Patents

Literature

30results about How to "Change radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing monodisperse cadium sulfide-silicon dioxide nucleo capsid structure

InactiveCN1579994AHigh refractive indexReduce absorptionFinal product manufactureWater bathsSurface-active agents

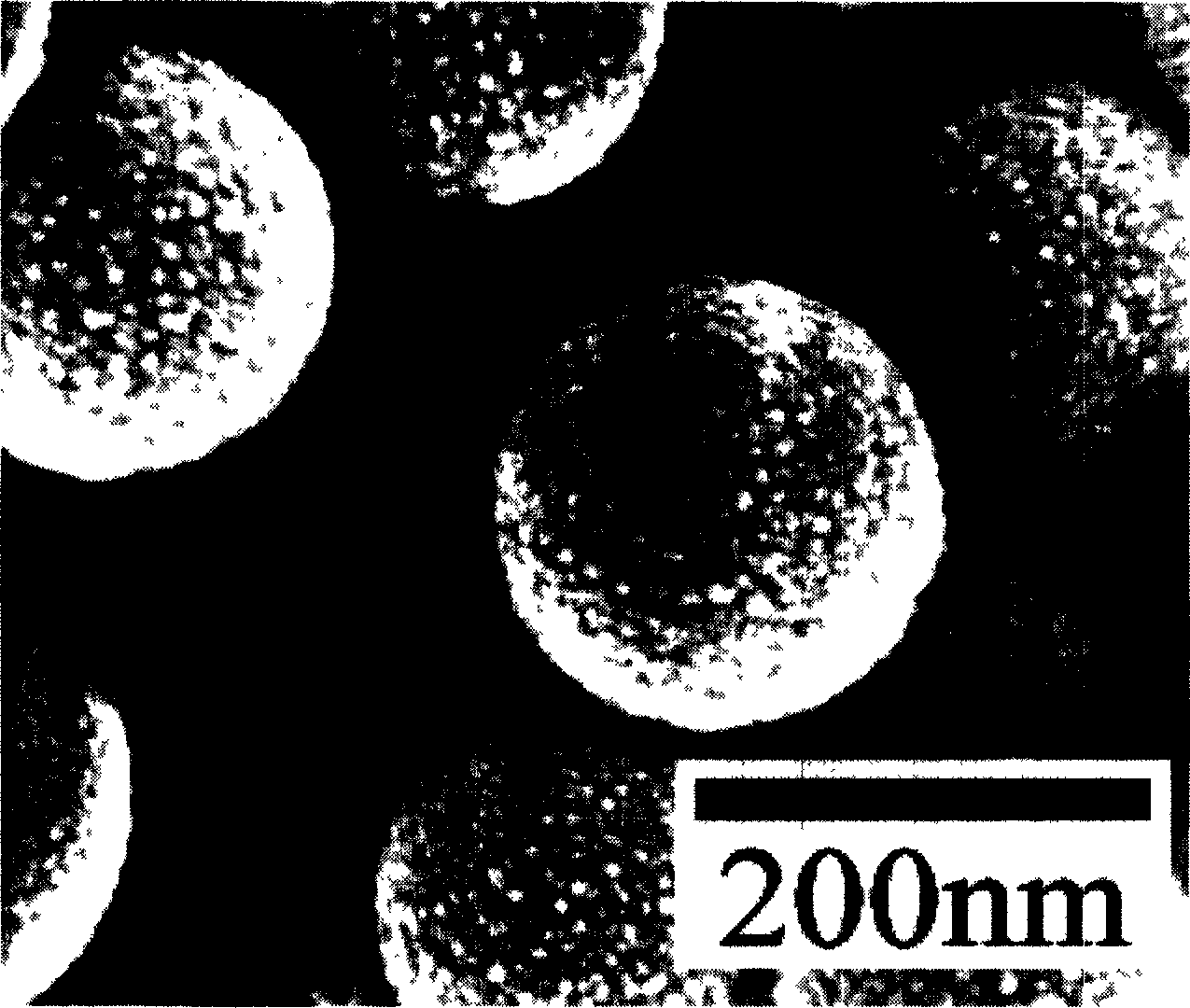

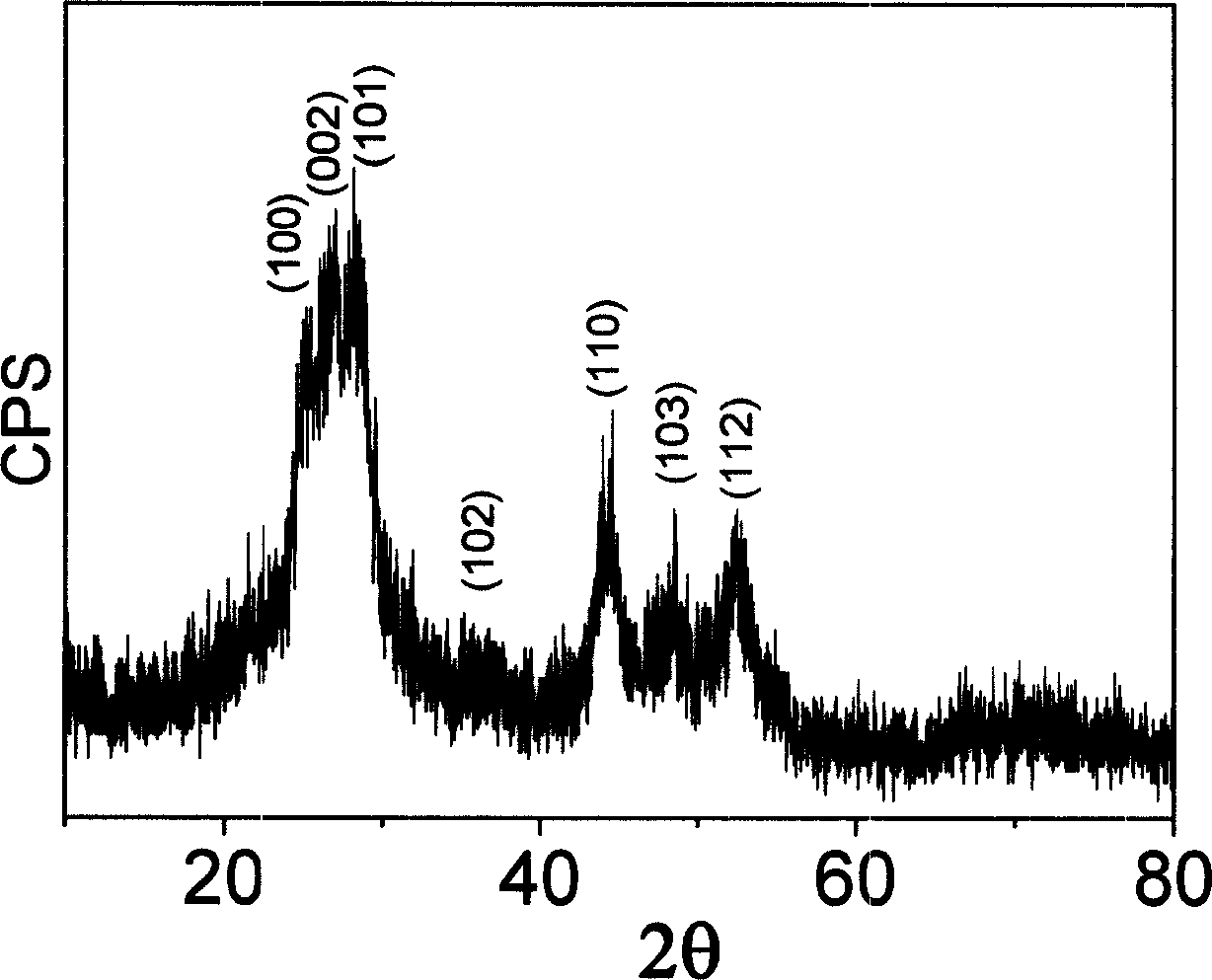

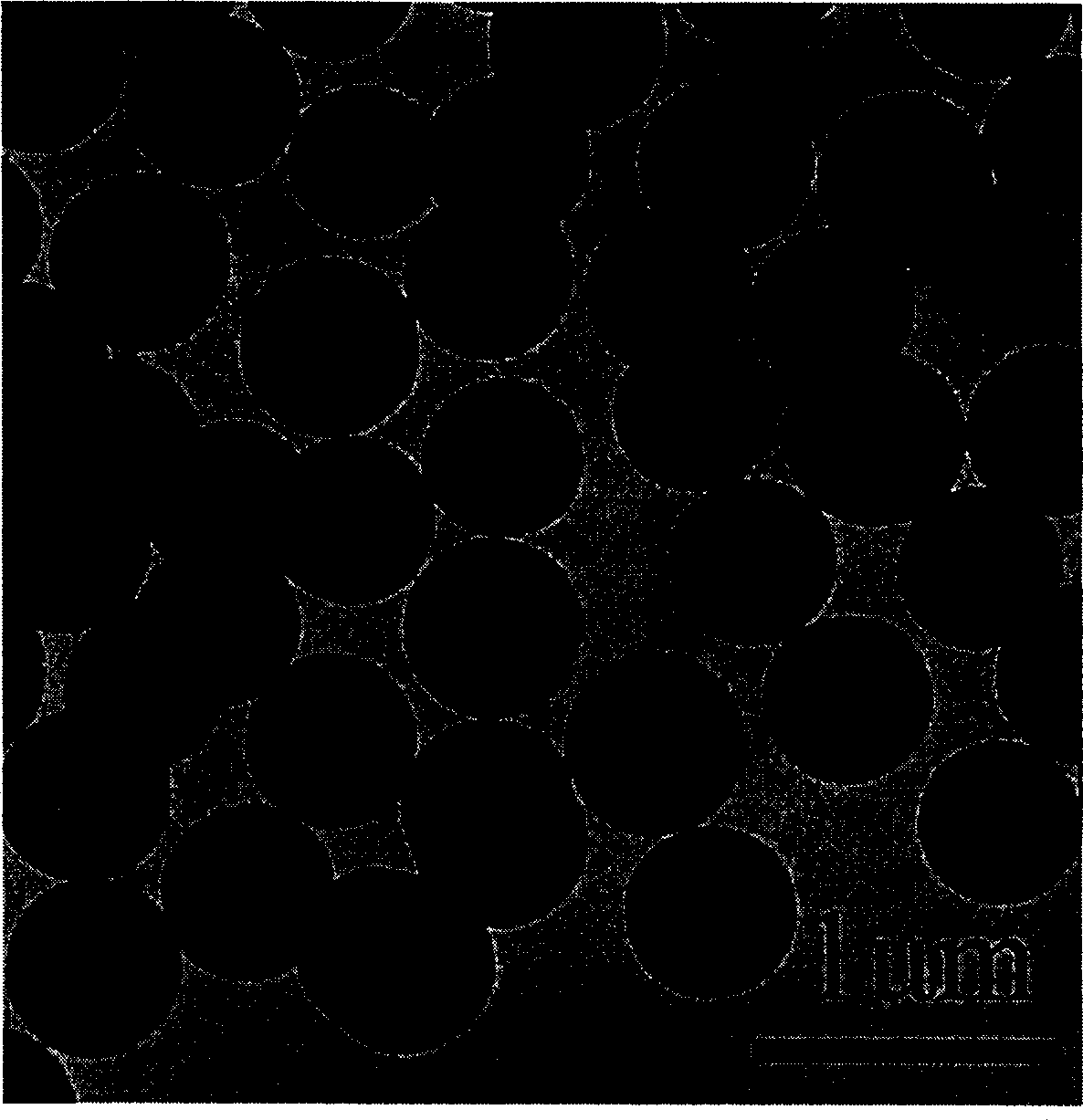

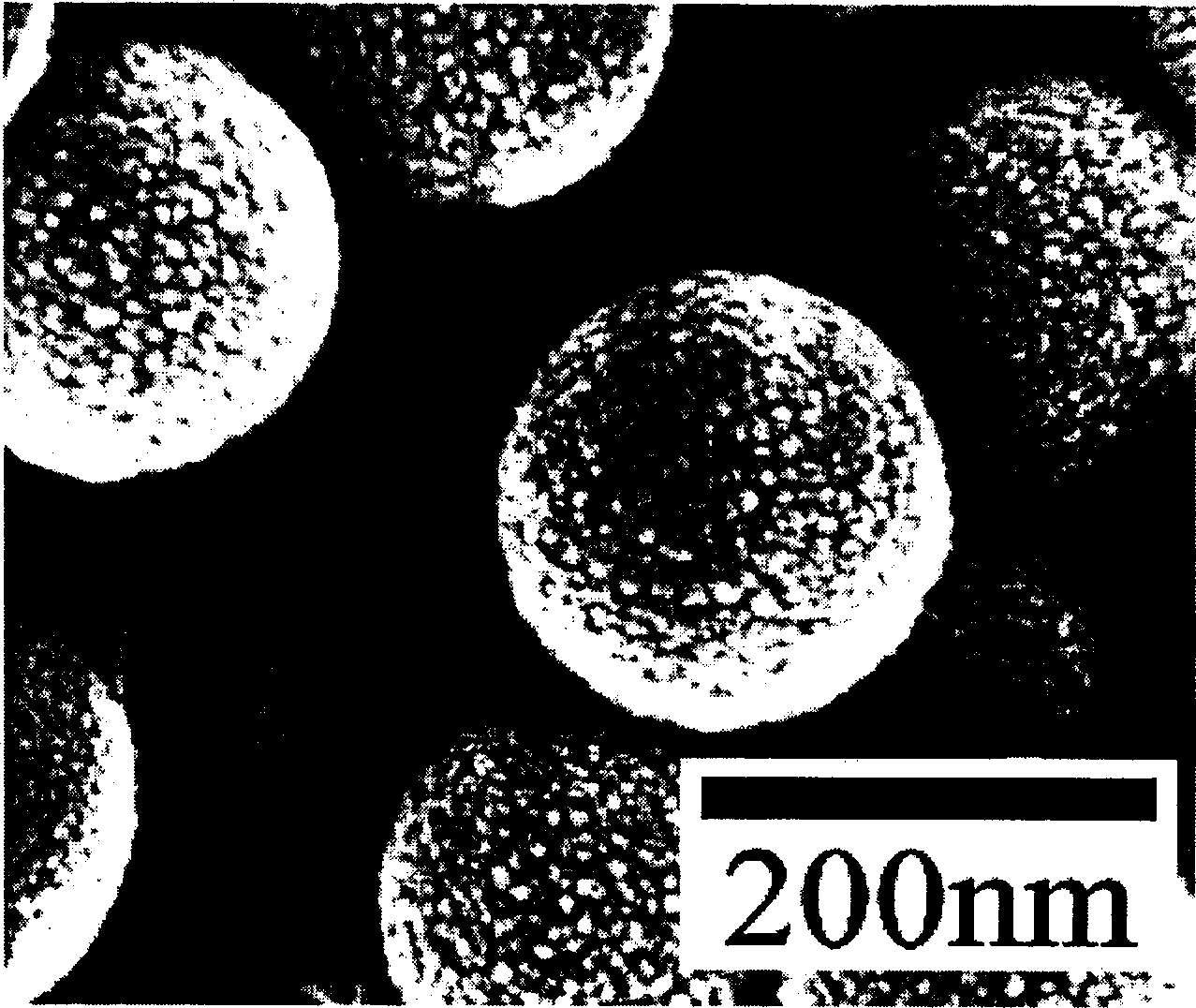

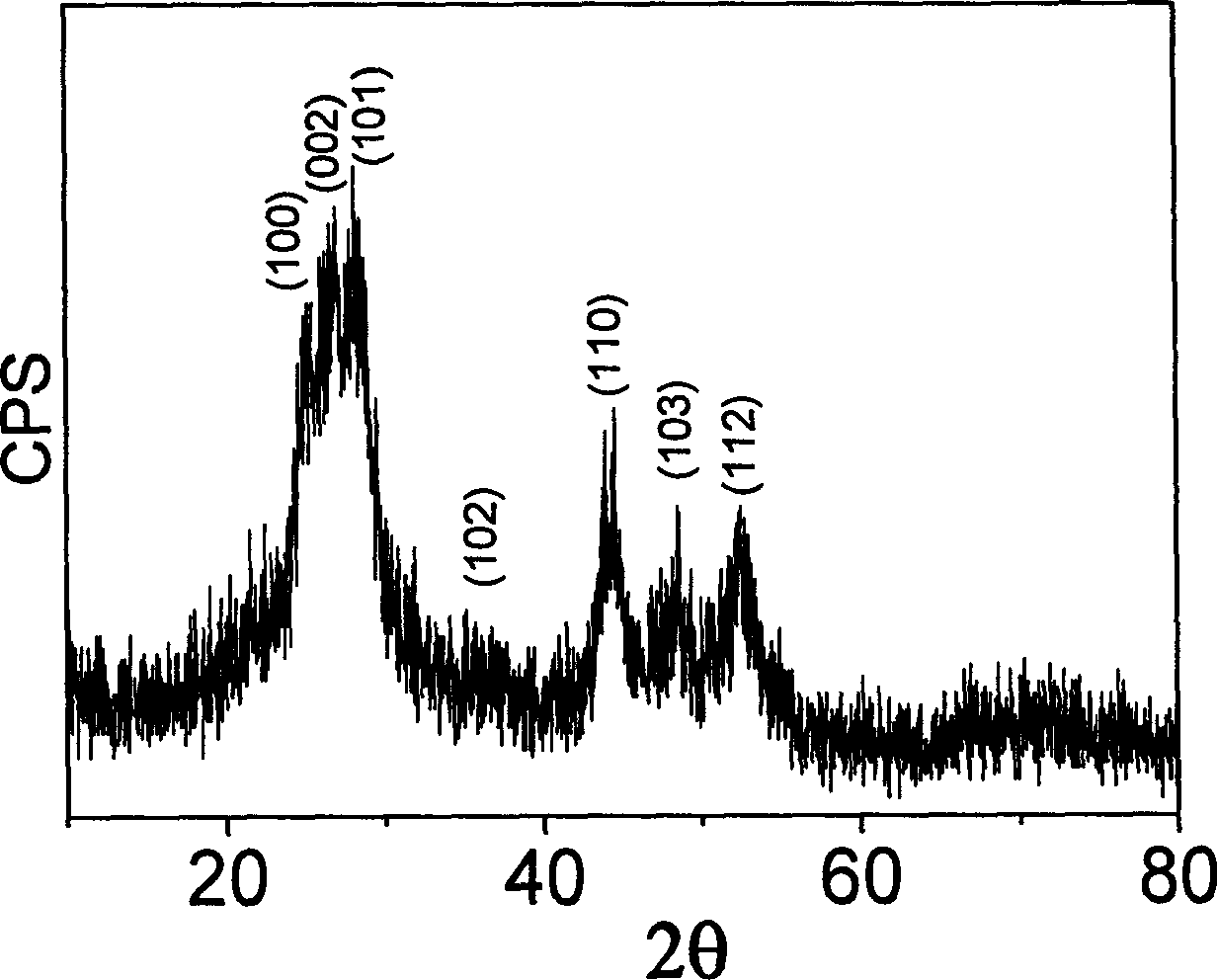

The invention discloses an approach to produce monodisperse cadmium sulphide-silicon dioxide nucleocapsid construction. Adopting chemistry water bath sedimentation, it includes nether steps: 1): Use sonic oscillation to make even monodisperse silicon dioxide sphere disperse into solution of deionized water; add sodium citrate as complexing agent, alkylol amine as surface active agent; use ammonia to adjust PH value to 8-13; magnetic stirring in constant temperature of 50-90deg.C; add cadmium chloride and sulfur to react for 1-3 hours; and then get nucleocapsid construction suspending liquid of cadmium sulphide enwrapping silicon dioxide sphere. 2): Use deionized water and absolute ethyl alcohol to clean circularly; remove reaction remnants and drying. The invention has a low cost and simple process. The produced nucleocapsid construction has a averaging diameter without cadmium sulphide grains and heterocoagulation. It can be used as construction primitive to produce three-dimensional photon crystal with unique band gap performance.

