Cutting method for protective film covering surface of glass face plate

A glass panel and surface covering technology, which is applied in metal processing and other directions, can solve the problems of irregularity, easy shrinkage, and low precision of protective film application, and achieve the effects of avoiding shrinkage, good order, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

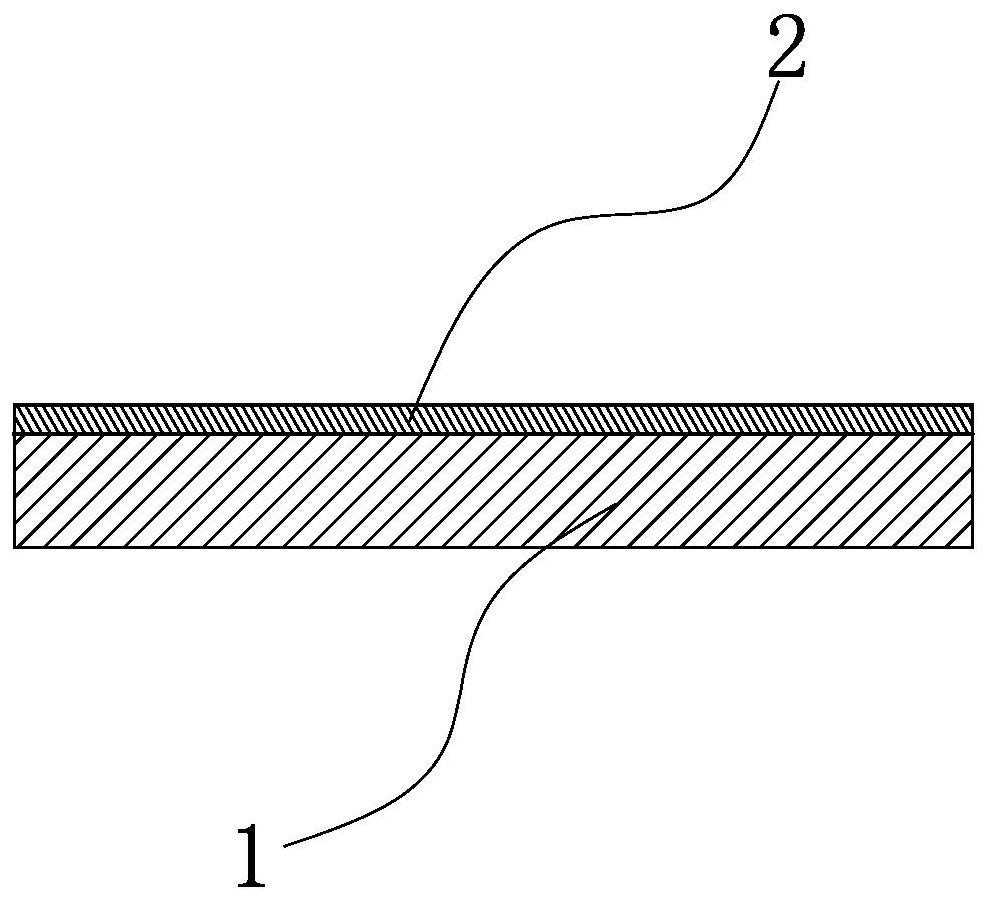

[0030] The cutting process of the glass panel 1 surface protection film 2 of the present embodiment is as follows:

[0031] After cleaning and drying the surface of the corresponding glass panel 1 that needs to be filmed, stick the protective film 2 on the surface of one side of the glass panel 1 manually or with a CCD film laminating machine for protection, and the size of the protective film 2 exceeds the size of the glass panel 1. Size, that is to say, the size of the protective film 2 is slightly larger than the size of the glass panel 1. Here, the protective film 2 is an explosion-proof film; defoaming is carried out after the film is pasted, so that the protective film 2 is completely attached to the surface of the glass panel 1, and the quality is checked. Happening;

[0032]Use carbon dioxide to cool the area to be cut on the protective film 2 to cool the protective film 2, and use a laser radium engraving machine to carry out radium engraving and cutting processing to...

Embodiment 2

[0035] The cutting process of the glass panel 1 surface protection film 2 of the present embodiment is as follows:

[0036] After cleaning and drying the surface of the glass panel 1 that needs to be filmed, use a special CCD film laminating machine to attach the protective film 2 to one side of the glass panel 1 for protection, and the size of the protective film 2 exceeds the size of the glass panel 1 , that is to say, the size of the protective film 2 is slightly larger than the size of the glass panel 1, and the protective film 2 here is an explosion-proof film; defoaming is carried out after the film is pasted, so that the protective film 2 is completely attached to the surface of the glass panel 1, and the quality is checked ;

[0037] Use carbon dioxide to blow the surface of the protective film 2 to cool the area to be cut on the protective film 2. After cooling the protective film 2, use a laser laser engraving machine to carry out radium engraving and cutting. The pr...

Embodiment 3

[0040] The cutting process of the glass panel 1 surface protection film 2 of the present embodiment is as follows:

[0041] After cleaning and drying the surface of the glass panel 1 that needs to be filmed, use a special CCD film laminating machine to attach the protective film 2 to one side of the glass panel 1 for protection, and the size of the protective film 2 exceeds the size of the glass panel 1 , that is to say, the size of the protective film 2 is slightly larger than the size of the glass panel 1. Here, the protective film 2 adopts ARAF optical film; defoaming is carried out after the film is pasted, so that the protective film 2 is completely attached to the surface of the glass panel 1, and the quality is checked Happening;

[0042] The cooling of the protective film 2 by cooling treatment is carried out synchronously with the laser engraving and cutting of the excess part of the protective film by a laser engraving machine, and the cutting area in front of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com