Patents

Literature

104results about "Perchlorates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical composition and method

The invention relates to a novel composition useful as a feed at production of chlorine dioxide, said composition being an aqueous solution comprising from about 1 to about 6.5 moles / liter of alkali metal chlorate, from about 1 to about 7 moles / liter of hydrogen peroxide and at least one of a protective colloid, a radical scavenger or a phosphonic acid based complexing agent, wherein the pH of the aqueous solution is from about 1 to about 4. The invention also concerns a process for producing chlorine dioxide using the novel composition.

Owner:EKA CHEM AC LTD

Strontium peroxide catalyzed oxygen generating compositions

InactiveUS6866794B1Improved chemical oxygen generation compositionImprove performance uniformityChloratesOther chemical processesReaction rateOxygen

The oxygen generating compositions are formed from a metal powder as a fuel, strontium peroxide as a chlorine suppressant, a catalyst, a reaction rate modifier, and an oxygen source selected from the group consisting of alkali metal chlorates, alkali metal perchlorates, and mixtures thereof. The oxygen generating compositions can optionally also further comprise a transition metal oxide catalyst, and can optionally further include a binder as a pressing aid for forming an oxygen generating oxygen generating block or core. The oxygen generating compositions can be formed from zero to about 15% by weight of metal powder as a fuel, about 0.1%-20% by weight strontium peroxide, from zero to about 15% by weight of a transition metal oxide catalyst, from zero to about 5% of an optional binder, and the remainder of an oxygen source selected from the group consisting of alkali metal chlorates, alkali metal perchlorates, and mixtures thereof.

Owner:BE INTPROP

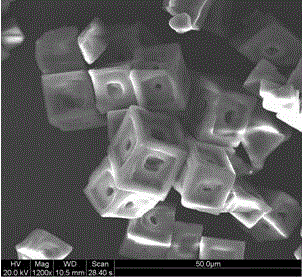

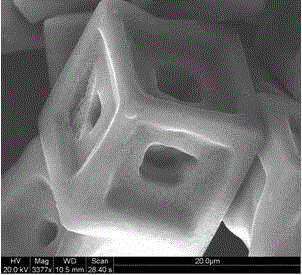

Hollow ultrafine ammonium perchlorate and preparation method thereof

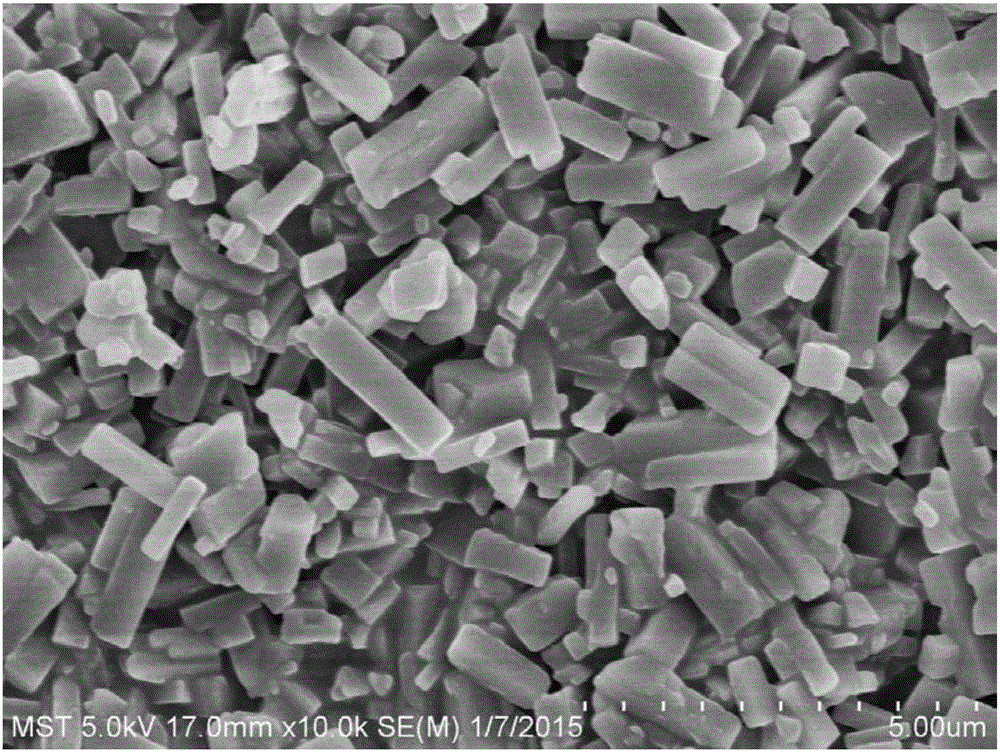

The invention relates to a hollow ultrafine ammonium perchlorate and a preparation method thereof. The ammonium perchlorate is a material with a multilayer cavity structure in the middle part and has the particle size of 1-100mu m. The preparation method adopts a desolvation-recrystallization method, and comprises the following steps of: (1) dissolving the ammonium perchlorate into an N,N-dimethyl formamide / acetone mixed solvent to prepare a saturated solution; (2) under the conditions of certain stirring speed and solvent-anti solvent volume ratio, adding the ammonium perchlorate saturated solution into anti solvent ethyl acetate, and separating out the ammonium perchlorate by crystallization when supersaturation; and (3) after crystallization, filtering, washing and drying the product, thus obtaining the hollow ultrafine ammonium perchlorate. The ammonium perchlorate is an ultrafine powder material and has hollow morphology, thus being good in dispersity and ordered in structure and effectively improving the performance of a solid propellant. The desolvation-recrystallization method is simple, safe and convenient in operation.

Owner:NANJING NORMAL UNIVERSITY +1

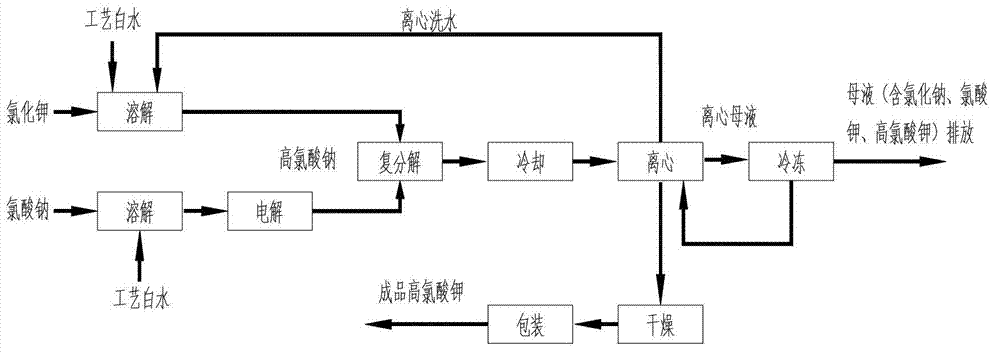

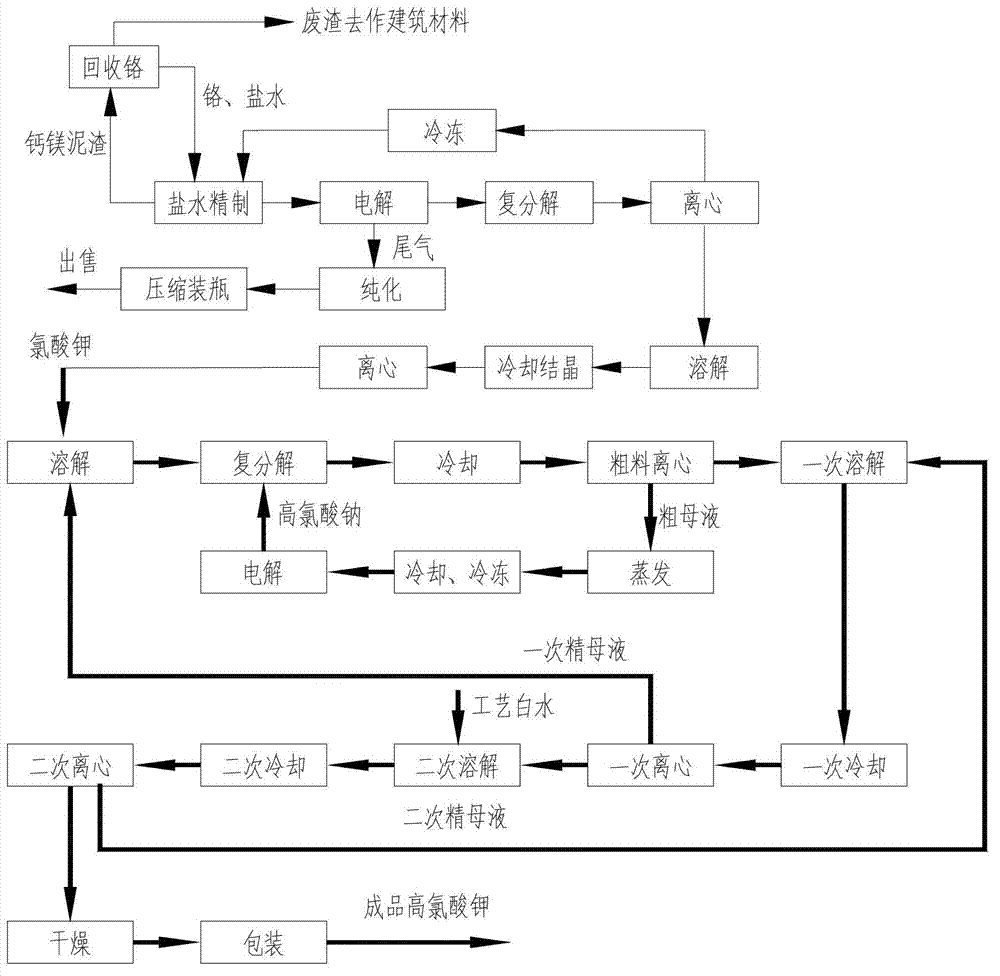

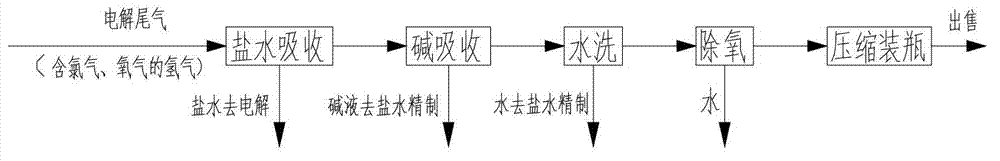

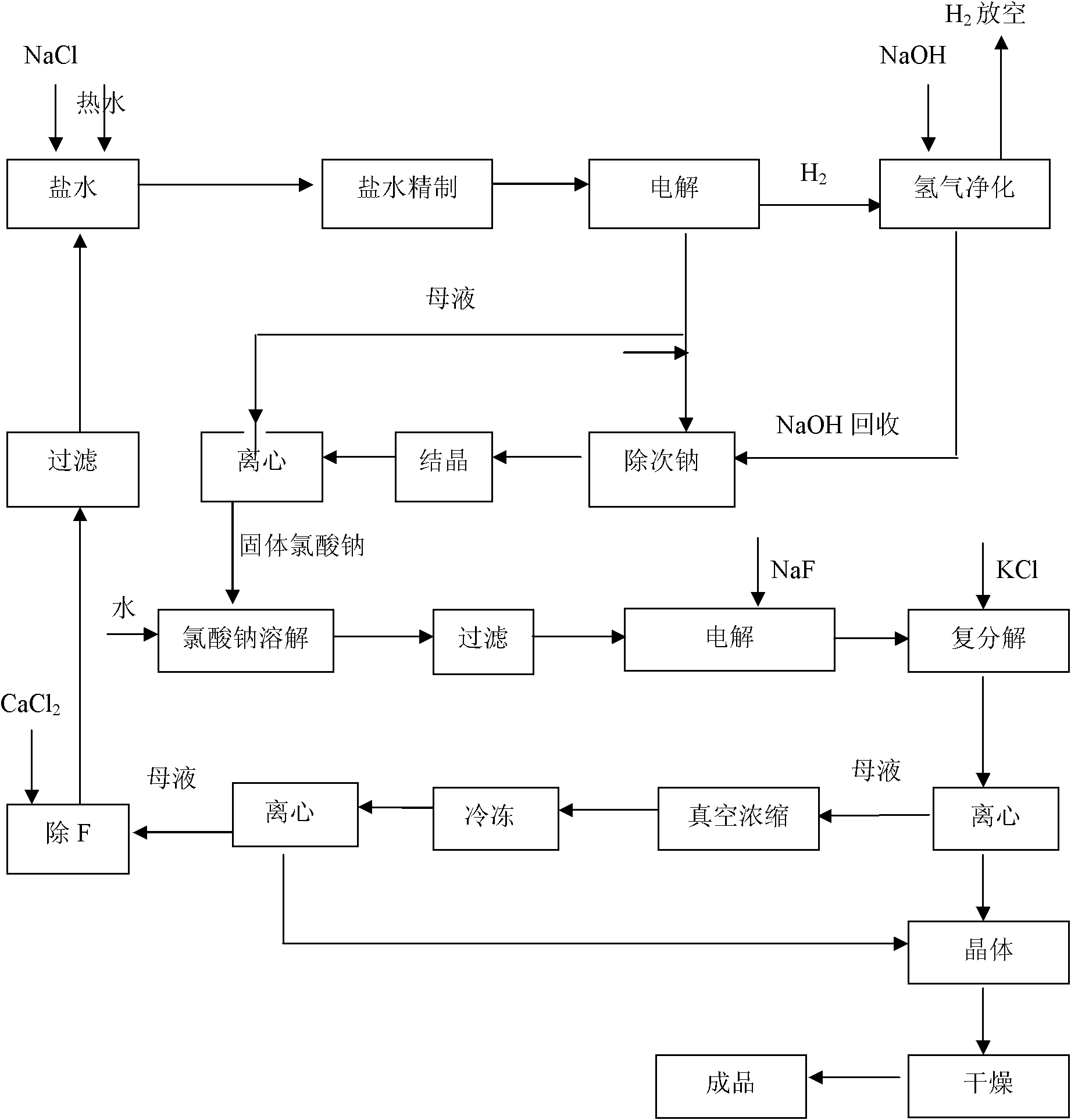

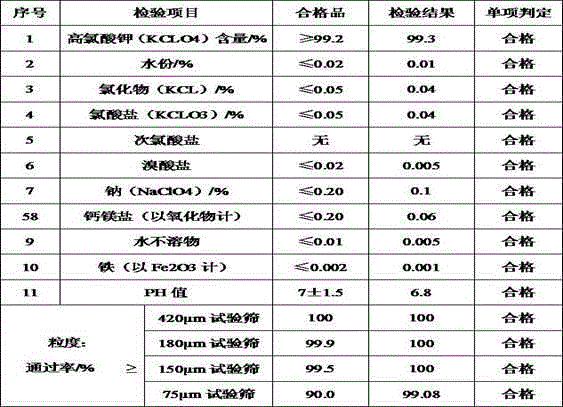

Potassium perchlorate production technology with zero wastewater discharge and products thereof

InactiveCN102807192AMeet the strategic requirements of sustainable social and economic developmentThorough responseElectrolysis componentsPerchloratesElectrolysisDecomposition

The invention relates to the technical fields of cleaner production and circulating production, in particular to a potassium perchlorate production technology with zero wastewater discharge and products of the potassium perchlorate production technology. The steps of electrolytic double decomposition are as follows: (1) electrolyzing sodium chlorate to sodium perchlorate; (2) taking potassium chlorate as a double decomposition raw material, and performing double decomposition reaction of potassium chlorate and sodium perchlorate to generate the potassium perchlorate crude materials; and (3) recrystallizing and purifying the potassium perchlorate crude materials to obtain the products, and electrolyzing and recycling double decomposition mother solution sodium chlorate. The invention has the following advantages that: the water in the production process can be recycled, the production wastewater is not discharged, the chromium-containing waste residues in the production are recycled after being extracted simultaneously, and the rest of solid waste residues are used for other purposes, so that the strategic requirements of the sustainable development of the social economy can be met, and the production technology is suitable for popularization; and moreover, the environmental protection problem is completely solved, the product quality is improved, the product purity is high, the firing is fast, the reaction is complete, no residue is caused; and the production technology is safer and more stable, the product cost performance is higher, and the competitive power is stronger.

