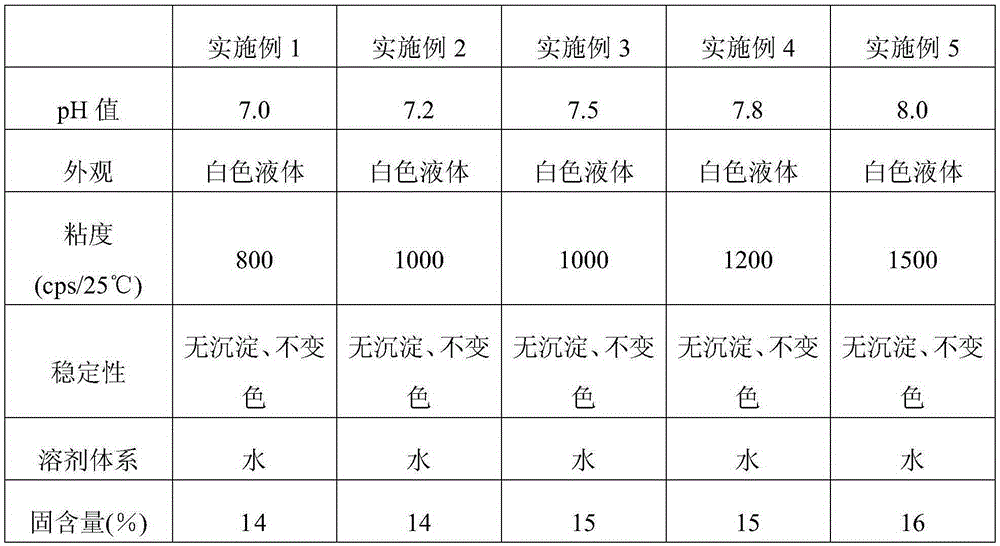

Matte injection-molding waxy-feel treatment agent for synthetic leather and preparation method thereof

InactiveCN103103777AComply with environmental standardsGood effectFibre treatmentExtinctionTherapeutic effect

The invention relates to a matte injection-molding waxy-feel treatment agent for synthetic leather. The matte injection-molding waxy-feel treatment agent is composed of the following components: modified polyurethane injection-molding resin, acetone, toluene, DMF (Dimethyl Formamide), silica extinction powder, wool grease, fatty acid salt and oleamide. The invention further relates to a preparation method of the matte injection-molding waxy-feel treatment agent for the synthetic leather. The matte injection-molding waxy-feel treatment agent for the synthetic leather has a good hand feel and a good comprehensive treatment effect and is environment-friendly; and the preparation method of the matte injection-molding waxy-feel treatment agent is simple in process and dispenses with the change of production equipment and the increase of cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

