Method for producing wet-process phosphoric acid and alpha hemihydrate phosphogypsum by using medium-grade phosphorite

A technology of phosphogypsum hemihydrate and wet-process phosphoric acid, which is applied in chemical instruments and methods, phosphorus compounds, calcium/strontium/barium sulfate, etc., can solve the problems of high gypsum impurity content, unsuitability for medium and low-grade phosphate rock production, and constraints Comprehensive utilization of phosphogypsum and other issues to achieve the effect of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

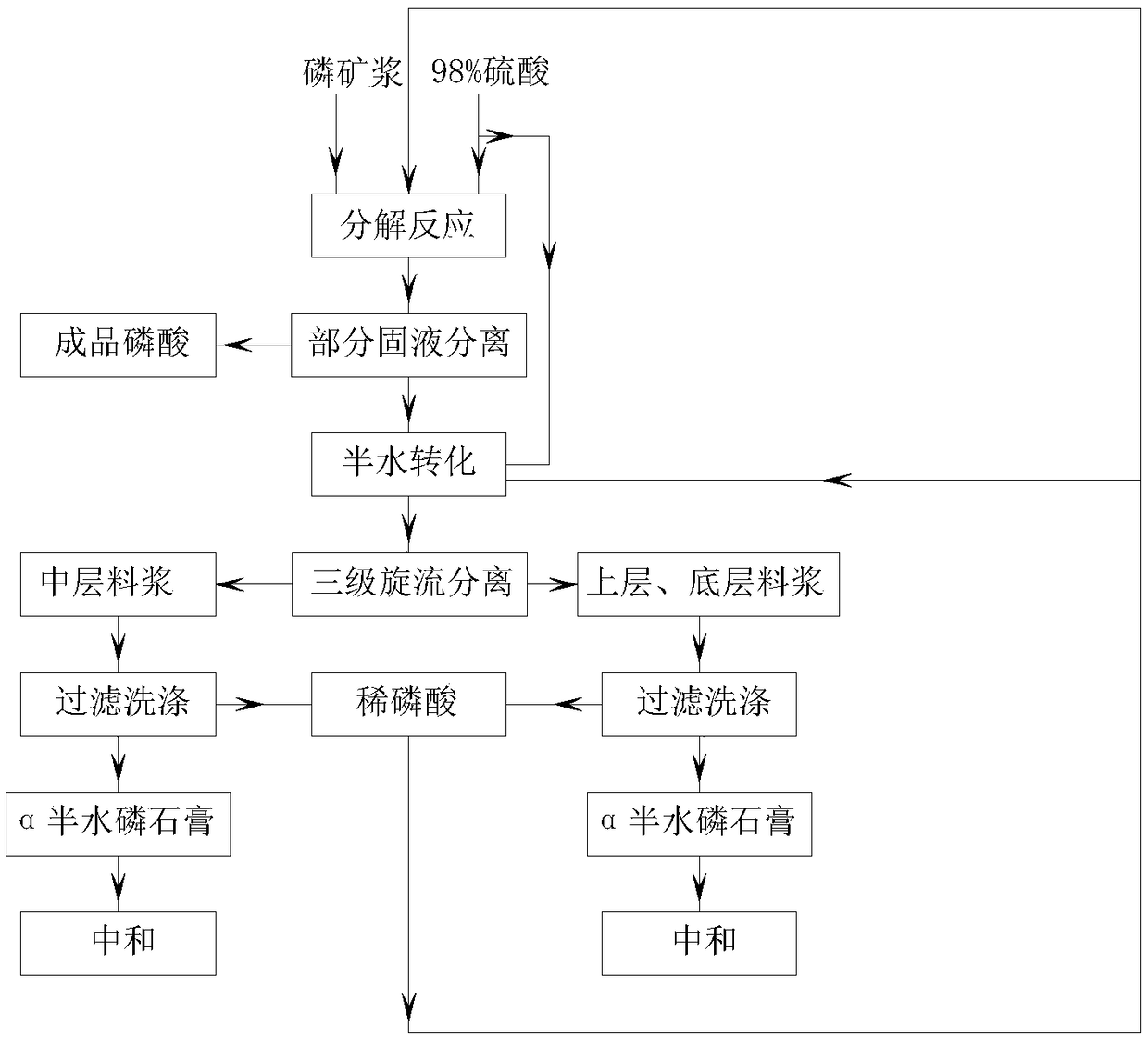

Method used

Image

Examples

Embodiment 1

[0034] Step 1, 1# phosphate rock described in table 1 is ground into phosphate rock slurry (30wt.%H 2 O) and 98wt.% concentrated sulfuric acid are added continuously to the decomposition tank with the amount of 7.1t / h, 0.8t / h respectively, add simultaneously the ω (P 2 o 5 ) 32.7wt.% of dilute phosphoric acid and a mixture of primary washing liquid, and the three carry out the decomposition reaction of phosphate rock, wherein the phosphate rock slurry is converted into dry basis, and 98wt.% concentrated sulfuric acid is converted into pure H 2 SO 4 , dilute phosphoric acid converted into P 2 o 5 The mass ratio of the latter three is 1:0.16:1.6, and the process index of the control decomposition tank: temperature 80-85°C; free sulfate ion (SO 4 2- ) concentration of 10-20g / L; the solid content of the slurry is 25wt.%; the reaction time is 2.5-3h to obtain the phosphate ore decomposition mixed slurry.

[0035] Step 2, in step 1, mixed slurry (accounting for 47wt.%) carries...

Embodiment 2

[0046] Step 1, 2# phosphate rock described in table 1 is ground into phosphate rock slurry (30wt.%H 2 O) and 98wt.% concentrated sulfuric acid are added continuously to the decomposer with the amount of 8.6t / h, 2.1t / h respectively, add simultaneously the ω (P 2 o 5 ) 28wt.% of dilute phosphoric acid and a mixture of primary washing liquid, the three carry out the decomposition reaction of phosphate rock, wherein the phosphate rock slurry is converted into dry basis, and 98wt.% concentrated sulfuric acid is converted into H 2 SO 4 , dilute phosphoric acid converted into P 2 o 5 The mass ratio of the latter three is 1:0.32:1.3, and the technical indicators of the decomposition tank are controlled: temperature 80-85°C; free sulfate (SO 4 2- ) concentration of 10-20g / L; the solid content of the slurry is 25wt.%; the reaction time is 2.5-3h to obtain the phosphate ore decomposition mixed slurry.

[0047] Step 2, mixed slurry (accounting for 47wt.%) in step 1 carries out solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com