Owner:浏阳市化工厂有限公司

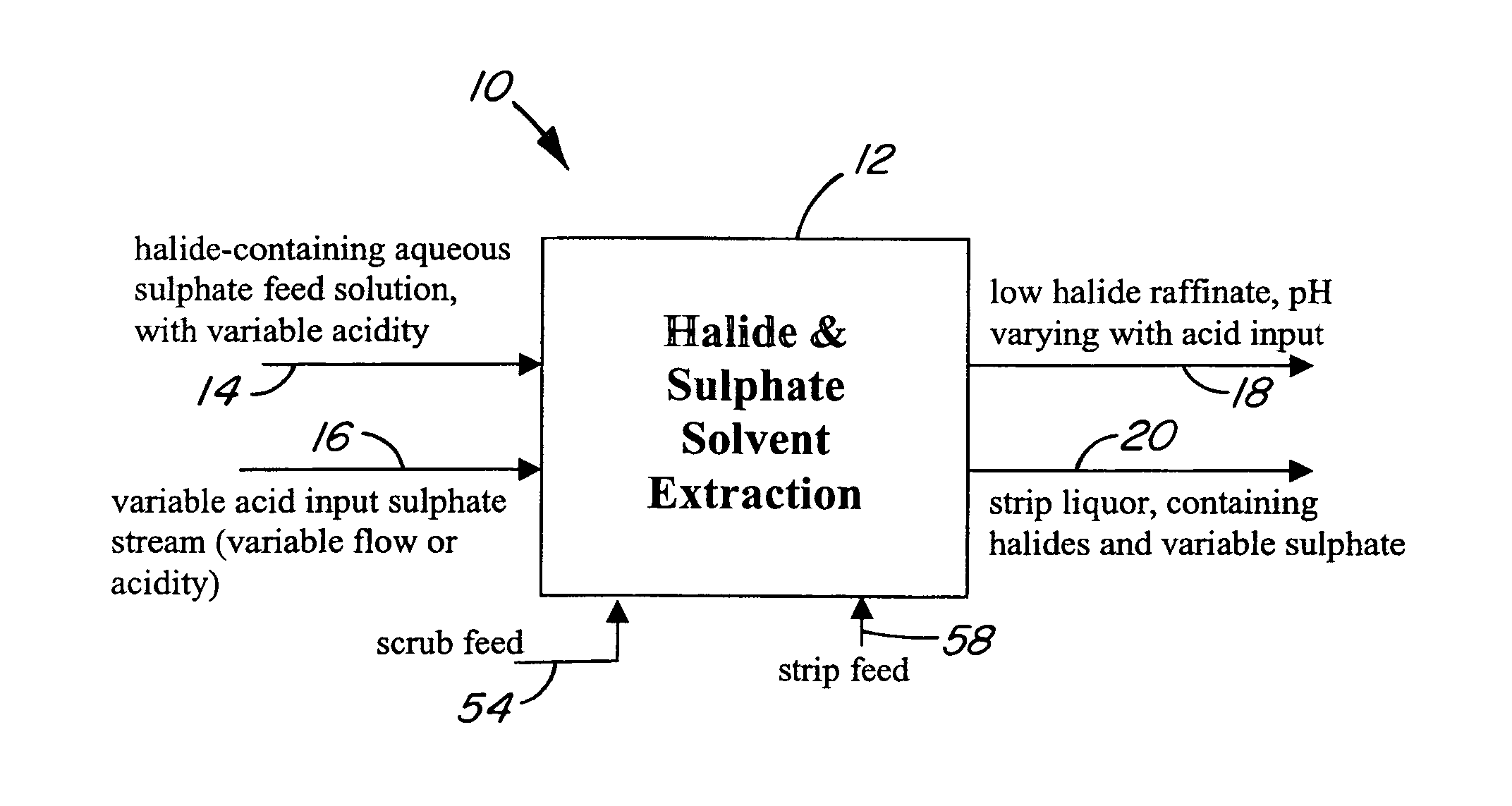

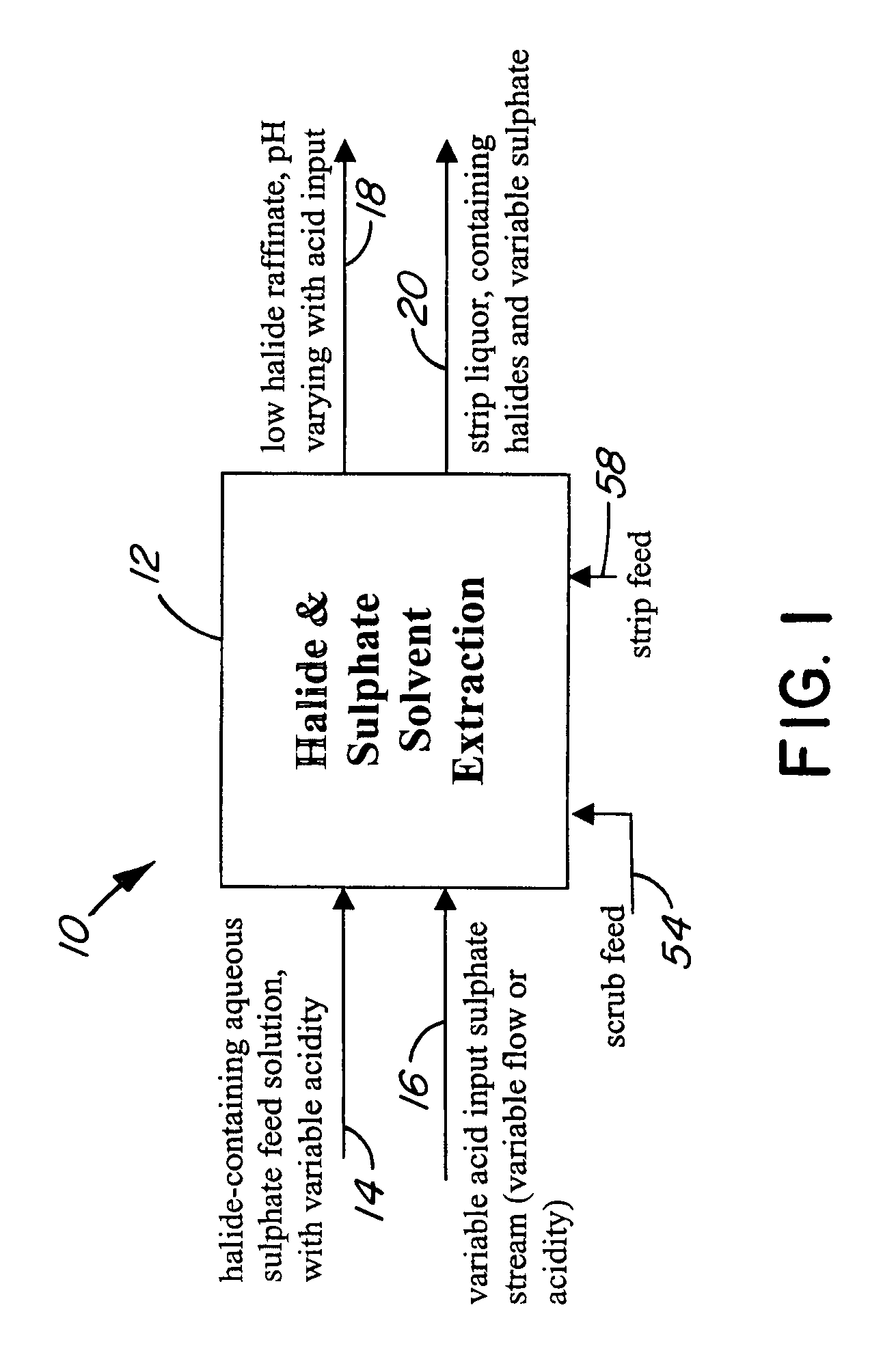

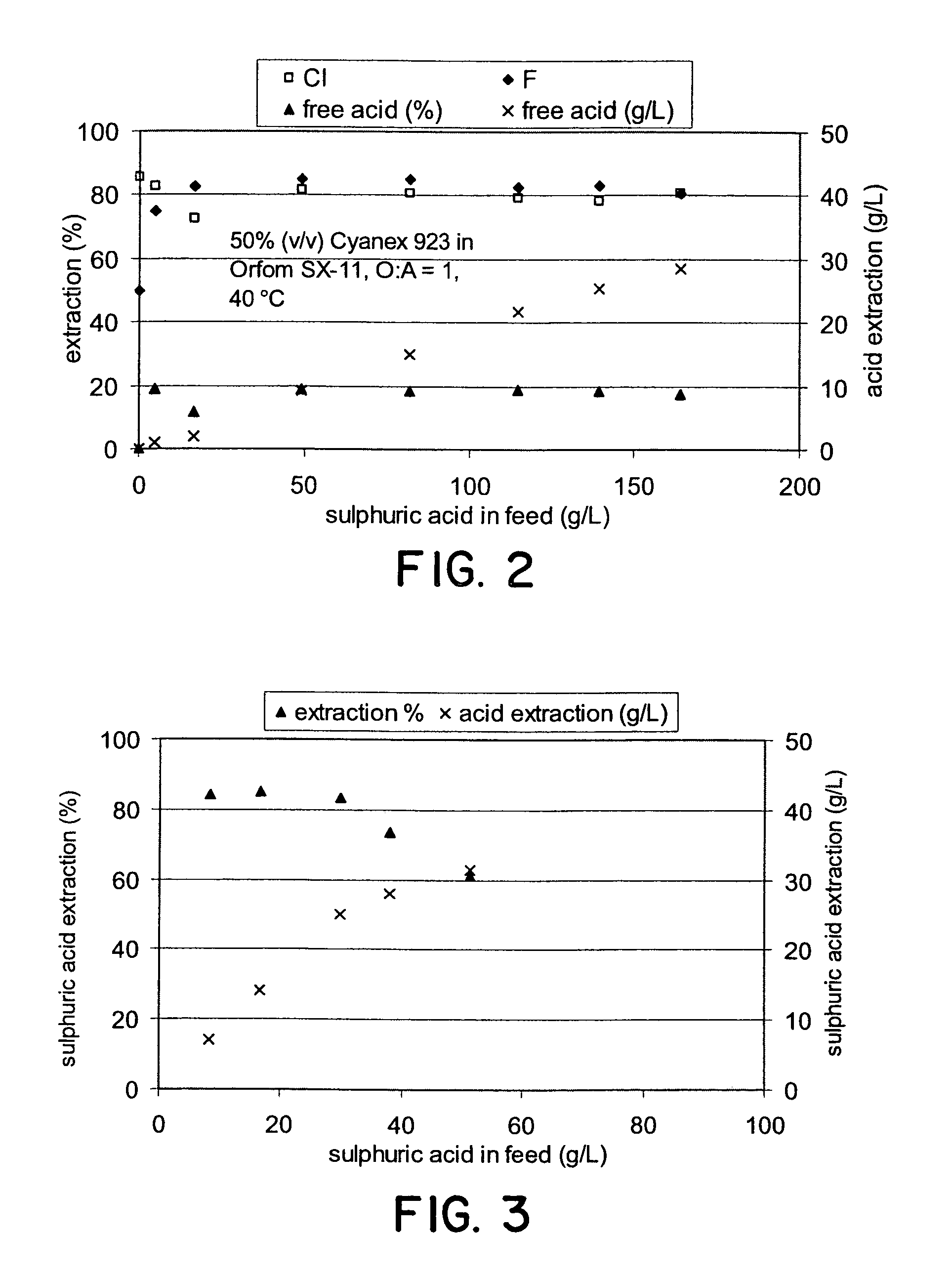

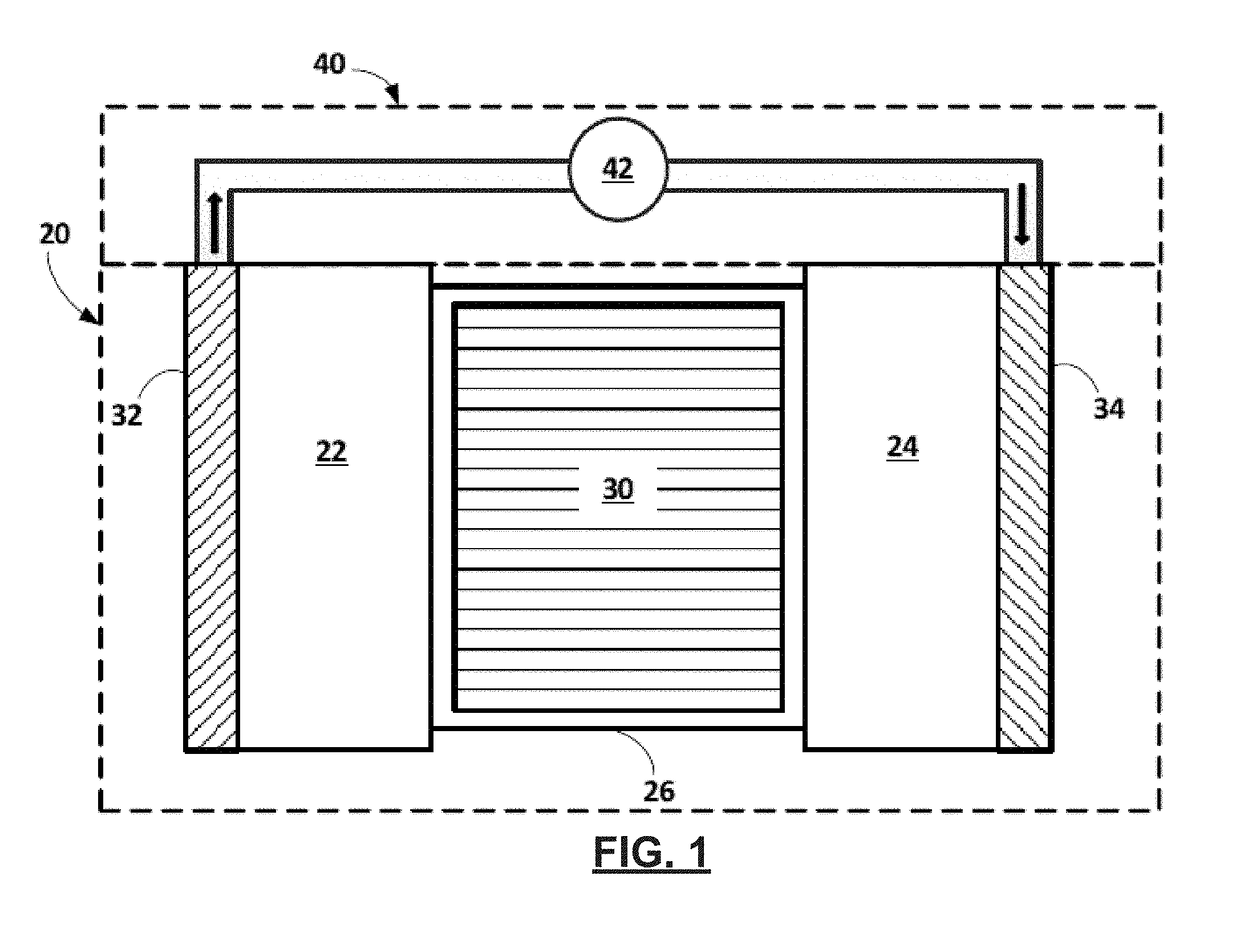

Solvent extraction of a halide from a aqueous sulphate solution

A method of extracting a halide and sulphate from an aqueous sulphate solution, such as a zinc sulphate solution, comprises subjecting the solution to solvent extraction to extract halide and sulphate from the solution and controlling the amount of sulphate extracted by selective adjustment of the acidity of the aqueous solution.

Owner:TECK METALS

Ammonium nitrate bodies and a process for their production

InactiveUS6572833B1Reduce chanceLow usageAmmonium nitratesPerchloratesParticulatesAlkaline earth metal

A process for the production of ammonium nitrate bodies in particulate form wherein an ammonium nitrate / water liquid mixture containing at least 92% and preferably at most 97.5% by weight ammonium nitrate, optionally with a proportion of the ammonium nitrate substituted by alkali- and / or alkaline earth metal nitrate, and a small amount of poly-styrene sulphonate crystal-habit modifier is sprayed as droplets into an atmosphere in which cooling effects crystallization of the ammonium nitrate and which the crystallized particles are dried to remove moisture, wherein the liquid mixture also contains ammonium sulphate, the concentration of poly-styrene sulphonate in the liquid mixture being at least 0.01%, preferably in the range 0.02 to 0.06%, by weight, and the concentration of ammonium sulphate in the liquid mixture being greater than that of the poly-styrene suphonate and at least 0.04%, preferably in the range 0.06 to 0.15%, by weight. Ammonium nitrate bodies, preferably prills, produced by the process may contain less than 0.1% by weight water and be able to absorb not less than 6% of their weight of fuel oil while remaining a pourable particulate material.

Owner:ORICA EXPLOSIVES TECH PTY LTD

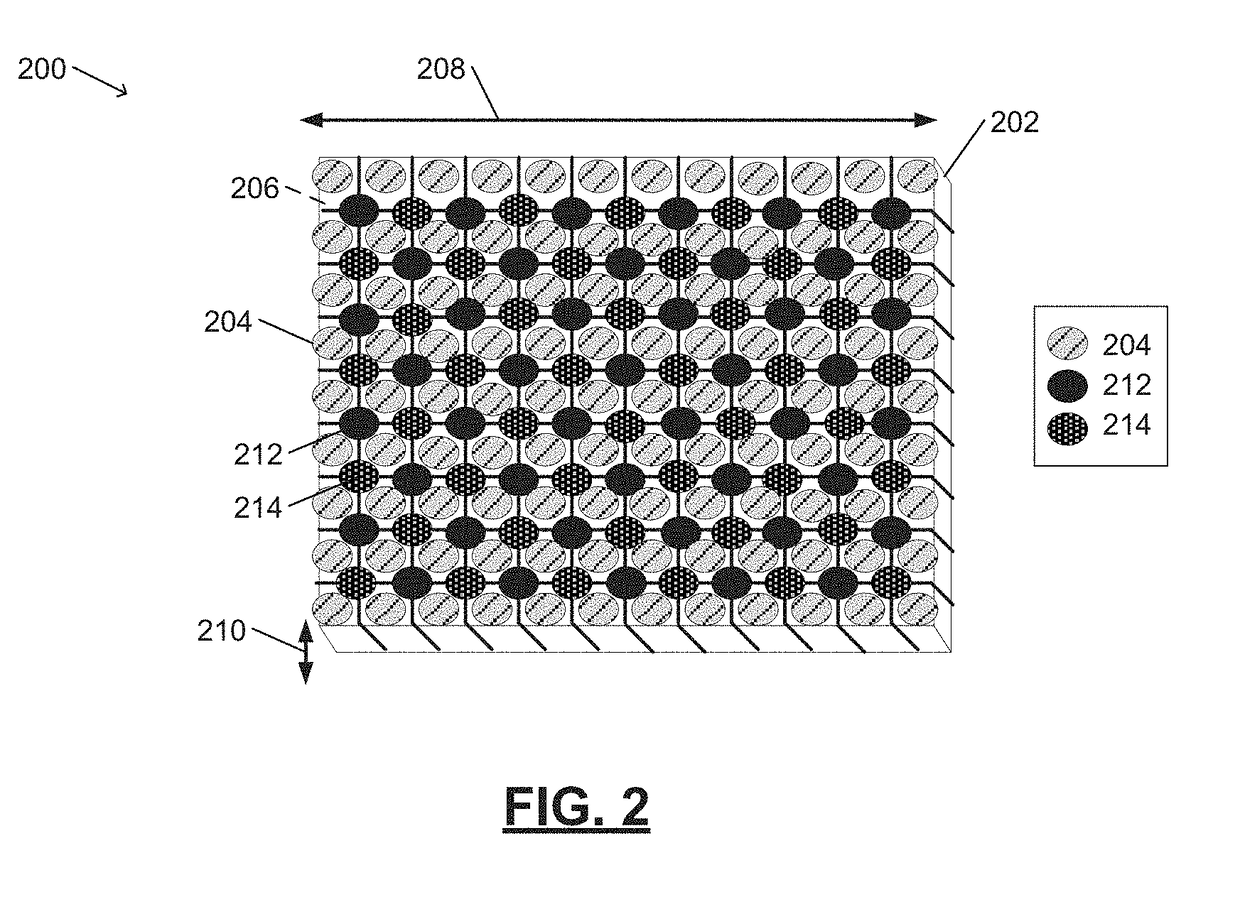

Hybrid metal-organic framework separators for electrochemical cells

ActiveUS20190089006A1High bulk densityImprove structural stabilityLithium organic compoundsCell seperators/membranes/diaphragms/spacersLithiumIndium

A hybrid separator for an electrochemical cell is provided, along with methods of making the hybrid separator. The hybrid separator includes a first metal-organic framework comprising copper and having a plurality of first pores and a second distinct metal-organic framework comprising indium or zinc and having a plurality of second pores. The hybrid separator is capable of adsorbing one or more lithium salts in at least one of the plurality of first pores or the plurality of second pores so as to be ionically conductive. The hybrid separator may have a conductivity greater than or equal to about 0.1 mS / cm to less than or equal to about 1 mS / cm and is substantially free of any polymeric binder.