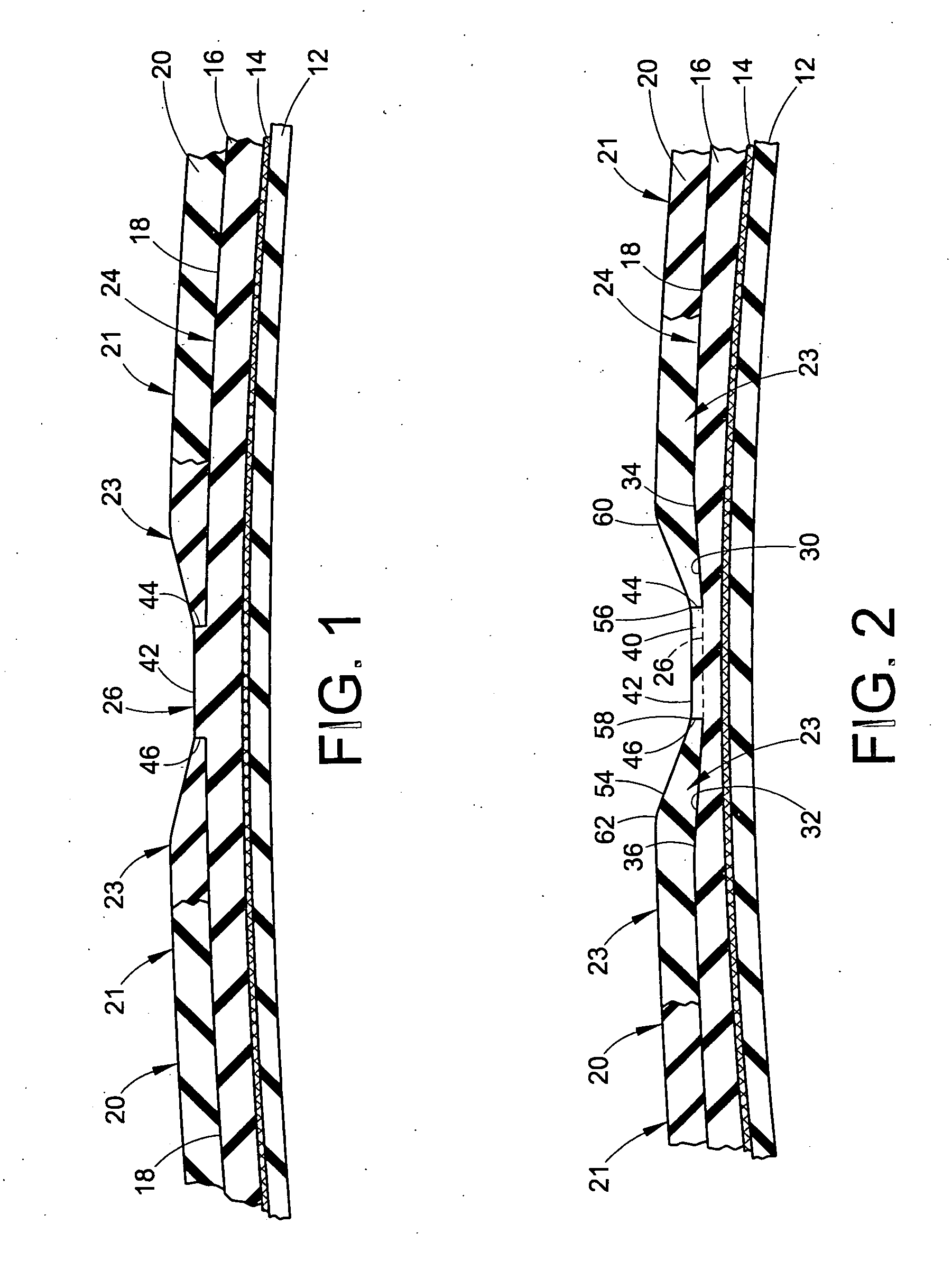

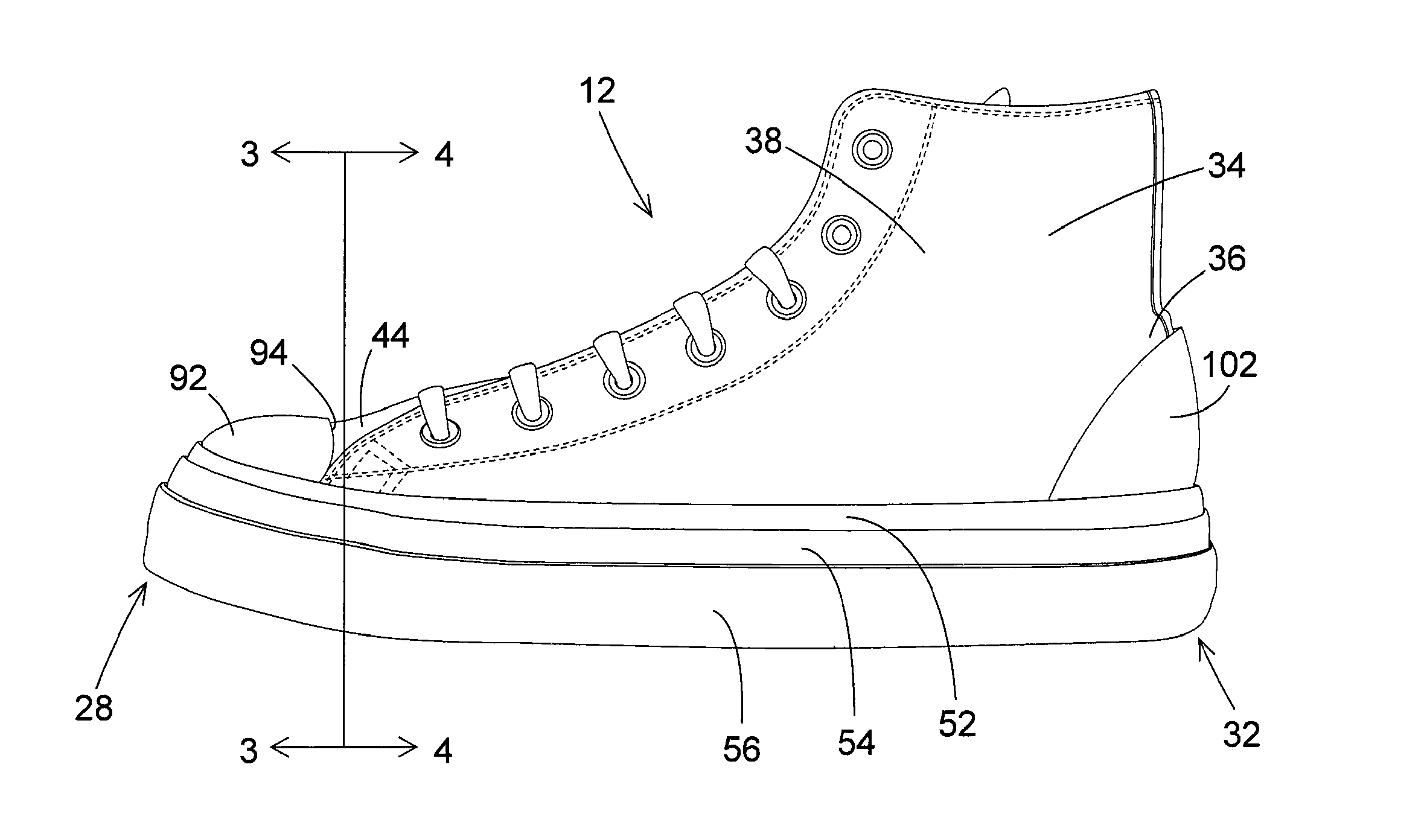

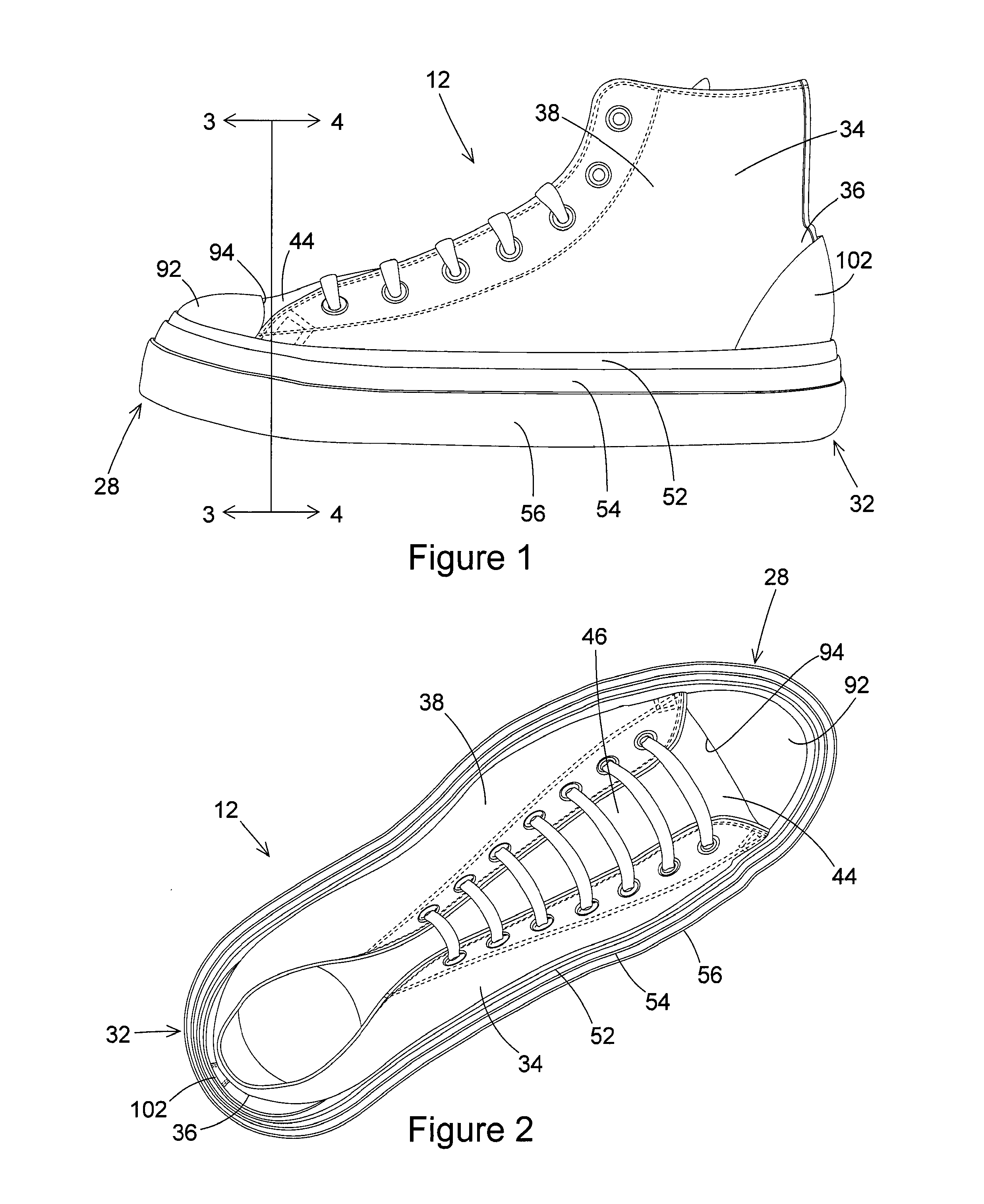

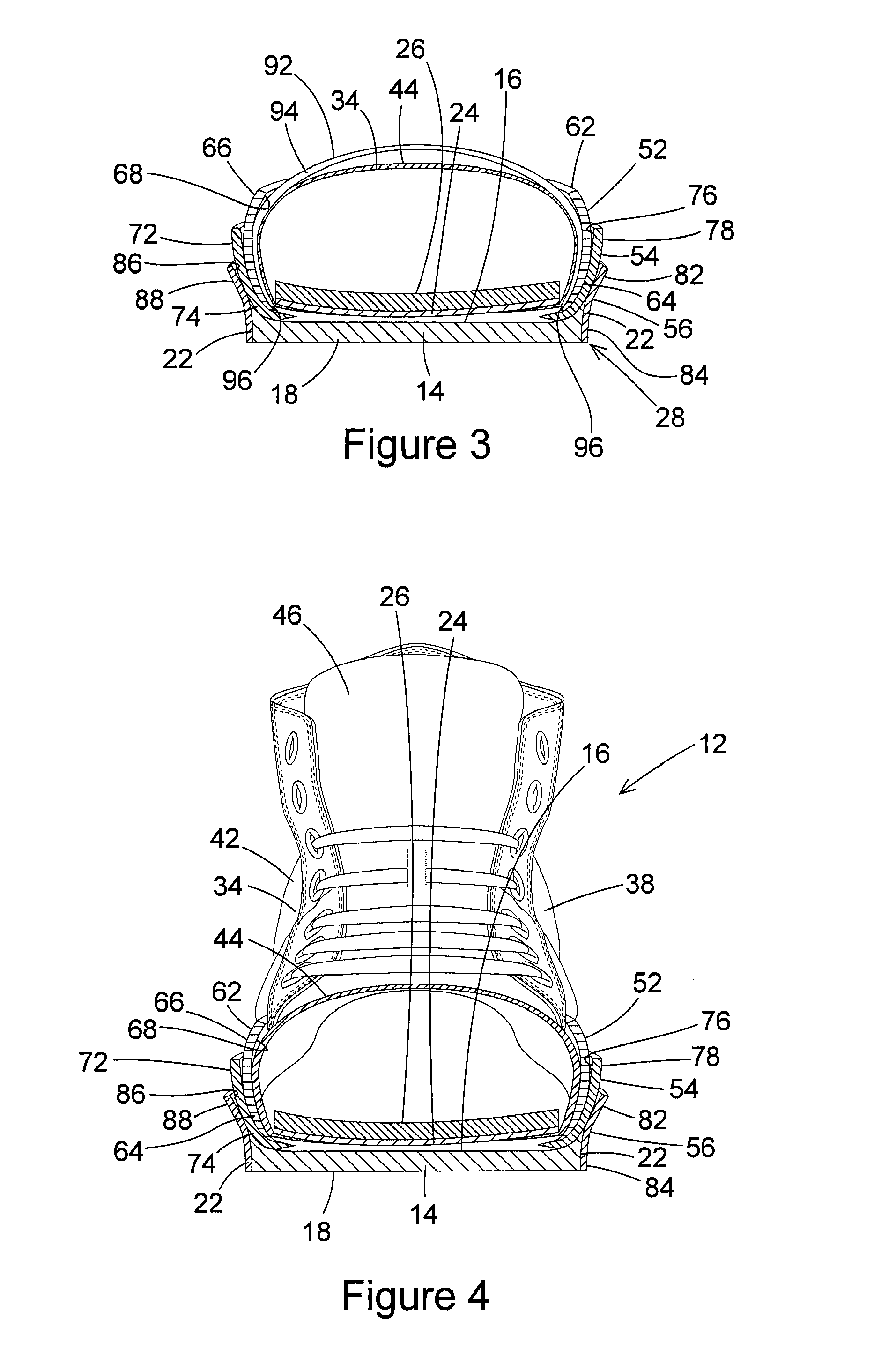

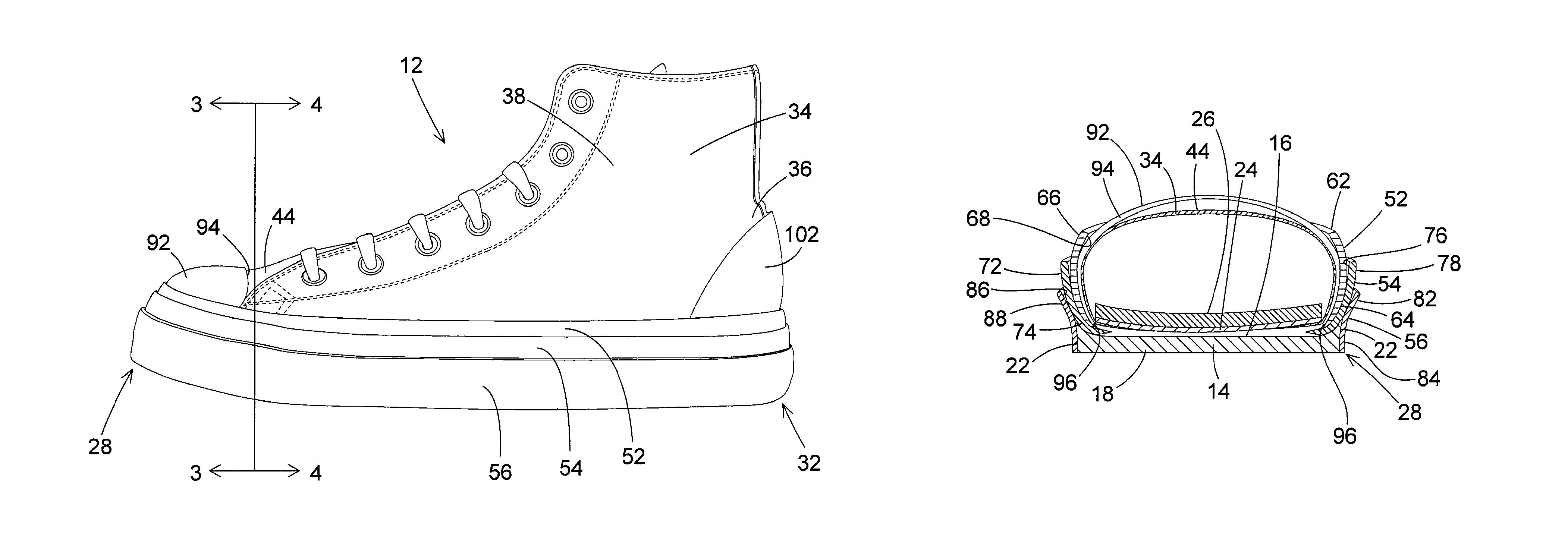

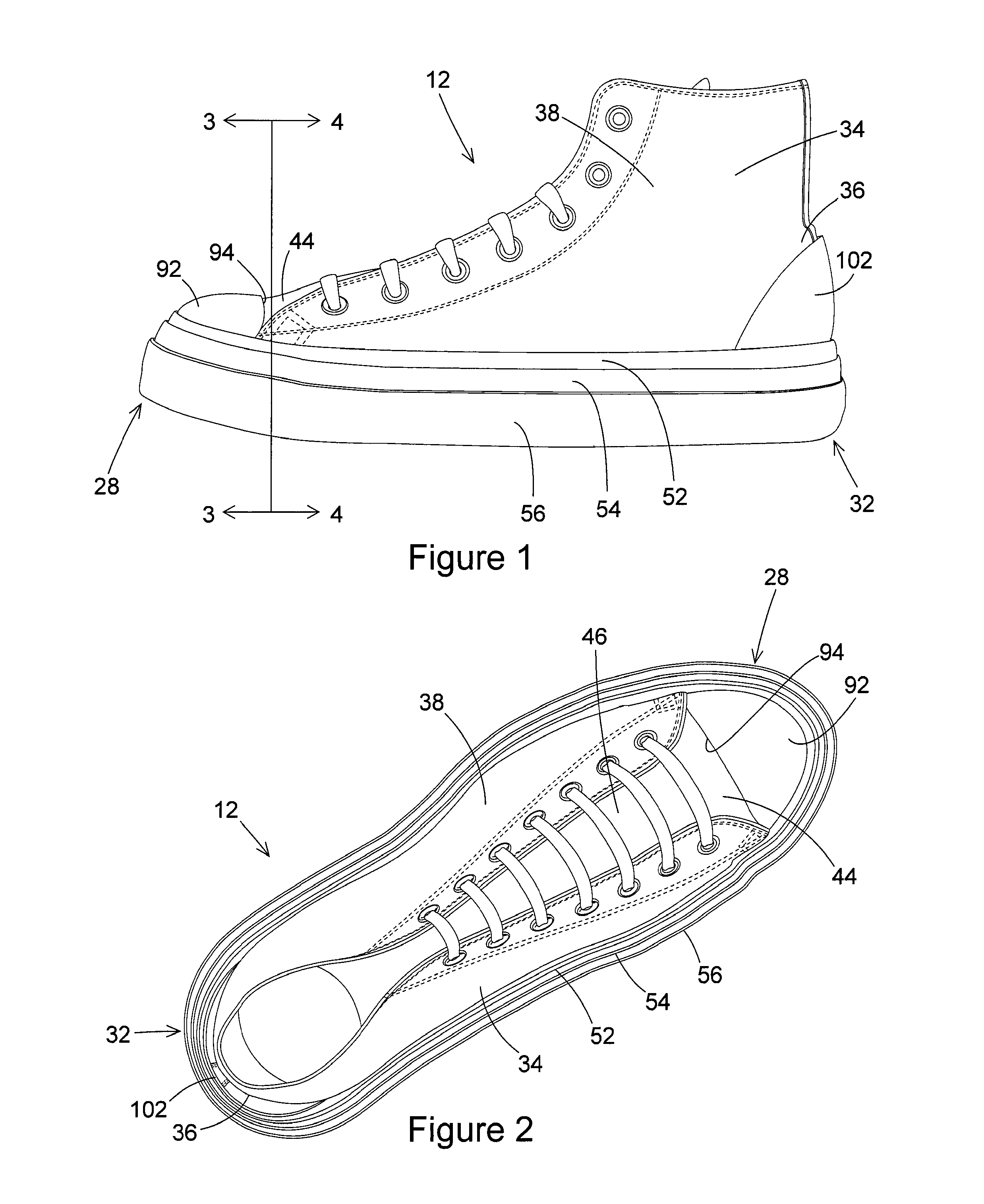

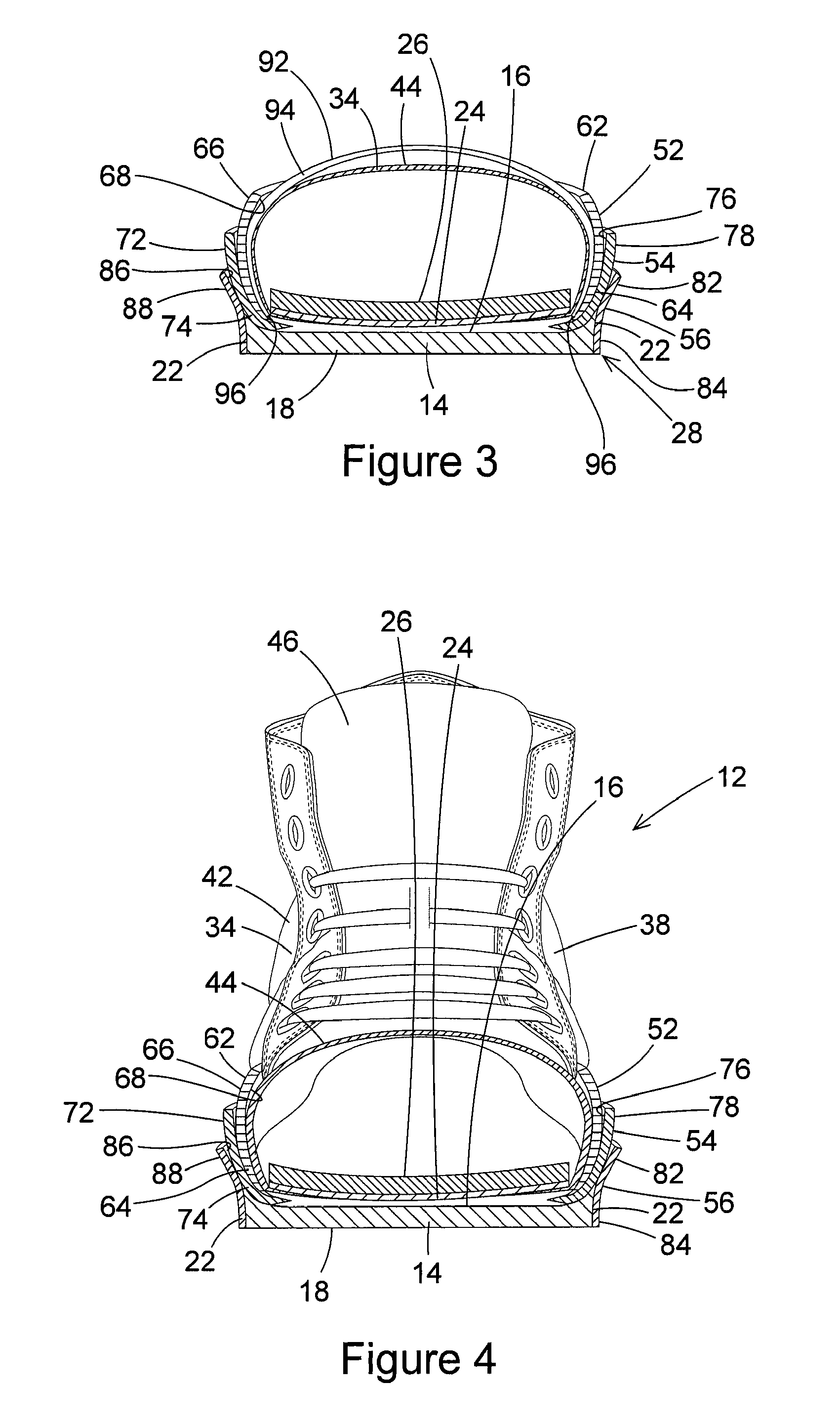

Footwear with Free Floating Upper

A novel shoe construction provides a unique fit and feel to the shoe wearer's foot. The shoe construction is a variation in what is typically called vulcanized shoe construction. Wherein the conventional vulcanized shoe construction bands of flexible material are permanently adhered or vulcanized to the shoe sole and to a portion of the upper adjacent the shoe sole, in the shoe construction of the invention upper sections of the bands are let loose by being unattached to the shoe upper. In addition, a toe cap of the shoe and a heel counter of the shoe are secured to the shoe sole, but are unattached to the shoe upper. This construction results in a shoe that not only has a unique appearance, but also has a unique feel to the shoe wearer's foot with the upper surrounding the foot being free floating along the sides of the foot as well as across the toes and heel of the foot.

Owner:CONVERSE

Soap with fragrant of golden chain for protecting skin, and fabricating technique

InactiveCN101050403AGood skin care and whitening effectUnique sense of beautyCosmetic preparationsToilet preparationsFlavorVegetable oil

