Production device and method of potassium perchlorate

A technology of potassium perchlorate and production equipment, applied in perchloric acid, perchlorate, electrolysis process and other directions, can solve problems such as waste of acid and alkali, achieve the effects of preventing harmful solid waste, easy quality and increasing crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

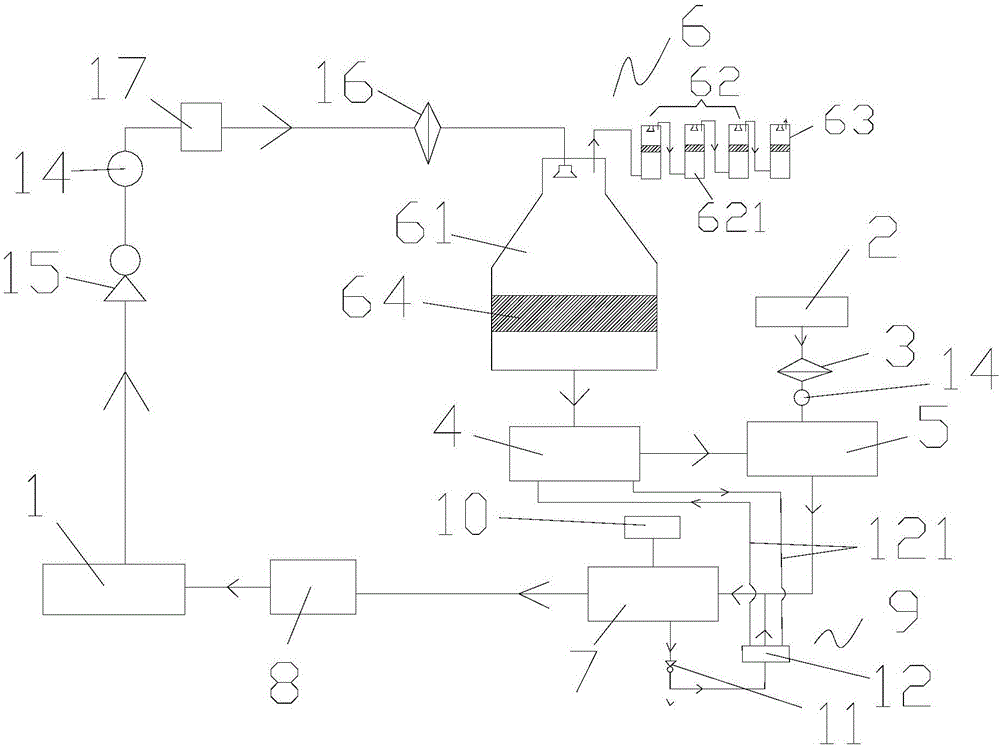

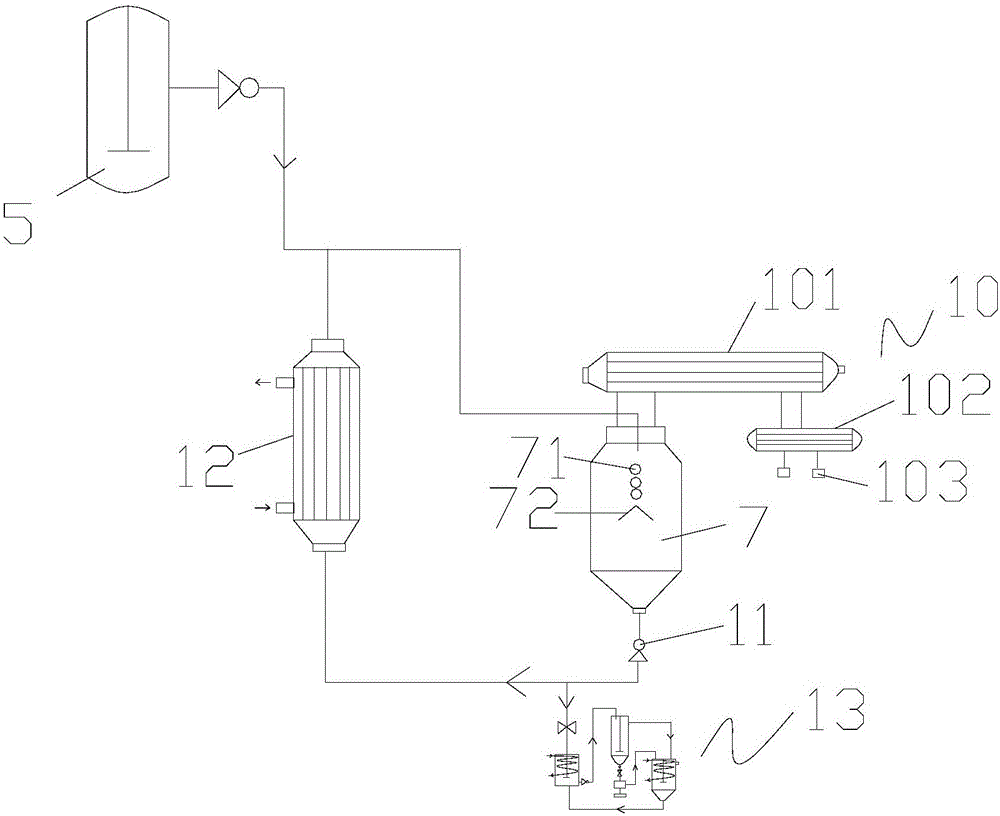

[0036] Such as Figure 1-Figure 4 The production equipment of a kind of potassium perchlorate shown comprises circulation electrolyzer 18, and circulation electrolyzer 18 communicates with the first reactor 19, and the first reactor 19 communicates with the bottom of the second reactor 21 by the 3rd circulation pump 20, the second The upper part of the reactor 21 communicates with the first reactor 19 ; the top of the second reactor 21 communicates with the extraction and cooling device 22 .

[0037] The temperature control is realized by the induced draft fan and the frequency converter 222, instead of the traditional coil water cooling system, the water is evaporated by liquid heat dissipation to obtain a higher concentration of electrolyte, and the circulating cooling water is canceled at the same time. The concentrated and cooled crystals at the bottom of the first reactor pass through the bottom valve to remove the system, and return to the crystallization system for purifi...

