Patents

Literature

123 results about "Stain remover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

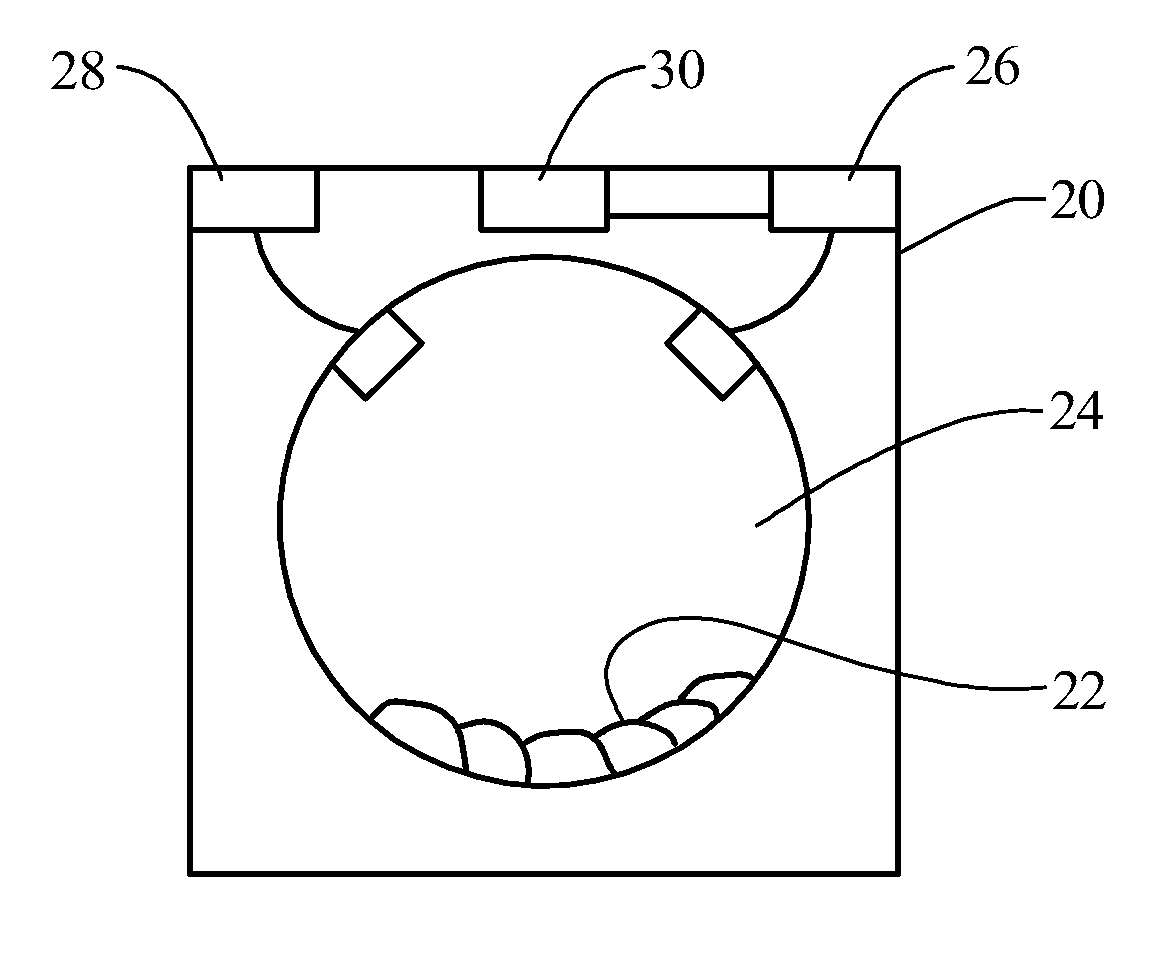

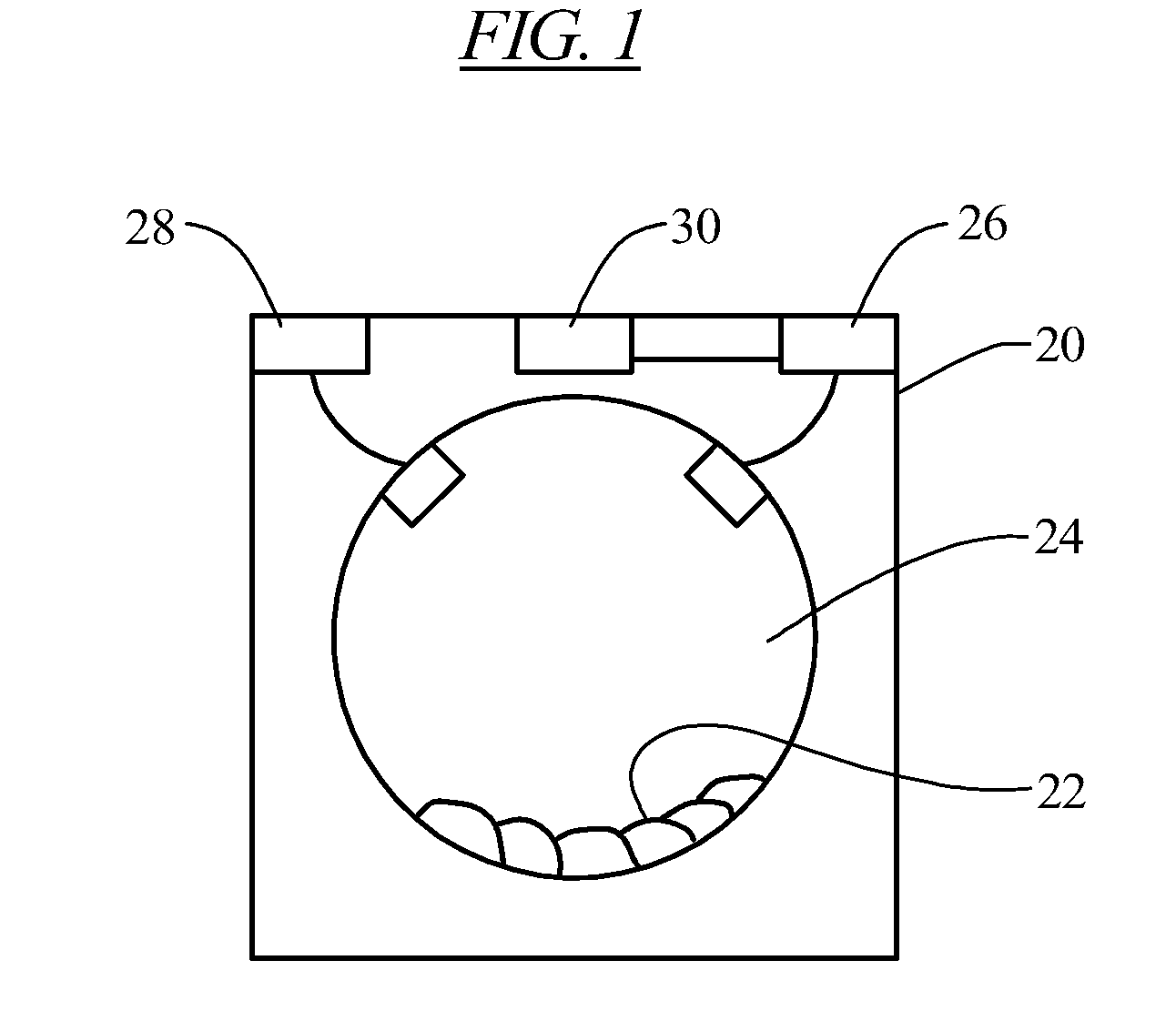

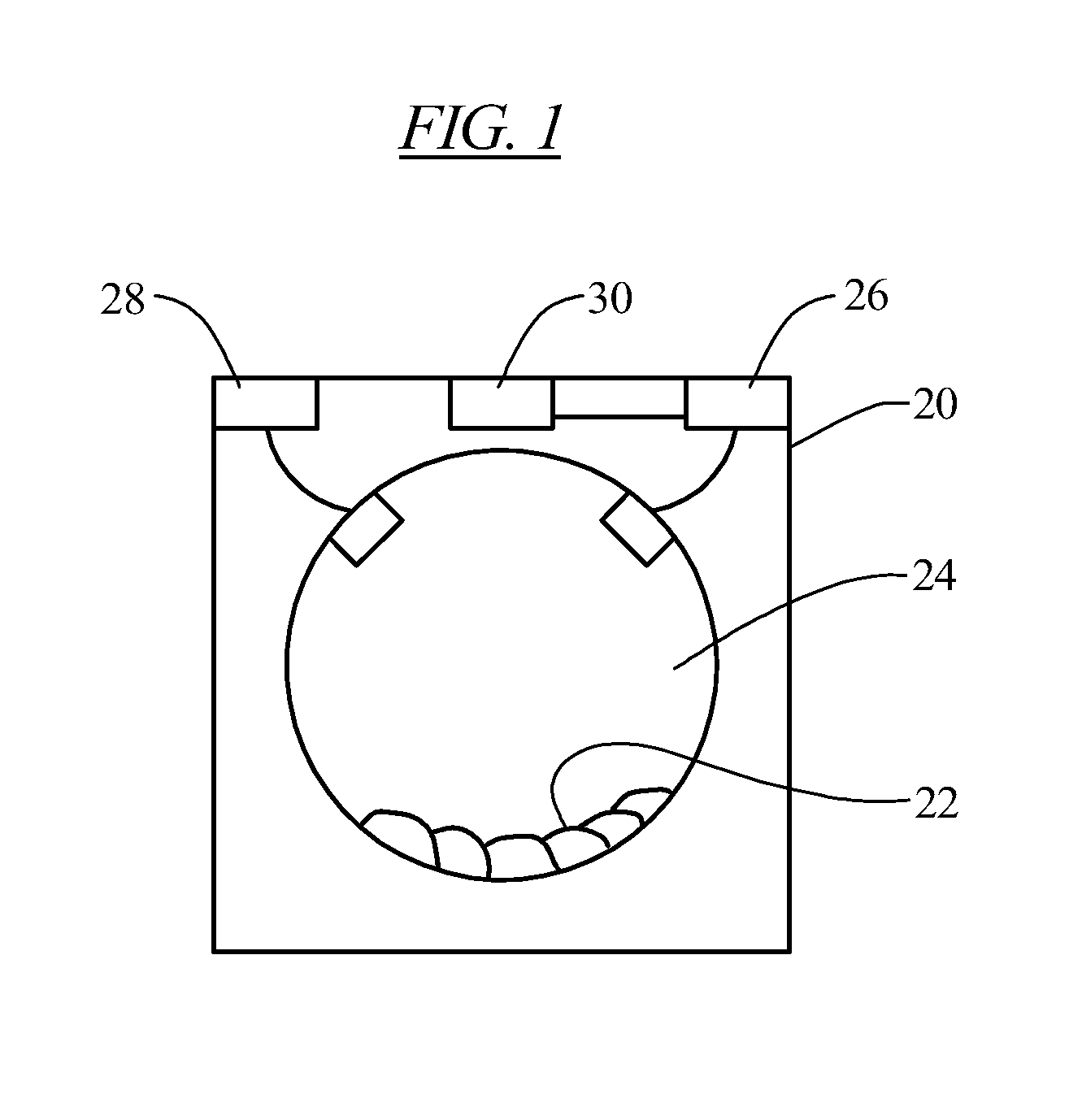

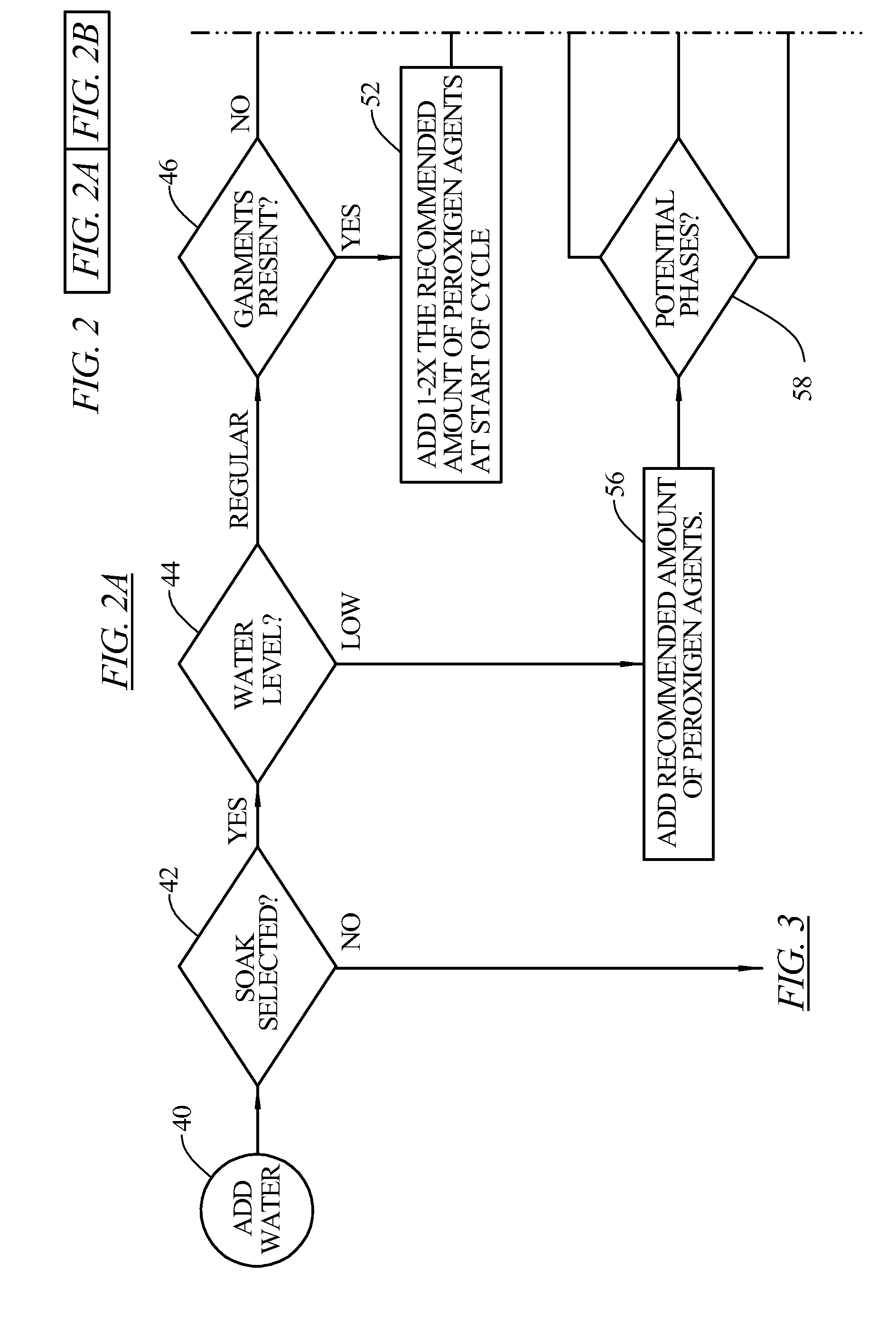

Washer and washer control with cycles for laundry additives and color safe bleaches/in-wash stain removers

A washer and a control for an automatic washer to operate the washer through a wash cycle selected based upon a range of conditions of a fabric load to be washed. The control has a plurality of selectable stain type entrées, each with a particular dedicated wash cycle. The control also has dispensing control over at least two wash liquor additives, one being a detergent and the other being an oxidizing agent. The control operates the dedicated wash cycles, as selected, using both the detergent and the oxidizing agent, however, the detergent and the oxidizing agent may be dispensed in different orders and at different times and in different amounts, depending on the stain type selected.

Owner:WHIRLPOOL CORP

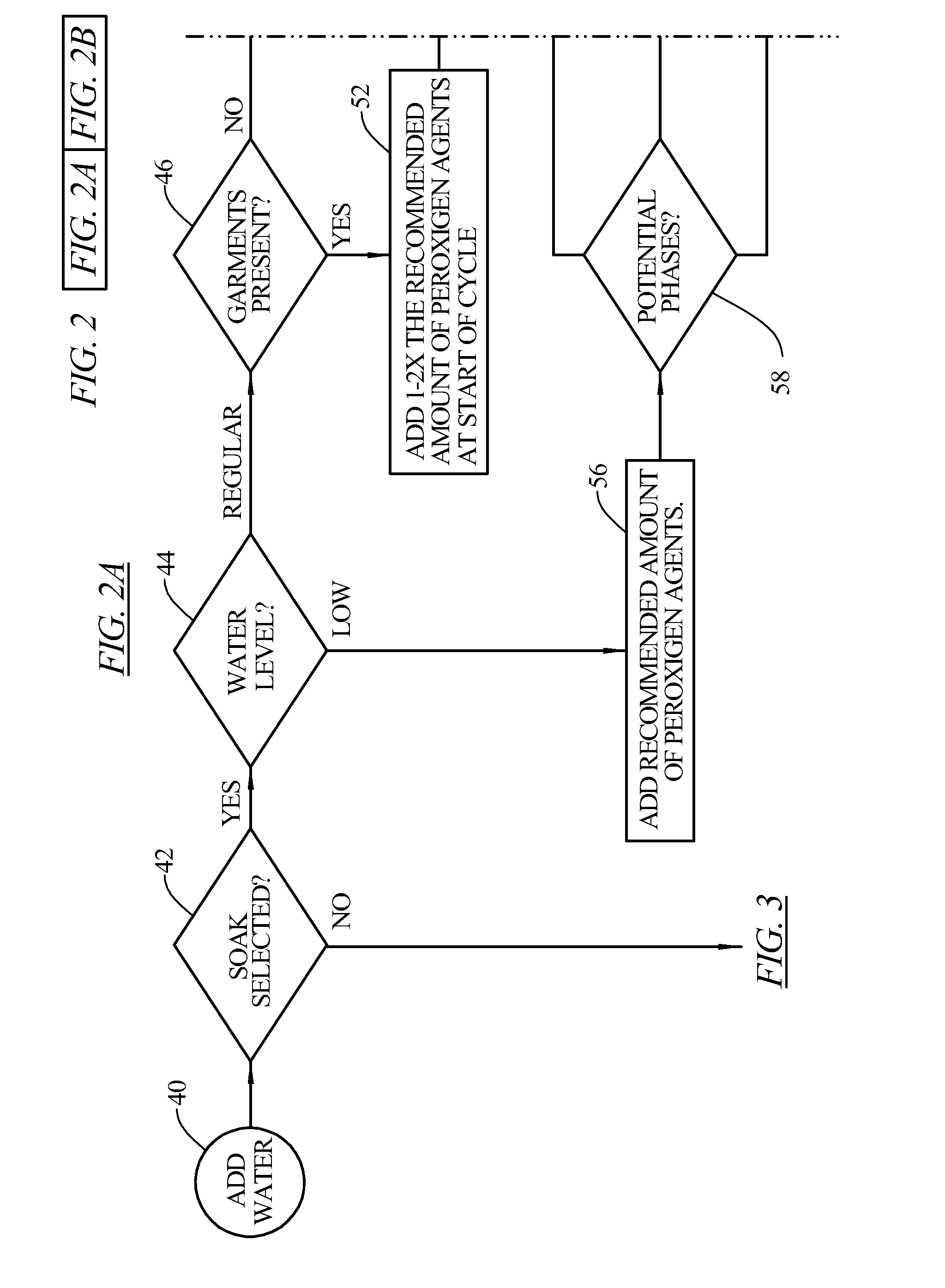

Papanicolau staining process

ActiveUS7186522B2Reduce in quantityPreparing sample for investigationBiological testingStainingBiochemistry

A method for treating a biological sample with a Papanicolaou staining process is provided. The method comprises incorporating a detergent treatment into the staining process at any of various steps. The method has been found to advantageously reduce the number of artifacts produced during Papanicolaou staining. Also provided is a sample stained by such a process.