This invention relates to a process for producing skincare fragrant soap containing Trollius chinensis. The process comprises: melting raw materials including fresh or dried Trollius chinensis, natural plant oil, natural essential oil, synthetic essence and soap matrix, stirring, and cooling. The skincare fragrant soap has bright Trollius chinensis in it, and has the natural fragrance of Trollius chinensis. Besides, the skincare fragrant soap has such advantages as natural fragrance, fine foam, and good appearance.

Owner:徐海波

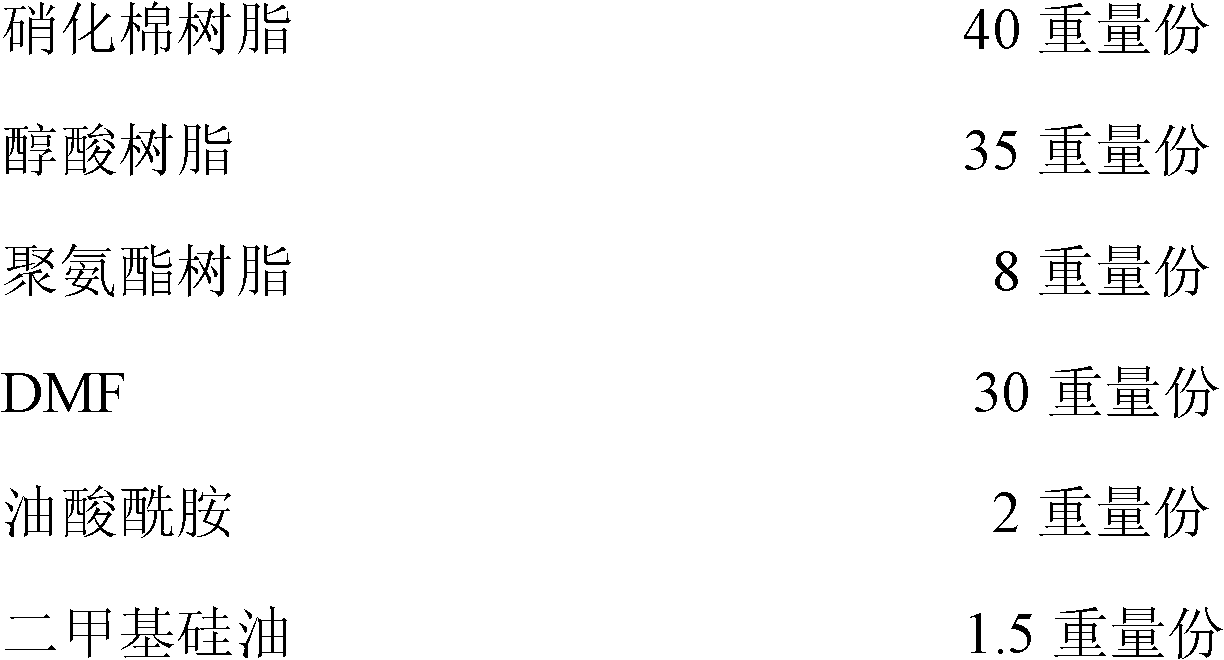

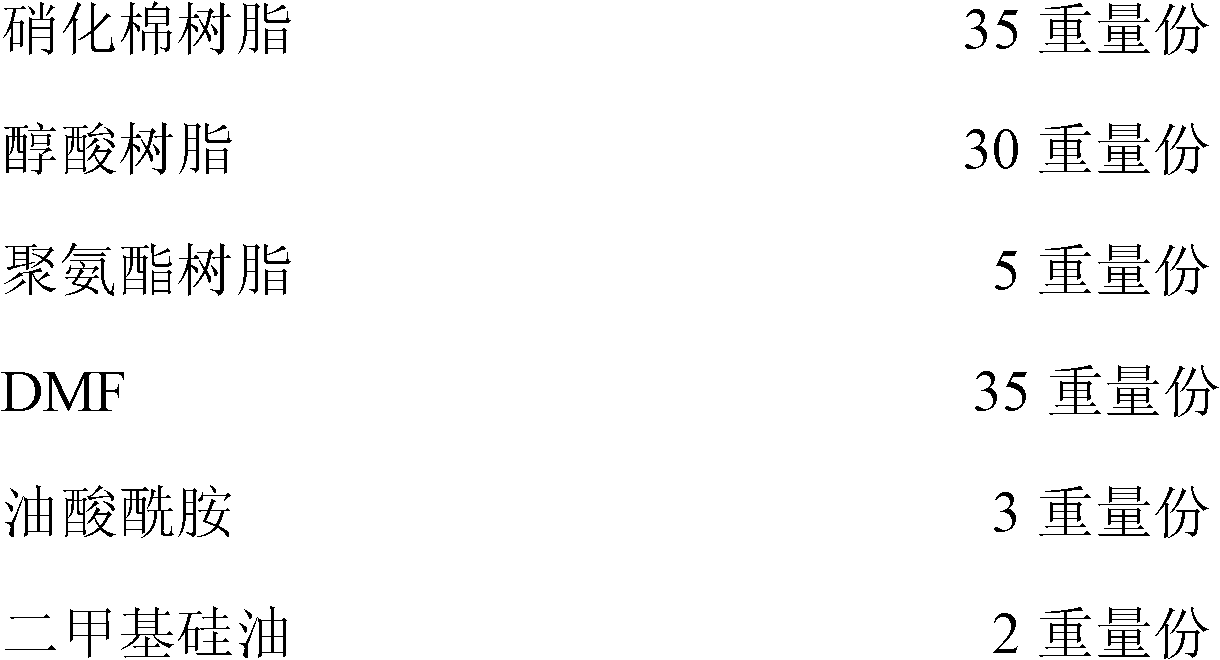

Burst resin for synthetic leather and preparation method of burst resin

The invention discloses burst resin for synthetic leather and a preparation method of burst resin. The burst resin for the synthetic leather provided by the invention consists of the following components: nitro-cotton resin, alkyd resin, urethane resin, DMF (Dimethyl Formamide), oleamide and dimethyl silicone oil. The burst resin for the synthetic leather provided by the invention is an environment-friendly material and meets an environmental protection standard of European Union; each component for constituting the burst resin for the synthetic leather has the advantages of good mud-cracking effect, glossy bright face, high transparency and unique handfeel of slippery wax; and the synthetic leather using the burst resin has a good comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Manufacturing method of FDY (fully drawn yarn) fine denier differentiation series products

