Patents

Literature

51results about How to "Good neatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

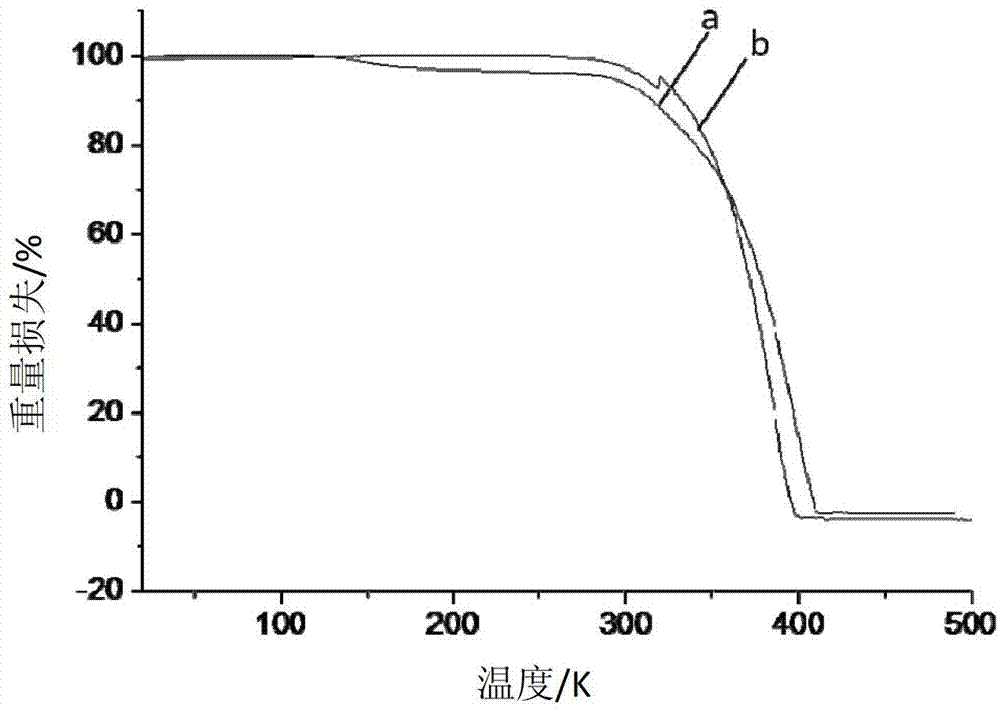

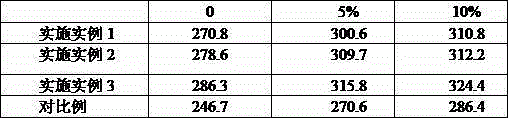

Phosphoric flame-proof copolyester ionomer and preparation method thereof

The invention discloses a phosphorus-containing flame retardant copolyester ionomer and the preparation method, which is characterized in that: based on a plurality of building units synthesizing polyester represented by I and II, a plurality building units represented by IV or a plurality building units represented by III and IV are introduced and the copolyester ionomer is prepared by random copolymerization; wherein, the number of the building units represented by III is 0 to 20 percent of the number of the building units represented by I, the number of the building units represented by IV is 0.1 to 20 percent of the number of the building units represented by I, the number of the building units represented II: the number of the building units represented by [I+III+IV] equals 1, the intrinsic viscosity of the prepared copolyester ionomer [Eta] is in the rang of 0.25 to 0.95dL / g. The phosphorus-containing flame retardant copolyester ionomer has the advantages that: because the ionic groups are phosphorus-containing groups, the flame-retardance modification and the ionization modification of polyester are realized simultaneously; meanwhile, the melt viscosity of polyester is enhanced by the incarbonization produced by the phosphorus-containing ionic groups and the ''physical crosslinking'' produced by the ''ionic aggregate'', thus, the flame retardant and anti-dripping performance is given to polyester.

Owner:SICHUAN UNIV

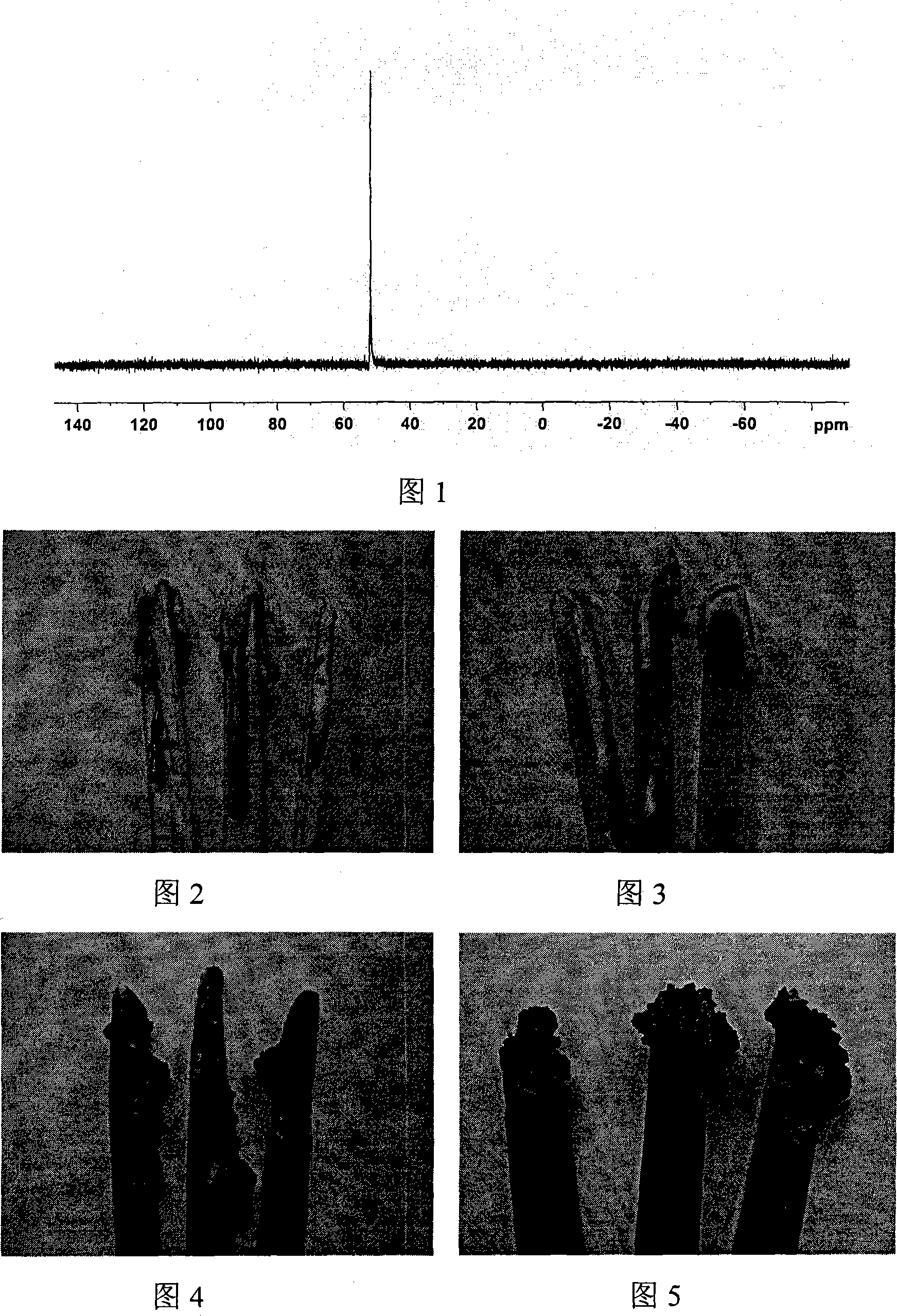

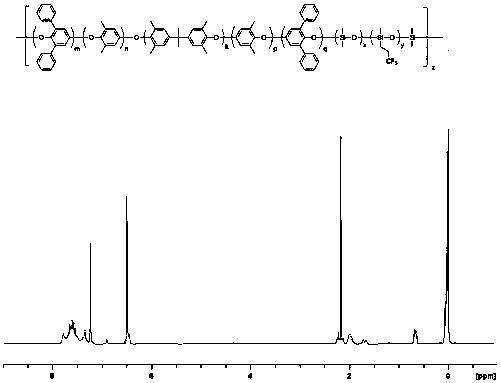

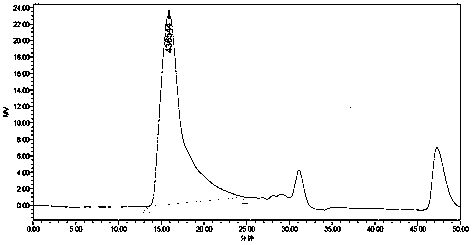

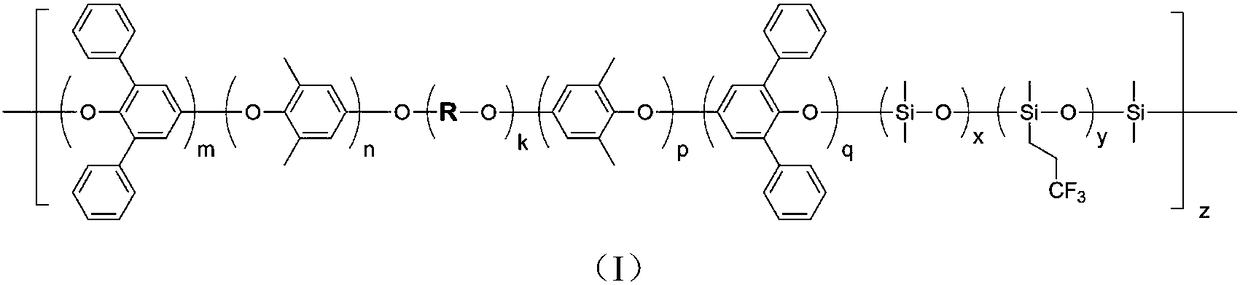

Polyarylether-polysiloxane copolymer and preparation method thereof

The invention relates to the technical field of organosilicone industry, and provides a polyarylether-polysiloxane copolymer and a preparation method thereof in order to overcome defects of the priorart. By taking phenolic hydroxyl group terminated polyarylether and hydrogen terminated polysiloxane as raw materials and by utilizing a catalytic dehydrogenation and polycondensation method, an Si-Hbond at the tail end of a polysiloxane molecular chain is activated through a catalyst, so that the two raw materials are in dehydrogenation coupling reaction, an (AB)n type multi-block copolymer of which the structure is regular is formed through polycondensation, and soft / hard segments are connected together through an Si-O-Ph bond; an obtained (AB)n type polyarylether-polysiloxane multi-block copolymer has good mechanical performance, good heat resistance and good oil and solvent resistance.