Owner:CYTYC CORP

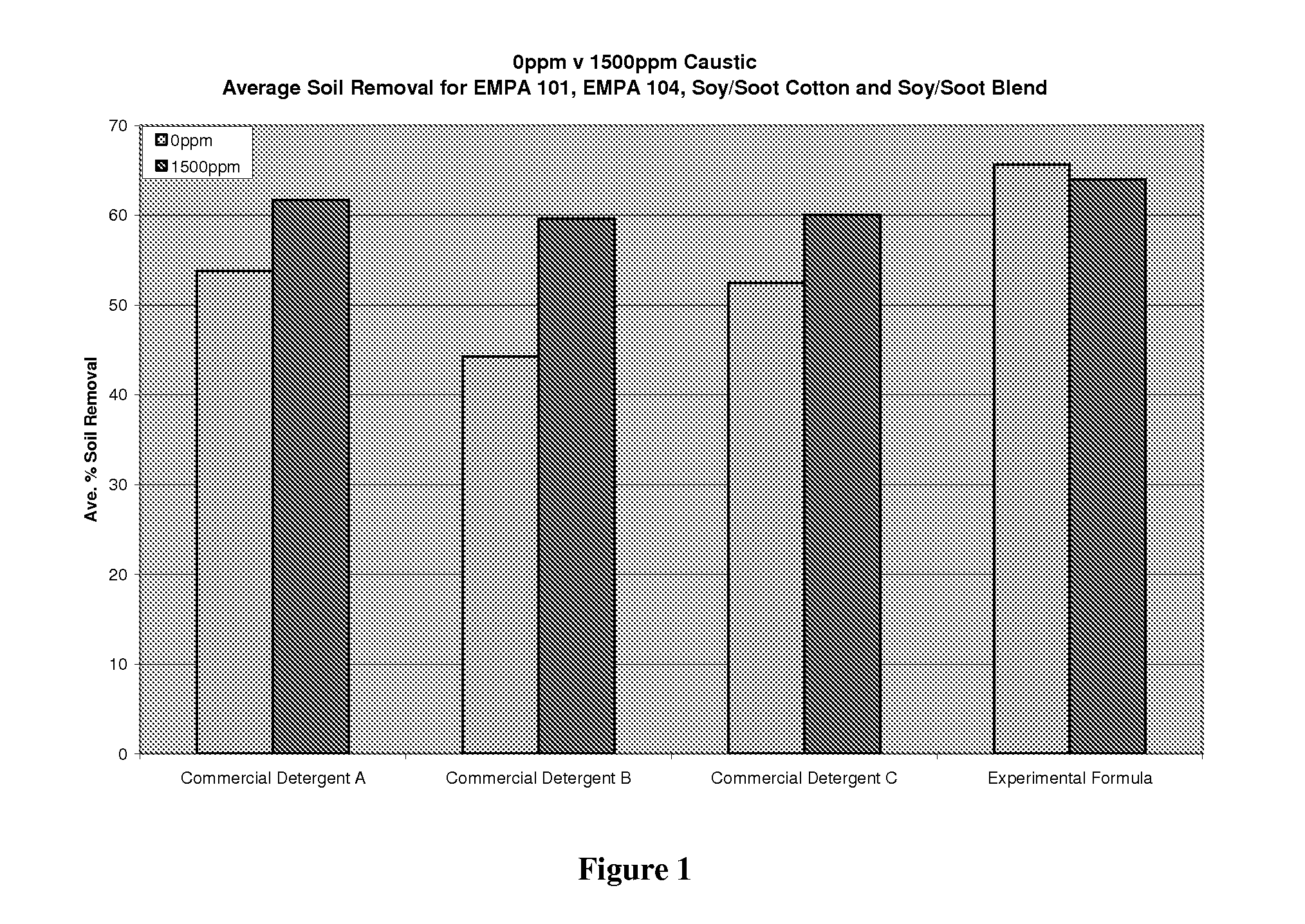

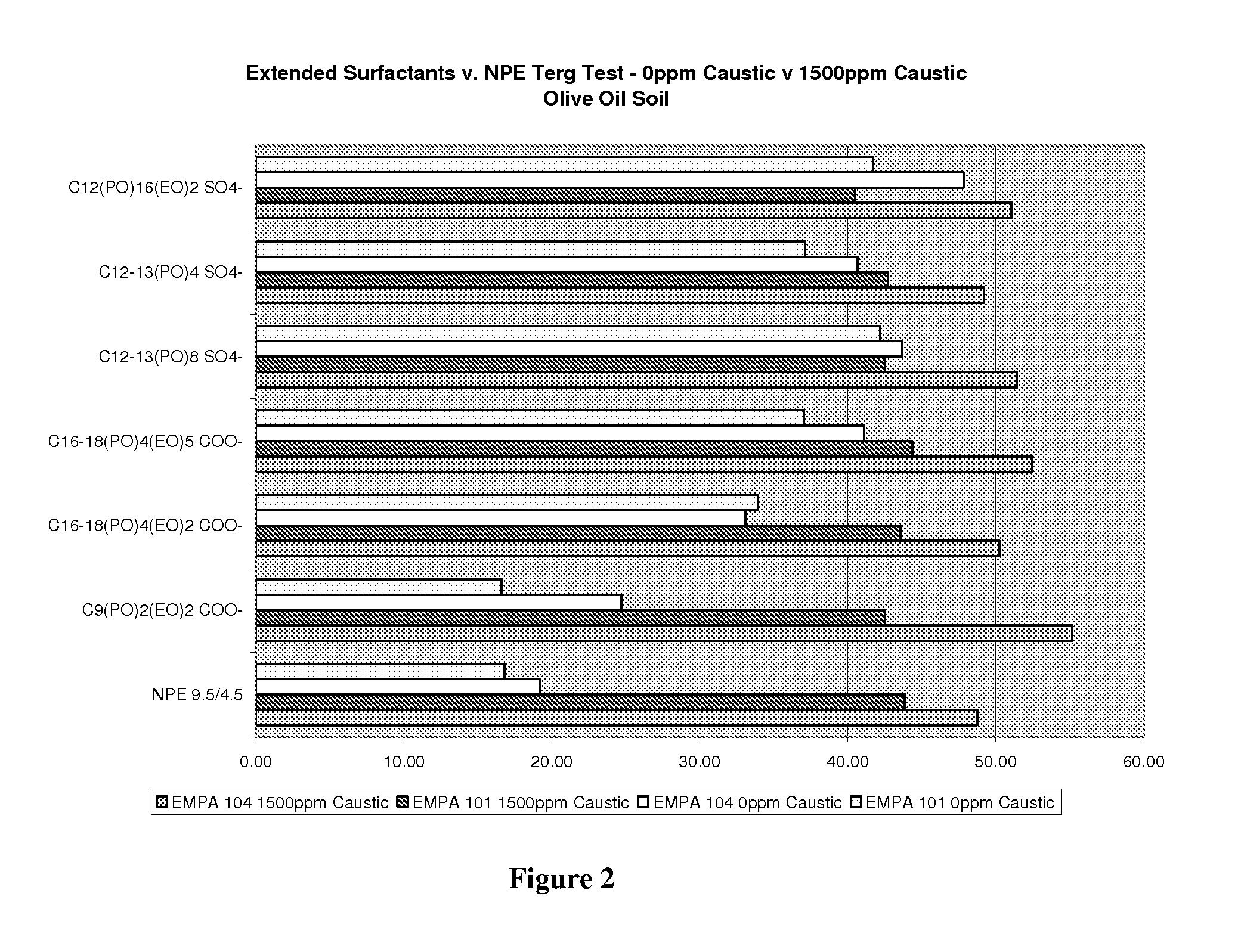

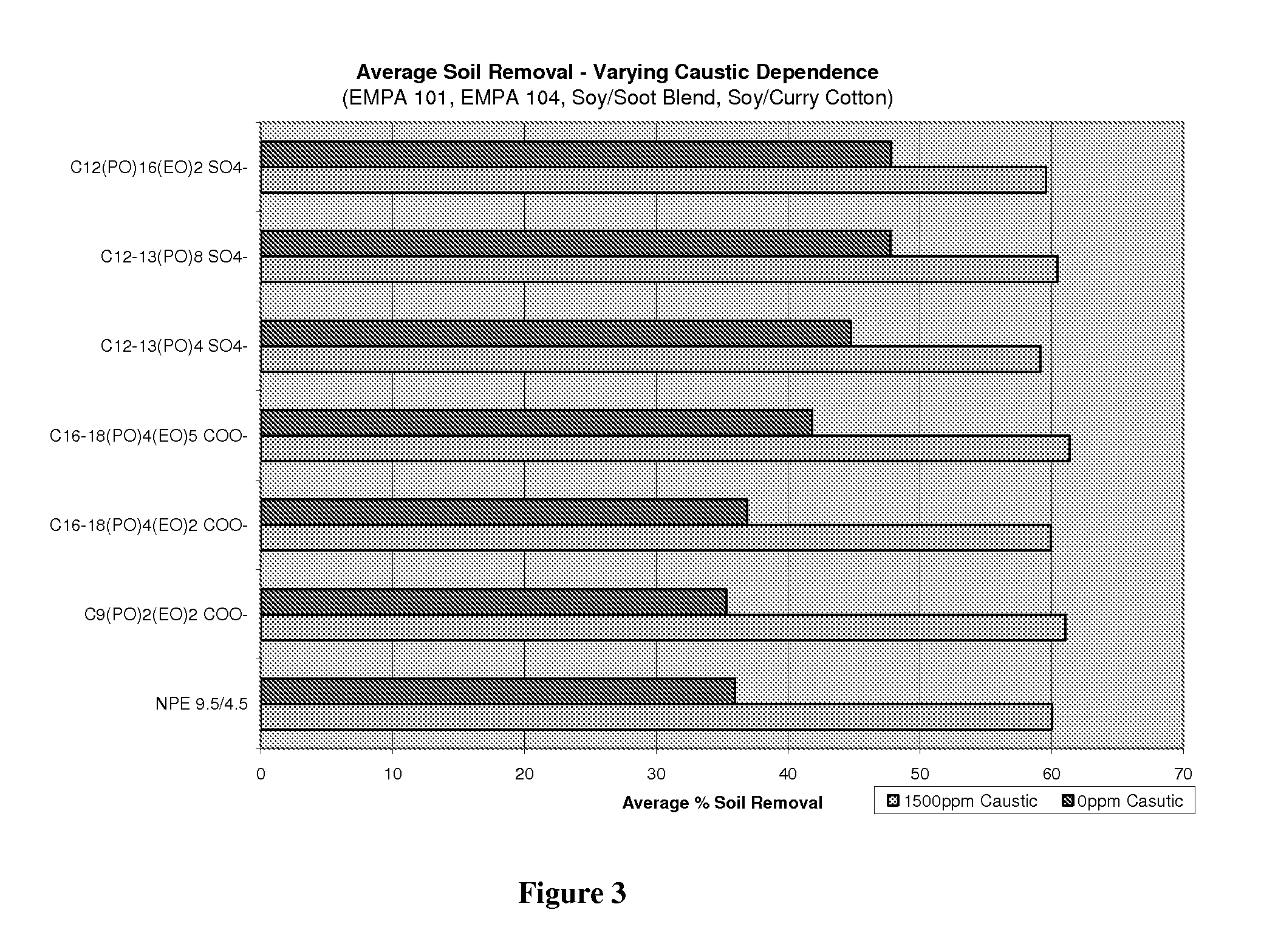

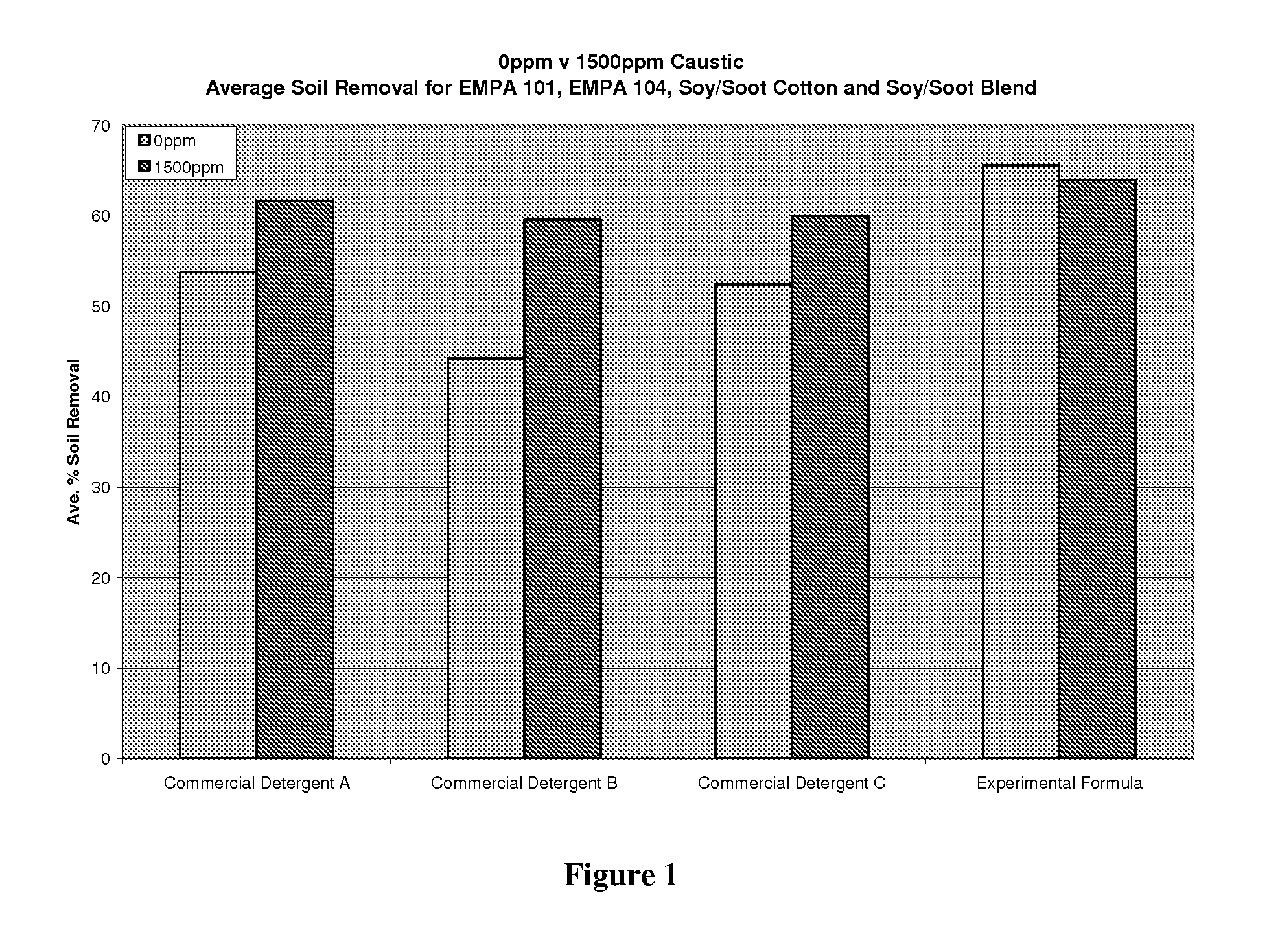

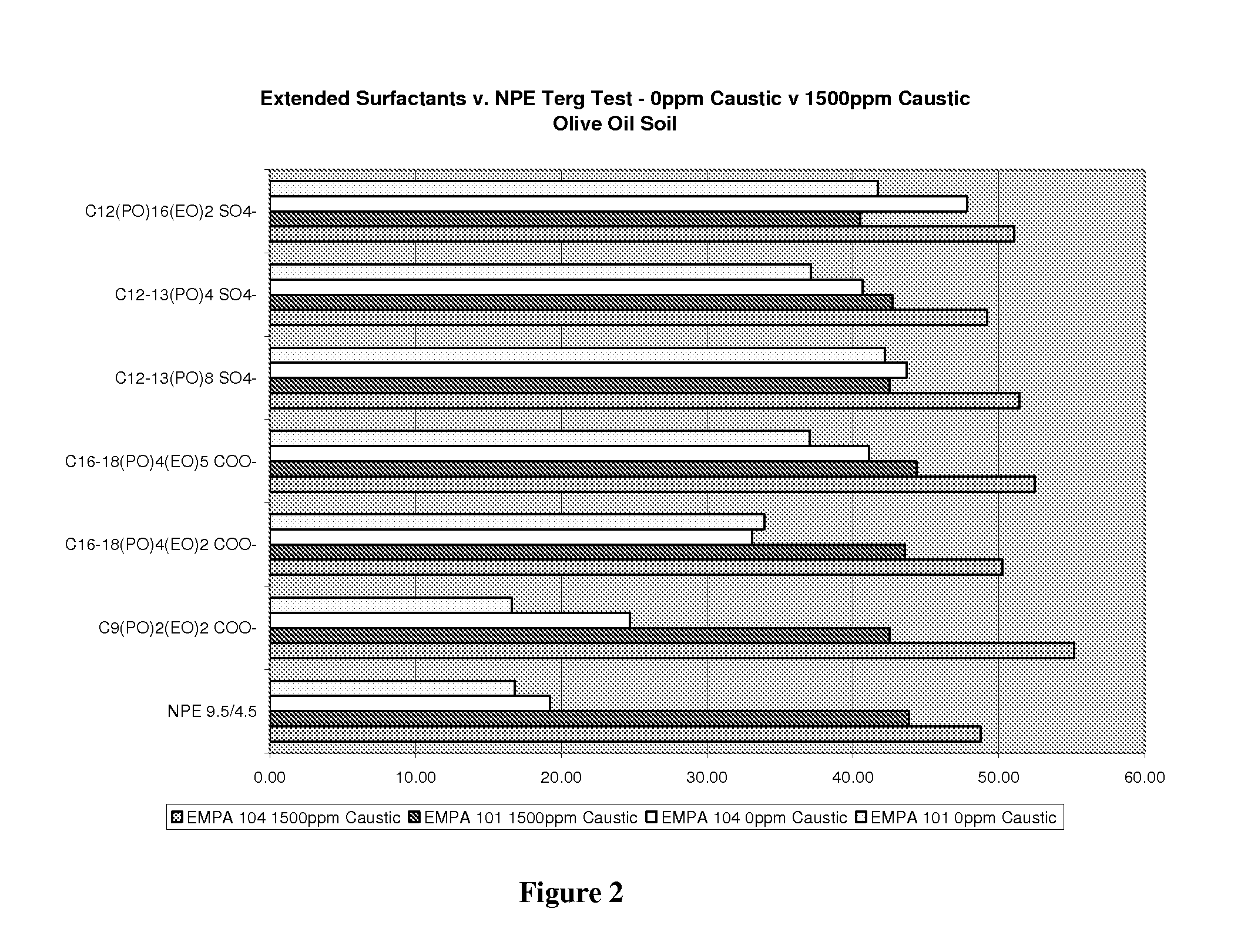

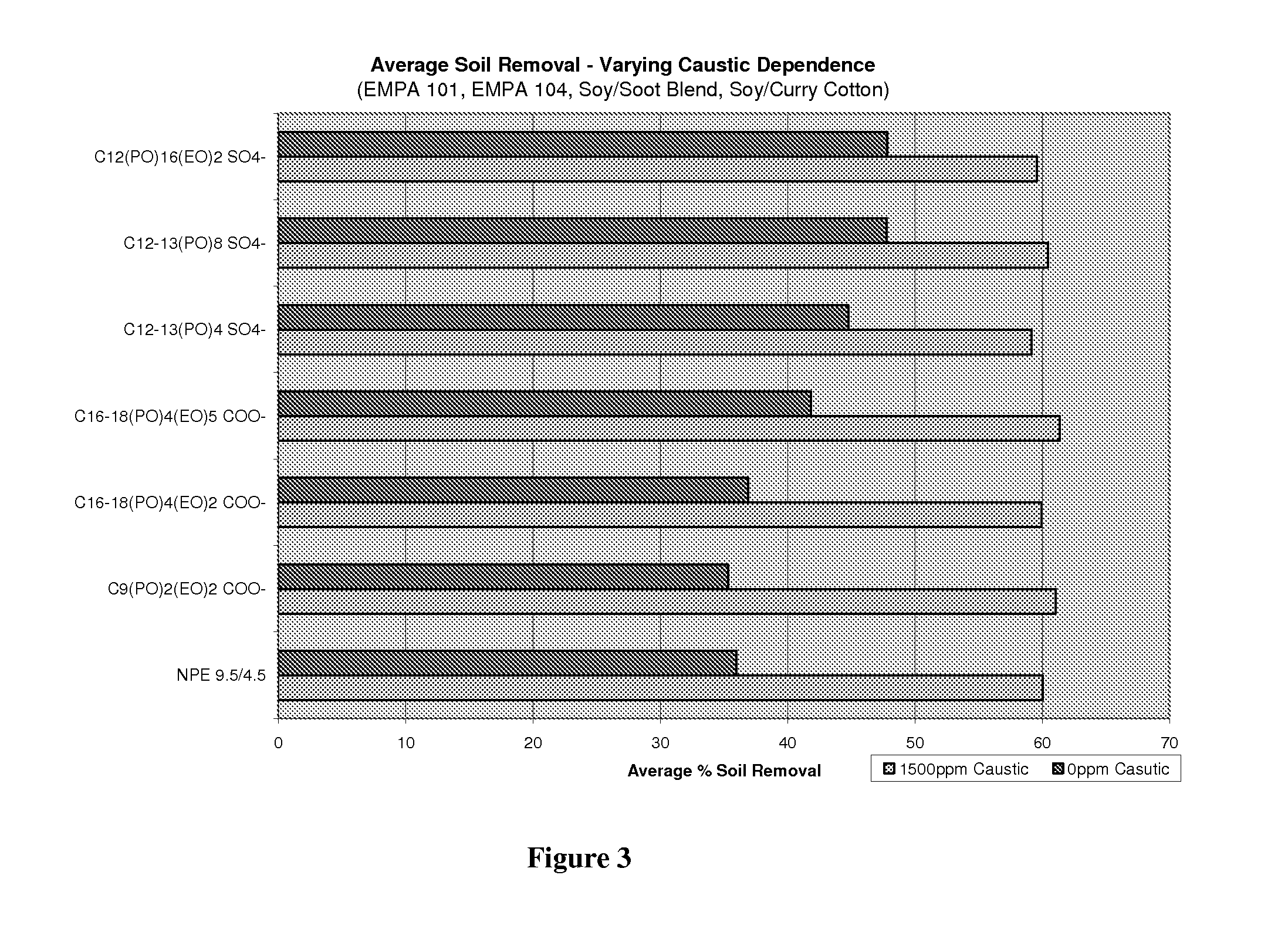

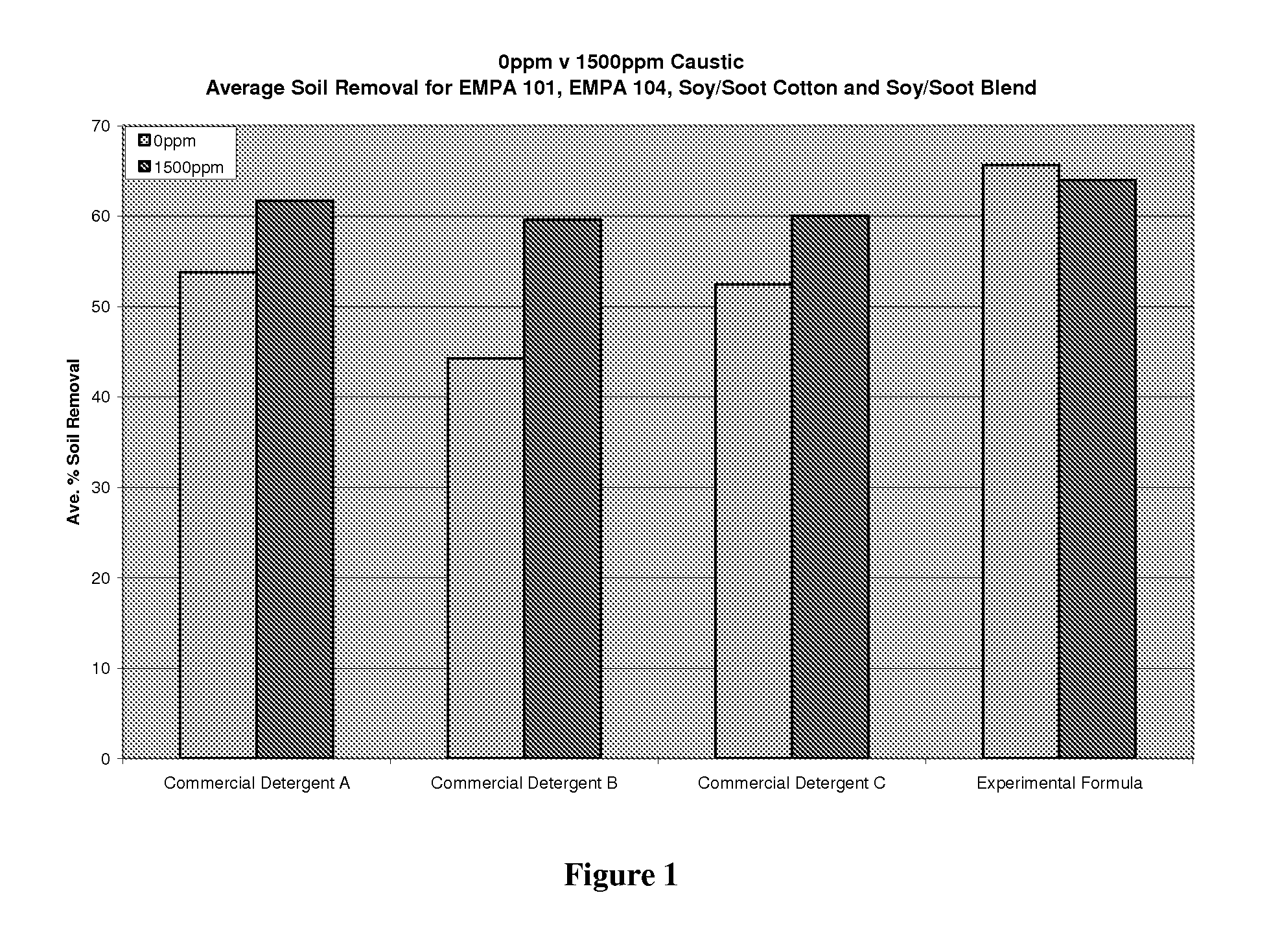

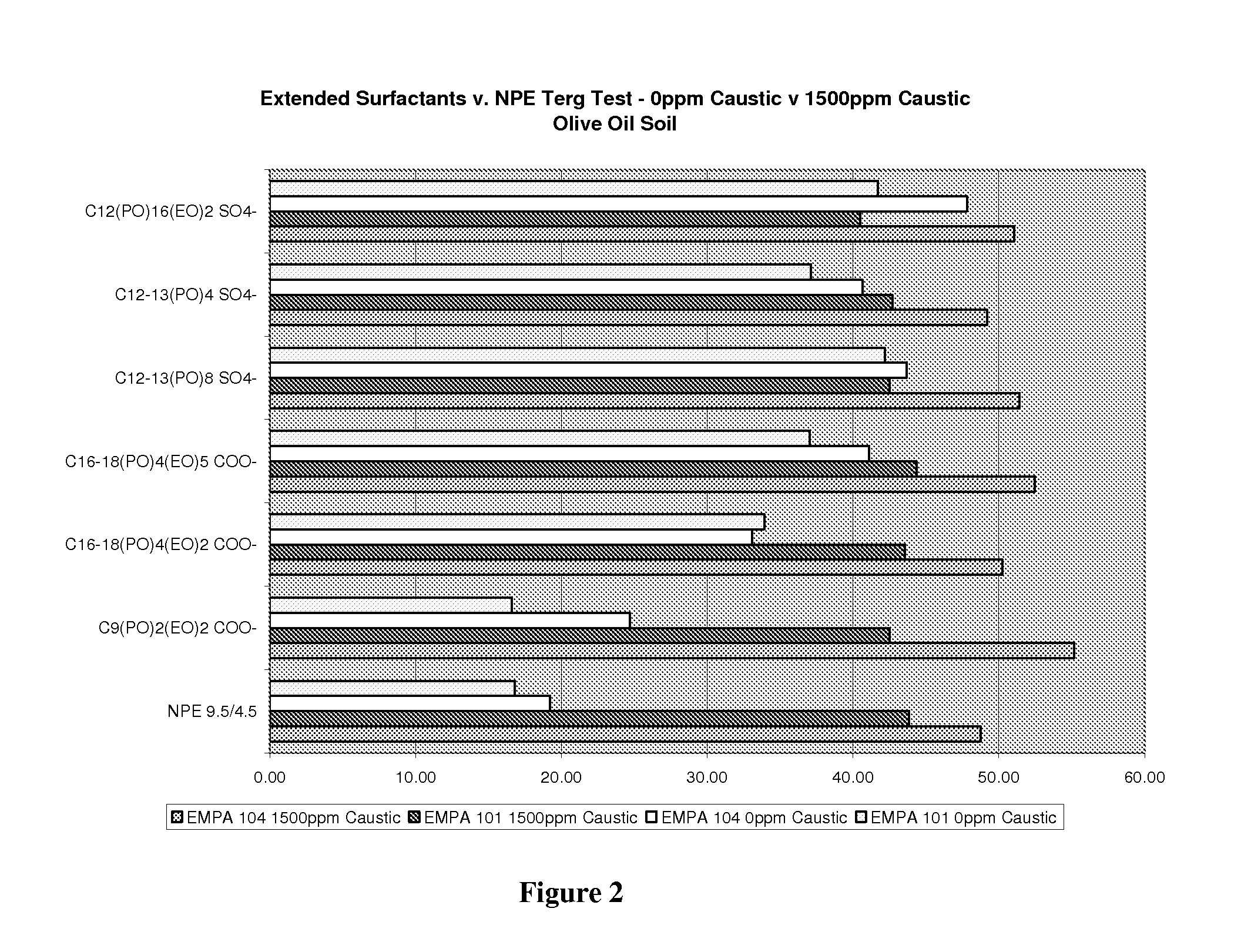

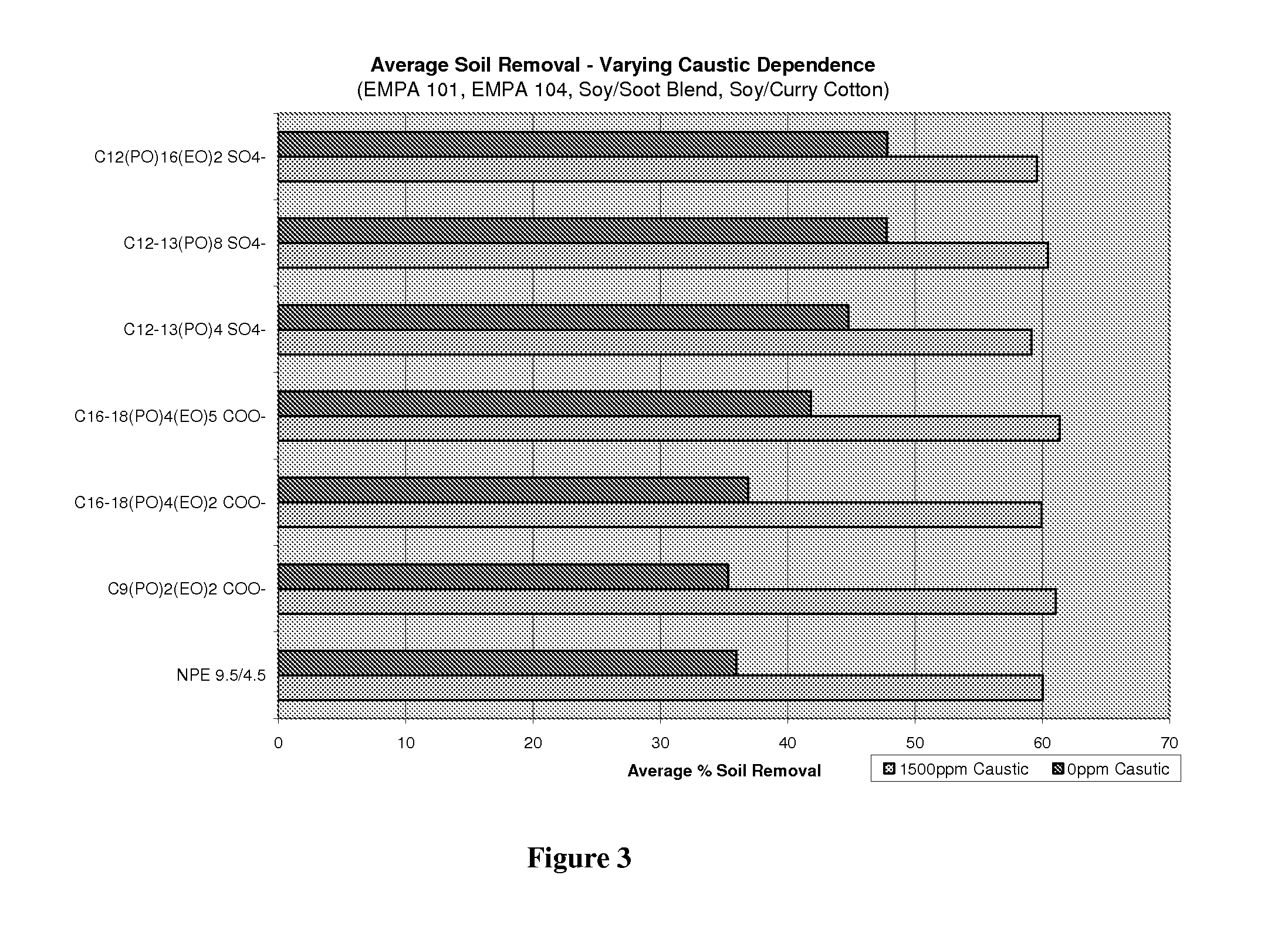

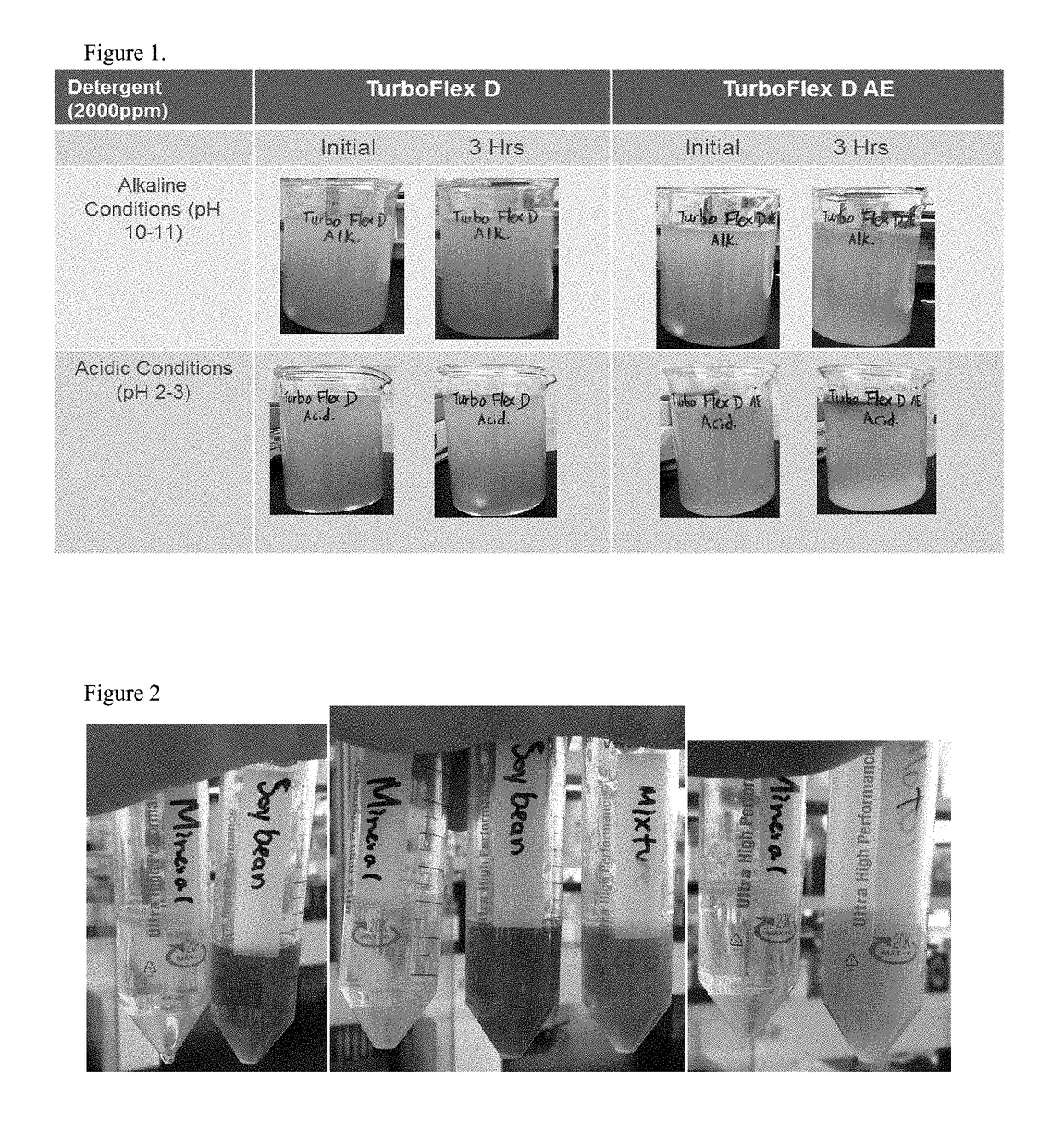

Reduced caustic laundry detergents based on extended chain surfactants

ActiveUS20120066840A1Reduce dependenceEasy to cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsEmulsionSurface cleaning

The invention discloses synergistic combinations of surfactants blends and cleaning composition. In certain embodiments a surfactant