Suction type filtering-condensing apparatus

A thickening device and filter plate technology, which is applied to fixed filter element filters, filtration separation, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of reduced operating performance, clogged filtration performance, and reduced filtration efficiency, and eliminate Reduced filtration efficiency, effect of ensuring filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

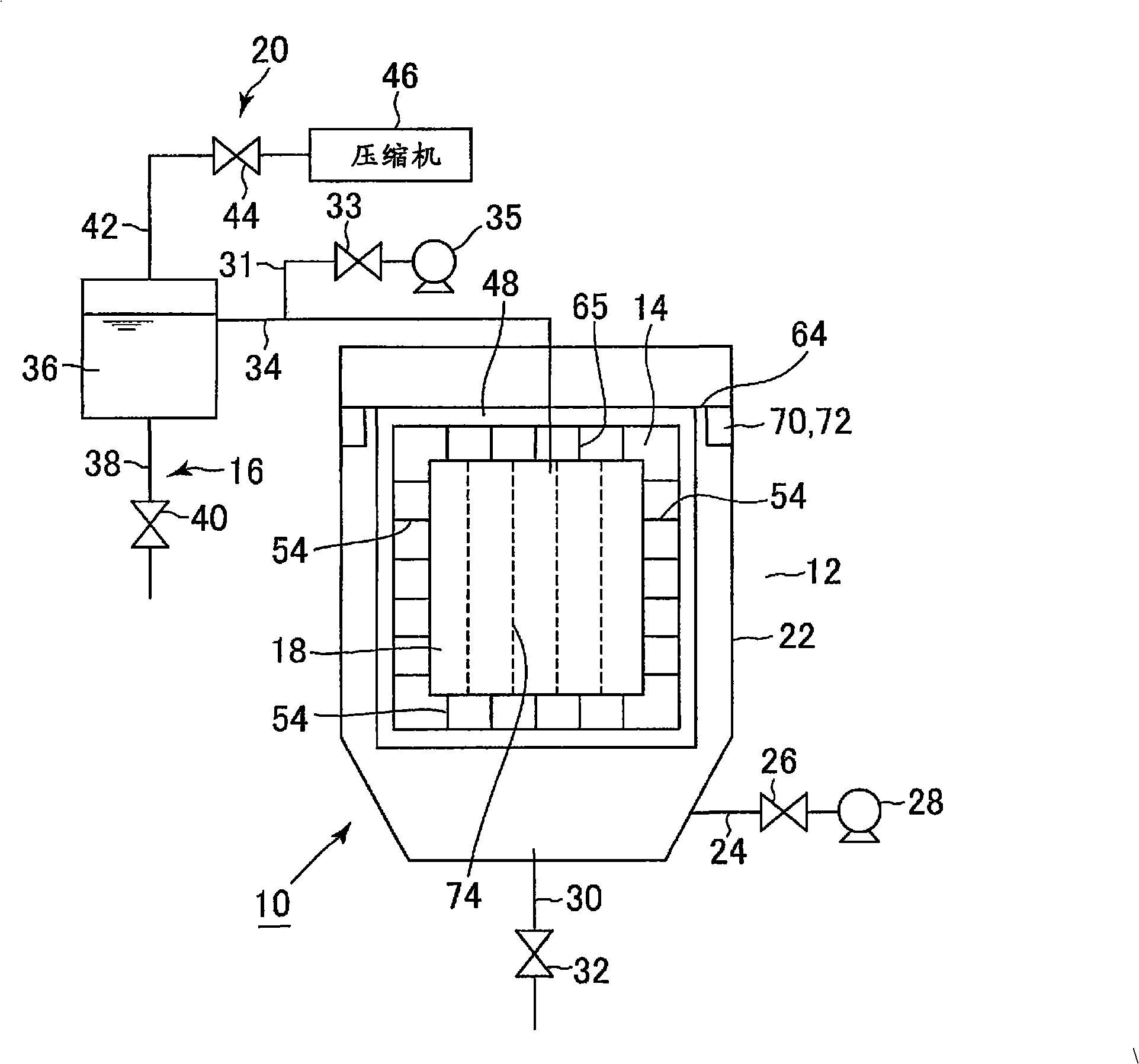

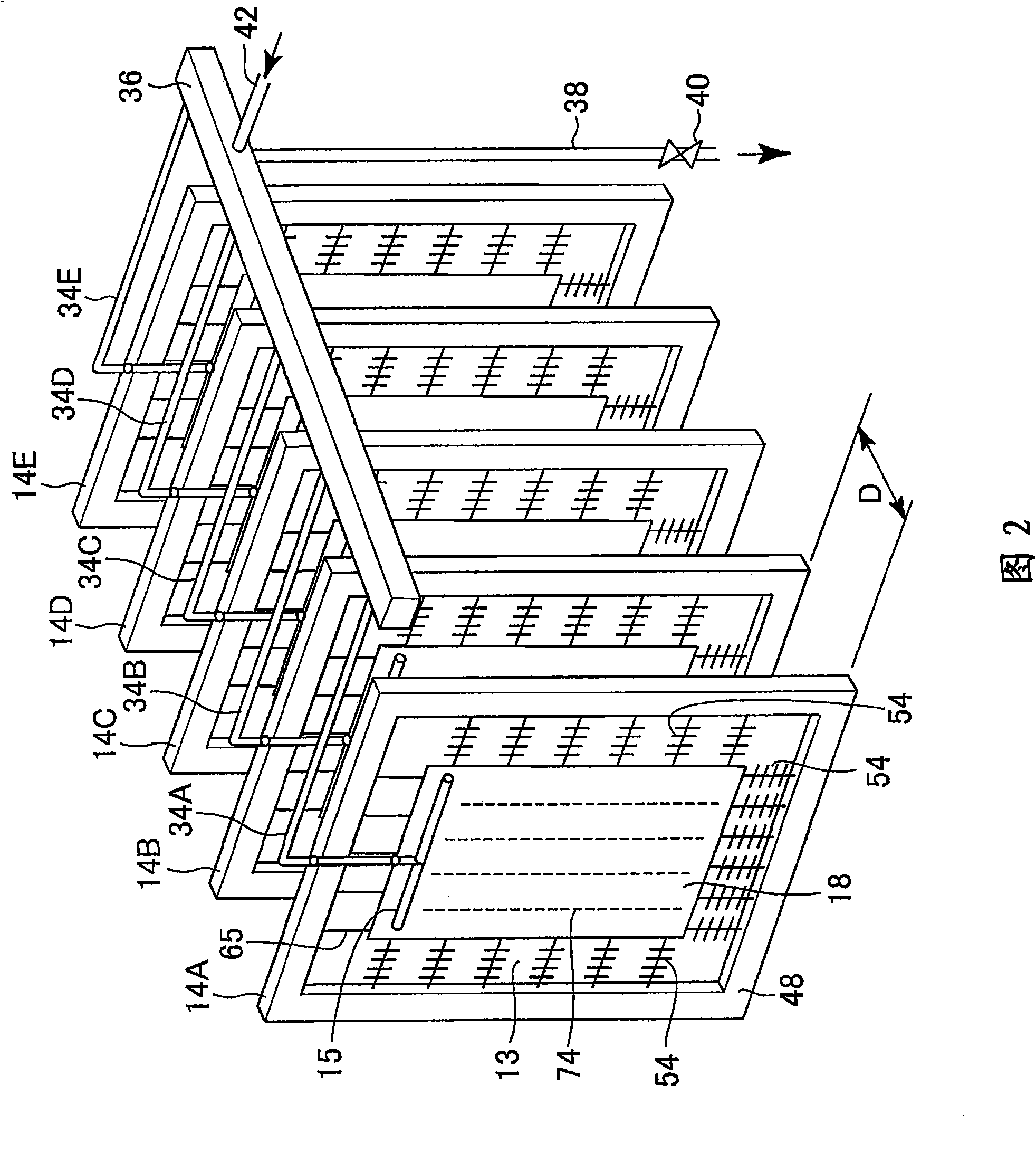