Owner:GM GLOBAL TECH OPERATIONS LLC

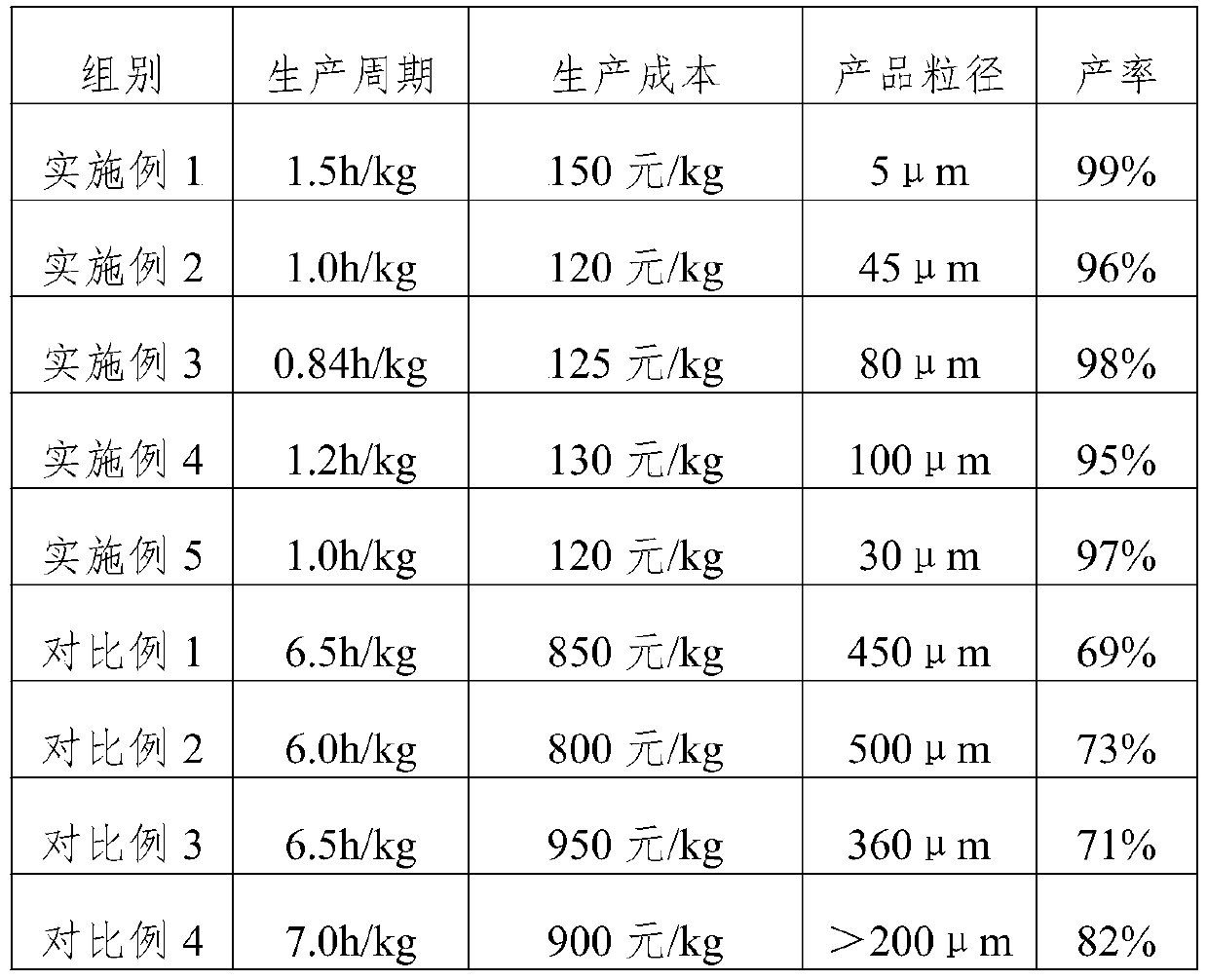

Method for preparing micro-ammonium perchlorate

ActiveCN105253857AGood dispersionRegular shapePerchloratesAmmonium perchlorate explosive compositionsCalcium perchlorateDispersity

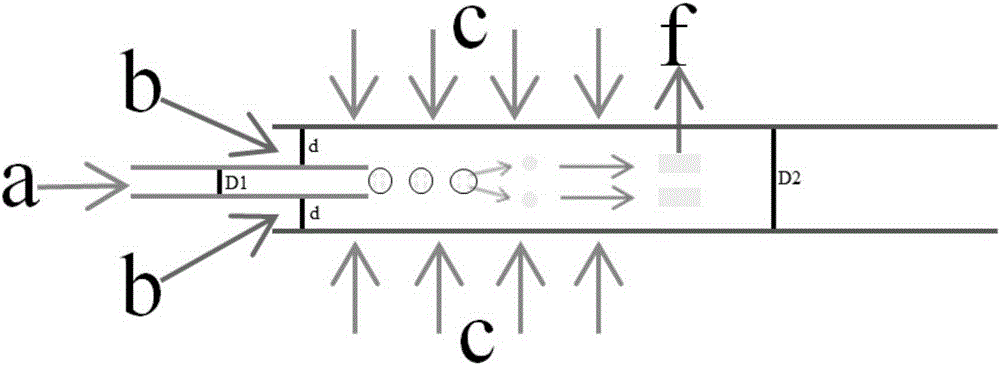

The invention relates to a method for preparing micro-ammonium perchlorate. The method comprises the specific steps that an ammonium perchlorate saturated solution containing a surface active agent is prepared; an anti-solvent is conveyed to enter an external channel of a flowing focused type micro-mixer, ultrasound is started, a saturated solution is conveyed to enter an internal channel of the flowing focused type micro-mixer to be mixed with the anti-solvent; the obtained product is filtered and dried to obtain the micro-ammonium perchlorate with the good dispersity. The inner diameter of the internal channel, the distance between the internal channel and the external channel, the standing time of total materials inside the external channel, the volume ratio of the solvent to the saturated solution to the anti-solvent, ultrasonic parameters and the like are adjusted to prepare the micro-ammonium perchlorate with the controllable average grain diameter being 0.3-2 micrometers and the regular morphology. The process of preparing the micro-ammonium perchlorate by means of the flowing focused type micro-mixer is continuous and controllable, and the method has the advantages of being simple in technology, rapid, high in yield and safety performance, free of amplification effects and the like.

Owner:NANJING UNIV OF TECH

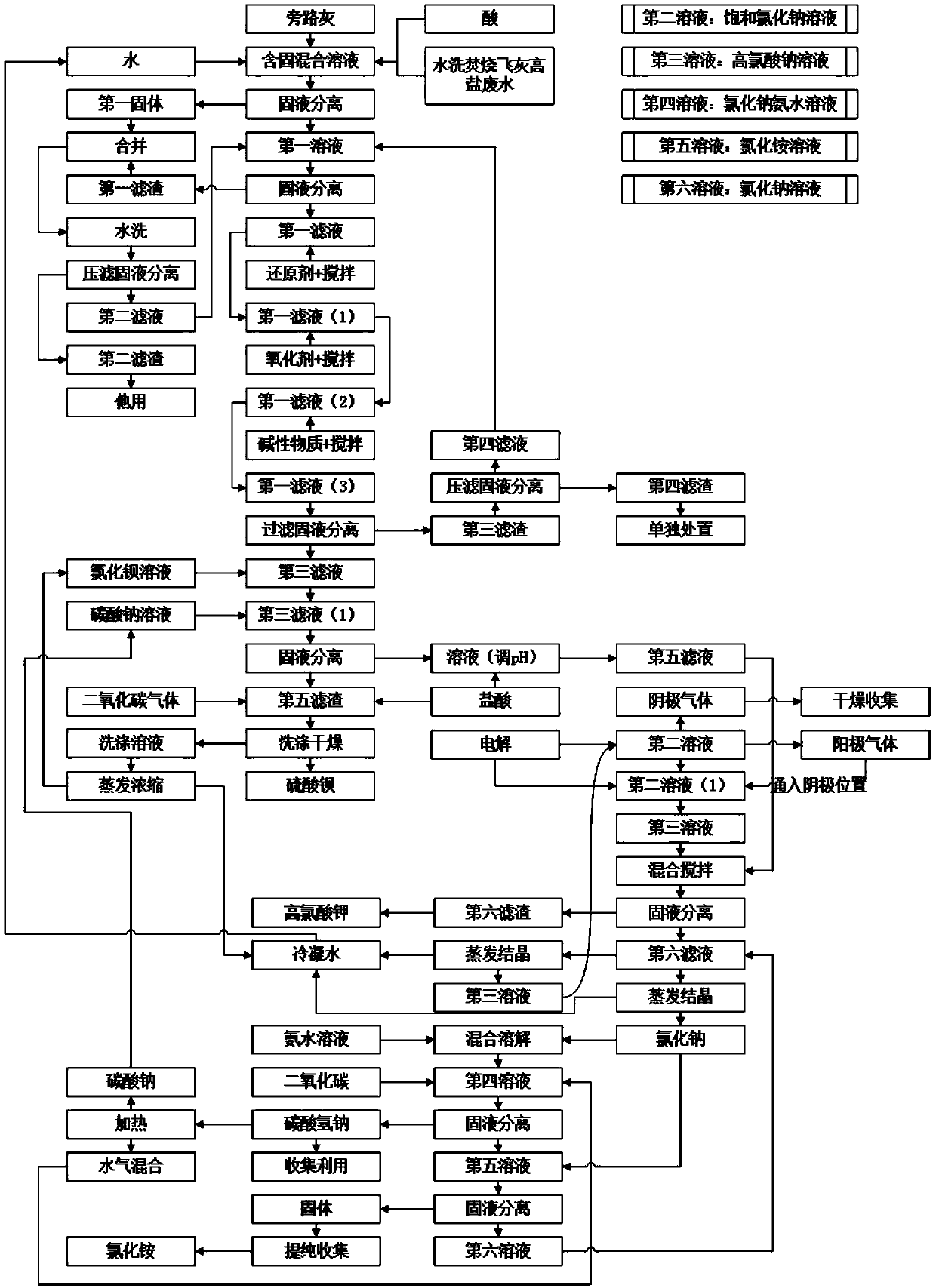

Combined resource utilization method for washing fly ash high-salinity wastewater and bypass ash

ActiveCN109665495AEfficient removalAchieve emission reductionPerchloratesCalcium/strontium/barium sulfatesResource utilizationChemical products

The invention relates to a combined resource utilization method for washing fly ash high-salinity wastewater and bypass ash. The method is capable of using fly ash washing liquid, water, and acid to dissolve and extract soluble components in incineration fly ash and the bypass ash, and through a series of treatment, acquiring multiple chemical products with higher purity. The method is convenientin raw material source, rational in process route, and capable of effectively expanding an utilization mode of the incineration fly ash and the bypass ash, realizing product diversification and improving an additional value of the product, effectively remedying a problem that only a crystalloid salt product is produced in a cement kiln co-processing fly ash process, and effectively using a carbondioxide resource.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Method for recovering ferrocene derivatives and ammonium perchlorate from composite solid propellant

The invention provides a method for recovering ferrocene derivatives and ammonium perchlorate from a composite solid propellant, which belongs to the field of fabrication of composite solid propellants. The method comprises an immersion step of immersing the composite solid propellant in dichloromethane, 1,2-dichloroethanes or N,N-dimethylacetamide, a distillation step of distilling an organic solvent so as to obtain a crude product of ferrocene derivatives, a purification step of purifying the crude product of ferrocene derivatives through recrystallization or sublimation, an extraction step of using a saturated solution of ammonium perchlorate as an extractant and a recrystallization step for obtaining ammonium perchlorate. According to the invention, the method of organic solvents is utilized in the invention for separation and recovery the active components of ammonium perchlorate and ferrocene derivatives, and a high recovery rate is achieved; implementation process of the invention is simple, and the method is easy to form a flow and has a good industrial prospect.

Owner:BEIJING UNIV OF CHEM TECH +1

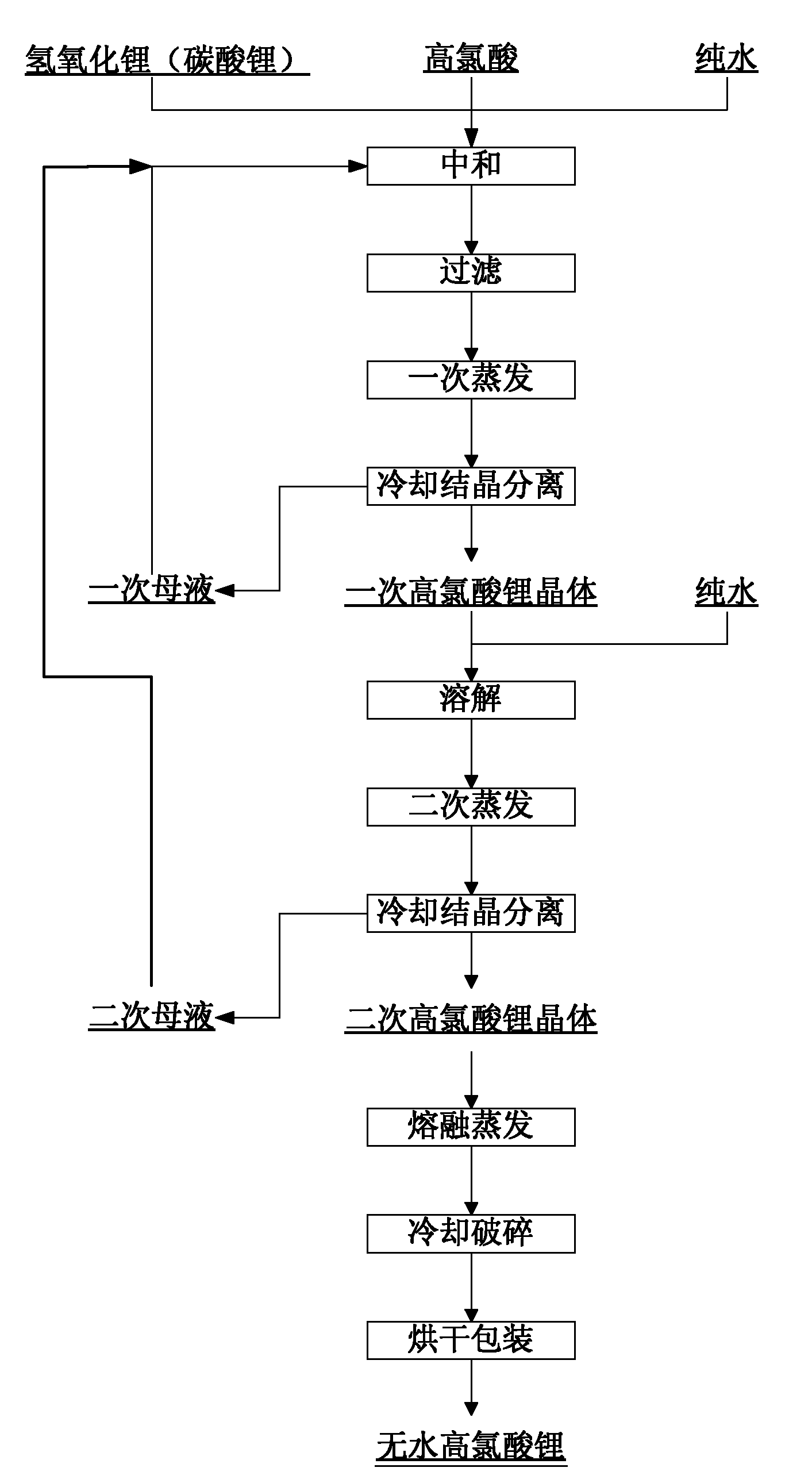

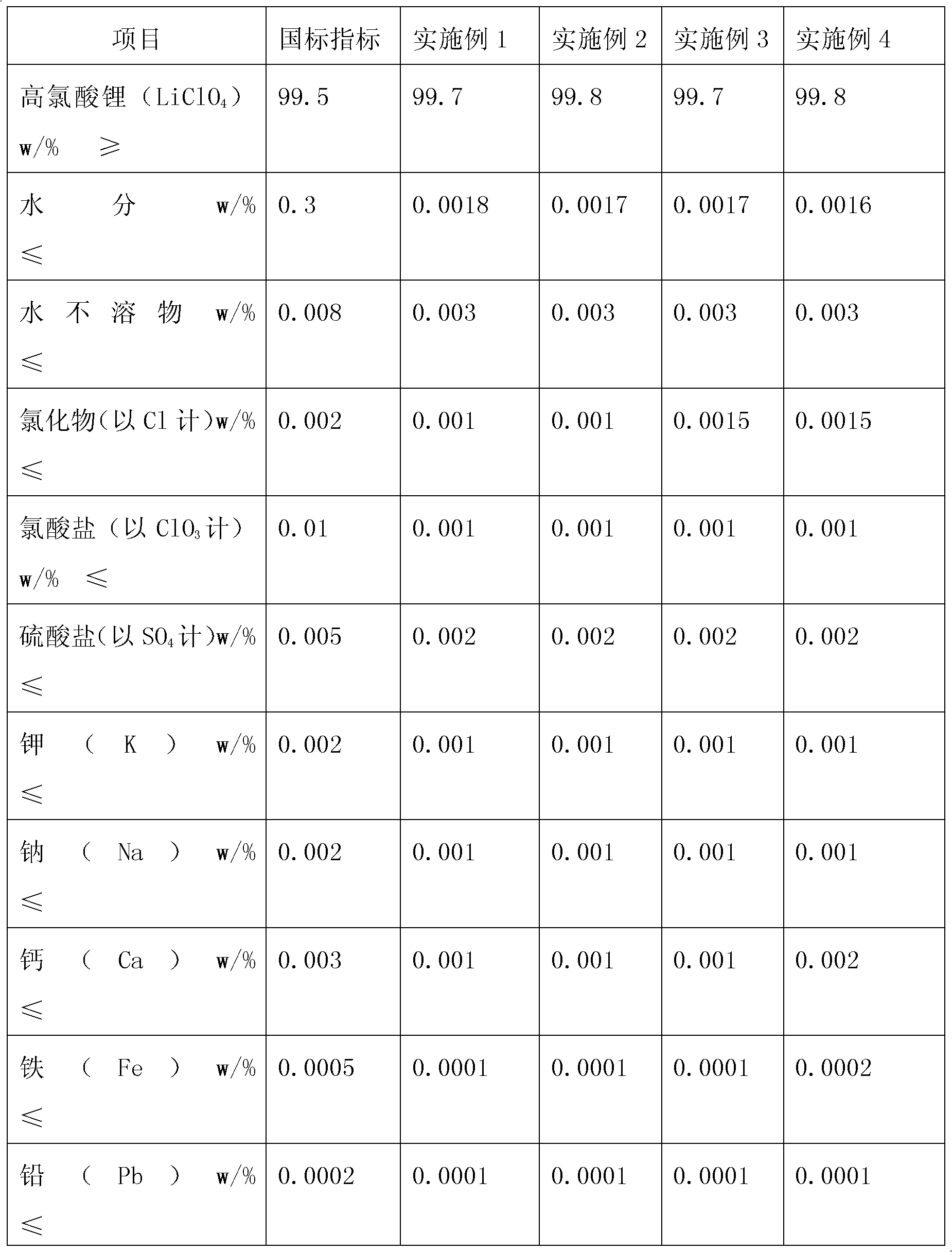

Method for producing anhydrous lithium perchlorate

The invention belongs to the technical field of electrolyte preparation of lithium battery electrolyte and discloses a method for producing anhydrous lithium perchlorate. The water content of anhydrous lithium perchlorate sold in the market is about 3,000ppm, so a factory using the anhydrous lithium perchlorate needs to remove water from the anhydrous lithium perchlorate before preparing electrolyte from the anhydrous lithium perchlorate. But the water is not completely removed and fluctuation frequently exists, the yield and the quality of the electrolyte are restricted. At the same time, with the development of lithium batteries, the requirements on the impurity content and the stability of a pH value of lithium perchlorate are higher and higher. The method, namely reaction between lithium hydroxide or lithium carbonate and perchloric acid, solves the problems. The method sequentially comprises the following steps of: neutralizing, filtering, evaporating for the first time, cooling for crystallization, performing centrifugal separation to obtain a solid, dissolving, evaporating for the second time, cooling for crystallization, performing centrifugal separation to obtain a solid,melting and evaporating, cooling and crushing, and drying and packing. The produced anhydrous lithium perchlorate has low impurity content and the water content of lower then 200ppm; the pH value of aqueous solution of the anhydrous lithium perchlorate is stable; and the anhydrous lithium perchlorate can be directly used for producing the electrolyte.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

Stabilization composition for halogen-containing polymers

The invention is a stabilizer composition for halogen-containing polymers, comprising a carrier material of the general formula CaxAl2(OH)2(x+2)HPO3.m H2O, wherein x is a number from 2 to 12 and m is a number from 0 to 12, and a salt of a halogen-containing oxy acid or a mixture of two or more such salts, at least one salt of a halogen-containing oxy acid being present in finely distributed form on the carrier material, to a process for the preparation thereof, and to the use thereof.

