Method for preparing facial mask base material by using modified antibacterial silks as substrate

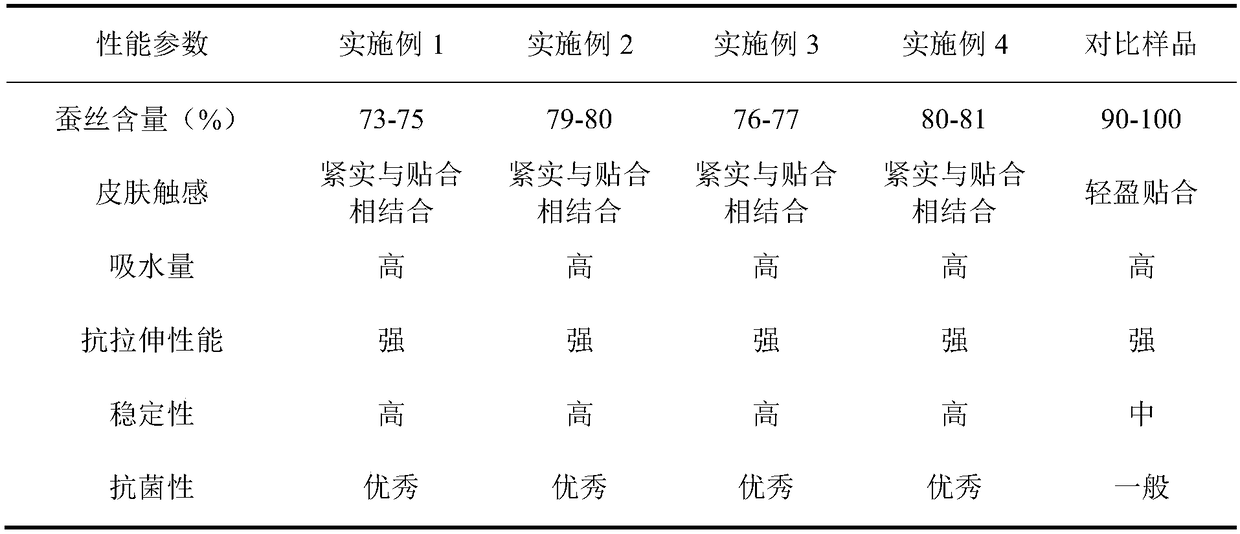

A mask and modification technology, applied in the field of skin care products, can solve the problems of residual pollution, easy loss of coating, and unstable silk performance, and achieve good antibacterial properties, not easy to fall off, and good antibacterial and anti-inflammatory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a mask base material based on modified antibacterial silk, comprising the steps of:

[0031] 1) put the nano-silver particles with a particle size of 20nm into deionized water, use 20KHz ultrasonic treatment for 10min, and prepare a nano-silver solution with a concentration of 20mg / L;

[0032] 2) the nano-silver solution obtained in step 1) is mixed with part of sucrose, glycerin, and sodium hydroxide to make a nano-silver containing 2% sucrose, 4% glycerol and 2% sodium hydroxide by weight fraction Compounding solution;

[0033] 3) Soak the mulberry leaves for feeding into the nano-silver complex solution obtained in step 2), raise the temperature of the solution to 40°C, use 15KHz ultrasonic treatment for 20min, put the mulberry leaves in a blast drying oven and dry them at 60°C for 2h , to obtain nano silver-containing mulberry leaves;

[0034] 4) Use the N,N'-carbonyldiimidazole solution with a weight fraction of 8%, spray it on the nano-sil...

Embodiment 2

[0038] A method for preparing a mask base material based on modified antibacterial silk, comprising the steps of:

[0039] 1) put the nano-silver particles with a particle size of 25nm into deionized water, use 30KHz ultrasonic treatment for 15min, and prepare a nano-silver solution with a concentration of 50mg / L;

[0040] 2) the nano-silver solution obtained in step 1) is mixed with part of sucrose, glycerin, and sodium hydroxide to make a nano-silver containing 3% sucrose, 5% glycerol and 3% sodium hydroxide by weight fraction Compounding solution;

[0041] 3) Soak the mulberry leaves for feeding into the nano-silver complex solution obtained in step 2), raise the temperature of the solution to 50°C, use 20KHz ultrasonic waves for 25 minutes, and put the mulberry leaves in a blast drying oven to dry at 75°C for 3 hours , to obtain nano silver-containing mulberry leaves;

[0042] 4) use the N, N'-carbonyldiimidazole solution of 10% by weight fraction, spray on the nano-silv...

Embodiment 3

[0046]A method for preparing a mask base material based on modified antibacterial silk, comprising the steps of:

[0047] 1) put the nano-silver particles with a particle size of 21nm into deionized water, use 23KHz ultrasonic treatment for 12min, and prepare a nano-silver solution with a concentration of 30mg / L;

[0048] 2) the nano-silver solution obtained in step 1) is mixed with part of sucrose, glycerin, and sodium hydroxide to make nano-silver containing 2.2% sucrose, 4.2% glycerol and 2.2% sodium hydroxide by weight fraction Compounding solution;

[0049] 3) Soak the mulberry leaves for feeding into the nano-silver complex solution obtained in step 2), raise the temperature of the solution to 42°C, use 17KHz ultrasonic treatment for 22min, and put the mulberry leaves into a blast drying oven to dry at 65°C for 2.3 h, to obtain mulberry leaves containing nano-silver;

[0050] 4) Use the N, N'-carbonyldiimidazole solution with a weight fraction of 9%, spray it on the na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com