InactiveCN102560701AChanging the internal orientation structure of the moleculeGood compatibilitySpinnerette packsMelt spinning methodsYarnEngineering

The invention discloses a manufacturing method of FDY (full drawn yarn) fine denier differentiation series products, which includes the following production steps of polymerizing in a final-polymerization kettle; distributing by a melt distributor, boosting by a boosting pump; conveying melts; cooling by a cooler, mixing by a static mixer, distributing by a melt distribution valve and spinning in a spinning box; extruding the melts through a metering pump; utilizing a spinning component and a circular blower; cooling and forming; applying oil on double oil nozzles; passing a spinning shaft; setting a pre-network; passing a first heat roll and a second heat roll; setting a main network; passing a yarn guider, a yarn breakage detector and a winder; doffing, dyeing and grading; and performing quality inspection and package, wherein spinneret plates with the ratio L / D of the length (L) to the diameter (D) of 3.56-3.75 are utilized in the step of spinning in the spinning box and staggered in a W-shaped manner, heating devices are arranged on the peripheries of the spinneret plates, the distance between the surface of each spinneret plate and an airless area at the upper end of the cooling blower is set to be 75mm in the step of passing the circular blower. Accordingly, the FDY fine denier differentiation series products manufactured by the manufacturing method are more excellent in quality.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

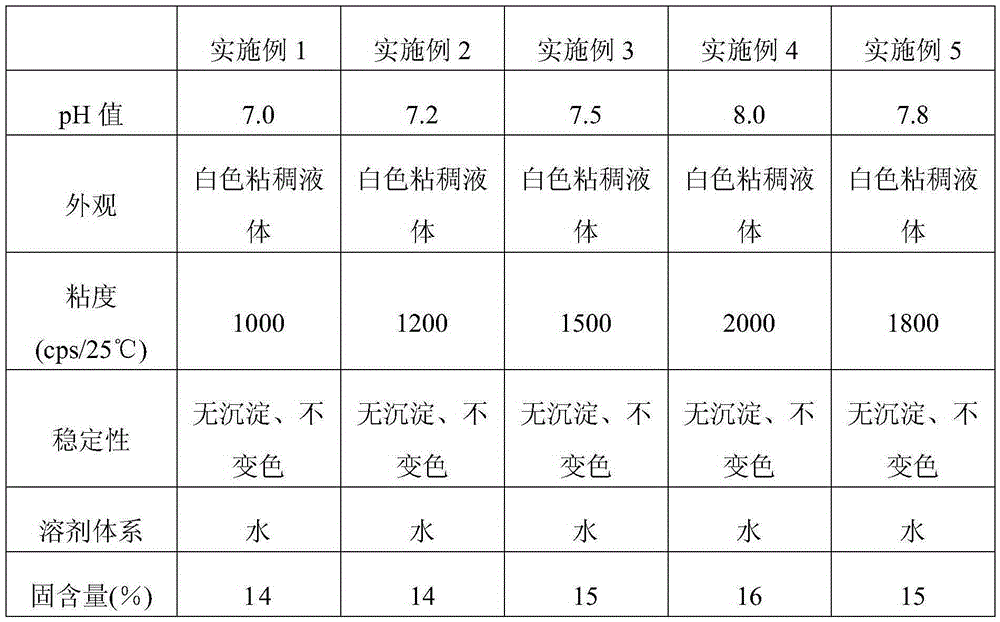

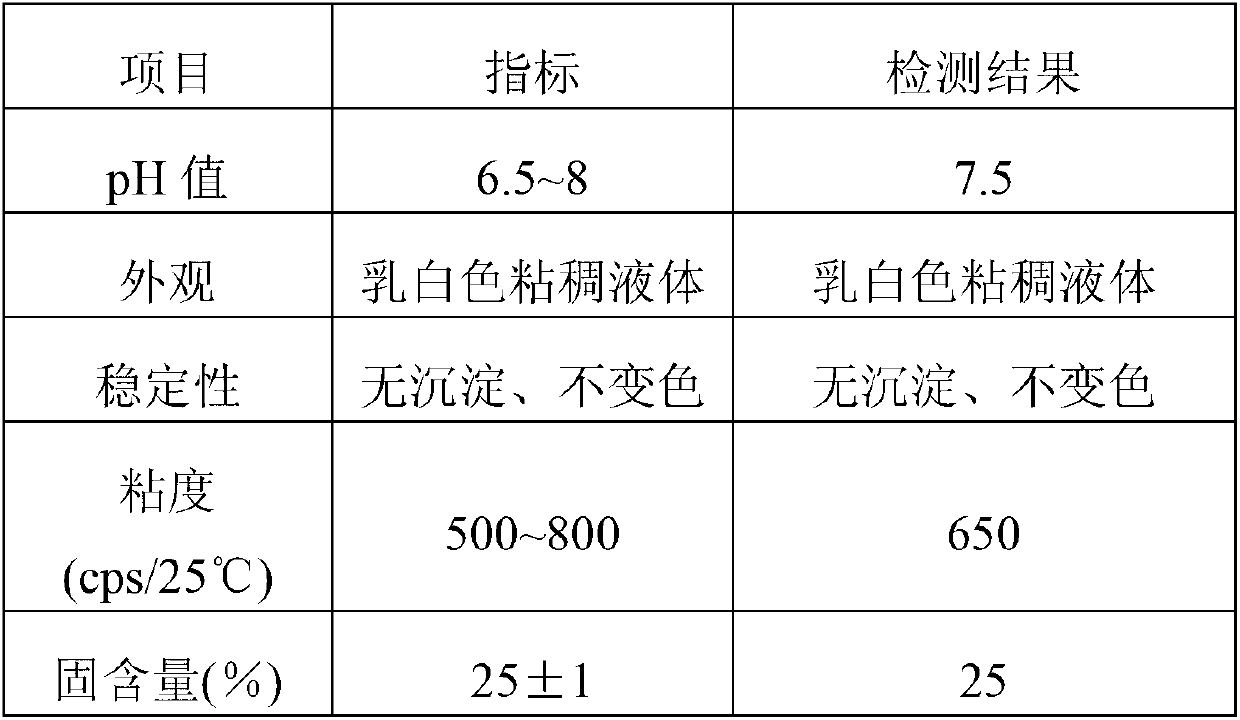

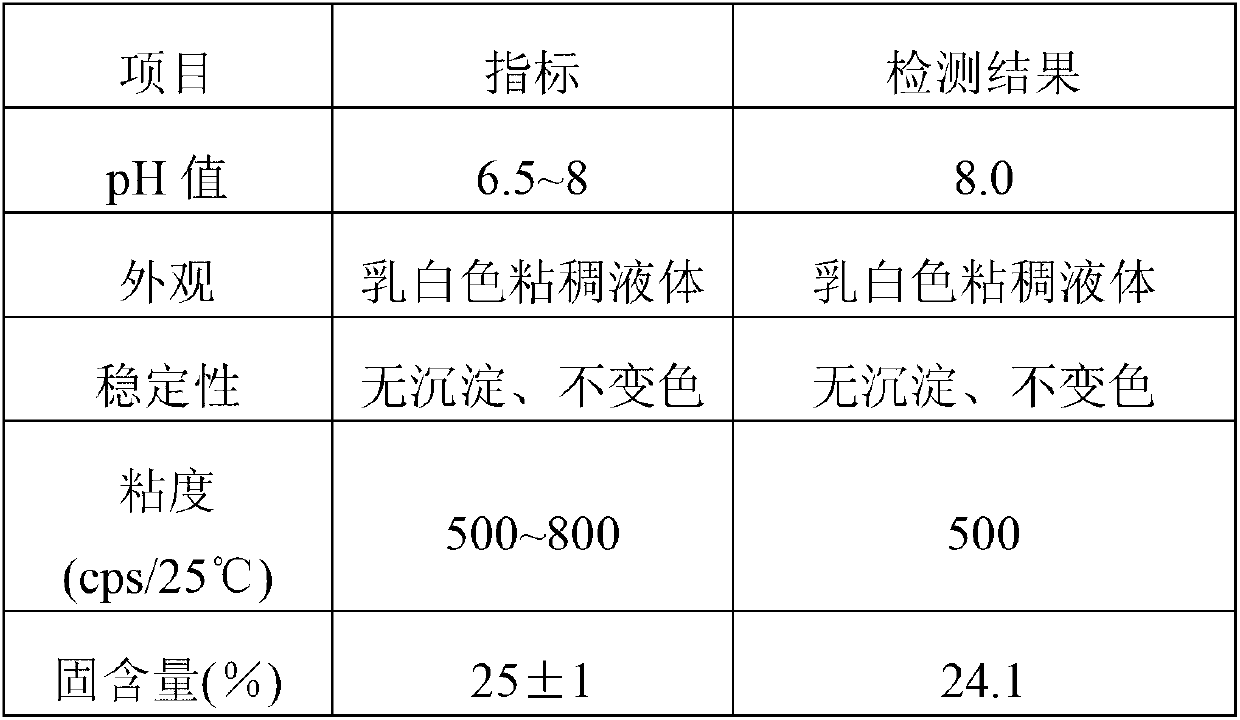

Water-based super-fogging super-blackening treating agent for synthetic leather and preparation method thereof

The invention relates to a water-based super-fogging super-blackening treating agent for synthetic leather, and the water-based super-fogging super-blackening treating agent is applied to a later period technology of the synthetic leather. The water-based super-fogging super-blackening treating agent is prepared from water-based resin, a water-based dispersing agent, a defoaming agent, silicon dioxide matting powder, a wetting agent, a Deuchem thickening agent and water. The invention further relates to a preparation method of the water-based super-fogging super-blackening treating agent for the synthetic leather. According to the water-based super-fogging super-blackening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster, better in color developing and excellent in comprehensive effect, meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based super-fogging super-blackening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU silky waxy-feeling treatment agent for synthetic leather and its preparation method

The invention relates to a water-based PU silky waxy-feeling treatment agent for synthetic leather and its preparation method. The treatment agent consists of water-based PU resin varnish, water-based amino-modified silicone oil, water, modified wax emulsion, silicon dioxide matting agent, organosilicon leveling agent, organosilicon defoaming agent and water-based PU thickening agent. The treatment agent realizes intercoordination and coaction of components of the treatment agent, has good film forming property and firm adhesive property, and forms coating with solvent resistance, cold resistance, hydrolysis resistance and thermal aging resistance, and synthetic leather treated via the treatment agent achieves perfect cloudy effect, unique silky hand feeling, strong real leather feeling, fine texture, air permeability and hand feeling, smoothness, water-proof property and wax feeling comprehensive effects.