Owner:BAERLOCHER

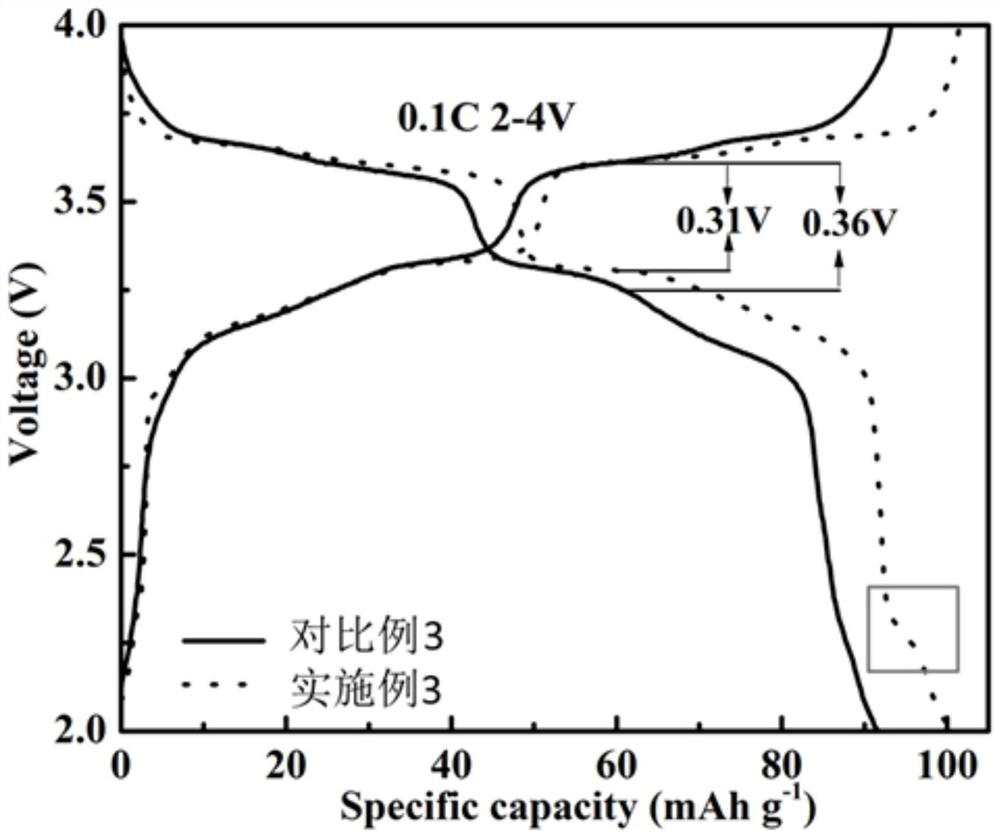

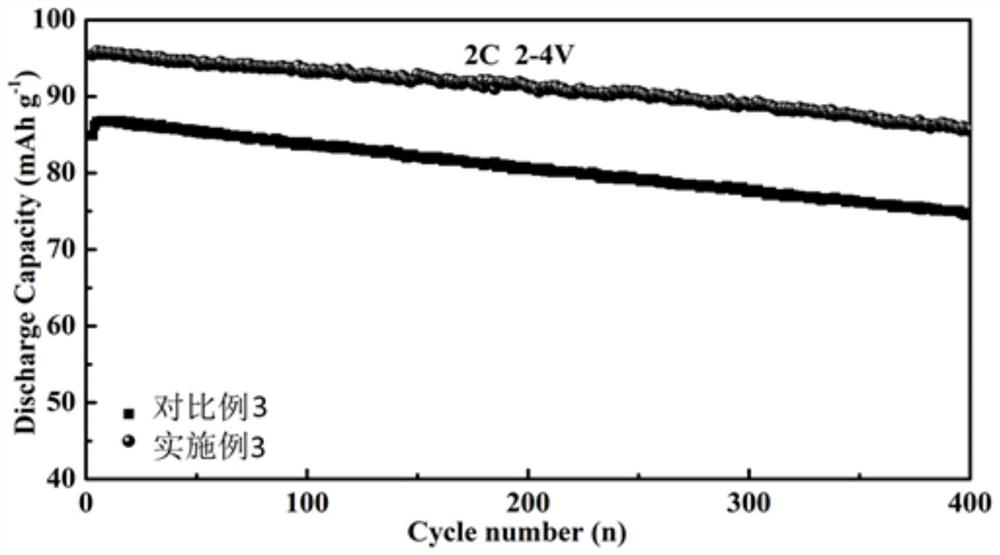

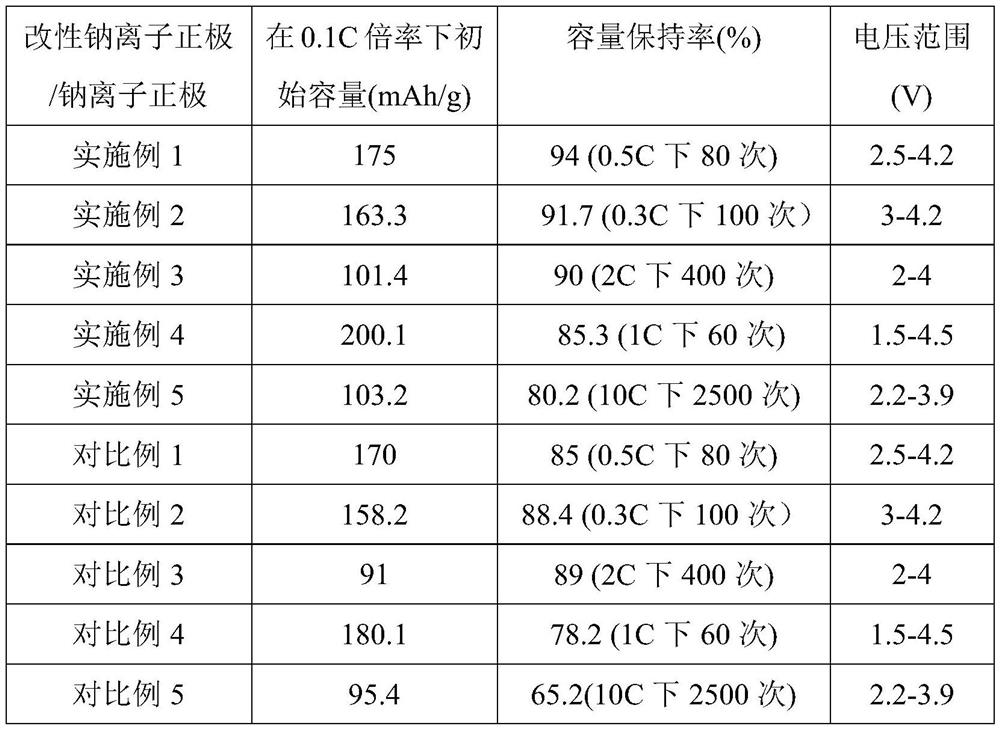

Modified sodium ion positive electrode material, modified sodium ion electrode and preparation method

InactiveCN112968165AHigh specific capacityImprove cycle stabilityPerchloratesSecondary cellsSlurryAluminum foil

The invention relates to a modified sodium ion positive electrode material, a modified sodium ion electrode and a preparation method. A sodium source, a metal element and a fluorine source are mixed and sintered to form the modified sodium ion positive electrode material, the molar ratio of the F element is 0.01-50%, the modified sodium ion positive electrode material, an adhesive and a conductive agent are prepared into slurry, the surface of an aluminum foil is coated with the slurry to prepare a sodium ion modified electrode. The beneficial effects are that the specific capacity of the modified sodium ion positive electrode material can be remarkably improved, the cycling stability of the material under high multiplying power is improved, and the high-temperature cycling performance of the prepared modified sodium ion positive electrode can also be improved; and the material is prepared only through a high-temperature calcination method, and is simple in process, low in price and suitable for industrial production.

Owner:天津中电新能源研究院有限公司

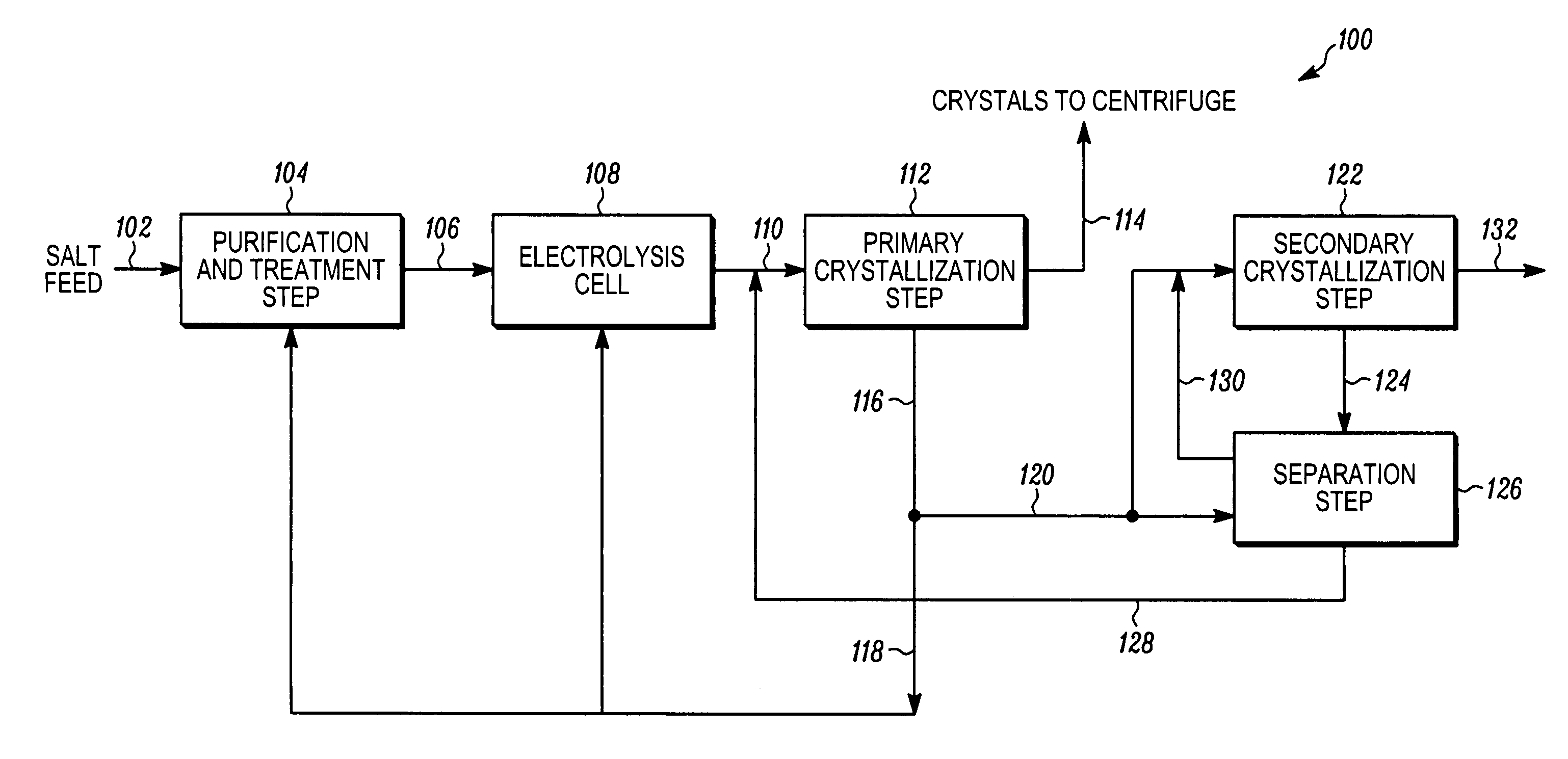

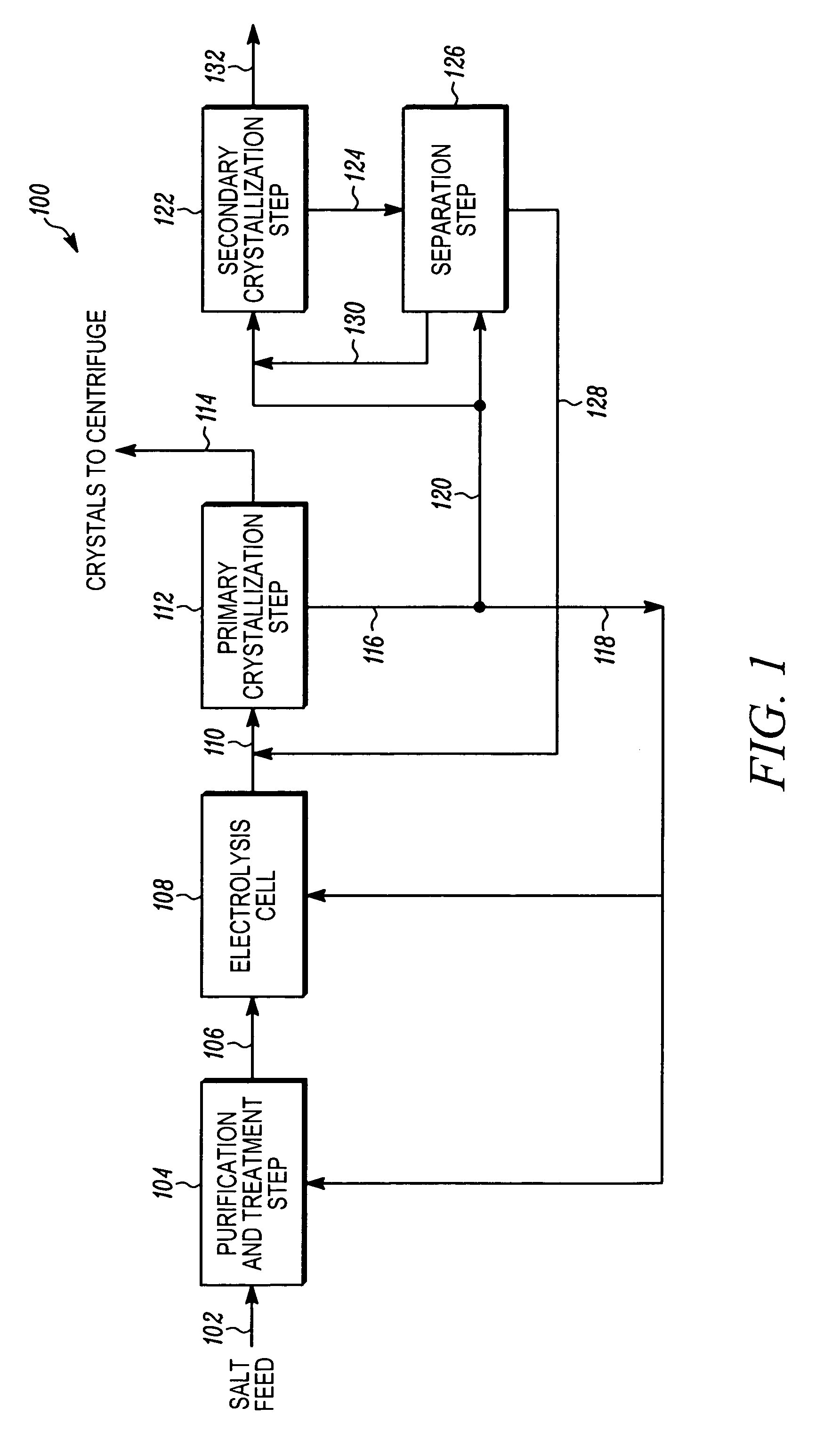

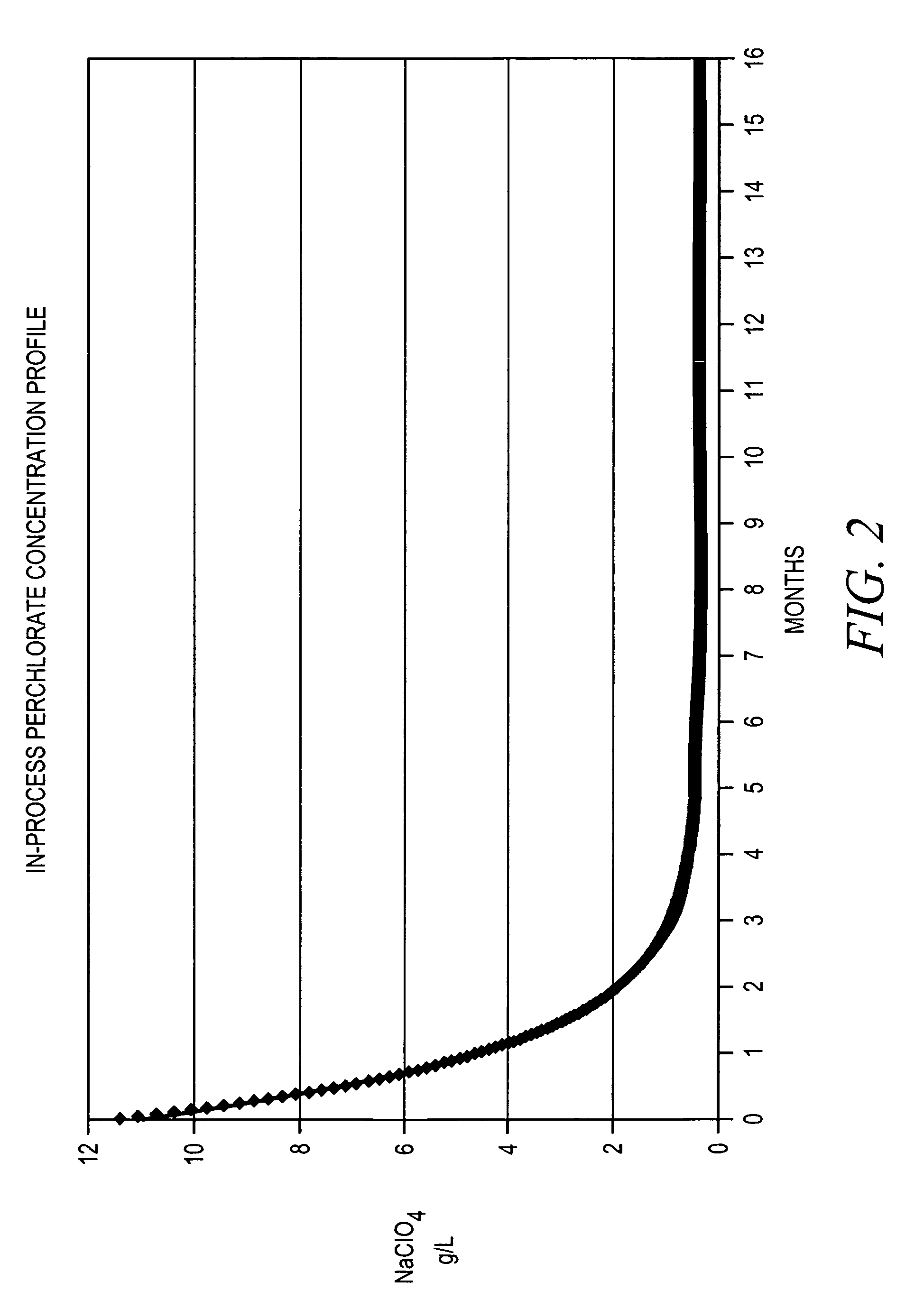

Perchlorate removal from sodium chlorate process

InactiveUS7250144B2Extended operating timeHigh material utilizationPolycrystalline material growthFrom normal temperature solutionsSodium chlorateAmmonium perchlorate

Novel methods for the removal of sodium perchlorate from electrolytic processes for the production of sodium chlorate have been discovered, allowing sodium chlorate production processes to proceed with low levels of sodium perchlorate. A portion of the mother liquor from the sodium chlorate crystallization is fed to a secondary crystallization step to concentrate sodium perchlorate in a second mother liquor. In this manner, at least a portion of the sodium perchlorate in the sodium chlorate production process is isolated in the second mother liquor, which can be removed from the sodium chlorate production process. The process is run until the concentration of sodium perchlorate in the second mother liquor reaches a desired concentration, at which point at least a portion of the second mother liquor can be removed, thereby removing a portion of the sodium perchlorate from the sodium chlorate production process. The removal of sodium perchlorate from the electrolytic production process allows extended process operating time, improved raw material utilization, and improved reaction efficiency.