Owner:ZHEJIANG UNIV

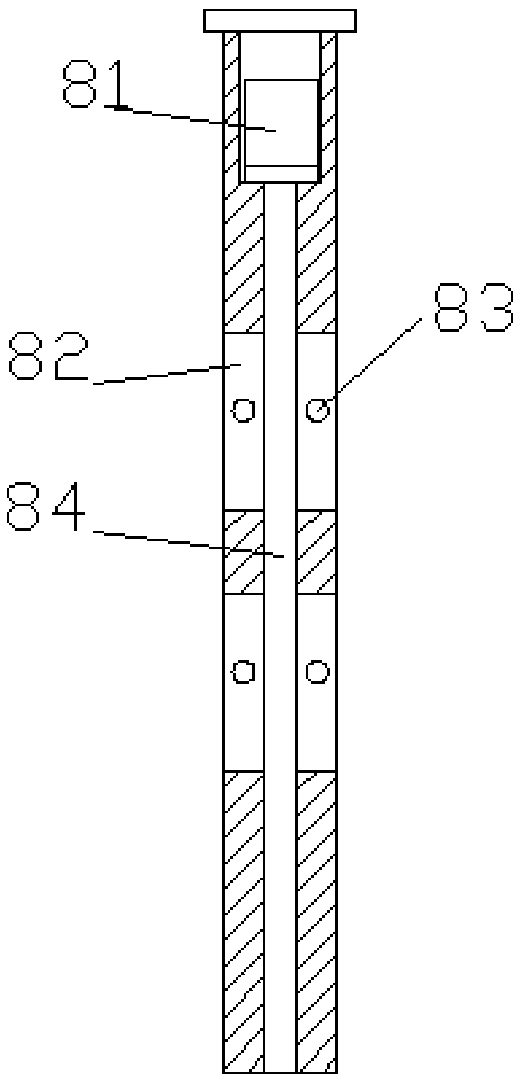

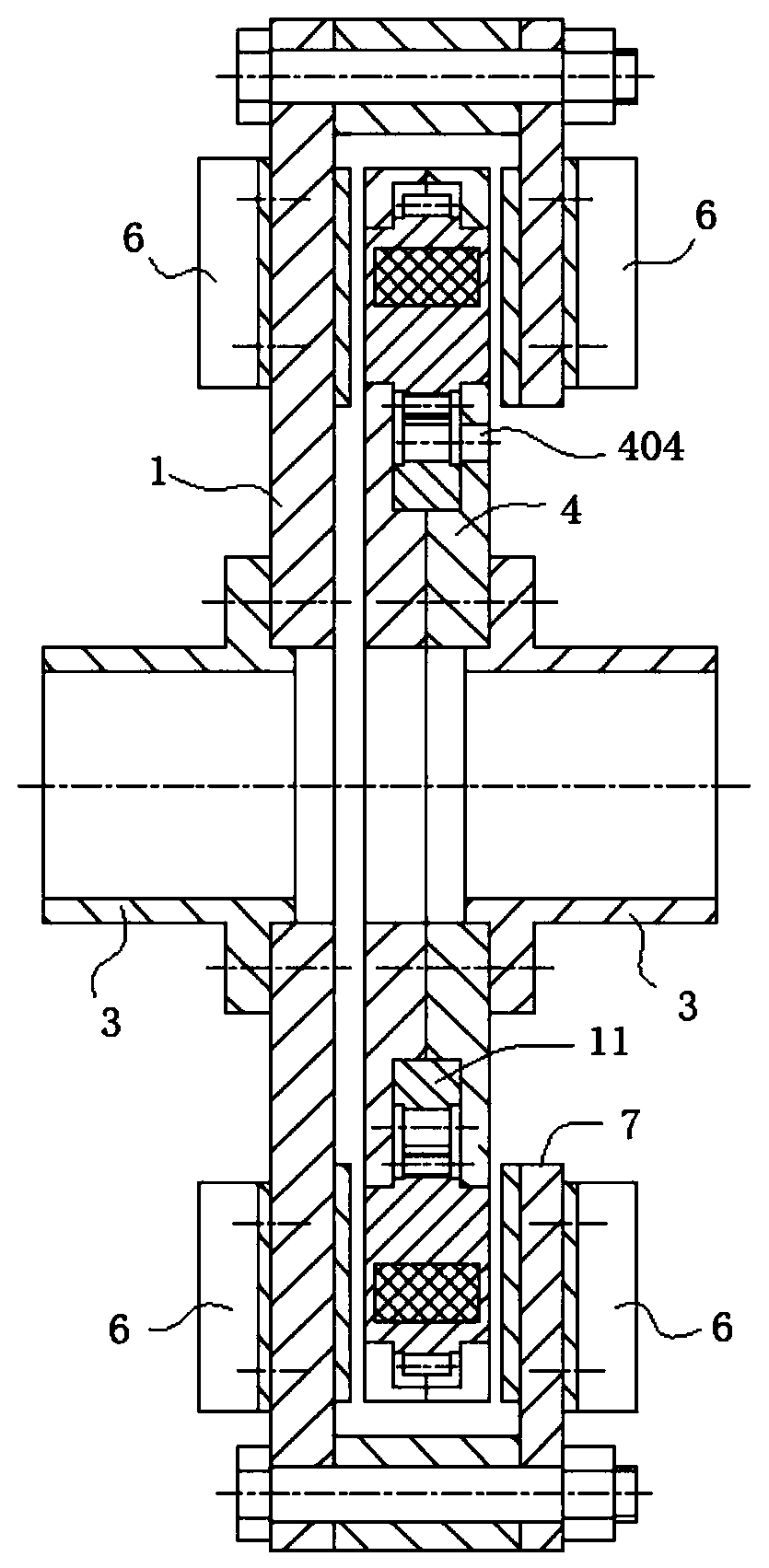

