A fabric cutting machine for clothing production

A cloth cutting machine and clothing technology, applied in transportation and packaging, cutting of textile materials, textiles and papermaking, etc., can solve the problems of high labor intensity, irregular cloth edges, easy to deviate from the track, etc., and achieve good fixing reliability , Reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

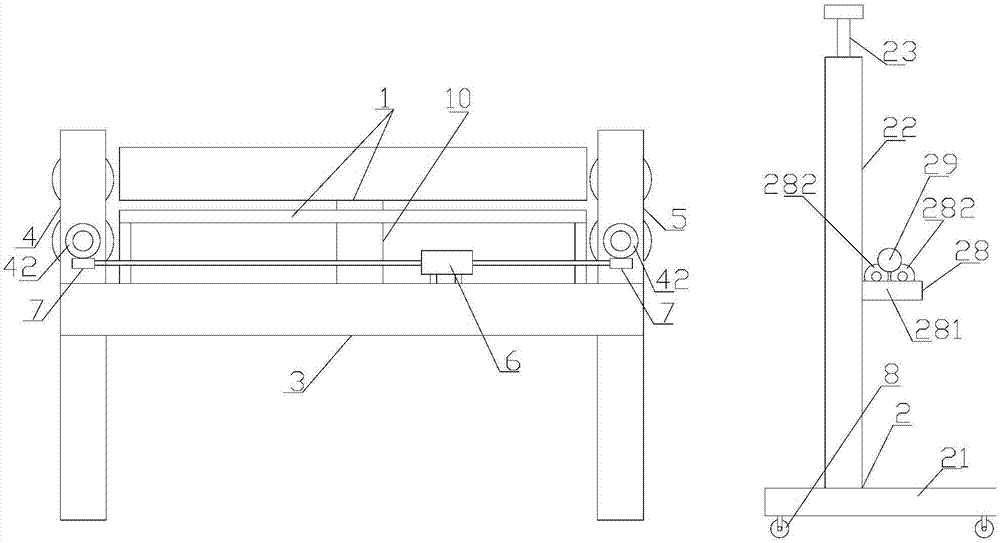

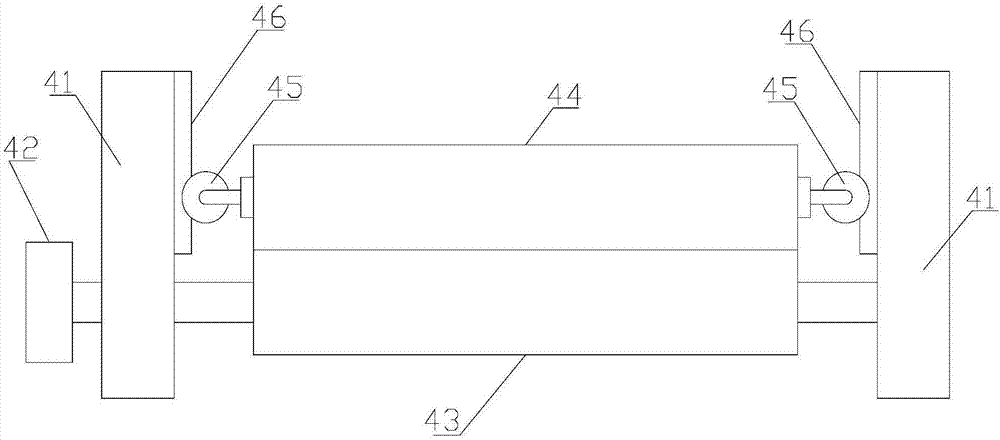

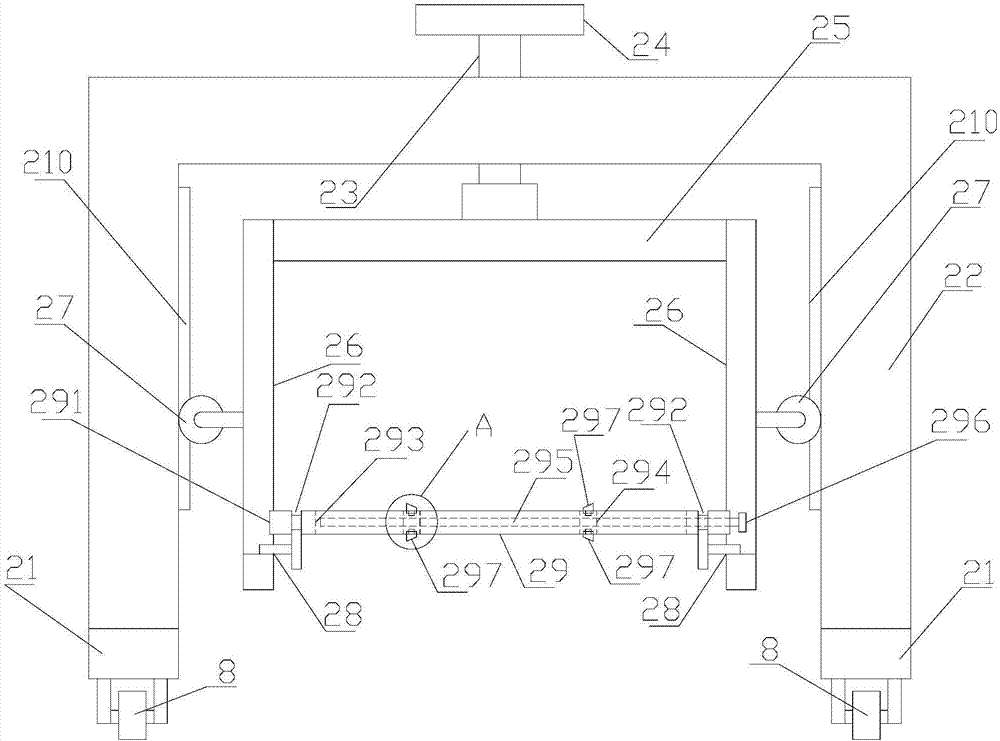

[0023] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6, a cloth cutting machine for producing garments according to the present invention, comprising a cutting device 1, an unwinding device 2, a frame body 3, a front conveying mechanism 4, a rear conveying mechanism 5 and a motor 6, and the rear of the frame body 3 is provided with a The roll device 2, the front and rear ends of the frame body 3 are respectively provided with a front conveying mechanism 4 and a rear conveying mechanism 5, and the frame body 3 is provided with a motor 6 for driving the front conveying mechanism 4 and the rear conveying mechanism 5. The frame body 3 is provided with a cutting device 1 between the front conveying mechanism 4 and the rear conveying mechanism 5, and the cutting device 1 includes an upper mounting seat 11, a cylinder 12, an upper template 13, a lower template 14, and a lower mounting seat 15 and two positioning rods 17, the frame body 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com