Owner:EMD ACQUISITION LLC +1

Novel zinc-containing calcium-aluminium double salts

Neutral calcium-aluminum double salts of the formula (A):Ca2m(Zn2n)Al2(OH)6+2(2m+2n−1)An.oH2O (A),where the following apply for m and n:m=0.5 to 3 and 0.5m≧n>0; An=CO3, where this may be replaced completely or partially by at least one of the following groups selected from OH, ClO4 and H3CS(═O)2O (triflate) and o=0 to 3. The present invention further relates to their preparation, use in compositions and stabilizer systems and uses thereof.

Owner:NABALTEC AG

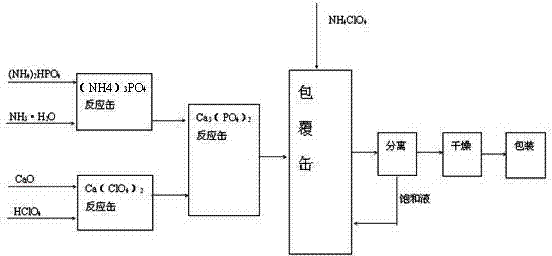

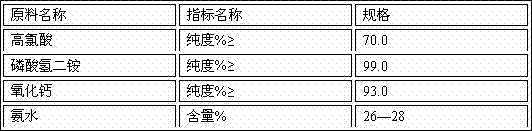

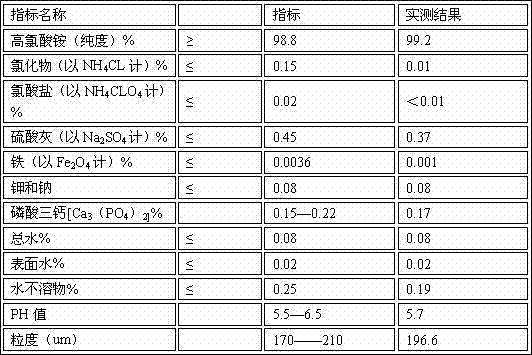

New nanoscale ammonium perchlorate cladding technology

ActiveCN103708423ABlocking bondFor long-term storagePerchloratesCalcium biphosphateAmmonium perchlorate

The invention relates to a new nanoscale ammonium perchlorate cladding technology. The technology is characterized in that, in a cladding anti-caking process of ammonium perchlorate, a superfine calcium phosphate cladding anti-caking agent is prepared, and a wet process cladding anti-caking technology is employed to make the ammonium perchlorate adsorb the cladding anti-caking agent uniformly. The technological process includes: preparing a cladding anti-caking solution according to the adding proportion of the cladding anti-caking agent, placing the cladding anti-caking solution in a cladding crockeryware, and starting stirring; and then adding ammonium perchlorate, conducting stirring for half an hour, performing centrifugal separation, and subjecting the product to drying and packaging immediately. According to the invention, the cladding anti-caking agent has particle fineness reaching the nanoscale, effectively blocks caking among particles, is convenient for long-term storage, and is superior to organic cladding anti-caking agents. And by adopting the wet process anti-caking technology, the cladding sphericity is high.

Owner:DALIAN GAOJIA CHEM

Potassium perchlorate production method and recycling method of sodium chloride mother liquid

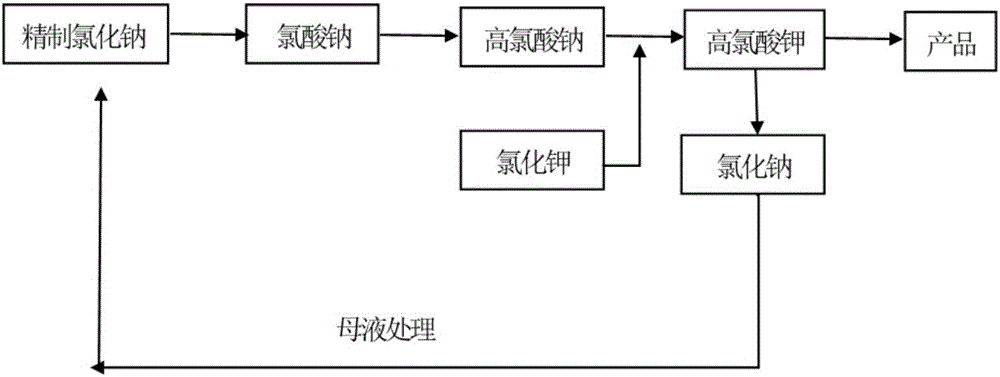

ActiveCN106744694APotassium content decreasedAvoid short circuitElectrolysis componentsPerchloratesPotassium ionsPotassium perchlorate

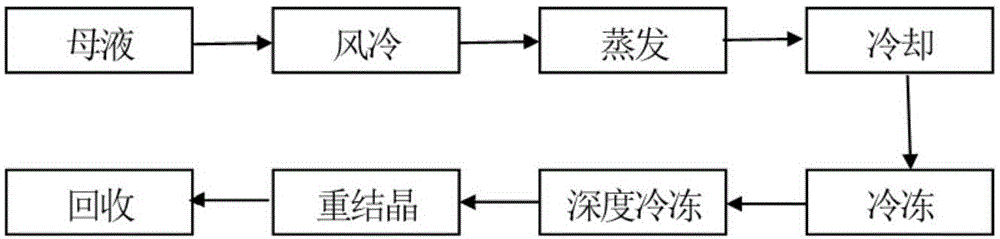

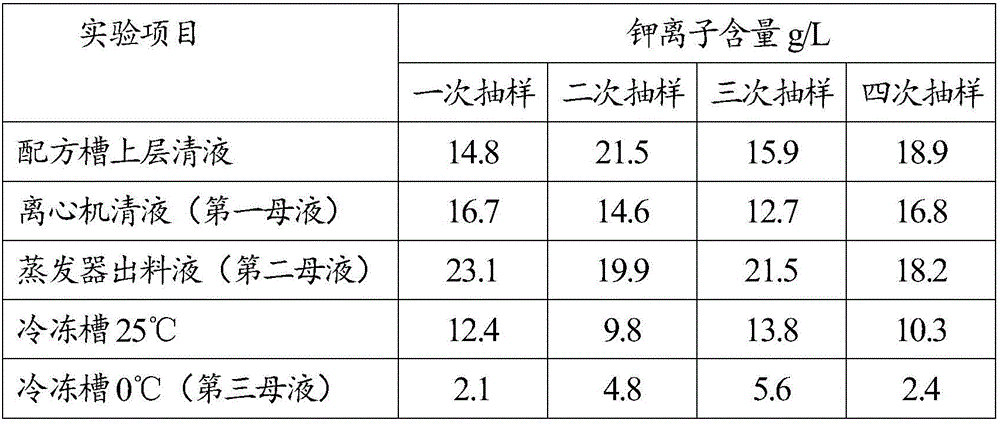

The invention discloses a recycling method of sodium chloride mother liquid in a potassium perchlorate production process. The method comprises the following steps: cooling a mixture of potassium perchlorate and sodium chloride to 40 DEG C; performing air cooling of the mixture; performing centrifugal separation of the mixture after the air cooling to obtain a potassium perchlorate product and a first mother liquid; evaporating the first mother liquid to obtain a second mother liquid; performing primary cooling, secondary cooling and centrifugal separation of the second mother liquid respectively to obtain a third mother liquid; and performing deep freezing and centrifugal separation of the third mother liquid to obtain a potassium perchlorate crystal and a fourth mother liquid. In the method, the content of potassium ions in the sodium chloride mother liquid can be reduced to be or below 4 g / L, and the resources are fully utilized to avoid waste and pollution.

Owner:浏阳市化工厂有限公司

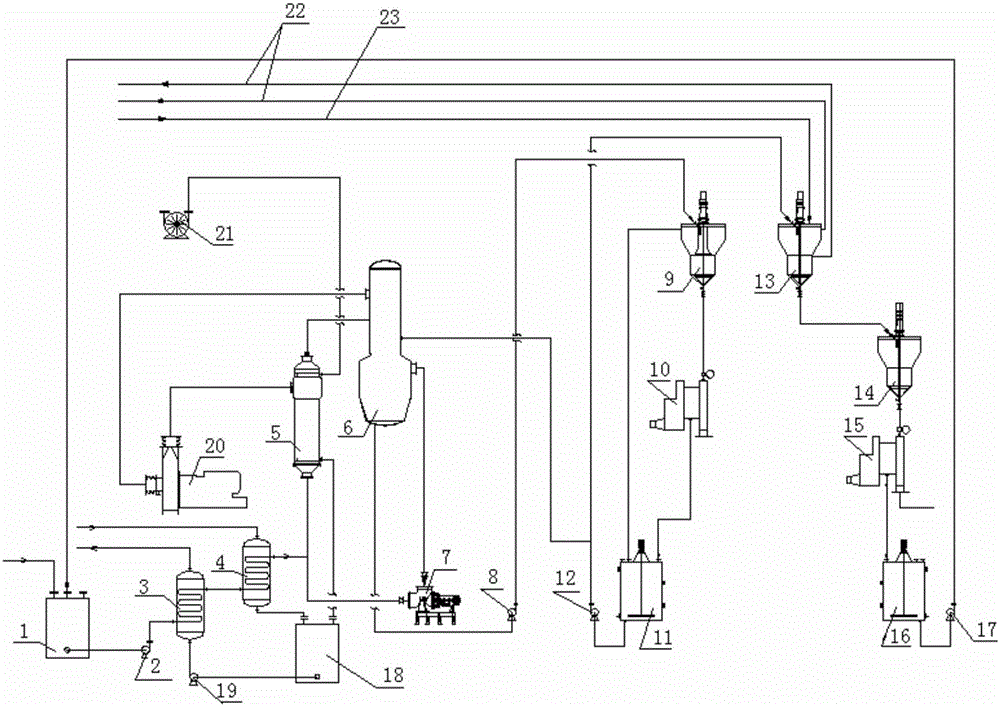

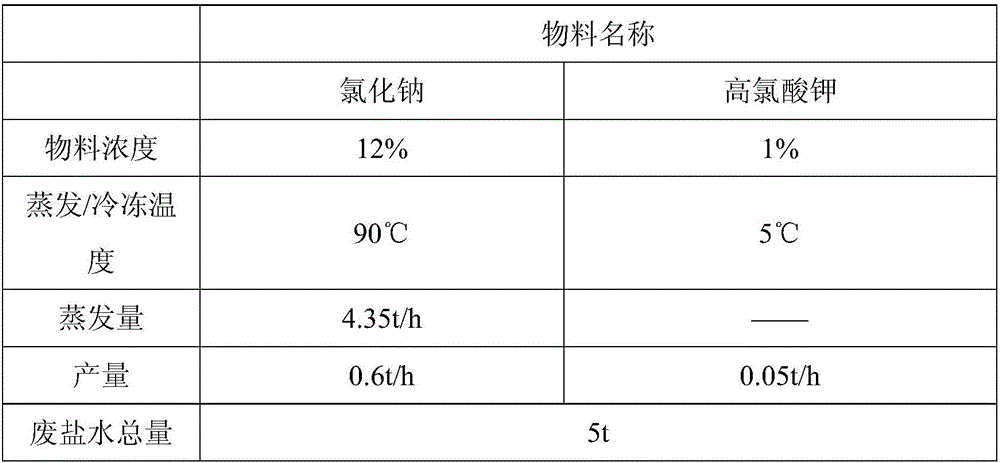

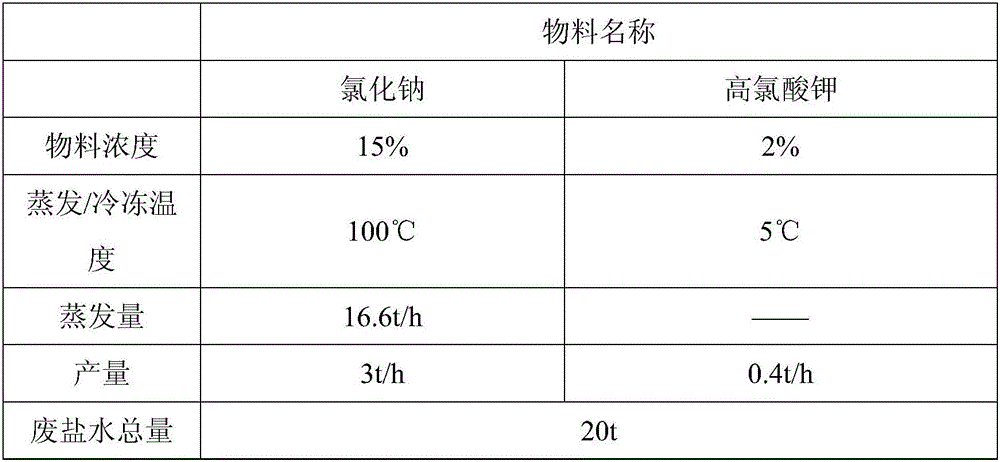

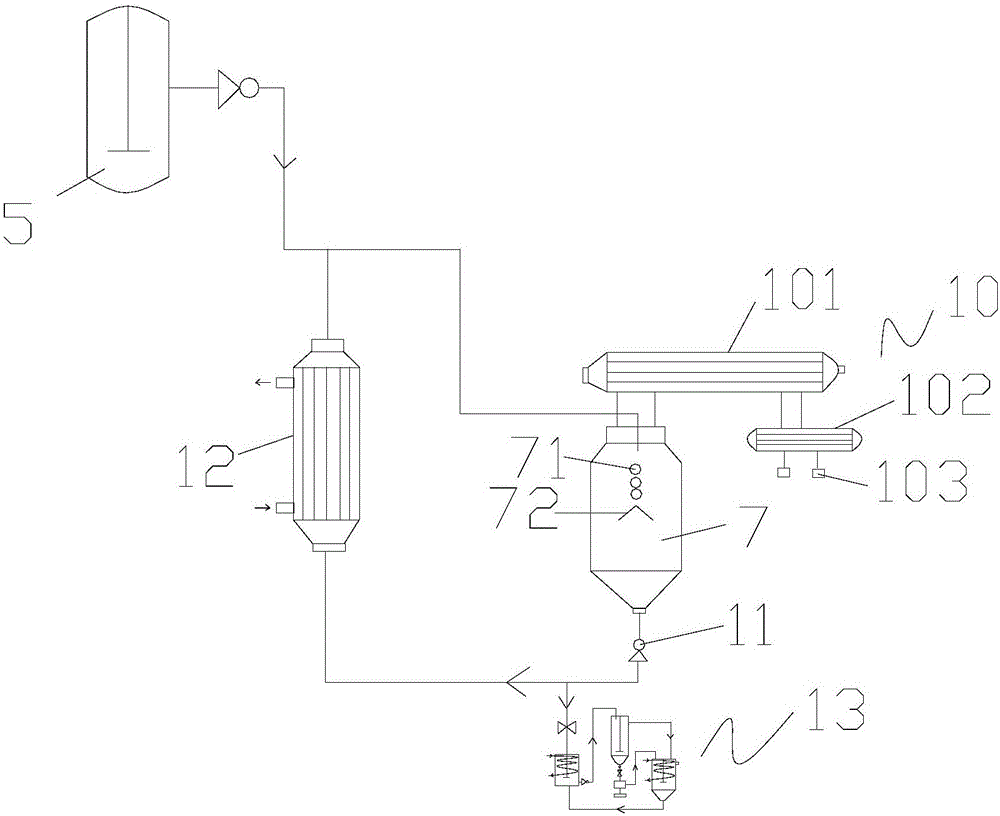

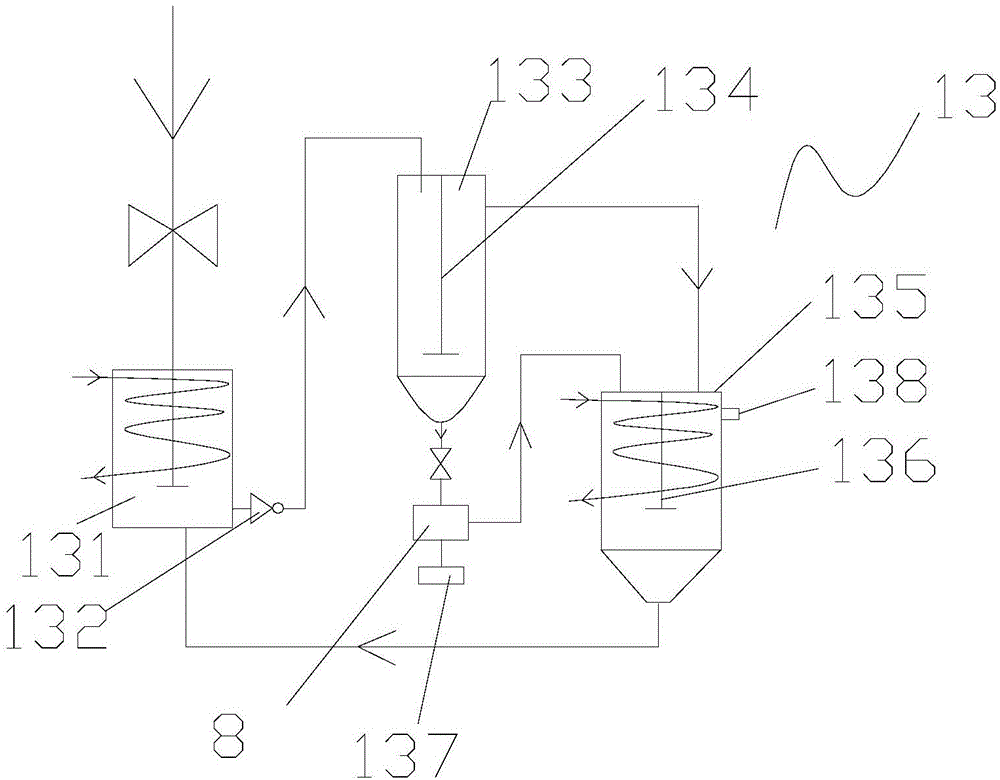

Potassium perchlorate effluent brine treatment apparatus, and technology for recovering potassium perchlorate and sodium chloride from potassium perchlorate effluent brine

ActiveCN106007135AHigh thermal efficiencySave energyWater/sewage treatment by centrifugal separationPerchloratesSolubilityNuclear chemistry

The invention discloses a potassium perchlorate effluent brine treatment apparatus and a technology for recovering potassium perchlorate and sodium chloride from potassium perchlorate effluent brine. The apparatus comprises an evaporative concentration and crystallization system and a freezing crystallization system. The potassium perchlorate effluent brine treatment apparatus fully utilizes the difference of the solubility and the concentration of sodium chloride and potassium perchlorate in the potassium perchlorate effluent brine, sodium chloride first precipitates through evaporative concentration at a high temperature, potassium perchlorate then precipitates through cooling crystallization at a low temperature, potassium perchlorate precipitates through further freezing, and a mother liquid is recycled, so effective separation and recovery of sodium chloride and potassium perchlorate in the potassium perchlorate effluent brine are realized, no waste liquids or waste residues are generated, and comprehensive utilization of the potassium perchlorate effluent brine is truly realized.

