Eco-solvent silky waxy-feeling treatment agent for Yangbuck and its preparation method

A technology of weak solvent and treatment agent, applied in the field of preparation of the weak solvent silky waxy treatment agent for yambar, can solve the problems of no scratch resistance, hydrolysis resistance, influence of yambar effect, high production cost, and unique effect. , Smooth and delicate silk feel, natural luster effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

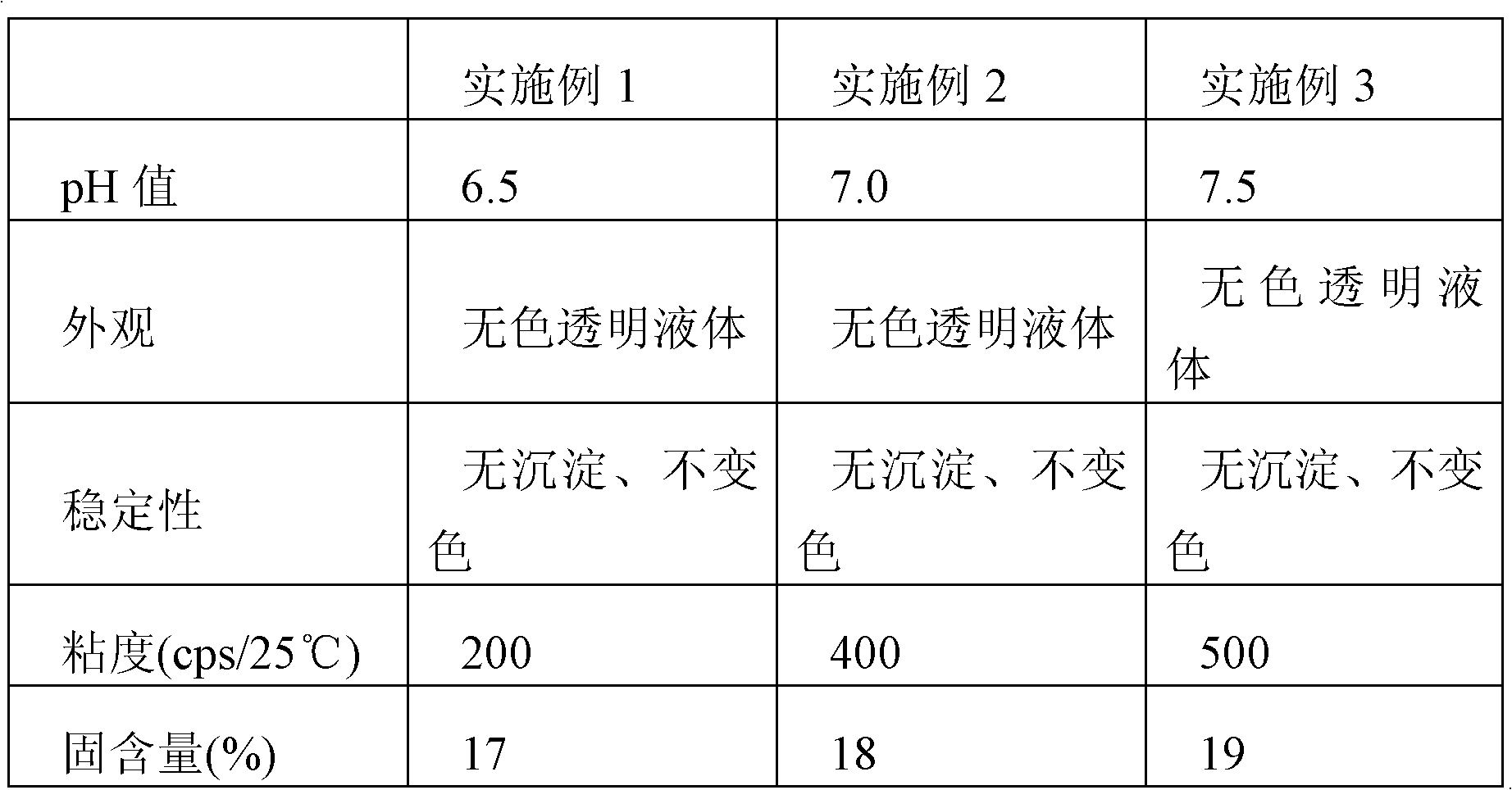

Embodiment 1

[0022] The weak solvent silky wax feeling treatment agent for Yangbuck consists of 45 parts by weight of modified polyurethane resin, 20 parts by weight of butyl acetate, 20 parts by weight of isopropanol, 3 parts by weight of silica matting powder, and 0.3 parts by weight of modified silicon dioxide alkane, 0.3 parts by weight of modified polyether silicone oil, and 0.8 parts by weight of polyethylene micropowder.

[0023] The preparation method of the above-mentioned weak solvent silky wax feeling treatment agent for yangbuck is: fully mix 30 parts by weight of modified polyurethane resin, 20 parts by weight of butyl acetate, 20 parts by weight of isopropanol, and 3 parts by weight of silica matting powder After stirring for at least 30 minutes, grind and filter; add 0.3 parts by weight of modified siloxane, 0.3 parts by weight of modified polyether silicone oil and 0.8 parts by weight of polyethylene micropowder to the resulting mixture and stir evenly for at least 30 minute...

Embodiment 2

[0026] The weak solvent silky wax feeling treatment agent for Yangbuck consists of 50 parts by weight of modified polyurethane resin, 23 parts by weight of butyl acetate, 23 parts by weight of isopropanol, 4 parts by weight of silica matting powder, and 0.3 parts by weight of modified silicon dioxide alkane, 0.3 parts by weight of modified polyether silicone oil, and 1 part by weight of polyethylene micropowder.

[0027] The preparation method of the above-mentioned weak solvent silky waxy feeling treatment agent for yangbuck is: fully mix 25 parts by weight of modified polyurethane resin, 23 parts by weight of butyl acetate, 23 parts by weight of isopropanol, and 4 parts by weight of silica matting powder After stirring for at least 30 minutes, grind and filter; add 0.3 parts by weight of modified siloxane, 0.3 parts by weight of modified polyether silicone oil and 1 part by weight of polyethylene micropowder to the resulting mixture and stir evenly for at least 30 minutes; ad...

Embodiment 3

[0030] The weak solvent silky wax feeling treatment agent for Yangbuck consists of 47 parts by weight of modified polyurethane resin, 25 parts by weight of butyl acetate, 25 parts by weight of isopropanol, 5 parts by weight of silica matting powder, and 0.5 parts by weight of modified silicon dioxide alkane, 0.5 parts by weight of modified polyether silicone oil, and 0.9 parts by weight of polyethylene micropowder.

[0031] The preparation method of the above-mentioned weak solvent silky waxy feeling treatment agent for yangbuck is: fully mix 30 parts by weight of modified polyurethane resin, 25 parts by weight of butyl acetate, 25 parts by weight of isopropanol, and 5 parts by weight of silica matting powder After stirring for at least 30 minutes, grind and filter; add 0.5 parts by weight of modified siloxane, 0.5 parts by weight of modified polyether silicone oil and 1 part by weight of polyethylene micropowder to the resulting mixture and stir evenly for at least 30 minutes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com