Burst resin for synthetic leather and preparation method of burst resin

A synthetic leather and resin technology, applied in textiles and papermaking, etc., can solve problems such as bright surface, poor permeability, synthetic leather viscosity, stability, poor hand feeling, and poor resin cracking effect, etc. , to achieve a unique oily wax feel, which is conducive to large-scale industrial production and has a good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

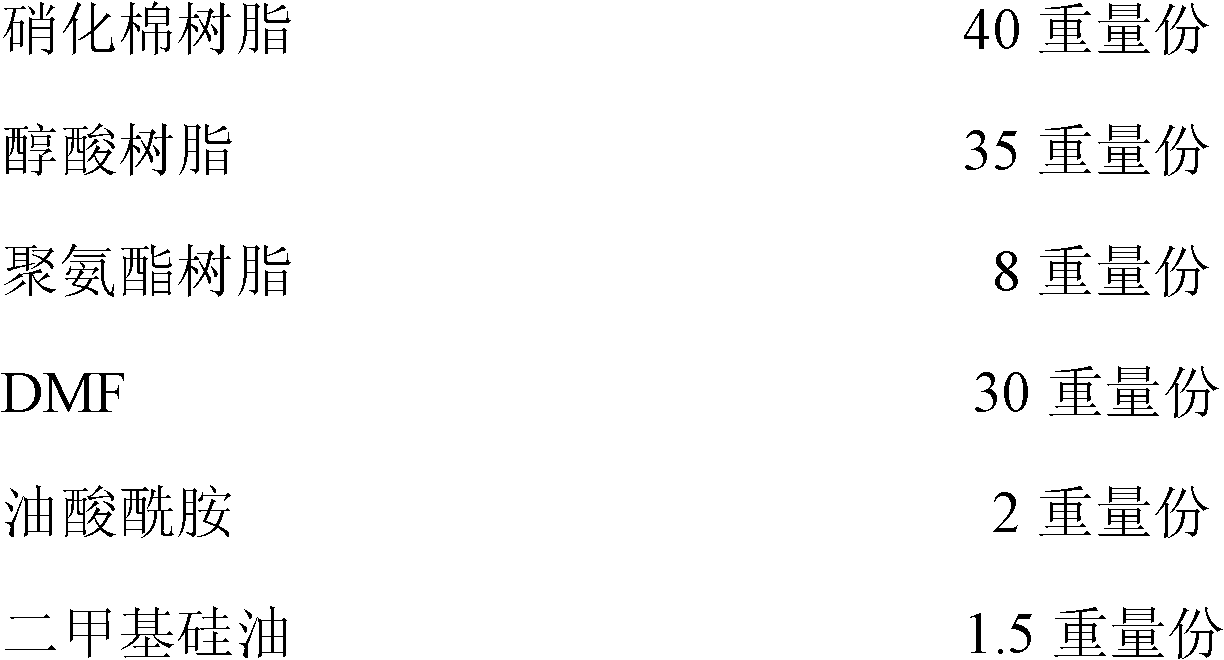

[0027] According to the following weight ratio (parts by weight):

[0028]

[0029] The nitrocellulose resin of 40 parts by weight and the DMF of 30 parts by weight are mixed, stir; Add the polyurethane resin of 8 parts by weight and the alkyd resin of 35 parts by weight in the mixture obtained, stir evenly; Then in the mixture obtained Add 1.5 parts by weight of simethicone oil and 2 parts by weight of oleic acid amide, uniformly mix and filter to obtain the bursting resin for synthetic leather of the present invention. The bursting resin prepared above was tested for its technical performance, and the results are shown in Table 1.

[0030] The stirring, filtering and other methods used in the above preparation process are all conventional methods in the art.