Owner:HANGZHOU NORMAL UNIVERSITY

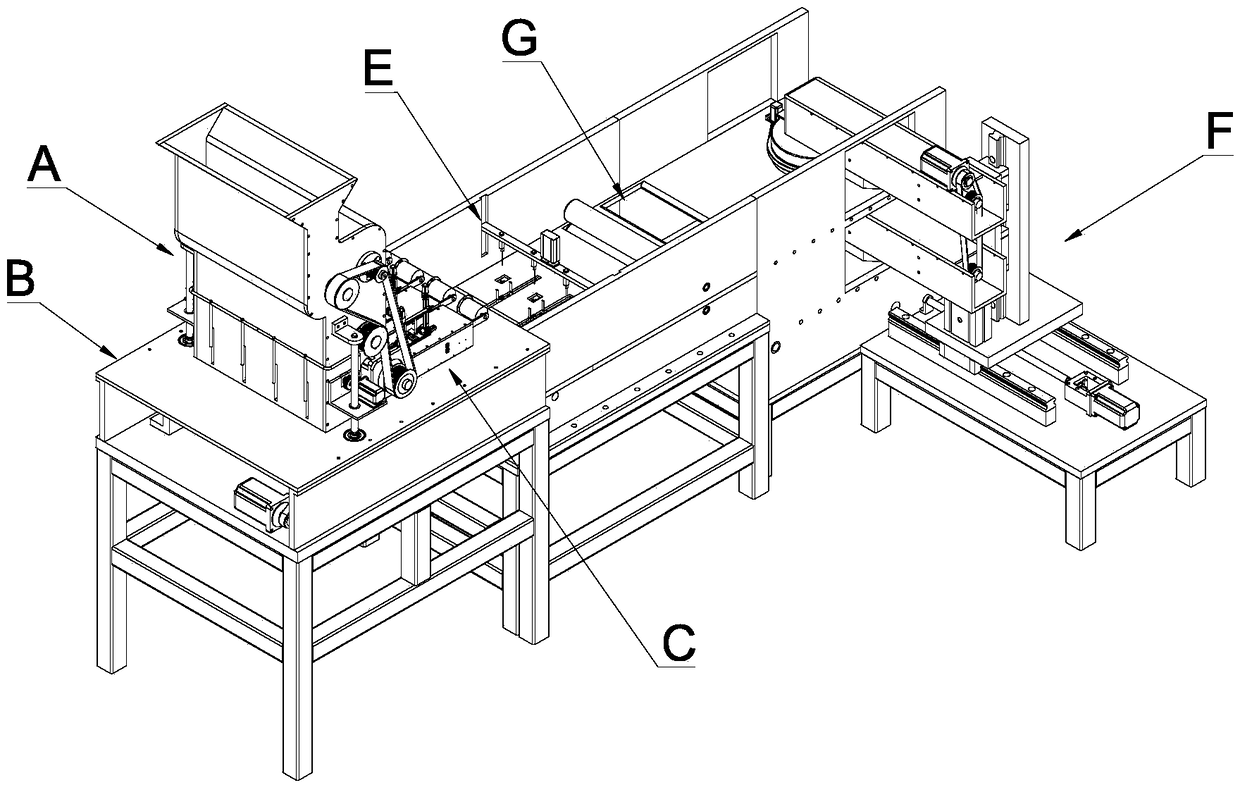

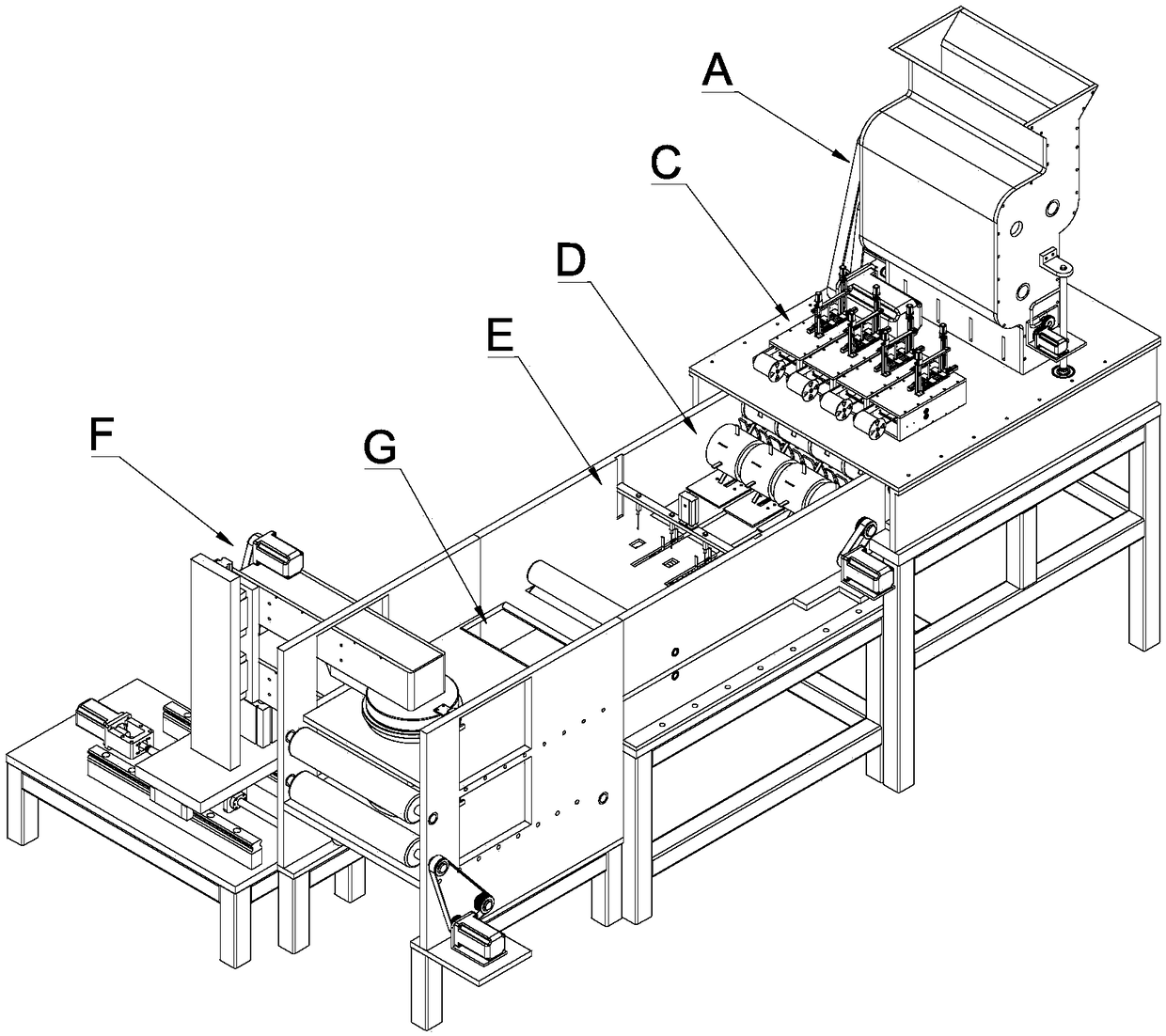

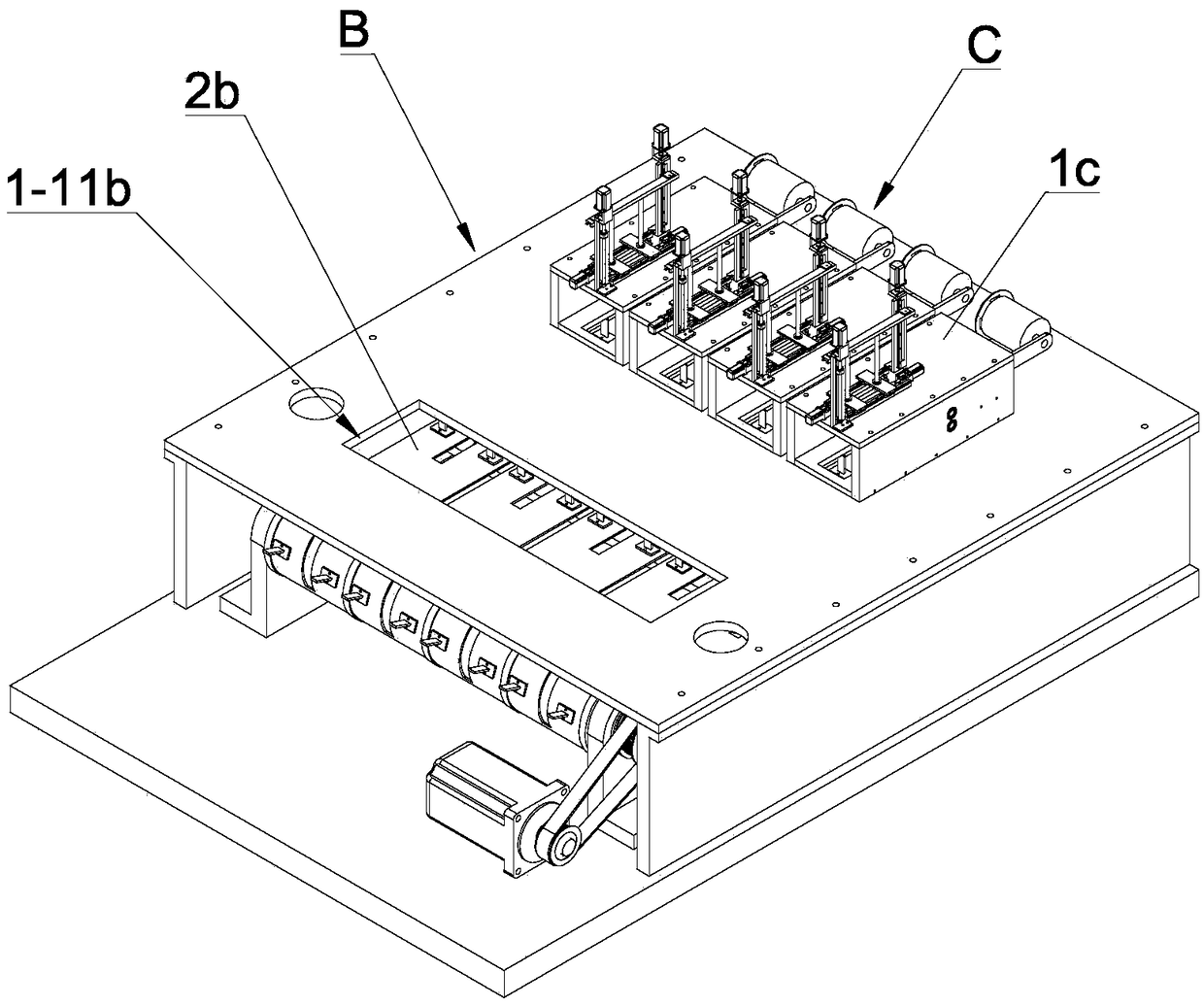

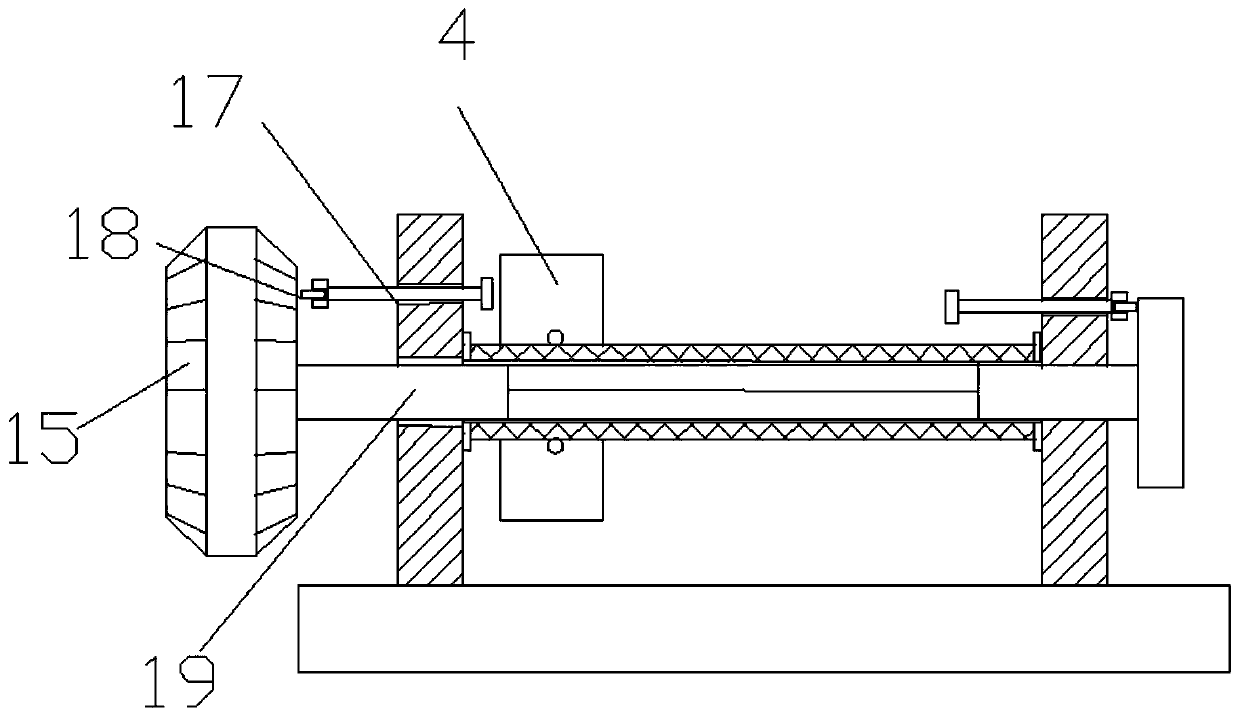

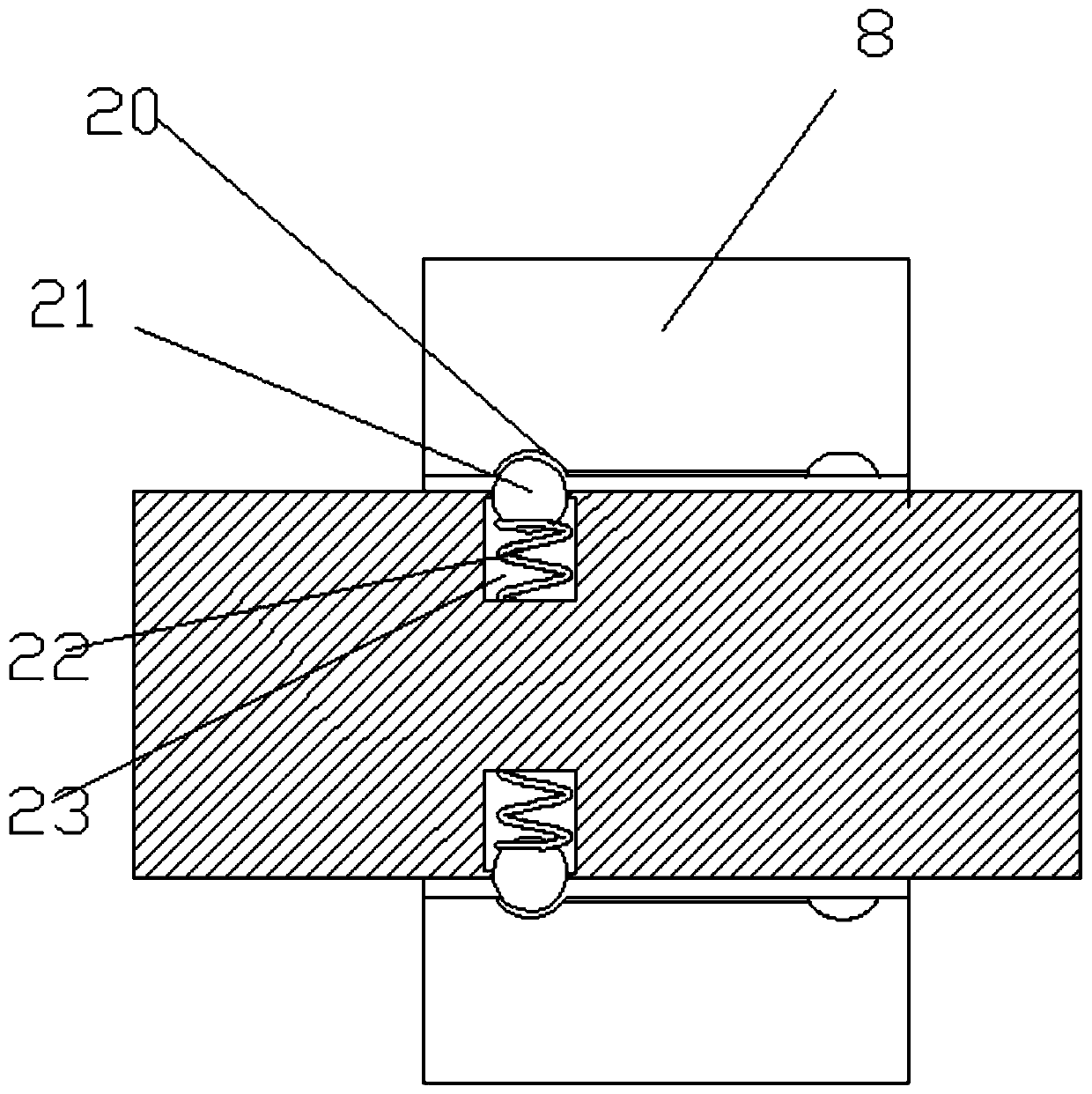

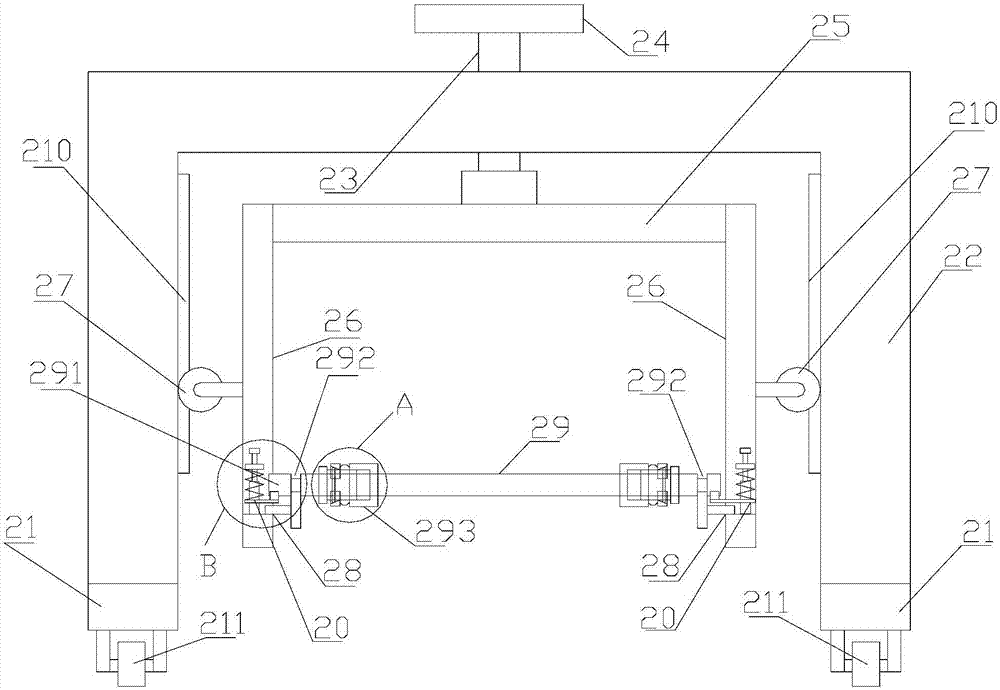

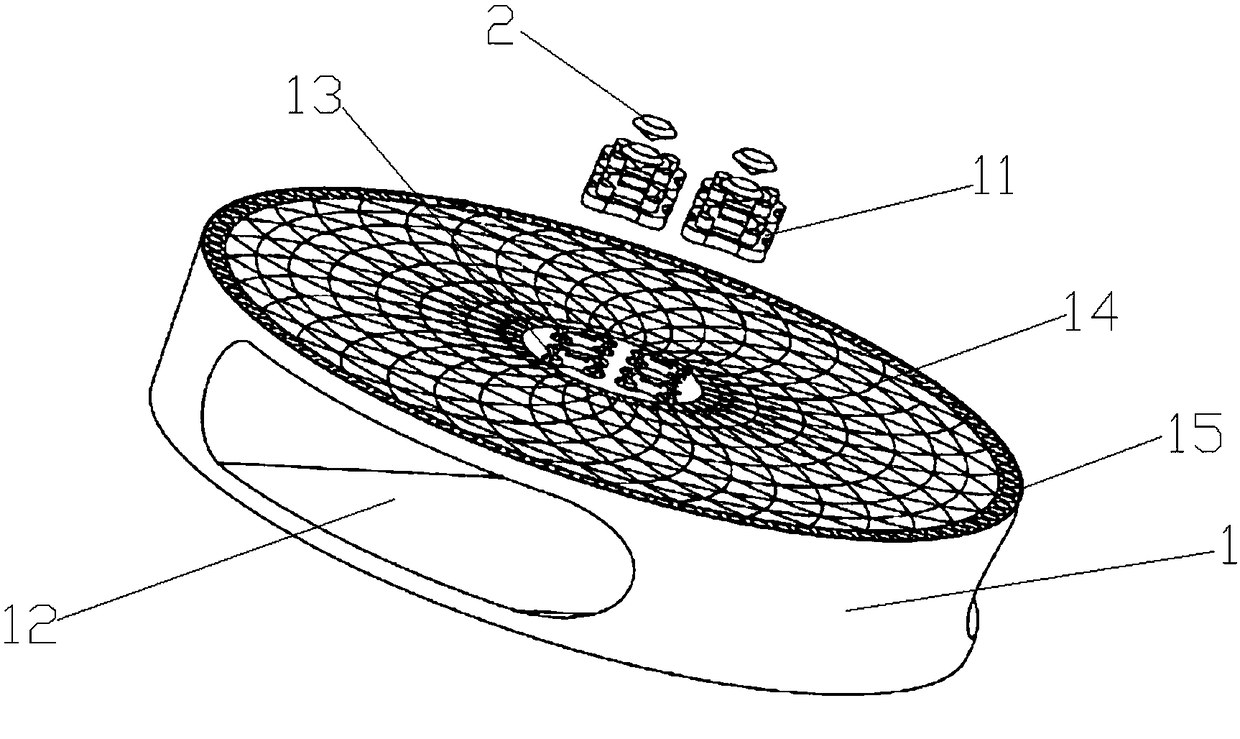

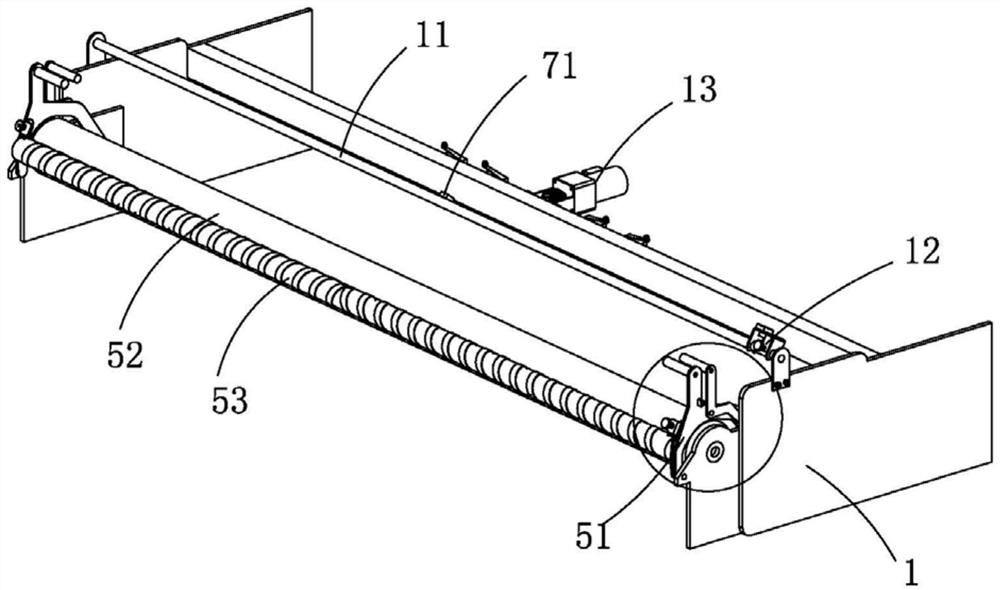

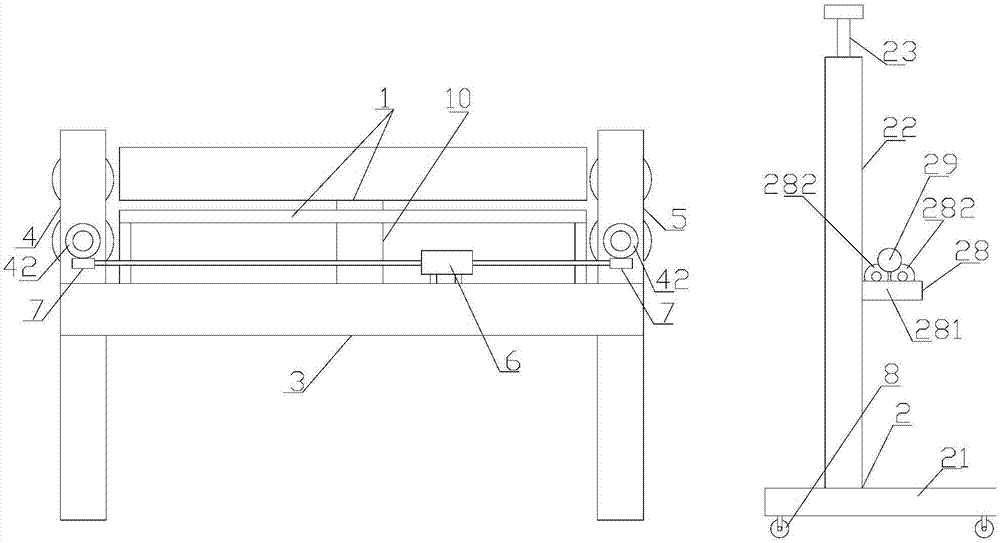

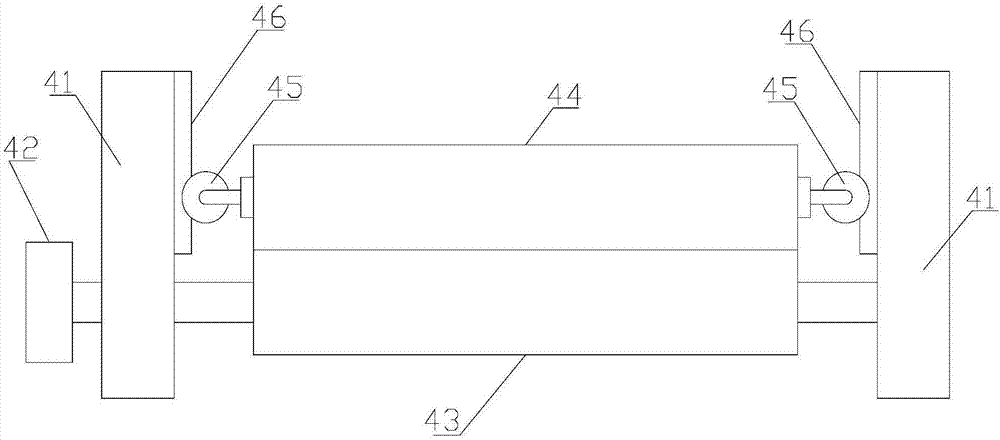

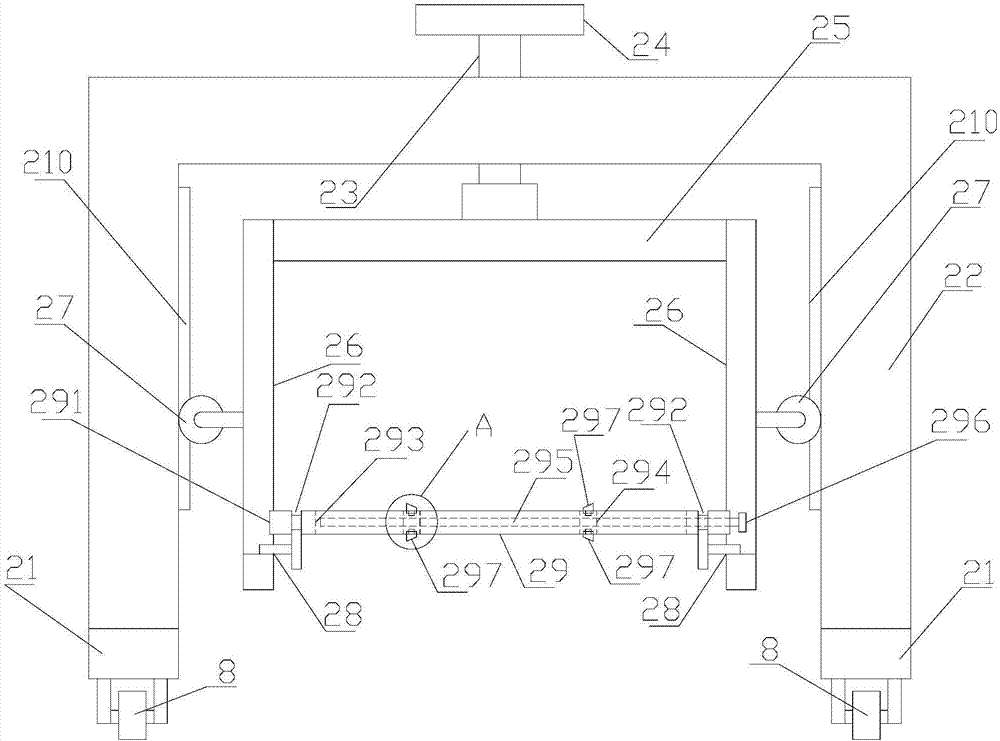

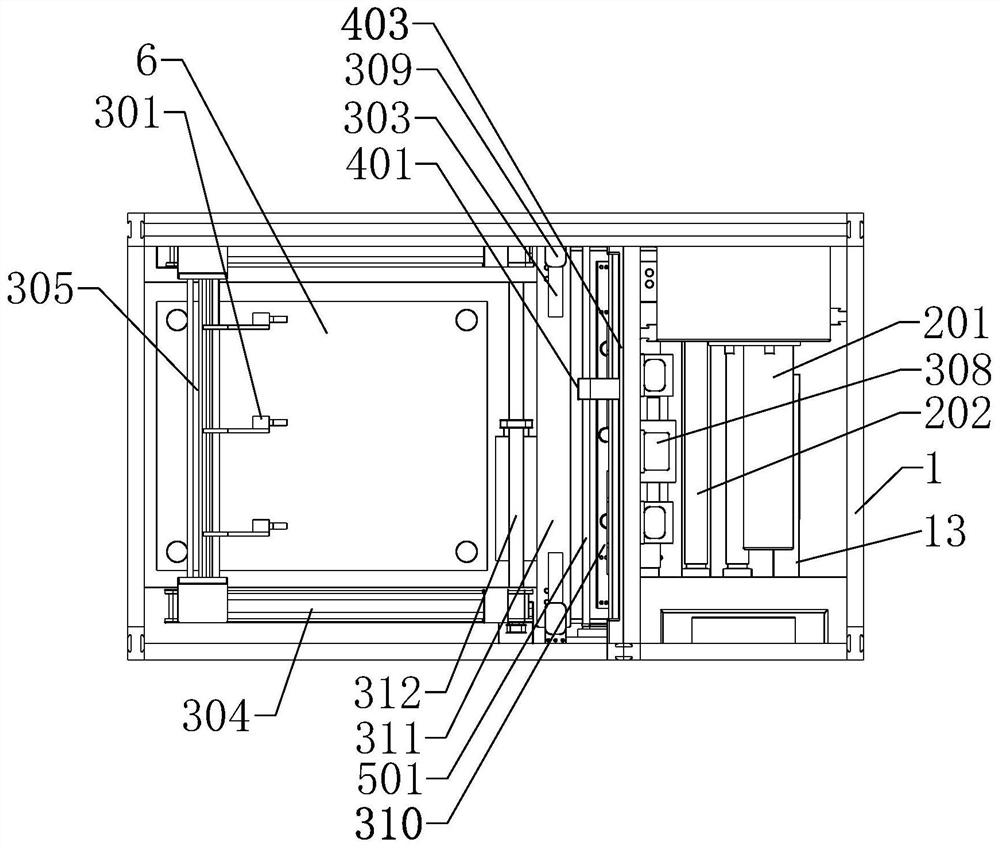

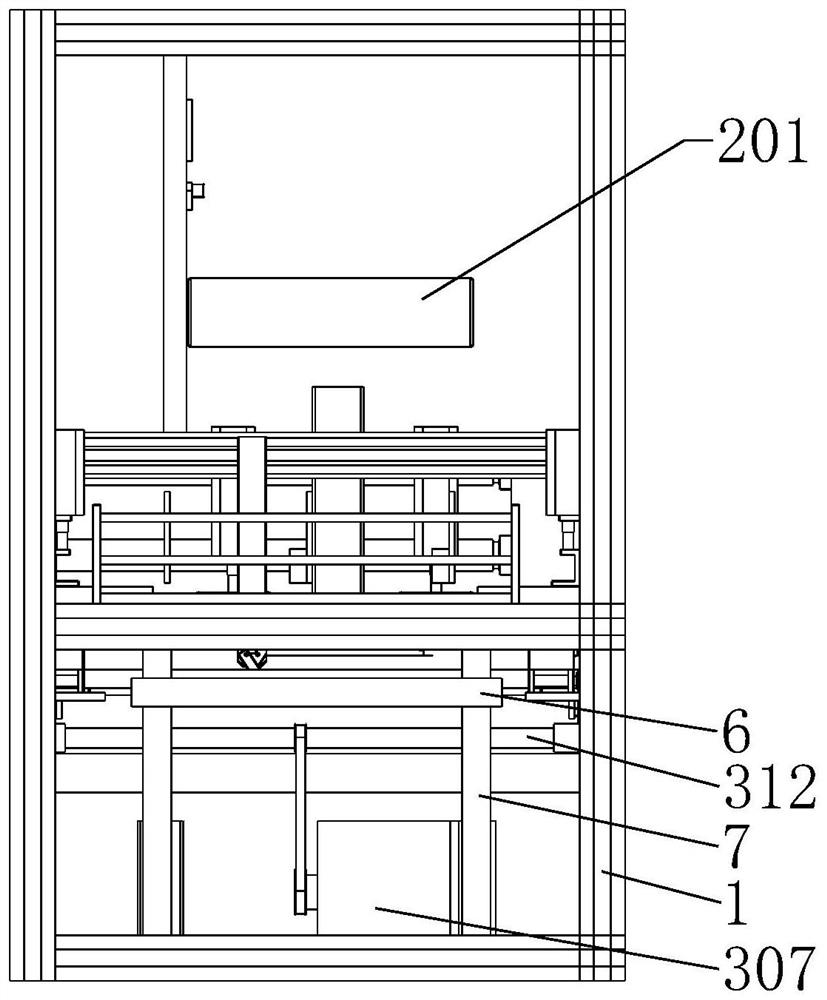

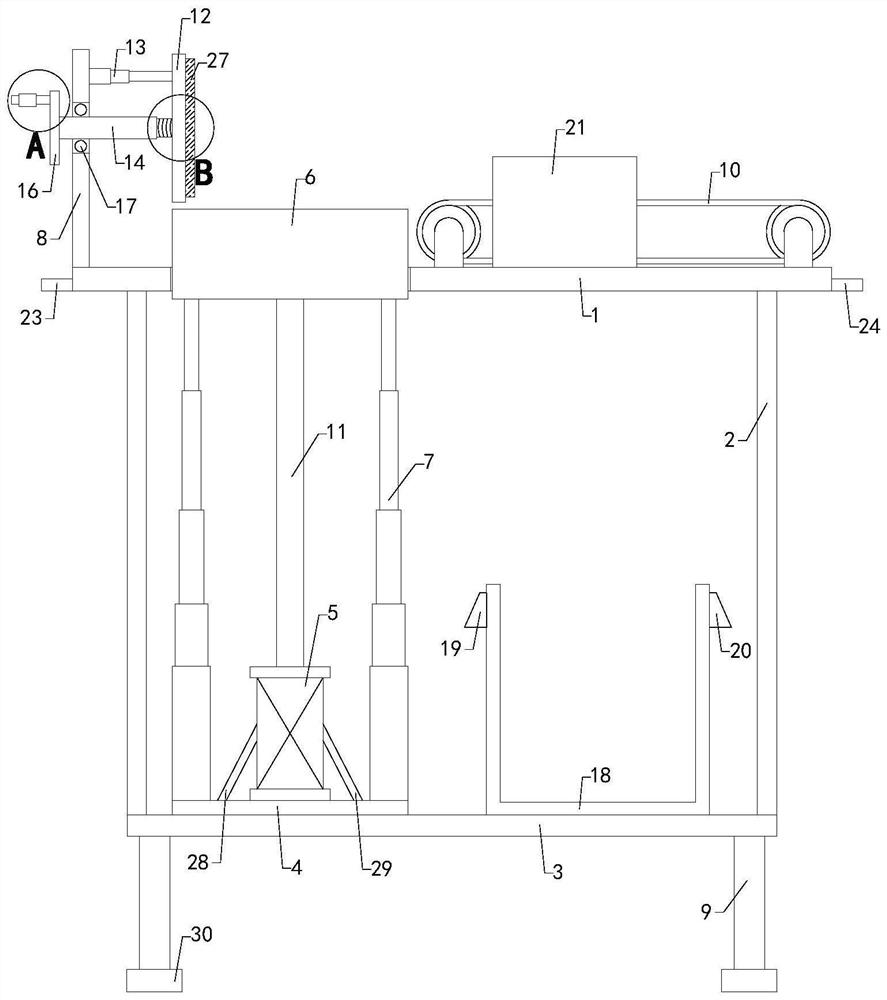

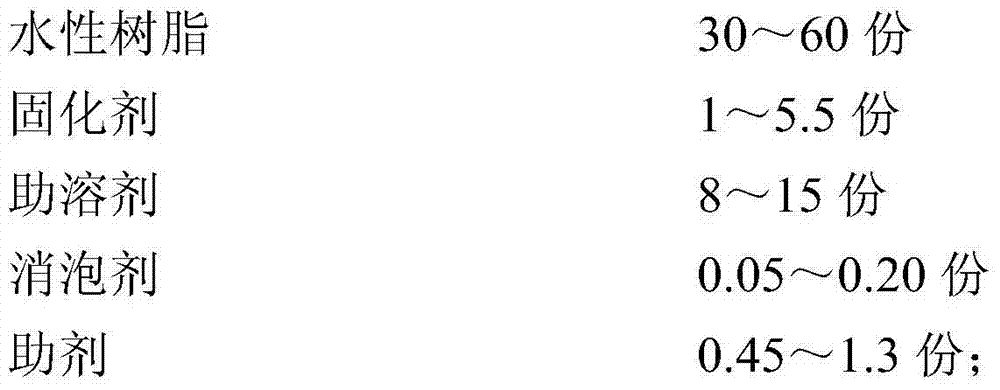

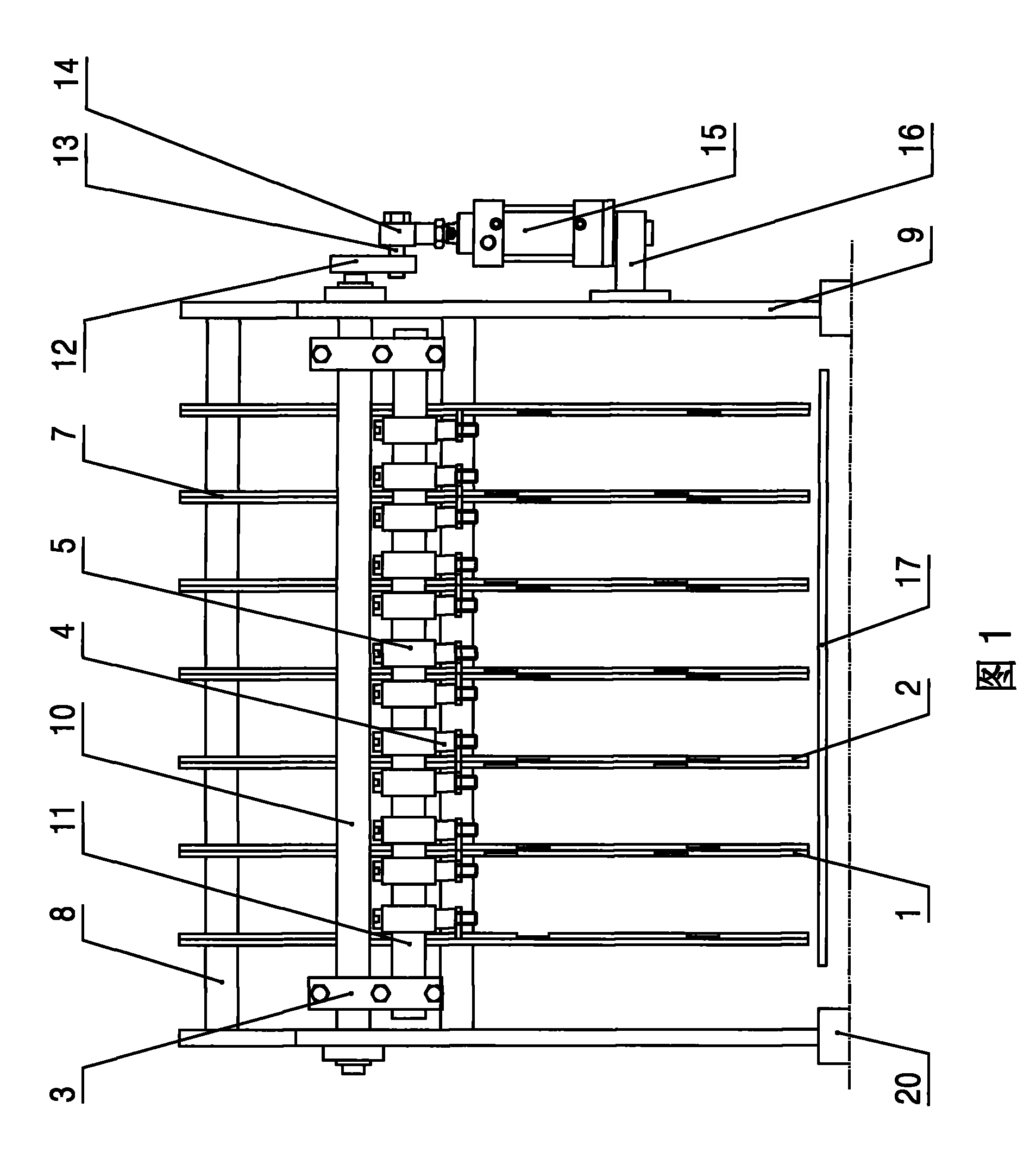

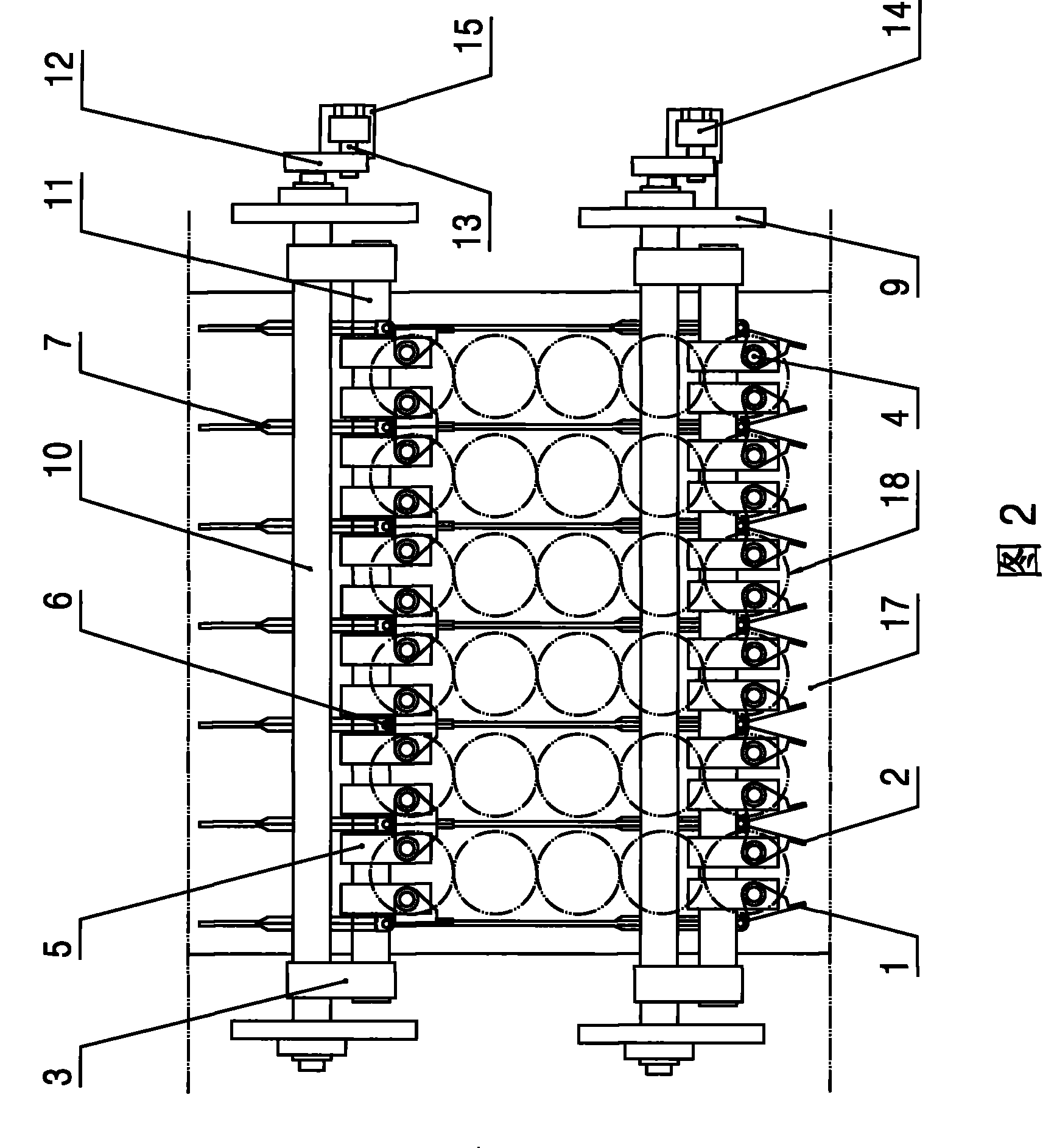

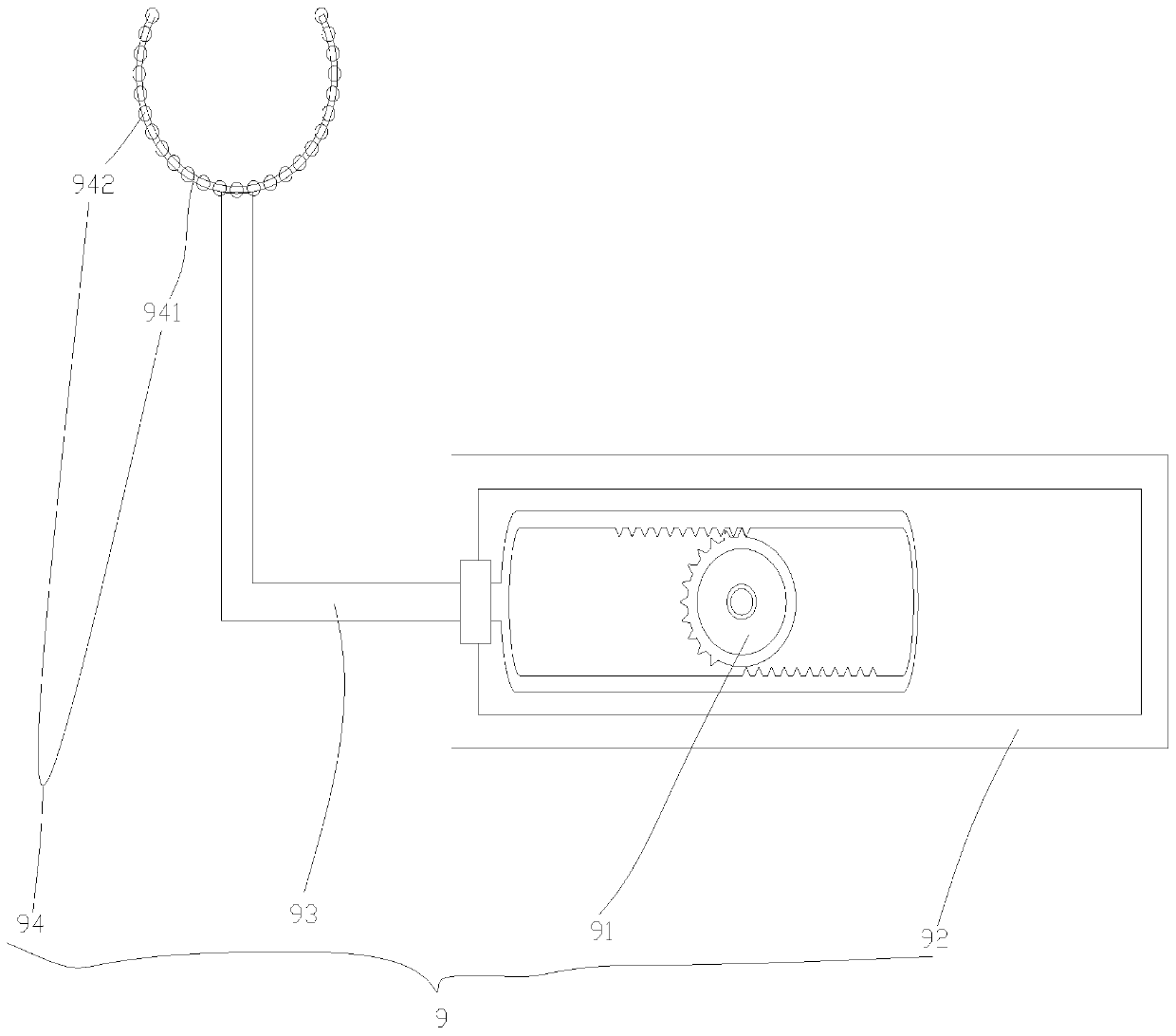

Production line for straw weaving

ActiveCN109291179AQuality improvementImprove weaving efficiencyCane mechanical workingTransfer mechanismPre treatment

The invention discloses a production line for straw weaving. The production line comprises a feeding module, a conveying module, a bundling module, a setting module, a weaving module and a receiving module, wherein the feeding module comprises a hopper and a dispersing mechanism used for dispersing straws; the conveying module comprises a transversal conveying mechanism and pre-tightening mechanisms used for pre-tightening quantified straws; the bundling module comprises a rope feeding mechanism and a bundling rope fixing mechanism; the setting module comprises setting rollers, limiting setting plates and a guide driving mechanism used for driving the setting rollers to rotate; the weaving module comprises a weaving transfer mechanism, a sewing mechanism and a shifting-forward mechanism, wherein the sewing mechanism is used for sewing a straw bundle, and the shifting-forward mechanism is used for driving a woven straw mat to shift forward; and the receiving module comprises a rolling mechanism and a cutting-off mechanism used for cutting off burrs on the surface of the straw mat. The production line is capable of realizing full-automatic feeding, conveying, pretreatment, weaving and receiving, and is capable of increasing weaving efficiency, and quality of the straw mat.

