Method for preparing acrylate/ silane coupling agent shared modified casein leather finishing agent by adopting soap-free polymerization method

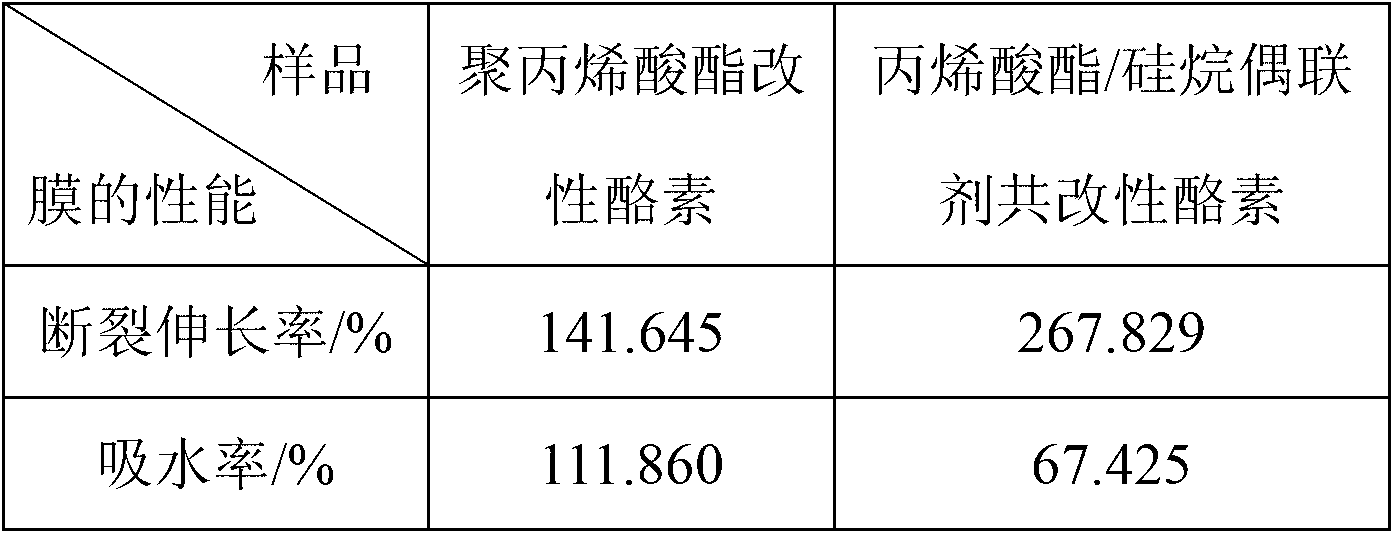

A silane coupling agent, leather finishing agent technology, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, leather surface treatment, etc. The elongation needs to be further improved, the casein coating has poor water resistance and poor flexural resistance, etc., to achieve the effect of good modification effect, elimination of adverse effects, and improvement of film elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of casein solution:

[0026] Take 5 parts by mass of casein, 1.25 parts of triethanolamine and 69 parts of deionized water, and react at a constant temperature in a water bath at 60° C. for 2 hours to obtain a casein solution;

[0027] 2) Preparation of caprolactam-modified casein emulsion:

[0028] Dissolve 1 part by mass of caprolactam in 10 parts of deionized water to obtain a caprolactam solution, adjust the temperature of the water bath to 70°C, add the caprolactam solution dropwise to the casein solution in 20 minutes, and after the dropwise addition, Insulation reaction for 2h, to obtain caprolactam-modified casein emulsion;

[0029] 3) Preparation of acrylate / silane coupling agent co-modified casein leather finishing agent:

[0030] The persulfide initiator sodium persulfate of 0.4 parts by mass is dissolved in 10 parts of deionized water to obtain an initiator solution; 1.5 parts by mass of methyl methacrylate and 6.5 parts of butyl acrylate M...

Embodiment 2

[0032] 1) Preparation of casein solution:

[0033] Take 6 parts by mass of casein, 1.5 parts of triethanolamine and 63 parts of deionized water, and react at a constant temperature in a water bath at 62° C. for 2 hours to obtain a casein solution;

[0034] 2) Preparation of caprolactam-modified casein emulsion:

[0035] Dissolve 2 parts by mass of caprolactam in 11 parts of deionized water to obtain a caprolactam solution, adjust the temperature of the water bath to 74°C, add the caprolactam solution dropwise to the casein solution within 25 minutes, and after the dropwise addition, Insulated for 2.5 hours to obtain a caprolactam-modified casein emulsion;

[0036] 3) Preparation of acrylate / silane coupling agent co-modified casein leather finishing agent:

[0037]The persulfide initiator potassium persulfate of 0.5 parts by mass is dissolved in 11 parts of deionized water to obtain an initiator solution; 2 parts by mass of methyl methacrylate and 7 parts of butyl acrylate M...

Embodiment 3

[0039] 1) Preparation of casein solution:

[0040] Take 7 parts by mass of casein, 1.75 parts of triethanolamine and 56 parts of deionized water, and react at a constant temperature in a water bath at 65° C. for 3 hours to obtain a casein solution;

[0041] 2) Preparation of caprolactam-modified casein emulsion:

[0042] Dissolve 3 parts by mass of caprolactam in 12 parts of deionized water to obtain a caprolactam solution, adjust the temperature of the water bath to 78°C, add the caprolactam solution dropwise to the casein solution in 30 minutes, after the dropwise addition, Insulated for 2.5 hours to obtain a caprolactam-modified casein emulsion;

[0043] 3) Preparation of acrylate / silane coupling agent co-modified casein leather finishing agent:

[0044] The persulfide initiator ammonium persulfate that is 0.6 parts by mass is dissolved in 12 parts of deionized water to obtain an initiator solution; 2.5 parts by mass of methyl methacrylate and 7.5 parts of butyl acrylate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com