Intermediate pressure level low-smoke zero-halogen flame-retardant silicon rubber insulating material and manufacturing process thereof

A silicone rubber insulation and manufacturing process technology, applied in the direction of rubber insulators, organic insulators, etc., to achieve the effects of improving thermal aging and permanent deformation properties, improving mechanical properties, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

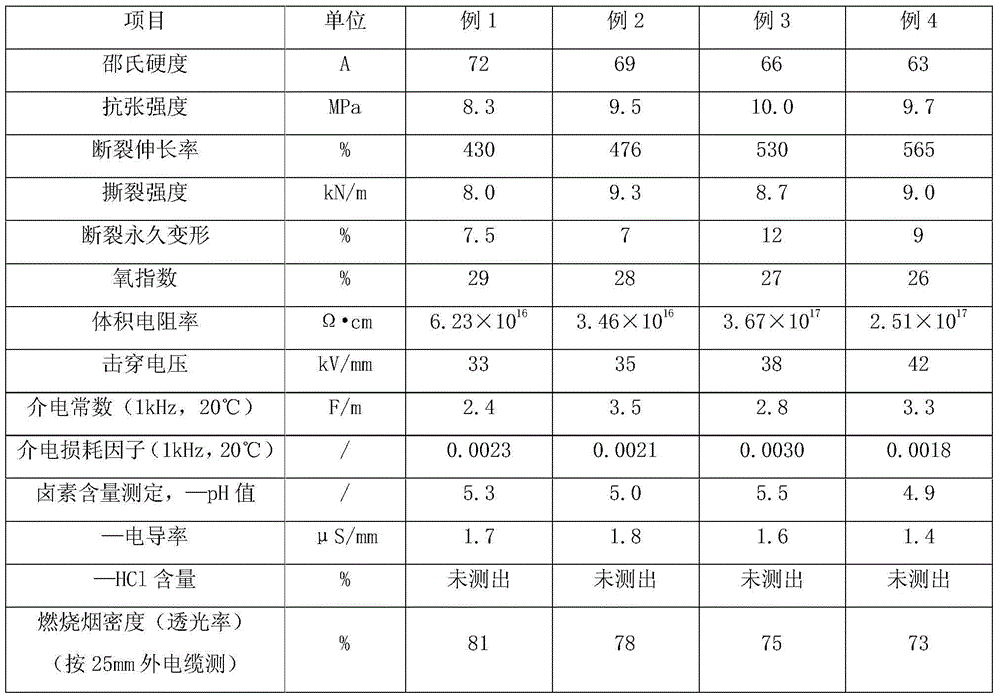

Examples

Embodiment Construction

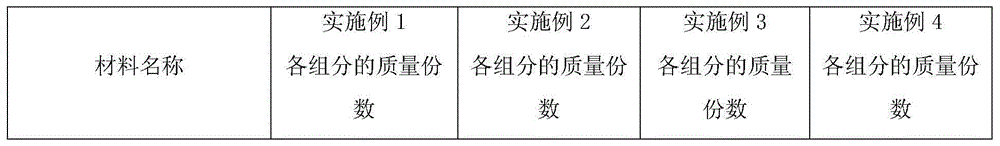

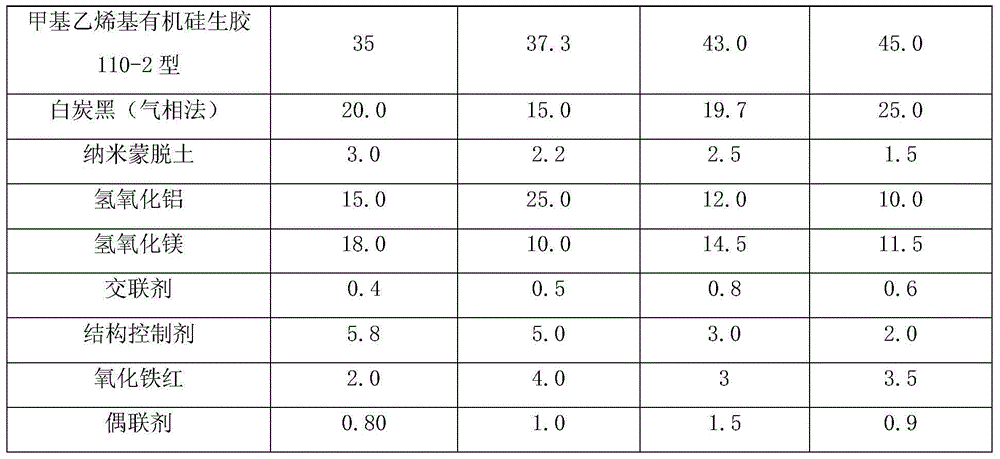

[0035] In specific implementation, the medium-voltage grade low-smoke halogen-free flame-retardant silicone rubber insulating material according to the present invention is composed of raw materials in parts by mass as listed in Table 1:

[0036] Table 1 Component ratio of medium-voltage low-smoke halogen-free flame-retardant silicone rubber insulating material

[0037]

[0038]

[0039] In the specific implementation, the raw methyl vinyl silicone rubber is 110-2 type, the vinyl mole fraction is 0.10-0.15%, and the weight-average relative molecular weight is 460,000-600,000; the white carbon black is produced by the gas phase process; the crosslinking agent It is 2,5-dimethyl-2,5 di-tert-butylperoxyhexane DBPMH or 2,4-dichlorobenzoyl peroxide DCBP or dicumyl peroxide DCP; the structure control agent is diphenyl Silicone glycol, hydroxyl silicone oil or a combination thereof; the coupling agent is a silane coupling agent, an alkoxy titanate coupling agent, a pyrophosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com