system is disclosed which includes extended anionic surfactants, linker surfactants, and a multiply charged cation component. This system forms emulsions with, and can remove greasy and oily stains, even those comprised of non-trans fats. In another embodiment anionic surfactants are combined with a solvent, and amine oxide to remove sunscreen stains. The compositions may be used alone, as a pre-spotter or other pre-treatment or as a part of a soft surface or hard surface cleaning composition.

Owner:ECOLAB USA INC

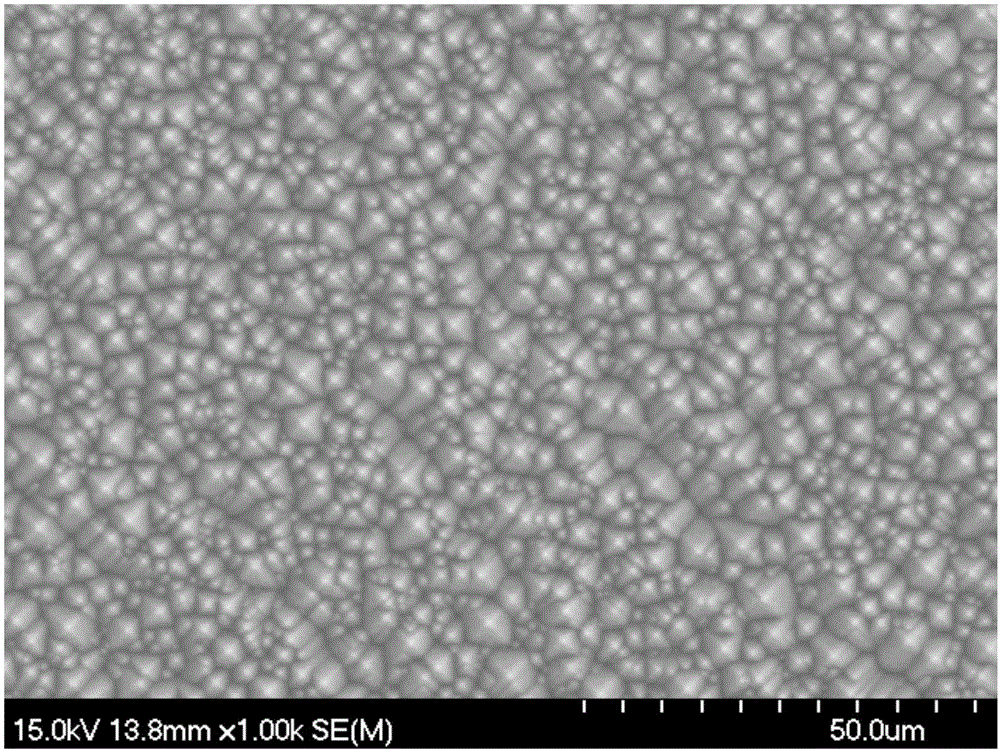

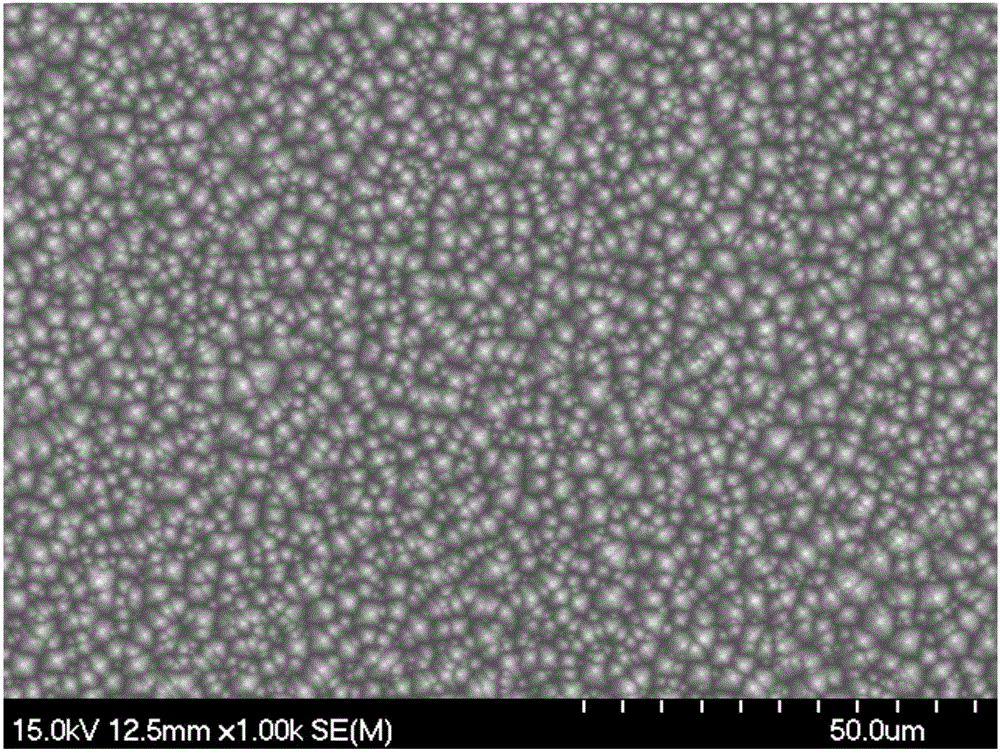

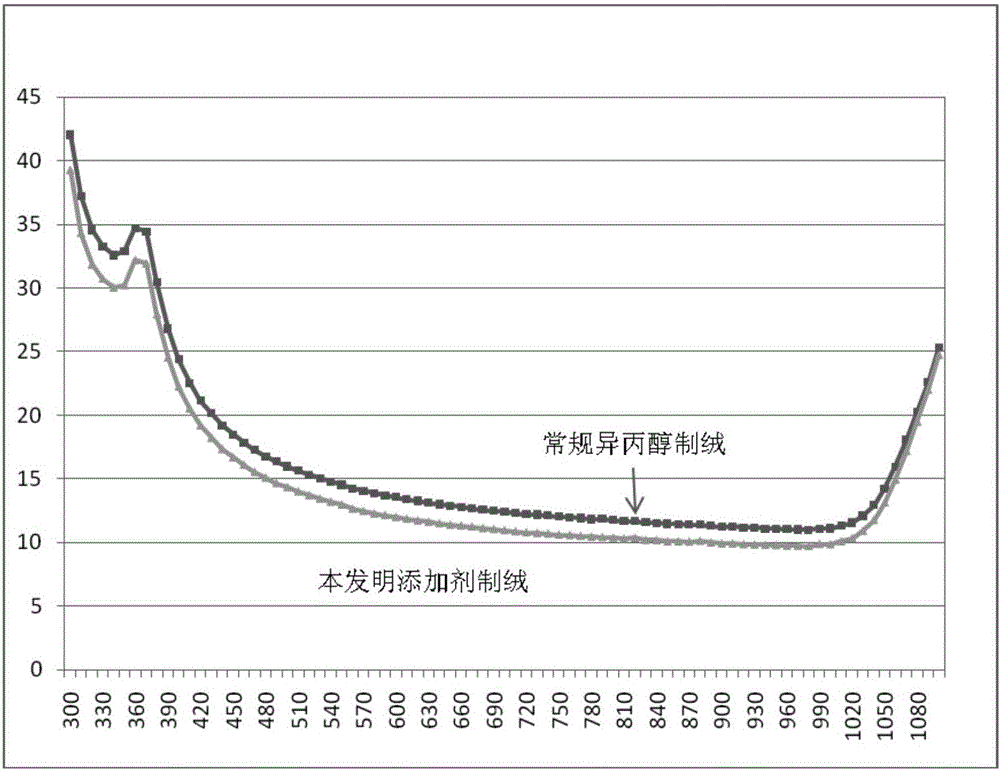

Additive for diamond linear cutting monocrystalline silicon wafer suede manufacture and application method of additive

