Sunshine fabric with high oxygen index and preparation method thereof

A sunshine fabric, high oxygen index technology, applied in rayon manufacturing, fabric surface trimming, fire and flame retardant filament manufacturing and other directions, can solve the problems of poor weather resistance and flame retardancy, and achieve improved weather resistance, high strength, processing good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

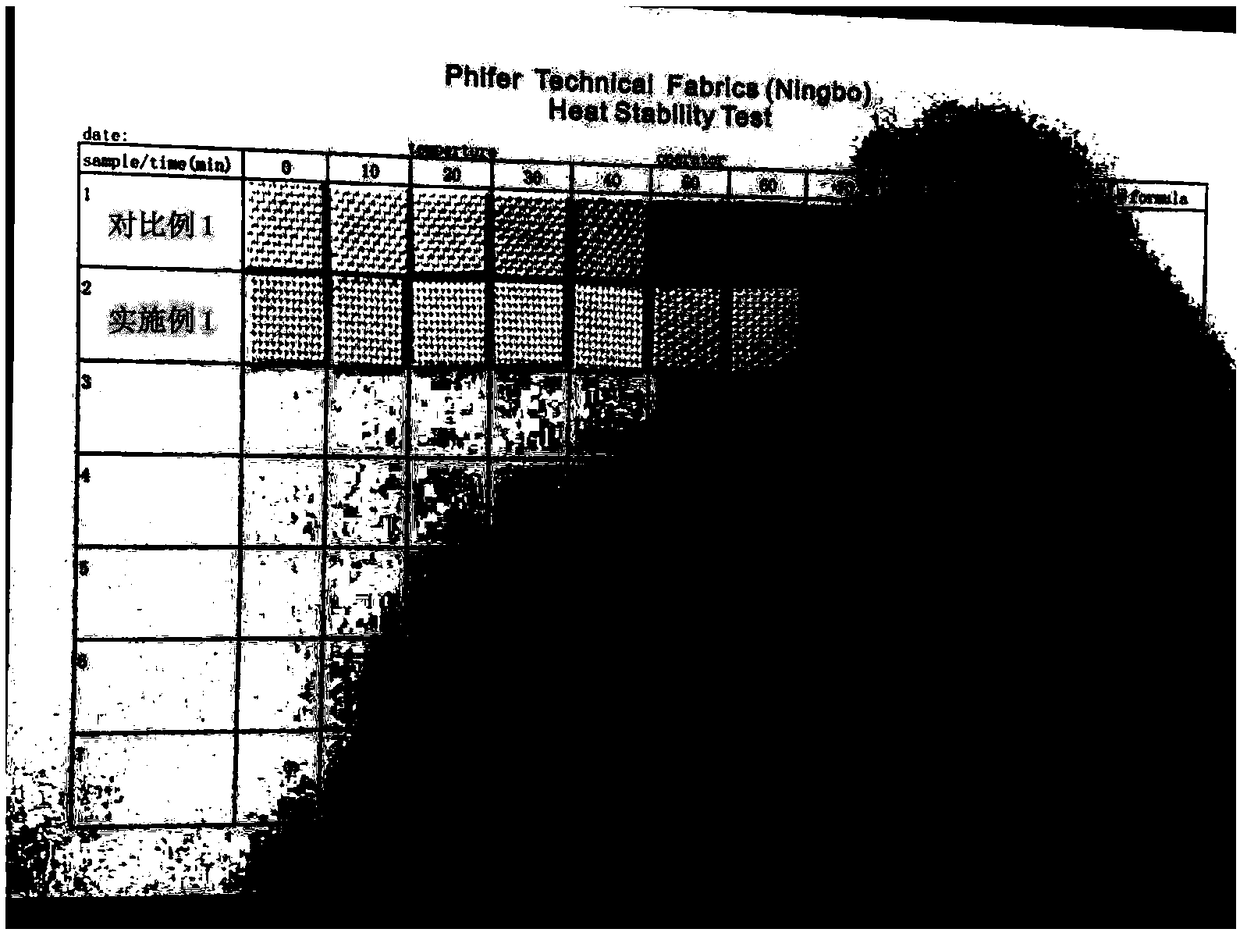

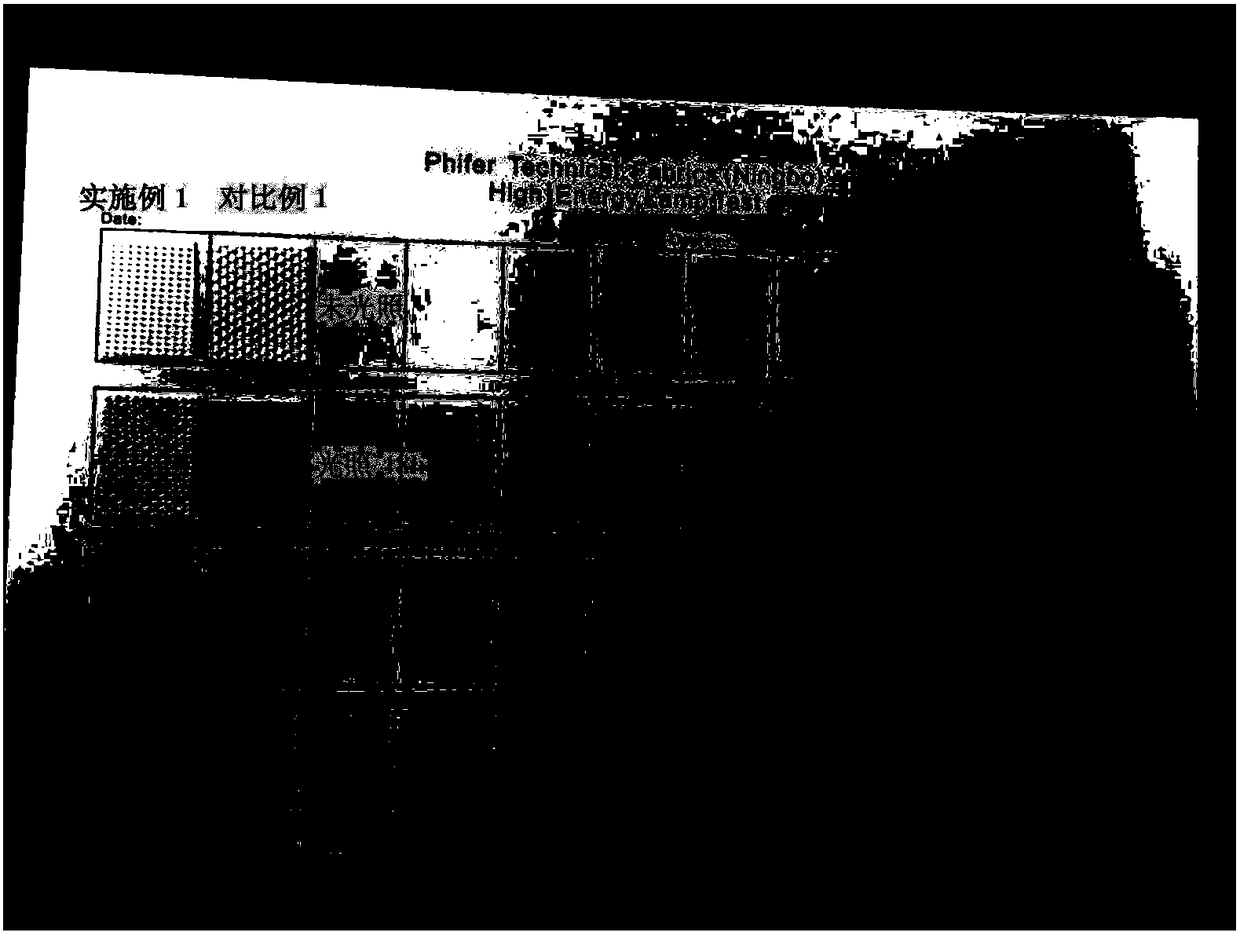

Image

Examples

Embodiment 1

[0033] (1) 90 parts of S-65 type PVC resin, 10 parts of chlorinated polyvinyl chloride, 5 parts of phthalic plasticizer general-purpose DINP, 20 parts of phosphate plasticizer DPO, 7 parts of antimony trioxide, chlorine 10 parts of paraffin wax, 5 parts of zinc hydroxystannate, 10 parts of decabromodiphenylethane, 6 parts of magnesium hydroxide, 1.5 parts of benzophenone and benzotriazole composite ultraviolet absorber with a mass ratio of 1:1, 0.4 parts of lubricant CWO315 oxidized polyethylene wax, 1 part of processing aid P551A acrylic resin, 4 parts of liquid Ba / Zn heat stabilizer, compound antibacterial agent of isothiazolinone and zinc pyrithione with a mass ratio of 2:1 0.4 parts and 6 parts of rutile titanium dioxide were physically blended to obtain mixed PVC particles.

[0034] (2) The PVC particles described in step (1) are melted by an extruder and coated with PET precursors to obtain coated yarns, which are then warped, woven, and heat-set to obtain a high oxygen ...

Embodiment 2