Owner:JIANGSU BAOZE POLYMER MATERIAL

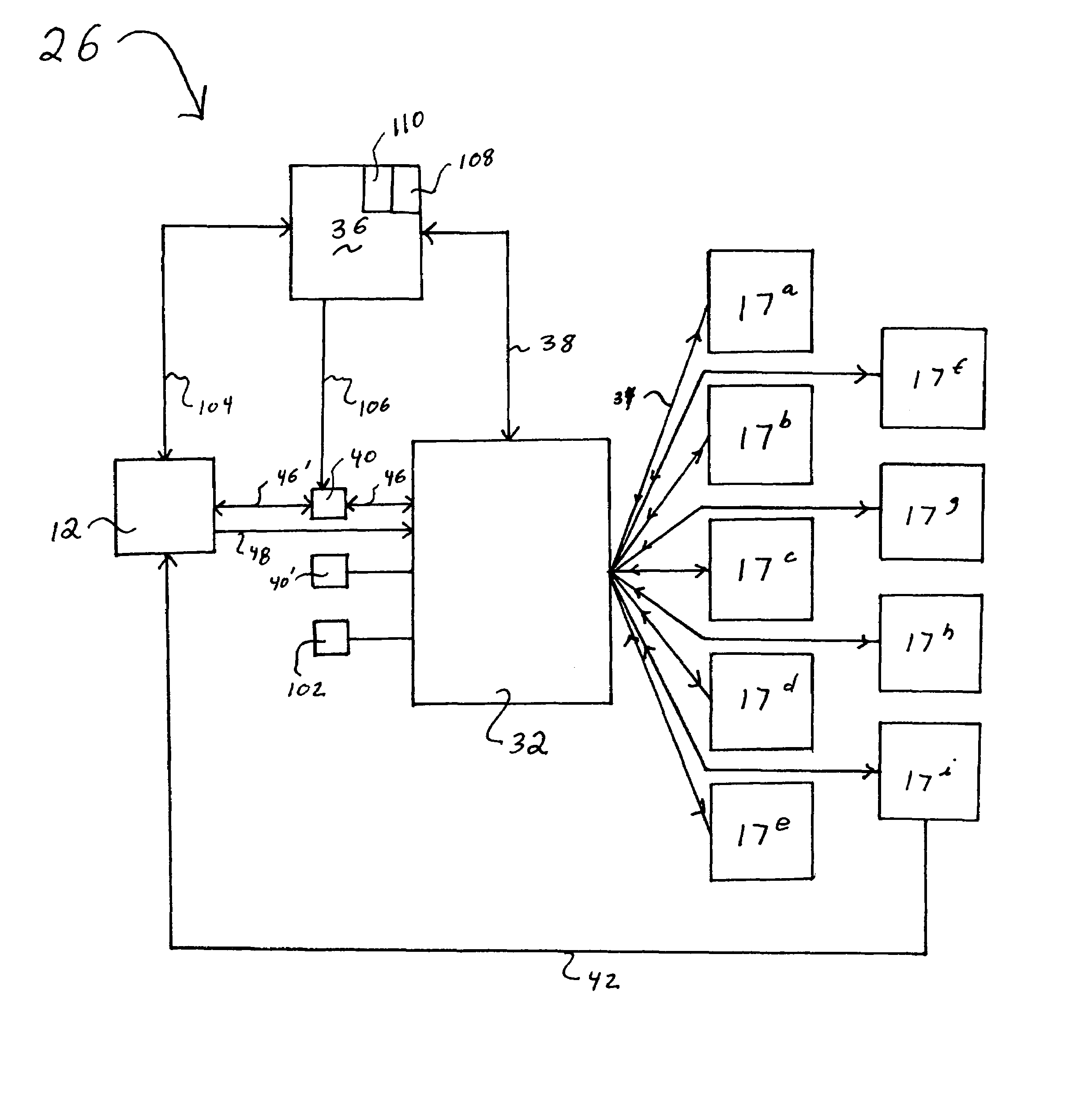

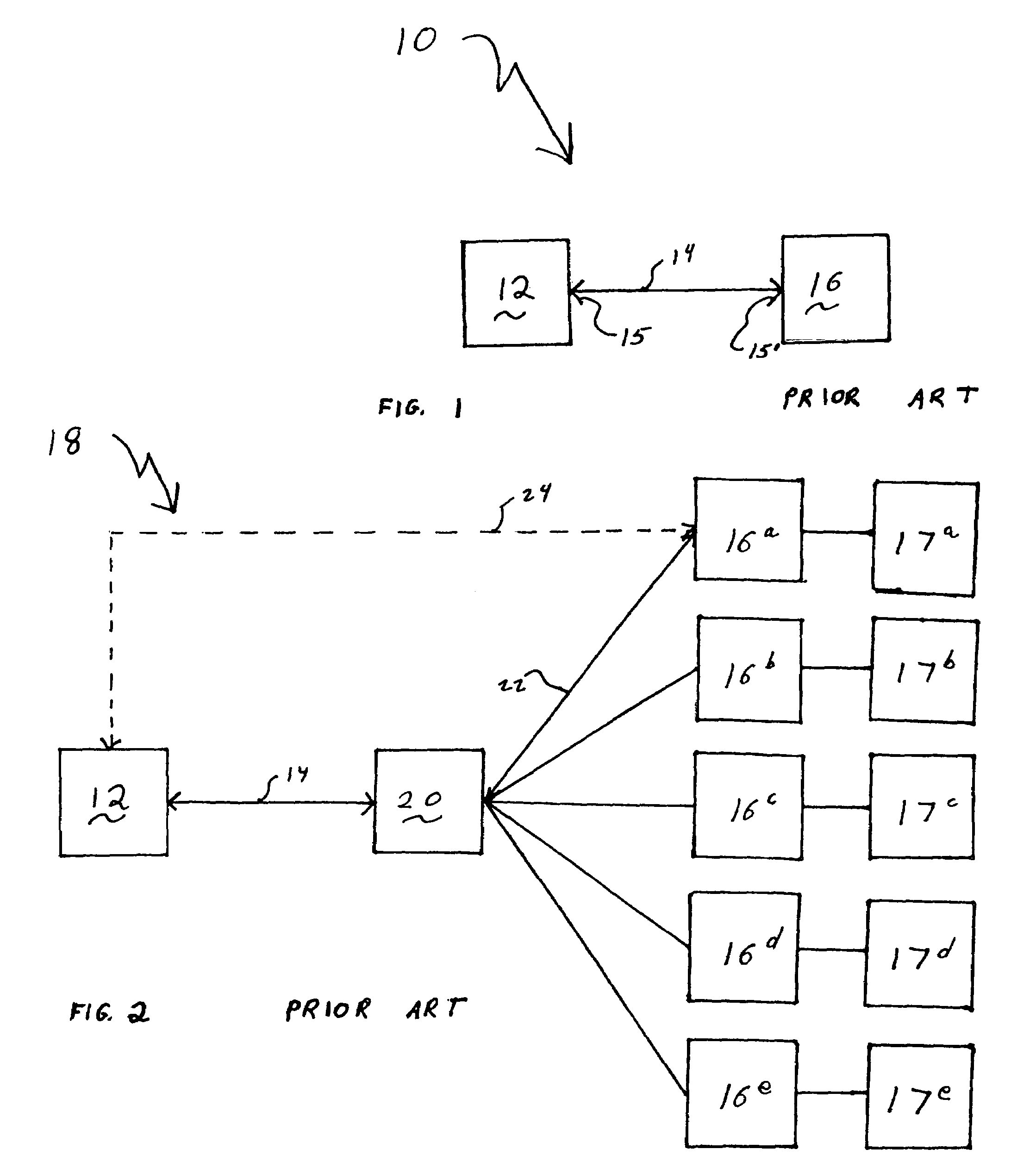

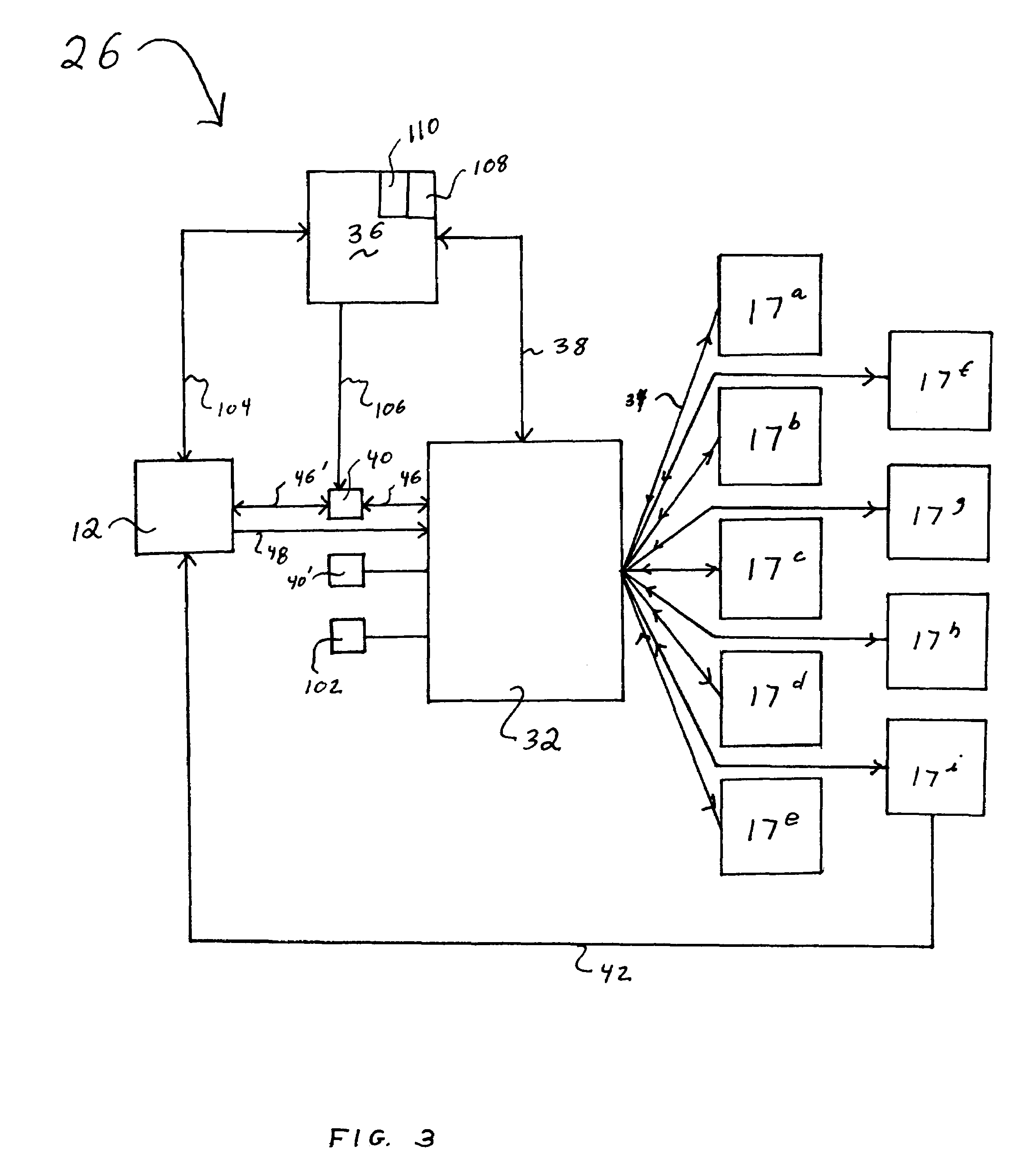

Method to create a customized e-commerce store

InactiveUS7634427B1Little and no costEasy to operateBuying/selling/leasing transactionsLogisticsProduct selectionE-commerce

An electronic commerce system includes a host with two-way communication to a plurality of distributors. Each of these distributors offers an addressable inventory of merchandise that consists of discrete items. The host sorts the discrete items according to a class designation such that members of a same class are assigned a unique tag. A store builder may electronically request at least one of the unique tags. The host then creates a customized store with a unique name, look and feel, and product selection for the store builder. This store provides a consumer with access, via said distributor, to items assigned that unique tag.

