Patents

Literature

41results about How to "Improve heat aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-acrylate curing agents

InactiveUS7528189B2Reduce Shrinkage ProblemsImprove claritySemiconductor/solid-state device detailsSolid-state devicesCross-linkAdhesive

The disclosure relates to using metal acrylate compounds such as zinc diacrylate (ZDA), zinc dimethacrylate (ZDMA), among others for curing epoxy functional (and other cross-linking compounds), and to compositions containing such compounds for use in powder coat, film, adhesive, among other applications. ZDA and ZDMA containing compounds can cure the epoxy component of the compositions while being substantially free of conventional curing agents.

Owner:DENOVUS

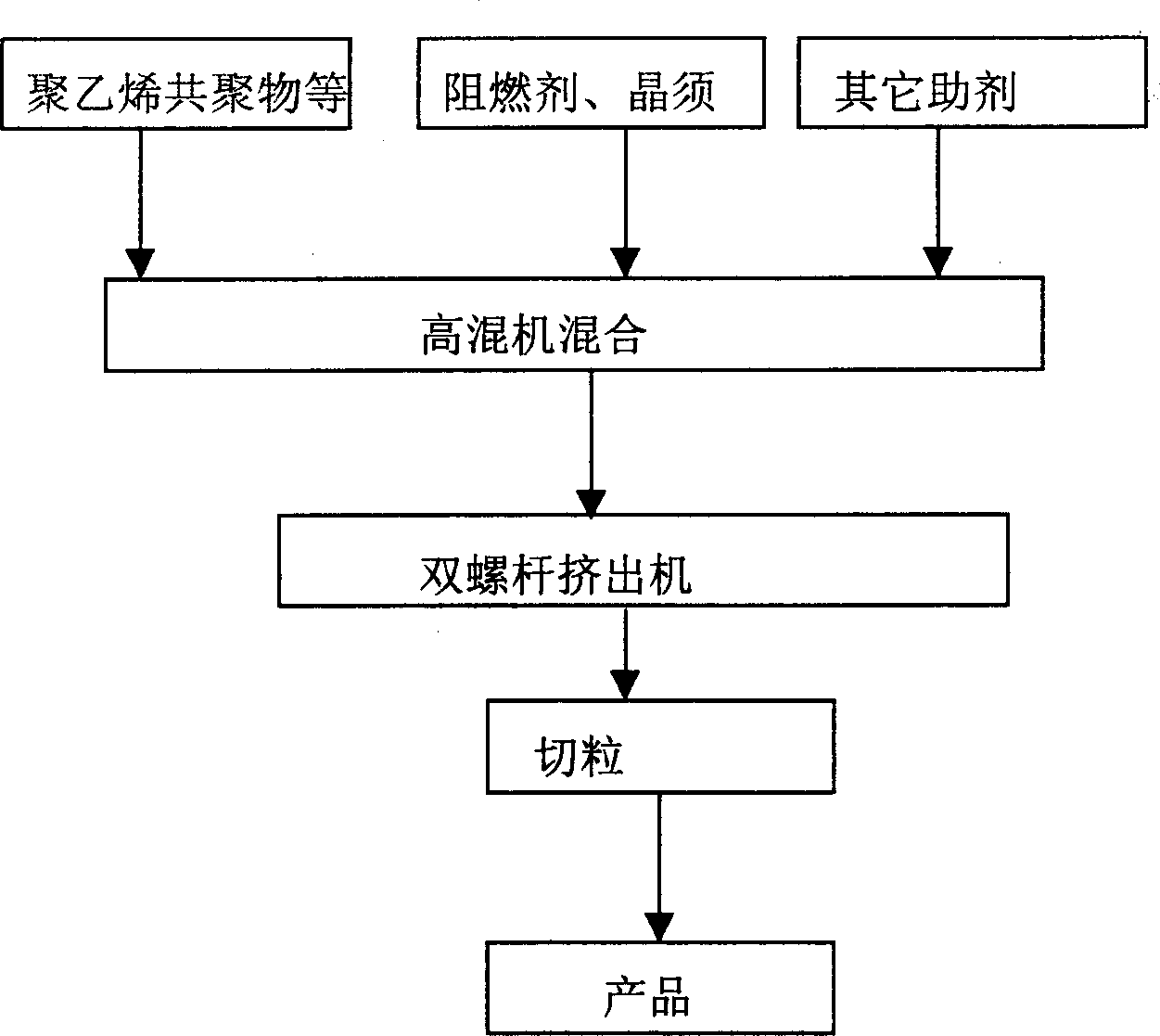

Thermoplastic non-halogen low fume fire resistant cable isolation material and processing tech. thereof

InactiveCN1787120AGood mechanical propertiesExcellent processing performanceRubber insulatorsPlastic/resin/waxes insulatorsInorganic crystalsMagnesium

The invention relates to a formula design for a thermoplastic halogen-free low-smoke flame-retardant cable insulating material and the manufacturing process thereof, concretely, using polyethene copolymer and / or modified ethylene-propylene rubber as a substrate, adding in halogen-free and nontoxic flame-retardant agent (nano magnesium hydroxide or aluminum hydroxide) and inorganic crystal whisker strengthening material as primary components, and adding in proper assistant, proportioning, mixing, plasticizing and making grains to make the insulating material. Its technical characters: not containing halogen, P, Al and other heavy metals; having god mechanical property, machining property and superior flame retardancy and having excellent thermal deforming, thermal ageing and thermal shock properties. The made cables have high safety and reliability. It is applied to the cables operating at 70 deg.C-105 deg.C long time, such as ship cables, cables for nuclear power plants, power and control cables for high-rise buildings, etc.

