Composition for encapsulating organic light-emitting diodes and displays manufactured using the same

A technology for light-emitting diodes and components, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of light-emitting characteristics and reliability degradation of organic light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

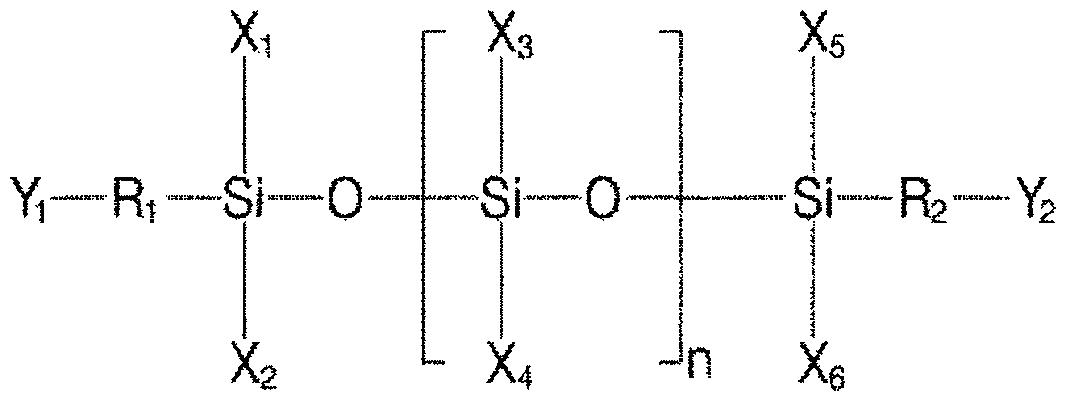

[0141] Preparation example 1: Preparation of silicon-containing monomer

[0142] In a 1000ml flask with a cooling tube and a stirrer, put 300ml ethyl acetate, 25g 3-phenyl-1,1,3,5,5-pentamethyltrisiloxane (Gelest Corporation (Gelest) , Inc.)) and 43 g of allyl alcohol (Daejung Chemicals & Metals Co. Ltd.), followed by nitrogen purging for 30 minutes. After that, 72 ppm platinum / carbon black powder (Aldrich Chemical) was put into the flask, and the temperature of the flask was increased to 80° C., followed by stirring for 4 hours. Residual solvent was removed by distillation. After introducing 71.5 g of the obtained compound into 300 ml of methylene chloride, 39 g of triethylamine was added thereto, followed by slowly introducing 34.3 g of acryloyl chloride while stirring the components at 0°C. The residual solvent was removed by distillation, whereby the compound represented by Formula 3 was prepared. The obtained compound (molecular weight: 522.85 g / mol) had a purity of 97...

preparation example 2

[0146] Preparation example 2: Preparation of silicon-containing monomer

[0147] Except using 21g 3,3-diphenyl-1,1,5,5-tetramethyltrisiloxane instead of 25g 3-phenyl-1,1,3,5,5-pentamethyltrisiloxane alkane, and using 30.2 g of methacryloyl chloride instead of 34.3 g of acryloyl chloride, the compound represented by Formula 4 was prepared in the same manner as in Preparation Example 1. The obtained compound (molecular weight: 584.92 g / mol) had a purity of 96%, as determined by HLPC.

[0148] (1H NMR: δ7.52, m, 6H: δ7.42, m, 4H: δ6.25, d, 2H: δ6.02, dd, 2H: δ5.82, t, 1H: δ5.59, d, 2H: δ3.86, m, 4H: δ1.52, m, 4H: δ0.58, m, 4H: δ0.04, m, 12H)

[0149]

[0150]

preparation example 3

[0151] Preparation example 3: Preparation of silicon-containing monomer

[0152]Except using 21g 1,3,5-triphenyl-1,3,5-trimethyltrisiloxane instead of 25g 3-phenyl-1,1,3,5,5-pentamethyltrisiloxane alkane, and using 31 g of methacryloyl chloride instead of 34.3 g of acryloyl chloride, the compound represented by Formula 5 was prepared in the same manner as in Preparation Example 1. The obtained compound (molecular weight: 646.99 g / mol) had a purity of 94% as determined by HLPC.

[0153] (1H NMR: δ7.51, m, 3H: δ7.29, m, 12H: δ6.25, d, 2H: δ6.02, dd, 2H: δ5.82, t, 1H: δ5.59, d, 2H: δ3.86, m, 4H: δ1.52, m, 4H: δ0.58, m, 4H: δ0.16, m, 9H)

[0154]

[0155]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com