Owner:义乌市诠铈新材料有限公司

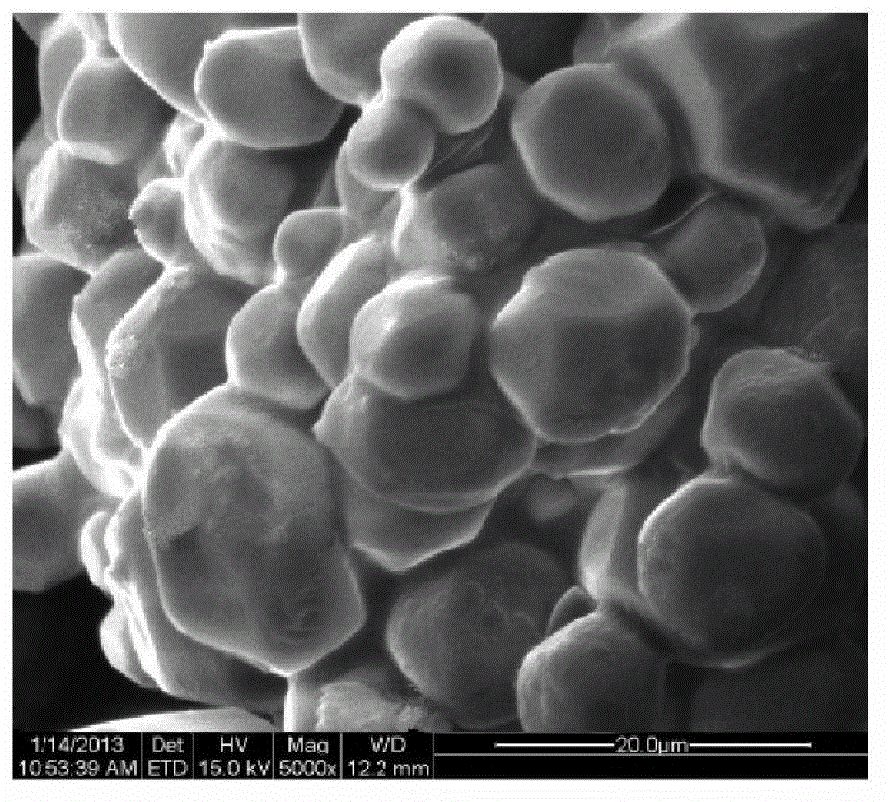

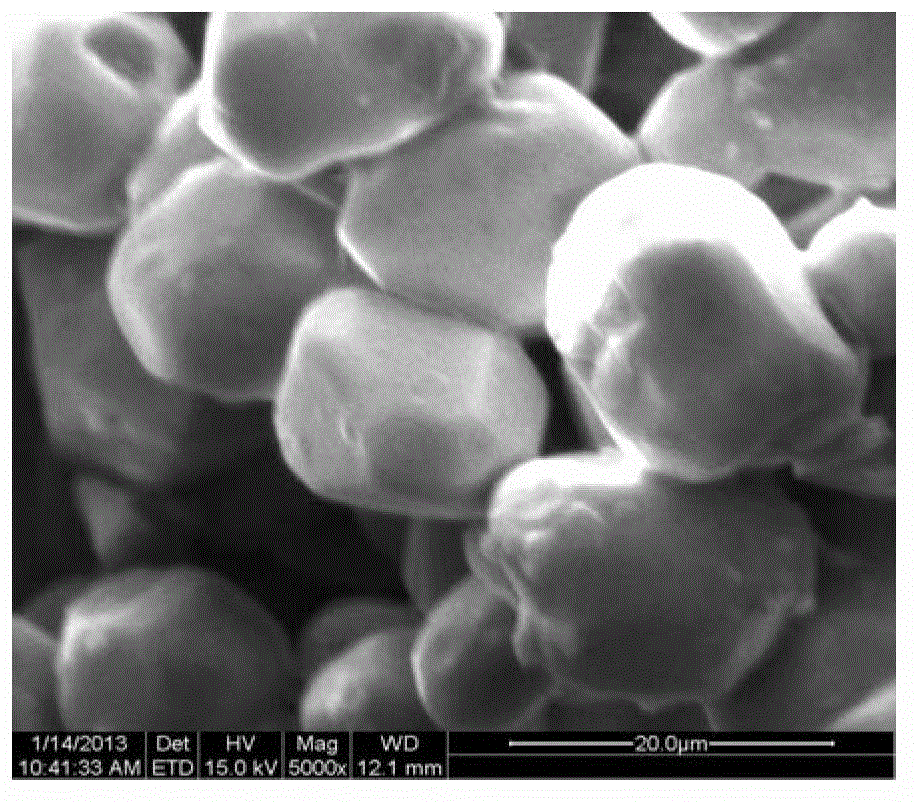

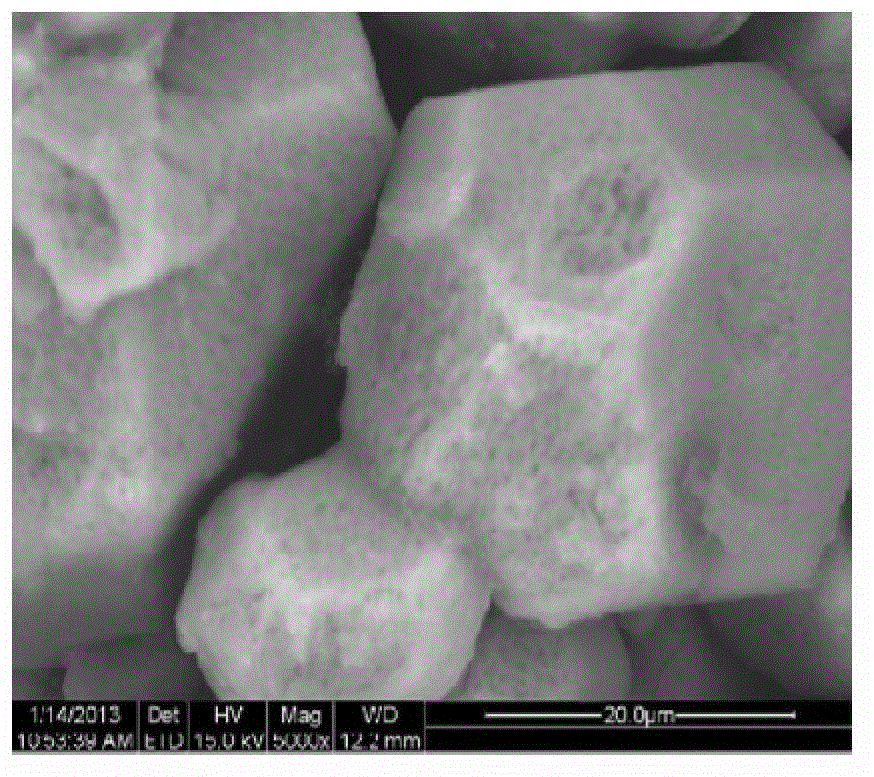

Preparation method for styrene-coated ammonium perchlorate

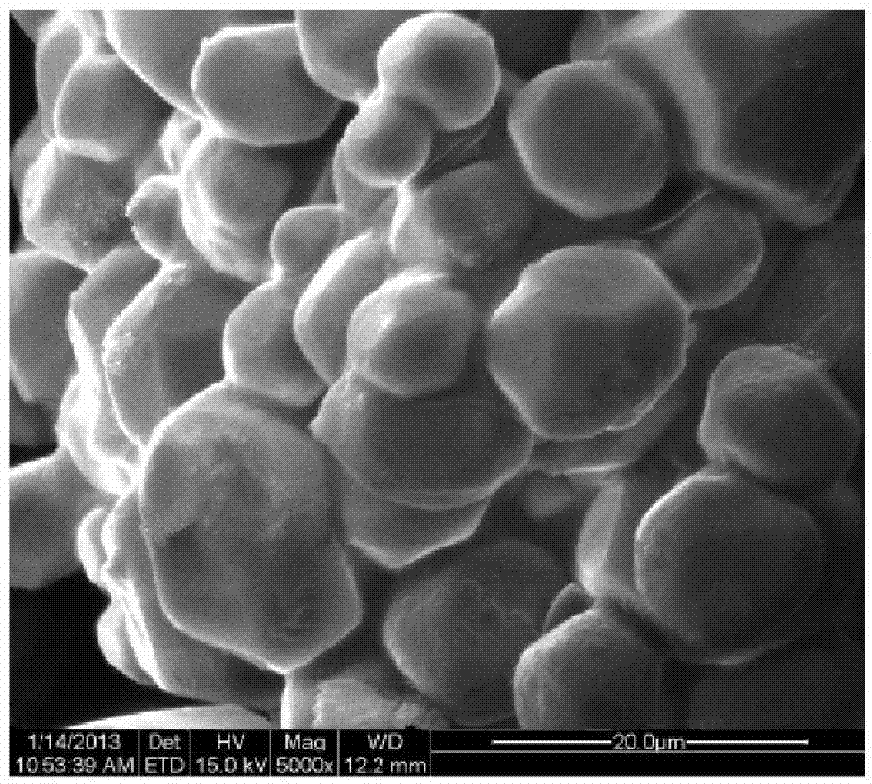

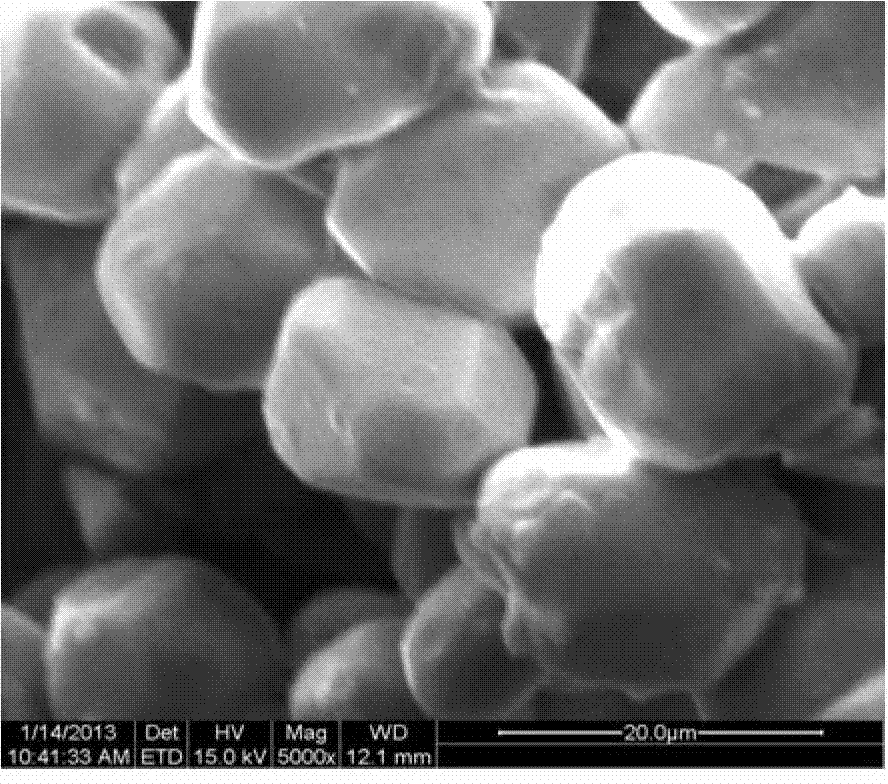

InactiveCN103086815AGood dispersionGood neatnessAmmonium perchlorate explosive compositionsAnti solventAmmonium perchlorate

The invention discloses a preparation method for styrene-coated ammonium perchlorate. The preparation method comprises the following steps of: preparing a styrene monomer; ultrasonically dispersing; coating ammonium perchlorate with the styrene; and preparing styrene-coated ammonium perchlorate. According to the preparation method disclosed by the invention, the surface of the ammonium perchlorate is coated by adopting styrene; the coating film is very thin, and the mass of the coating film is smaller than that of the ammonium perchlorate; the influence to the energy characteristic of the propellant is very small; the dispersion and regularity are good; the grain size range is 10 microns to 30 microns; the film coating thickness is controllable; and petroleum ether is adopted as an anti-solvent, so that the styrene-coated ammonium perchlorate material can be prepared within a short time. The preparation method disclosed by the invention has the advantages of being safe and reliable, convenient to operate and low in production cost. The ammonium perchlorate has spherical appearance, good dispersion and uniform grain size after being coated, and so the preparation method can be used for coating the ammonium perchlorate.

Owner:SHAANXI NORMAL UNIV

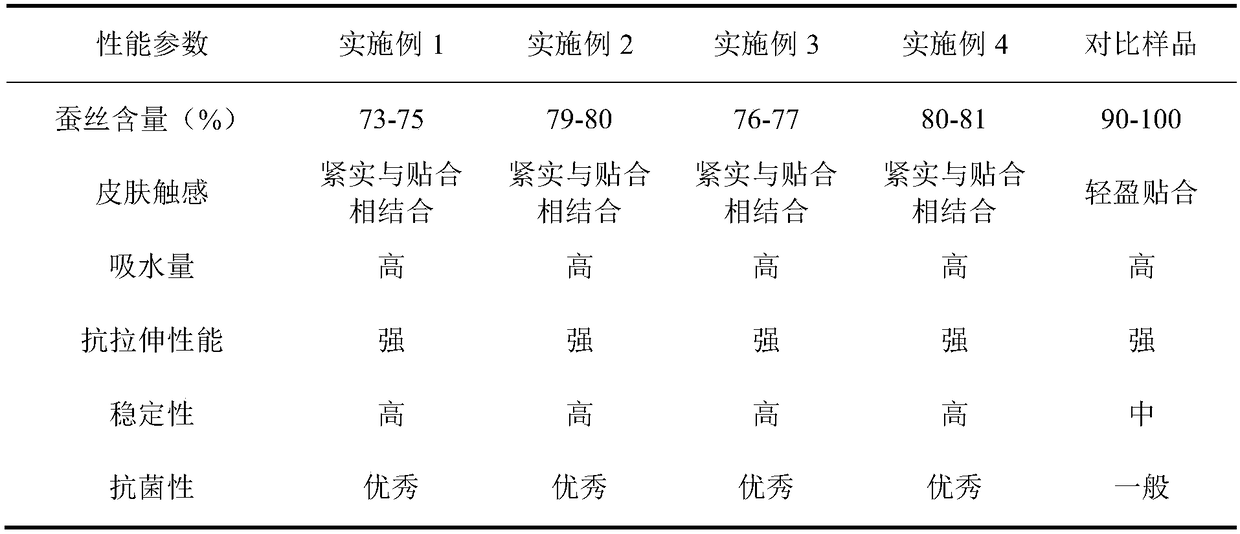

Method for preparing facial mask base material by using modified antibacterial silks as substrate

InactiveCN109183172AEvenly distributedNot easy to fall offMonocomponent fibroin artificial filamentAccessory food factorsCocooningSkin Care Product

The invention relates to the technical field of skin-care products, and discloses a method for preparing a facial mask base material by using modified antibacterial silks as substrate. The method comprises the following steps (1) preparing a nano-silver solution; (2) preparing a nano-silver matching fluid; (3) preparing nano-silver containing mulberry leaves; (4) preparing modified mulberry leaves; (5) adding the nano-silver mulberry leaves to a mount cocooning frame for silkworms developing to the fourth day of the fifth instar, and reeling silkworm cocoons until the silkworms grow to the mounting stage to obtain nano-silver-containing mulberry silks; and (6) preparing silk fibers from the silks, cross spinning cotton staples and silk fibers into a facial mask. The facial mask prepared bythe method can be applied to various facial mask products, and has an important practical significance to development of the skin-care product industry in China.

Owner:ZHEJIANG SCI-TECH UNIV

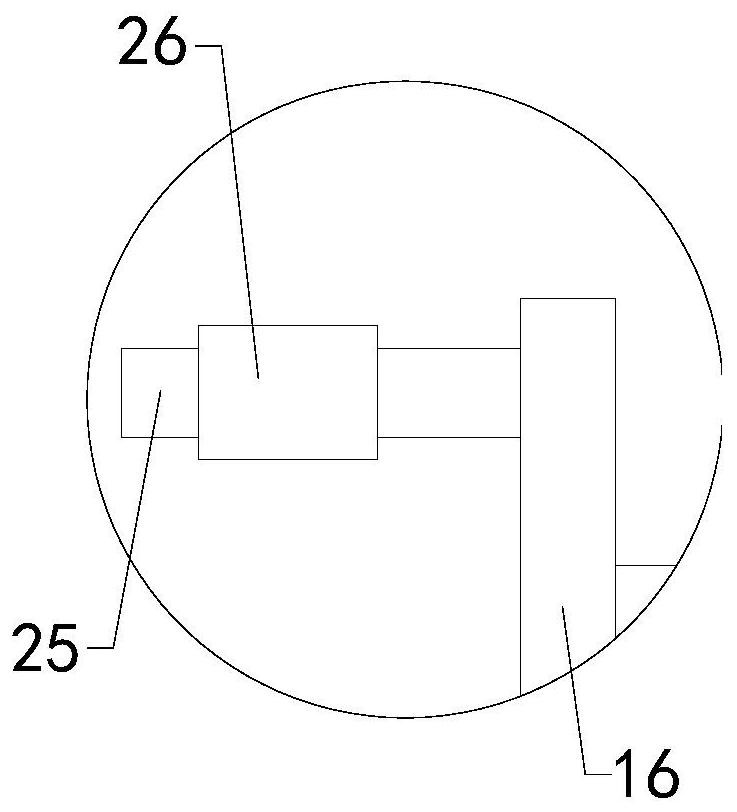

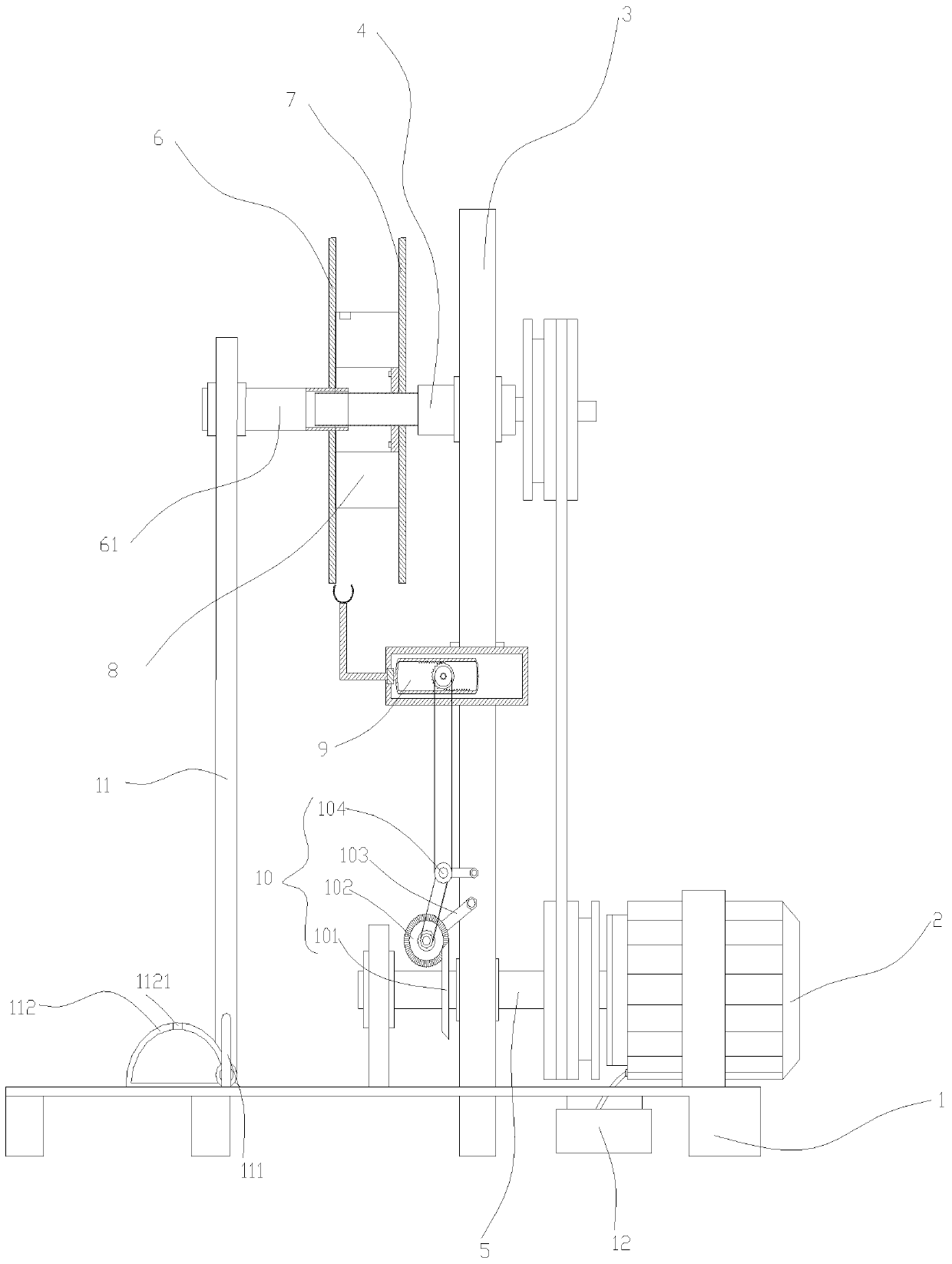

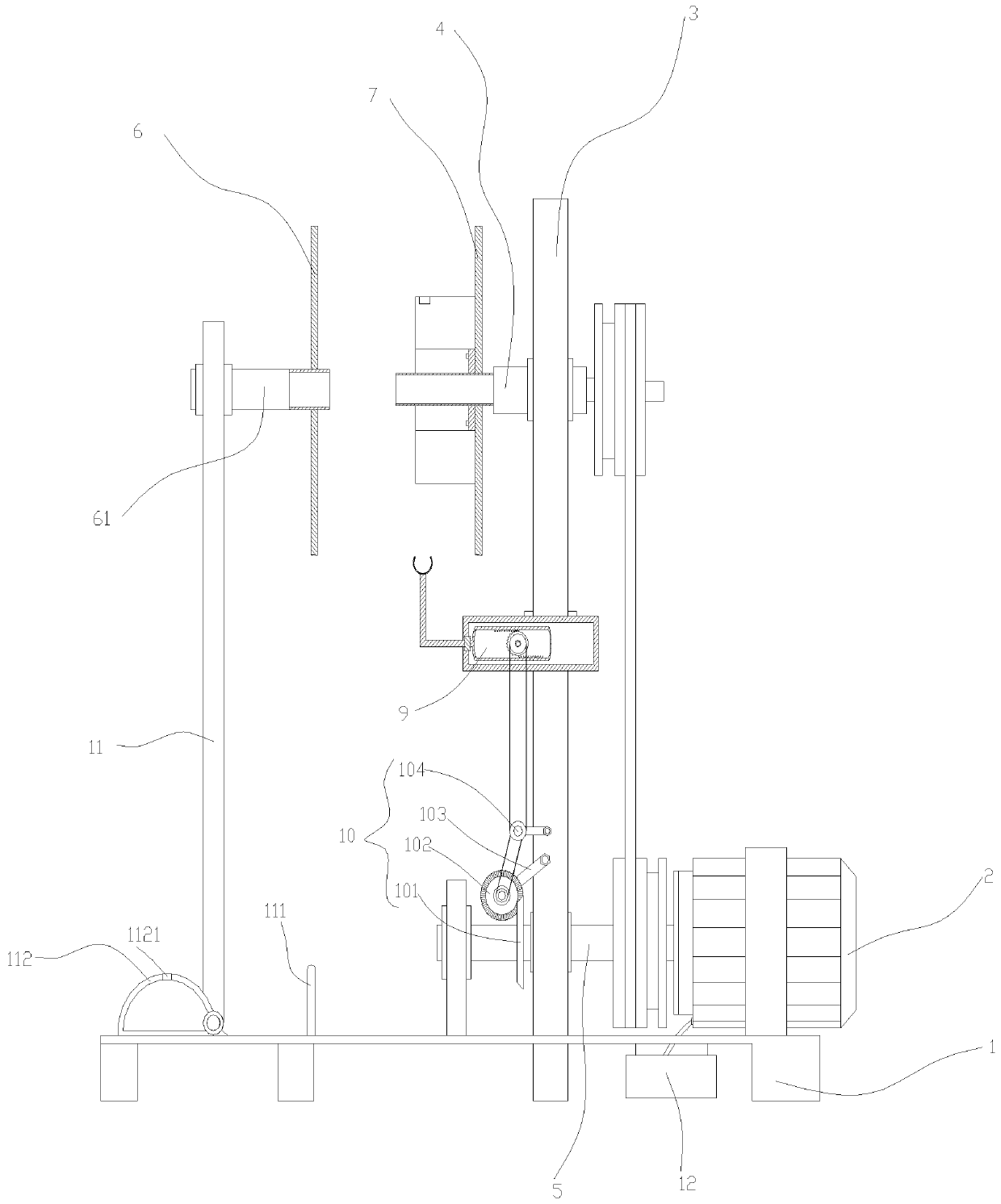

Energy-saving electronic cable winding device

The invention relates to the technical field of cable processing, and particularly discloses an energy-saving electronic cable winding device. The energy-saving electronic cable winding device comprises a base and a cable roller, wherein a supporting frame and a supporting seat are fixedly arranged on the upper surface of the base; a motor is fixedly arranged on the side wall of one end of the supporting frame; an output shaft of the motor is coaxially and fixedly connected with a driving belt wheel and a rotating shaft; an inner driving gear, a driven belt wheel and an outer driving gear which are coaxially and fixedly connected are rotationally arranged on the side wall of the other end of the supporting frame; a transmission gear and a driven gear are arranged on the supporting frame; the driven gear is coaxially connected with a rotating rod; a threaded groove rod is rotationally arranged between the supporting frame and the supporting seat; the rotating rod is nested in the threaded groove rod in a sliding mode; a sliding block is nested on the threaded groove rod; a rotating roller is arranged on the sliding block; and sliding rods are nested on the two sides of the sliding block on the supporting frame and the supporting seat in a sliding mode. The energy-saving electronic cable winding device has the advantages of being simple in structure, convenient to operate, low inmanufacturing cost, good in regularity, smooth in sliding, good in stability and convenient to popularize and implement.

Owner:GUANYUN POWER SUPPLY OF JIANGSU ELECTRIC POWER

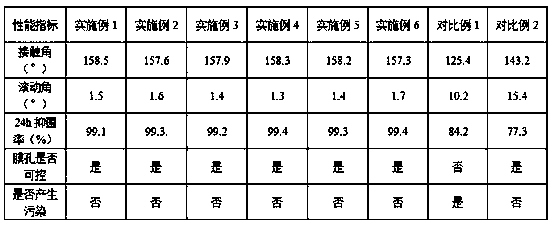

Silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane and preparation method

ActiveCN109126479AGood neatnessIncrease roughnessSemi-permeable membranesMembranesEtchingPorous membrane

The invention provides a silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane and a preparation method. The method comprises the following steps: first, preparing acellular polystyrene porous membrane according to a breath figure method, and performing reverse repeated etching by taking the polystyrene porous membrane as a template to produce a polyperfluorinated ethylene porous membrane with micro-nanograde bulge array, and further depositing a layer of etching silver nanowire orientation film on the surface of the polyperfluorinated ethylene porous membrane, thereby producing the silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane. Compared with the traditional method, the super-hydrophobic porous membrane prepared according to the method of the invention is not only large in water contact angle, small in rolling angle, and strong in super-hydrophobic capacity and self-cleaning ability, but also has high antibacterial capability; the preparation method is simple, the membrane pore structure can be dynamically controlled or regulated, and the pollution cannot be produced.

