Wash-durable face mask with antimicrobial properties and/or improved washability

An antimicrobial agent and face mask technology, which is applied in the field of finishing fabric materials, can solve the problems that antimicrobial fibers are not washable and face masks cannot be reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

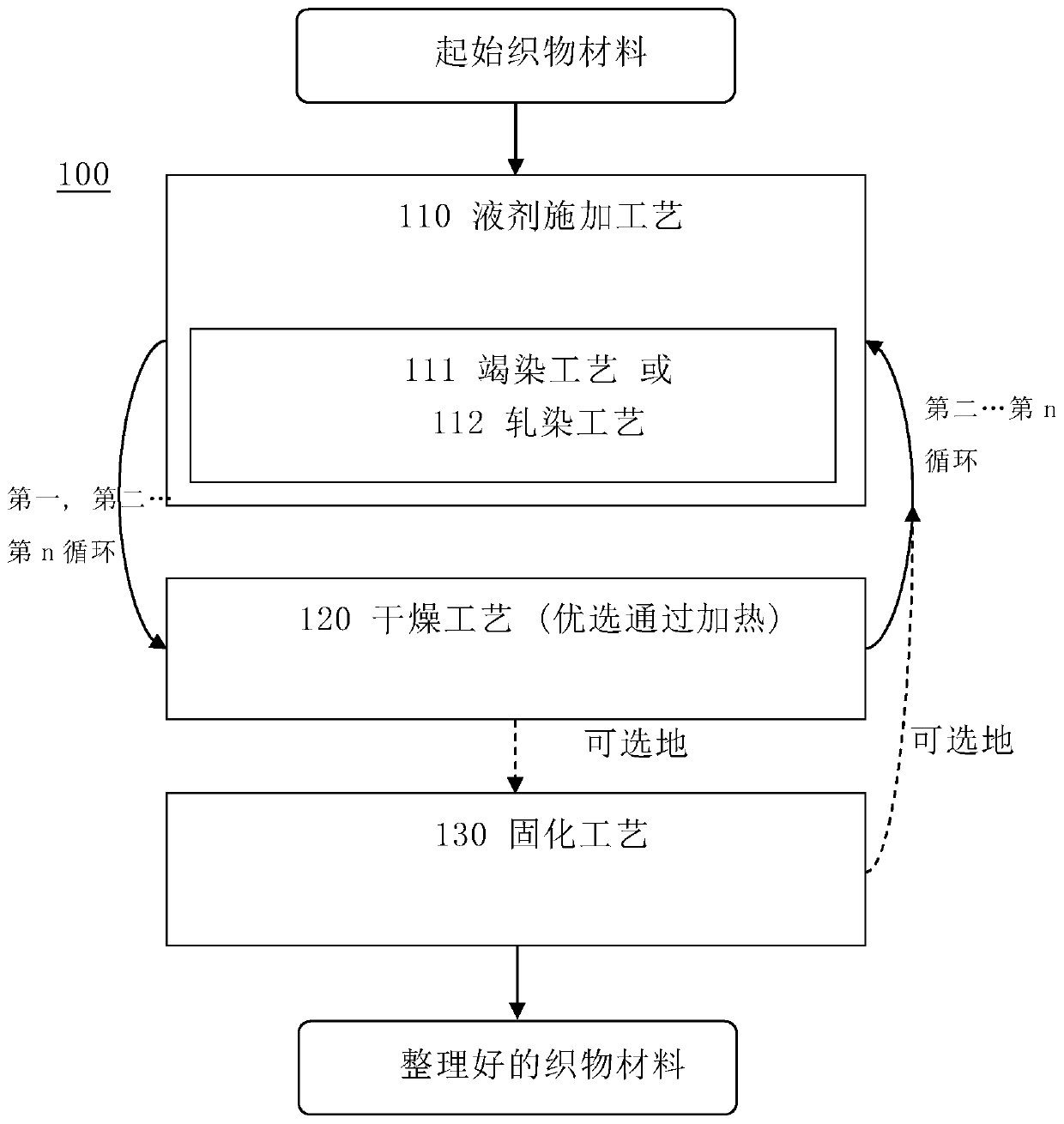

Method used

Image

Examples

example

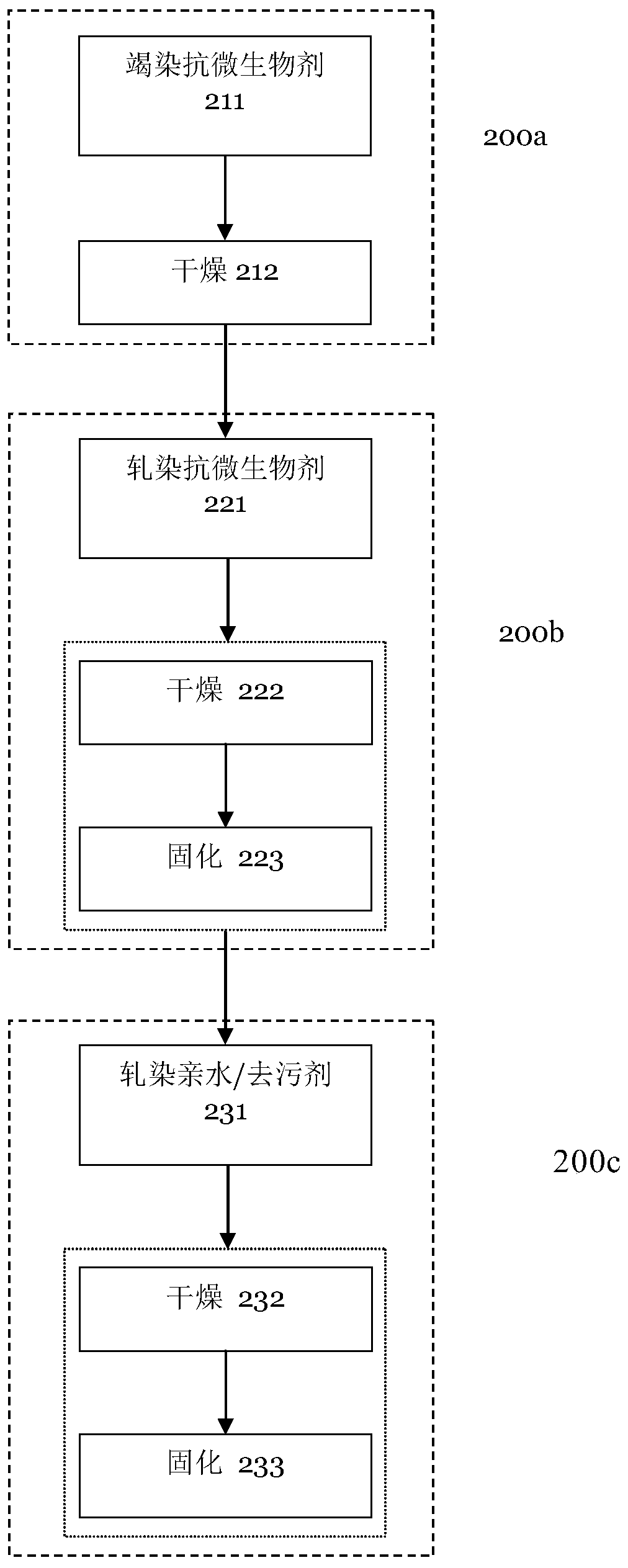

[0330] A series of different fabric materials were finished and the finished fabric materials, different multi-layer filter materials and different face masks were tested according to the test protocol described herein. The collation process and test results as well as the reference to the basic test scheme are summarized in Figure 3 to Figure 12 in the table. All finished fabric materials are treated with antimicrobial agents and can be used in multi-layer filter materials and face masks. Multilayer filter materials are assembled by sandwiching one to four layers of granular filter material between two layers of finished fabric material. The layers were joined to each other using ultrasonic welding in a rectangular shape of approximately 144 mm x 76 mm to form a pad. The pad is equipped with straps on all four corners of the pad, thus forming a mask that can fit over the wearer's mouth and nose.

[0331] The finishing process is summarized above each table under the "Appl...