Embodiment 2

[0050] Such as Figure 4 A kind of production method of potassium perchlorate shown, comprises the steps:

[0051] Step 1, sodium chlorate solution is added into the circulating electrolyzer 18 and relies on the hydrogen produced by electrolysis, and the electrolysis is automatically circulated. The first reactor 19 and the second reactor 21 are circulated and communicated, and the electrolytic solution is concentrated by the air extraction cooling device 22; the potassium chlorate solid is directly put into The first reactor 19 is mixed with the electrolyte;

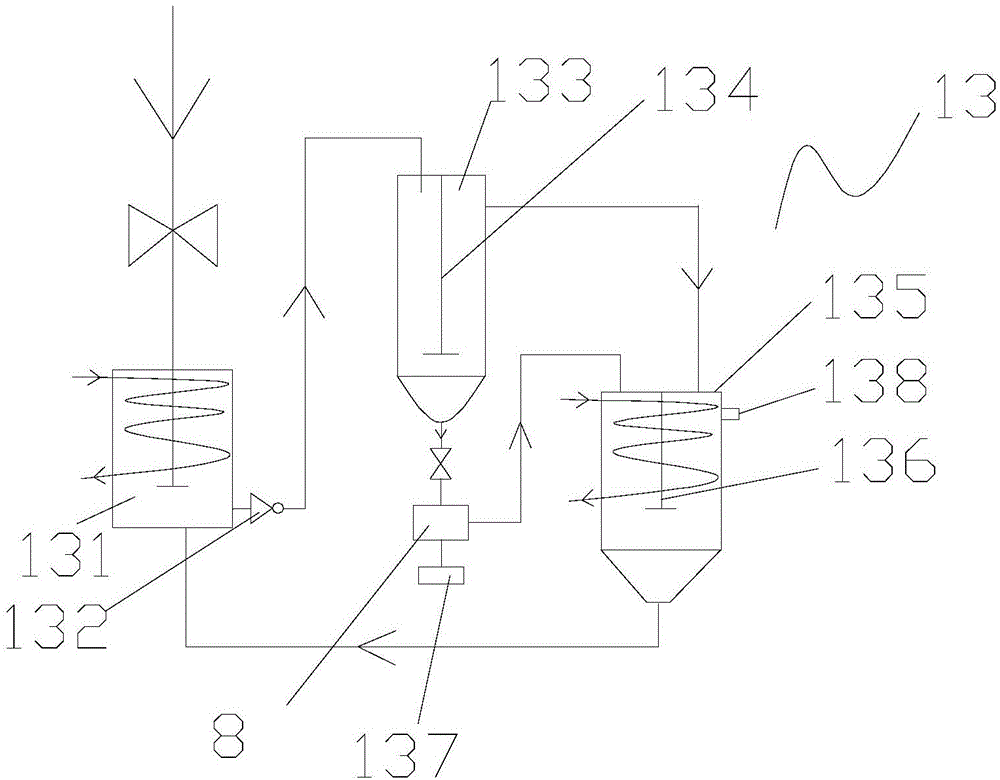

[0052] Step 2, the electrolytic solution in the first reactor 19 enters potassium perchlorate double decomposition tank 25, forms potassium perchlorate crystallization, and the solution circulation that contains potassium perchlorate crystallization enters grinding device 27, smashes recrystallization through potassium perchlorate crystallization, potassium perchlorate double decomposition tank 25 The number of circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com