Owner:大连圣迈化学有限公司

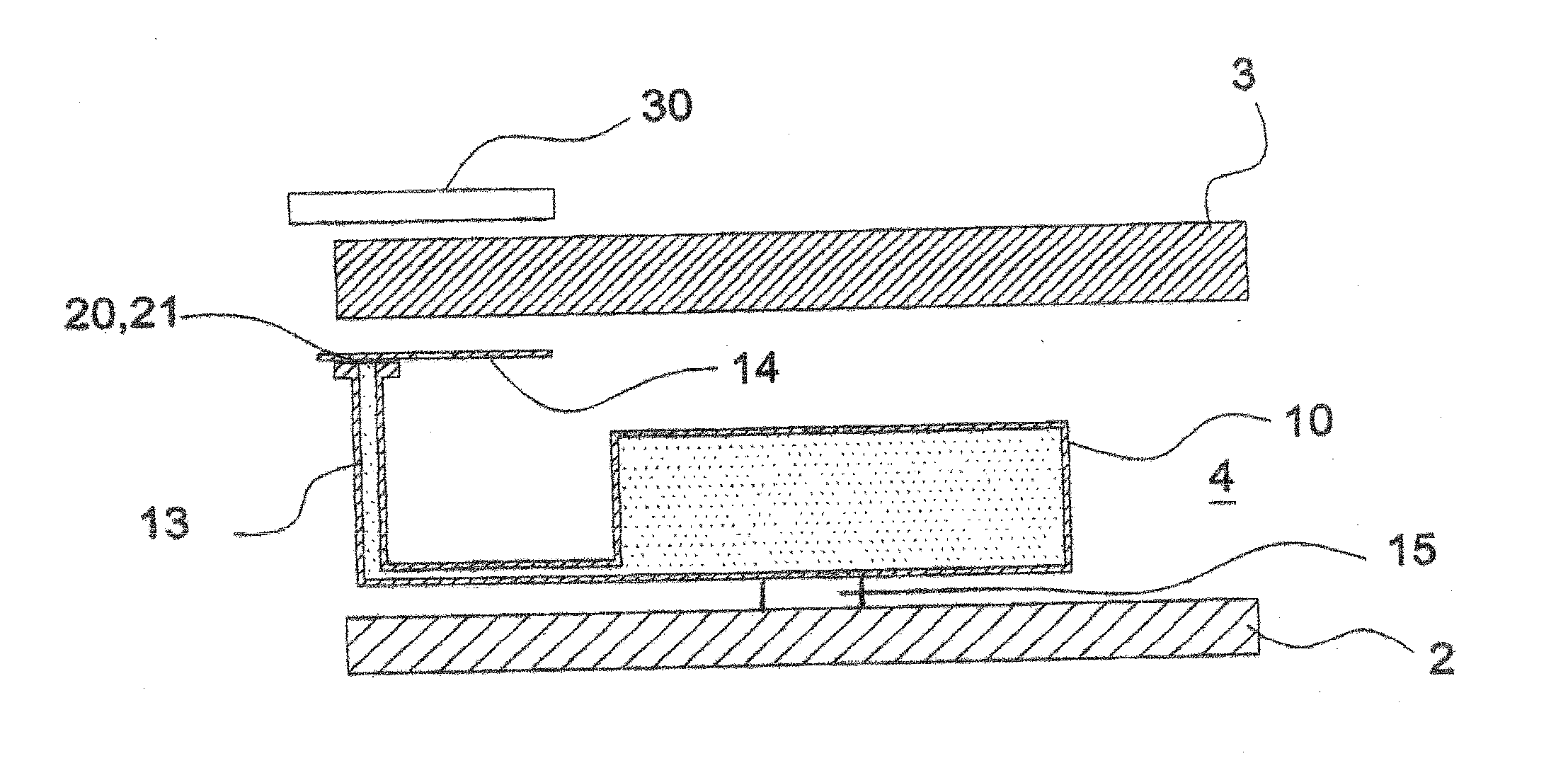

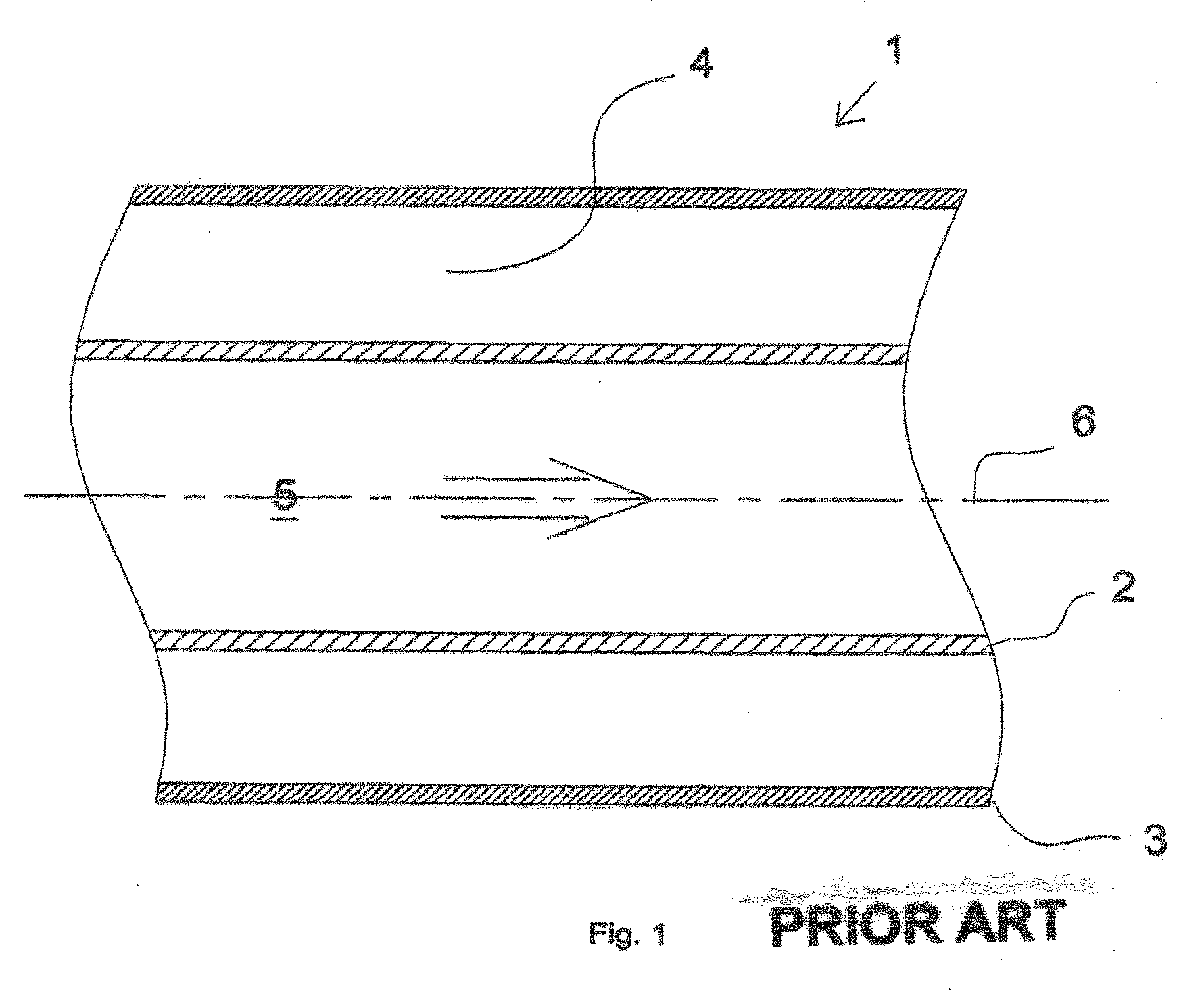

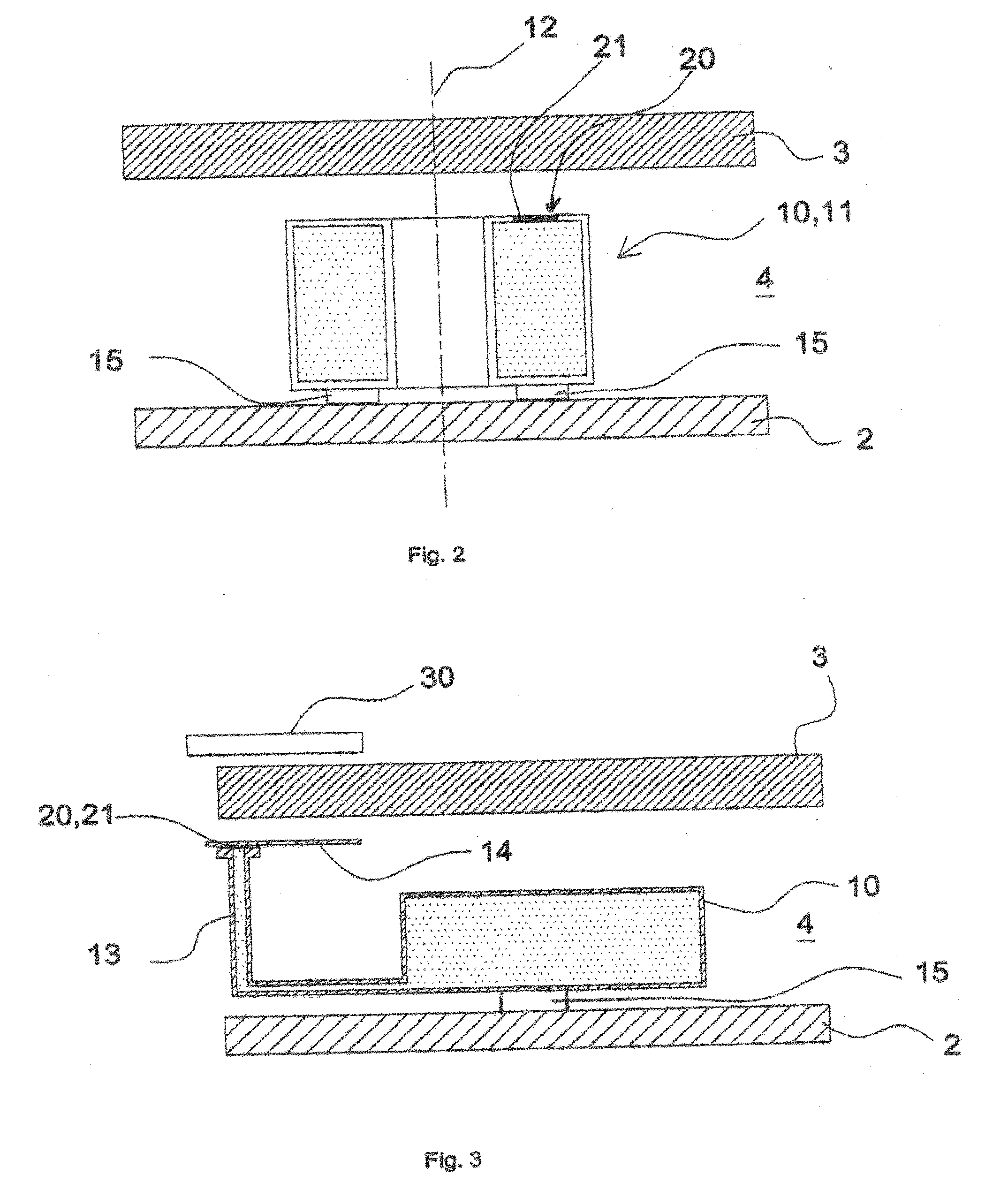

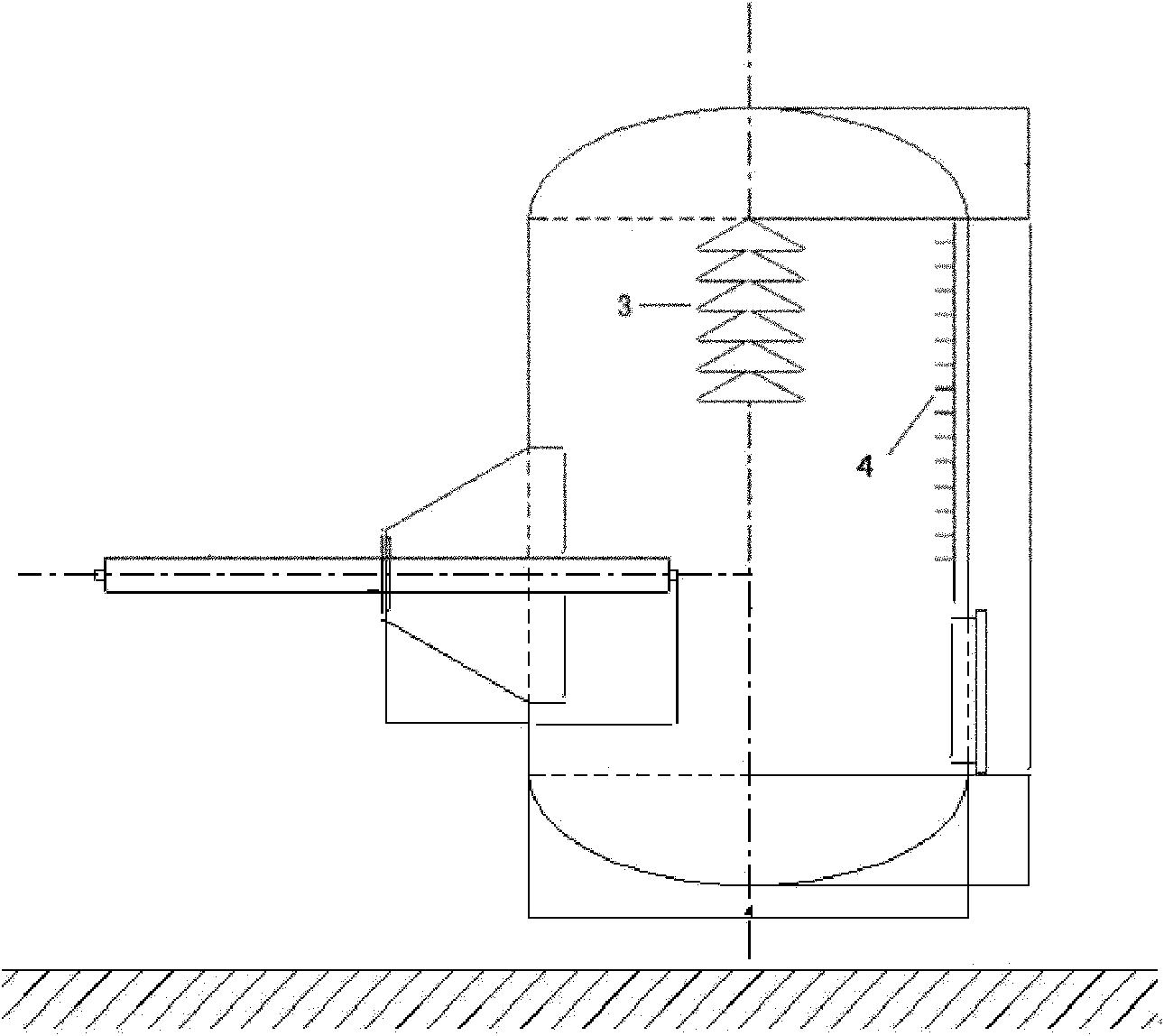

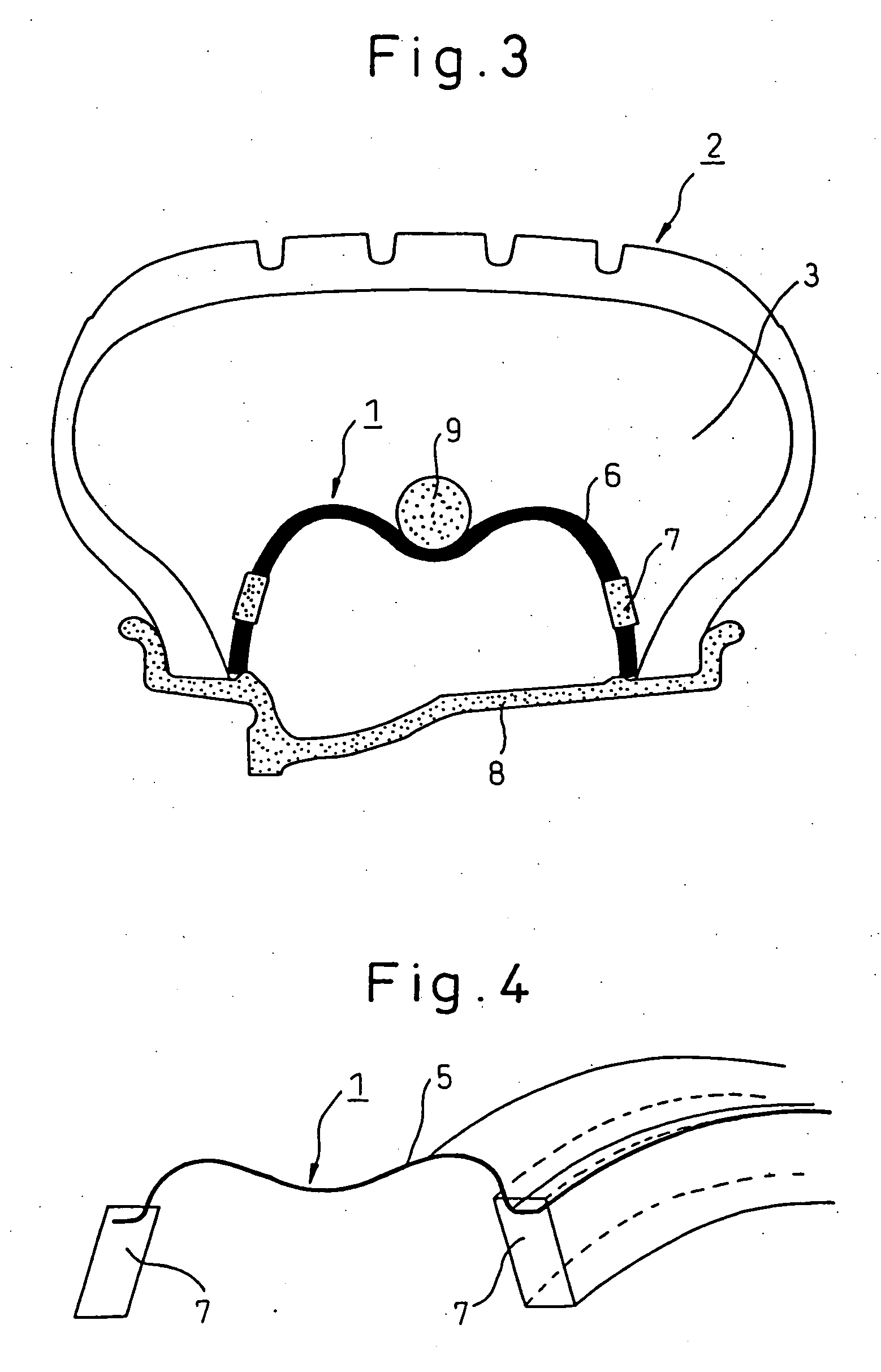

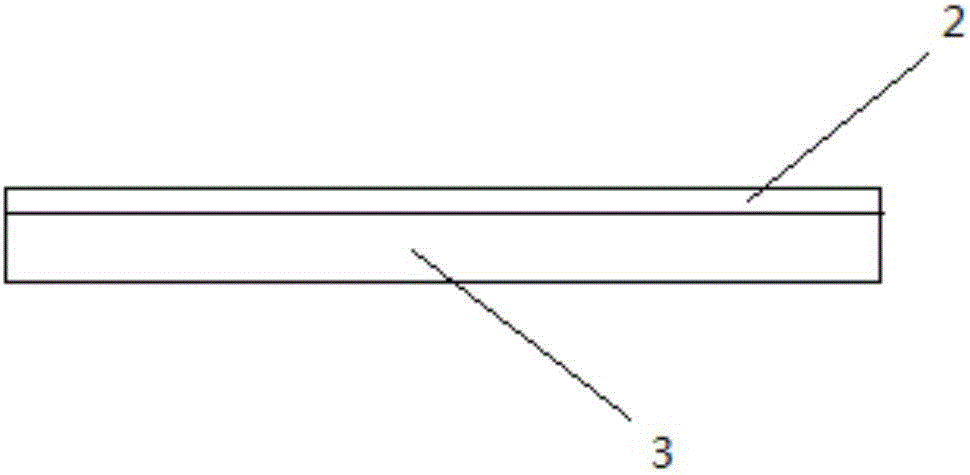

Tubular radiation absorbing device for a solar power plant with improved efficiency

ActiveUS20070235024A1Low thermal conductivityImprove heat lossSolar heating energySolar heat devicesHeat carrierPower station

The tubular radiation absorbing device (1) for solar thermal applications has a central tube (2) and a glass tubular jacket (3) surrounding the central tube (2) so that a ring-shaped space (4) is formed between the central tube (2) and the tubular jacket (3). The ring-shaped space (4) contains at least one inert gas with a partial pressure of 3 to 200 mbar. Alternatively in another embodiment a gas-tight closed container (10) filled with at least one inert gas is arranged in the ring-shaped space (4). The container (10) has a device for supplying inert gas to the ring-shaped space (4) in order to compensate for increased heat losses due to diffusion of hydrogen into the ring-shaped space (4) from the heat carrier medium.

Owner:SCHOTT AG

Highly-weather-resistant type ASA (acrylonitrile Styrene acrylate copolymer)-based color co-extrusion material with low heat absorption effect and preparation method thereof

ActiveCN104212107AReduced heat absorption capacityLow weather resistanceASA-polymerWeather resistance

The invention discloses a highly-weather-resistant type ASA (acrylonitrile Styrene acrylate copolymer)-based color co-extrusion material with low heat absorption effect and a preparation method thereof. The highly-weather-resistant type ASA-based color co-extrusion material is characterized by comprising the following components in parts by weight: 85-94 parts of ASA, 1-4 parts of a light stabilizer, 1-2 parts of an ultraviolet absorber, 1-3 parts of an antioxidant and 2-6 parts of pigments. The preparation method of the highly-weather-resistant type ASA-based color co-extrusion material comprises the following steps: (1) weighing base stock, the light stabilizer, the ultraviolet absorber, the antioxidant and the pigments in proportion; (2) firstly adding the light stabilizer, the ultraviolet absorber, the antioxidant and the pigments to uniformly mix, and then adding the base stock to uniformly mix; and (3) extruding and pelletizing the uniformly-mixed materials to prepare the highly-weather-resistant type ASA-based color co-extrusion material with low heat absorption effect. Compared with the prior art, the highly-weather-resistant type ASA-based color co-extrusion material has low heat absorption and more superior weather resistance.

Owner:FOSHAN KAIYUE GRAND SKY PLASTIC TECH CO LTD

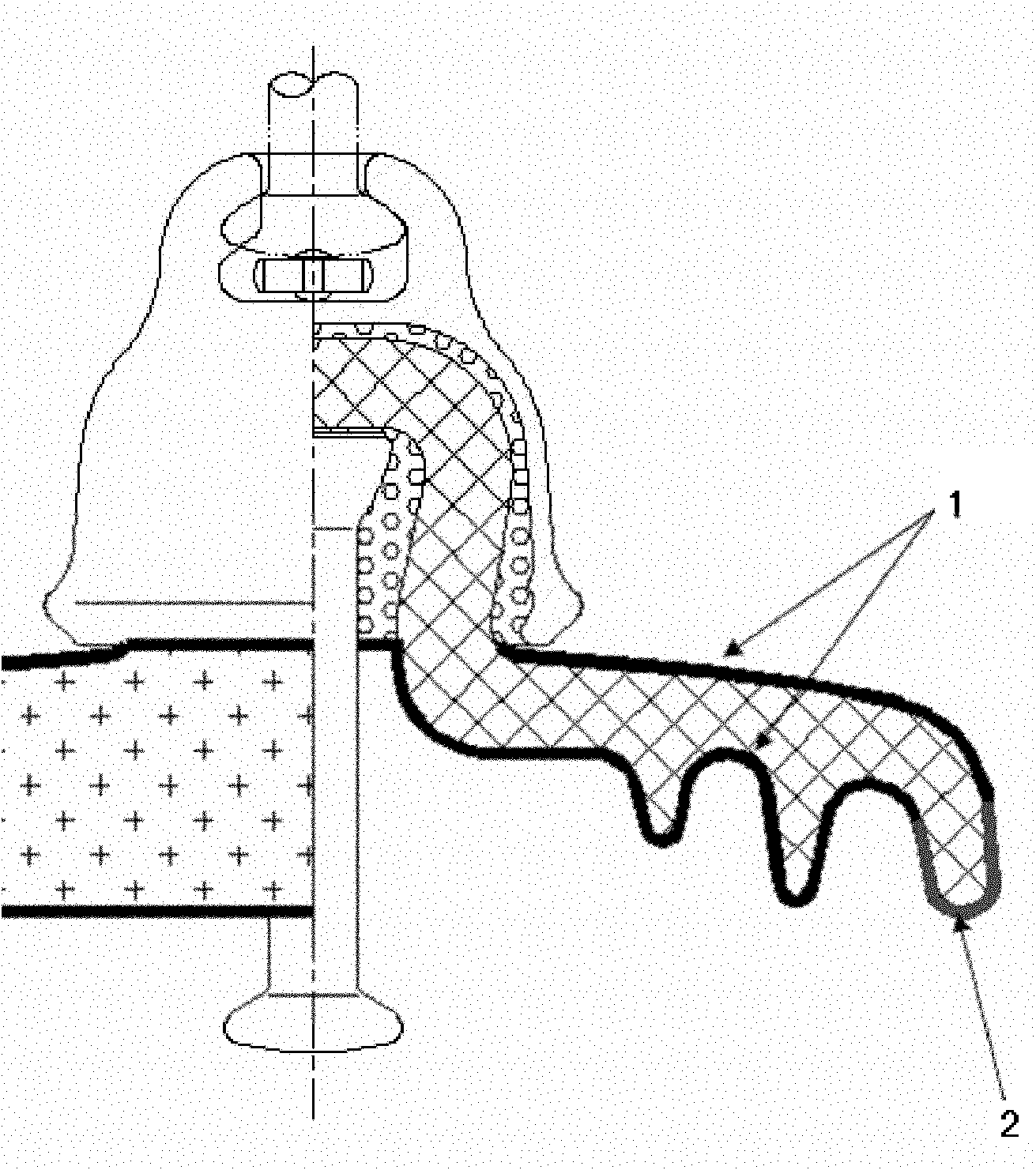

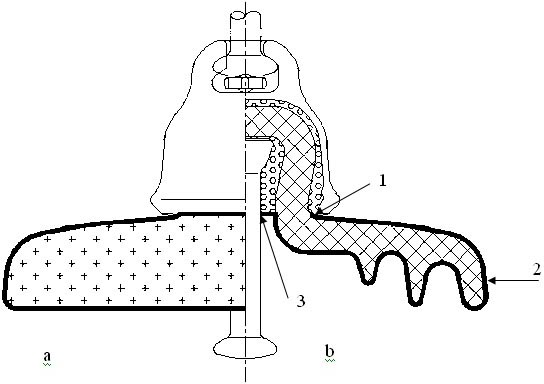

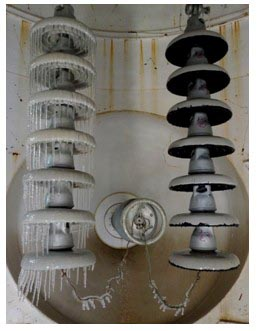

Anti-icing coating for insulator

InactiveCN102140310AHydrophobicIncrease pollution flashover voltageSuspension/strain insulatorsCoatingsMetallurgyHigh resistivity