Owner:湖南傲创科技有限公司

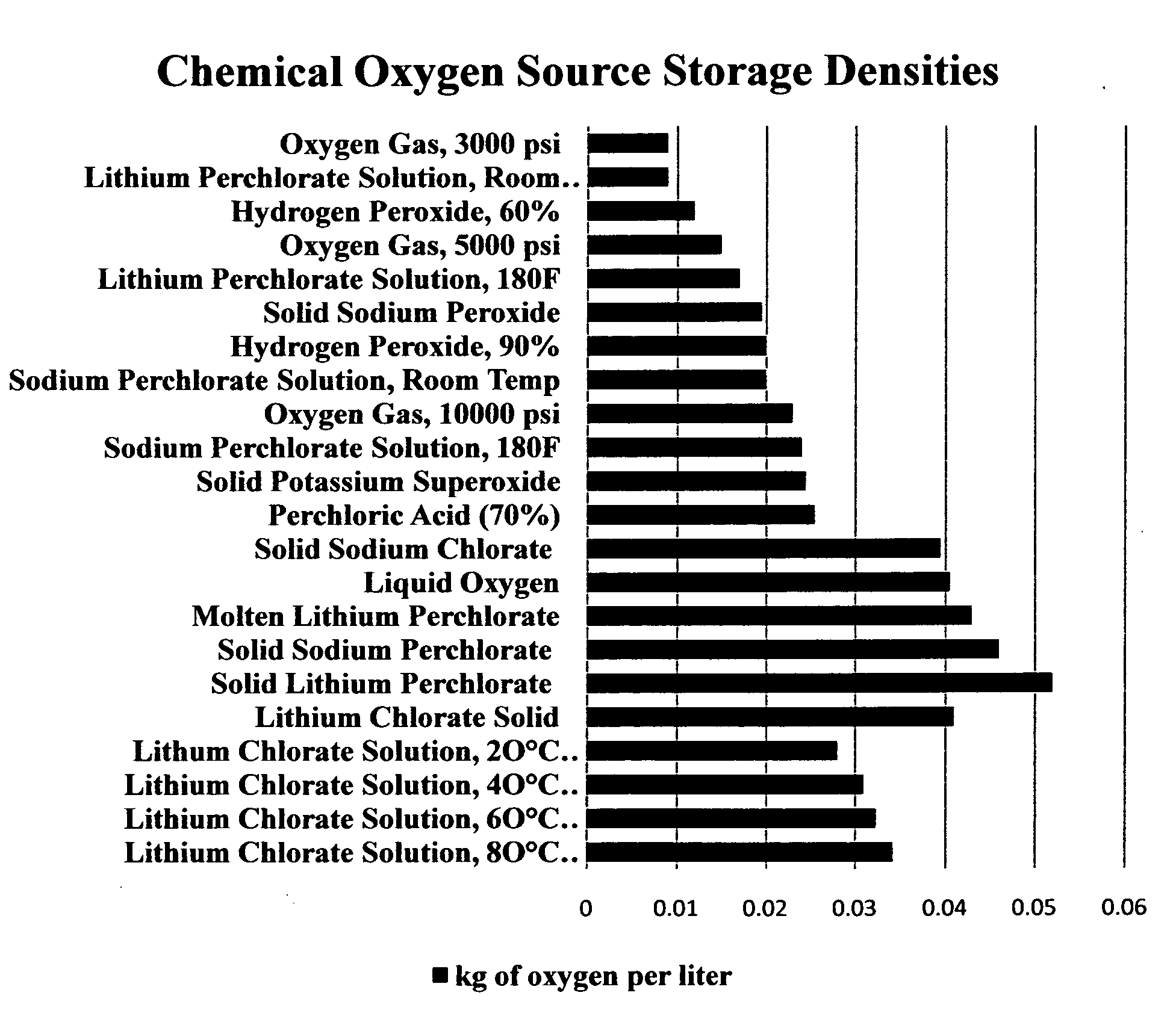

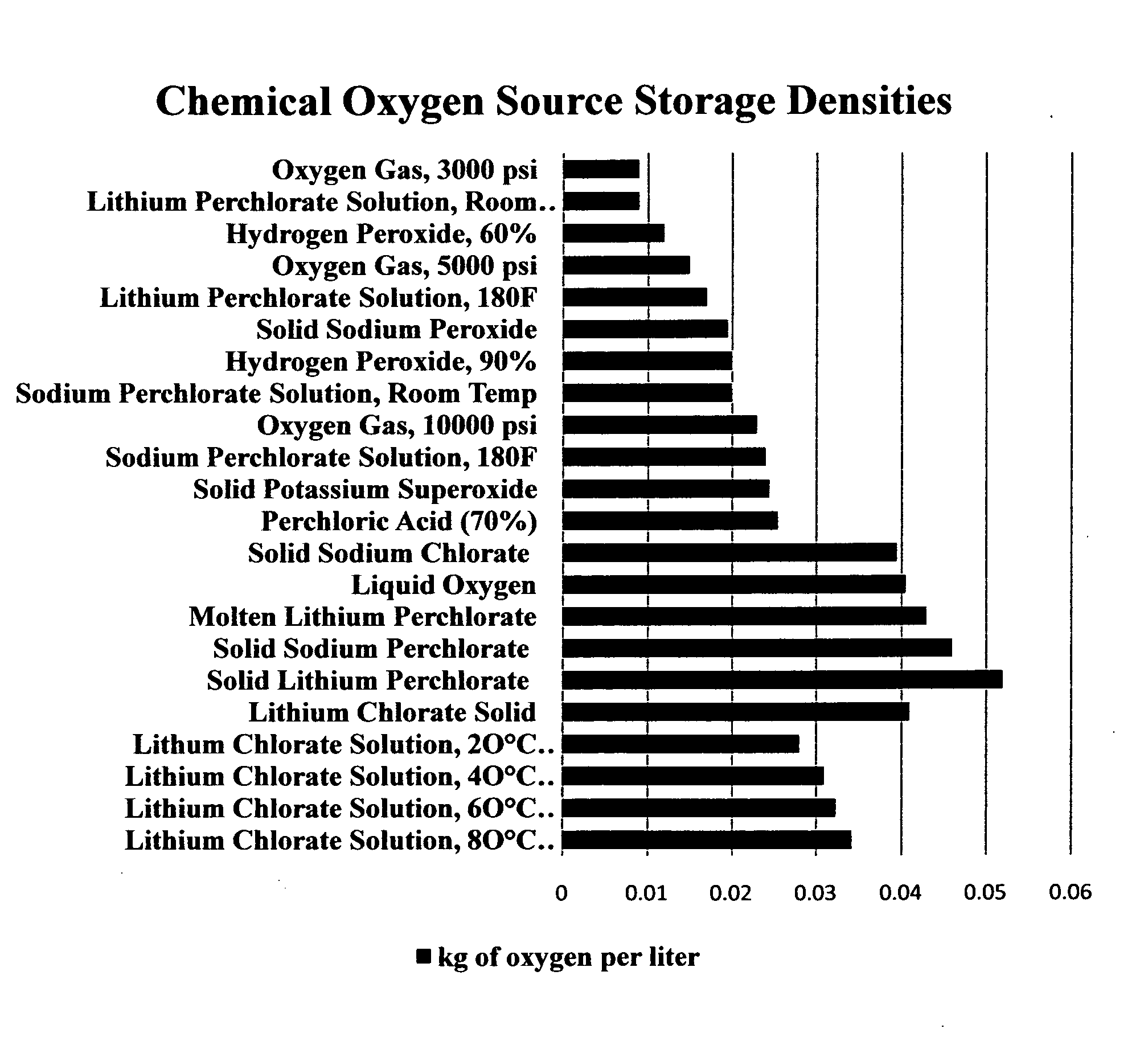

Oxygen-generating liquid composition

InactiveUS20110140038A1Increase contentEffective oxygen generating compoundChloratesOther chemical processesOxygenLiquid composition

An oxygen-generating liquid composition is described comprising compositions of water plus lithium chlorate as a saturated solution and as a mixture of saturated solution plus precipitated solids. The composition further comprises catalysts. The oxygen is produced via thermal decomposition. Uses of the composition include generation of oxygen for power production or for breathable air. A principal benefit is that the composition is an easily handled liquid stored in un-pressurized tank.

Owner:API ENG

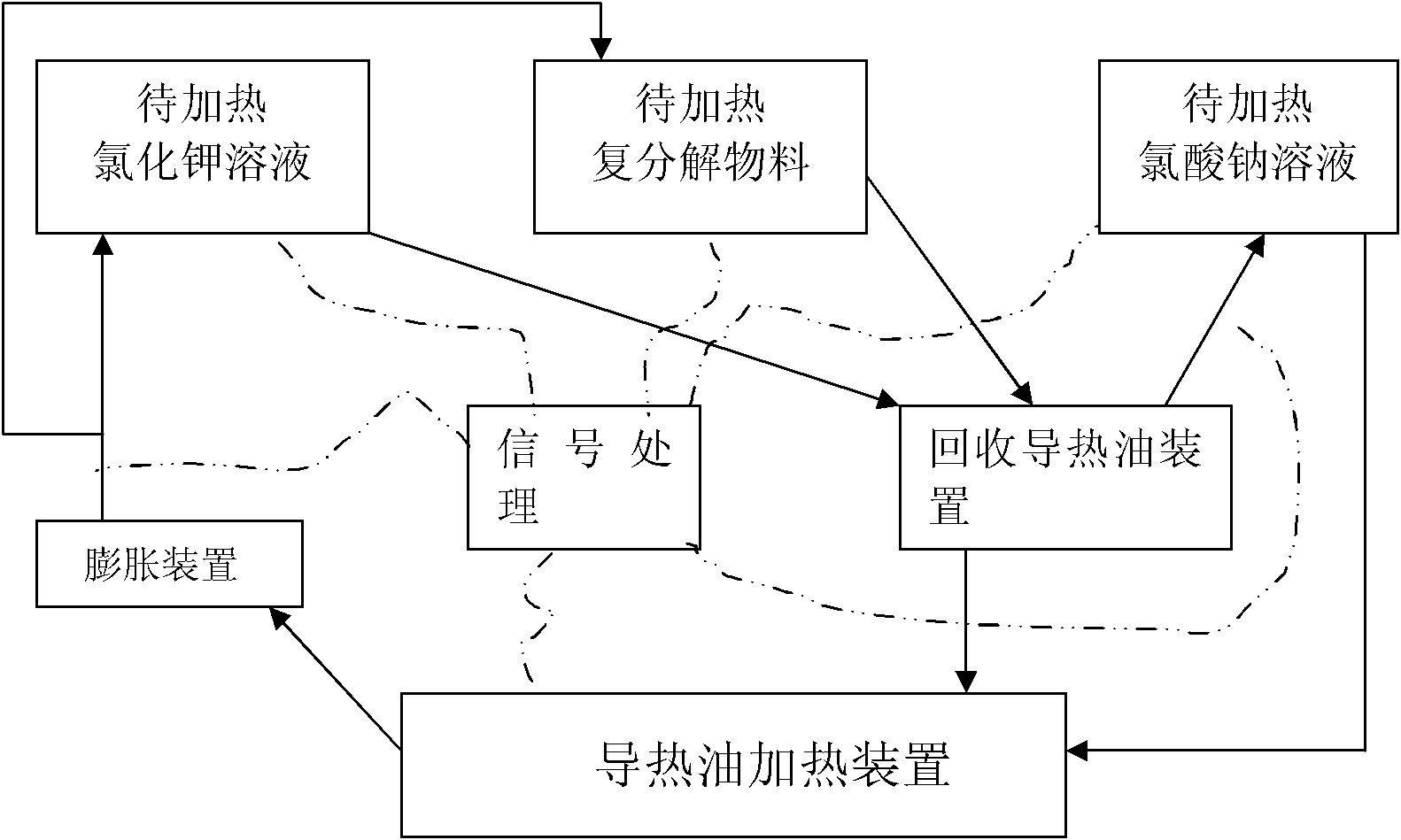

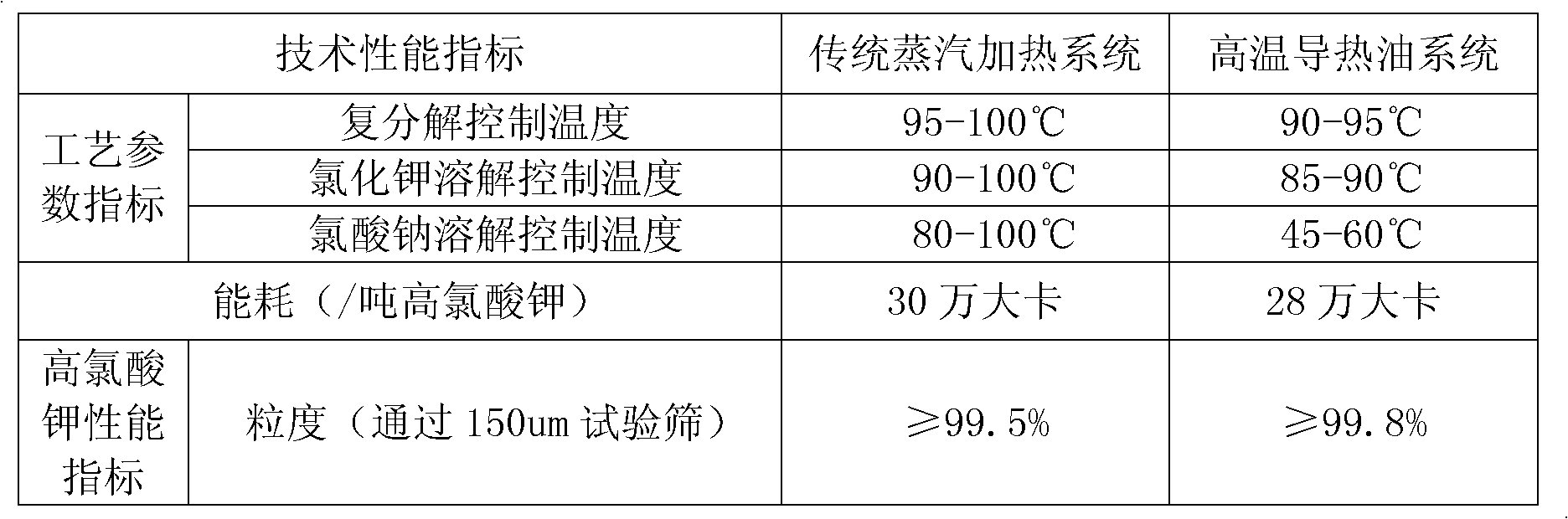

Comprehensive utilization method of heat energy in potassium perchlorate production process

InactiveCN101962174AAbundant power resourcesLow electricity priceElectrolysis componentsPerchloratesThermal energyHeat conducting

The invention relates to a comprehensive utilization method of heat energy in a potassium perchlorate production process, which belongs to the technical field of potassium perchlorate production. The invention aims to solve the technical problem of providing a new heat supplying method for the technical field of potassium perchlorate production, increases energy utilization efficiency and solves environmental pressure caused by the three wastes generated by the coal consumption of a boiler. The invention has the technical schemes of: heating by adopting high-temperature heat conducting oil, in particular to a conduction process that after the heat conducting oil is heated, transmitting heat to materials which need to be heated to cause that the temperature of the heat conducting oil is reduced, and repeatedly heating. The comprehensive utilization method increases energy utilization efficiency and reduces the environmental pressure caused by the three wastes generated by the coal consumption of a boiler, and otherwise, the comprehensive utilization method increases continuous production capacity, is suitable for large-scale production requirements and breaks the tradition that a perchloric acid double-decomposition process is only heated by steam in a long period.

Owner:茂县鑫盐化工有限公司

Refining method for removing chlorate from perchlorate

The present invention discloses a refining process for removing chlorate from perchlorate. According to the content of chlorate in the perchlorate the stoichiometric metasulfite solution or solid can be added, and reacted with chlorate to decompose the chlorate into the compound which can be easily dissolved in water. The perchlorate in the product does not produce reaction with said compound, and the small quantity of acid produced by reaction can be neutralized by alkali to make pH value of solution be 7-9, the content of chlorate in the perchlorate can be controlled in below 0.003% (by chloride) so as to reach to the index of high-quality product.

Owner:吴建国 +2

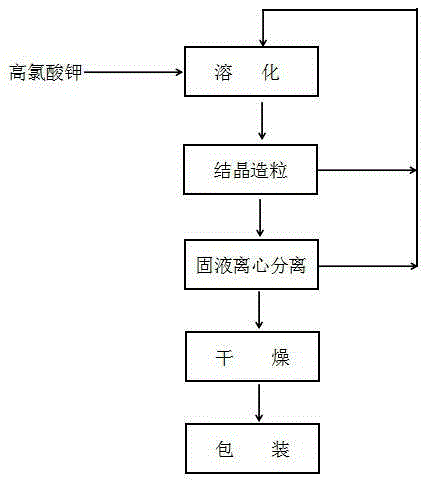

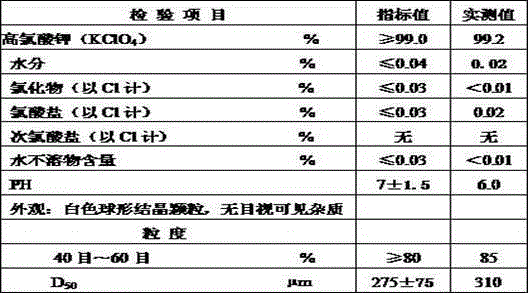

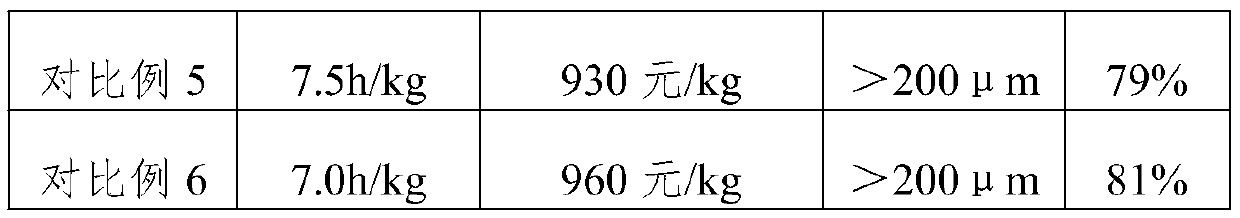

Spherical potassium perchlorate production technology

ActiveCN105271125ALow costMature and practical technologyPerchloratesFluidized bed dryingCalcium perchlorate

The invention relates to a spherical potassium perchlorate production technology. The technology comprises the steps that naturally crystallized potassium perchlorate is adopted, by means of recrystallization technology preparation, the raw material potassium perchlorate is added into a refining tank, potassium perchlorate saturated liquid is added, a potassium perchlorate refined solution is obtained, the refined solution is continuously mixed with the circulation potassium perchlorate saturated liquid through a rotor flow meter, the mixture enters a multitubular heat exchanger after mixing is conducted, by means of dividing wall heat exchanging, heat brought by the refined solution is exchanged, the degree of supersaturation is formed, the grain size of precipitated potassium perchlorate reaches over 200 microns, the precipitated potassium perchlorate is sent into a centrifuge to complete solid-liquid separation, the solid is sent into a fluidized bed dryer to conduct drying, and a finished product is obtained. According to the spherical potassium perchlorate production technology, an existing ordinary crystallization device is utilized to conduct production, special equipment does not need to be designed, a large amount of cost is reduced, the technology is manure and practical, the spherical degree is high, the average grain size is far larger than 200 microns, the yield is large, and requirements of a modern market are met.