[0037] (1) 90 parts of S-65 type PVC resin, 10 parts of chlorinated polyvinyl chloride, 25 parts of phthalic plasticizer general-purpose DINP, 5 parts of phosphate plasticizer DPO, 7 parts of antimony trioxide, chlorine 10 parts of paraffin wax, 5 parts of zinc hydroxystannate, 8 parts of decabromodiphenylethane, 6 parts of magnesium hydroxide, 1.5 parts of benzophenone and benzotriazole composite ultraviolet absorber with a mass ratio of 1:1, 0.4 parts of lubricant CWO315 oxidized polyethylene wax, 1 part of processing aid P551A acrylic resin, 4 parts of liquid Ba / Zn heat stabilizer, compound antibacterial agent of isothiazolinone and zinc pyrithione with a mass ratio of 2:1 0.3 parts and 6 parts of rutile titanium dioxide were physically blended to obtain mixed PVC particles.

[0038] (2) The PVC particles described in step (1) are melted by an extruder and coated with PET precursors to obtain coated yarns, which are then warped, woven, and heat-set to obtain a high oxygen i...

Embodiment 3

[0041] (1) 90 parts of S-65 type PVC resin, 10 parts of chlorinated polyvinyl chloride, 20 parts of phthalic plasticizer general-purpose DINP, 10 parts of phosphate plasticizer DPO, 7 parts of antimony trioxide, chlorine 10 parts of paraffin wax, 0.5 parts of zinc hydroxystannate, 10 parts of decabromodiphenylethane, 6 parts of magnesium hydroxide, 1.5 parts of benzophenone and benzotriazole composite ultraviolet absorber with a mass ratio of 1:1, 0.4 parts of lubricant CWO315 oxidized polyethylene wax, 1 part of processing aid P551A acrylic resin, 4 parts of liquid Ba / Zn heat stabilizer, compound antibacterial agent of isothiazolinone and zinc pyrithione with a mass ratio of 2:1 0.3 parts and 6 parts of rutile titanium dioxide were physically blended to obtain mixed PVC particles.

[0042] (2) The PVC particles described in step (1) are melted by an extruder and coated with PET precursors to obtain coated yarns, which are then warped, woven, and heat-set to obtain a high oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com