InactiveCN106222756AReduce consumptionReduce light reflectivityPolycrystalline material growthAfter-treatment detailsAlcoholMicrometer

The invention provides an additive for diamond linear cutting monocrystalline silicon wafer suede manufacture. The additive comprises the following components in weight percentage, 0.05-5% of defoaming agents, 1-10% of stain removers, 0.01-1% of suede optimizers and the balance water. The additive is simple in formula, convenient to operate, simple in flocking process and good in flocking repeatability, chemical consumption and production cost are reduced, and alcohols such as isopropanol or ethyl alcohol are omitted. When the additive is applied to diamond linear cutting monocrystalline silicon wafer suede manufacture, the additive has an excellent surface cutting mark eliminating effect, surfaces are black and clean, uniform, small and dense suede pyramids can be obtained, the size of each pyramid ranges from 2 micrometers to 3 micrometers, the light reflectivity of monocrystalline silicon wafers is reduced, and battery piece conversion efficiency is correspondingly improved.

Owner:杭州飞鹿新能源科技有限公司

Natural soil and stain removers

InactiveUS7629305B1Organic detergent compounding agentsSurface-active detergent compositionsSolventCleansing Agents

A cleaning composition with a limited number of natural ingredients contains a nonionic surfactant, a solvent and a short chain syndetic. The cleaning composition can be used to clean laundry, soft surfaces, and hard surfaces and cleans as well or better than commercial compositions containing synthetically derived cleaning agents.

Owner:THE CLOROX CO

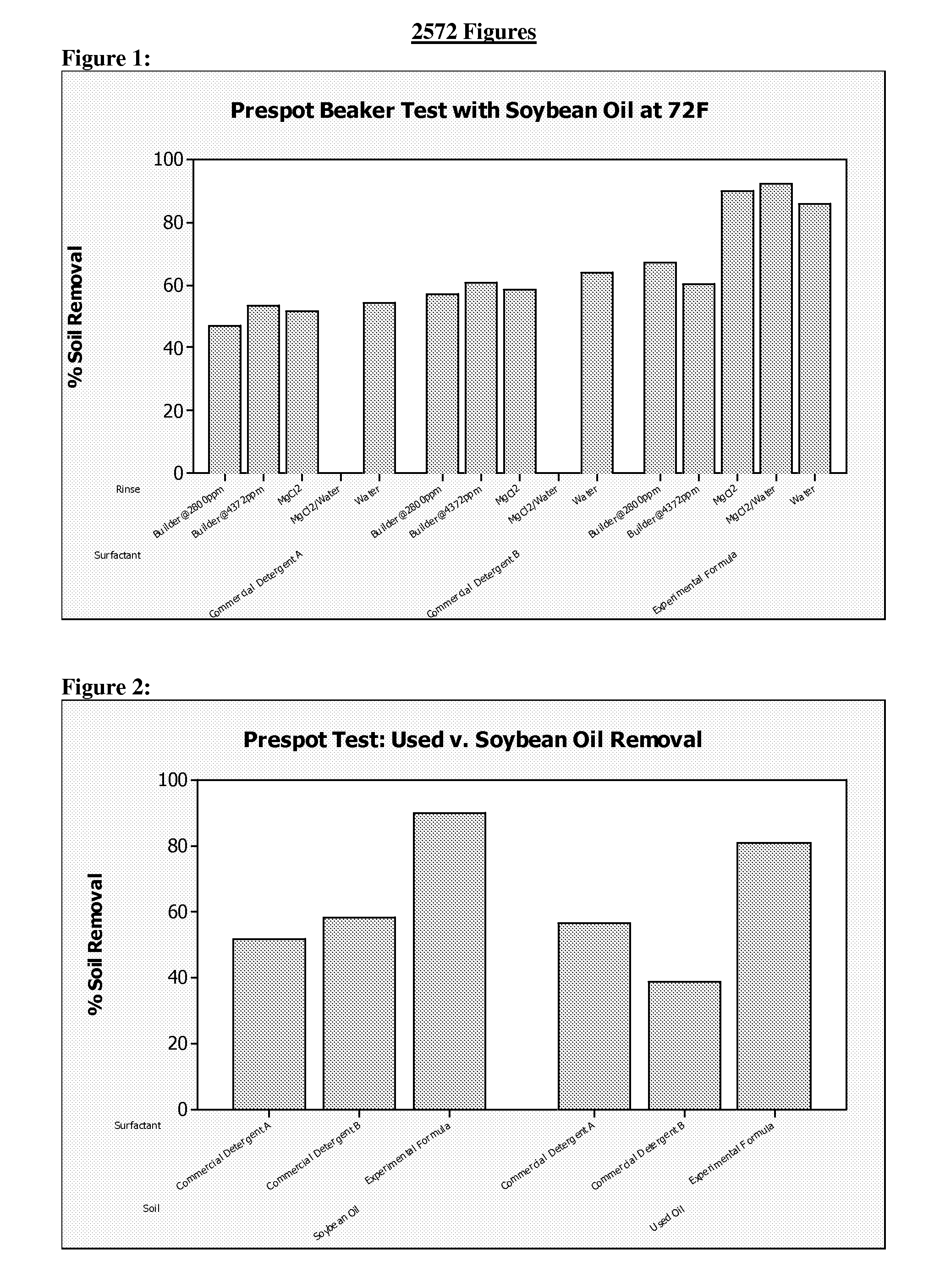

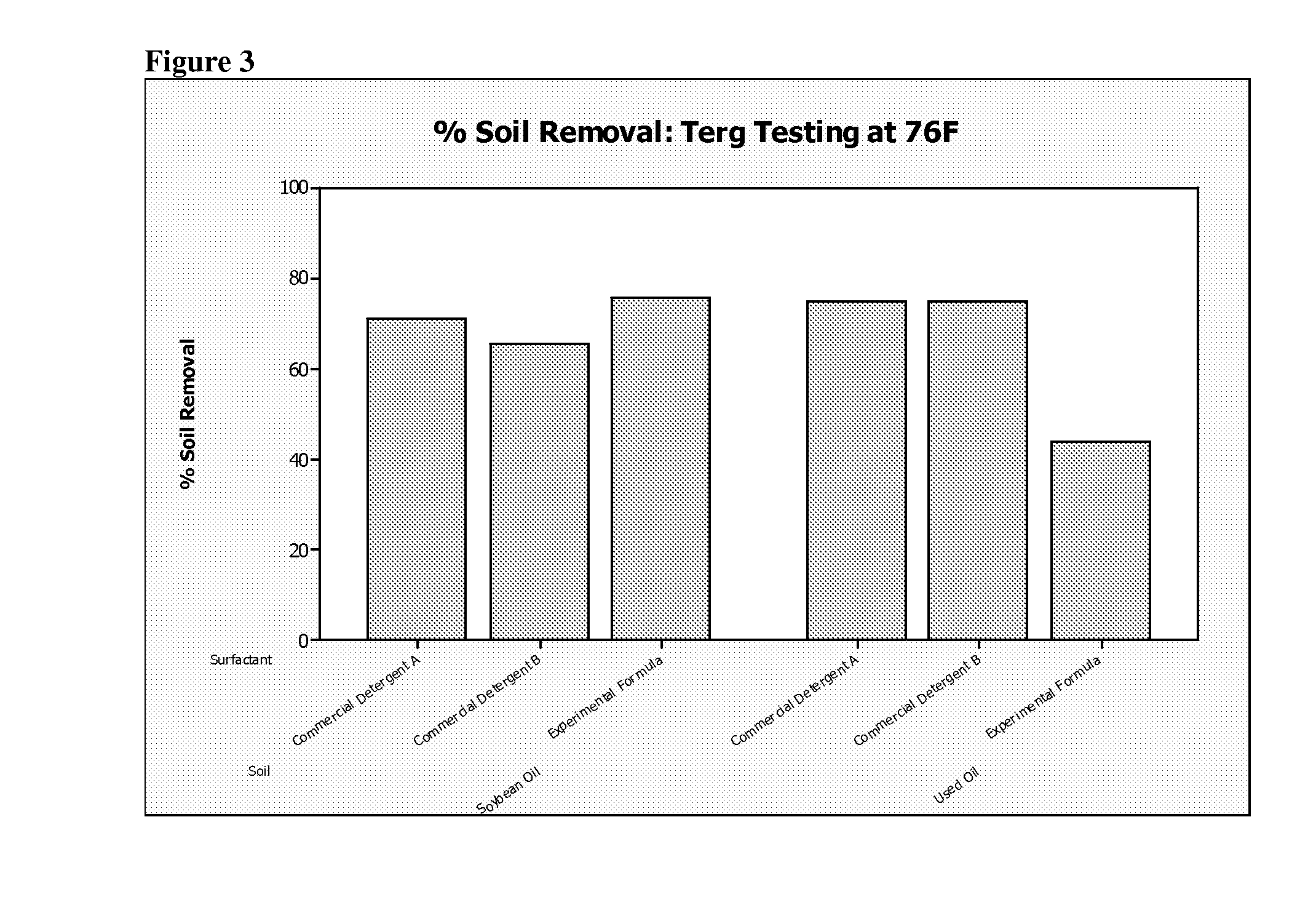

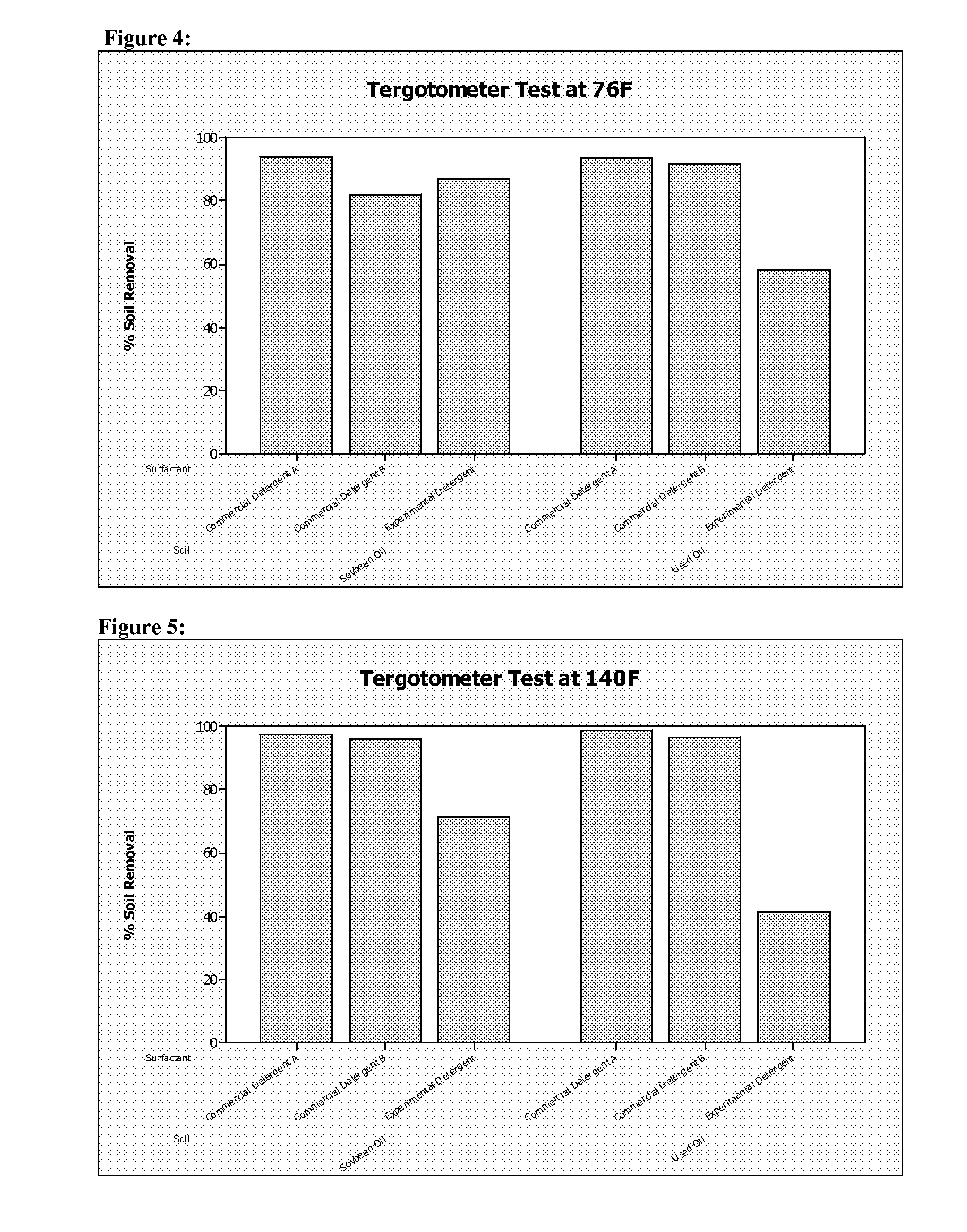

Cleaning compositions employing extended chain anionic surfactants

ActiveUS20120066839A1Remove non-transfatRemove fatty acid stainCationic surface-active compoundsNon-ionic surface-active compoundsEmulsionSurface cleaning

The invention discloses synergistic combinations of surfactants blends and cleaning composition. In certain embodiments a surfactant system is disclosed which includes extended anionic surfactants, linker surfactants, and a multiply charged cation component. This system forms emulsions with, and can remove greasy and oily stains, even those comprised of non-trans fats. The compositions may be used alone, as a pre-spotter or other pre-treatment or as a part of a soft surface or hard surface cleaning composition.