The invention discloses an anti-icing coating for an insulator. The anti-icing coating consists of a high-resistivity coating and a low-resistivity coating. The high-resistivity coating consists of silicon rubber and carbon black, wherein the weight percentage content of the carbon black is lower than 1 percent; and the high-resistivity coating is coated at the outermost edge of the skirt of the insulator. The low-resistivity coating consists of silicon rubber and carbon black, wherein the weight percentage content of the carbon black is between 10 percent and 30 percent; and the low-resistivity coating is coated on the surface of the insulator except the outermost edge. Two coatings with high resistivity and low resistivity are prepared respectively by adding carbon black into the silicon rubber according to different proportions; the upper surface and the lower surface of the skirt of the insulator are coated with the low-resistivity coating; and the outermost edge of the skirt of the insulator is coated with the high-resistivity coating. By adopting the high-resistivity coating, ice is prevented from growing at the skirt edge by adopting the high-resistivity coating, the flashover voltage is prevented from being lowered by ice bridging, the working stability of the insulator is enhanced, and safe and reliable power transmission is ensured.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

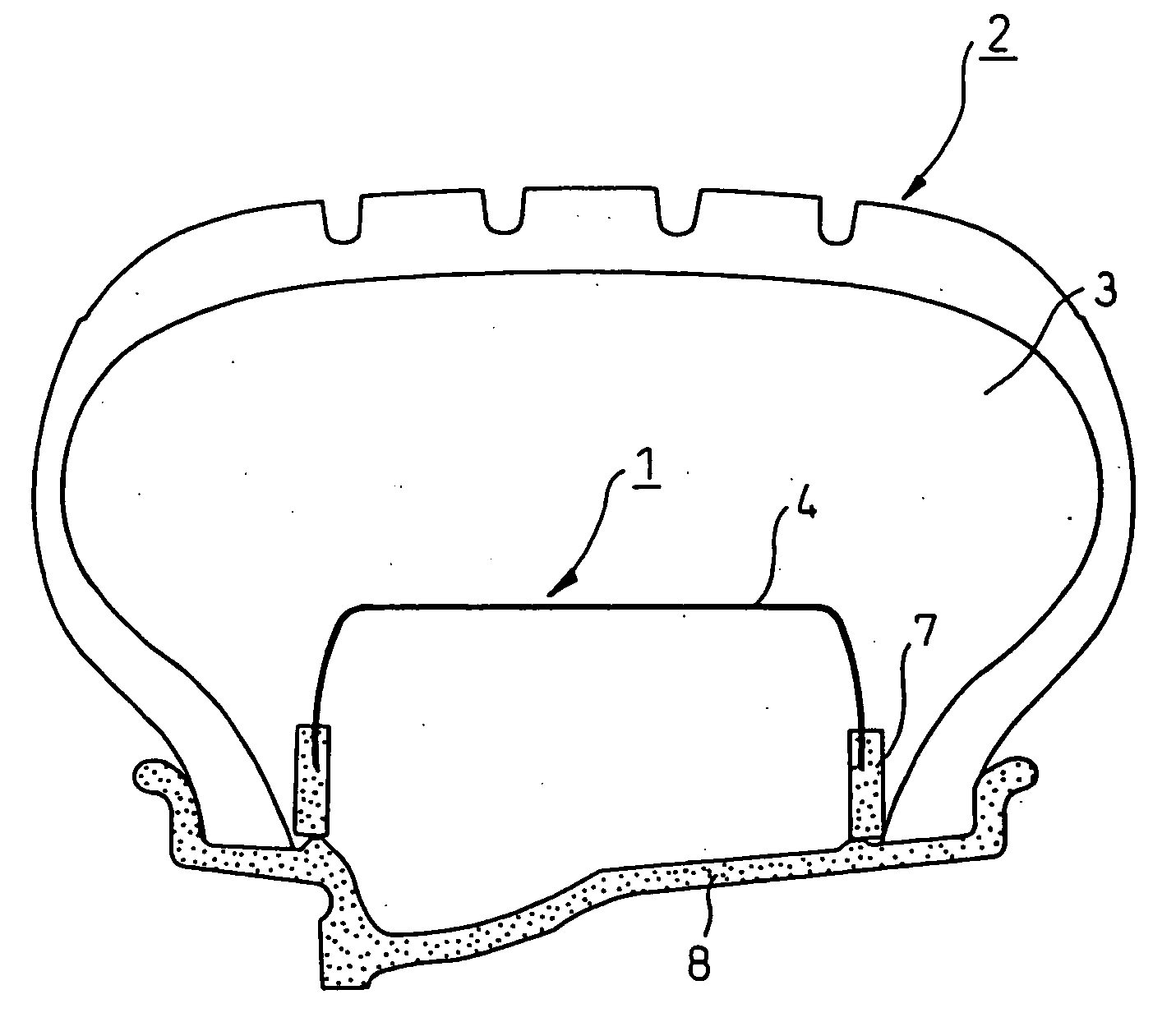

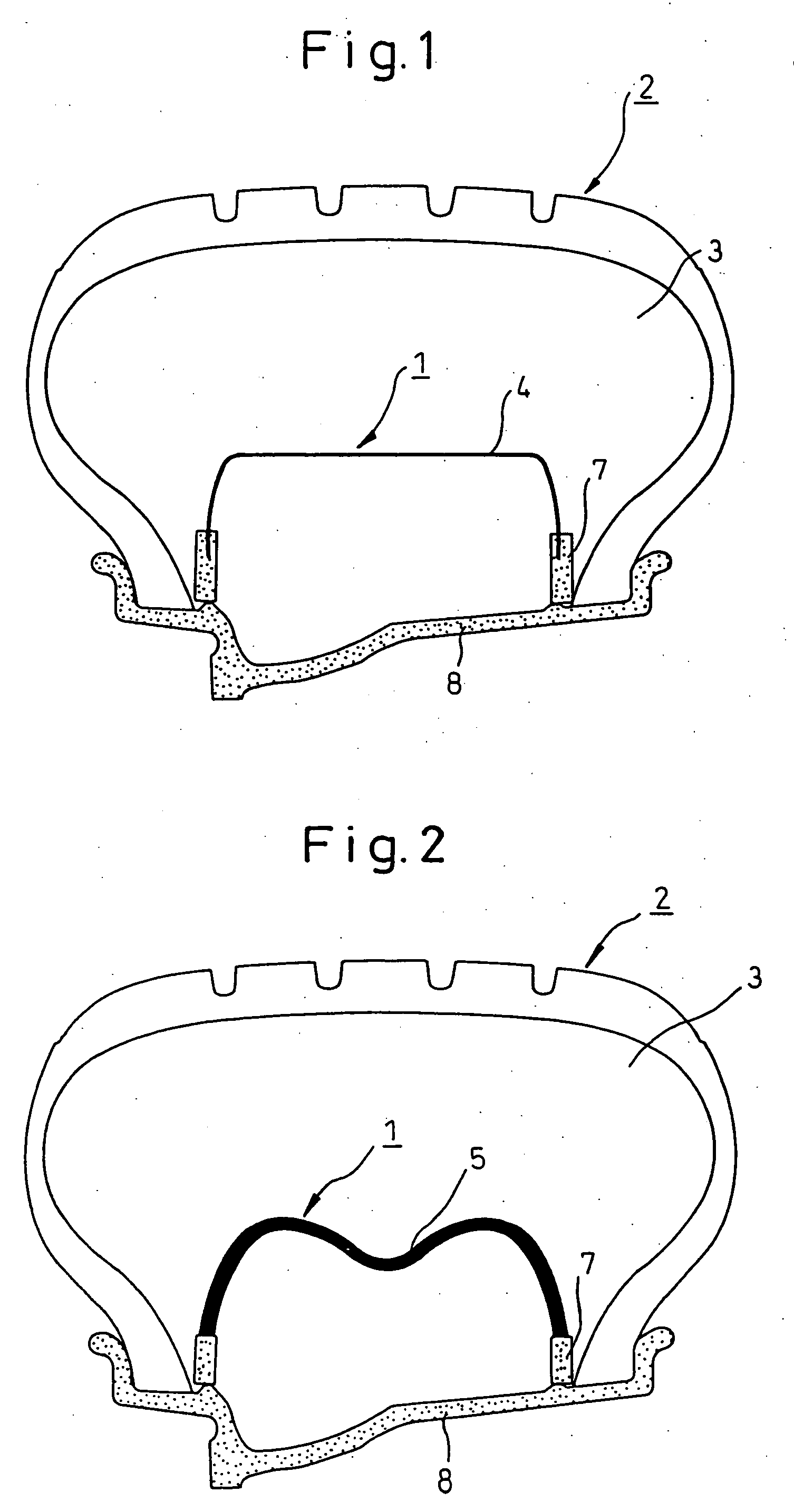

Tire wheel assembly

InactiveUS20070084537A1Improve adhesionReduce processSpecial tyresInflatable tyresEngineeringSilicon dioxide

A run flat tire wheel assembly having a run flat support member formed by a ring-shaped metal shell and rubbery elastic members in an inside cavity of a tire / rim, wherein the rubbery elastic member comprises a rubber composition including (A) 100 parts by weight of a diene-based rubber and (B) (i) 0.1 to 5 parts by weight of cobalt acetyl acetonate and / or (B) (ii) (a), as a reinforcing filler, 40 to 90 parts by weight of carbon black / silica in a ratio of 10 / 1 to 1 / 2 (weight ratio) and (b) 1 to 20% by weight based upon the weight of the silica, of a silane coupling agent, whereby the bondability between the ring-shaped metal shell and rubbery elastic members is improved.

Owner:YOKOHAMA RUBBER CO LTD

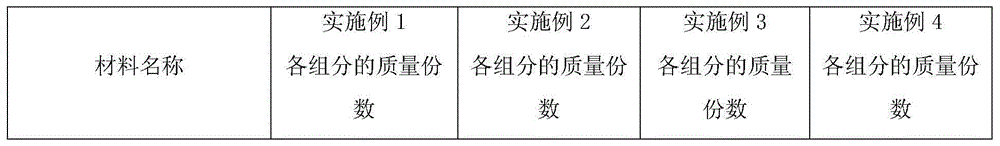

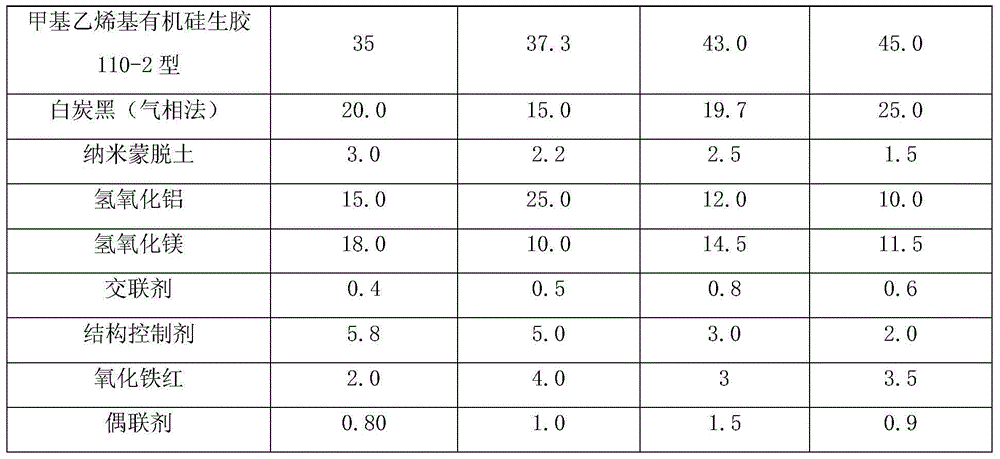

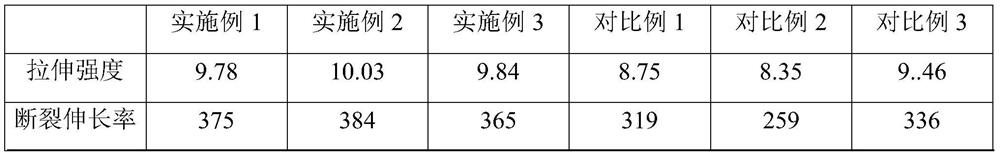

Intermediate pressure level low-smoke zero-halogen flame-retardant silicon rubber insulating material and manufacturing process thereof

ActiveCN104087001AIncrease elasticityImprove aging resistanceRubber insulatorsSilicone rubberIntermediate pressure

The invention discloses an intermediate pressure level low-smoke zero-halogen flame-retardant silicon rubber insulating material and a manufacturing process thereof. The material is characterized by being prepared from the following raw materials in parts by weight: 35-45 parts of methyl vinyl organic silicon rubber, 15-25 parts of white carbon black, 1.5-3 parts of nano-montmorillonite, 10-25 parts of aluminum hydroxide, 10-18 parts of magnesium hydroxide, 0.4-0.8 part of an across-linking agent, 2-5.8 parts of a structure control agent, 2-4 parts of iron oxide red and 0.80-1.5 parts of a coupling agent. The insulating material disclosed by the invention not only can satisfy the requirements on heat resistance, high electrical insulating performance and the like of an intermediate pressure level cable insulating material, a cable accessory and the like, but also has high mechanical strength, so that the novel application field of the silicon rubber material is opened up.

Owner:ANHUI HANGTIAN CABLE GROUP

Metal-acrylate curing agents

InactiveUS20050119373A1Reduce Shrinkage ProblemsImprove claritySemiconductor/solid-state device detailsSolid-state devicesCross-linkAdhesive

The disclosure relates to using metal acrylate compounds such as zinc diacrylate (ZDA), zinc dimethacrylate (ZDMA), among others for curing epoxy functional (and other cross-linking compounds), and to compositions containing such compounds for use in powder coat, film, adhesive, among other applications. ZDA and ZDMA containing compounds can cure the epoxy component of the compositions while being substantially free of conventional curing agents.