Owner:GOOGLE LLC

Yangbuck and cajiao treating agent for synthetic leather and preparation method thereof

The invention relates to a yangbuck and cajiao treating agent for synthetic leather. The treating agent comprises the following components: polyurethane gloss oil, DMF, acetone, silica matting powder, polytetrafluoroethylene wax powder, modified siloxane, yangbuck foam powder and a water-drawing agent. The invention also relates to a preparation method of the yangbuck and cajiao treating agent for synthetic leather. The treating agent and the preparation method have the advantages that the treating agent conforms to the environmental protection standard of EU; the synthetic leather treated with the treating agent has natural gloss and soft and smooth touch sense and has excellent comprehensive effects in handfeel, visual effect and the like; and the method is simple in process and lower in production cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

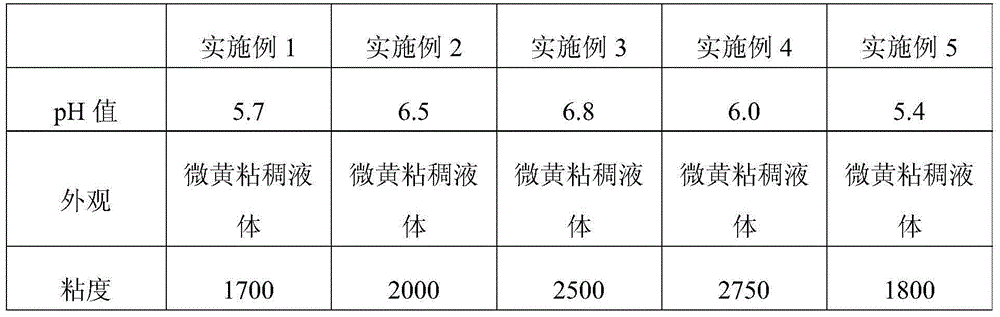

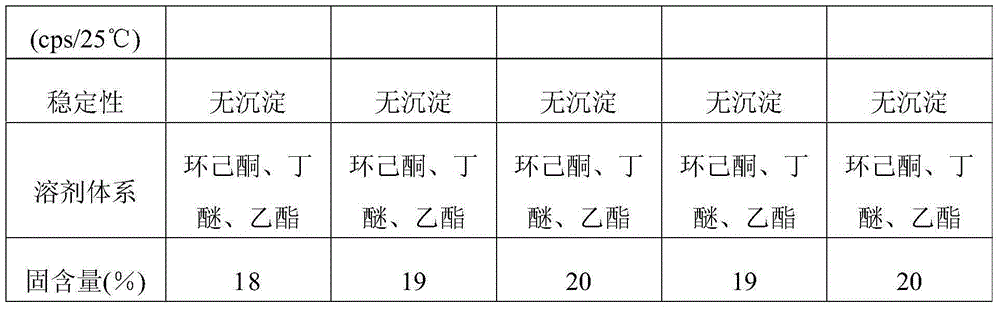

Scraping-resistant polishing treating agent for synthetic leather and preparing method thereof

InactiveCN105220466AStrong sense of transparencyUnique feelFibre treatmentProduction lineCyclohexanone

The invention relates to a scraping-resistant polishing treating agent for synthetic leather. The scraping-resistant polishing treating agent is used for the later-stage printing technology for the synthetic leather. The scraping-resistant polishing treating agent is prepared from polyurethane resin, nitrocotton, ethyl ester, cyclohexanone, butyl ether, silicon dioxide matting agents, methyl-phenyl silicone oil, organic silicone oil and dispersing agents. The invention further relates to a preparing method of the scraping-resistant polishing treating agent for the synthetic leather. The components of the scraping-resistant polishing treating agent for the synthetic leather are coordinated and carry out combined action, the polished surface of the leather is high in lucent feeling and unique in hand feeling, the leather treated with the treating agent is natural in luster and clear in color, the polished surface of the leather is quite good in scraping resistance, and the comprehensive effect is good; the scraping-resistant polishing treating agent is a novel material for later-stage printing and can be used for an existing synthetic leather production line, the technology is simple, production devices do not need to be changed, production cost can not be increased, and the scraping-resistant polishing treating agent can also be used for pretreatment and is wide in application range.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Luster improving polishing treatment agent for synthetic leather and preparation method thereof

The invention relates to a luster improving polishing treatment agent for synthetic leather and a preparation method thereof. The treatment agent comprises alkyd resin, nitro-cotton, butanone, butyl ether, ethyl ester, silica extinction powder, organic modified methyl phenyl silicone oil and a dispersing agent. The luster improving polishing treatment agent for synthetic leather is a novel material for back-section printing of synthetic leather. By application of the treatment agent, the leather surface of synthetic leather is natural in gloss, clear in color and luster and high in temperature resistance and can be subjected to embossing, and polished synthetic leather has a good surface brightening effect, a good leather effect and excellent comprehensive effects.

Owner:浙江宝泽高分子材料有限公司

Footwear with free floating upper

A novel shoe construction provides a unique fit and feel to the shoe wearer's foot. The shoe construction is a variation in what is typically called vulcanized shoe construction. Wherein the conventional vulcanized shoe construction bands of flexible material are permanently adhered or vulcanized to the shoe sole and to a portion of the upper adjacent the shoe sole, in the shoe construction of the invention upper sections of the bands are let loose by being unattached to the shoe upper. In addition, a toe cap of the shoe and a heel counter of the shoe are secured to the shoe sole, but are unattached to the shoe upper. This construction results in a shoe that not only has a unique appearance, but also has a unique feel to the shoe wearer's foot with the upper surrounding the foot being free floating along the sides of the foot as well as across the toes and heel of the foot.

Owner:CONVERSE

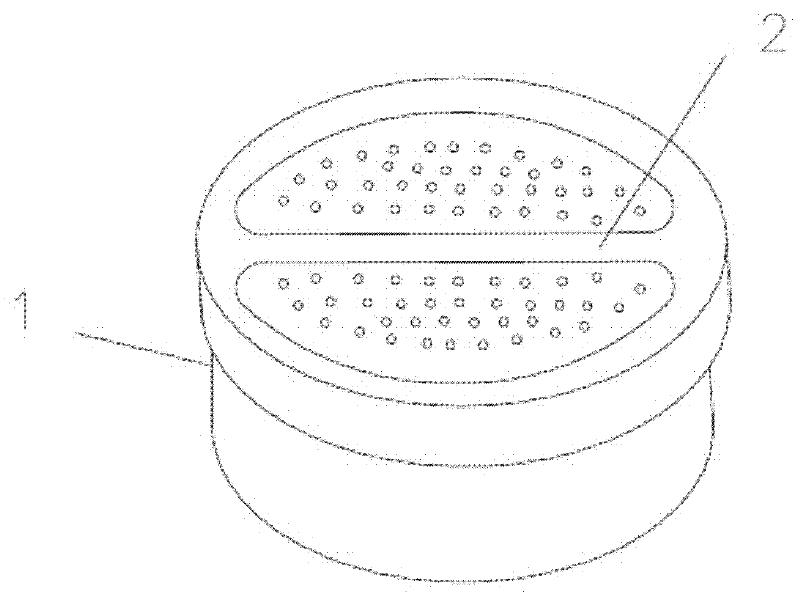

Hydraulic PU pressing color-changing resin for synthetic leather

The invention discloses a hydraulic PU pressing color-changing resin for synthetic leather; the hydraulic PU pressing color-changing resin is constituted by the following raw materials by weight percentage: 35-45 percent of waterborne polyurethane, 25-35 percent of water, 5-15 percent of silicon dioxide color changing powder, 5-10 percent of extinction powder, 0.3-1 percent of organic silicon flatting agents, 1-3 percent of silicone defoaming agents, and 0.5-2 percent of waterborne polyurethane thickeners. The hydraulic PU pressing color-changing resin for synthetic leather takes water as solvent, toxic solvents such as dimethyl fomamide and butanone are replaced, therefore, the hydraulic PU pressing color-changing resin has non-inflammable, safe, environmental-protection, cost-saving performances, and the pressing color-changingresin has the advantages of good film forming property, firm adhesion, solvent-proof, cold-resistance, hydrolyzation-resistance and heat-proof ageing coating. The finished products manufactured by the pressing color-changing resin has the advantages of full handle, good pressing double-color effect, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Radix isatidis antiviral fiber spunlace non-woven wet wipe base cloth and preparation method thereof

InactiveCN108950869AImprove performanceLong-lasting and stable effectCosmetic preparationsToilet preparationsPolyesterWet wipe

The invention relates to a Radix isatidis antiviral fiber spunlace non-woven wet wipe base cloth and a preparation method thereof, wherein the base cloth is made of the following raw material of weight ratio: the weight content of Radix isatidis antiviral fiber is 10-100%, the weight content of soybean protein fiber is 0-90%, the weight content of chitin fiber is 0-70%, the weight content of chitosan fiber is 0-70%, the weight content of antibacterial viscose fiber (or viscose fiber) is 0-70%, and the weight content of antibacterial polyester fiber (or polyester fiber) is 0-70%. The developedRadix isatidis antiviral fiber spunlace non-woven wet wipe base cloth not only has the characteristics of cleaning, nourishing, disinfecting and moisturizing and the like, but also has the functions of refreshing, sanitary, maintenance, nursing, quick and health care and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

High-color-fastness knitted fabric effectively prevented from ignition

InactiveCN106240000AThree-dimensionalAntibacterialWoven fabricsProtective garmentFiberColour fastness

The invention relates to a high-color-fastness knitted fabric effectively prevented from ignition. The high-color-fastness knitted fabric comprises a knitted fabric body. A radiation protection layer, an antistatic layer and a waterproof layer are sequentially arranged on the upper surface of the knitted fabric body. An antibacterial layer, an inflaming retarding layer, a waterproof layer and a closed-fitting layer are sequentially arranged on the lower surface of the knitted fabric body. A lining fabric layer is arranged on the back face of the closed-fitting layer. The lining fabric layer comprises wefts and warps which are interwoven, velveteen is interwoven between the warps and the wefts, the warps and the wefts are made of carbon fiber, the velveteen is made of cotton yarn, and an inflaming retarding layer, the waterproof layer and the antistatic layer are arranged on the velveteen from interior to exterior. The high-color-fastness knitted fabric effectively prevented from ignition has third dimension and has the functions of resisting bacteria, abrasion and inflaming, preventing radiation, water and static electricity and having high color fastness, and fabric ignition can be effectively prevented.

Owner:JIANGYIN YASHUN GARMENT

Skin-feel nap up and nap down jumbuck resin and preparation method thereof

The invention provides a skin-feel nap up and nap down jumbuck resin and a preparation method thereof. The skin-feel nap up and nap down jumbuck resin consists of the following components: modified urethane resin, toluene, butanone, modified organosilicon, foamed microspheres and an organic wax sheet. Compared with the jumbuck resin in the prior art, the skin-feel nap up and nap down jumbuck resin has the advantages of better color development, leveling property and stability; leather, which is made of the skin-feel nap up and nap down jumbuck resin provided by the invention, has unique hand-feel, an obvious nap up and nap down effect, a strong real leather effect and an excellent comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Kangti(fitness) cream and preparation method thereof

InactiveCN108969440APromote absorptionSolve the problem of poor absorptionCosmetic preparationsToilet preparationsHormone precursorPhysiology

The invention relates to a Kangti(fitness) cream and a preparation method thereof. By applying the Kangti cream, contained hormone precursor substances are absorbed in a transdermal manner; through blood circulation, hormone required by an antocrine body of a human body is stimulated until balance is reached, so that physiological functions are restored into a young health state, and thus, the effects of eliminating endocrine disorder, improving the skin qualitym and resisting aging are achieved; the Kangti cream is economic, convenient to use, good in permeability and is skin friendly and non-irritating, has no harm to the skin, and can be used for internally preserving the health and externally shaping; moreover, the problem in the prior art is solved.

