Rolling device for lining cloth

A technology of winding device and interlining cloth, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc. It can solve the problems of wasting time, inconvenient fixing and disassembly, and reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

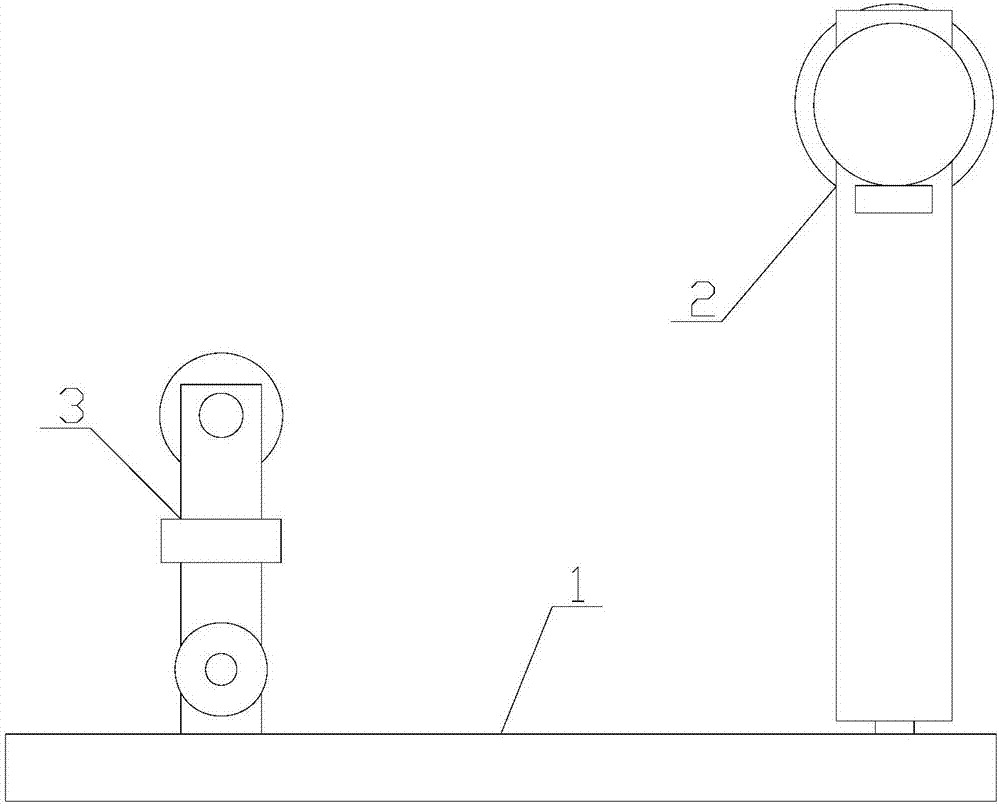

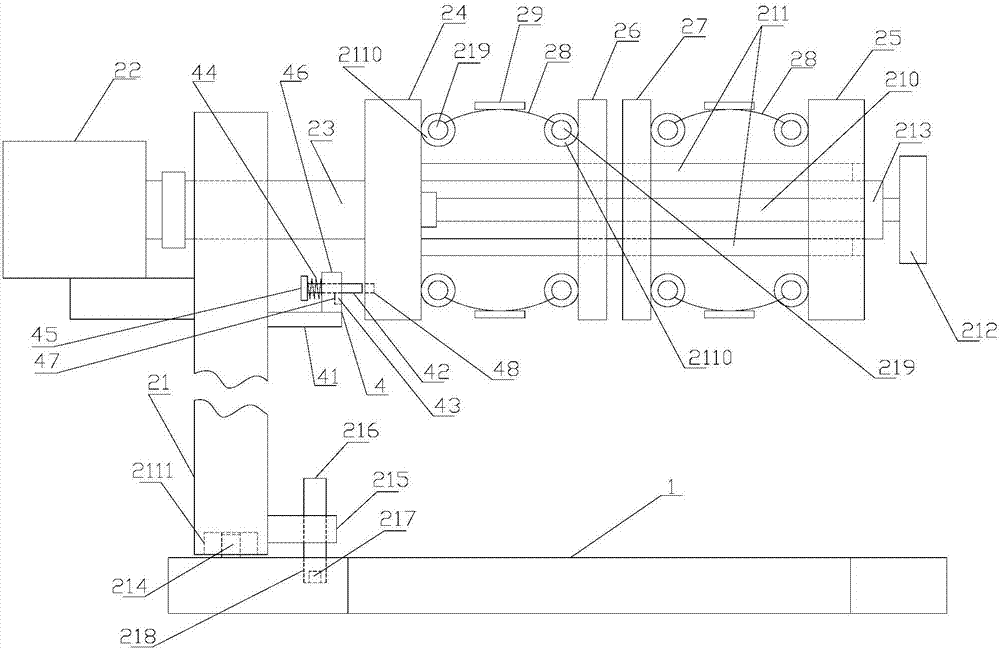

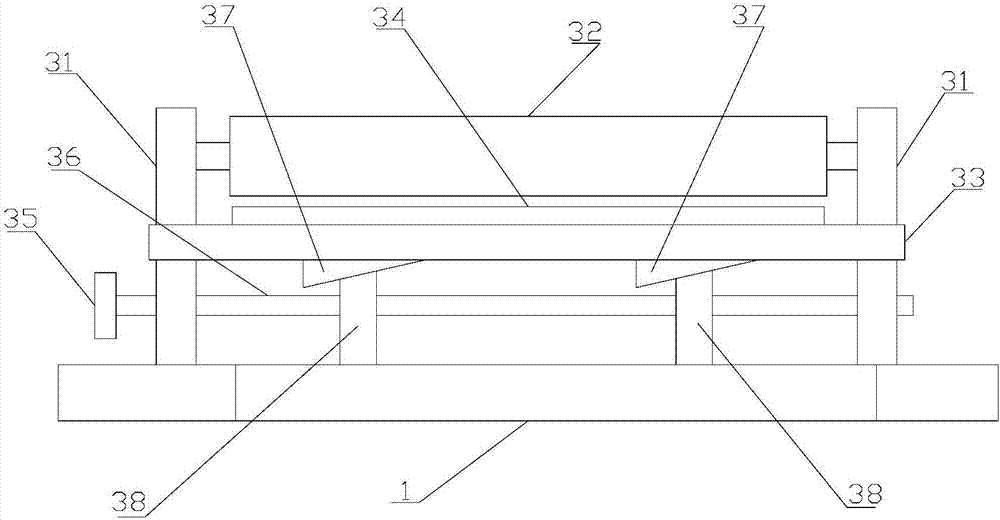

[0022] refer to figure 1 , figure 2 and image 3, a new interlining rolling device of the present invention, comprising a base 1, a rolling device 2 and a clamping device 3, the rolling device 2 and the clamping device 3 are sequentially installed on the base 1 from front to back, and the forming The roll device 2 includes a mounting seat 21, a motor 22, a rotating shaft 23, a first seat body 24, a second seat body 25, a first moving seat 26, a second moving seat 27, several arc-shaped elastic bodies 28, several supporting bodies 29, Screw body 210, two positioning rods 211 and manual disk 212, described base 1 is provided with rotatable and fixable mounting base 21, and the upper end of described mounting base 21 is provided with rotatable rotating shaft 23, and described mounting base 21 is provided with a motor 22 that drives the rotating shaft 23 to rotate. The rear end of the rotating shaft 23 is provided with a first seat 24, and the rear end of the first seat 24 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com