Owner:DALIAN GAOJIA CHEM

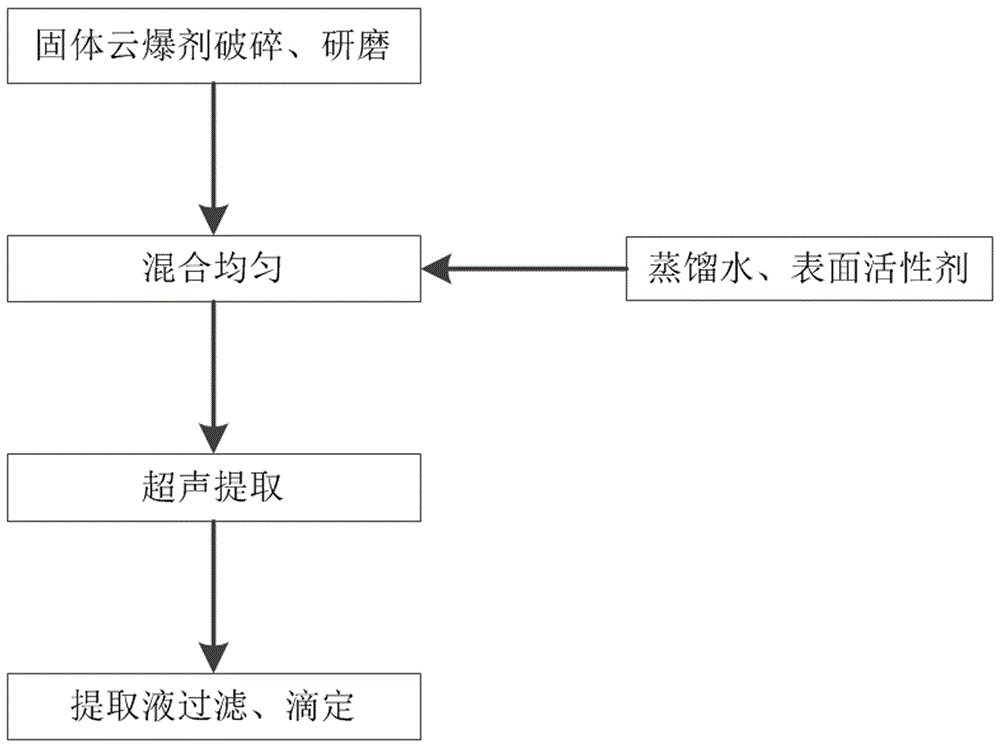

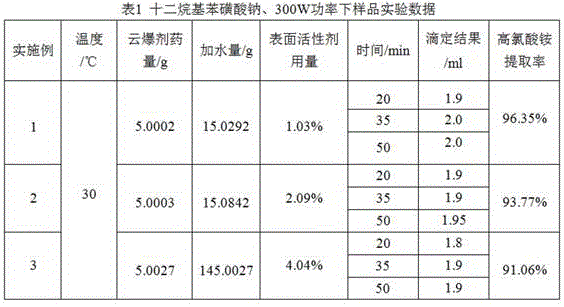

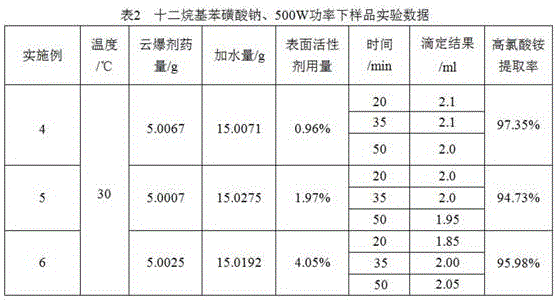

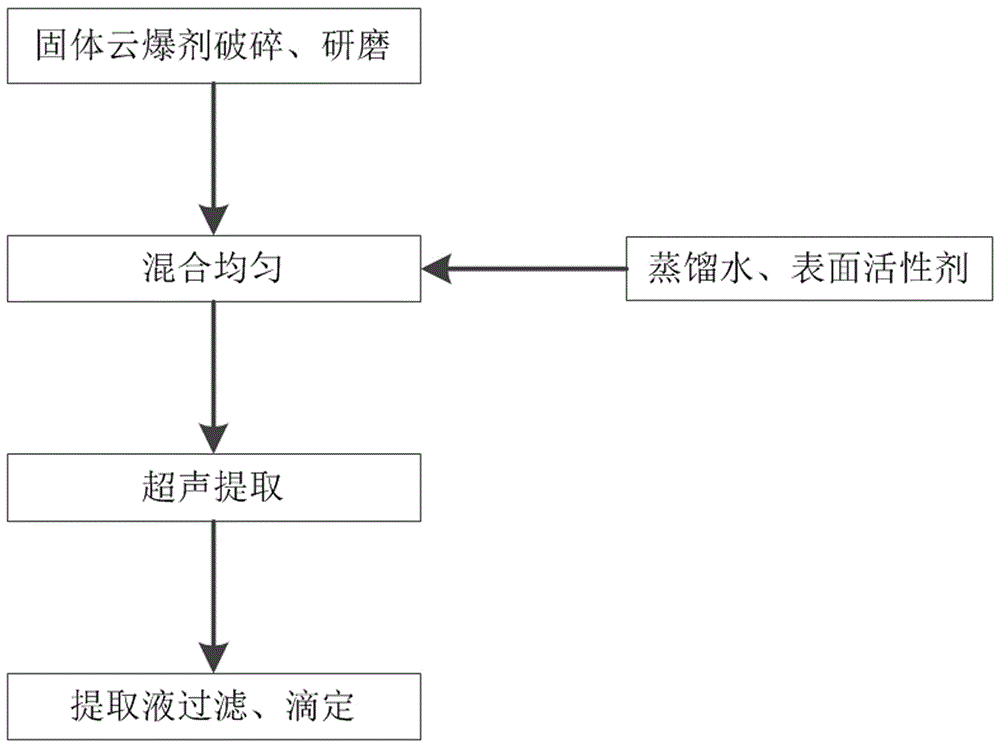

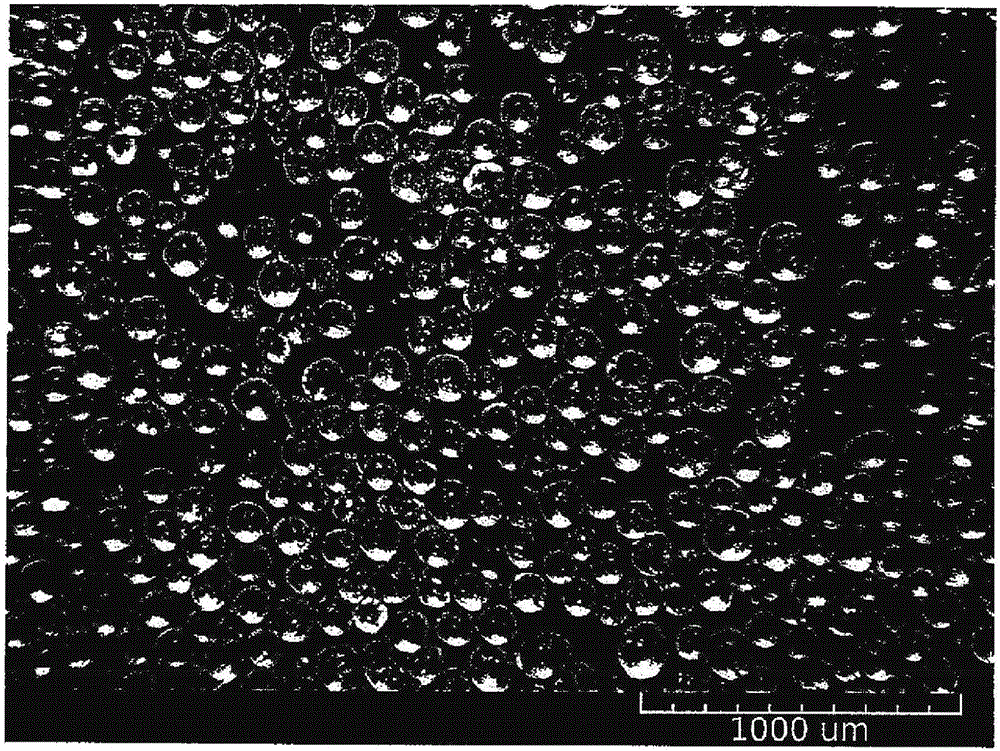

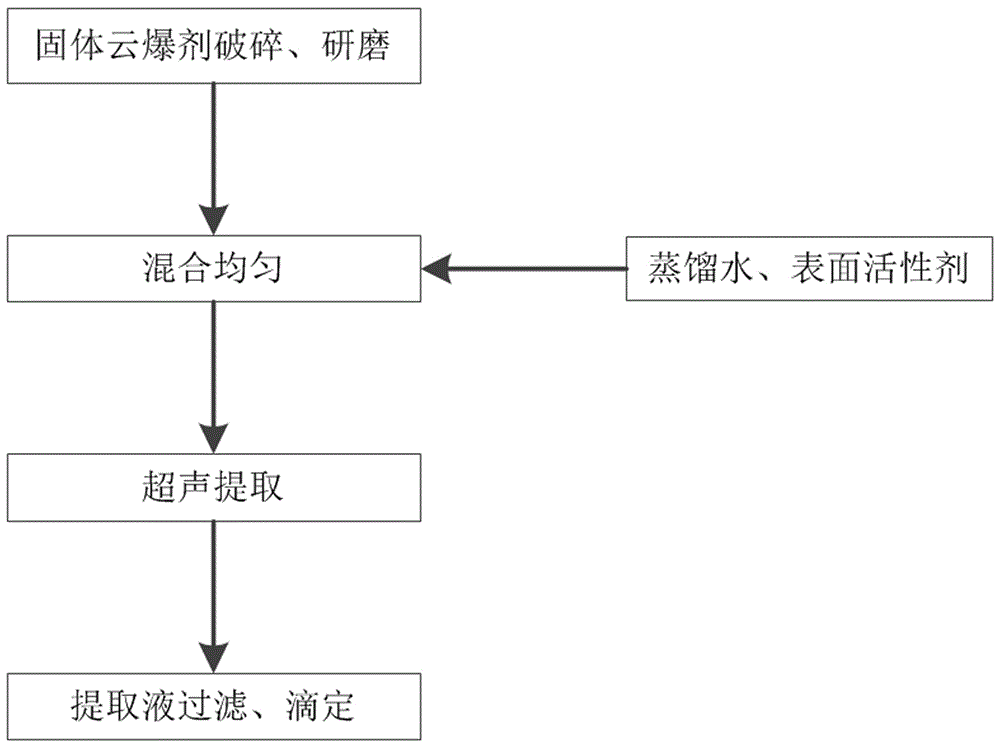

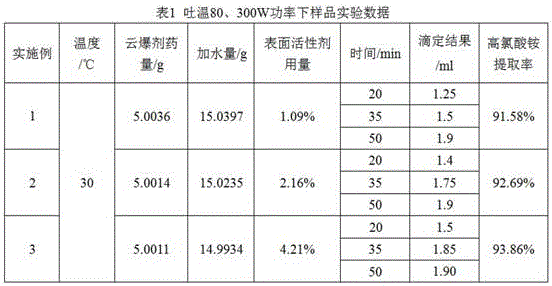

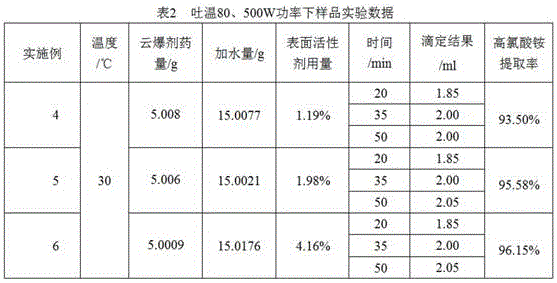

Safe extraction method of ammonium perchlorate in solid cloud detonation agent

InactiveCN106744693AIncrease movement speedStrong penetrating powerPerchloratesEnergy based chemical/physical/physico-chemical processesDetonationAmmonium perchlorate

The invention relates to the technical field of security treatment of solid energetic materials, and particularly discloses a safe extraction method of ammonium perchlorate in a solid cloud detonation agent. The method comprises the steps of mixing a powdery cloud detonation agent containing ammonium perchlorate, a certain amount of water and a surfactant evenly, wherein the dosage of the surfactant is 1-4% of weight of the solid cloud detonation agent; and carrying out ultrasonic extraction on a mixed feed liquid by using an ultrasonic extraction device at room temperature, and extracting the ammonium perchlorate into a water solution, wherein the surfactant is a sodium sulfonate anionic surfactant. According to the method, the ammonium perchlorate in the solid cloud detonation agent can be recovered at room temperature, so that the extraction time is obviously shortened, the extraction efficiency is significantly improved and the safe extraction method has higher extraction rate, is safe in operation and easy to control and implement.

Owner:NO 63908 TROOPS PLA

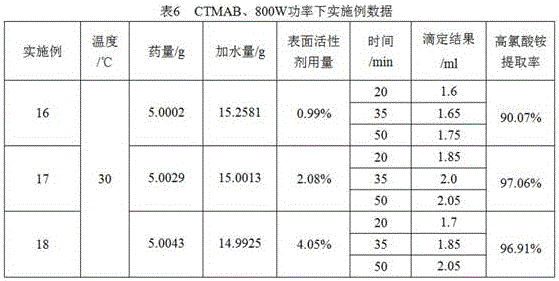

Safe extracting method of ammonium perchlorate in solid FAE (Fuel Air Explosive)

InactiveCN106586968AIncrease movement speedStrong penetrating powerPerchloratesEnergy based chemical/physical/physico-chemical processesAmmonium perchlorateRoom temperature

The invention relates to the technical field of safe treatment of solid energetic materials, and particularly discloses an extracting method of ammonium perchlorate in solid FAE (Fuel Air Explosive). The extracting method comprises the following steps: uniformly mixing a powdery solid FAE containing the ammonium perchlorate with a certain amount of water and surfactant, wherein the dosage of the surfactant is 1 to 4 percent of the weight of the solid FAE; carrying out ultrasonic extraction on mixed liquid by using an ultrasonic extraction device under room temperature, wherein the ammonium perchlorate is extracted into a water solution, and the surfactant is a brominated quaternary ammonium cationic surfactant. According to the extracting method disclosed by the invention, the ammonium perchlorate in the solid FAE can be recycled under normal temperature, the extracting time is remarkably shortened, the extracting efficiency is remarkably increased, a higher extracting rate is obtained, the operation is safe, and control and implementation are easy.