Embodiment 2

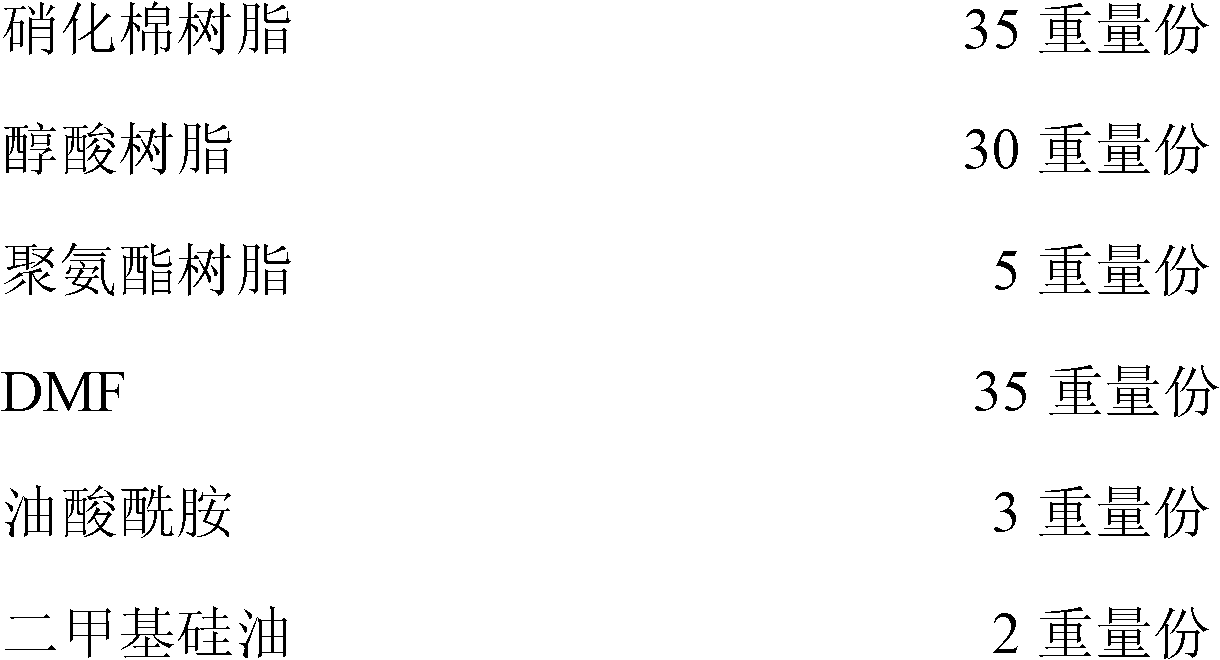

[0032] According to the following weight ratio (parts by weight):

[0033]

[0034] The nitrocellulose resin of 35 parts by weight and the DMF of 25 parts by weight are mixed, stir; In the mixture obtained, add the polyurethane resin of 5 parts by weight and the alkyd resin of 30 parts by weight, stir evenly; Then in the mixture obtained Add 2 parts by weight of simethicone and 3 parts by weight of oleic acid amide, uniformly mix and filter to obtain the bursting resin for synthetic leather of the present invention. The bursting resin prepared above was tested for its technical performance, and the results are shown in Table 1.

[0035] The stirring, filtering and other methods used in the above preparation process are all conventional methods in the art.

Embodiment 3

[0037] According to the following weight ratio (parts by weight):

[0038]

[0039]

[0040] The nitrocellulose resin of 45 parts by weight and the DMF of 25 parts by weight are mixed, stir; In the mixture obtained, add the polyurethane resin of 10 parts by weight and the alkyd resin of 40 parts by weight, stir evenly; Then in the mixture obtained Add 1 weight part of simethicone oil and 1 weight part of oleic acid amide, mix evenly and filter to obtain the bursting resin for synthetic leather of the present invention. The bursting resin prepared above was tested for its technical performance, and the results are shown in Table 1.

[0041] The stirring, filtering and other methods used in the above preparation process are all conventional methods in the art.

[0042] Table 1

[0043] project

[0044] Through the detection of the technical performance of the bursting resin, it can be seen that the bursting resin of the present invention has good large crackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com