Owner:上海优梯熙光学材料有限公司

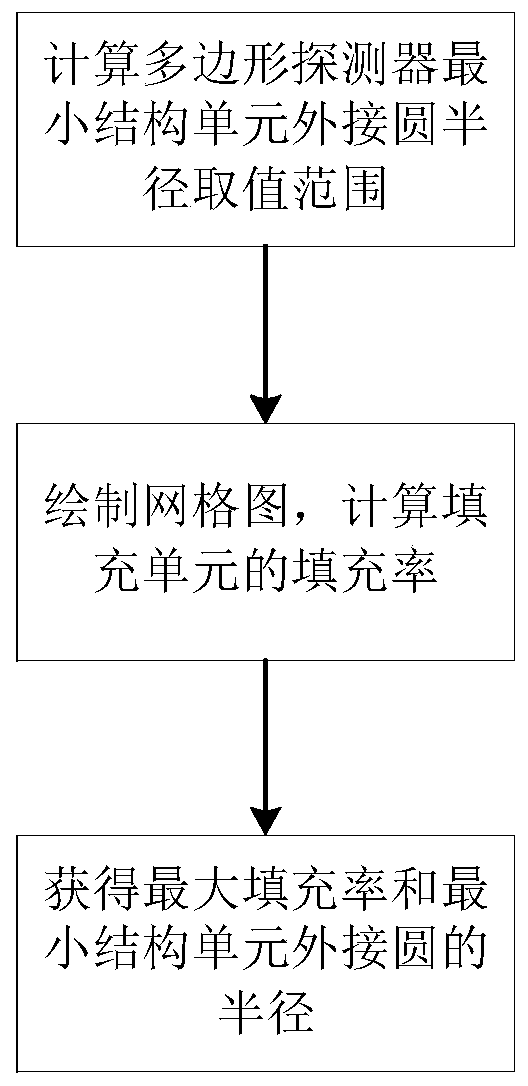

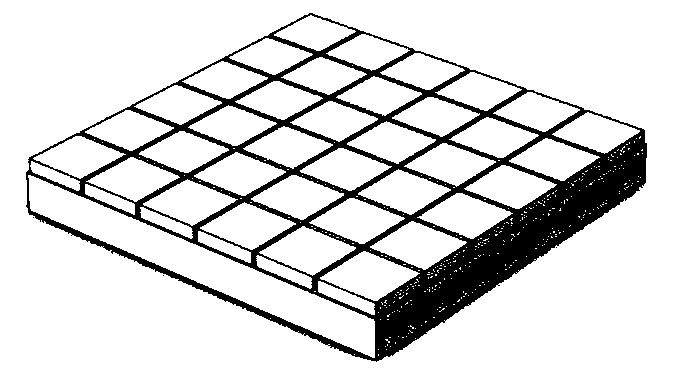

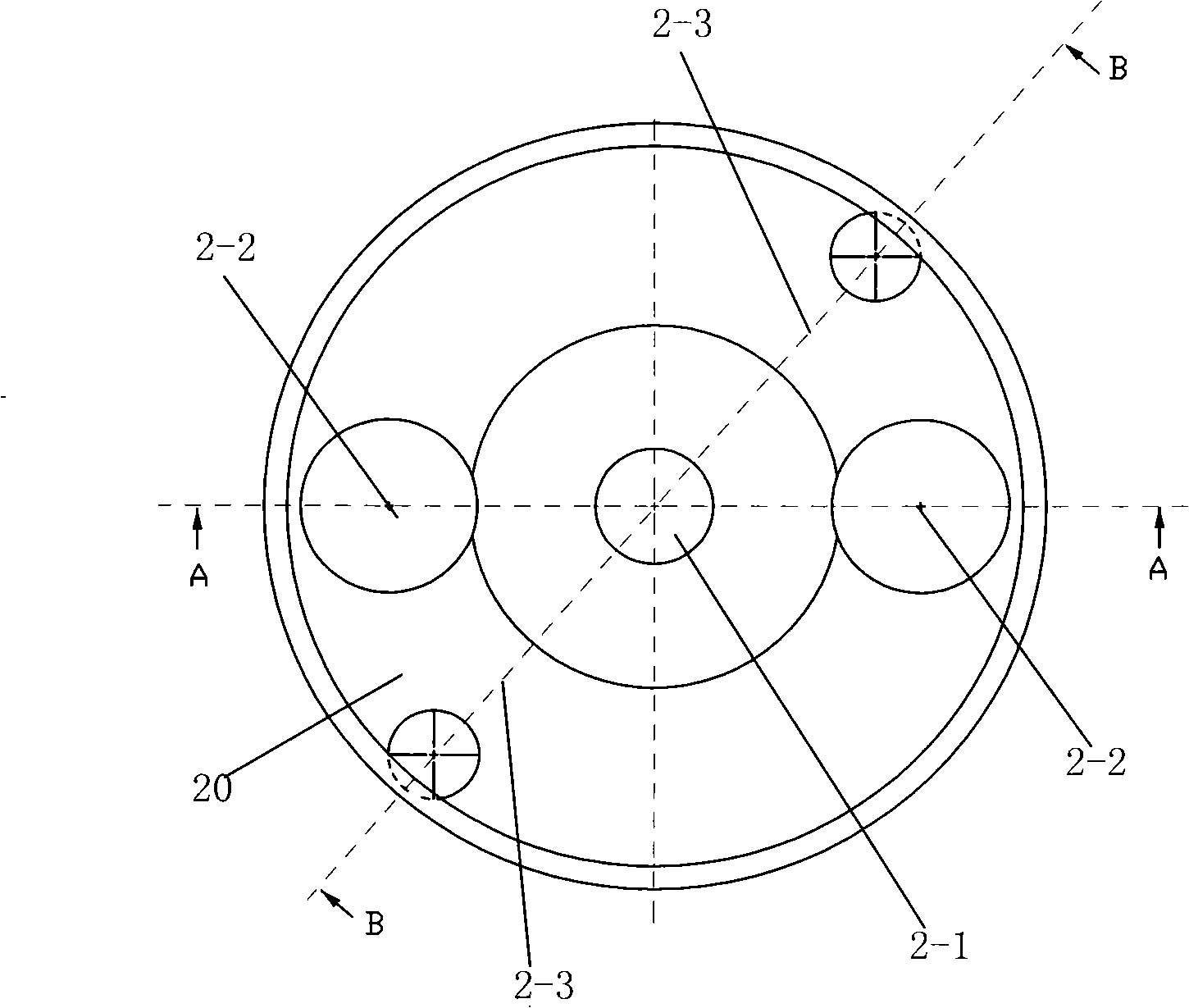

Method for optimizing layout of discrete crystals in polyhedral detector

ActiveCN110568470ACapable of decodingGuaranteed effective area utilizationRadiation intensity measurementFilling rateComputer science

The invention belongs to the field of crystal detectors, and discloses a method for optimizing the layout of discrete crystals in a polyhedral detector. The method comprises the following steps: (a) for a polyhedral detector, determining the shape of a minimum structure unit and the radius value range of a circumcircle; (b) drawing a plurality of grid charts, placing the minimum structure unit ineach grid chart, and calculating the maximum number of filling units included in the minimum structure unit in each grid chart so as to calculate the filling rate of the minimum structure unit; and (c) taking the grid size of the grid chart corresponding to the maximum filling rate in all the grid charts as the size of the circumcircle of the minimum structure unit so as to obtain the size of theminimum structure unit and the filling rate of the minimum structure unit and realize the optimization of the layout of discrete crystals in the polyhedral detector. According to the invention, the optimal layout of discrete crystals in the polygonal detector is realized, and the effective coverage area of the detector is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

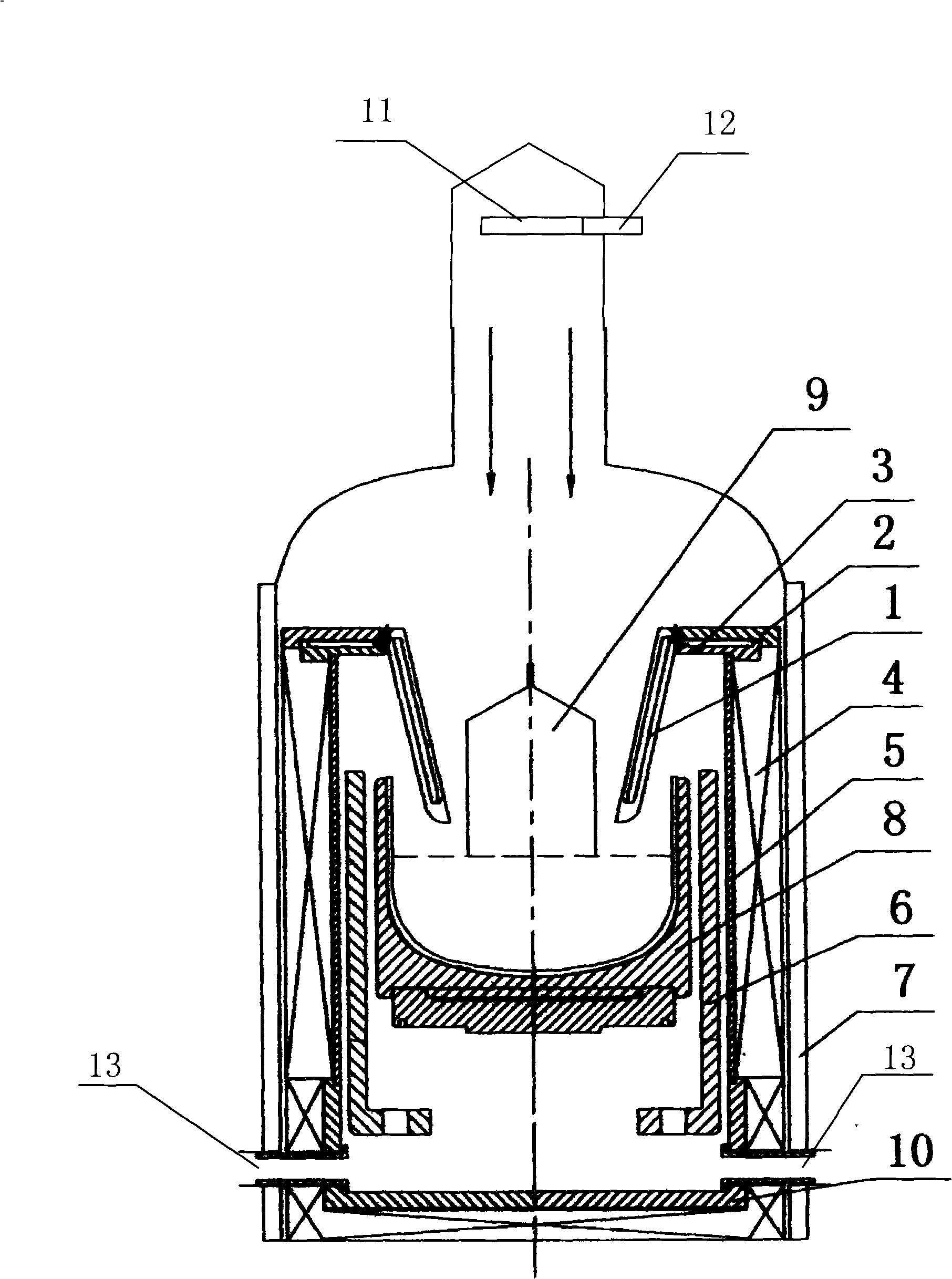

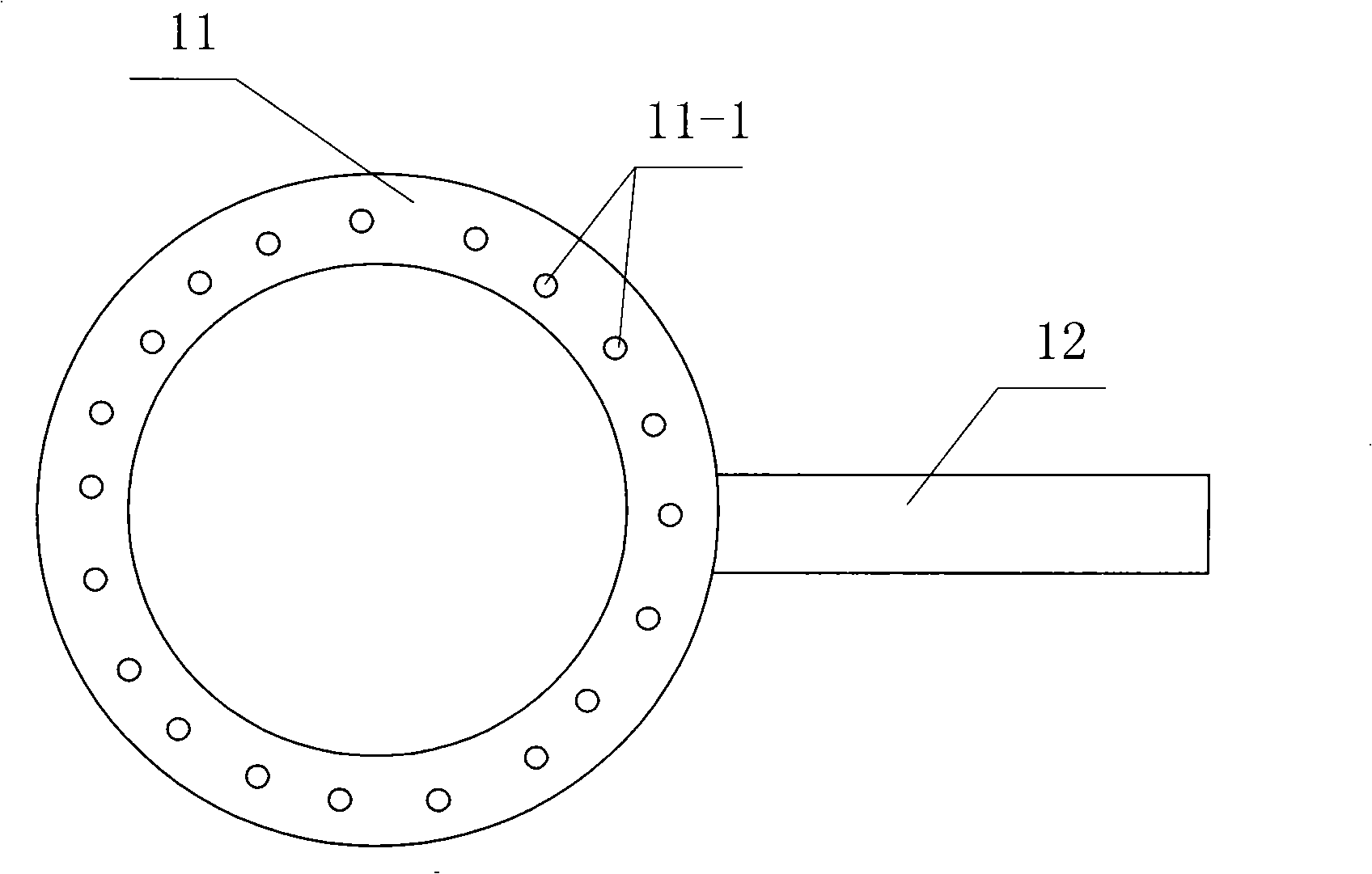

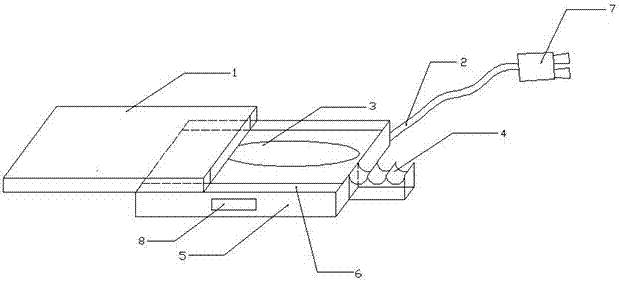

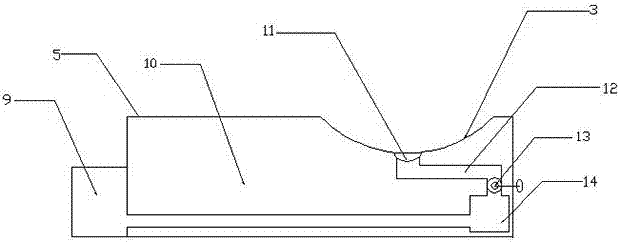

Vertical pulling type single crystal growth furnace

InactiveCN101319352AGrowth does not affectGood neatnessBy pulling from meltUnder a protective fluidGraphiteSingle crystal

The invention provides a Czochralski single-crystal growth furnace in order to solve the technical problem of reducing the argon gas consumption of the Czochralski single-crystal growth furnace. The Czochralski single-crystal growth furnace comprises an argon gas input pipe and an annular gas distributor which is communicated with the argon gas input pipe, and is characterized in that: the pressure of argon gas inputted through the argon gas input pipe is between 0.8x10 < 3 > and 0.9x10 < 3 >Pa, and the flow rate of the argon gas is 30 liters per minute. The Czochralski single-crystal growth furnace also comprises a bowl-shaped air flow guide device which is arranged between the lower part of a crucible supporter and an air outlet, wherein, the bowl-shaped air flow guide device comprises a center shaft hole, a pair of electrode holes, and a ventholes which are opposite to the air outlet; a graphite center shaft passes through the center shaft hole of the air flow guide device; electrode poles respectively pass through the electrode holes; the air outlet is communicated with the ventholes of the air flow guide device; and the upper end part of the air flow guide device is arranged between an insulated cylinder and a heating element.

Owner:常州中弘光伏有限公司

High-temperature-resistant robot crawler and preparation method thereof

InactiveCN105131248AImprove thermal deformation resistanceReduce weightPolyurethane elastomerPolyester

The invention discloses a high-temperature-resistant robot crawler and a preparation method thereof and relates to a robot crawler and a preparation method. The crawler is made of the following components in parts by weight: 100 parts of polymer polyol with number-average molecular weight of 1000 to 3000, 18 to 22 parts of polyisocyanate, 0.2 to 0.4 part of catalyst, 5 to 15 parts of chain extender, 5 to 10 parts of heat-resistant agent, 3 to 8 parts of antioxidant and 5 to 10 parts of modifier. The invention adopts regular polyester polyol with good symmetry, higher degree of functionality and high content of benzene ring and isocyanate as raw materials, uses the larger steric hindrance of ring bodies to obstruct the relative movement of molecule chain segments during heating and separates soft chain segment zones and hard chain segment zones of a polyurethane elastomer, and remarkably improves the heat-resistant deformation performance of the polyurethane elastomer.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Inkstone for ink recovery

The invention discloses an inkstone with recycled ink, which comprises an inkstone cover, an inkstone stand and an inkstone base. The side of the top of the inkstone base is correspondingly provided with a chute, and the inkstone cover and the chute are correspondingly slidably connected. An ink hole is fixed at the bottom of the ink hole, and the bottom end of the ink hole is fixedly connected to the micropump set in the inkstone base through a conduit. The micropump is electrically connected to the wire on the back of the inkstone base, and an ink container is provided , the micropump is flexibly connected with the ink container through the conduit. The present invention is novel in design and strong in practicability. The slider is more convenient to open and close by providing a chute on the inkstone base, and the normal use of the slider ensures the cleanliness of the inkstone and inkstand, which is conducive to neat writing; The pen stand is provided to facilitate the storage of the writing brush, and the clothes on the body are not easy to be soiled. The micro pump is provided, and the micro pump works, so that the remaining ink is conveniently extracted into the ink container, and the utility model is convenient for recycling.

Owner:朱石明

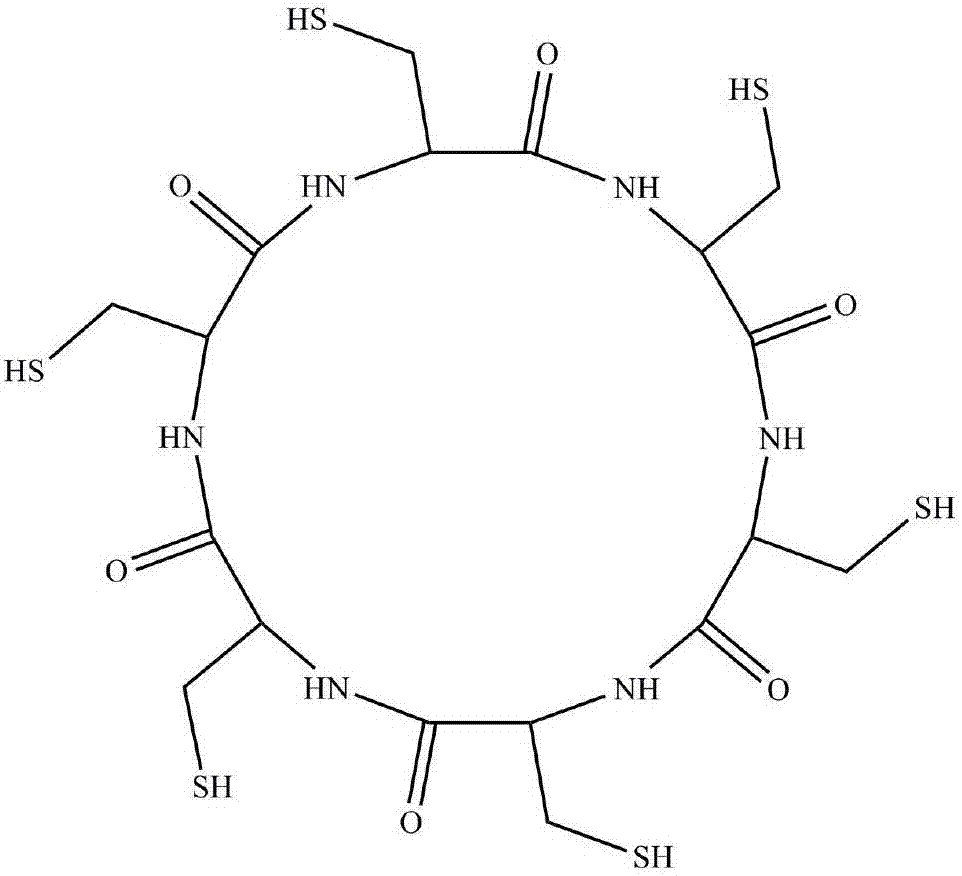

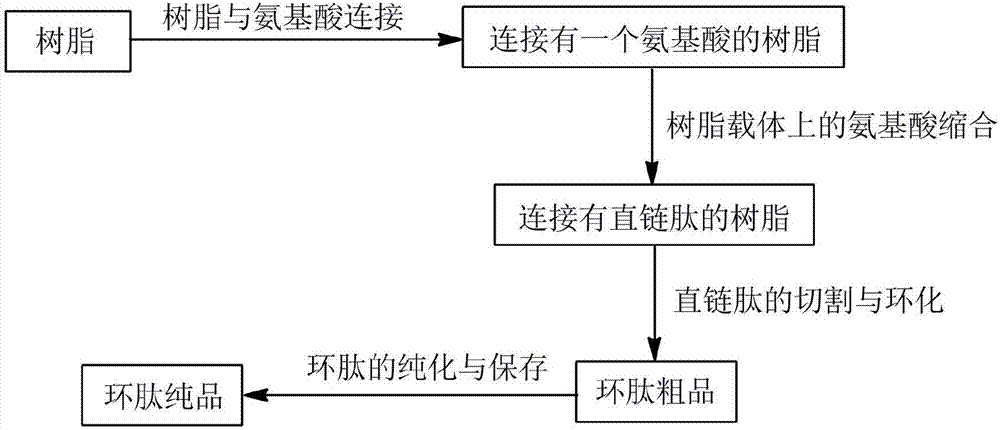

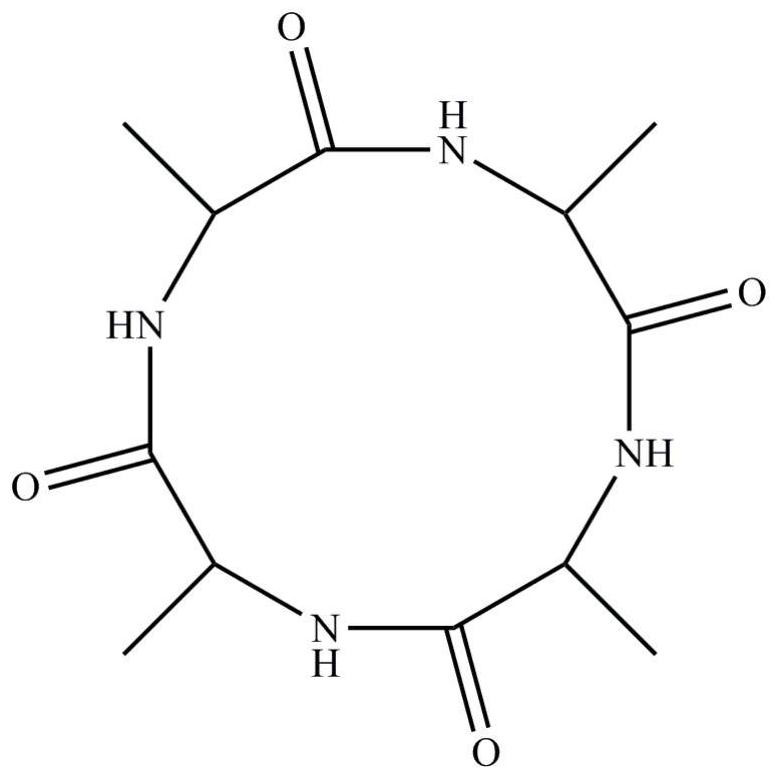

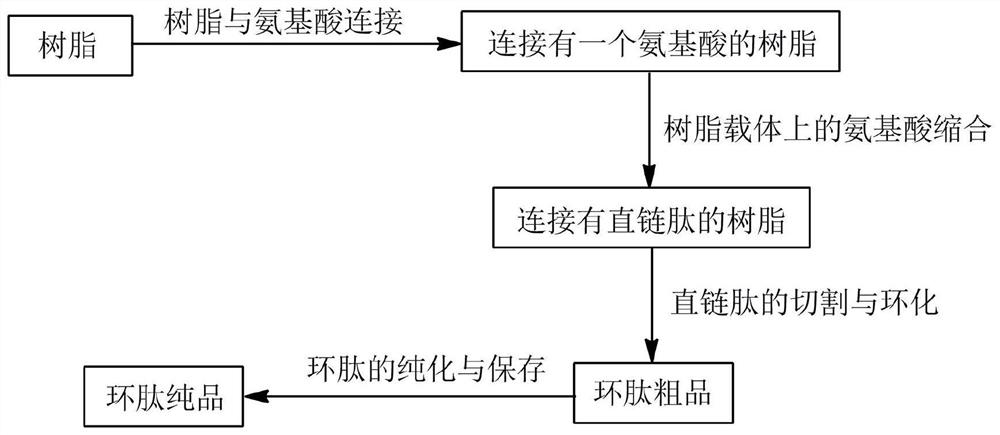

Preparation method for uniform cyclic peptide Cyclo-(Cys)6

ActiveCN107474118AGood regularity and multi-directional symmetryGood reactivityPeptide preparation methodsBulk chemical productionSide chainMembrane channel