Owner:ECOLAB USA INC

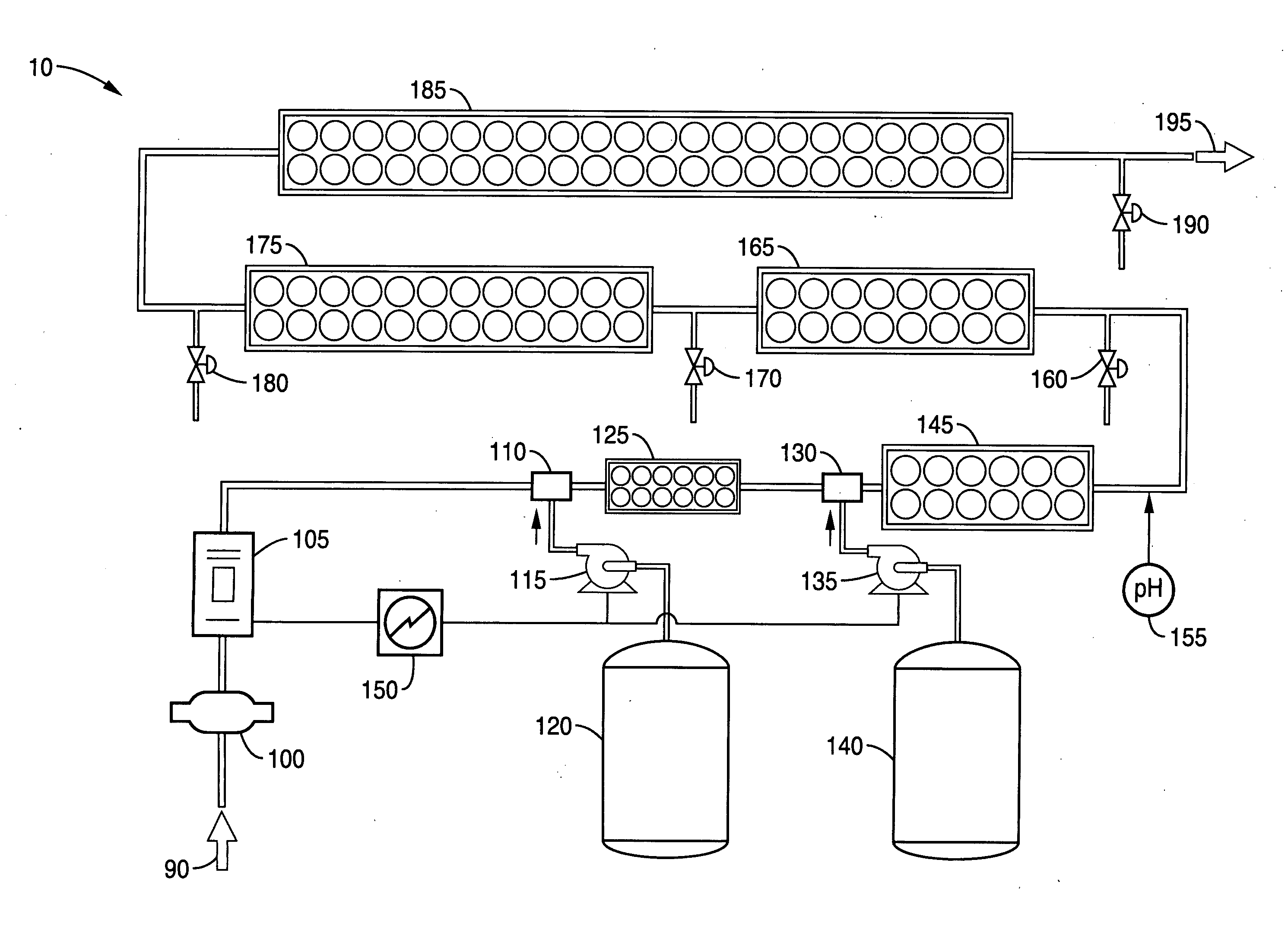

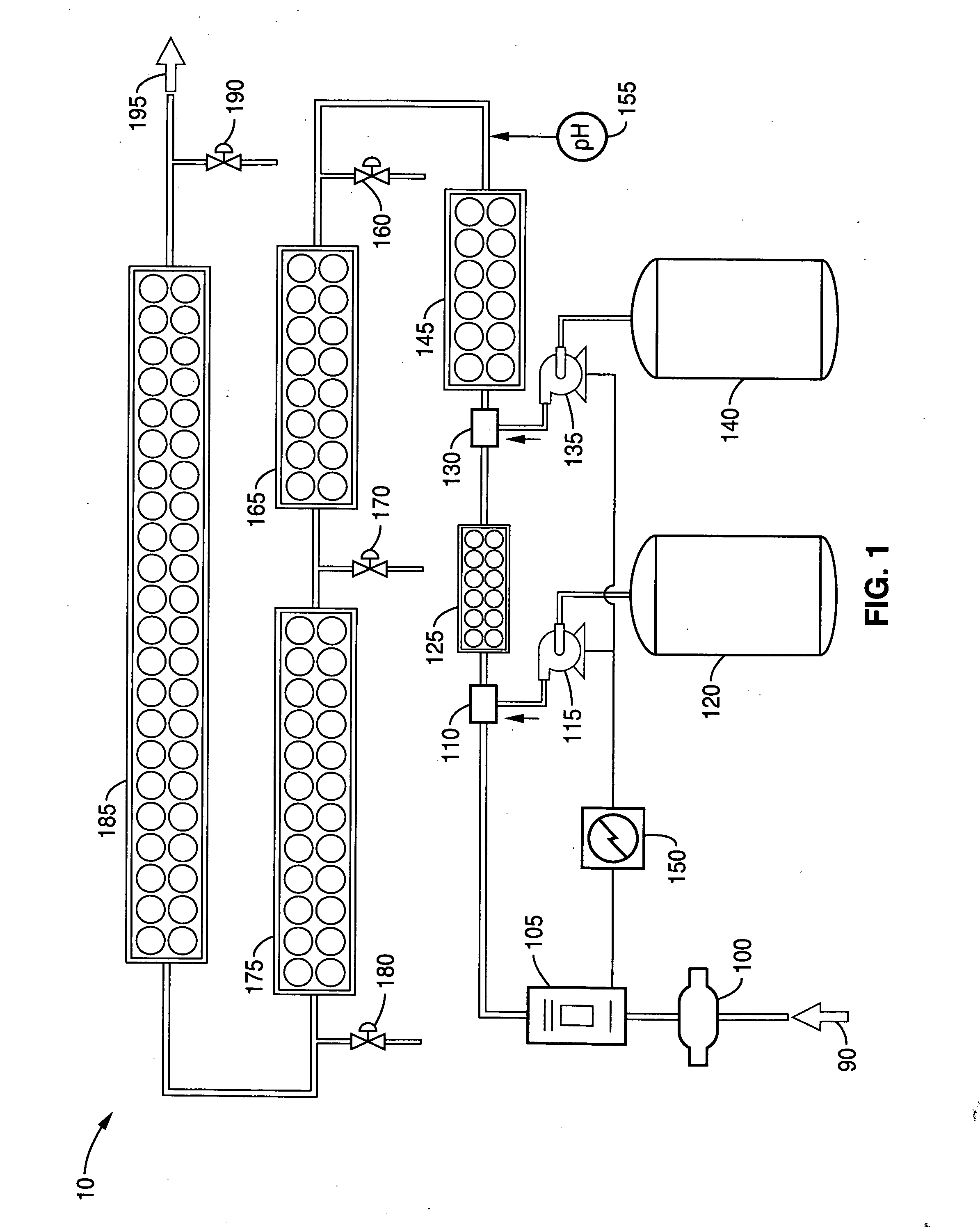

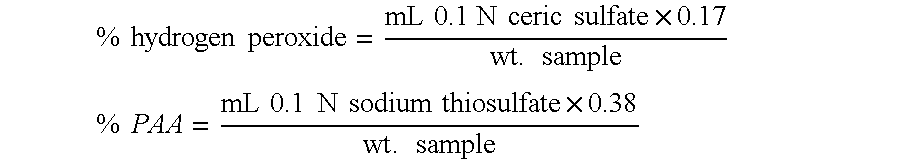

Methods and compositions for the generation of peracetic acid on site at the point-of-use

ActiveUS20120245228A1Easy to implementReduce operating costsBiocideDetergent mixture composition preparationAlkaline earth metalBleach

Methods and compositions for the generation of a peroxyacetic acid sanitizer in proximity to the point-of-use are disclosed. These methods comprise introducing a hydrogen peroxide-acetyl precursor solution to water, mixing, and then adding an aqueous source of a alkali metal or earth alkali metal hydroxide. Triacetin is a preferred acetyl precursor and is converted rapidly and with a high conversion rate into peracetic acid. These methods produce solutions with a high level of peracetic acid. Methods for preparing the hydrogen peroxide-acetyl precursor solution are also provided. Also disclosed are solid compositions comprising a liquid acetyl precursor, a water-soluble source of hydrogen peroxide, and a water-soluble source of alkalinity. The solid composition is a freely-flowable solid that is used as a bleaching agent and a stain remover for the treatment of articles such as fabrics, dentures, textile garments, and equipment used in the food and beverage industry.

Owner:ENVIRO TECH CHEM SERVICES

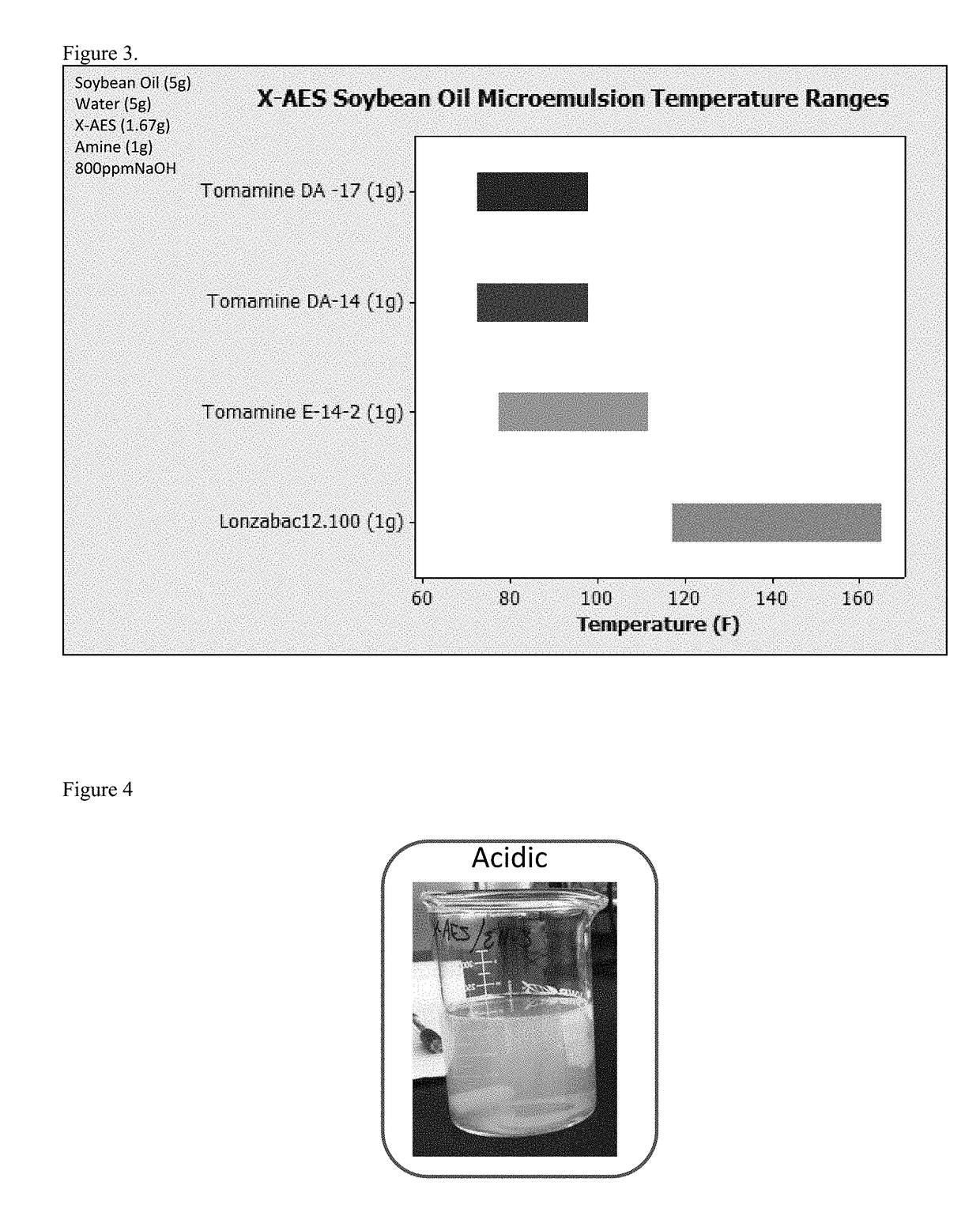

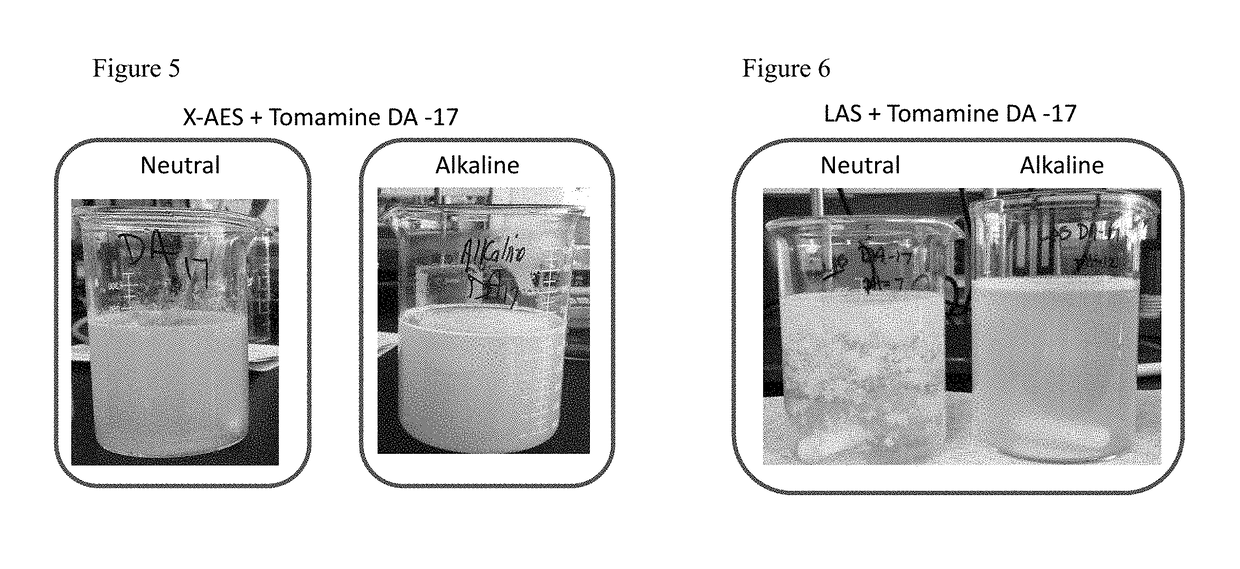

Laundry composition for treatment of sunscreen stains based on extended chain surfactants

ActiveUS20120071384A1Easy to cleanReduce dependenceOrganic detergent compounding agentsNon-ionic surface-active compoundsSunscreen agentsSurface cleaning

The invention discloses synergistic combinations of surfactants blends and cleaning composition. In certain embodiments a surfactant system is disclosed which includes extended anionic surfactants, linker surfactants, and a multiply charged cation component. This system forms emulsions with, and can remove greasy and oily stains, even those comprised of non-trans fats. In another embodiment anionic surfactants are combined with a solvent, and amine oxide to remove sunscreen stains. The compositions may be used alone, as a pre-spotter or other pre-treatment or as a part of a soft surface or hard surface cleaning composition.

Owner:ECOLAB USA INC

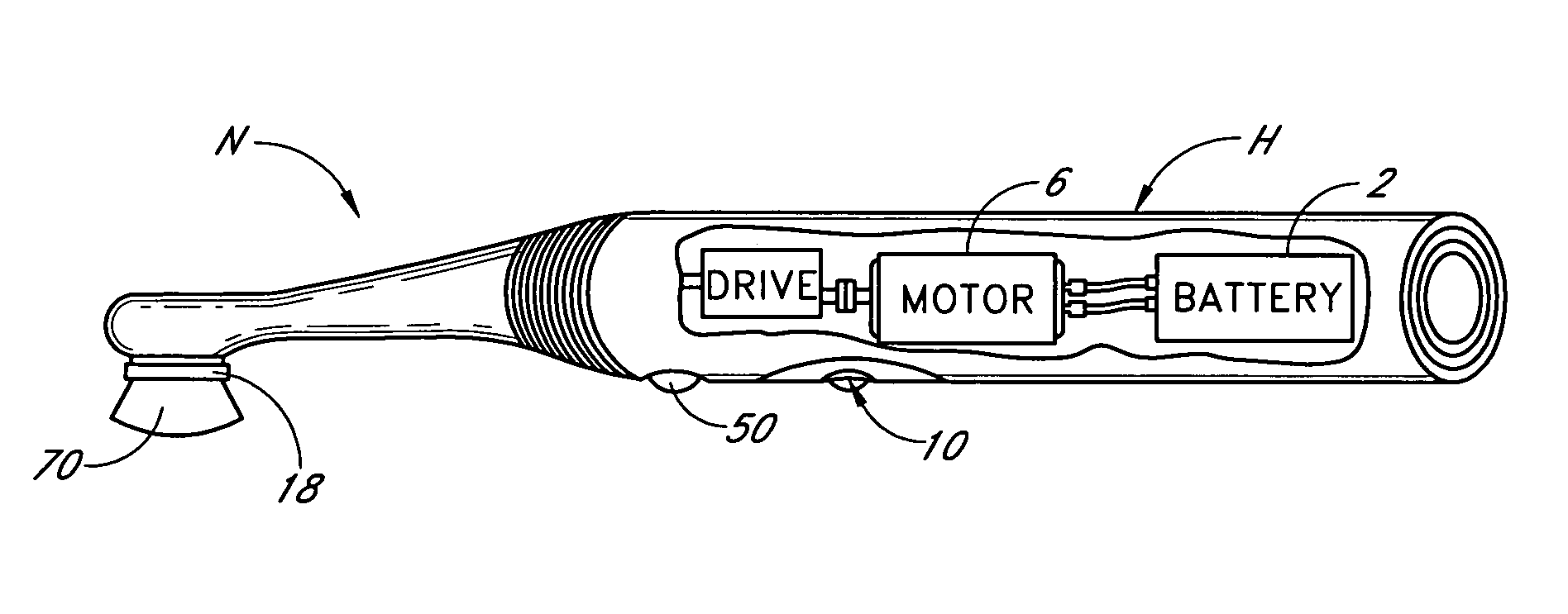

Dental stain remover

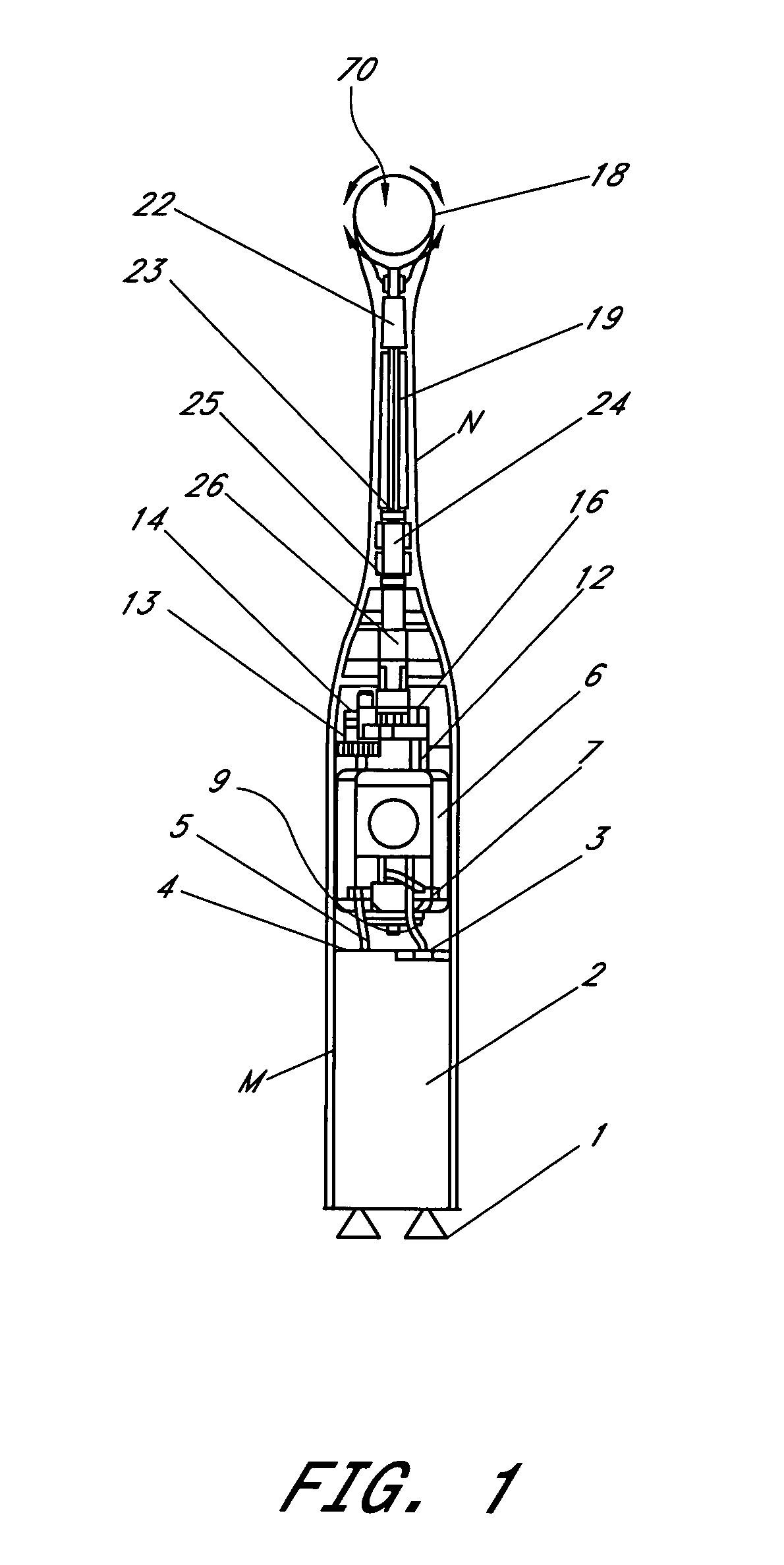

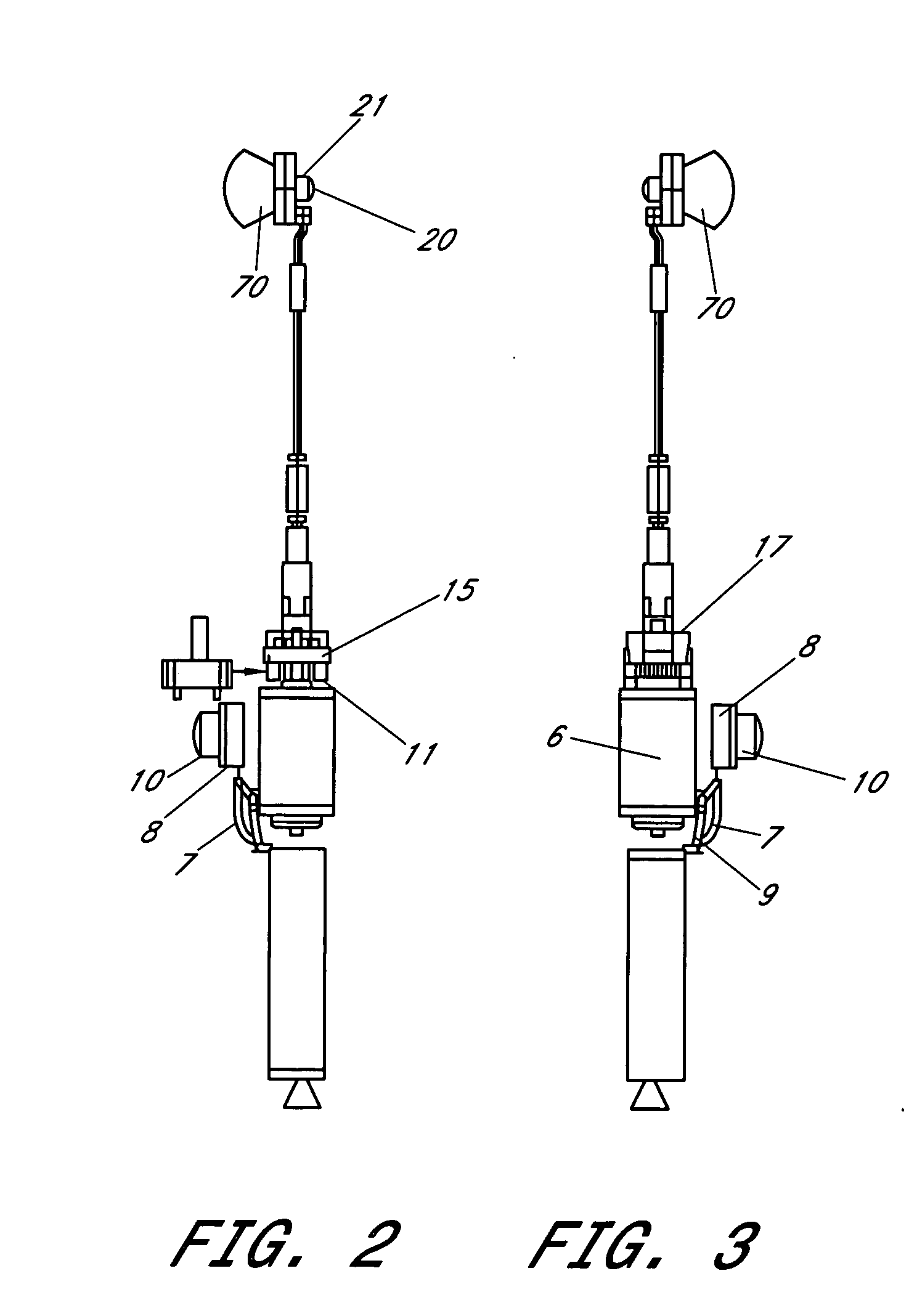

InactiveUS20050214712A1Safe removalEasy to operateDental toolsTooth cleaningEngineeringStain remover

In one embodiment, a dental stain removing device is disclosed. The dental stain removing device preferably comprises a polishing cup, a handle having a longitudinal axis generally perpendicular to a longitudinal axis of the polishing cup, and a neck. The neck is connected to the handle at a proximal end and is connected to the cup at its distal end. A motor and power source are located within the handle, and a shock-absorbing adapter for coupling the neck to the handle is also disposed within the device.