Owner:山东华夏良子健康管理有限公司

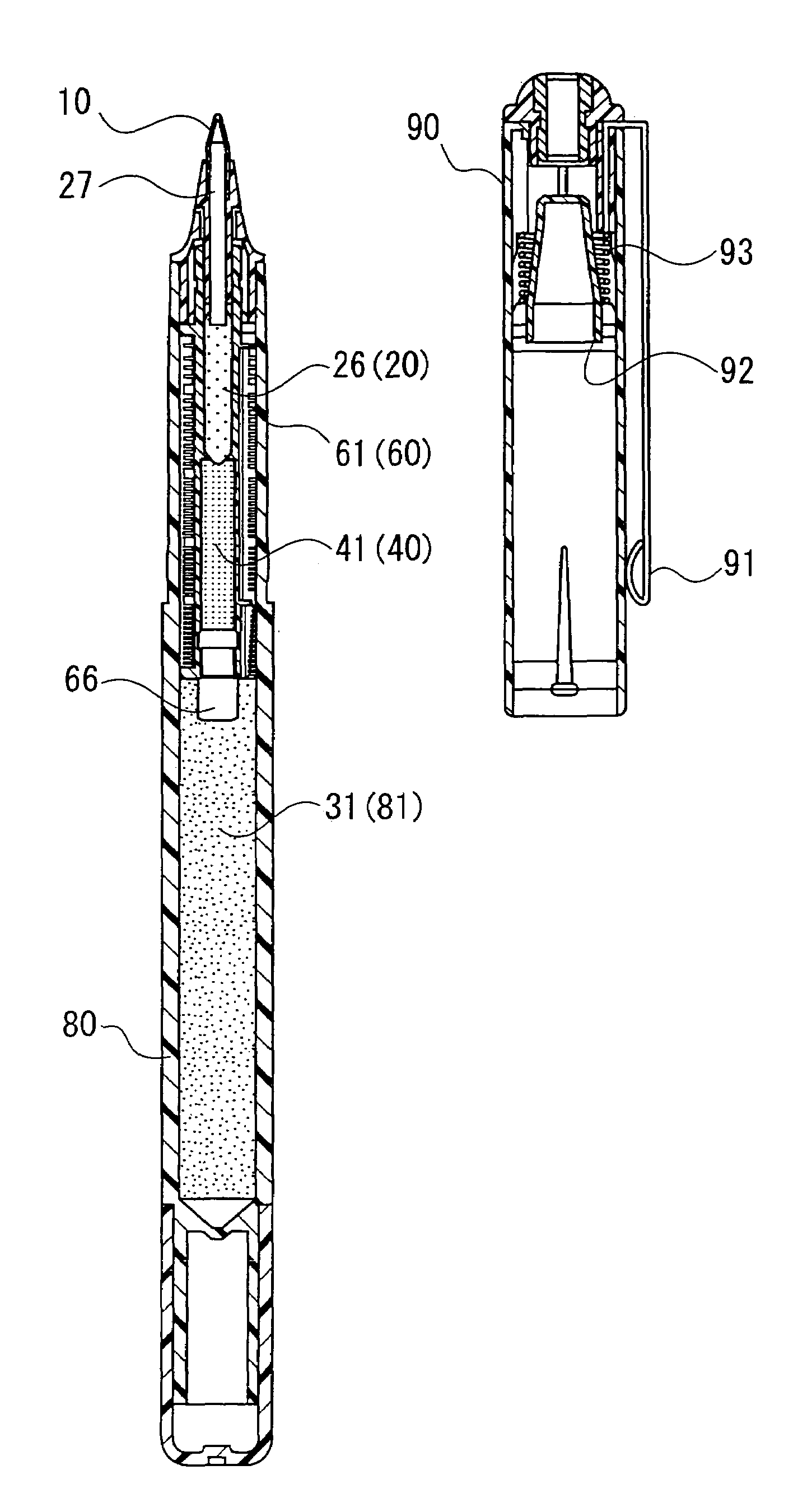

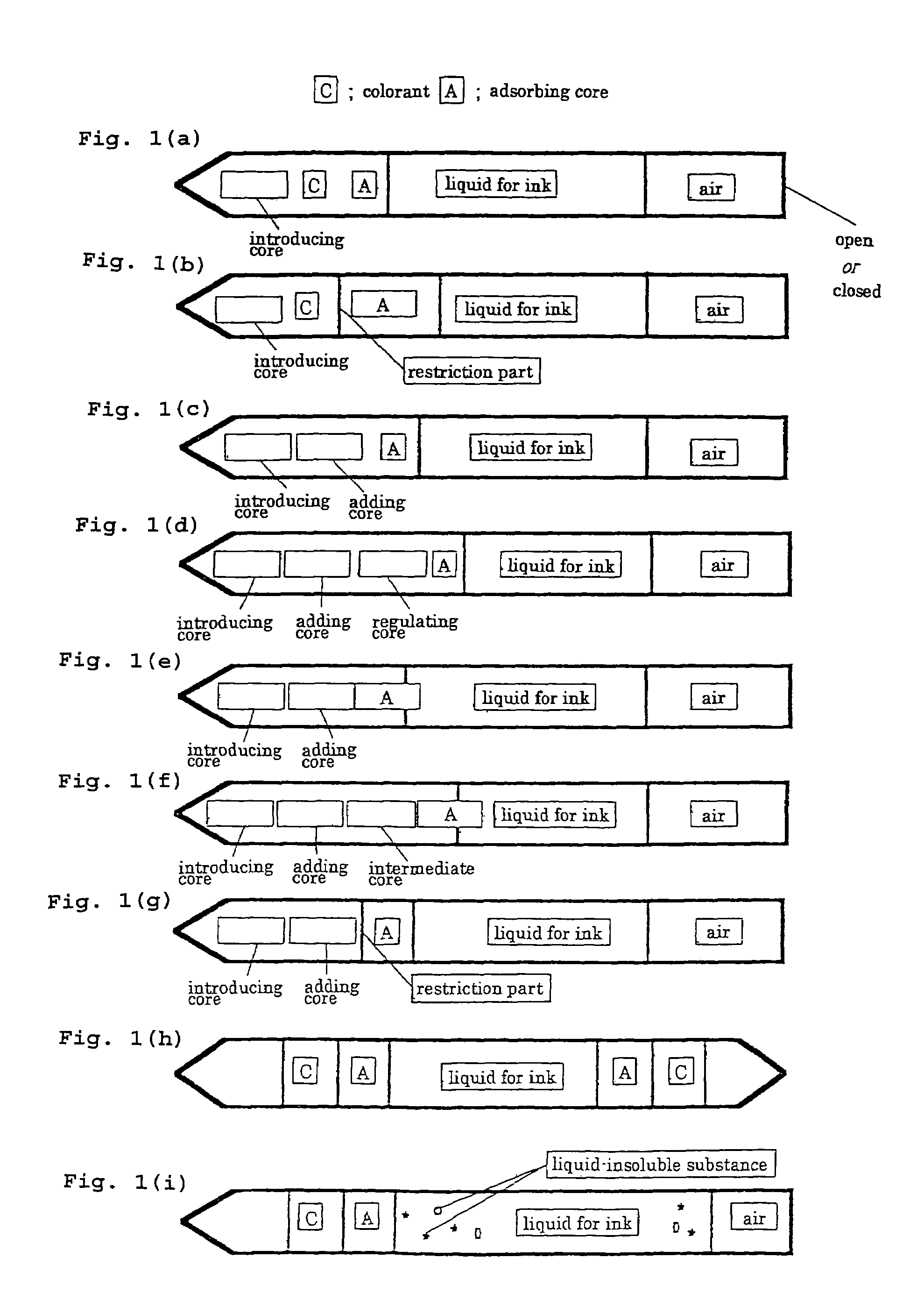

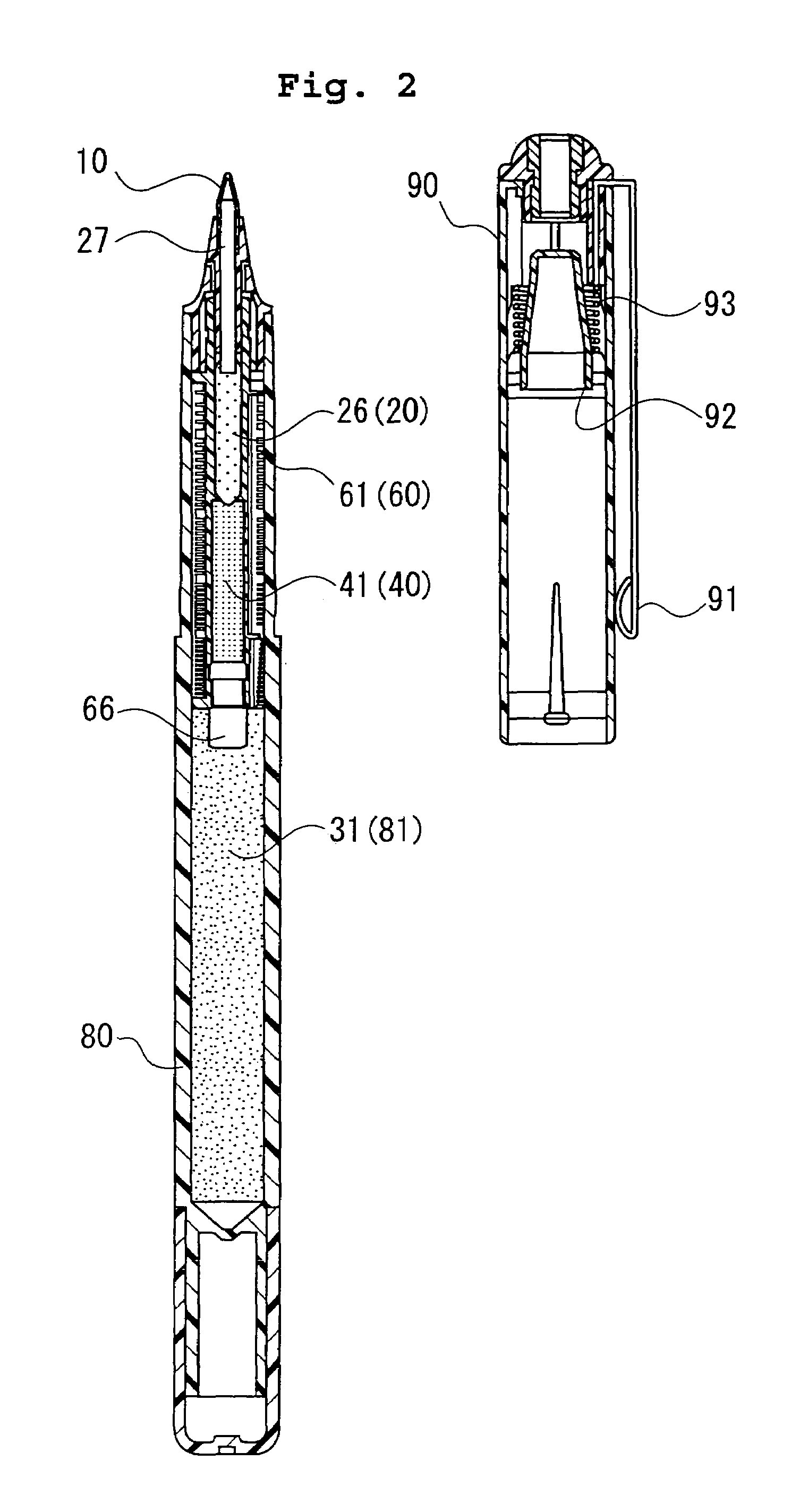

Writing implement

InactiveUS7083349B2Prevent leakageUnique feelBrushesBall-point pensEngineeringMechanical engineering

A writing implement includes a cylindrical shaft member, a pen tip member which is fixed to one end of the shaft member and from which colored ink seeps out, liquid for ink which is stored in the shaft member and which comprises a part of the colored ink seeping out from the end of the pen tip member, and colorant to be added to the above described liquid for ink to be the colored ink. Moreover, at least a part of a cylindrical side surface of the shaft member corresponding to the storing part of the liquid for ink is formed to be transparent. Between the liquid for ink and the colorant-storing part storing the colorant is provided a colorant-adsorbing core which introduces the liquid for ink into the colorant-storing part while capturing the colorant diffusing toward the storing part of the liquid for ink.