The invention discloses a preparation method for uniform cyclic peptide Cyclo-(Cys)6. The method comprises the following steps: (1) connecting resin with cysteine with protecting group through reaction, thereby forming the resin connected with cysteine; (2) continuously condensing the cysteine connected with the resin and the cysteine with protecting group, thereby forming the resin connected with linear chain peptide; (3) cutting the linear chain peptide off from the resin, connecting end to end and cycling, thereby acquiring a crude product of cyclic peptide; (4) purifying and storing the cyclic peptide. The Cyclo-(Cys)6 prepared according to the invention is of a uniform cyclic peptide structure formed by single amino acid and has the structure similar to the structure of crown ether compound; the molecule structurally has excellent regularity and multidirectional symmetry; the cyclic peptide is easier to be self-assembled into an ion channel or a nanometer tube, so as to be used as a drug carrier, a membrane channel and a molecular device; a side chain contains a plurality of sulfydryl functional groups, so that the cyclic peptide has higher reaction activity and can be used as a precursor reagent for efficient click reaction; and meanwhile, the process is reasonable, the operation is simple and convenient and the compounding efficiency is higher.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

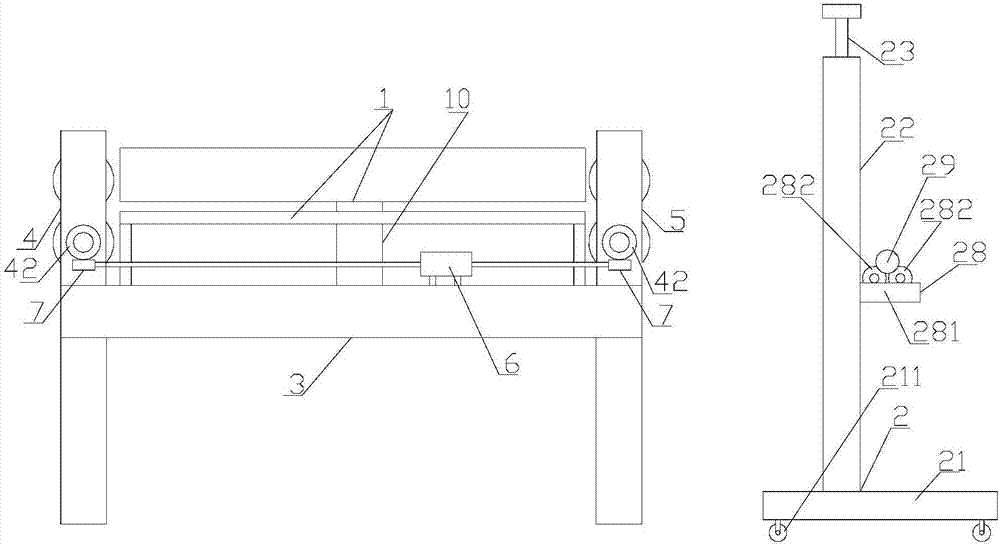

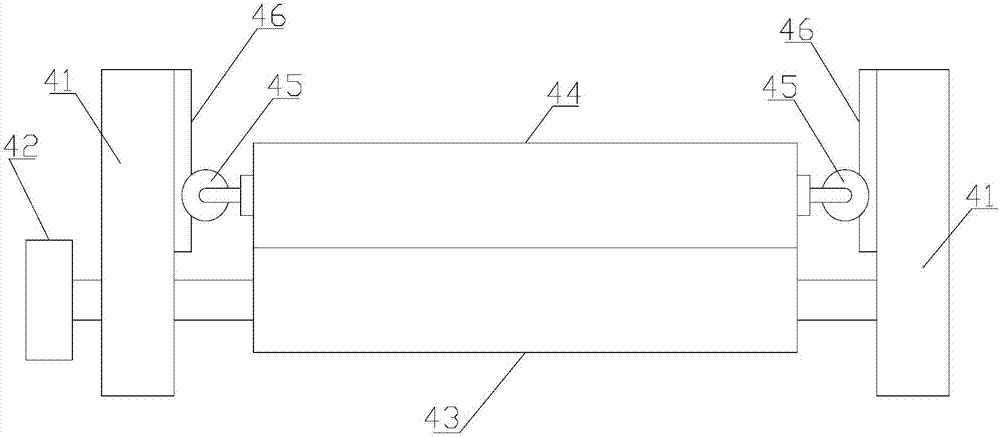

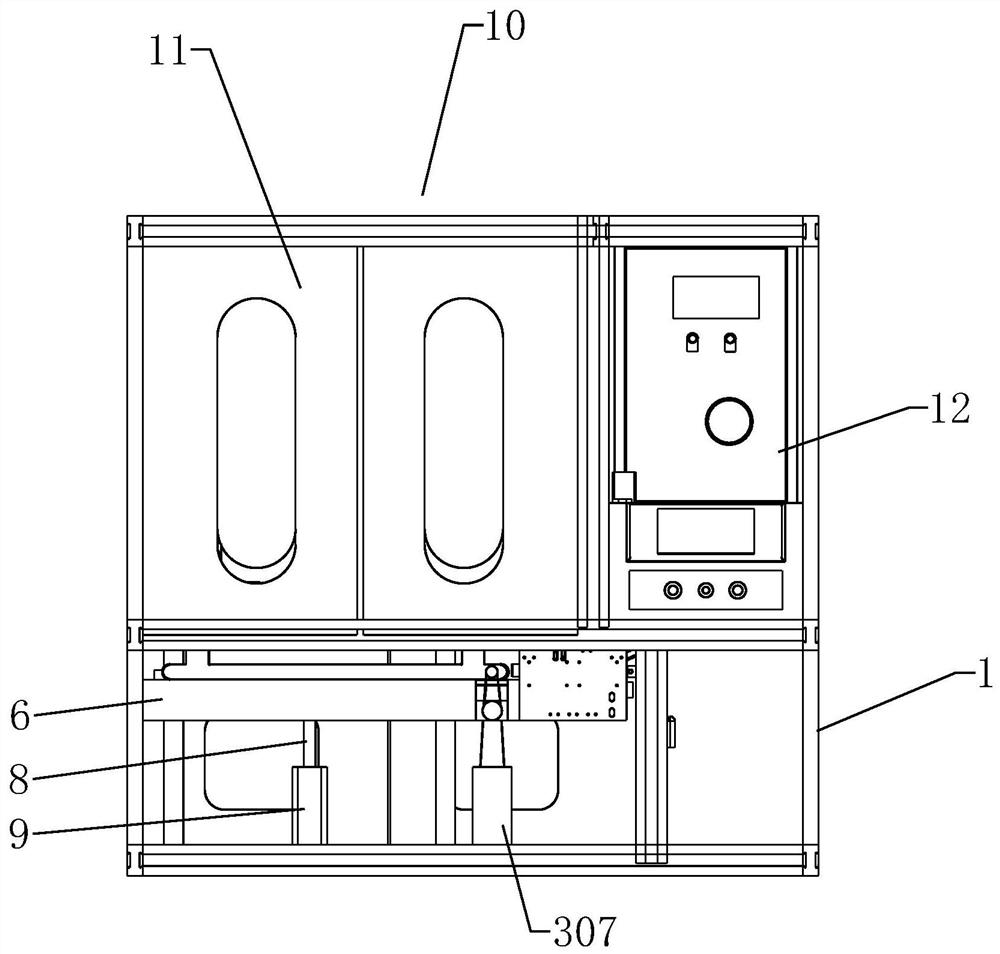

Improved cloth cutting machine used for producing clothes

InactiveCN107326643AEasy to disassemble and fixImprove reliabilitySevering textilesEngineeringMechanical engineering

The invention discloses an improved cloth cutting machine used for producing clothes. The machine comprises a cutting device, an unwinding device, a frame body, a front delivering mechanism, a rear delivering mechanism and motors, the unwinding device is arranged at the rear portion of the frame body, the front delivering mechanism and the rear delivering mechanism are arranged at the front end and the rear end of the frame body respectively, the frame body is provided with the motors for driving the front delivering mechanism and the rear mechanism, the cutting device is arranged between the front delivering mechanism and the rear delivering mechanism, and comprises an upper mounting base, an air cylinder, an upper template, a lower template, a lower mounting base and two positioning rods, the frame body is provided with a supporting pillar, the upper mounting base is arranged at the upper end of the supporting pillar, and the upper mounting base is provided with slidable positioning rods in a penetrated mode. Compared with the prior art, the work efficiency can be improved, the manual labor intensity is lowered, the completeness is high, the cloth curtain is convenient to fix and dismantle, the reliability is good, and the situation that cloth drops to the ground since the cloth curtain continues to be rotated and unwound under the effect of inertia is avoided.

Owner:王文华

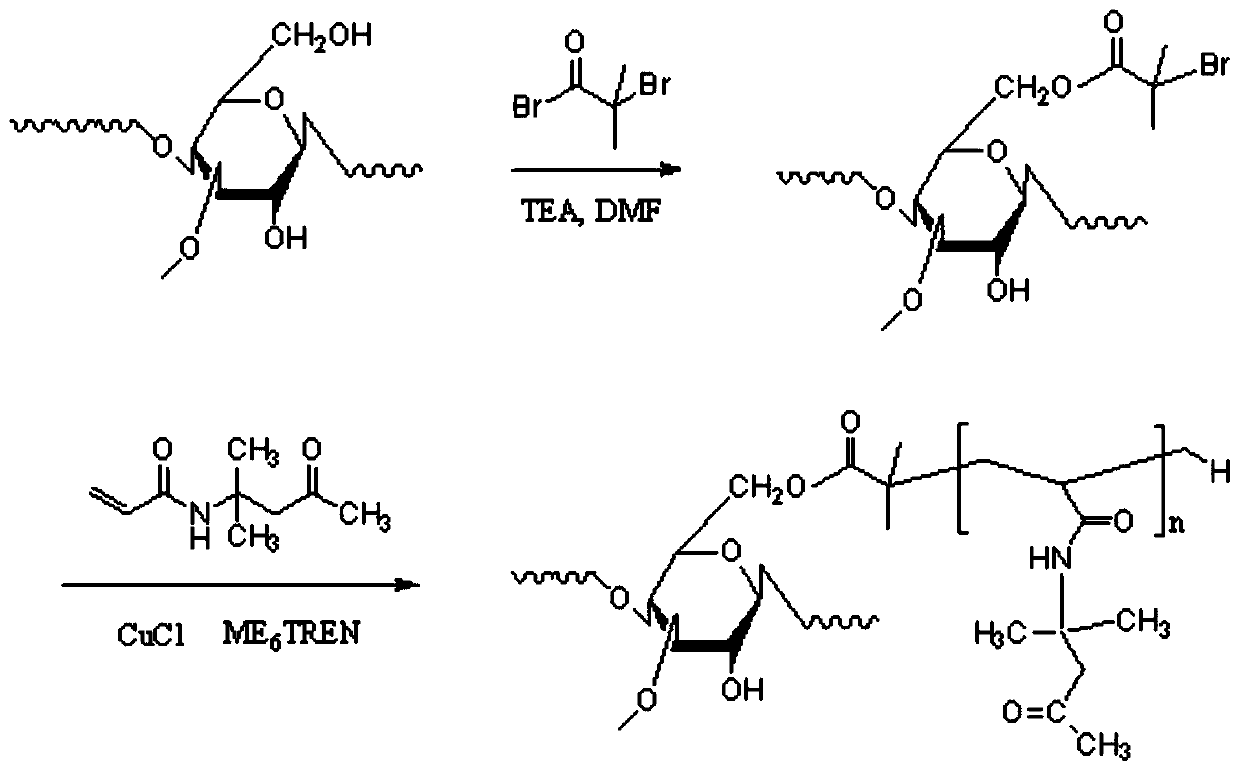

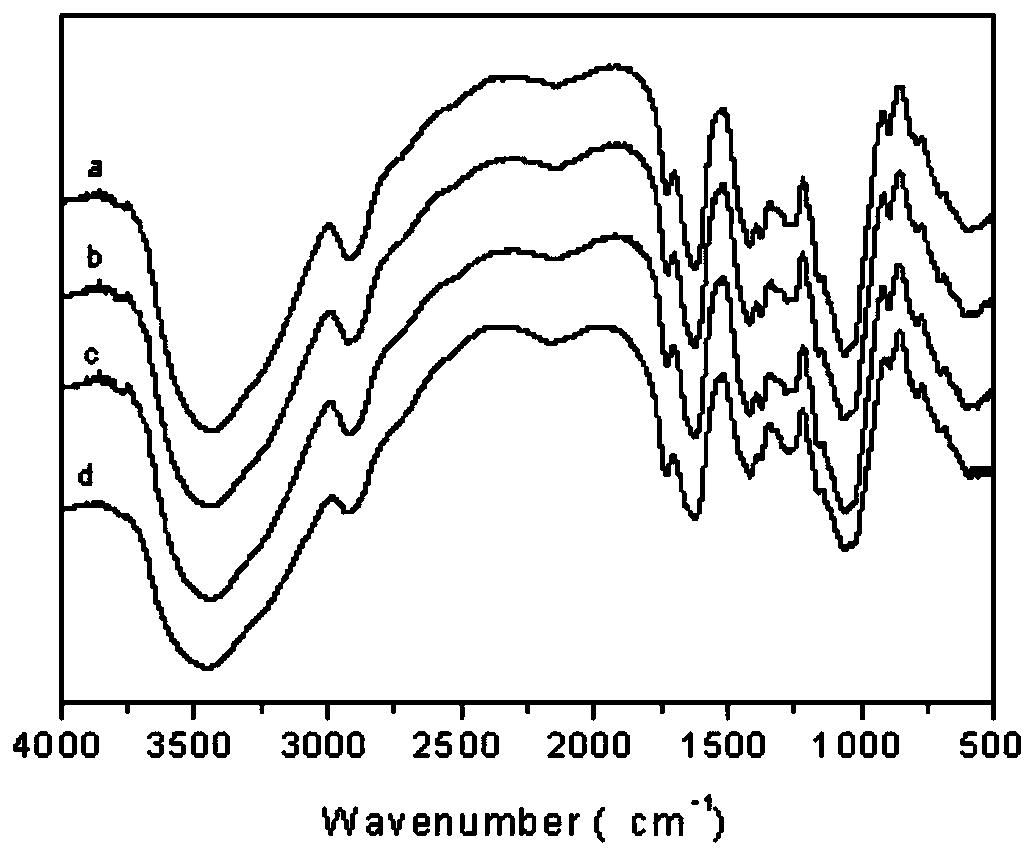

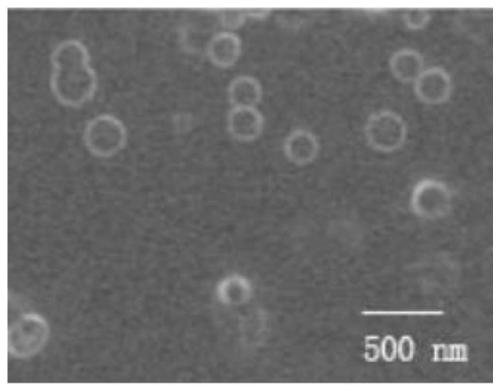

Preparation method and application of xanthan gum copolymer nano micelles

ActiveCN110302155AParticle size controllableGrafting rate controllablePowder deliveryOrganic active ingredientsN dimethylformamideBiocompatibility Testing

The invention provides a preparation method of xanthan gum copolymer nano micelles. The preparation method comprises the following steps that after degradation, dynamic viscosity of xanthan gum with concentration of 0.5w% is reduced to 110 mPa s, then after dried, crushed and screened, the xanthan gum is dissolved in N, N-dimethyformamide, a N, N-dimethyformamide solution of 2-bromoisobutyryl bromide is added, a small amount of triethylamine is added for reaction, after obtaining brominated xanthan gum through a method of precipitation, the brominated xanthan gum is dissolved into N, N-dimethylformamide, diacetone-acryloamide is added, under the condition of no oxygen, tri[2-(dimethylamino)ethyl]amine and cuprous chloride are added to be reacted, a xanthan gum copolymer is obtained througha method of precipitation, and dissolved in a polarity organic solvent to obtain a copolymer mother solution, stirring is conducted and water is dropped into the copolymer mother solution until a micelle solution is formed, and through dialysis, the xanthan gum copolymer nano micelles are obtained. According to the preparation method, the prepared xanthan gum copolymer nano micelles have good morphological regularity, good biocompatibility and stable performance as an anti-cancer drug carrier.

Owner:JIANGNAN UNIV

Preparation method for styrene-coated ammonium perchlorate

InactiveCN103086815BGood dispersionGood neatnessAmmonium perchlorate explosive compositionsAnti solventAmmonium perchlorate

The invention discloses a preparation method for styrene-coated ammonium perchlorate. The preparation method comprises the following steps of: preparing a styrene monomer; ultrasonically dispersing; coating ammonium perchlorate with the styrene; and preparing styrene-coated ammonium perchlorate. According to the preparation method disclosed by the invention, the surface of the ammonium perchlorate is coated by adopting styrene; the coating film is very thin, and the mass of the coating film is smaller than that of the ammonium perchlorate; the influence to the energy characteristic of the propellant is very small; the dispersion and regularity are good; the grain size range is 10 microns to 30 microns; the film coating thickness is controllable; and petroleum ether is adopted as an anti-solvent, so that the styrene-coated ammonium perchlorate material can be prepared within a short time. The preparation method disclosed by the invention has the advantages of being safe and reliable, convenient to operate and low in production cost. The ammonium perchlorate has spherical appearance, good dispersion and uniform grain size after being coated, and so the preparation method can be used for coating the ammonium perchlorate.