Owner:SHAYGAN FARZAD

Chewing gum and confectionery compositions with encapsulated stain removing agent compositions, and methods of making and using the same

A composition in the form of a chewing gum composition or a confectionery composition containing an encapsulated stain removing agent selected from anionic and non-ionic surfactants and methods of preparing and using the same to remove stains from dental material including teeth.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Papanicolau staining process

InactiveCN1764469AReduce the number of artifactsHydrolasesPeptide/protein ingredientsStainingBiochemistry

A method for treating a biological sample with a Papanicolaou staining process is provided. The method comprises incorporating a detergent treatment into the staining process at any of various steps. The method has been found to advantageously reduce the number of artifacts produced during Papanicolaou staining. Also provided is a sample stained by such a process.

Owner:SITEK CORP

Preparation method of tooth whitening strip

InactiveCN105640787AEasy to prepareEasy to useCosmetic preparationsToilet preparationsWhitening AgentsCurative effect

The invention belongs to the field of oral care, and particularly relates to a preparation method of a tooth whitening strip. The tooth whitening strip adopts a single-layer viscolloid substance, the pH value ranges from 6.5 to 7.5, and the viscolloid is prepared from a whitening agent, a desensitizer, a gelatinizing agent, a stain remover, a sweetener, a humectant, purified water and an appropriate amount of pH regulator. The preparation method of the tooth whitening strip comprises the steps that the whitening agent, the desensitizer, the gelatinizing agent, the stain remover, the humectant, the sweetener, the pH regulator and the purified water are subjected to vacuum emulsification according to a conventional method to prepare the viscolloid, and the tooth whitening strip is directly prepared through continuous processes of coating, slitting, impressing, waste collecting, cutting and the like. The tooth whitening strip prepared through the method is simple in preparation method and convenient to use, and the curative effect is equal to that of a conventional three-layer tooth whitening strip.

Owner:ZHEJIANG ZHEBEI PHARM CO LTD

Self-pressurized spray stain remover

InactiveUS20070015675A1Obviating benefitOrganic detergent compounding agentsDetergent solventsEngineeringPressurized spray

Self-pressurized spray product for removing stains from textiles. Also disclosed is a method for removing stains from textiles. The self-pressurized spray product is designed to deliver a directed product stream. When directed at textile stains, the product stream does not obscure the user's vision of the stain with foam during treatment and further enables the user to observe stain removal during application of the product stream to the stain.

Owner:THE PROCTER & GAMBLE COMPANY

Laundry composition for treatment of sunscreen stains based on extended chain nonionic surfactants

ActiveUS8314057B2Reduce dependenceEasy to cleanNon-ionic surface-active compoundsOrganic detergent compounding agentsEmulsionSurface cleaning

The invention discloses synergistic combinations of surfactants blends and cleaning composition. In certain embodiments a surfactant system is disclosed which includes extended anionic surfactants, linker surfactants, and a multiply charged cation component. This system forms emulsions with, and can remove greasy and oily stains, even those comprised of non-trans fats. In another embodiment anionic surfactants are combined with a solvent, and amine oxide to remove sunscreen stains. The compositions may be used alone, as a pre-spotter or other pre-treatment or as a part of a soft surface or hard surface cleaning composition.

Owner:ECOLAB USA INC

Oral stain remover and oral composition

ActiveUS20090280072A1Efficient removalAvoid depositionCosmetic preparationsToilet preparationsStain removerStain removal

An oral stain remover which can remove a stain or a dental plaque effectively without a need of brushing the surface of teeth with a toothbrush or the like, and an oral composition containing the stain remover. An oral stain remover contains a salt of ultraphosphoric acid, and an oral composition contains the oral stain remover.

Owner:REGENETISS

Non-Aqueous Liquid Oxygen Bleach Composition

ActiveUS20100155659A1No loss of available oxygenImprove abilitiesOxygen/ozone/oxide/hydroxideNon-ionic surface-active compoundsOrganic solventBleach

This invention relates to a novel non-aqueous liquid oxygen bleach composition prepared by dispersing solid peroxygen compound in the liquid in which the content of an anhydrous non-polar organic solvent and a non-ionic and anionic surfactant is controlled. The composition is formed in a high viscous paste or a gel-type suspension and can be used as a multi-purpose composition, for example, the bleach and stain remover of clothes and the cleanser of bathroom and kitchen since they have a chemical / physical stability of no loss of available oxygen, an excellent bleaching and cleaning ability due to their alkaline pH range, no change of viscosity or no phase separation during the storage and so on.

Owner:DC CHEM

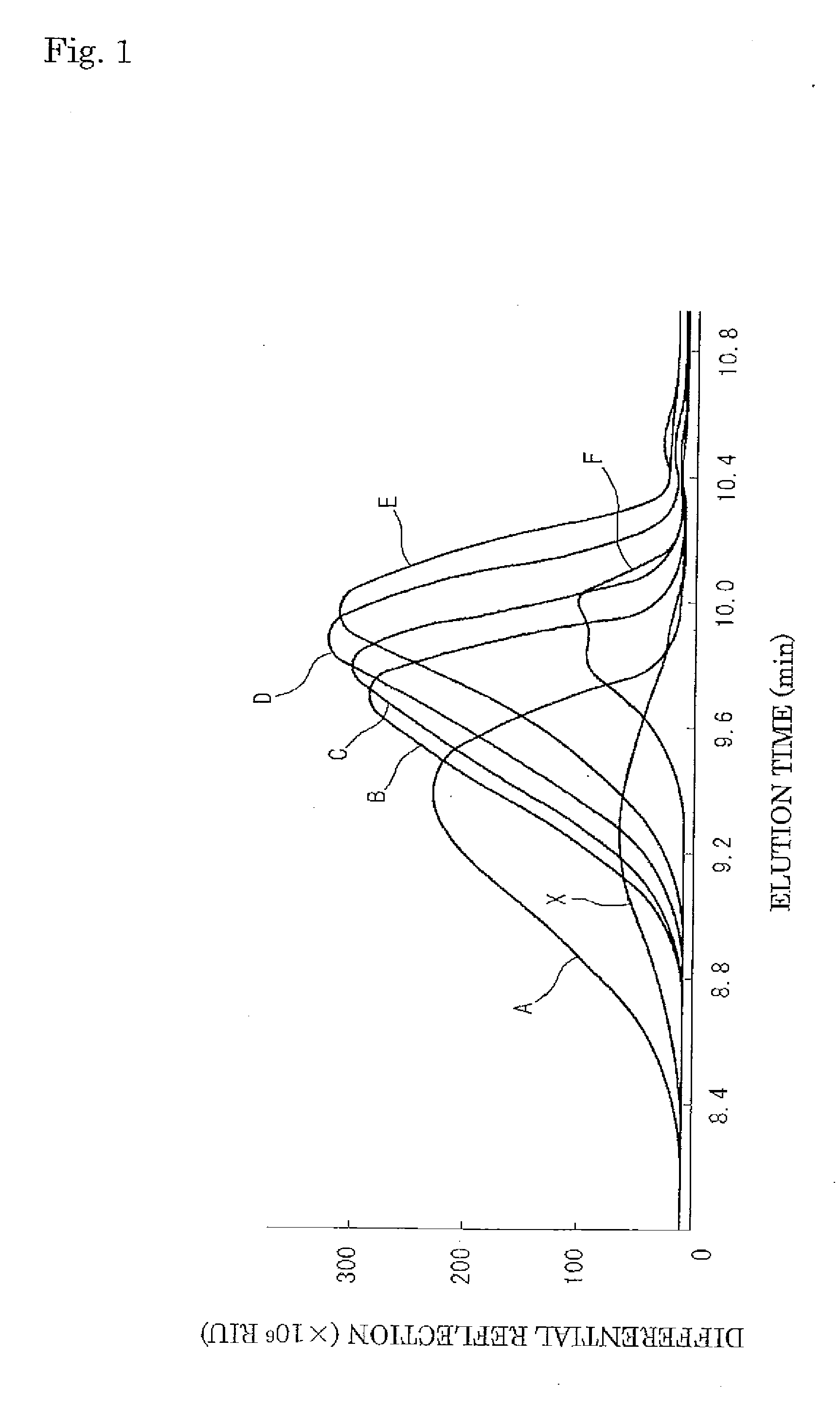

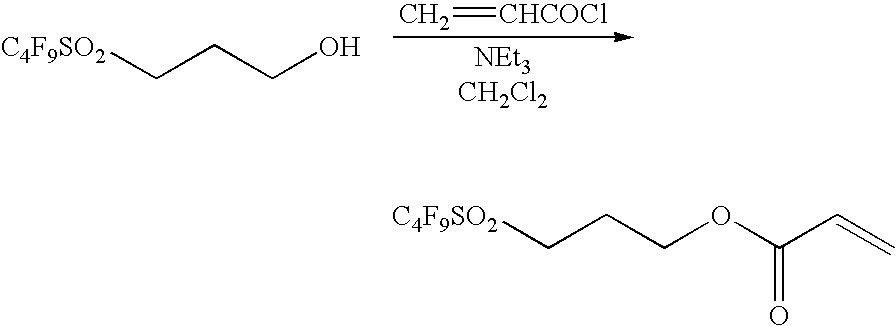

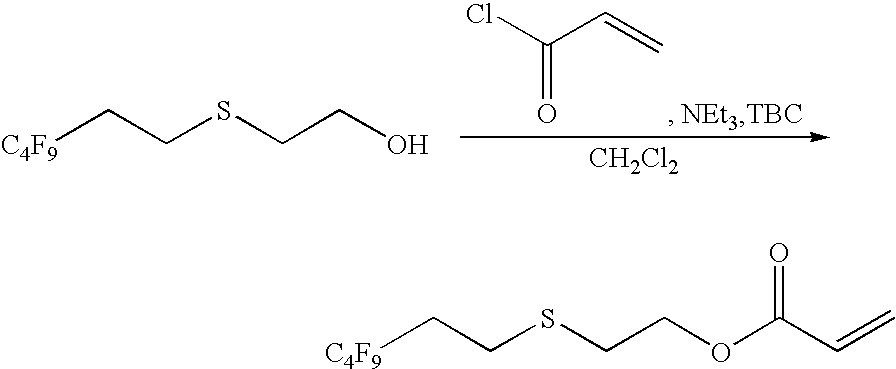

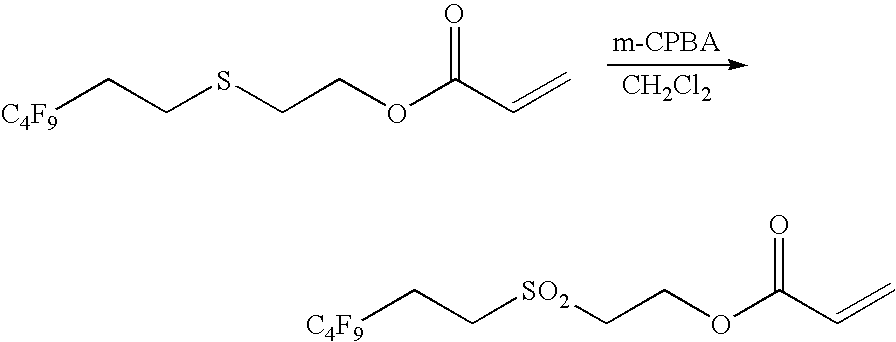

Fluoropolymer and soil remover

InactiveUS20090256102A1Excellent washing durabilityHigh flip-flop propertyFibre treatmentBromineChemistry

A fluorocopolymer formed from, as essential ingredients,(a) a fluoromonomer represented by the general formula:CH2═C(—X)—C(—O)—Y—[—(CH2)m-Z-]p-(CH2)n—Rf (1)[wherein X is hydrogen, C1-21 linear or branched alkyl, fluorine, chlorine, bromine, iodine, —CFX1X2 (wherein X1 and X2 each is hydrogen, fluorine, chlorine, bromine, or iodine), cyano, C1-21 linear or branched fluoroalkyl, (un)substituted benzyl, or (un)substituted phenyl; Y is —O— or —NH—; Z is —S— or —SO2—; Rf is C1-21 fluoroalkyl; m is 1-10; n is 0-10; and p is 0 or 1] and(b) a polyalkylene glycol (meth)acrylate. A soil remover containing this fluorocopolymer imparts to a woven fabric, etc. excellent oil repellency, unsusceptibility to fouling, and the property of releasing stains therefrom, while maintaining durability in washing.

Owner:DAIKIN IND LTD

Aluminum or aluminum alloy surface nanoscale treatment process

InactiveCN105002542AUniform surface porosityExcellent Micro ReamingAnodisationViscosityBinding force

The invention provides an aluminum or aluminum alloy surface nanoscale treatment process. The aluminum or aluminum alloy surface nanoscale treatment process includes the following steps that firstly, aluminum or aluminum alloy is placed in a sulfuric acid solution with the 190 g / L concentration, temperature is kept at 18-22 DEG C, voltage is kept at 17.5 V, and oxidation is conducted for 12-15 minutes; secondly, washing is conducted twice; thirdly, the aluminum or aluminum alloy is placed in a stain remover with the 160 ml / L concentration and the 9-11 PH and immersed for 5-7 minutes at normal temperature; fourthly, washing is conducted twice; fifthly, the aluminum or aluminum alloy is placed in a pore-expanding agent with the 400 ml / l concentration and the 9-11 PH and immersed for 5-7 minutes at normal temperature; sixthly, washing is conducted twice; seventhly, the aluminum or aluminum alloy is placed in a binding agent with the 300 ml / L concentration and the 9-11 PH and immersed for 5-7 minutes at normal temperature; eighthly, washing is conducted twice; and ninthly, the aluminum or aluminum alloy is dried for 10 minutes at the temperature of 65 DEG C. Surface pores of the prepared aluminum or aluminum alloy are uniform, and excellent micro-pore-expanding property and strong viscosity are achieved. When the aluminum or aluminum alloy prepared through the process is subjected to a next injection molding procedure, the binding force of the aluminum or aluminum alloy and plastic particles is extremely strong, firmness is greatly improved, and the drawing force is strong.

Owner:DONGGUAN CITY MAGNESIUM RU AO METAL SURFACE TREATMENT MATERIALS CO LTD

Cleaning compositions employing extended chain anionic surfactants

ActiveUS20180208875A1Reduce energy consumptionReduce water useCationic surface-active compoundsNon-ionic surface-active compoundsAlcoholEmulsion

The invention discloses synergistic combinations of surfactant blends and cleaning compositions employing the same. In certain embodiments a surfactant system is disclosed which includes an extended anionic surfactant with novel co-surfactants including one or more of an alkyl glycerol ether, an ethoxylated alkyl glycerol ether, an alcohol ethoxylate and / or a gemini surfactant. This system forms emulsions with, and can remove greasy and oily stains, even those comprised of non-trans fats. The compositions may be used alone, as a pre-spotter or other pre-treatment or as a part of a soft surface or hard surface cleaning composition.

Owner:ECOLAB USA INC

Underarm stain remover composition

InactiveUS20120304397A1Surface-active detergent compositionsDry-cleaning apparatus for textilesMedicineAxilla

Owner:MD TECHN SOLUTIONS

Leather brightening and stain removing agent

InactiveCN104356955ADelay aging oxidationIncrease brightnessSurface-active detergent compositionsDetergent compounding agentsPolymer scienceAcrylic resin

The invention discloses a leather brightening and stain removing agent, which is prepared from the following raw materials in parts by weight: 13 to 19 parts of glycerol trioleate, 6 to 10 parts of N-alkyl stearamide, 3 to 7 parts of a mildew preventive, 6 to 11 parts of nonylphenol polyoxyethylene ether, 3 to 8 parts of acetone, 7 to 13 parts of montan wax emulsion, 3 to 6 parts of propylparaben, 2 to 5 parts of ethanol, 1 to 5 parts of methyl hydrogen silicone oil, 2 to 8 parts of oleic acid, 1 to 3 parts of lavender essential oil, 4 to 10 parts of amino silicone oil and 2 to 10 parts of waterborne acrylic resin emulsion. The leather brightening and stain removing agent has the benefits of stains on the surface of leather can be well removed; meanwhile, a layer of protective film is formed on the surface of the leather, so that the aging and oxidation of the leather are retarded, and the brightness of the leather is improved.

Owner:QINGDAO KELIKE INFORMATION TECH

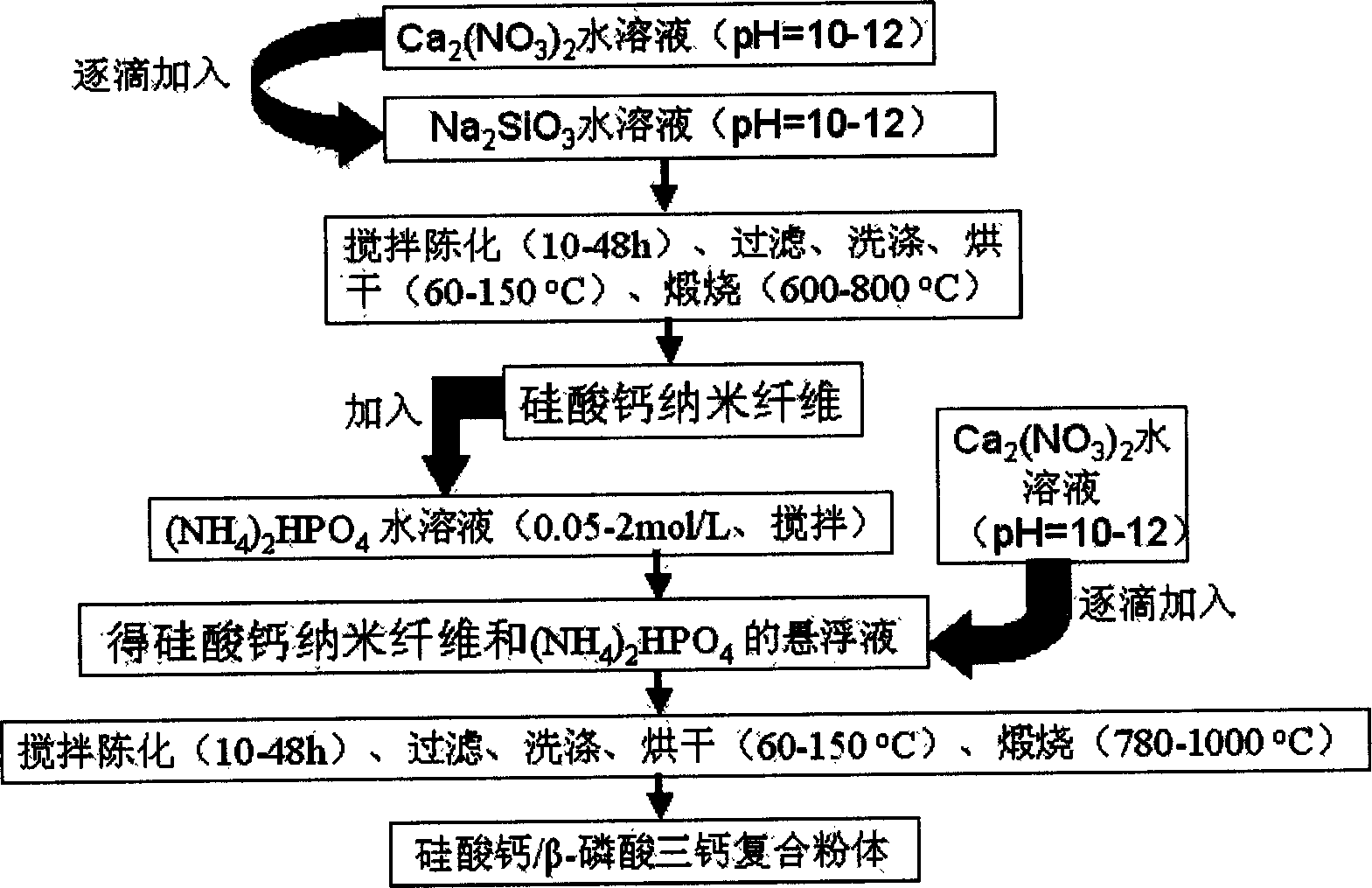

Method for preparing calcium silicate/beta- tricalcium phosphate composite powder by two-step chemical precipitation method

The invention relates to a method for preparing calcium silicate / beta- tricalcium phosphate nanometer complex powder in the field of biology medical material. It is characterized in that it adopts soluble silicate, calcium nitrate, diammonium phosphate and ammonia and so on as raw material. It uses the soluble silicate and calcium nitrate as raw material to prepare calcium silicate nanometer fiber powder by chemical precipitation, it distracts the calcium silicate nanometer fiber powder into the water solution of diammonium phosphate and adjusts the PH value to obtain the stain remover, it then drops the silicate nanometer fiber powder into the stain remover to do the second chemical precipitation to generate the tricalcium phosphate precipitation, then it washes and burns at 780-1000 deg. to obtain the calcium silicate / beta- tricalcium phosphate nanometer complex powder.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ceramic floor tile slip preventing agent and preparation method thereof

InactiveCN107141852AHigh anti-slip coefficientImprove durabilityAntifouling/underwater paintsPaints with biocidesWaxMetallurgy

The invention discloses a ceramic floor tile slip preventing agent. The ceramic floor tile slip preventing agent comprises the following components in percent by weight: 12% of tartaric acid, 10% of citric acid, 15% of sodium dodecyl sulfate, 0.8% of a defoaming agent, 6% of sodium chloride, 3.2% of an emulsifying agent, 6% of a stain remover, 4% of a wax remover and 43% of deionized water. The ceramic floor tile slip preventing agent is non-toxic, harmless, high in non-slip coefficient and high in durability and has relatively high stain removing performance.