Owner:MITSUBISHI PENCIL CO LTD

Waterborne matte polishing treatment agent for synthetic leather and preparation method thereof

InactiveCN103103786ANon-combustibleEnvironmentally friendlyFibre treatmentEmulsionTherapeutic effect

The invention relates to a waterborne matte polishing treatment agent for synthetic leather. The waterborne matte polishing treatment agent is composed of the following components: waterborne polyurethane resin varnish, modified polyurethane emulsion, water, silica extinction powder, methoxy silicone oil, penetrant, an organosilicone levelling agent, an organosilicone defoamer and a waterborne polyurethane thickener. The invention further relates to a preparation method of the waterborne matte polishing treatment agent for the synthetic leather. The waterborne matte polishing treatment agent for the synthetic leather has a good hand feel and a good comprehensive treatment effect and is environment-friendly; and the preparation method of the waterborne matte polishing treatment agent is simple in process and dispenses with the change of production equipment and the increase of cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

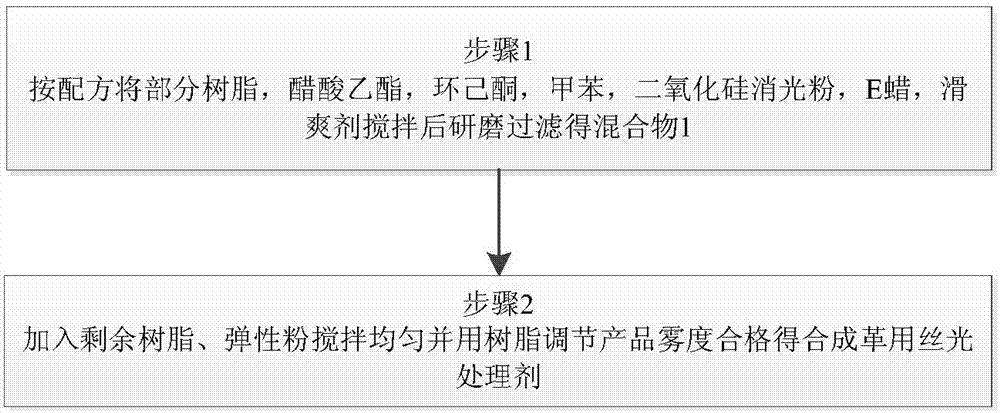

Mercerizing agent for synthetic leather and preparation method thereof

The invention relates to a mercerizing agent for synthetic leather. The mercerizing agent comprises the following components in parts by mass: 30-35 parts of resin, 5-7 parts of acetic ester, 35-37 parts of toluene, 13-17 parts of cyclohexanone, 0.4-0.8 parts of silica matting powder, 0.6-1 part of E wax, 5-10 parts of elastic powder, and 0.1-0.3 parts of a smoothing agent. The invention also discloses a preparation method of the mercerizing agent for synthetic leather. Partial resin, acetic ester, cyclohexanone, toluene, silica matting powder, E wax, and the smoothing agent are stirred according to the formula, grinding and filtering are carried out in order to obtain a mixture 1, residual resin and the elastic powder are added into the mixture 1 with uniform stirring, resin is used for adjusting haze of a product, after the product is qualified, the mercerizing agent for synthetic leather is obtained; after treatment, the leather surface has good layering, unique hand feeling and good haze; leather prepared by using the mercerizing agent has natural luster, clear color, good mercerizing effects, good scraping resistance, and good integrative effects.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Oil-wax polishing treatment agent for synthetic leather and preparation method thereof

The invention relates to an oil-wax polishing treatment agent for synthetic leather. The oil-wax polishing treatment agent for the synthetic leather is applied to a posterior printing technology of the synthetic leather and comprises the following components: nitrocotton, butyl ester, butyl ether, silicon dioxide extinction powder, methyl phenyl silicone oil, organic silicone oil and a dispersing agent. The invention also relates to a preparation method of the oil-wax polishing treatment agent for the synthetic leather. The oil-wax polishing treatment agent for the synthetic leather has the advantages that all the components are mutually coordinated and act jointly, crystalistic sense of polished leather surface is strong, handfeel is unique, and the leather obtained by virtue of the oil-wax polishing treatment agent is strong in oil-wax feel, clear in colour and lustre and excellent in comprehensive effect; meanwhile, the oil-wax polishing treatment agent for the synthetic leather is a novel material applied to posterior printing and can be applied to an existing synthetic leather production line, technology is simple, production equipment does not need to be changed, and production cost can not be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

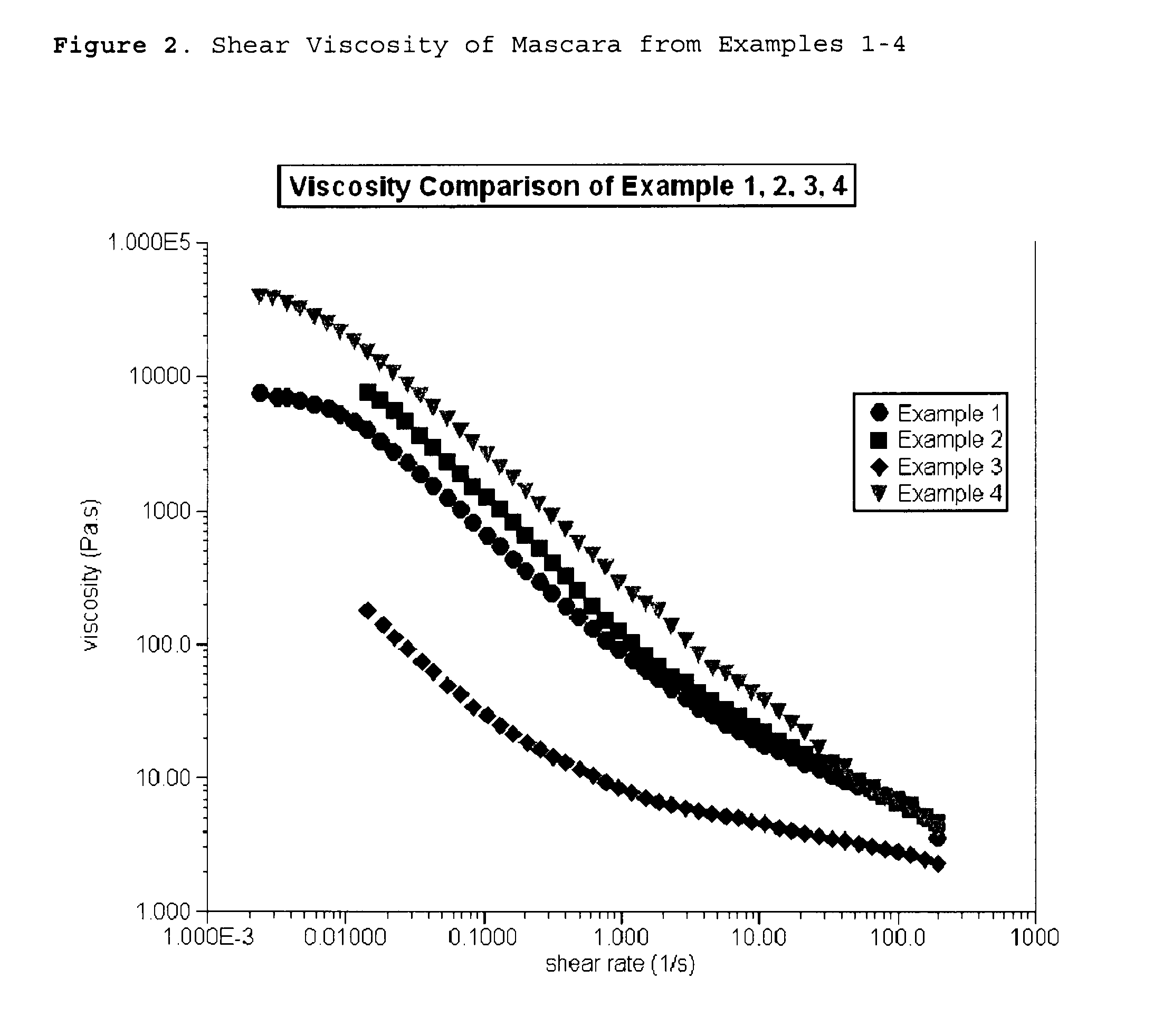

Volumizing smudge resistant mascara composition

The present invention is directed to a volumizing eye make-up composition having a creamy texture and feel containing: (a) at least one alkyl ethoxylated polymer wax; (b) at least one polar modified polymer; (c) water; (d) optionally, at least one non-volatile solvent; (e) optionally, at least one volatile solvent; and (f) at least one colorant, and wherein the composition preferably has a solids content of less than 40% by weight, based on the weight of the composition.

Owner:LOREAL SA

Water-based fog-washing and brightening treating agent for synthetic leather and preparation method thereof

InactiveCN105316946ANo pollution in the processNo health hazardFibre treatmentProduction lineWater based

The invention relates to a water-based fog-washing and brightening treating agent for synthetic leather, and the water-based fog-washing and brightening treating agent is applied to a later period technology of the synthetic leather. The water-based fog-washing and brightening treating agent is prepared from water-based resin, a water-based thickening agent, a defoaming agent, silicon dioxide matting powder, a levelling agent, propylene glycol monomethyl ether and water. The invention further relates to a preparation method of the water-based fog-washing and brightening treating agent for the synthetic leather. According to the water-based fog-washing and brightening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster and excellent in comprehensive effect after being washed; meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based fog-washing and brightening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-borne skin-touch lustering material treating agent for synthetic leather and preparing method thereof

InactiveCN106367973ANatural lusterClear colorHeat resistant fibresGrip property fibresSilicon dioxidePigment

The invention relates to a water-borne skin-touch lustering material treating agent for synthetic leather and a preparing method thereof. The water-borne skin-touch lustering material treating agent is prepared from water-borne resin, smooth hand feeling agent, antifoaming agent, silicon dioxide matting agent, wetting agent, German thickener, water and BCS. The components of the water-borne skin-touch lustering material treating agent mutually coordinate and act together, the treated material has the advantages of a unique hand feeling and no occurrence of crack at high baking temperature, meanwhile, a prepared spray finished dilute solution has good storage stability, and a pigment is not prone to sedimentation. Leather prepared by the treating agent is natural in luster, clear in color, and good in color developing and general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

High-viscosity water-based suede-like water-based resin and preparation process thereof

InactiveCN109972413AHigh solid contentExcellent self-thickening propertyTextiles and paperPolyesterFiber

The invention discloses a high-viscosity water-based suede-like water-based resin. The high-viscosity water-based suede-like water-based resin is prepared from, by weight, waterborne polyurethane resin, matting powder, foam powder, deionized water, suede powder and a thickening agent and can also be prepared from a carbon fiber part, a spandex fiber part, a raw bamboo fiber part and a coupling part; the waterborne polyurethane resin is prepared from polyether polyol, polyester polyol, isocyanic acid, deionized water, a primary chain extender and a secondary chain extender, wherein the primarychain extender is prepared from 2,2-dihydroxymethyl butyric acid, tributylmethoxy tin and methyl fluoronic acid, and the secondary chain extender is selected from amine chain extenders. The preparation method comprises the steps that the isocyanic acid is added for a reaction after the polyether polyol and the polyester polyol are dehydrated; the primary chain extender is added, and ammonium hydroxide is added, so that neutralization is performed to generate salt, and partial deionized water is added while cutting is performed at a high speed for mixing; the secondary chain extender is added,the deionized water is added while stirring is performed at a low speed, and standing is carried out to obtain the waterborne polyurethane resin, and the waterborne polyurethane resin continues to bemixed with remaining components of the high-viscosity water-based suede-like water-based resin to obtain the high-viscosity water-based suede-like water-based resin.

Owner:浙江诚迅新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com