Owner:SHAANXI NORMAL UNIV

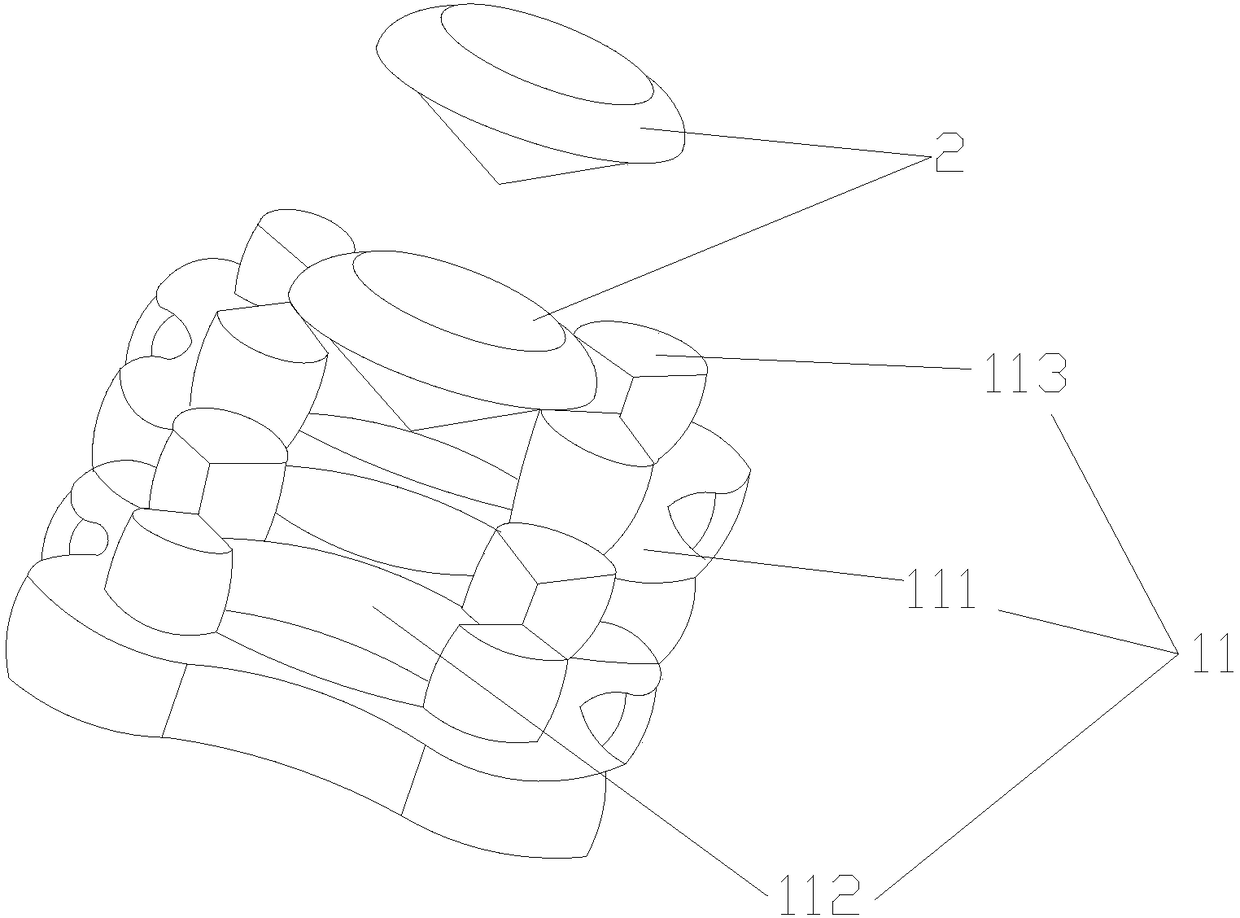

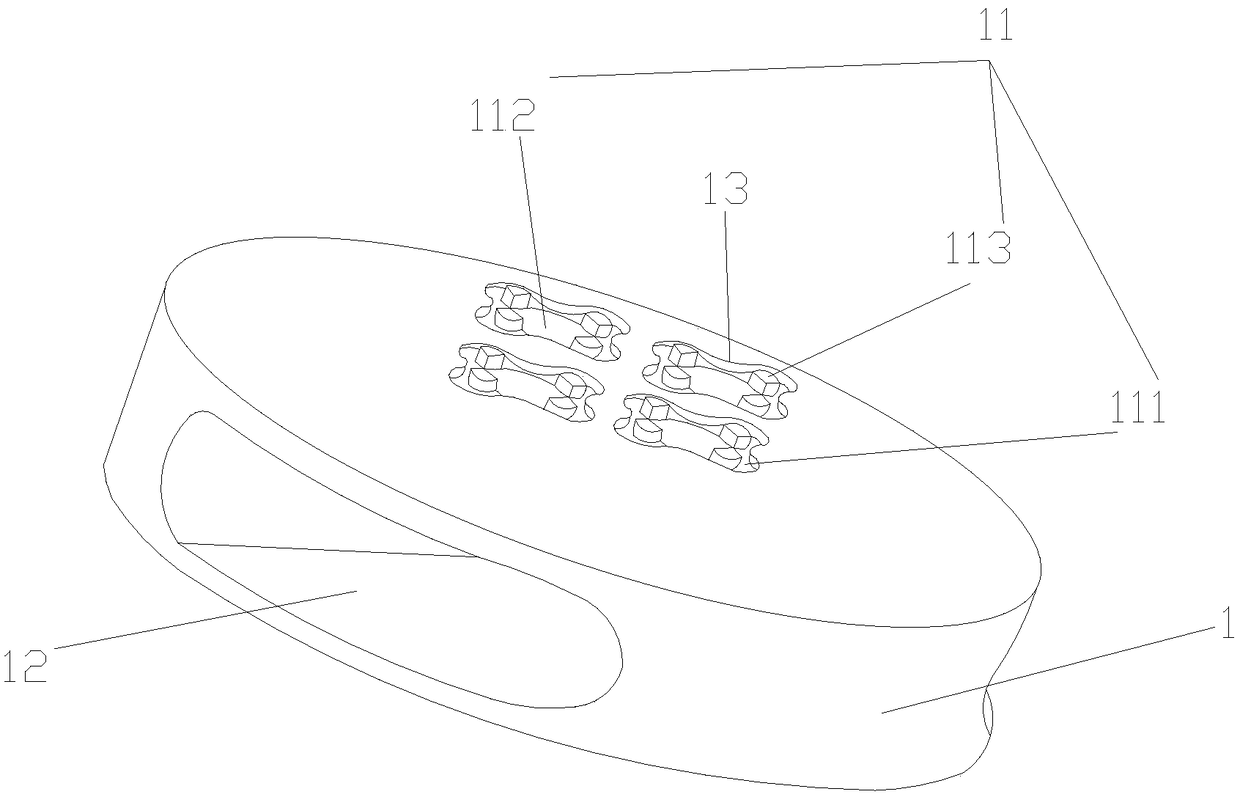

Jewelry and production process thereof

PendingCN108185596AHighlight gloss and light releasePrecise sizeJewelleryManufacturing engineeringNumerical control

The invention discloses jewelry and a production process thereof. The jewelry comprises a pendant body and precious stone, wherein an embedding assembly is arranged at the upper part of the pendant body; the precious stone is fixed on the pendant body through the embedding assembly. The jewelry can prevent the precious stone from falling off from the pendant body; clothes cannot be hooked; skin cannot be injured through being hooked by the pendant body; the luster degree and the light release degree of the precious stone can be shown to the maximum degree, so that the precious stone achieve aneffect of floating on the base; the diamond looks bigger and more brilliant; jewelry meets the requirements of a customer on the gold purity. According to the production process, the CNC (computerized numerical control) technology is used for replacing the complicated edge shoveling work procedure after the manual artificial position nailing in the prior art; the product neatness degree and the efficiency are optimized; the problems of nonuniform length and nonuniform thickness of the product are solved; the frequently occurring problems of incorrect position, out of roundness and the like due to manual operation are solved; through the process technology improvement and creation, the technical flow process is changed; the cost such as the labor cost and the production time is greatly reduced.

Owner:中科国金股份有限公司

Cloth laying machine

PendingCN113734882ARapid detectionHigh precisionUnfolding thin materialsWebs handlingElectric machineryEngineering

A cloth laying machine comprises a bedplate and a main engine, the main engine is movably arranged on the bedplate, the main engine comprises a rack and a cradle, the cradle is arranged on the rack in a left-right moving mode, an upper conveying device is arranged on the cradle, a lower conveying device and an edge aligning device are arranged on the rack, the edge aligning device comprises a controller, a cradle motor, a first sensor, a second sensor and an edge detecting sensor used for detecting the edge position of cloth, the first sensor is arranged at the middle between the upper conveying device and the lower conveying device, the second sensor is arranged on the rack and used for detecting the other end of a roller frame, and the second sensor can be triggered when the roller frame is rotated to enable a third roller shaft to press a second roller shaft. According to the cloth laying machine, the upper conveying device and the lower conveying device can pull open the cloth in the left-right direction while the cloth is conveyed so that the cloth is smooth, the detection of the edge detecting sensor is improved, the laid cloth is neat and good in effect, and the misoperation of the cradle is limited. The installation of the edge detecting sensor is convenient, the precision is high, and a cloth pressing device is low in cloth pressing noise.

Owner:石狮市一帆机械设备有限公司

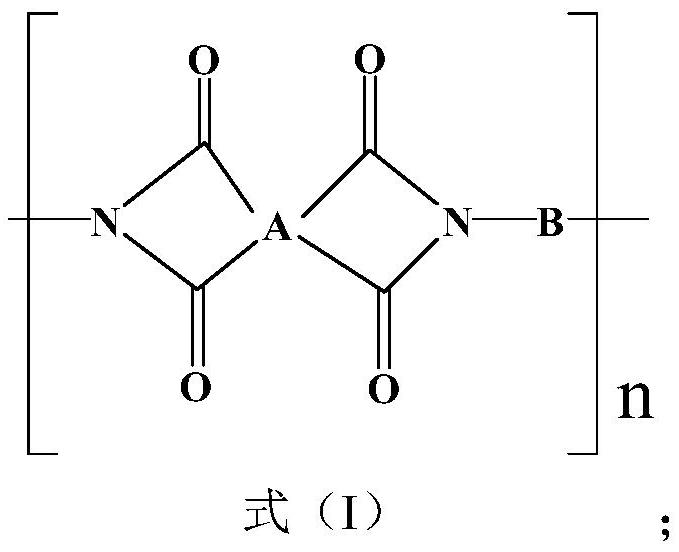

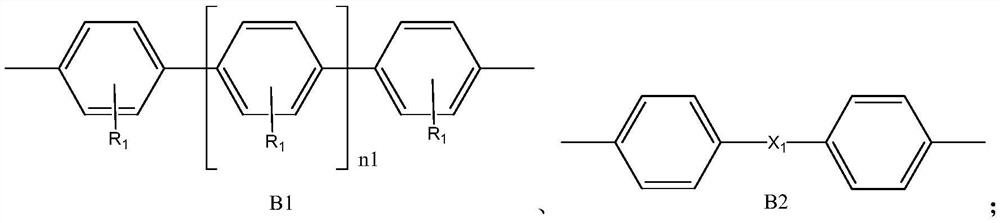

Polyimide and application thereof in metal laminated plate

ActiveCN113563585AGood neatnessImprove heat resistanceLaminationLamination apparatusPolymer scienceFlexible circuits

The invention relates to polyimide and application thereof in a metal laminated plate. The prepared polyimide has good regularity and ordered biphenyl, terphenyl and other long-chain structures; the good heat resistance of the polyimide is maintained, combination of C = O in an imide ring and a metal surface is promoted, so that adhesion between the polyimide and the metal layer is improved; with the introduction of a phenyl ester group-containing monomer, the dielectric loss can be further reduced; the polyimide can directly coat the metal layer to form a flexible copper-clad plate, the coating of a bonding layer material is not needed; the prepared flexible copper-clad plate has excellent heat resistance, peel strength and dielectric properties, and can be applied to the fields of flexible circuit substrate materials and communication.

Owner:SHANGHAI BAYI SPACE ADVANCED MATERIAL CO LTD

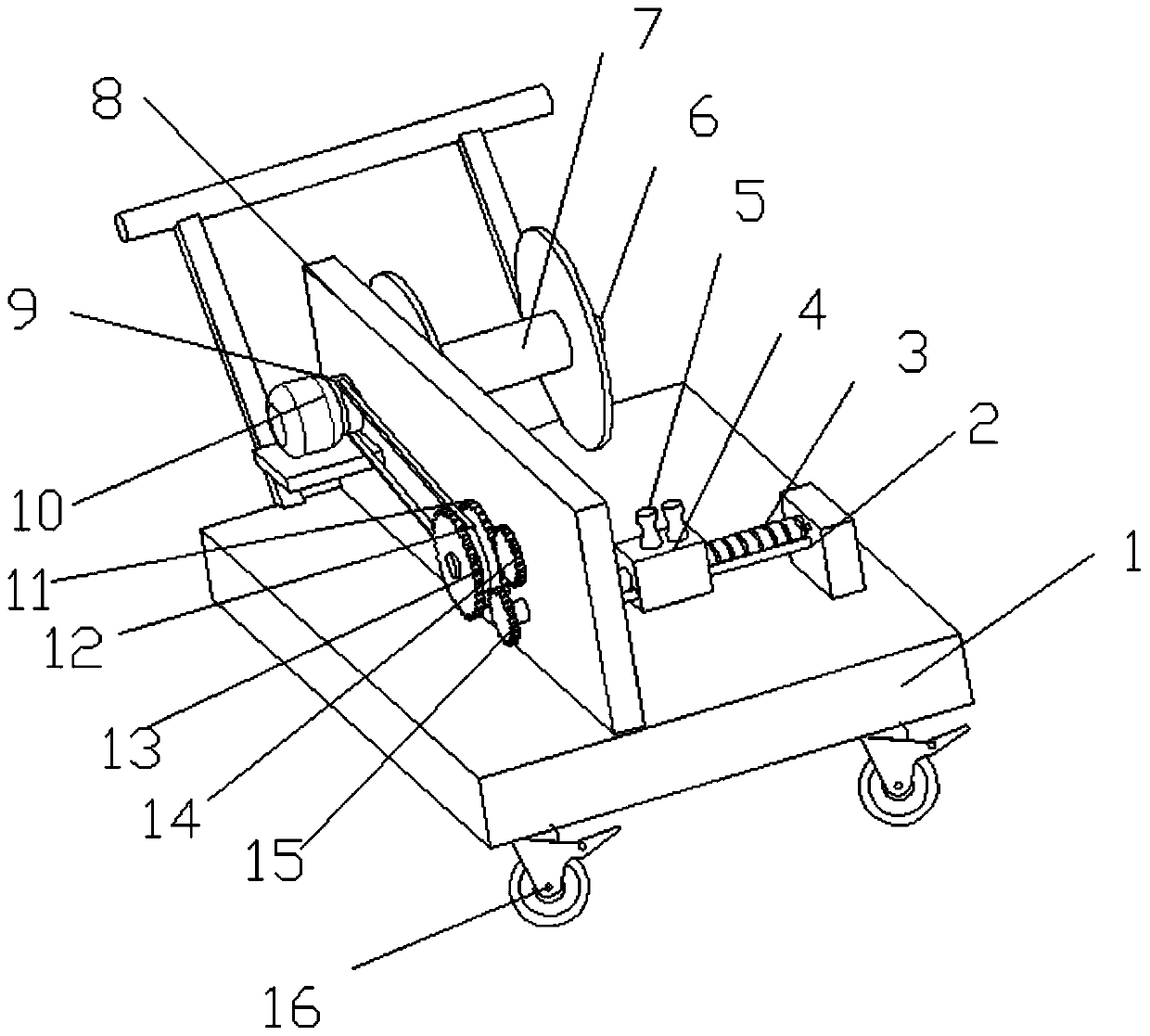

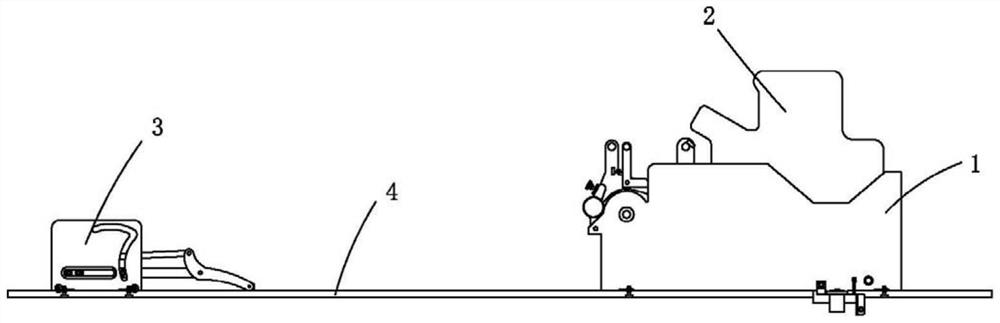

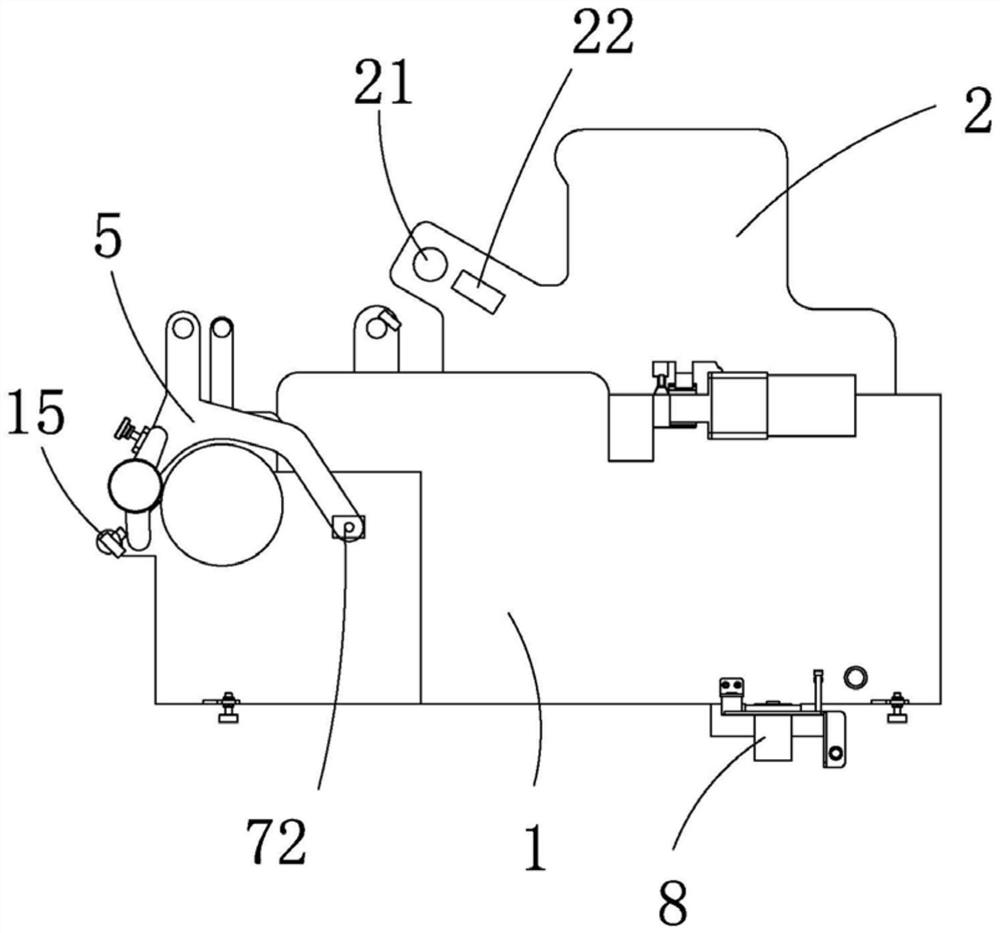

A fabric cutting machine for clothing production

InactiveCN107313238AImprove fixed reliabilityImprove work efficiencySevering textilesWebs handlingAgricultural engineeringTransfer mechanism

The invention provides a fabric cutting machine for clothing production. The fabric cutting machine comprises a cutting device, an unwinding device, a rack body, a front conveying mechanism, a rear conveying mechanism and a motor. The unwinding device is arranged behind the rack body; the front end and the rear end of the rack body are provided with the front conveying mechanism and the rear conveying mechanism respectively; the rack body is provided with the motor used for driving the front conveying mechanism and the rear conveying mechanism; the rack body is provided with the cutting device between the front conveying mechanism and the rear conveying mechanism; the cutting device comprises an upper installing base, an air cylinder, an upper die plate, a lower die plate, a lower installing base and two locating rods; the rack body is provided with a supporting pillar; the upper installing base is arranged on the upper end of the supporting pillar; the locating rods which can slide are arranged on the upper installing base in a penetrating manner. Compared with the prior art, the fabric cutting machine can increase the working efficiency, reduce the labor intensity of workers, and guarantee neatness and reliable fixation of fabric rolls.

Owner:王文华

Automatic cutting machine for protective film

PendingCN111761616AEasy to produceReduce human inputMetal working apparatusStructural engineeringMechanical engineering

The invention discloses an automatic cutting machine for a protective film. The automatic cutting machine comprises a rack and further comprises a discharging mechanism, a clamping mechanism, a cutting mechanism and a bending mechanism. The discharging mechanism is used for containing the protective film; the clamping mechanism is used for opening and fixing the coiled protective film; the cuttingmechanism is used for cutting the protective film; the bending mechanism is used for bending one side of the protective film; and the protective film is cut and folded after being treated through themechanisms, the working procedure is optimized, the whole process is automatic, manpower input is not needed, the work efficiency is high, and one machine can meet the requirement for a large amountof production.

Owner:NANJING CHINA ELECTRONICS PANDA LIGHTING

Cutting method for protective film covering surface of glass face plate

The invention relates to a cutting method for a protective film covering the surface of a glass face plate, and belongs to the technical field of glass surface film cutting treatment. The cutting method aims to solve the problem of low film attaching precision in the prior art. According to the cutting method for the protective film covering the surface of the glass face plate, the method comprises the following steps that the protective film is attached to the surface of the glass face plate for protection, and the size of the protective film is greater than that of the glass face plate; anda laser engraving cutting procedure is entered, the protective film is cooled by adopting cooling treatment, and then the redundant part, exceeding the size of the glass face plate, of the protectivefilm is cut off along the peripheral edge of the glass face plate by adopting laser engraving cutting treatment to obtain the glass face plate to which the protective film corresponding to the glass face plate in size is correspondingly attached. According to the cutting method for the protective film covering the surface of the glass face plate, the cutting precision is high, the film attaching consistency is good, and the sizes of the protective film and the glass face plate are consistent, so that the 1 to 1 attaching requirement is met, and it can also be guaranteed that damage to the glass face plate is avoided.

Owner:台州星星光电科技有限公司

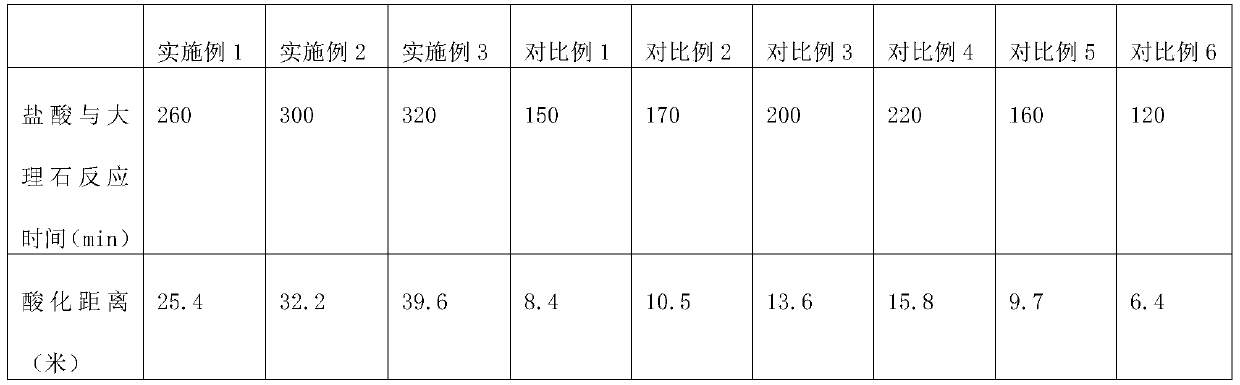

Acid-salt reaction speed reducer and preparation method thereof

InactiveCN110093148AImprove liquid diffusivityImprove acid absorption performance and speedDrilling compositionPolymeric surfaceZwitterion

The invention discloses an acid-salt reaction speed reducer. The speed reducer includes an acid absorbing polymer and a coating agent arranged on the surface of the acid absorbing polymer; and the acid absorbing polymer includes 25-35 wt% of a cationic polymer, 30-40 wt% of an anionic polymer and 30-45 wt% of a zwitterionic polymer. The speed reducer includes the acid absorbing polymer and the coating agent arranged on the surface of the acid absorbing polymer, the cationic polymer, the anionic polymer and the zwitterionic polymer are cooperatively used as the acid absorbing polymer, so that the liquid diffusivity of the acid absorbing polymer can be enhanced, and acid absorbing performance and speed can be increased; and through the arrangement of the coating agent on the surface of the acid absorbing polymer, the acid absorbing performance of the speed reducer can be further enhanced, and the regularity and compression resistance of the speed reducer can be improved.