Owner:DENOVUS

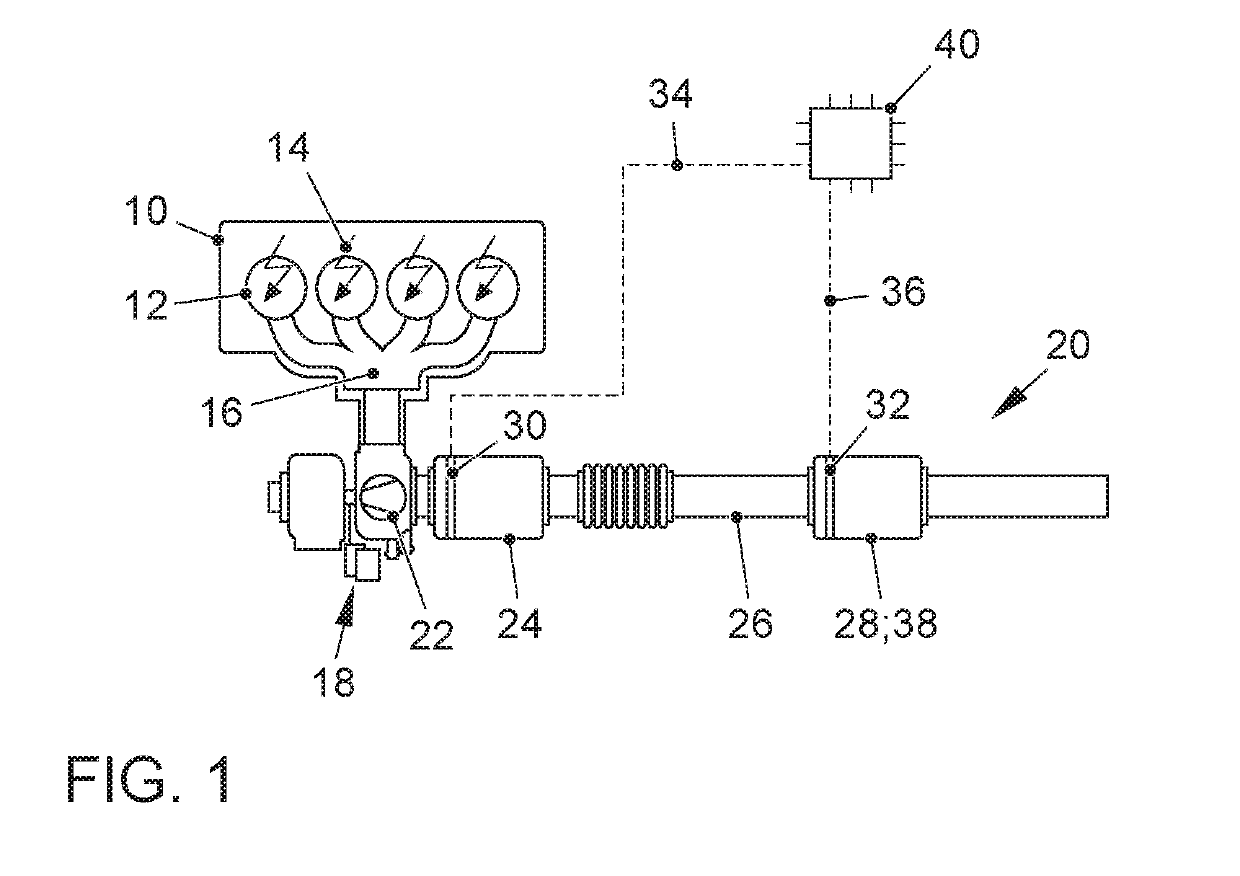

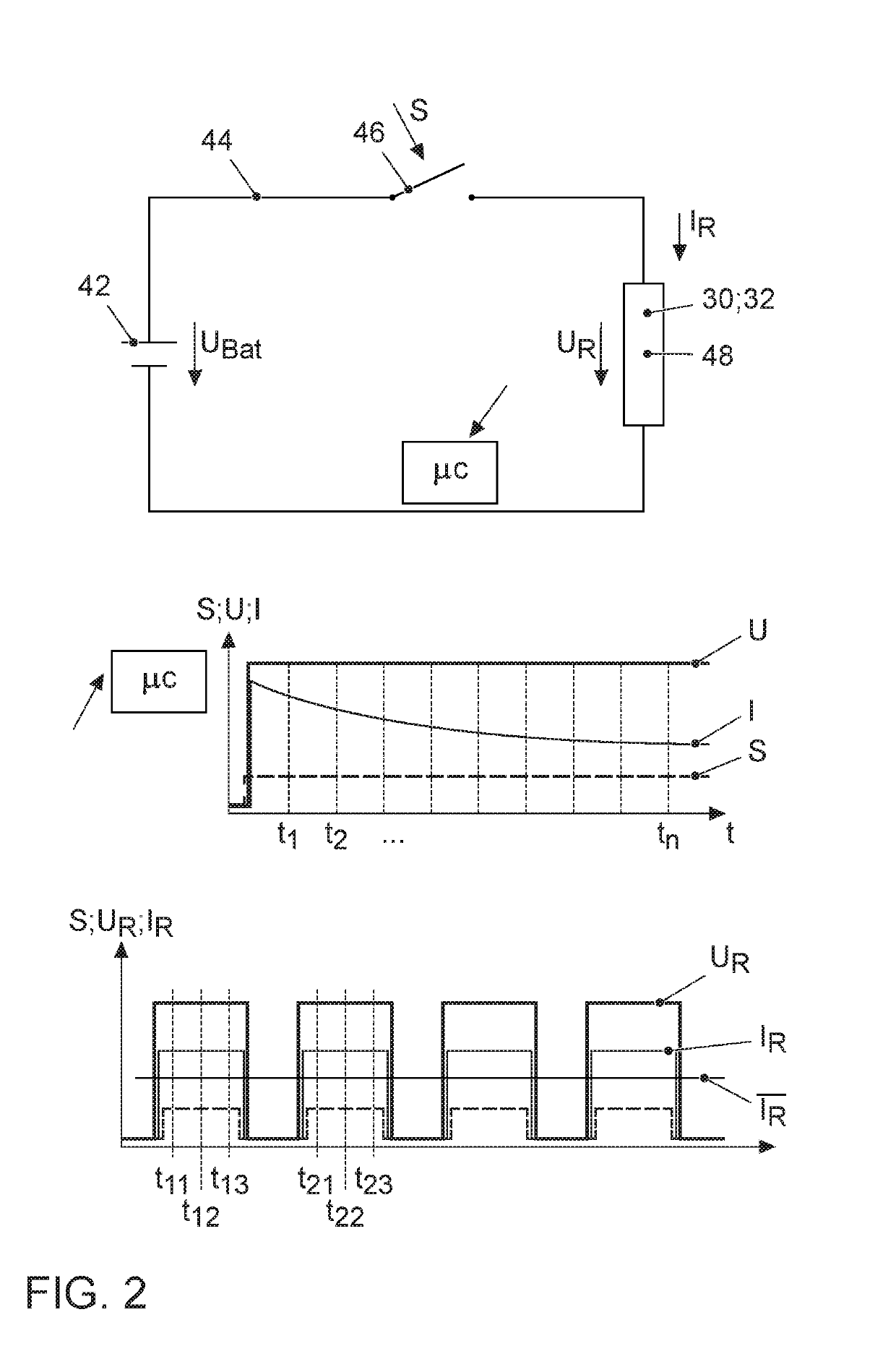

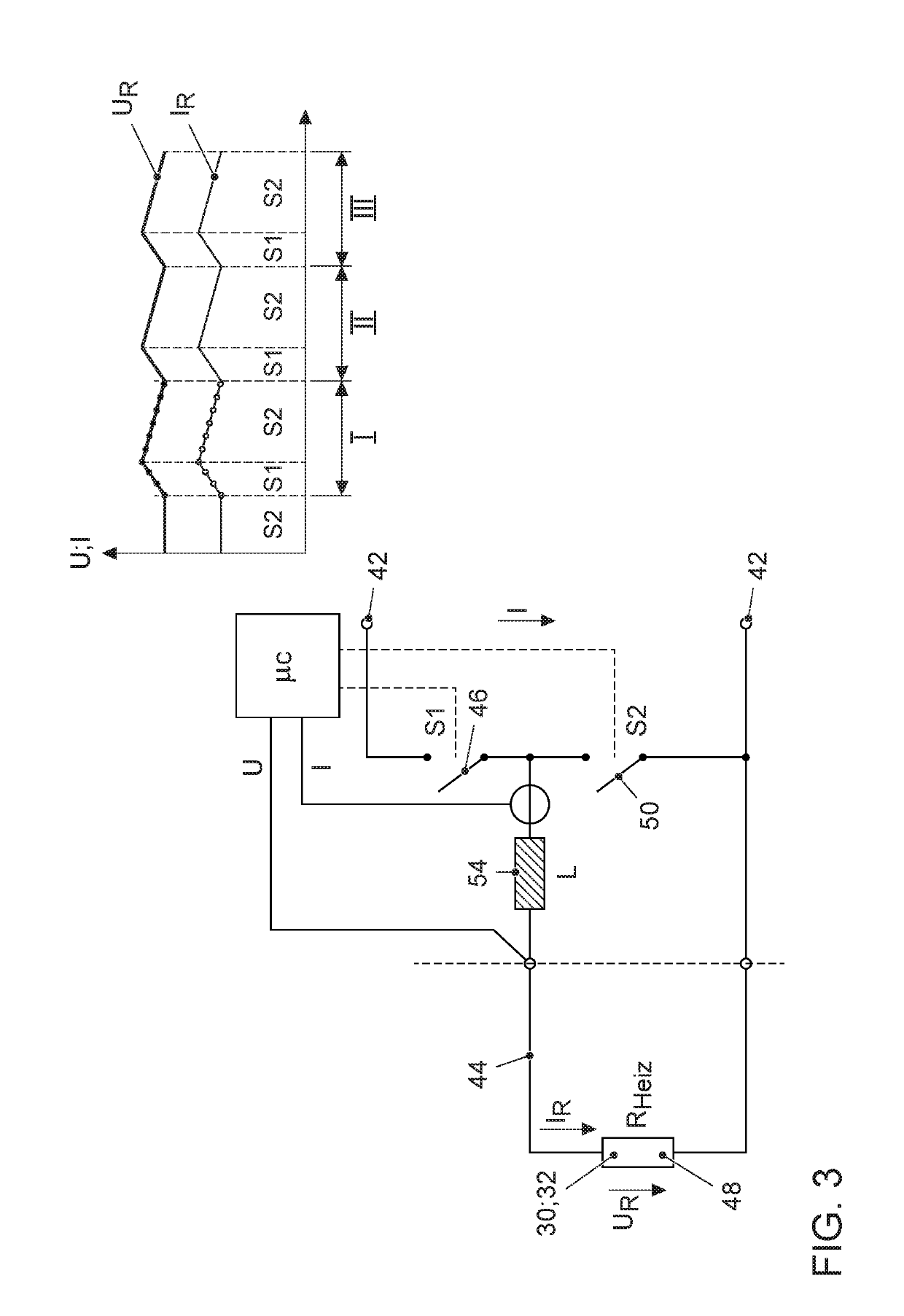

Method for determining the temperature of an electrically heatable catalytic converter

ActiveUS20190331015A1Improved determinationEfficient introductionInternal combustion piston enginesResistance/reactance/impedenceElectricityPower flow

A method for determining the temperature of an electrically heatable catalytic converter having an electric heating element that includes a heating resistor, the electrical resistance of which changes as a function of the component temperature of the electrically heatable catalytic converter. This resistance is determined from the current intensity and the voltage at the electrically heatable catalytic converter, and is used to determine the component temperature of the catalytic converter, based on a characteristic curve stored in the control unit. The energization of the heating resistor for determining the component temperature takes place in each case for only a short time in order to minimize the energy input into the heating resistor and thus avoid overheating of the heating resistor. In addition, by use of the short time interval, the aim is to minimize the energy requirements for determining the component temperature of the electrically heatable catalytic converter.

Owner:VOLKSWAGEN AG

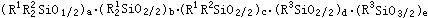

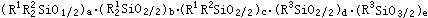

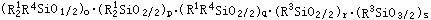

Polysiloxane curing agent

ActiveCN102660027AHigh refractive indexHigh light transmittanceSemiconductor/solid-state device detailsSolid-state devicesArylAdhesive

The invention relates to a semiconductor packaging adhesive, in particular to a polysiloxane curing agent for the semiconductor packaging adhesive. Each molecule of the polysiloxane curing agent at least contains two hydrogen atoms bonded to silicon and oxysilane of aryl. The curing agent has a structural formula as follows: (R1R4SiO1 / 2) O . (R12SiO2 / 2) p . ( R1R4SiO2 / 2) q . (R3SiO2 / 2) r . (R3SiO3 / 2) s, wherein R1 is alkyl, R3 is aryl, R4 is an H atom or alkyl, o + p + q + r + s is equal to 100, o is 1 to 20, p is 10 to 20, q is 0 to 20, r is 0 to 10, and s is 30 to 60. The organic silicone semiconductor packaging adhesive cured by the product provided by the invention has the characteristics of high refractive index, high light transmittance, high physical strength, resistance to yellowing, and resistance to ultraviolet and thermal aging.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

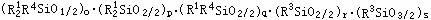

Sunshine fabric with high oxygen index and preparation method thereof

InactiveCN108360086AExcellent flame retardantEasy to processFlame-proof filament manufactureFilament manufactureYarnUltraviolet

The invention relates to a sunshine fabric with high oxygen index and a preparation method thereof, wherein the sunshine fabric comprises the following raw materials in parts by weight: 90-100 parts of PVC resin, 10-15 parts of chlorinated polyvinyl chloride, 5-25 parts of a phthalate plasticizer, 5-20 parts of a phosphate plasticizer, 7-10 parts of antimony trioxide, 10-15 parts of chlorinated paraffin, 0.5-7 parts of zinc hydroxystannate, 7-10 parts of decabromodiphenylethane, 5-8 parts of magnesium hydroxide, 0.5-1.5 parts of a composite ultraviolet absorber, 0.3-0.5 part of a lubricant, 1-1.5 parts of a processing aid, 0.3-0.4 part of an antibacterial agent, 3-5 parts of a heat stabilizer, and 1-10 parts of rutile titanium dioxide. The preparation method comprises the steps: blending the raw materials physically, melting by an extruder, coating PET protofilaments to obtain coated yarns, beaming, weaving, and carrying out heat setting to obtain the product. The prepared fabric has good properties of high flame retardancy, light resistance and thermal aging, and has good application prospects and research value.

Owner:PHIFER INC

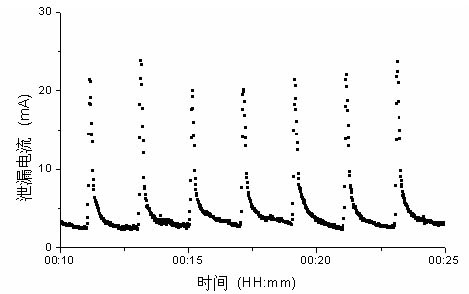

Insulator and transmission line

ActiveCN102511065AWith self-shutdown effectIncrease surface temperatureRubber insulatorsPower cables for overhead applicationConductive coatingEngineering

The present invention discloses an insulator comprising an insulation surface, wherein one part of the insulation surface is coated with conductive coating having special resistivity,the conducting coating area of the special resistivity and the uncondutive coating area are arranged in a discontinuous conduting channel between an upper armour clamp and a lower armour clamp of the insulator under a dry environment,and the conductive coating area of the special resistivity makes the leakage current value caused on the insulation surface reach to the temperature for preventing ice coating under ice coating weather conditions. The utility model also discloses a transmission device using the insulator. under the ice coating weather conditions, the conductive coating can improve the leakage current value of the surface of the insulator so as to prevent ice coating.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Polysiloxane for semiconductor packaging adhesive

ActiveCN102643430AHigh refractive indexHigh light transmittanceOther chemical processesAdhesivesAdhesiveRefractive index

The invention relates to a semiconductor packaging adhesive, and particularly relates to polysiloxane for the semiconductor packaging adhesive. According to the polysiloxane for the semiconductor packaging adhesive, in the polysiloxane, each of molecules at least includes one alkylene and aryl which are connected with silicon, and the structural formula is as follows: (R1R2 2silicon monoxide / 2) a*(R1 2silica / 2) b*(R1R2 silica / 2) c*(R3 silica / 2) d*(R3silicic acid / 2) e, wherein R1 represents alkyl, R2 represents alkylene and R3 represents aryl, a+b+c+d+e=100, a=(1-20), b=(10-20), c=(10-20), d=(0-10), and e=(30-60). According to the polysiloxane for the semiconductor packaging adhesive, in general, polysiloxane compositions are cured by heating, after the curing, a refractive index of visible lights at the temperature of 25 DEG C is not less than 1.5, and light transmittance is not less than 90%, so that the polysiloxane for the semiconductor packaging adhesive has the advantages of being high in refractive index, transmittance and physical strength, anti-yellowing, resistant to ultraviolet radiation and thermal aging.