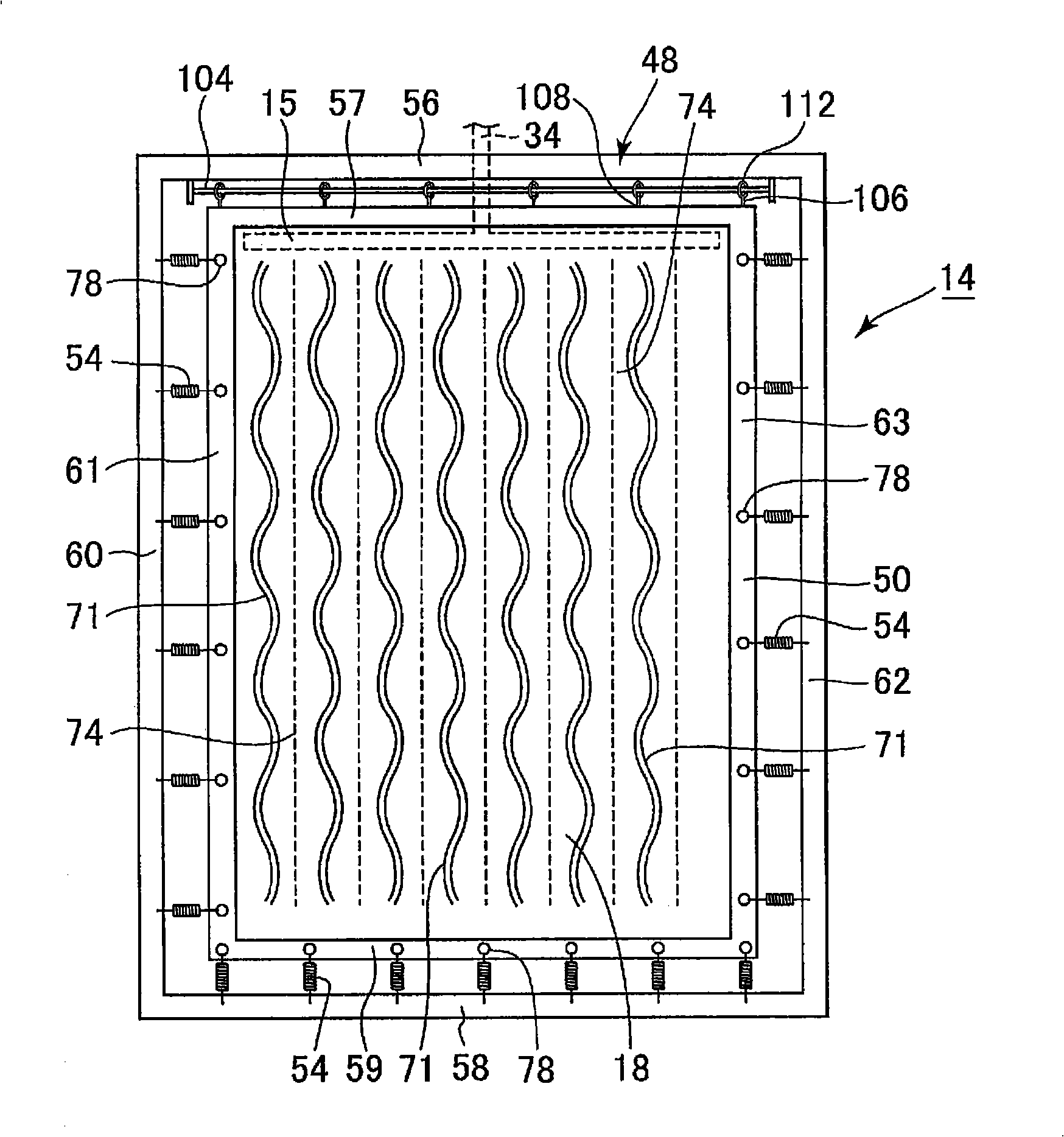

[0037] Taking the case where sludge produced in a sewage treatment plant or a water purification plant is used as an object of filtration and concentration, the first embodiment of the suction filter concentration device 10 of the present invention will be described in detail below with reference to the drawings.

[0038] figure 1 It is a schematic structural view of the suction-type filtration concentration device according to the first embodiment of the present invention. figure 2 It is a schematic perspective view showing a state in which a plurality of filter plates are adjacently arranged in the suction-type filtration concentration device according to the first embodiment of the present invention. image 3 It is a schematic side view showing the filter plate in the suction filter concentration device of the present invention. Figure 4 It is a partial plan view showing a state in which a plurality of filter plates are suspended from a sludge tank and supported by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com