Ink composition, package structure and semiconductor device

A composition and ink technology, applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of low curing shrinkage rate and inability to take into account high light curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

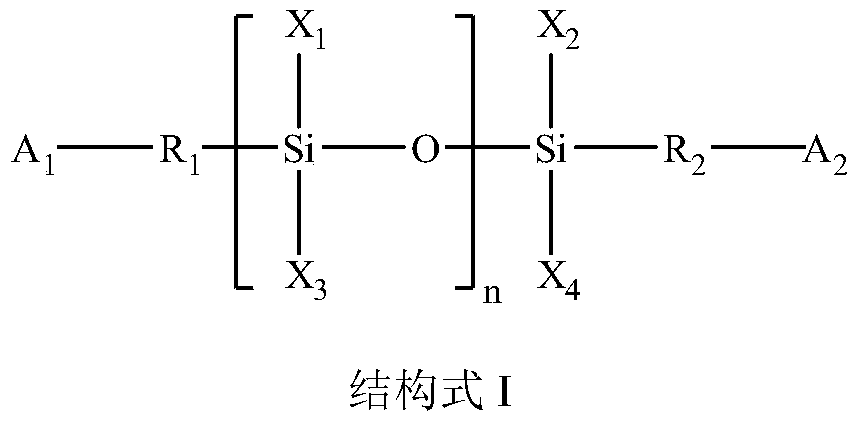

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

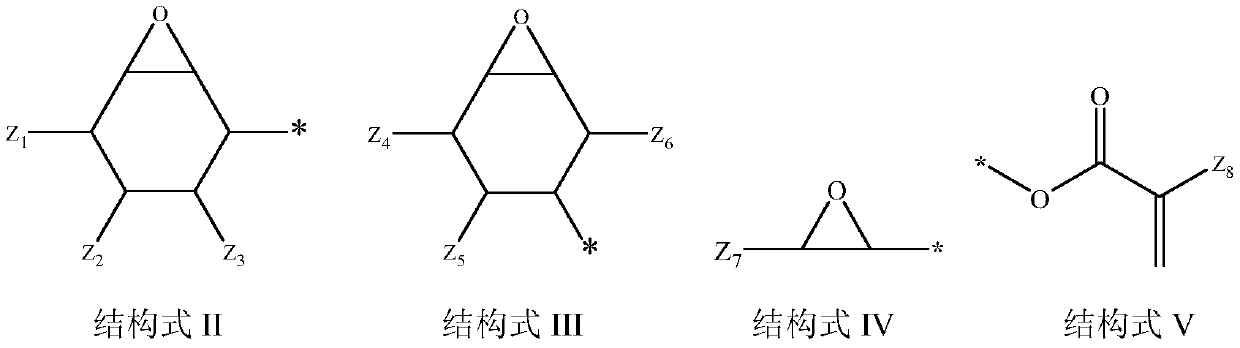

[0067] In a 1000 mL flask with cooling tube and stirrer, put 500 mL of toluene, 54.11 g of 1,1,3,5,5-pentamethyl-3-phenyltrisiloxane and 74.51 g of 4-vinyl -1-cyclohexene-1,2-epoxy, followed by nitrogen purging for 60 min. After that, 0.0063 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane was put into the flask, and the temperature of the flask was increased to 40° C., followed by Stir for 4h. The residual solvent was removed by distillation, thereby preparing a compound represented by formula 1, which is designated as I. 97% purity as determined by HPLC. m / e:588.24; 1 H NMR (400MHz, Chloroform-d) δ7.51(m, 1H), δ7.28(m, 2H), δ7.18(m, 2H), δ1.45(m, 4H), δ1.60(dd ,2H),δ2.87(dd,2H),δ1.60-1.70(dd,4H),δ1.43(m,2H),δ1.3(m,4H),δ0.21(m,12H) , δ0.66(s, 3H), δ0.8(m, 4H).

[0068] [Formula 1]

[0069]

Embodiment 2

[0071] In a 1000 mL flask with cooling tube and stirrer, put 800 mL of toluene, 33.26 g of 1,1,5,5-tetramethyl-3,3-diphenyltrisiloxane and 91.3 g of allyl glycidol ether, followed by a nitrogen purge for 60 min. After that, 0.0063 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane was put into the flask, and the temperature of the flask was increased to 70° C., followed by stirring 4h. Residual solvent was removed by distillation. Thus, a compound represented by formula 2 was prepared and designated as II. HPLC assay has a purity of 97%, m / e: 560.24; 1 H NMR (400MHz, Chloroform-d)δ7.53(m,2H),δ7.29(m,4H),δ7.19(m,4H),δ3.63(d,4H),δ3.38(m ,4H),δ2.86(dd,2H),δ2.38(dd,4H),δ1.5(m,4H),δ1.02(m,4H),δ0.21(s,12H).

[0072] [Formula 2]

[0073]

Embodiment 3

[0075] In a 1000mL flask with a cooling tube and a stirrer, put 800mL of toluene, 30g of 1,1,5,5-tetramethyl-3-diphenyltrisiloxane and 50g of allyl alcohol, followed by nitrogen purging for 60min . After that, 0.003 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane was put into the flask, and the temperature of the flask was increased to 70° C., followed by stirring 4g. Residual solvent was removed by distillation to obtain a crude product of an intermediate terminal with a hydroxyl group on one side. The crude product was separated by column chromatography of ethyl acetate and petroleum ether to obtain an intermediate product with a purity of 98% liquid chromatography. The above-mentioned intermediate was added to a three-necked flask containing 300 mL of anhydrous dichloromethane, and 21 g of triethylamine was added. Next, 45 g of acryloyl chloride were introduced slowly while stirring at 0°C. The residual solvent is removed by distillation, thereby preparing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com