Owner:小禾电子材料(德清)有限公司

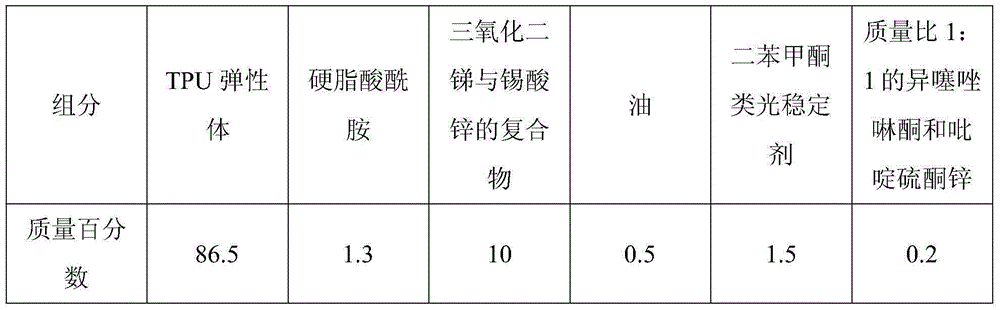

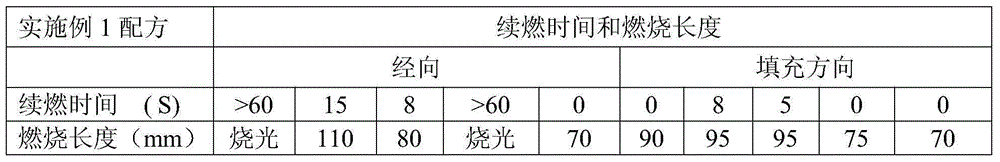

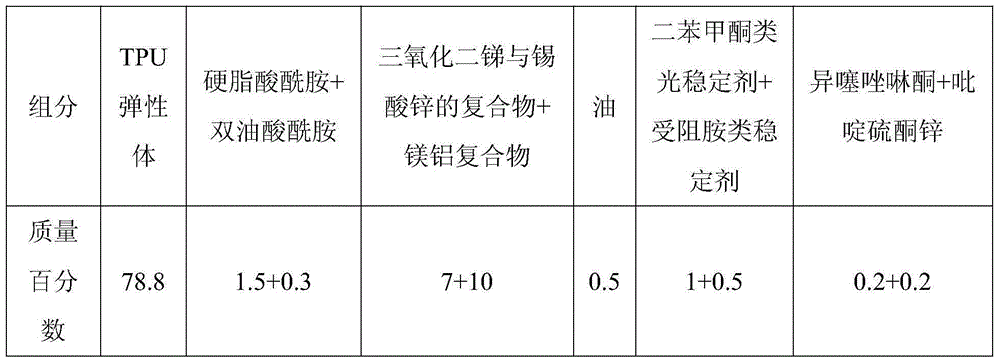

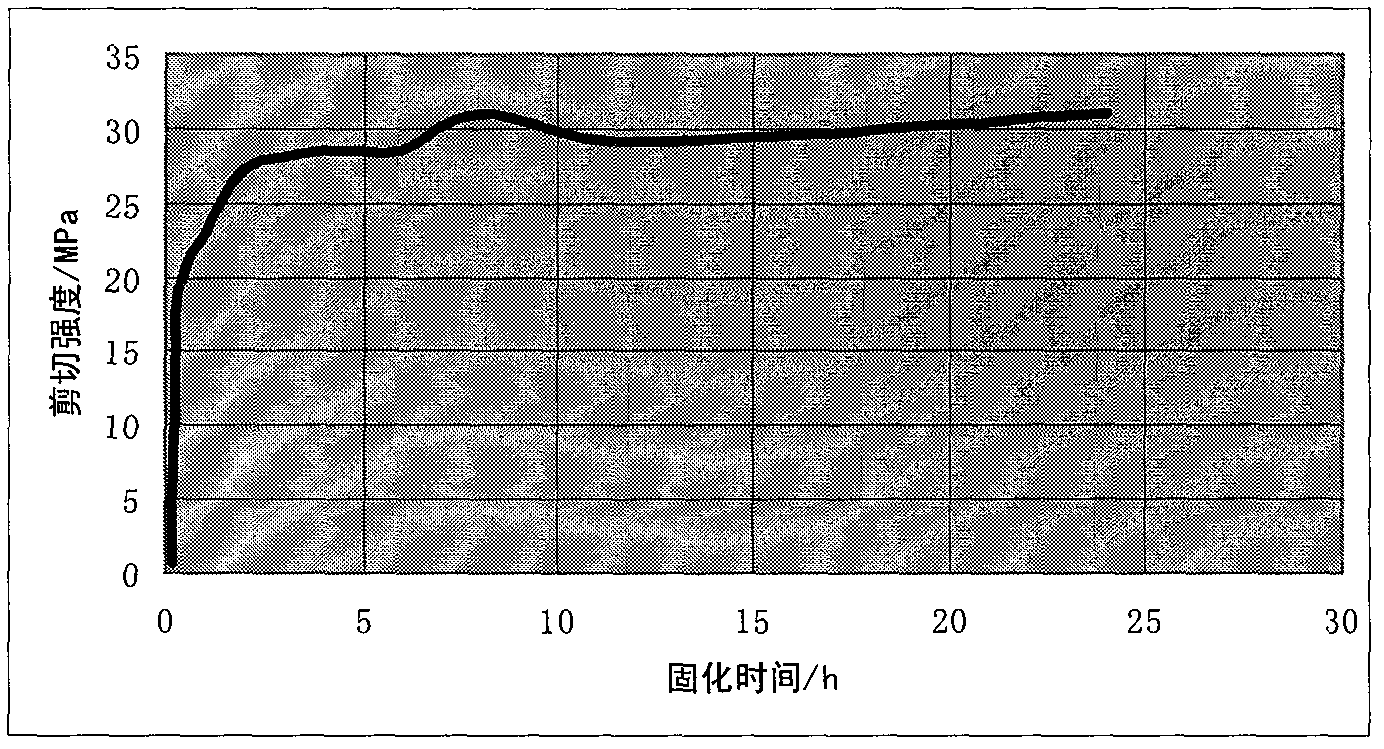

Preparation method of flame-retardant halogen-free TPU sunscreen fabric

ActiveCN105220313AImprove flame retardant performanceImprove heat agingHeating/cooling textile fabricsWoven fabricsThermal ageingYarn

The invention relates to a preparation method of flame-retardant halogen-free TPU sunscreen fabric. The preparation method comprises following steps: drying TPU and anti-sticking particles; physically blending dried TPU and fillers in proportion in order to obtain mixed TPU particles; melting obtained TPU particles via an extruder and coating TPU particles with PET original yarns in order to obtain coated yarns; and obtaining flame-retardant halogen-free TPU sunscreen fabric by warping, weaving and heat setting. The preparation method of flame-retardant halogen-free TPU sunscreen fabric has following beneficial effects: the obtained sunscreen fabric is high in flame retardance and antibacterial property, fine in anti-light aging property and anti-thermal ageing performance and is in accord with the environmental protection concept and has fine application prospect and great research value.

Owner:PHIFER INC

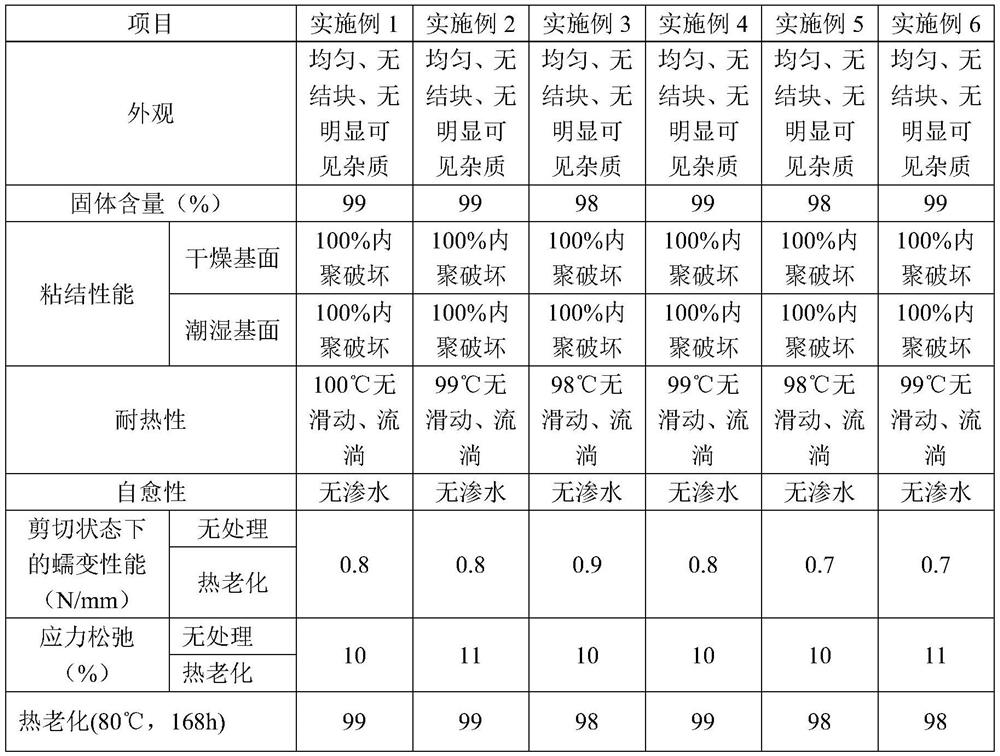

Heat-resistant non-cured rubber asphalt waterproof coating, preparation method and coiled material thereof

InactiveCN112280476AGood creepImprove heat resistanceReclaimed rubber coatingsRoof covering using flexible materialsRubberized asphaltSilane coupling

The invention provides a heat-resistant non-cured rubber asphalt waterproof coating, a preparation method and a coiled material thereof. The heat-resistant non-cured rubber asphalt waterproof coatingcomprises the following components in parts by weight: 55-65 parts of asphalt, 1-5 parts of tackifying resin, 1-5 parts of SBS, 20-35 parts of a plasticizer, 1-5 parts of modified SBR, 10-17 parts ofdesulfurized rubber powder, 2-4 parts of a silane coupling agent and 0.2-0.5 part of a heat-resistant modifier. The product obtained by adopting the technical scheme of the invention is green and environment-friendly, not only can keep a never-cured form, but also has higher heat resistance and cohesiveness, the heat resistance can reach 100 DEG C, the thermal aging property is good, and long-termand reliable waterproof and heat-resistant functions can be exerted.

Owner:北新防水(四川)有限公司

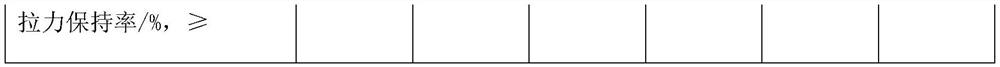

Preparation method of anti-aging polyester film material

ActiveCN114605687AImprove heat agingImprovement ingredientsImage analysisWeather/light/corrosion resistancePolyesterPolymer science

The invention relates to a preparation method of an anti-aging polyester film material. The preparation method comprises the following steps: preparing 0.1%-0.2% of W944, 0.1%-0.2% of UV329, 0.1%-0.2% of UV531, 0.4%-0.5% of zinc stearate, 0.4%-0.5% of zeolite, 0.05% of TiO2 and polyester; carrying out extrusion, film blowing and further stretching on the master batch to obtain an anti-aging polyester film; placing the polyester film in an aging environment with an ultraviolet light source, an infrared light source and a heat source for aging, acquiring an image of the polyester film, and sending the image into the neural network model for judging the anti-aging performance of the film and the consistency of the anti-aging performance; and optimizing the components, the proportion and the preparation process of the anti-aging polyester material master batch according to the judgment result. Therefore, the preparation process of the anti-aging polyester material can be optimized, and the polyester material with better light stability and heat stability is obtained.

Owner:河南银金达新材料股份有限公司

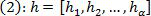

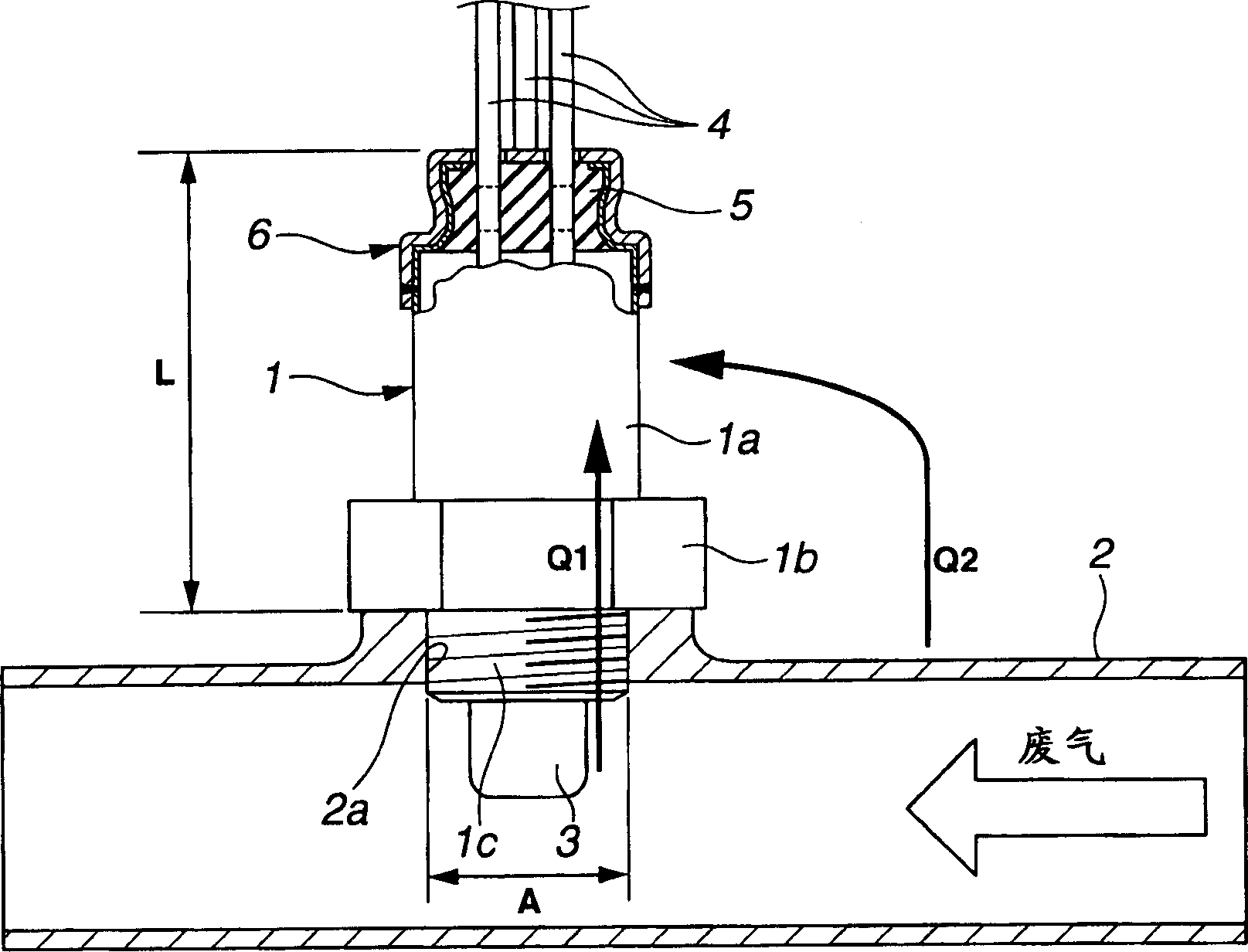

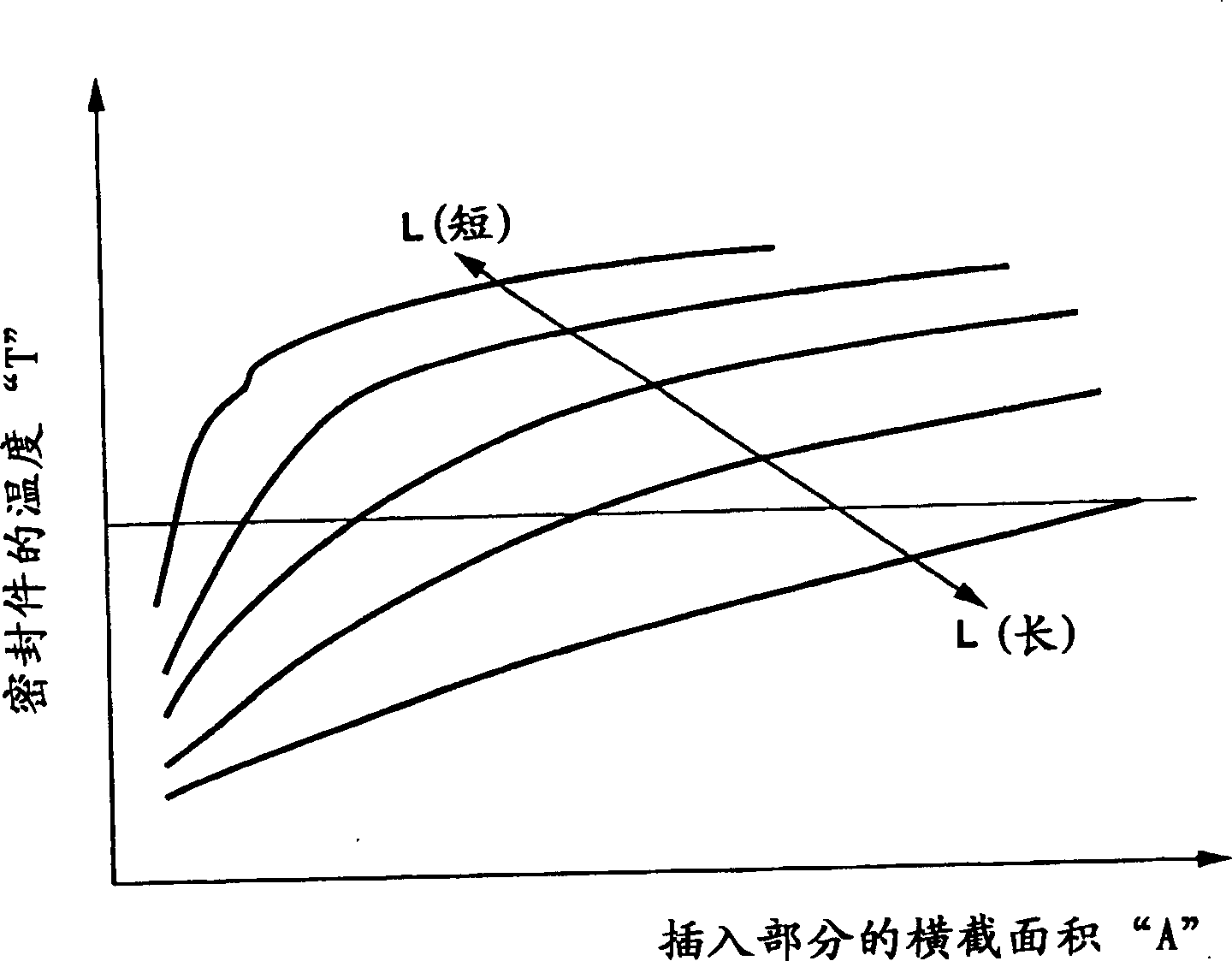

Oxygen sensor

InactiveCN1877316ASolve the real problemSolve the problems encounteredMaterial resistanceElectricityOxygen sensor

An oxygen sensor includes a generally cylindrical casing. A detecting section is disposed at an axially one end side of the casing so as to detect a concentration of oxygen. Lead wires are electrically connected with the detecting section and outwardly extend through an axially other end side of the casing. A seal member is disposed inside an end section located at the axially other end side of the casing. The lead wires pierce the seal member. An insertion section is located at the axially one end side of the casing so that the detecting section projects over the insertion section. The insertion section is inserted into a through-hole formed in a wall of an exhaust pipe, so as to install the oxygen sensor to the exhaust pipe in a condition where the detecting section projects into the exhaust pipe. A ratio of a length of an outer projecting section of the oxygen sensor to a cross-sectional area of the insertion section inserted into the through-hole is set at a value not lower than a value at which a temperature in the seal member reaches a heat resistant temperature limit of the seal member.