Owner:NANTONG KEYI CHEM

Automatic packaging box sorting device of production line

The invention relates to the technical field of sorting system accessory devices, in particular to an automatic packaging box sorting device of a production line. The sorting device can adjust the position of a limiting structure according to the size of a packaging box to play a good neatening role, and can collect sundries. The sorting device comprises a workbench, four stand columns, a bottom plate, a fixing plate, an air cylinder, a containing plate, four first telescopic pipes and a supporting plate; four supporting legs are arranged at the bottom end of the bottom plate; a conveying mechanism is arranged in the right half area of the top end of the workbench; a square hole is formed in the left half area of the top end of the workbench; and a telescopic rod is arranged at the top output end of the air cylinder. The sorting device further comprises a clamping plate, a second telescopic pipe, a threaded pipe, a threaded rod and a rotating disc; a rotating hole is transversely formed in the upper half area of the left side wall of the supporting plate; and a ball bearing is arranged between the threaded pipe and the inner side wall of the rotating hole. The sorting device further comprises a collecting box, a left handle and a right handle, a working cavity is formed in the collecting box, and a box opening is formed in the top end of the collecting box.

Owner:SUZHOU INDAL PARK INSTITUE OF VOCATIONAL TECH

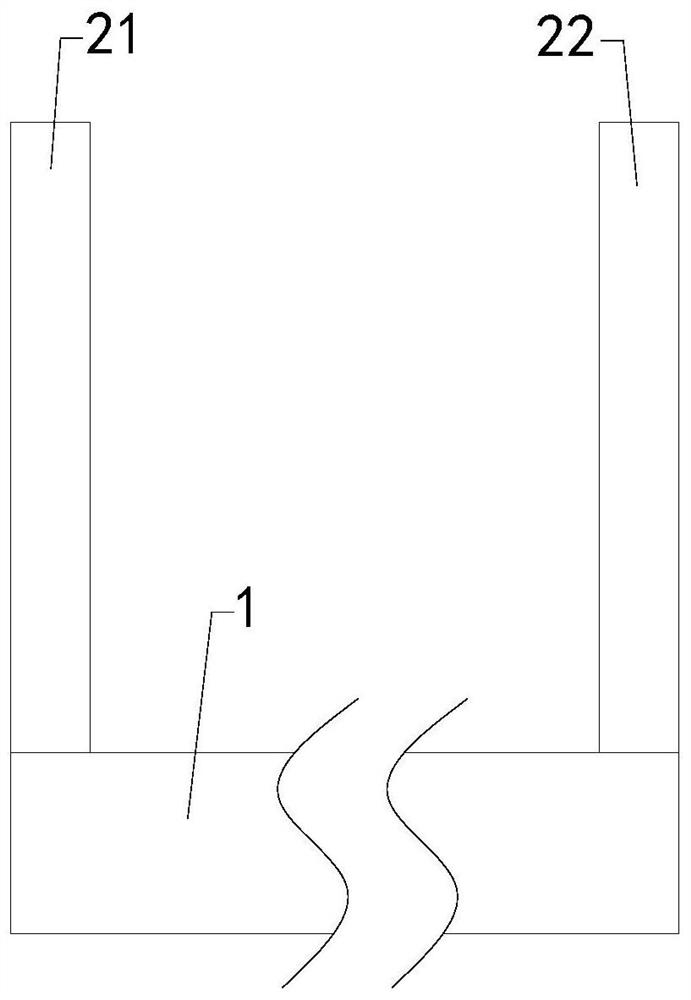

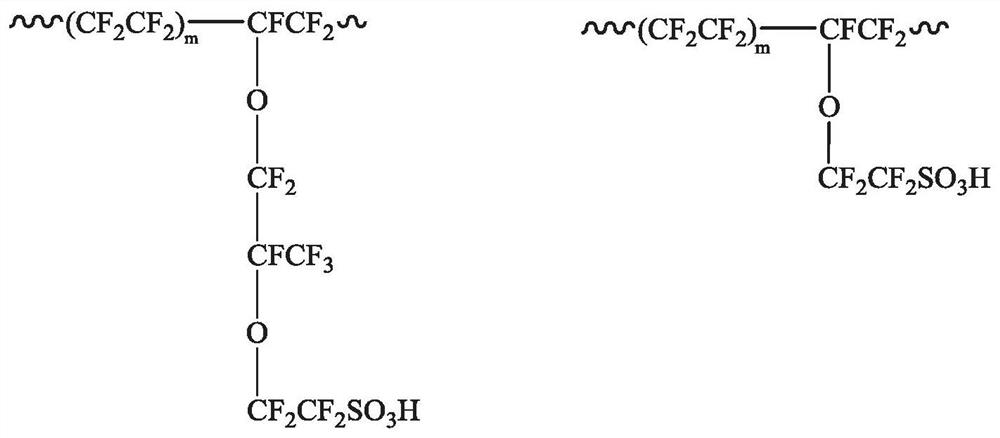

Proton exchange composite membrane and continuous preparation method thereof

PendingCN114204089ASolve the problem of complex bonding processReduced service lifeFuel cellsSide chainPorous membrane

The invention discloses a proton exchange composite membrane and a preparation method, the composite membrane comprises an anode layer, a middle layer and a cathode layer, the anode layer comprises long side chain perfluorinated sulfonic acid resin, a water-retaining agent and a microporous membrane, the cathode layer is short side chain perfluorinated sulfonic acid resin, the middle layer is a long side chain perfluorinated sulfonic acid resin layer, and the microporous membrane is a porous membrane. The preparation method comprises the steps that the microporous membrane and the supporting base membrane are attached and then coated, the long-side-chain perfluorinated sulfonic acid resin and the water-retaining agent are mixed to prepare the anode layer, and the phenomenon that the reaction efficiency is affected due to the fact that the anode side is excessively dry is avoided; the cathode layer is prepared from the short-side-chain perfluorinated sulfonic acid resin, so that the flexibility of a side chain is improved, the microphase separation degree of the membrane can be improved, and the conductivity of the membrane is improved; a layer of long-side-chain perfluorinated sulfonic acid resin solution is sprayed above the cathode layer, so that the prepared composite membrane is better in uniformity; the composite membrane prepared from the perfluorinated sulfonic acid resin with long and short side chains can realize high conductivity under low IEC, and the proton exchange composite membrane has good chemical stability, dimensional stability and high conductivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Carya illinoensis seed winter pregermination pretreatment method

InactiveCN107864715AImprove germination rateGood neatnessPlant growth regulatorsBiocideWater contentPretreatment method

The invention belongs to the technical field of carya illinoensis seed pregermination, and particularly relates to a carya illinoensis seed winter pregermination pretreatment method. The method comprises the following steps of picking healthy and full carya illinoensis seeds; drying the seeds until the water content is lower than 20 percent; performing heat insulation for 2 to 3 hours under the temperature condition of 2 to 5 DEG C next, putting the seeds into a treatment solution with the temperature being 35 to 40 DEG C; performing stirring soaking for 15 to 20 minutes; draining moisture; then, performing pregermination. Compared with the prior art, the method provided by the invention has the following advantages that the pregermination treatment method is used for performing physiological training on the seeds, so that the germinating effects at the low temperature is good; the low-temperature-resistant capability of young seedlings is effectively improved; the operation method issimple; the conditions can be easily controlled; the low production cost is ensured; meanwhile, the emergence rate of the seeds is effectively improved; the seedling regular rate is high; the method is suitable for being popularized and used.

Owner:全椒县香妃农业专业合作社

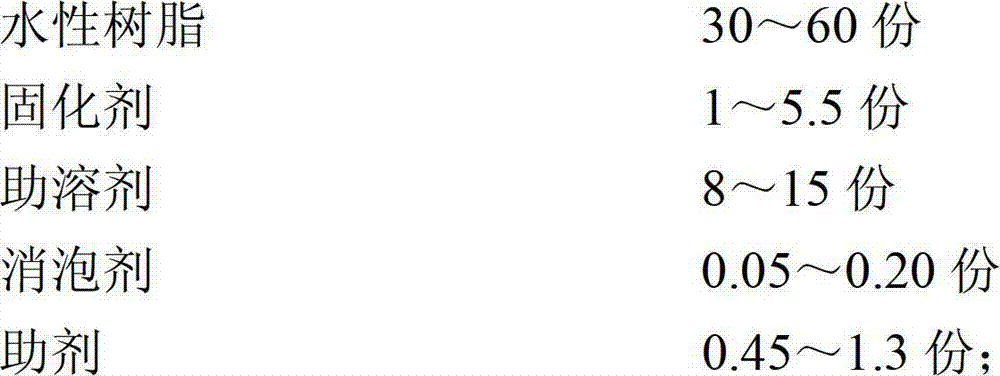

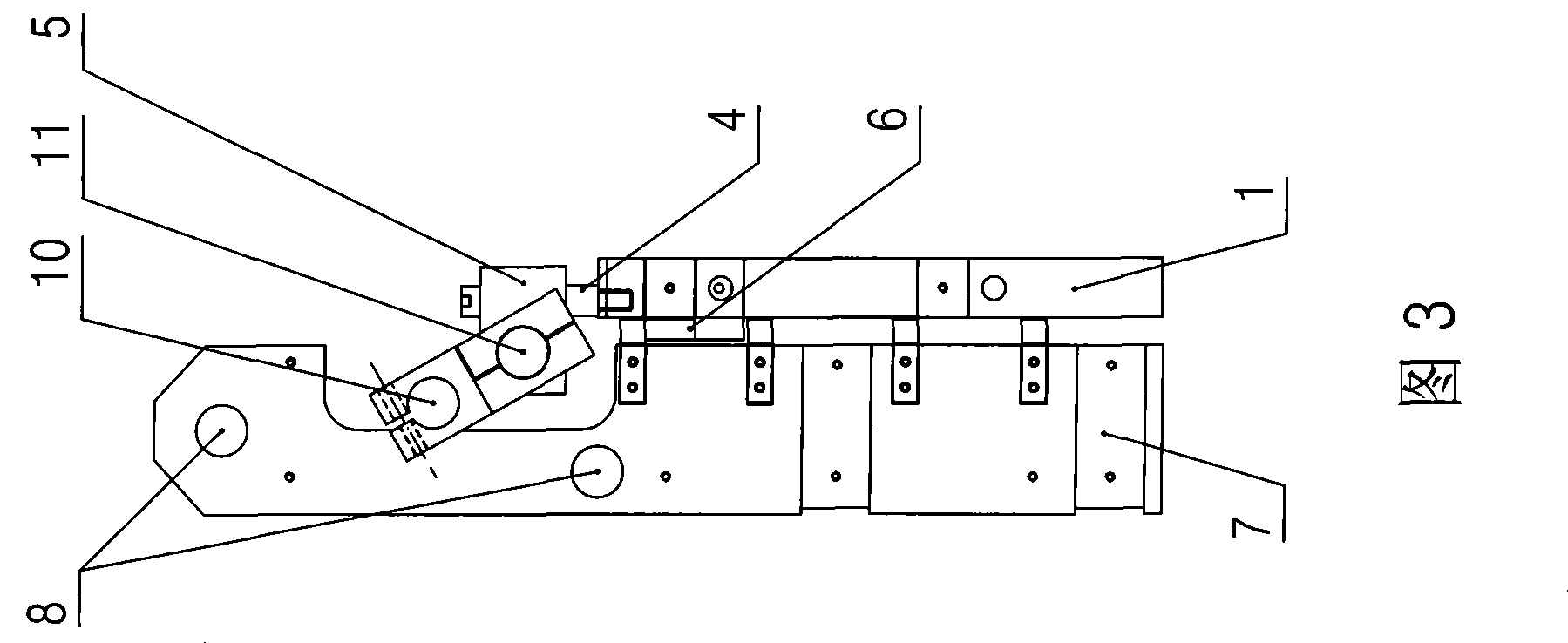

Hollow alkali washing aluminum aqueous protective paint and preparation method and application thereof

ActiveCN102766382BEasy to get materialsNo smellLiquid surface applicatorsPolyurea/polyurethane coatingsDefoaming AgentsAluminium

The invention provides hollow alkali washing aluminum aqueous protective paint and a preparation method and application of the hollow alkali washing aluminum aqueous protective paint. The hollow alkali washing aluminum aqueous protective paint adopts an aqueous formula for the first time and comprises the components by weight: 30-60 parts of aqueous resin, 1-5.5 parts of curing agent, 8-15 parts of cosolvent, 0.05-0.20 parts of defoaming agent and 0.45-1.3 parts of auxiliary agent. The hollow alkali washing aluminum aqueous protective paint is simple and convenient in preparation method; the obtained hollow alkali washing aluminum aqueous protective paint successfully solves the technical problems of the aqueous formula of the aqueous protective paint at present in the aspects of alkali resistance, closing performance, neat aluminum washing edges, flexibility, good adhesive force on an aluminum coated layer and the like by specifically selecting the formula components and the component proportion through a large amount of exploration and tests; the product is safe and environment-friendly; and successful application of the aqueous protective paint in the technical field of alkali washing aluminum is realized.

Owner:GUANGZHOU HUMAN CHEM

Subcontracting device in film packaging machine

The invention discloses a subcontracting device in a film packaging machine with high subcontracting speed, simple structure, low cost and convenient regulation. The subcontracting device in the film packaging machine comprises a stand, two sets of gate retractable mechanisms with the same structure, which span the stand, and N whole column channels arranged between the two sets of gate retractable mechanisms, wherein retractable gates corresponding to the whole column channels are arranged in each set of gate retractable mechanism. The invention can automatically subcontract in a whole column with high subcontracting speed under the condition that a conveyor belt does not stop and can conveniently regulate the package releasing opportunity and time according to the variation of the bottle shape and the specification.

Owner:ZHANGJIAGANG DESHUN MACHINERY

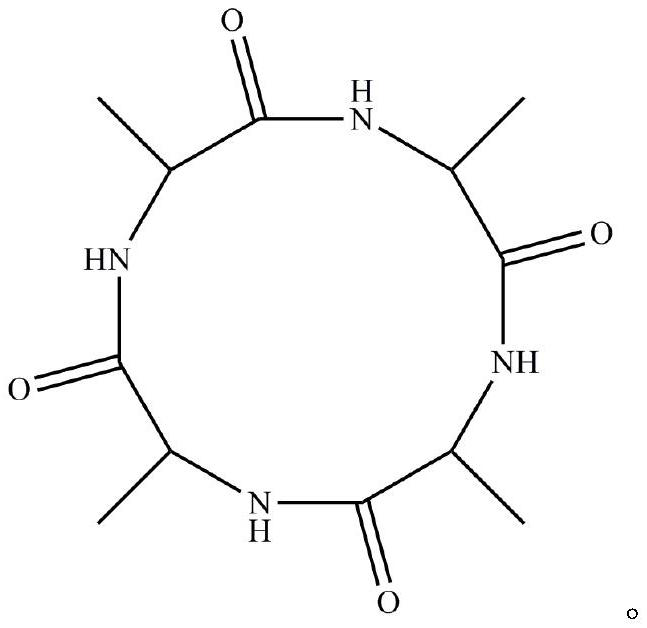

Preparation method of homocyclopeptide cyclo-(ala)4

ActiveCN107602669BGood neatnessIncrease fat solubilityPeptide preparation methodsBulk chemical productionCyclic peptidePolymer science

The invention discloses a preparation method of a homogeneous cyclic peptide Cyclo-(Ala)4. The preparation method comprises the steps: (1) allowing resin to react and be connected with alanine with aprotecting group to form resin connected with alanine, (2) conducting continuous condensation on alanine connected with the resin and alanine with the protecting group to form resin connected with a linear chain peptide, (3) cutting the linear chain peptide from the resin for end-to-end cyclization to form a cyclic peptide crude product, and (4) purifying and storing the cyclic peptide. Cyclo-(Ala)4 prepared by the method is in a homogeneous cyclic peptide structure formed by single amino acid, has a structure extremely similar to that of a crown ether compound; molecules having good regularity and multidirectional symmetry in structure can be self-assembled into an ion channel or a nano tube more easily as a drug carrier, a membrane channel, a molecular element and the like; no free aminogroup or carboxyl group is available in the molecules of the cyclic peptide, so that the cyclic peptide has extremely good liposolubility and biological in-vivo stability; at the same time, the method is reasonable in technology and simple in operation; the synthesis efficiency is higher.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

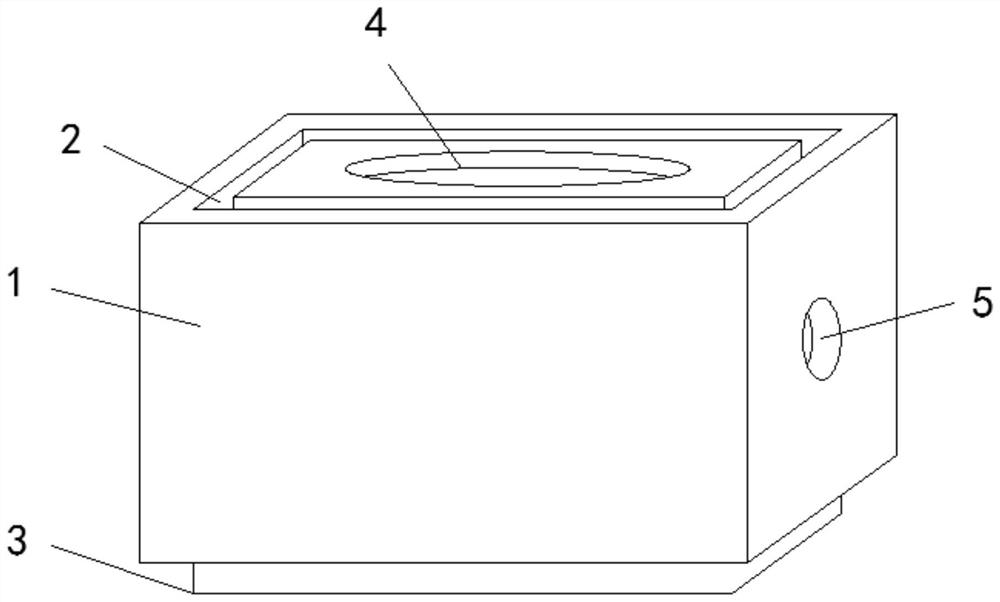

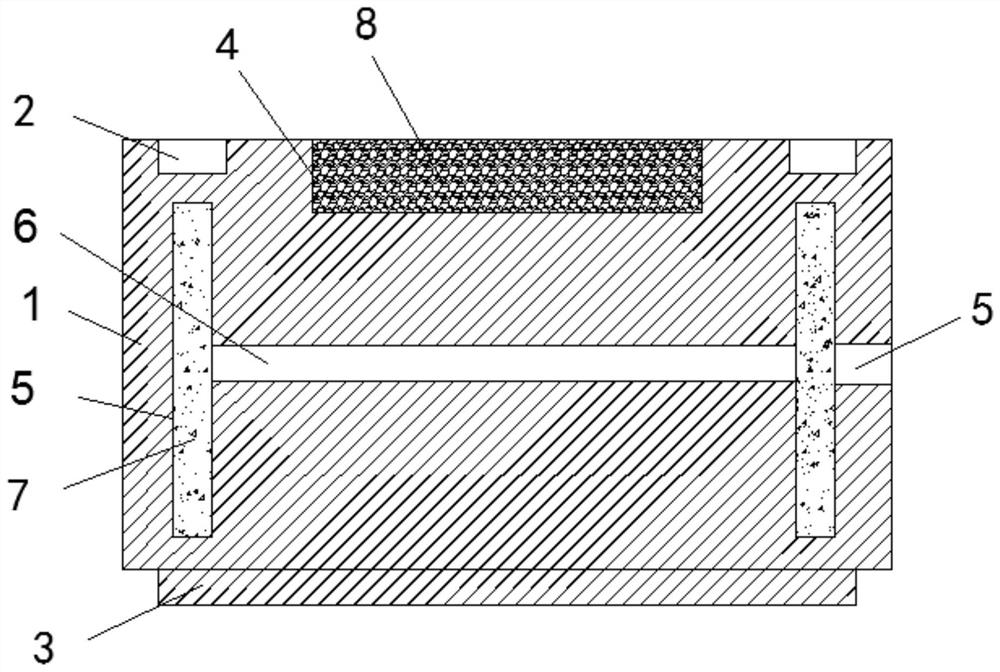

Building composite thermal insulation building block

InactiveCN112443079AAchieve heat preservationGood neatnessConstruction materialThermal insulationArchitectural engineering

The invention discloses a building composite thermal insulation building block which comprises a building block body, limiting grooves, limiting protruding strips, a filler groove, and a feeding port;the building block body is of a rectangular structure; rectangular limiting blocks are arranged on the peripheral side of the upper surface of the building block body; thermal insulation cavities areformed in the two sides of the interior of the building block body; and the thermal insulation cavities are communicated through a material conveying channel. By means of the design, the building block body can be filled with thermal insulation sand through the feeding port, so that thermal insulation is achieved; and the limiting grooves are formed in the circumferential side of the upper surface of the building block body, the limiting protruding strips matched with the limiting grooves are arranged on the bottom face of the building block body, and the building blocks located on the upperportion are connected with the limiting grooves of the building blocks located on the lower portion in a clamped mode through the limiting protruding strips, so that the building blocks are good in tidiness during building, and skew building is avoided.

Owner:徐州市贾汪区金牛彩砖有限公司

A diameter-adjustable coiling machine

ActiveCN108337887BReduce labor intensityDiameter adjustment is quick and easyClassical mechanicsElectric machinery

The invention relates to a diameter-adjustable pipe coiling machine, which comprises a base, a motor arranged on the base, and a bracket fixed on the base. The upper end of the bracket is fixed with an auxiliary rotating shaft; 1. The main turntable, the auxiliary bracket is parallel to the bracket, and is slidably fixed on the slideway of the base. The lower end of the auxiliary bracket is hinged with a foot pedal, which is a ring frame. A gap is provided on the ring frame body. Its inner diameter is pear-shaped, and it is engaged with the limit pin on the base. A conduit diameter adjustment mechanism is provided between the main turntable and the baffle. The turntable and the connecting rod connected between the turntable and the baffle, the two ends of the connecting rod are respectively fixed by pin shafts; the main turntable is provided with a track to limit the movement of the baffle; the rotation of the turntable drives the baffle to move away or away from the main turntable track Or move close to the center of the main turntable, and lock the main turntable with bolts.

Owner:广东泽洋金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com