Owner:上海地宝防滑防护科技有限公司

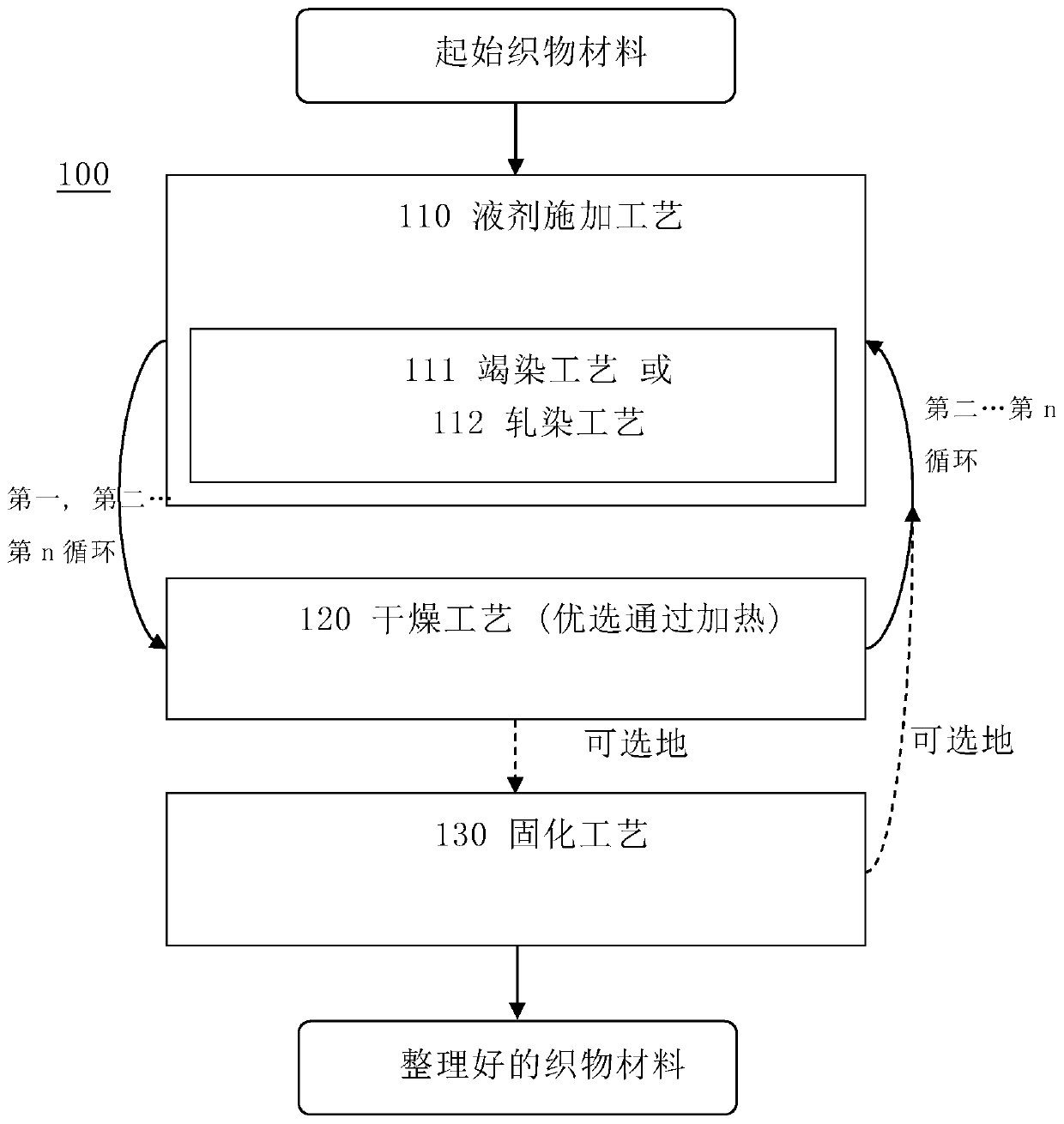

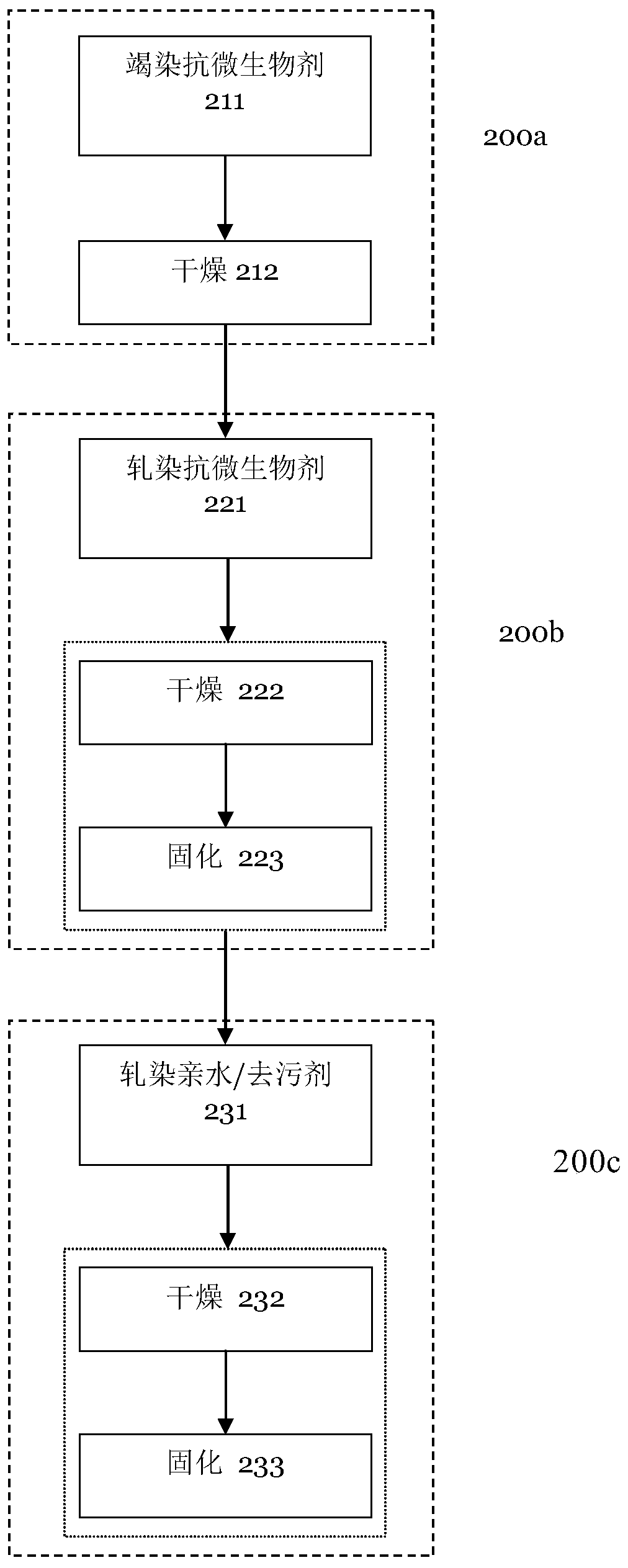

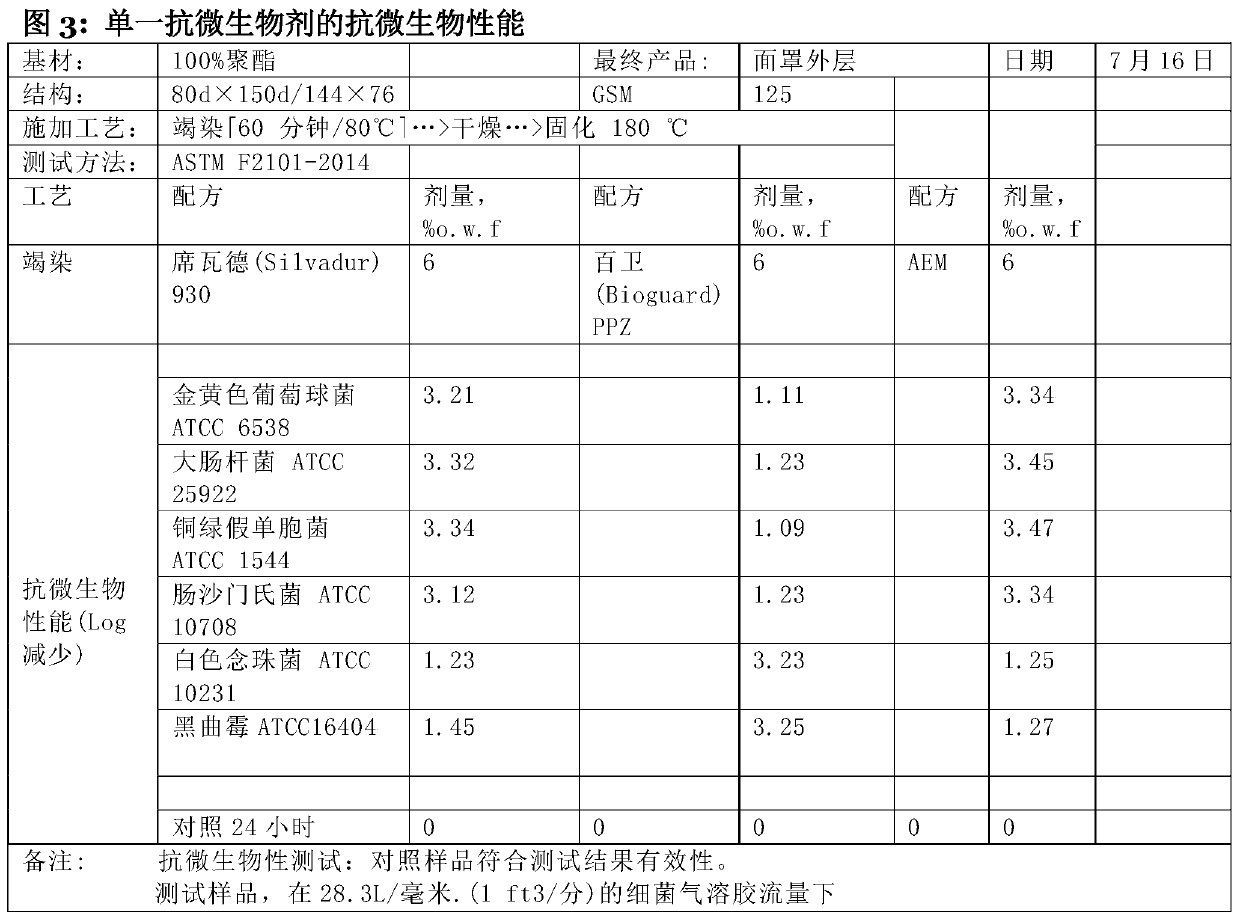

Wash-durable face mask with antimicrobial properties and/or improved washability

InactiveCN109862798AReduce high filtration efficiencyReduce filtration efficiencyBiocideCosmetic preparationsParticulatesEngineering

The present invention is directed to a face mask comprising a multi-layer filter material. One or more antimicrobial and / or hydrophilic and / or stain release agents are adhered to a textile material that forms the outer layers of the multi-layerfilter material. The agent(s) is / are adhered to the textile material in such a manner that they are not released from the textile material even if the facemask is washed, so that the face mask as such is re-usable. The particular arrangement of textile layers of the face mask according to the present invention also allows that the face mask can be washed. That is, the textile and the overall structure of the face mask is preserved albeit the physical stress applied during washing. In preferred embodiments, where one or more antimicrobial agents areadhered to the textile material, the face mask can be used to protect the wearer against airborne particulate and microbial pollution, and, in particular, sanitize the inhaled air. Likewise, the environment, such as other persons, are protected from particles and microbes that are exhaled by the wearer of a face mask according to the present invention. Washability and / or usability of the textile material within the multi-layerfilter material of the face mask is / are improved when one or more hydrophilic and / or stain release agents are adhered to the textile material, which is particularly advantageous to ensure that the face mask is rendered as clean as possible during wash, i.e. that absorbed or adsorbed stains are released from the textile. The invention further relates to a method of finishing a textile material by applying and binding antimicrobial and / or hydrophilic and / or stain release agents to the textile material so that the agents are essentially irreversibly adhered to the finished textile material.