experiment example 1

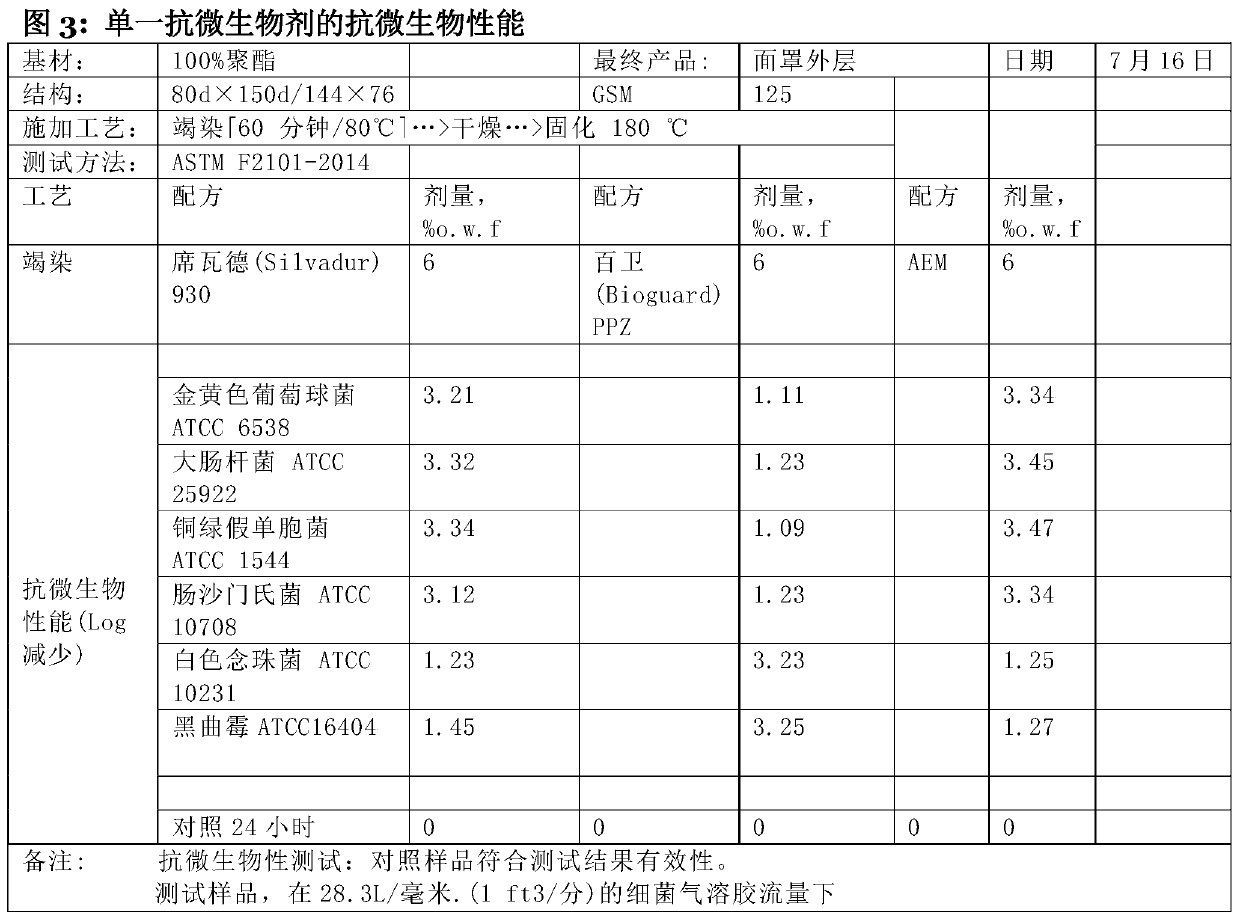

[0363] EXPERIMENTAL EXAMPLE 1: DIFFERENT COMBINATIONS OF ANTIMICROBIAL AGENTS

[0364] For Experimental Example 1, the effect of applying different amounts of reagents to the starting fabric material was investigated. The agents applied to polyester materials were taken from the group of silver, quaternary ammonium organosilanes and propiconazole, which are the three most preferred antimicrobial agents for treating polyester fabric materials.

[0365] (1) fabrics were treated with each agent from the corresponding group individually, (2) fabrics were treated with all triplet combinations of agents from each group, and (3) fabrics were treated with all three agents from each group together. The total amount of chemicals in all experiments was 6% o.w.f. Therefore, in the case of a single agent applied to the fabric, the corresponding chemical is used at 6% o.w.f; in the case of a combination of two agents applied to the fabric, the respective two chemicals are used at 3% o.w.f...

experiment example 2

[0371] Experimental Example 2: Particle Penetration and Breathing Resistance

[0372] The purpose of Experimental Example 2 was to study the effect of different grades of particulate filter material used in the multi-layer filter material of face masks on particle penetration and breathing resistance. Testing is performed according to standard test IS 9473:2002.

[0373] Figure 6 The data of Experimental Example 2 are shown, in which the inner layer material of the multi-layer filter material is N95 grade granular filter material. One, two, three or four layers of this N95 grade particulate filter material are sandwiched by fabric material. Breathing resistance is significantly increased by using more than one layer of N95-grade particulate filter material between two layers of outer fabric material. The required filtration efficiency of at least 95% is achieved by using at least two layers of N95-rated particulate filter material between two layers of outer fabric materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com