Owner:NO 63908 TROOPS PLA

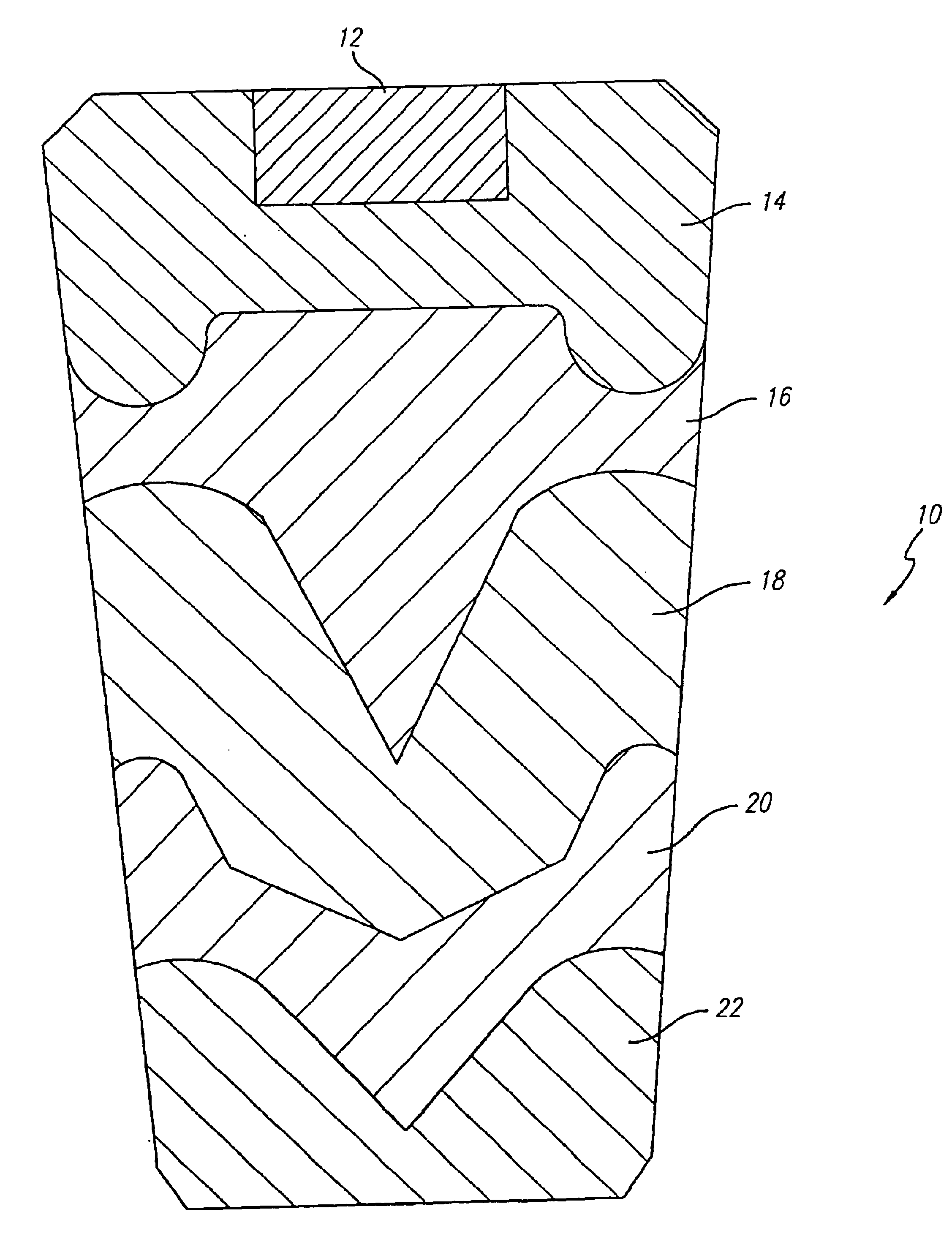

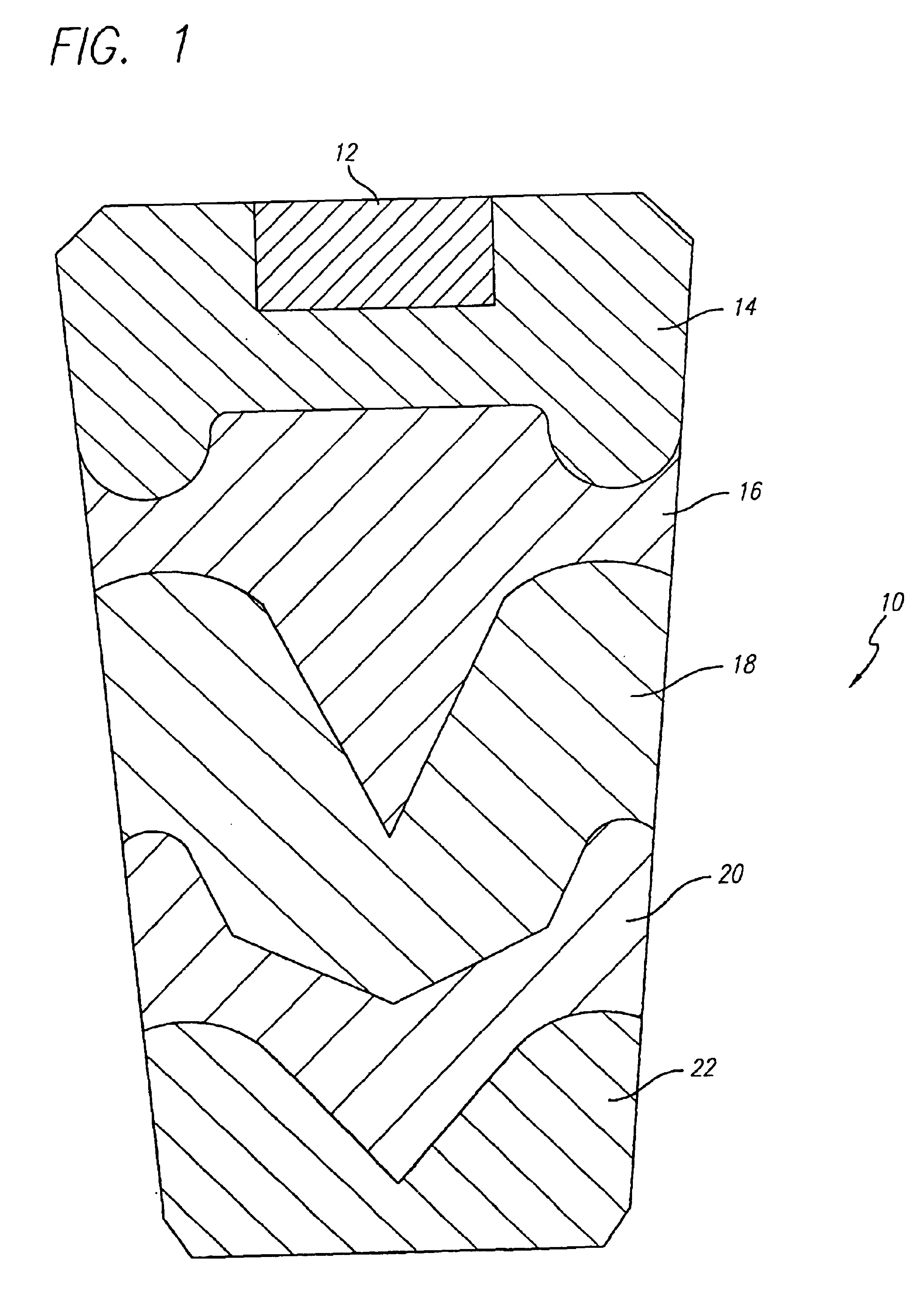

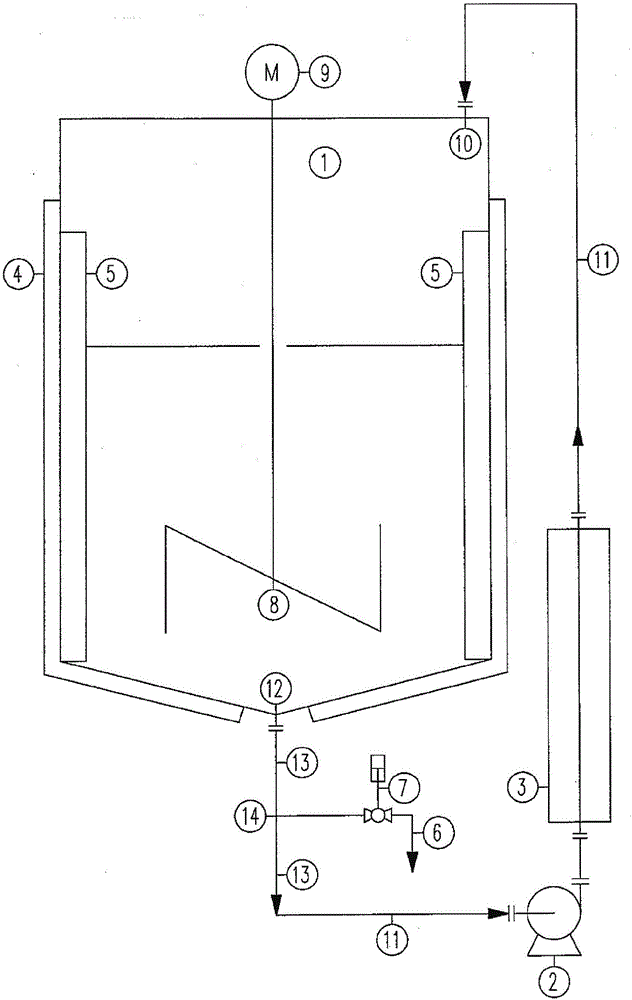

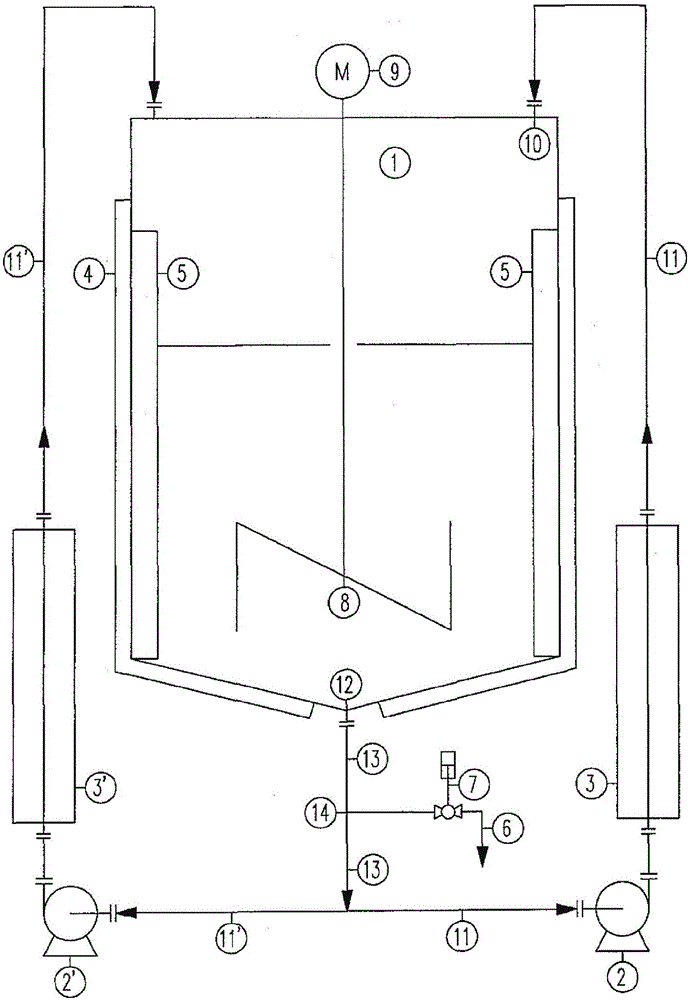

A discontinuous crystallization unit for the production of ball-shaped crystals

ActiveCN106457061AReduce procurement costsSimple designPolycrystalline material growthFrom normal temperature solutionsCooling curveInterconnection

The invention introduces a discontinuous crystallization unit for the production of ball- shaped crystals comprising a crystallizer (1) that consists of a metallic cylindrical vessel with its inner surface of a hard material, with an oval or circular cross-section with a conical or vaulted bottom (12), fitted along its length with a duplicator (4) for cooling of the solution and / or suspension of the solution and crystals and a high-speed agitator (8) of a hard material with a drive (9) enabling speed control and thus the rate of the impact of the mechanical action of the agitator on roundness of crystals inside the vessel together with the inner surface of the vessel containing at least 2 baffles (5) of a hard material while the vessel is fitted with at least 1 orifice (10) at the top that at least 1 independent branch of the circulation circuit (11) is connected to from the outside for the inlet of a heated solution and / or heated suspension of the solution and crystals by means of at least 1 circulation pump (2) and through at least 1 heat exchanger (3) and together with the duplicator (4) ensuring controlled periodic changes of temperatures of the crystal suspension around the cooling curve while an interconnection (13) pipeline is connected to the bottom (12) of the crystallizer (1) vessel that is connected to at least one branch of the circulation circuit (11).

Owner:ERUCA TECH SRO

Safe extraction method for ammonium perchlorate in solid fuel air explosive

ActiveCN106586967AIncrease movement speedStrong penetrating powerPerchloratesEnergy based chemical/physical/physico-chemical processesAmmonium perchlorateSolid fuel

The invention relates to the technical field of safe treatment of solid energetic materials and particularly discloses a safe extraction method for ammonium perchlorate in a solid fuel air explosive. The method includes the steps that the powdery solid fuel air explosive containing ammonium perchlorate and a certain amount of water and surfactant are mixed to be uniform, wherein the use amount of the surfactant is 1%-4% of the weight of the solid fuel air explosive; an ultrasonic extraction device is used for ultrasonically extracting mixed feed liquid at room temperature, and ammonium perchlorate is extracted into a water solution; the surfactant is Tween series nonionic surfactant. The method can be used for recycling ammonium perchlorate in the solid fuel air explosive at normal temperature, the extraction time is obviously shortened, the extraction efficiency is obviously improved, the higher extraction rate is achieved, operation is safe, and control and implementation are easy.

Owner:NO 63908 TROOPS PLA

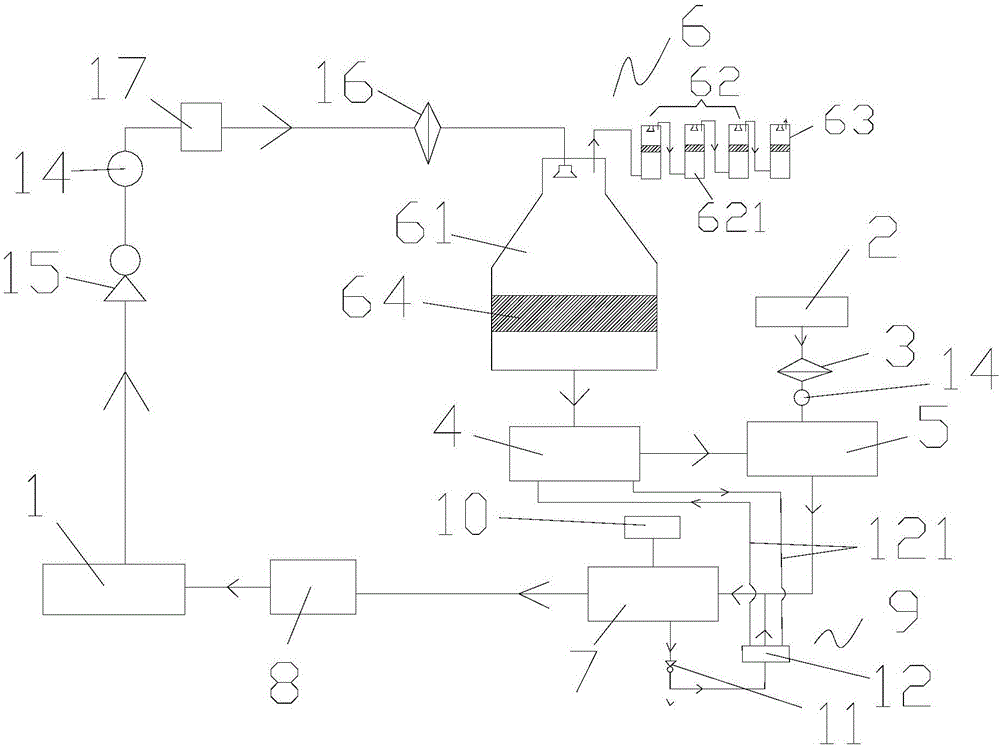

Production device and method of potassium perchlorate

InactiveCN106379861AAccurate measurementAvoid it happening againElectrolysis componentsPerchloratesEngineeringElectrolyte

The invention relates to a production device and method of potassium perchlorate. The device comprises a cyclic electrolytic cell. The cyclic electrolytic cell is communicated with a first reactor, the first reactor is communicated with the bottom of a second reactor through a third circulating pump, the upper part of the second reactor is communicated with the first reactor and the top of the second reactor is communicated with an air exhaust cooling device. An air exhaust cooling device carries out concentration and cooling on an electrolyte in potassium perchlorate production. A grinding device crushes and crystallizes potassium perchlorate. Through a re-crystallization method, high-purity potassium perchlorate crystals are produced. The method has simple processes. Through a liquid-liquid system arrangement method, measurement in potassium chloride production is accurate, quality can be easily controlled, a sandwich material is avoided, solid wastes are easily removed, and harmful solid waste production is prevented. Through a chlorine removal device, acid and alkali raw materials are saved. Through a solution condensation device, superfluous water in the solution can be removed. Through an eddy flow densification system, crystallization efficiency is improved.

Owner:汝城县三鑫电化有限公司

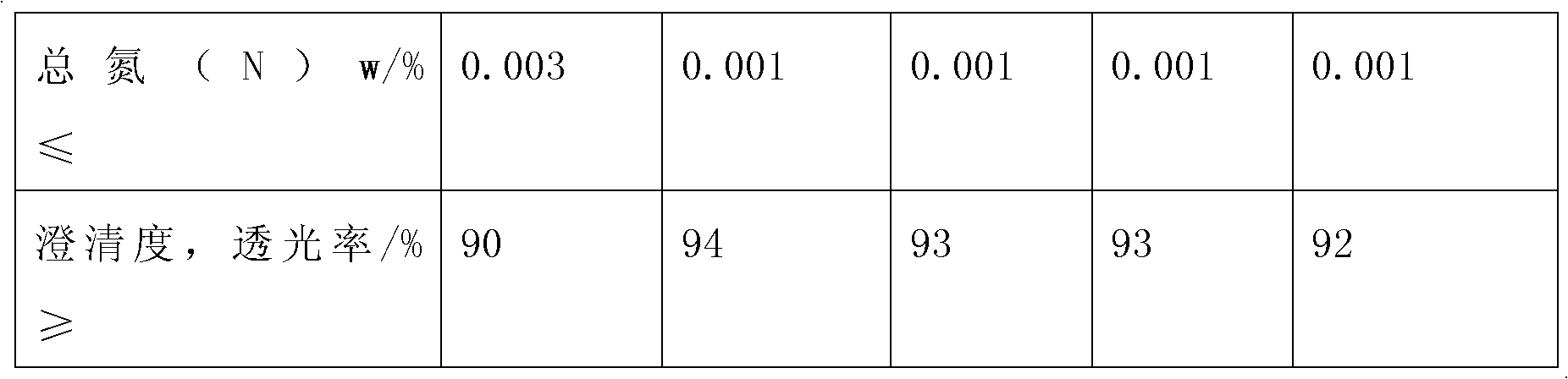

Method for preparing high-purity anhydrous lithium perchlorate from battery-grade lithium hydroxide monohydrate

ActiveCN110835096AAchieve dehydrationReduce the difficulty of dehydrationPerchloratesElectrolytic agentPhysical chemistry

The invention discloses a method for preparing high-purity anhydrous lithium perchlorate from battery-grade lithium hydroxide monohydrate, and belongs to the technical field of electrolyte preparationfor lithium battery electrolyte solutions. The method comprises the following process steps: A, dissolving of the lithium hydroxide monohydrate; B, a neutralization reaction; C, filtration for removing impurities; D, concentration and dehydration; E, ethanol dehydration; F, cooling crystallization; G, vacuum primary drying and crushing; and H, vacuum secondary drying, crushing and packaging. Themethod for preparing the high-purity anhydrous lithium perchlorate from the battery-grade lithium hydroxide monohydrate has the advantages of simple process, high yield, high economic values and smallenvironmental pollution.

Owner:GANFENG LITHIUM CO LTD

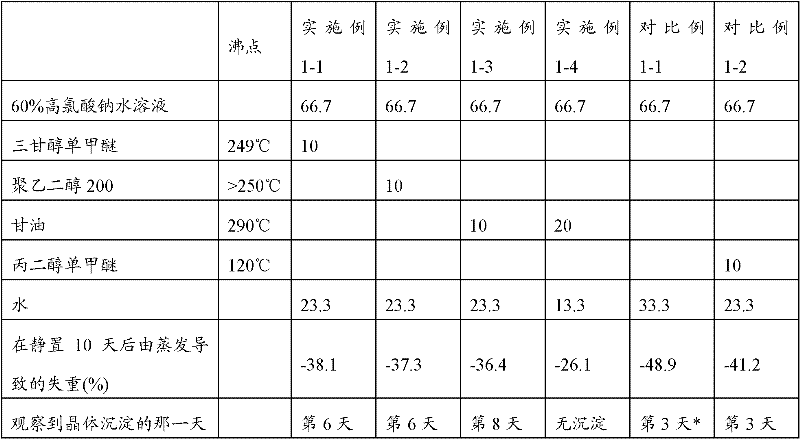

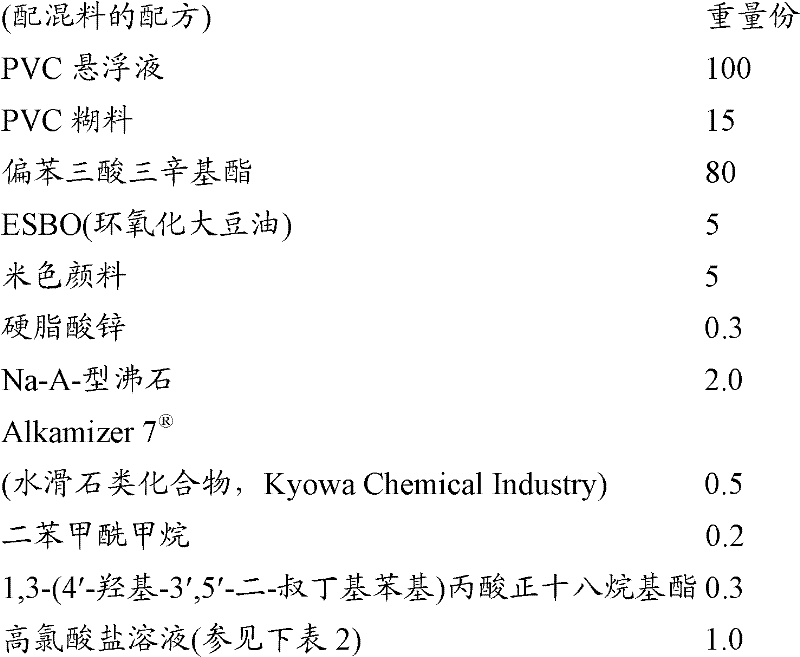

A perchlorate solution improved in safety, and a method for heat-stabilizing chlorine-containing resin compositions

To improve the handlability and safety of a perchlorate solution used as a stabilizer for chlorine-containing resins. This invention provides a perchlorate solution of improved handlablity and safety and a method for heat-stabilizing chlorine-containing resin compositions by adding (a) 0.004 to 10 parts by weight of a perchlorate solution containing 1 to 60 % by weight of perchlorate, 5 to 50 % by weight of water-soluble organic solvent and 20 to 94 % by weight of water, and (b) 0.001 to 10 parts by weight of at least one silicate compound represented by the general formula (I) to 100 parts by weight of a chlorine-containing resin: M(O)a nSiO2mH2O (I) in which M is at least one metal selected from alkaline earth metals and aluminum, a is 1 when M is an alkaline earth metal and 3 / 2 where M is aluminum, n is from 1 to 5, and m is any positive integer.

Owner:AKISHIMA CHEM IND

Method for preparing potassium perchlorate powder by using closed-loop spray dryer

InactiveCN110604932ASmall particle sizeReduce volumePerchloratesGranulation by liquid drop formationClosed loopOxygen

The invention discloses a method for preparing potassium perchlorate powder by using a closed-loop spray dryer, which comprises the following steps: preparing a potassium perchlorate solution by usingpotassium perchlorate solid as a raw material, and spraying the potassium perchlorate solution by using the closed-loop spray dryer to obtain the potassium perchlorate powder. The potassium perchlorate is used as a raw material; and the potassium perchlorate powder is prepared through the closed-loop spray dryer. The closed-loop spray dryer is small in size, oxygen isolation is achieved, the safety and reliability of the production process are guaranteed, the production efficiency is high, continuous operation can be achieved, the price is low, industrial production is easy, and the preparedpotassium perchlorate is small in particle size, high in raw material utilization rate and low in production cost. The equipment investment is low, the production process is simple and the period is greatly shortened; the whole production process is almost zero-emission and is green and environment-friendly. The method has the characteristics of simplicity, high efficiency, low energy consumption,low cost, safety, low impurity content and small particle size.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com