Owner:LIVINGUARD AG

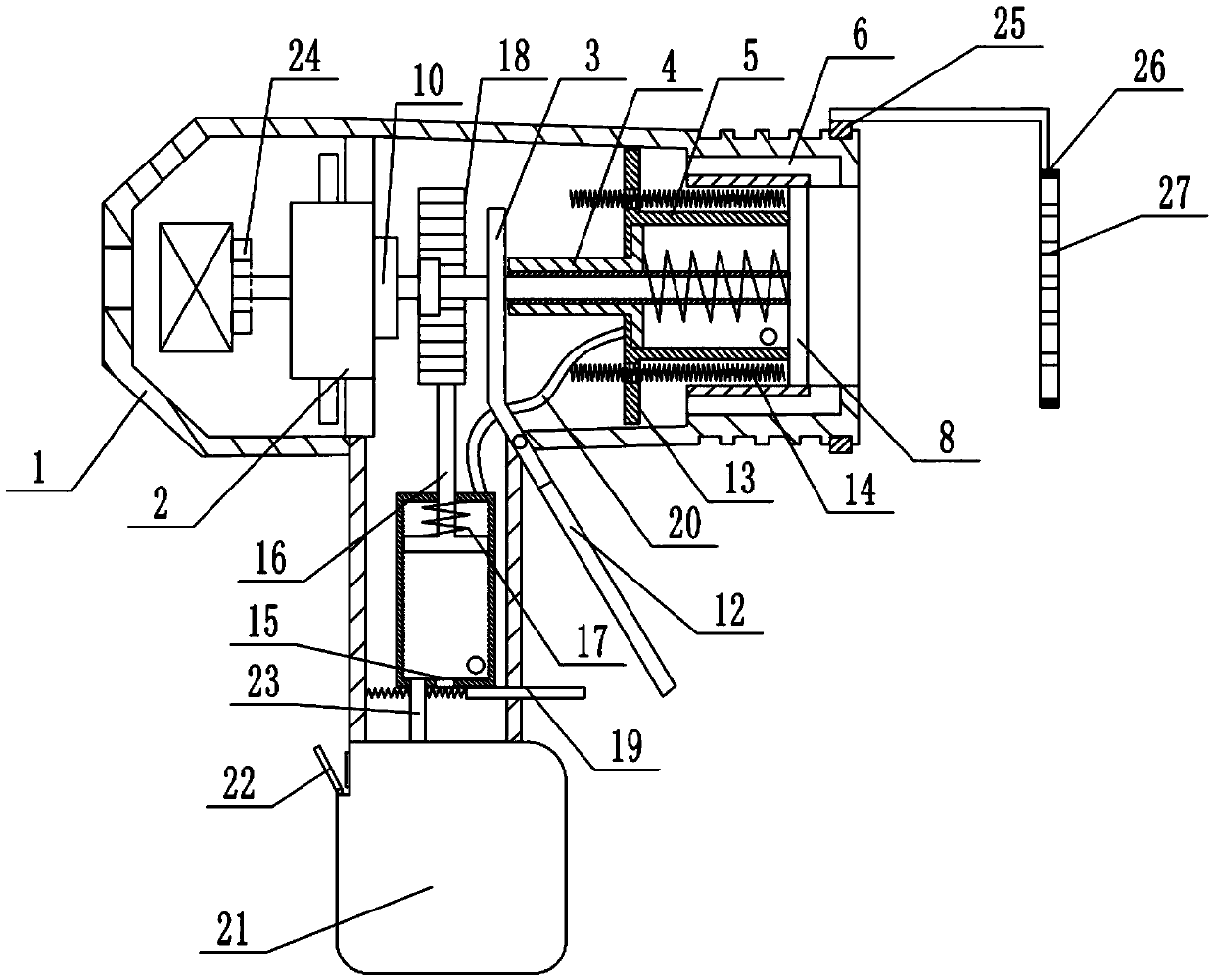

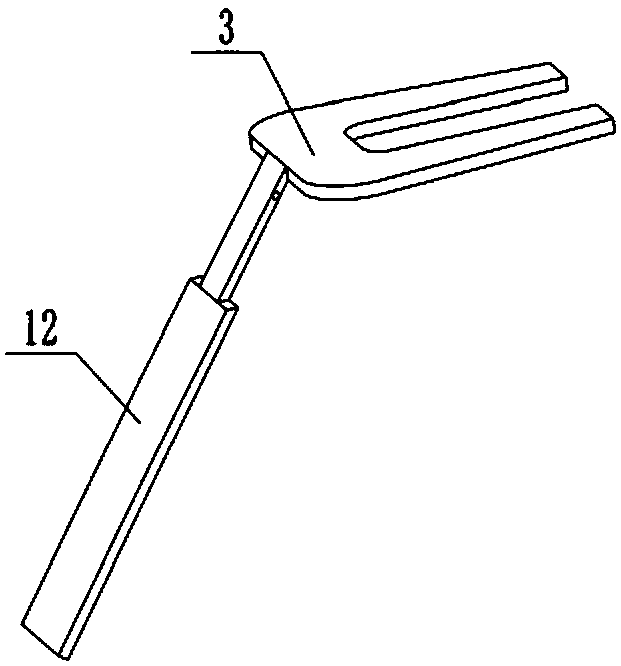

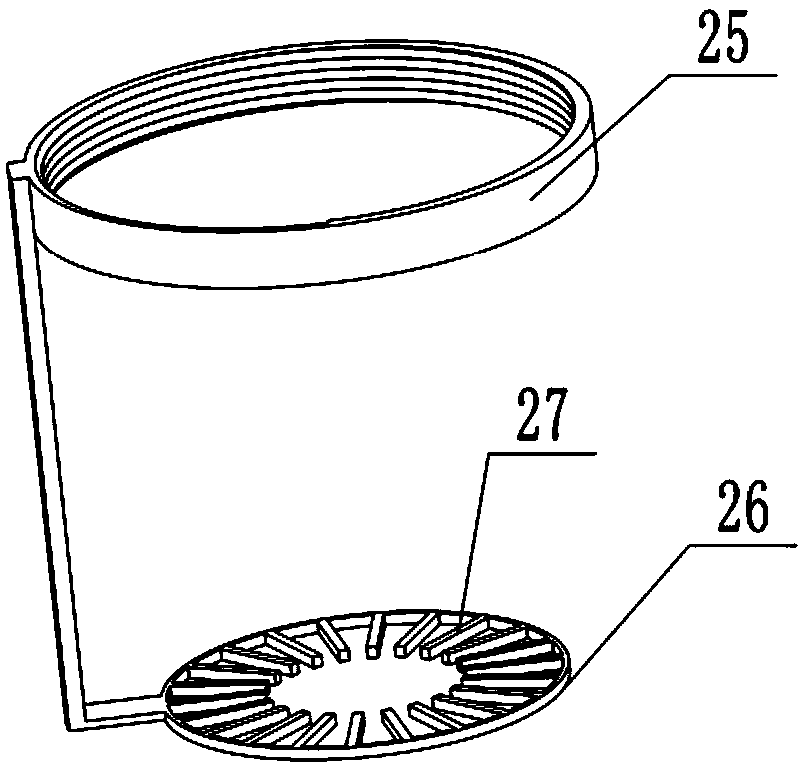

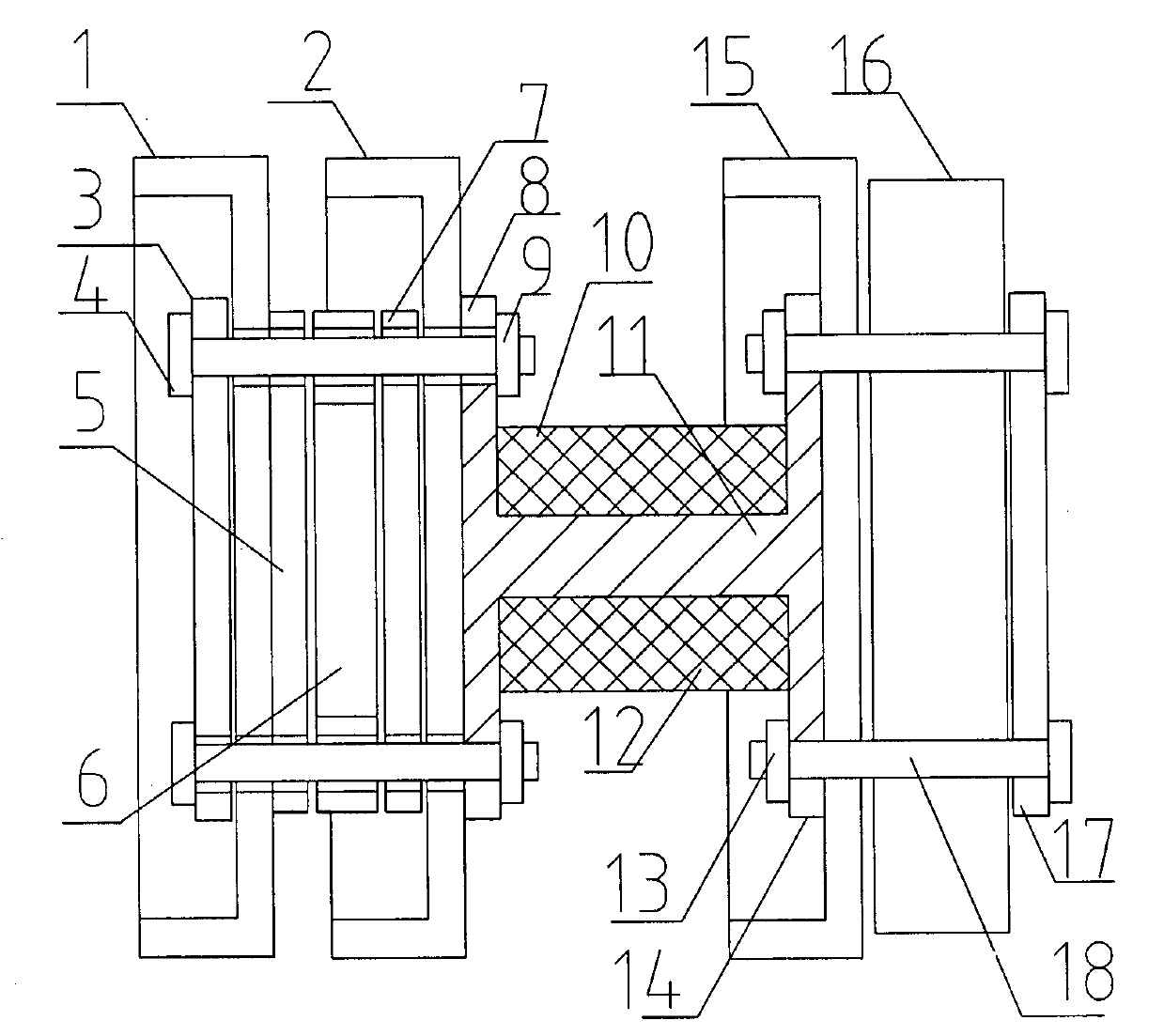

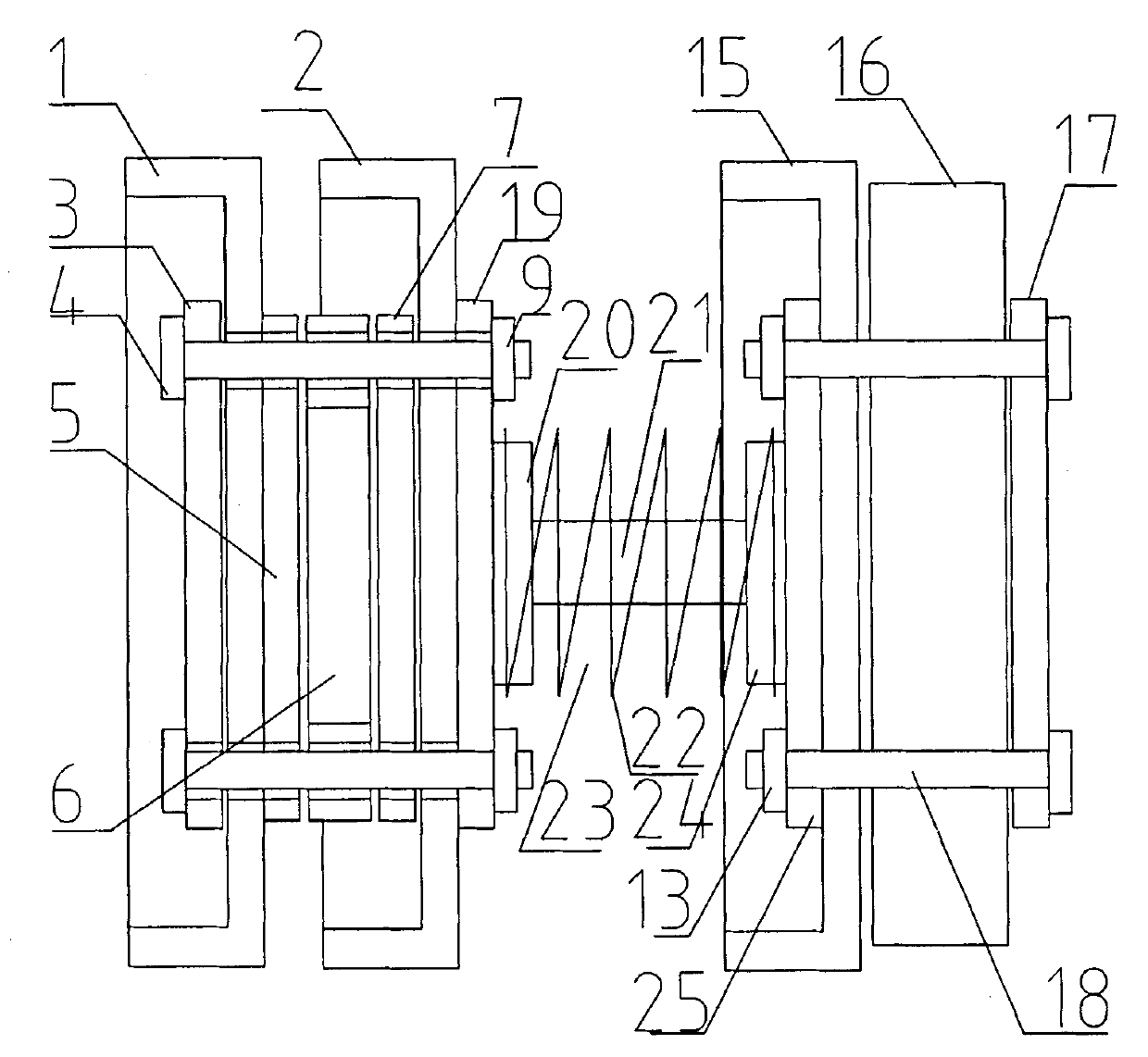

Handheld carpet stain remover

InactiveCN109567689AEasy to cleanReduce kneading forceCarpet cleanersFloor cleanersWater storage tankEngineering

The invention relates to the field of carpet cleaning supplies, in particular to a handheld carpet stain remover. The carpet stain remover comprises a shell and a handle, wherein a motor, a fan, a shift fork, a shift rod, a plunger, a liquid injection barrel, a ventilation channel and limit blocks are arranged in the shell, a first gear, an incomplete gear and a rotating disc are coaxially arranged on an output shaft of the motor, and an annular groove, a brush and water outlet holes are arranged on the rotating disc; a ring and a tooth part are arranged on a fan; support blocks, through holes, electric heating wires and first springs are arranged on the liquid injection barrel; an air cylinder air hole, a piston rod, a second spring, a rack, a cover plate, a third spring and a hose are arranged in a handle, a water storage tank is connected onto the handle and connected with an air cylinder, and a one-way valve is mounted in a water supply pipe. The handheld carpet stain remover solves the problems that carpets with down are not thoroughly cleaned and down is mixed and intertwined in the prior art and has the advantages of being portable and light.

Owner:象山谢海家具有限公司

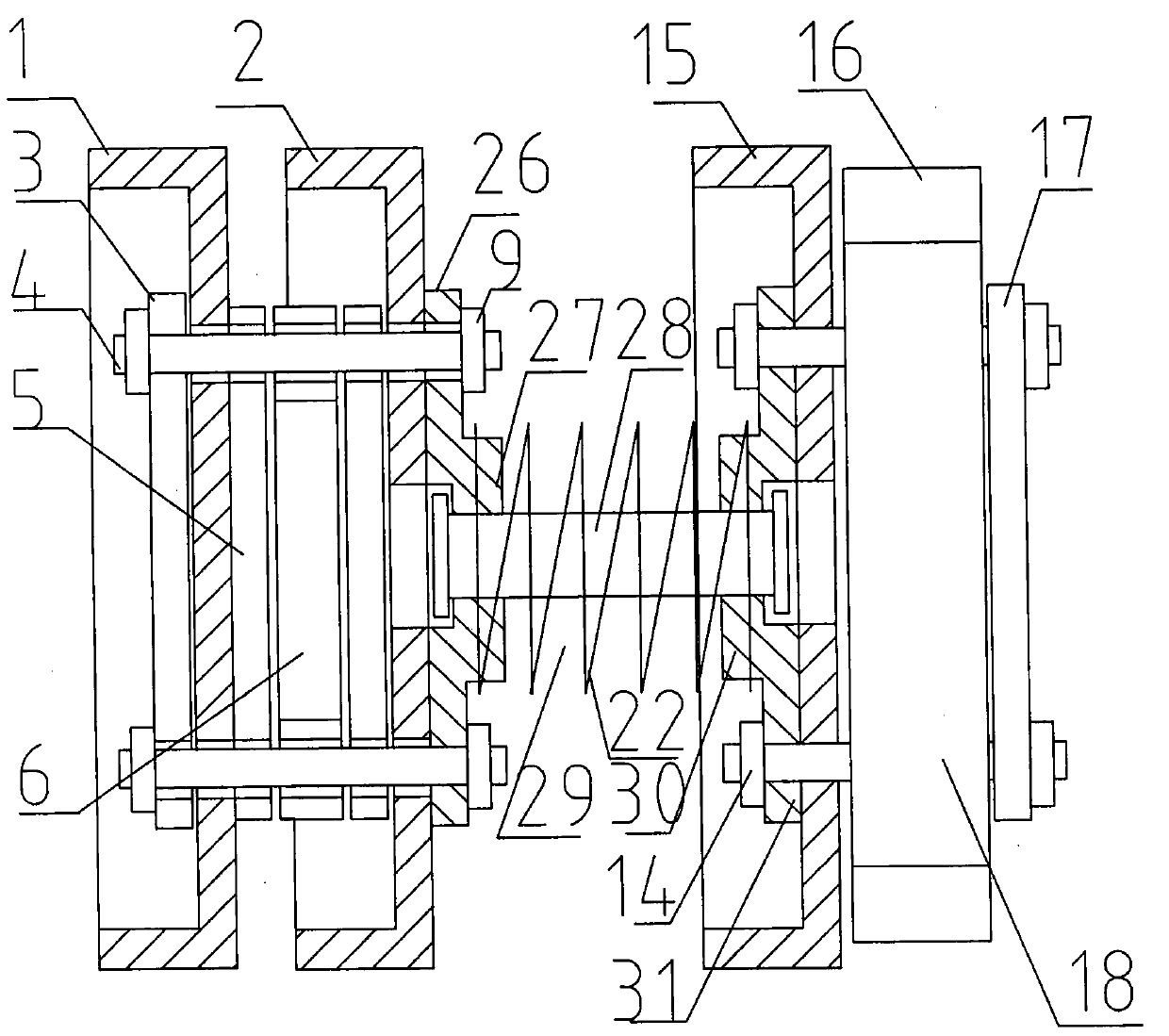

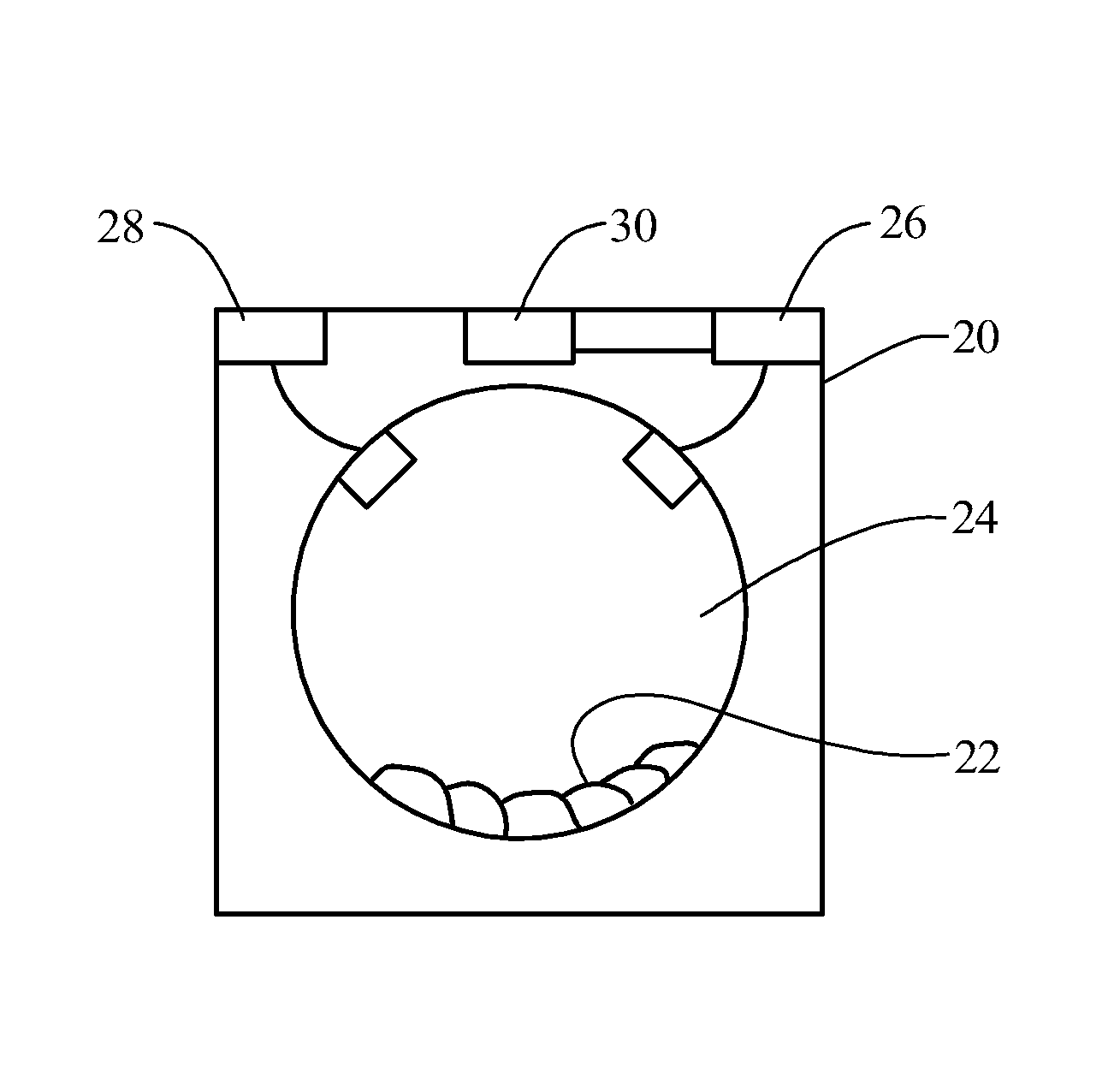

Pipeline stain remover

InactiveCN104174618AProtection intactExtended service lifeHollow article cleaningEngineeringMechanical engineering

The invention provides a pipeline stain remover, which consists of a first sealing leather cup, a second sealing leather cup, a third sealing leather cup, a stain removing wheel and a first elastic shaft, or a second elastic shaft, or a third elastic shaft, or a fourth elastic shaft, or a fifth elastic shaft, or a seventh elastic shaft. Compared with the prior art, the pipeline strain remover has the advantages that when the pipeline strain remover passes through a pipeline elbow, the self elastic shaft can naturally bend to turn along with the elbow, and after the pipeline strain remover passes through the pipeline elbow, through the self memory function, the working of immediately doing parallel movement to the pipeline axial line is realized, so that the undamaged completeness and the normal operation of the pipeline stain remover are protected, the service life of the pipeline stain remover is greatly prolonged, meanwhile, the pipeline stain remover is positioned at the elbow turning part, the pipeline stain remover can maintain the original state, the sealing performance is good, the air leakage is avoided, the resources are saved, the operation speed of the pipeline stain remover is uniform, the service life of the pipeline stain remover is prolonged, the scale removing cleaning efficiency is greatly improved, and the integral benefits are very obvious.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

Fabric stain remover

InactiveCN103131564AWill not corrodeWon't hurt handsSoap detergents with organic compounding agentsSoap detergents with inorganic compounding agentsSODIUM METAPHOSPHATEPhosphoric acid

The invention discloses fabric stain remover. The fabric stain remover is composed of following raw materials, by weight, 6-12 parts of sodium metaphosphate, 4-6 parts of stannic chloride, 4-6 parts of potassium oxalate, 2-4 parts of amyl acetate, 10-12 parts of white soap powder, 4-8 parts of citric acid, 1-2 parts of caustic soda and 10-20 parts of water. The fabric stain remover can remove stains on fabrics obviously, the fabrics do not corrode, hands are not hurt, and demands of people are met.

Owner:NANTONG SHUNYANG CHEM

Washer and washer control with cycles for laundry additives and color safe bleaches/in-wash stain removers

A washer and a control for an automatic washer to operate the washer through a wash cycle selected based upon a range of conditions of a fabric load to be washed. The control has a plurality of selectable stain type entrées, each with a particular dedicated wash cycle. The control also has dispensing control over at least two wash liquor additives, one being a detergent and the other being an oxidizing agent. The control operates the dedicated wash cycles, as selected, using both the detergent and the oxidizing agent, however, the detergent and the oxidizing agent may be dispensed in different orders and at different times and in different amounts, depending on the stain type selected.

Owner:WHIRLPOOL CORP

Dry-cleaning peel-off-type powder-residue-free decontaminating agent, and preparation method thereof

ActiveCN108676637ANo secondary residueDecontamination fastOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsFilm-forming agentChemistry

The invention discloses a dry-cleaning peel-off-type powder-residue-free decontaminating agent, and a preparation method thereof. The dry-cleaning peel-off-type powder-residue-free decontaminating agent comprises, by mass, 780 to 875 parts of a solvent, 30 to 45 parts of a decontamination auxiliary agent, 55 to 100 parts of an adsorbent, and 25 to 45 parts of a film forming agent. In applicationsof the dry-cleaning peel-off-type powder-residue-free decontaminating agent, the dry-cleaning peel-off-type powder-residue-free decontaminating agent is sprayed onto stain using an aerosol can, no powder is left after drying, a layer of thin film with toughness is formed, stain is degraded effectively and absorbed by the thin film; when the dry-cleaning peel-off-type powder-residue-free decontaminating agent on fabric stain is dried completely, the thin film can be removed through peeling off, no powder pollution is caused in decontamination process, no secondary residue is left, decontamination is quick, and treatment is convenient.

Owner:吉林市懋杰工贸有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com