Novel two-component acrylate structural adhesive and preparation method thereof

An acrylate and acrylate-based technology, applied in the field of two-component acrylate structural adhesives and their preparation, can solve problems such as short shelf life, and achieve excellent performance, good extrudability and thixotropy, and fast curing positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The acrylate monomers of component A are selected from methyl methacrylate, epoxy acrylate, hydroxyethyl methacrylate, ethoxylated bisphenol A dimethacrylate, trimethylolpropane trimethacrylate, Phenoxyethyl methacrylate; Methacrylic acid; Neoprene and MBS resin are selected as the toughening tackifier; The reducing agent is tertiary amine; Benzoquinone and EDTA-Na are selected as the stabilizing agent, other Pigment and fumed silica are selected as additives, and the specific component contents are shown in Table 1:

[0049] Table 1

[0050]

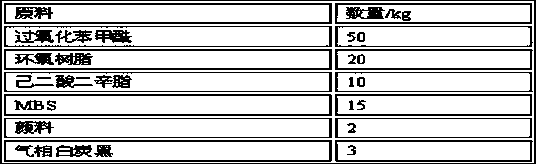

[0051] The oxidant of component B is benzoyl peroxide, the toughening agent is epoxy resin and ABS, the plasticizer is dioctyl adipate, and the auxiliary agent is pigment and fumed silica. The specific content is shown in Table 2:

[0052] Table 2

[0053]

Embodiment 2

[0055] The acrylate monomers of component A are selected from methyl methacrylate, epoxy acrylate, hydroxypropyl methacrylate, ethoxylated bisphenol A dimethacrylate, phenoxyethyl methacrylate, three Functional group methacrylate; methacrylic acid; the toughening and tackifying agent is selected from chloroprene rubber and ABS resin; the reducing agent is selected from tertiary amine; the stabilizer benzoquinone, naphthoquinone 2, 6-di-tert-butyl -4-Methylphenol and EDTA-Na, other additives are selected from pigments and fumed silica, and the specific component contents are shown in Table 3:

[0056] table 3

[0057]

[0058] The oxidant of component B is benzoyl peroxide, the toughening agent is epoxy resin and MBS, the plasticizer is dioctyl adipate, and the auxiliary agent is pigment and fumed silica. The specific content is shown in Table 4:

[0059] Table 4

[0060]

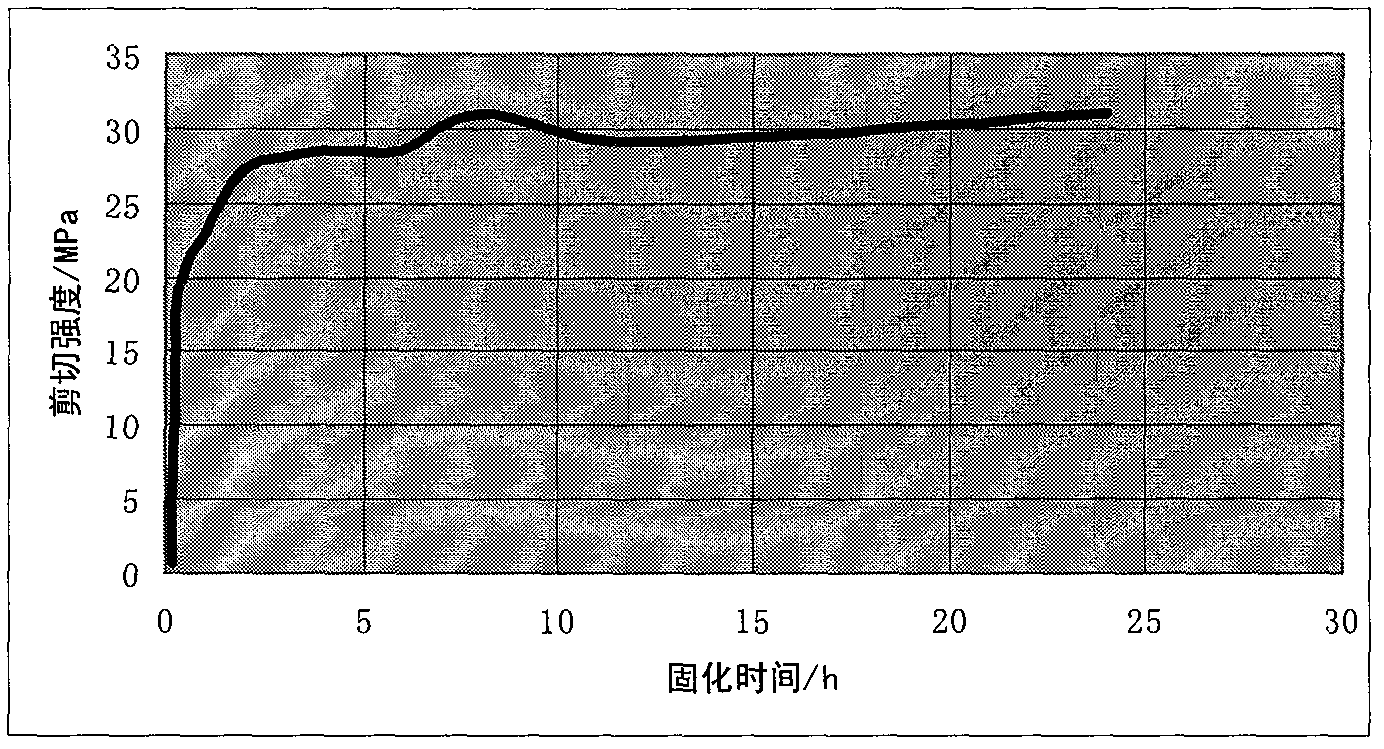

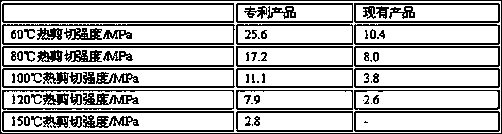

[0061] [0058] According to the examples, according to GB / T 7124-2008 Determination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com