Owner:HITACHI LTD

Preparation method of conductive adhesive

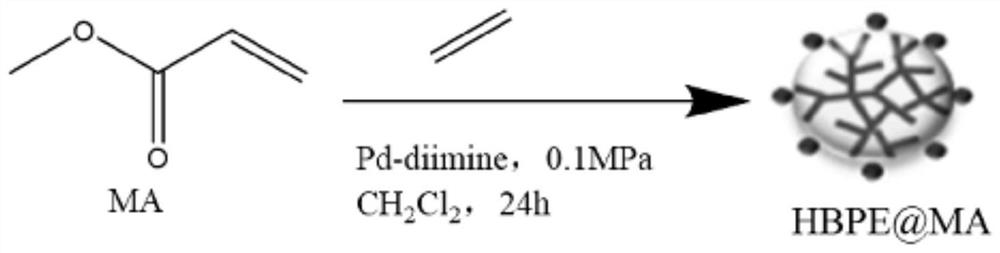

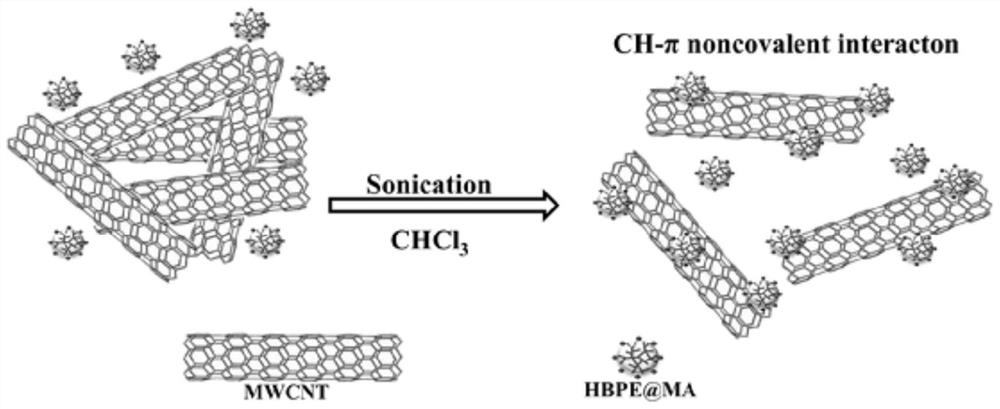

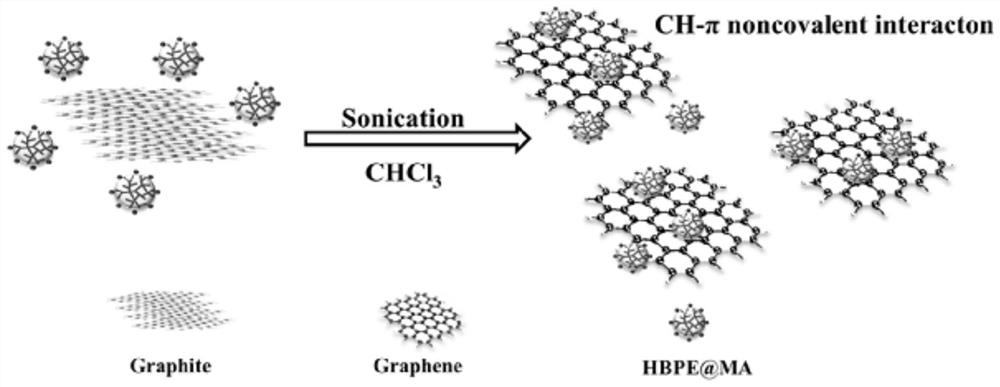

PendingCN114736631AReduce surface resistanceImprove electrical conductivityChemical industryElectrically-conducting adhesivesThin membraneChloroform

The invention discloses a method for preparing a conductive adhesive by taking multi-walled carbon nanotubes and graphene as mixed filler, which comprises the following steps: (1) mixing a certain amount of multi-walled carbon nanotubes or natural graphite and hyperbranched polyethylene-methyl acrylate in chloroform, carrying out ultrasonic treatment in an ultrasonic pool, and carrying out ultrasonic treatment for 2-3 hours; a multi-walled carbon nanotube solution and a graphene solution are obtained. And (2) carrying out centrifugation, vacuum filtration and ultrasonic operation on the solution to obtain a multiwalled carbon nanotube solution and a graphene solution with good dispersibility. And (3) dissolving the acrylate pressure-sensitive adhesive in chloroform by adopting a solution mixing method, then adding quantitative carbon tube solution, and uniformly mixing. And manually coating the adhesive layer on the release film by using an adjustable scraper, drying in a drying oven, and removing the solvent. And finally, transferring to a PET film, and measuring the surface resistance by using a high-resistance instrument. The method is simple, easy to operate, low in price and environmentally friendly.

Owner:浙江元盛塑业股份有限公司

Metallic acrylate curing agents and usage thereof in intermediate compositions

InactiveUS7396869B2Reduce Shrinkage ProblemsImprove clarityFibre treatmentEpoxy resin coatingsCross-linkAdhesive

The disclosure relates to using metallic acrylate compounds such as zinc diacrylate (ZDA), zinc dimethacrylate (ZDMA), among others for curing epoxy functional (and other cross-linking compounds), and to compositions containing such compounds for use in powder coat, film, adhesive, among other applications. ZDA and ZDMA containing compounds can also be supplied as an intermediate product that can cure the epoxy component of the compositions while being substantially free of conventional curing agents.

Owner:DENOVUS

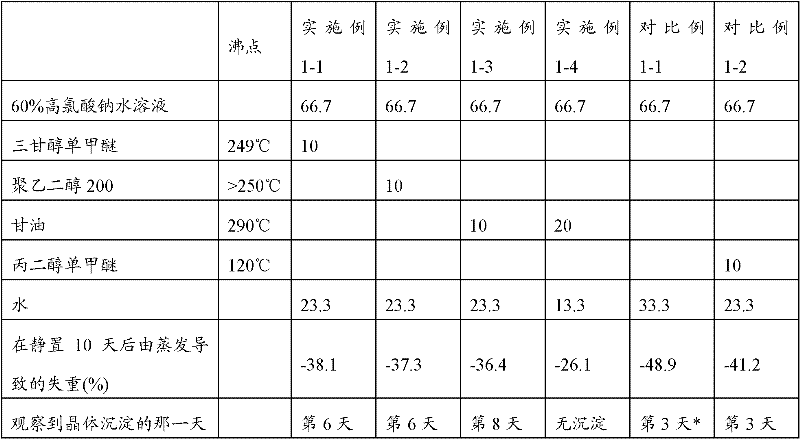

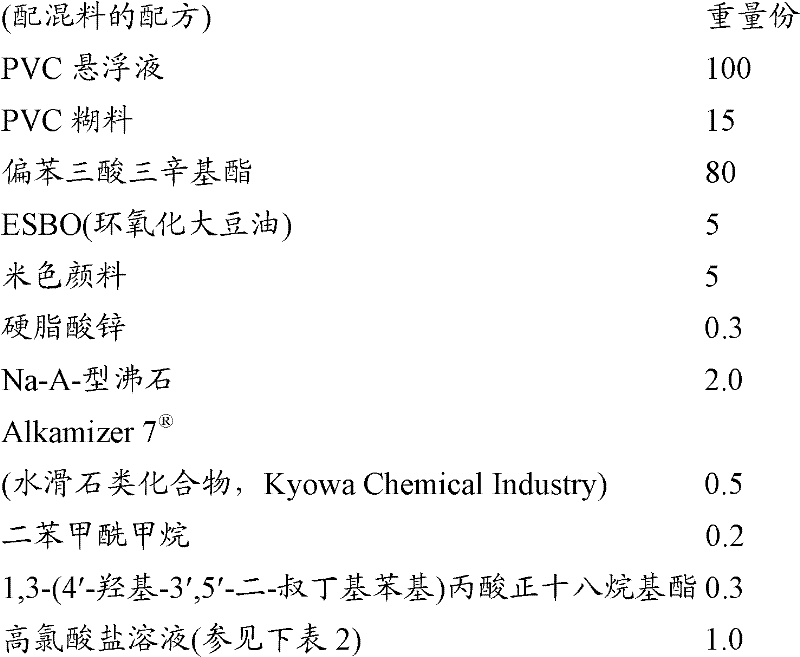

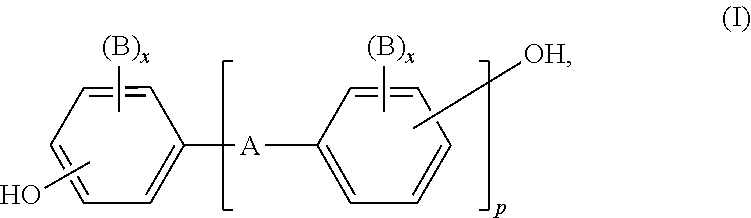

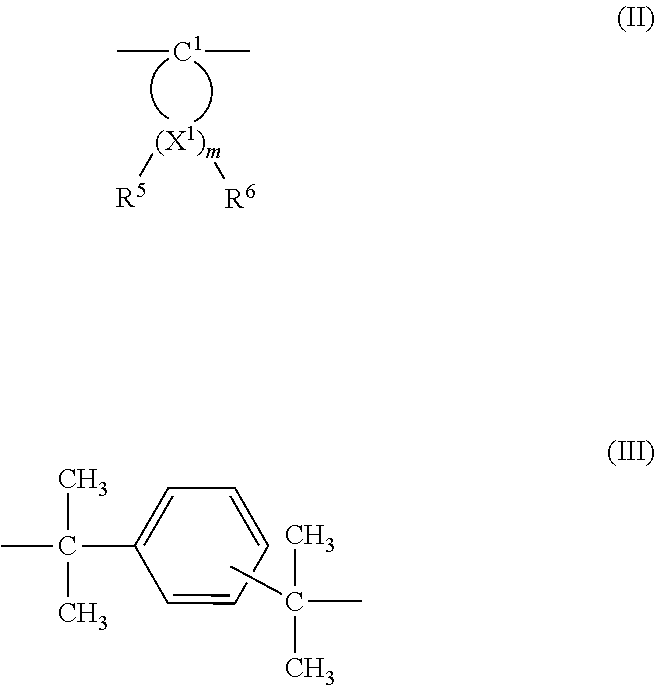

A perchlorate solution improved in safety, and a method for heat-stabilizing chlorine-containing resin compositions

To improve the handlability and safety of a perchlorate solution used as a stabilizer for chlorine-containing resins. This invention provides a perchlorate solution of improved handlablity and safety and a method for heat-stabilizing chlorine-containing resin compositions by adding (a) 0.004 to 10 parts by weight of a perchlorate solution containing 1 to 60 % by weight of perchlorate, 5 to 50 % by weight of water-soluble organic solvent and 20 to 94 % by weight of water, and (b) 0.001 to 10 parts by weight of at least one silicate compound represented by the general formula (I) to 100 parts by weight of a chlorine-containing resin: M(O)a nSiO2mH2O (I) in which M is at least one metal selected from alkaline earth metals and aluminum, a is 1 when M is an alkaline earth metal and 3 / 2 where M is aluminum, n is from 1 to 5, and m is any positive integer.

Owner:AKISHIMA CHEM IND

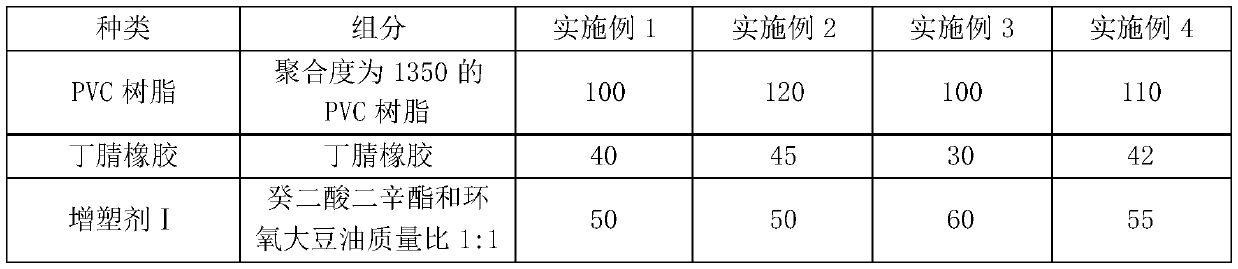

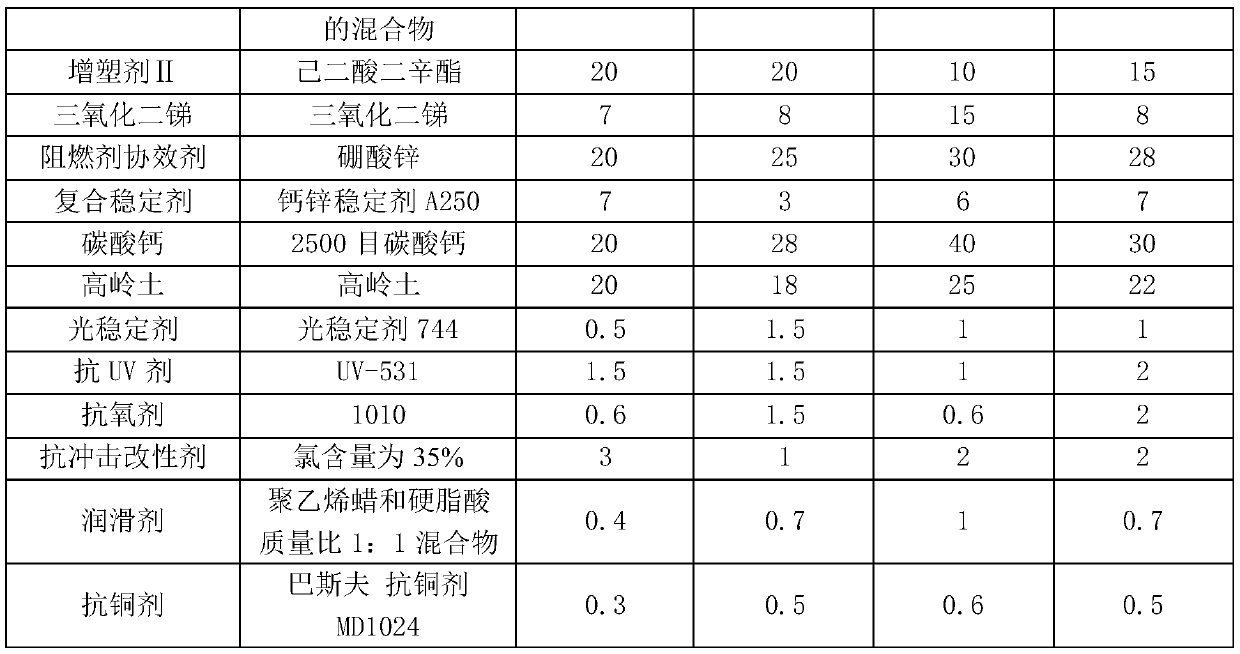

Environmental-friendly -40 DEG C resistant polyvinyl chloride (PVC) sheathing material for 5G communication cable and preparation method thereof

The invention belongs to the technical field of sheathing materials for communication cables, and particularly relates to an environmental-friendly -40 DEG C resistant polyvinyl chloride (PVC) sheathing material for a 5G communication cable and a preparation method thereof. The PVC sheathing material is prepared from the components: 100-130 parts of PVC resin, 30-45 parts of nitrile rubber, 45-65parts of a plasticizer I, 10-20 parts of a plasticizer II, 5-15 parts of antimony trioxide, 20-30 parts of a flame retardant synergist, 3-7 parts of a composite stabilizer, 20-40 parts of calcium carbonate, 15-30 parts of kaolin, 1-2 parts of an anti-UV agent, 0.5-2 parts of an antioxidant, 1-3 parts of an impact modifier, 0.4-1 part of a lubricant and 0.3-0.6 part of an anti-copper agent. The environmental-friendly -40 DEG C resistant PVC sheathing material is good in flame retardant performance, low in temperature performance and good in UV resistance performance and mechanical performance.

