Hollow ultrafine ammonium perchlorate and preparation method thereof

A technology of ammonium perchlorate and ammonium chlorate, which is applied in the direction of perchloric acid and perchlorate, can solve the problems of being unable to prepare hollow ultrafine ammonium perchlorate materials, and achieve good dispersion and regularity, Easy operation and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Hollow superfine ammonium perchlorate and preparation method thereof, the steps are as follows:

[0028] First, at room temperature, take a certain amount of spherical ammonium perchlorate with a size of about 250 μm and dissolve it in an equal volume of N,N-dimethylformamide (DMF) / acetone mixed solvent to make perchloric acid ammonium saturated solution; then add 10 ml of ammonium perchlorate saturated solution to 200 ml of ethyl acetate, keep stirring at 1000 rpm during the addition process, ammonium perchlorate crystals will crystallize out due to supersaturation; finally pump the mixture Filter, wash with ethyl acetate, and dry the product in an oven at 80°C to obtain hollow ultrafine ammonium perchlorate.

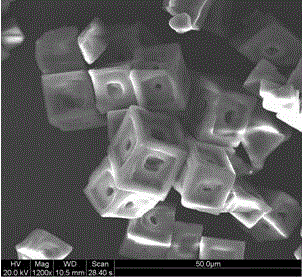

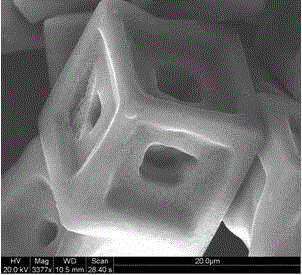

[0029] The electron micrograph of the hollow ultrafine ammonium perchlorate that makes is as follows figure 1 and figure 2 , with a cubic hollow shape, a multi-layer cavity structure in the middle of the particle, and a particle size of about 10 μm to 15 μm. ...

Embodiment 2

[0032] Hollow superfine ammonium perchlorate and preparation method thereof, the steps are as follows:

[0033] First, at 40 °C, a certain amount of spherical ammonium perchlorate with a size of about 250 μm was dissolved in a mixed solvent of DMF / acetone with a volume ratio of 3:1 to prepare a saturated solution of ammonium perchlorate; then 10 Add the saturated ammonium perchlorate solution in 250 ml to 250 ml of ethyl acetate, keep the stirring speed of 1500 rpm during the addition process, the ammonium perchlorate crystals will crystallize out due to supersaturation; finally the mixed solution is suction filtered, washed with ethyl acetate, The product is dried in an oven at 50-150 °C to obtain hollow ultrafine ammonium perchlorate.

[0034] The prepared hollow ultrafine ammonium perchlorate has a cubic hollow shape, and the middle part of the particle has a multi-layer cavity structure, and the particle size is about 5 μm to 10 μm.

[0035]

Embodiment 3

[0037] Hollow superfine ammonium perchlorate and preparation method thereof, the steps are as follows:

[0038] First, at 30 °C, a certain amount of spherical ammonium perchlorate with a size of about 250 μm was dissolved in a mixed solvent of DMF / acetone with a volume ratio of 1:4 to prepare a saturated solution of ammonium perchlorate; then 10 Add 1 ml ammonium perchlorate saturated solution to 100 ml ethyl acetate, keep the stirring speed of 2000 rpm during the addition process, ammonium perchlorate crystals will crystallize out due to supersaturation; finally the mixed solution is suction filtered, washed with ethyl acetate, The product is dried in an oven at 50-150 °C to obtain hollow ultrafine ammonium perchlorate.

[0039] The prepared hollow ultrafine ammonium perchlorate has a cuboid hollow shape, the middle part of the particle has a multi-layer cavity structure, and the particle size is about 10 μm to 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com