Owner:BAOSHENG SCI & TECH INNOVATION

Glass fiber grid double-sided adhesive sizing material for rubber sealing strip

InactiveCN102504731ASuitable for bondingImprove adhesionNon-macromolecular adhesive additivesEster polymer adhesivesThermal ageingFiberglass mesh

The invention discloses a glass fiber grid double-sided adhesive sizing material for a rubber sealing strip; the glass fiber grid double-sided adhesive sizing material is characterized in that the glass fiber grid double-sided adhesive sizing material is obtained by mixing the following components in parts by mass according to proportions in a formula: 100 parts of acrylic emulsion pressure-sensitive adhesive, 0-3% of multifunctional aziridine crosslinking agent, 0-10% of aqueous solution. The sizing material provided by the invention mainly aims at overcoming the defects that the emulsion pressure-sensitive adhesive is easy to degum and be left, and the like; and simultaneously the weather resistance, thermal ageing or temperature resisting performance and viscose holding effect of the glass fiber grid double-sided adhesive sizing material are increased; the glass fiber grid double-sided adhesive sizing material has wide application use and is suitable for bonding most of the rubber strips and has excellent bonding capacity with the rubber strips, excellent high and low temperature resistant performance and excellent enduring viscose force.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

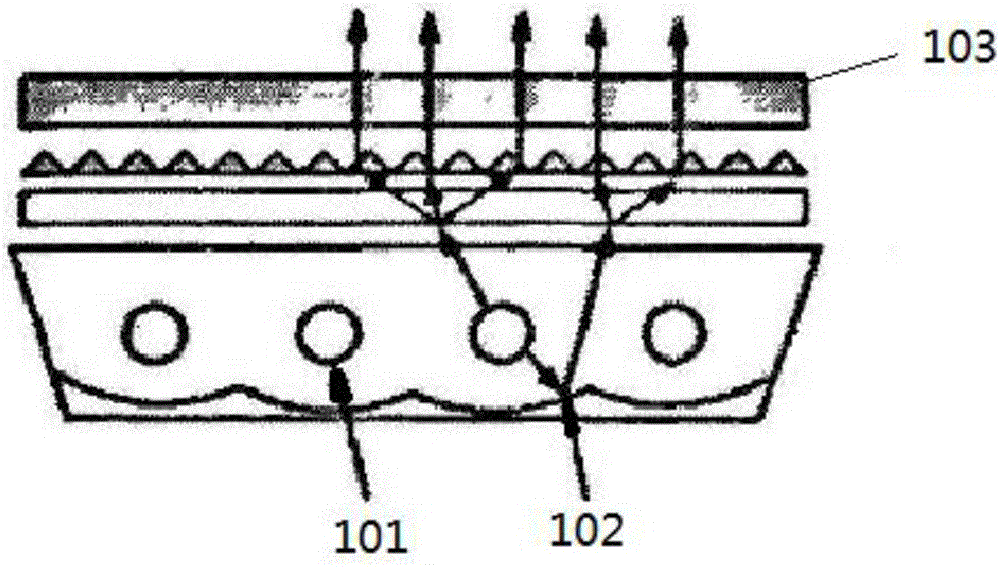

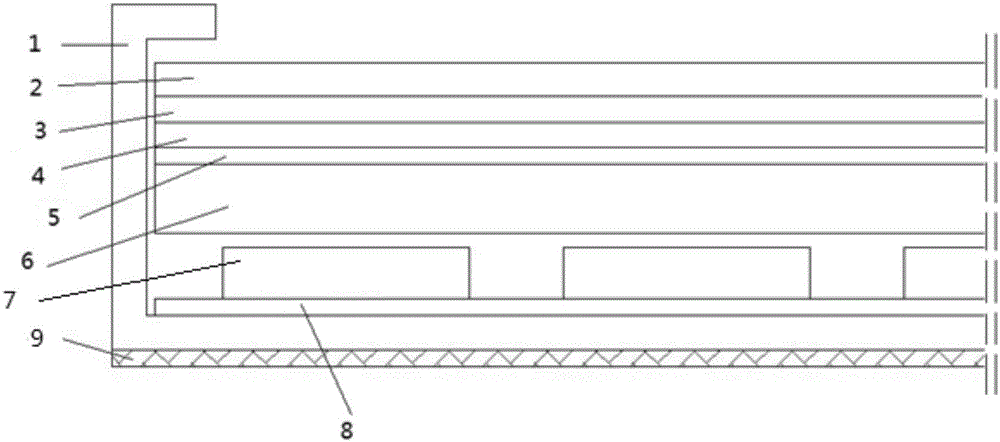

Direct-lit backlight module

InactiveCN106054455AImprove cooling effectImprove heat agingNon-linear opticsThermal energyThermal insulation

The invention relates to a direct-lit backlight module. The direct-lit backlight module comprises a back plate, an upper prismatic lens, a lower prismatic lens, a diffusion plate, a light guide plate, a light source and a flexible circuit board. The flexible circuit board is arranged above a bottom plate of the back plate, the light guide plate is arranged above the light source which is arranged above the flexible circuit board, and the lower prismatic lens and the upper prismatic lens are sequentially arranged above the diffusion plate which is arranged above the light guide plate. The backlight module further comprises a thermal insulation layer and a thermal radiation film, the thermal insulation layer is arranged on the upper prismatic lens, and the thermal radiation film is arranged on the lower surface of the bottom plate of the back plate. By addition of the thermal radiation film on the lower surface of the bottom plate of the back plate and addition of the thermal insulation layer on the upper prismatic lens, thermal energy generated by lighting can be quickly diffused from the back surface, and accordingly thermal radiation performance of the backlight module is greatly improved while the service life of a liquid crystal panel is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Impact-modified polycarbonate compositions

Owner:COVESTRO DEUTSCHLAND AG

Irradiation crosslinking flexible corrosion-resistant low-smoke halogen-free composition as well as preparation method and application thereof

The invention provides an irradiation crosslinking flexible corrosion-resistant low-smoke halogen-free composition as well as a preparation method and application thereof. The irradiation crosslinking flexible corrosion-resistant low-smoke halogen-free composition is prepared from the following raw materials in parts by weight: 10 to 15 parts of ethylene-vinyl acetate copolymer, 10 to 15 parts of flexibilizer, 15 to 20 parts of super-tough elastomer, 40 to 50 parts of magnesium hydroxide for chemical surface treatment, 0.7 to 1.5 parts of coupling aid, 3-6 parts by weight of an antioxidant, 2-3 parts by weight of a cross-linking agent, and 4-6 parts by weight of a lubricant. The invention also provides a preparation method of a cable. The irradiation crosslinking flexible corrosion-resistant low-smoke halogen-free composition can be used as a cable of an electric vehicle charging pile. The irradiation crosslinking flexible corrosion-resistant low-smoke halogen-free composition disclosed by the invention is high in temperature resistance grade and resistant to environmental corrosion.

Owner:苏州铂玛新材料有限公司

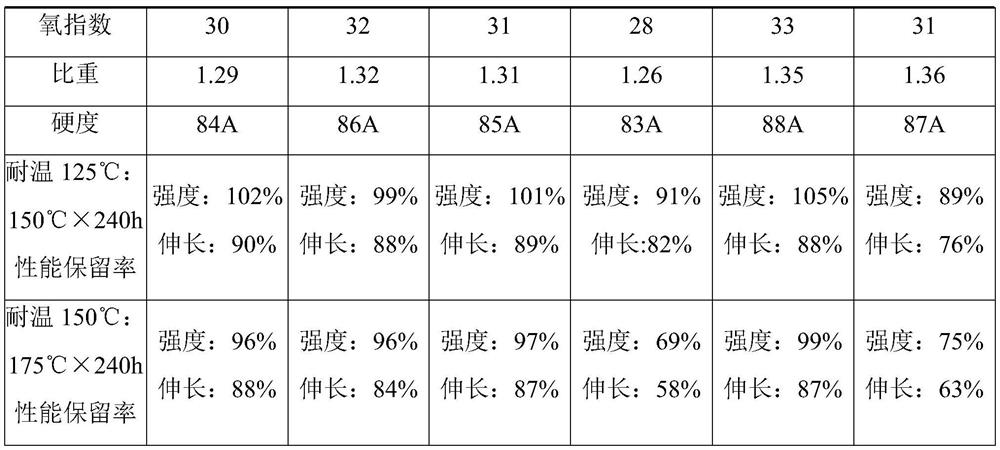

Novel two-component acrylate structural adhesive and preparation method thereof

InactiveCN102286253BHeat curing settling time is shortLong operating timeOrganic non-macromolecular adhesivePolymer sciencePlasticizer

The invention discloses a two-component acrylate structural adhesive and a preparation method thereof. The two-component acrylate structural adhesive comprises a component A and a component B, wherein the volume ratio of the component A to the component B is 10: 1. The component A comprises the following components by weight percent: 50%-75% of acrylate monomer, 20%-40% of toughening tackifier, 0.1%-3% of reducing agent, 0.1%-6% of stabilizer and 0.1%-10% of additive. The component B comprises the following components by weight percent: 20%-50% of oxidant, 20%-50% of plasticizer, 10%-20% of toughening agent and 0.1%-10% of additive.

Owner:TONSAN ADHESIVES INC

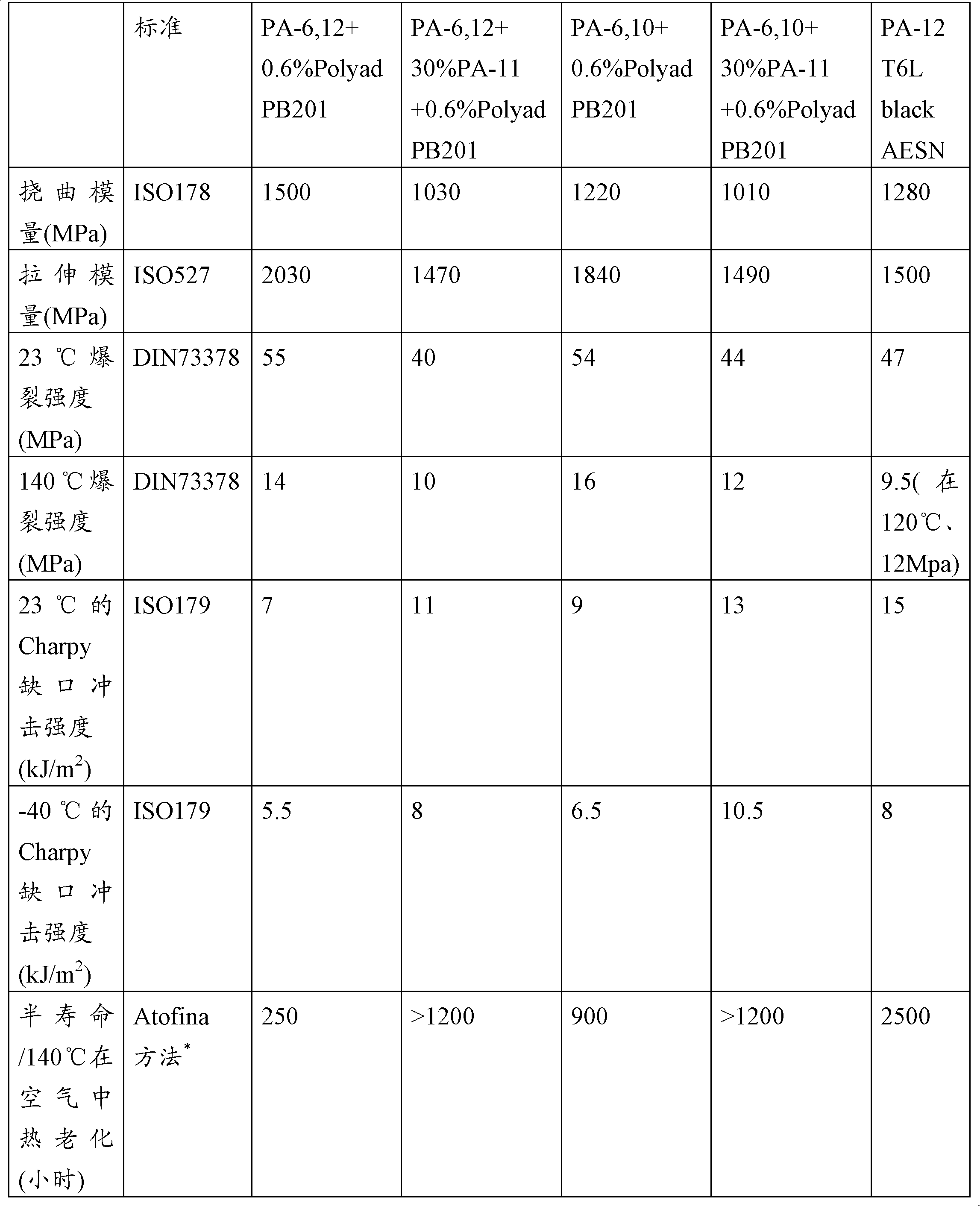

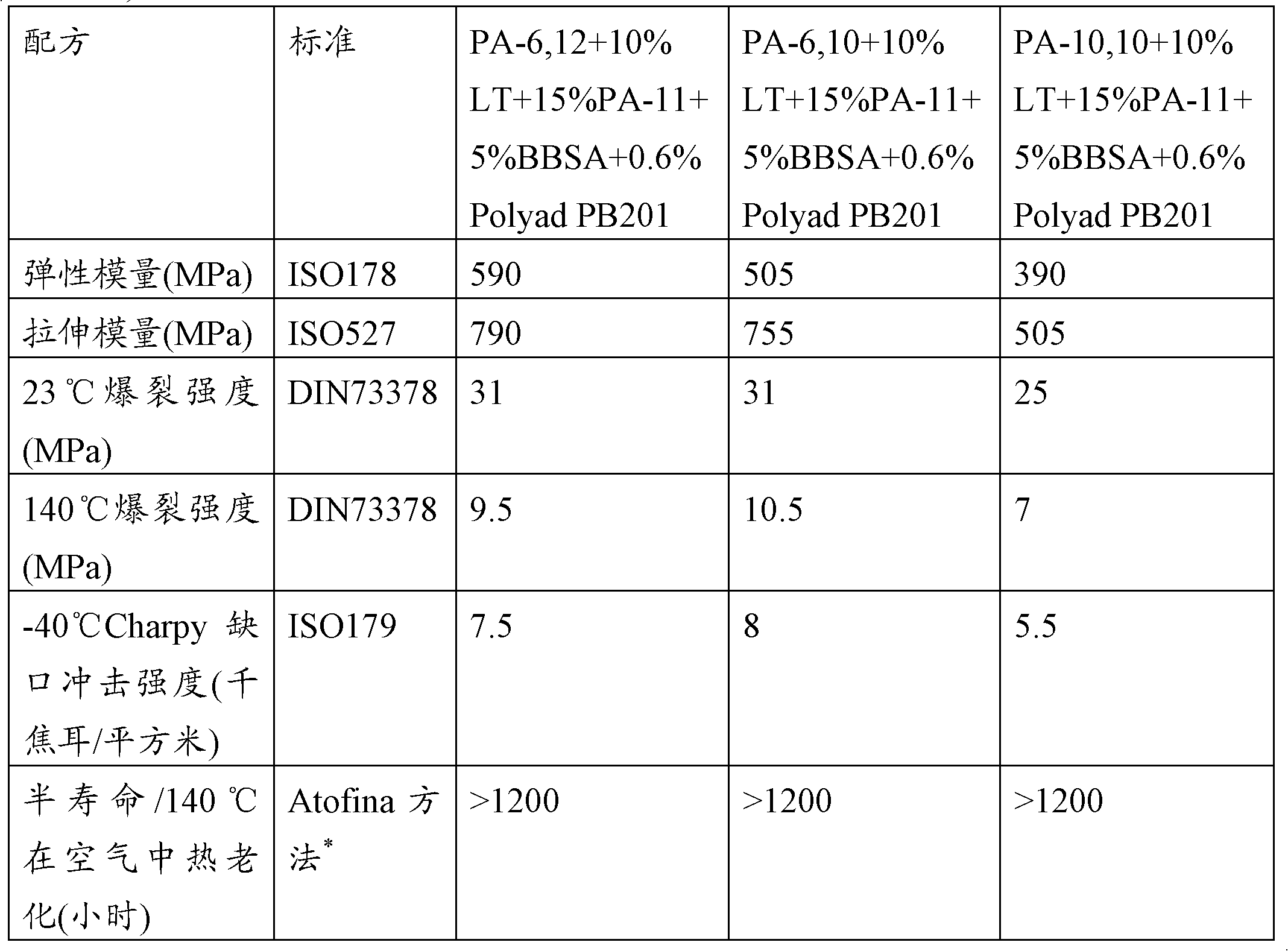

Polyamides semi-cristallins souples

ActiveCN102582184AHigh operating temperatureImprove heat agingSynthetic resin layered productsFlexible pipesPolymer sciencePlasticizer

The invention relates to the use of a composition, noted C, in a coating process for covering articles, said composition comprising, by weight, the total being 100 percent: to 50 to 100percent of at least one polyamide A1 of formula X.Y is divided by Z or 6.Y2 is divided by Z in which: X denotes the residues of an aliphatic diamine having from 6 to 10 carbon atoms, Y denotes the residues of an aliphatic dicarboxylic acid having from 10 to 14 carbon atoms , Y2 denotes the residues of an aliphatic dicarboxylic acid having from 15 to 20 carbon atoms and Z denotes at least one unit chosen from the residues of a lactam, the residues of an plus minus,e to aminocarboxylic acid, the unit X1, Y1 in which X1 denotes the residues of an aliphatic diamine and Y1 denotes the residues of an aliphatic dicarboxylic acid, the weight ratios Z is divided by (X plus Y plus Z) and Z is divided by (6plusY2plusZ) being between 0 and 15 persent; to 0 to 40 persent of a plasticizer; to 0 to 50 persent of an impact modifier; and to 0 to 50 persent of a polyamide A2. The invention also relates to coated articles covered with a layer consisting of the above composition C. This coating is useful for making devices for storing or transferring fluids, in particular in motor vehicles and heavy goods vehicles.

Owner:ARKEMA FRANCE SA

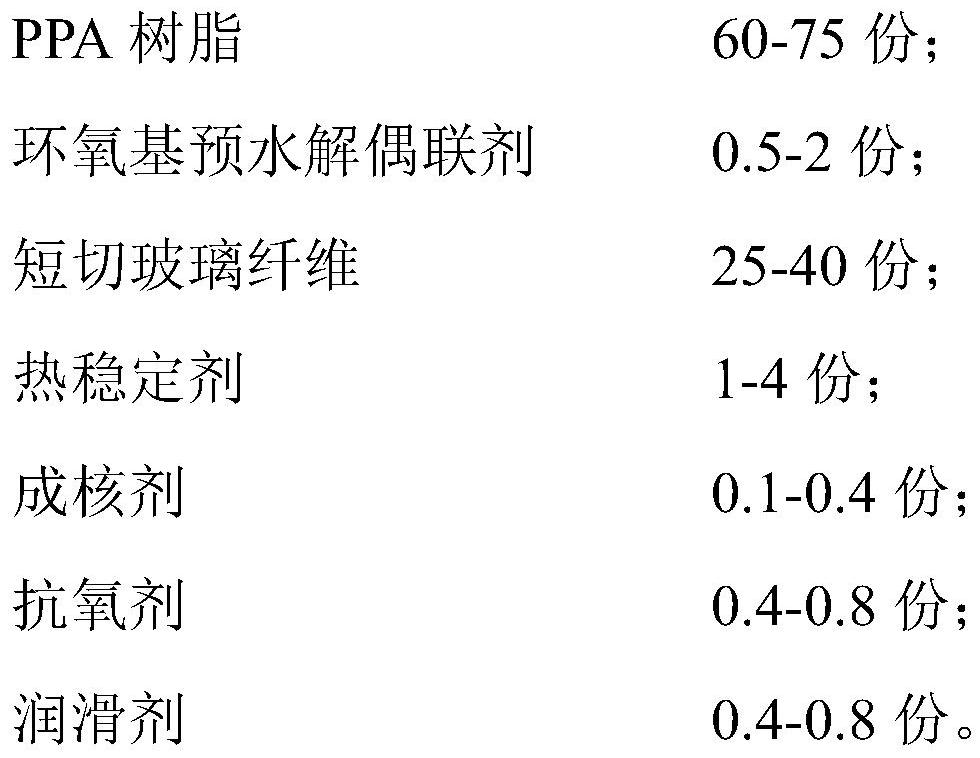

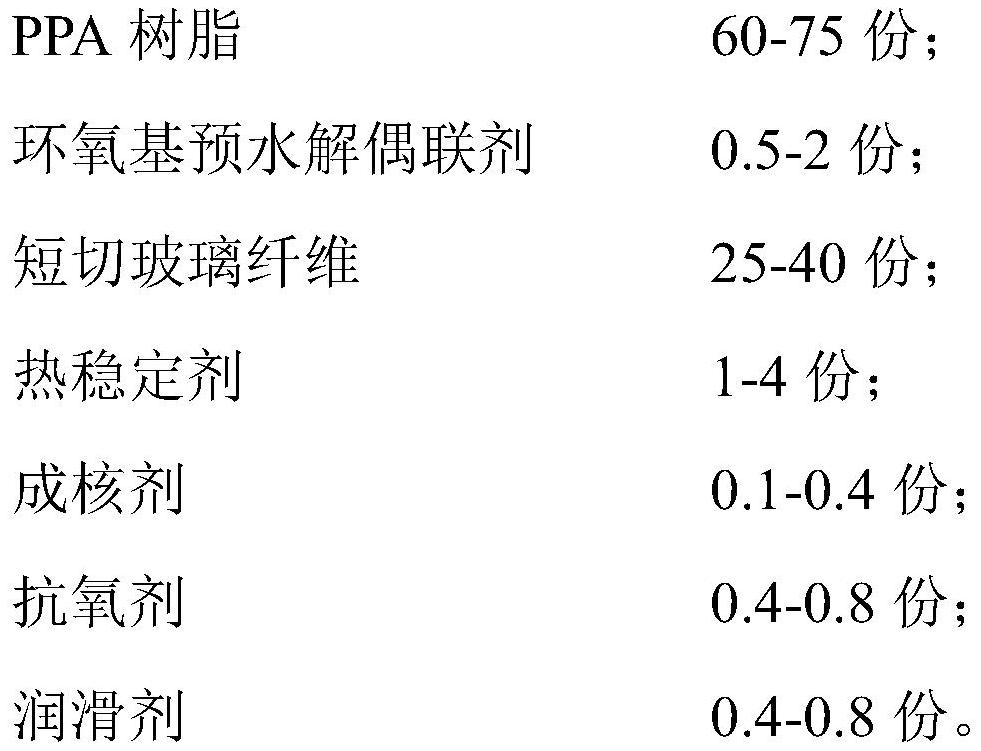

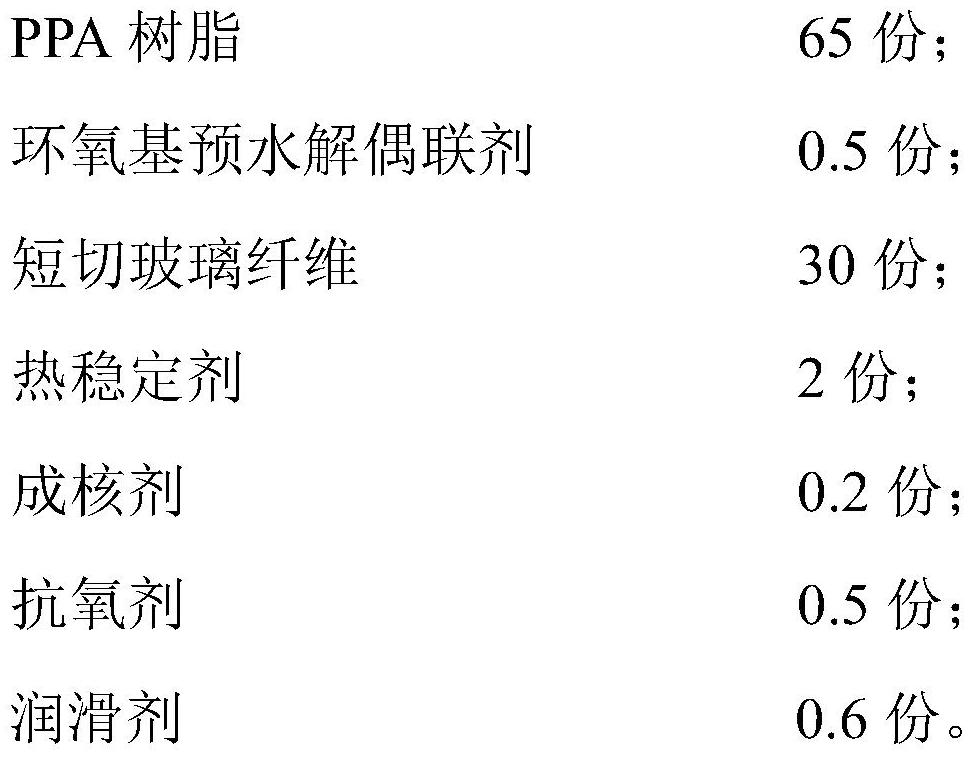

Alcoholysis-resistant heat-stable PPA composite material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and discloses an alcoholysis-resistant heat-stable PPA composite material and a preparation method thereof. The alcoholysis-resistant heat-stable PPA composite material disclosed by the invention is prepared from the following components in parts by weight: 60 to 75 parts of PPA resin, 0.5 to 2 parts of an epoxy group pre-hydrolysis coupling agent, 1 to 4 parts of a heat stabilizer, 25 to 40 parts of chopped glass fibers, 0.1 to 0.4 part of a nucleating agent, 0.4 to 0.8 part of an antioxidant and 0.4 to 0.8 part of a lubricating agent. The material provided by the invention has excellent mechanical properties and processability, and can solve the problems of high water absorption, poor hydrolysis resistance, poor creep resistance, poor thermal stability, poor dimensional stability and the like of long carbon chain nylon reinforced materials used in the industries of automobiles, electric tools and electronics.

Owner:横店集团得邦工程塑料有限公司

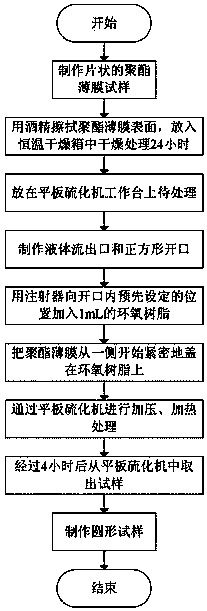

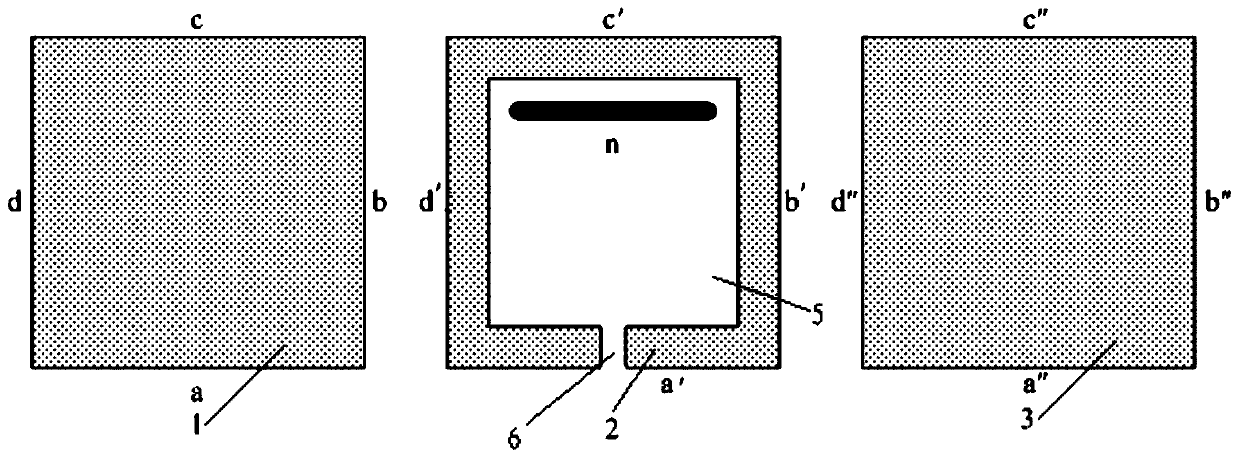

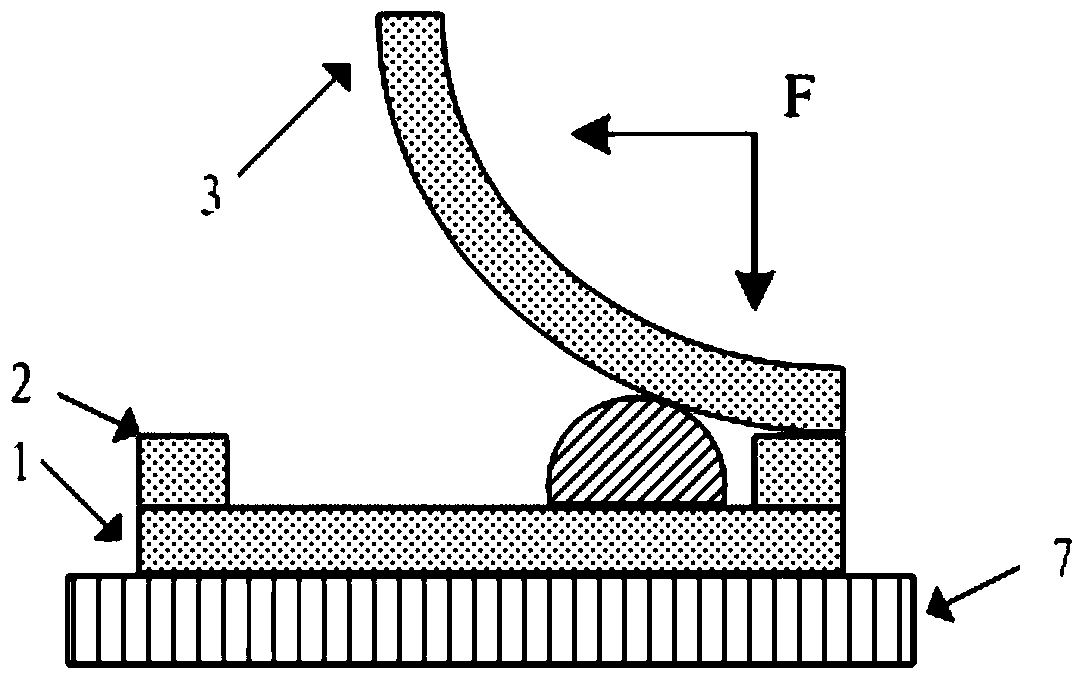

A sample making method and a sheet sample for studying the aging process of the inter-turn insulation of a dry-type air-core reactor

A method of making a sample for studying the aging process of insulation between turns of dry-type air-core reactors and a sheet sample, which relates to a sheet material sample and a method of making it. Method: Make a sheet-shaped polyester film; wipe the surface of the polyester film with alcohol and dry it; make a square opening and outlet, and then fit the two pieces of polyester film tightly without leaving any bubbles; drop the ring into the square opening Oxygen resin; stick the polyester film on the square opening; pressurize and heat the composite insulation material sample; make a round sample. Sample: Three square-shaped polyester films are closely attached. The second square-shaped polyester film has a square opening in the center and an outlet on the side. There is an epoxy resin filling structure in the square opening. body. The invention is suitable for conducting various aging tests such as thermal aging, electrical aging, moisture exposure, and mechanical vibration, and can be used for space charge testing and infrared spectrum measurement.

Owner:HARBIN UNIV OF SCI & TECH

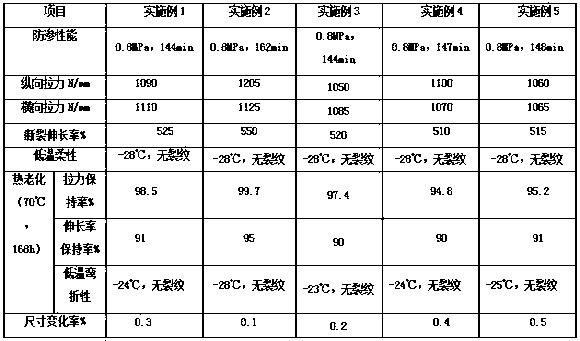

PVC anti-aging waterproof roll and preparation method thereof

InactiveCN110358467AImprove anti-seepage performanceIncrease longitudinal tensionFilm/foil adhesivesThermal ageingEpoxy

The invention provides a PVC anti-aging waterproof roll. The PVC anti-aging waterproof roll comprises modified polyvinyl chloride, thermoplastic butadiene styrene rubber, stabilizer, epoxy resin, paraffin, sterol, antiager, pyrophylite powder, isophoronediisocyanate and polyhexamethylene phosphate. The invention further comprises a preparation method of the PVC anti-aging waterproof roll. The preparation method comprises an ultrasonic dispersion step, the power is 1350-1400 W, and the ultrasonic time is 3-5 min. According to the PVC anti-aging waterproof roll, the deformation resistance is high, the size change rate is 0.1-0.5%, the elongation at break is 510-550%, and tension reaches 1050-1025 N; and thermal ageing tension retention rate is 94.8-99.7%, the elongation retention rate is 90-95%, the bending property at low temperature is as low as -28 DEG C, crack is avoided, scratch and wear resistance is achieved, and the property is durable and stable.

Owner:WEIFANG HUAGUANG WATERPROOF MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com