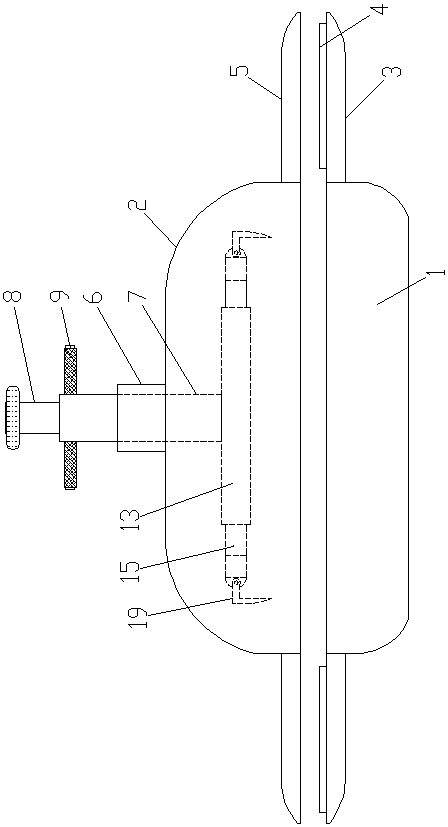

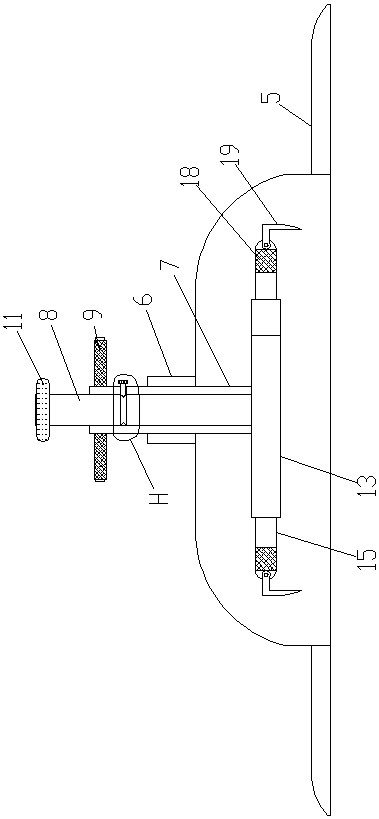

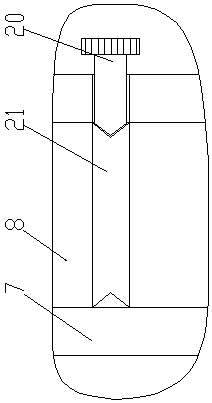

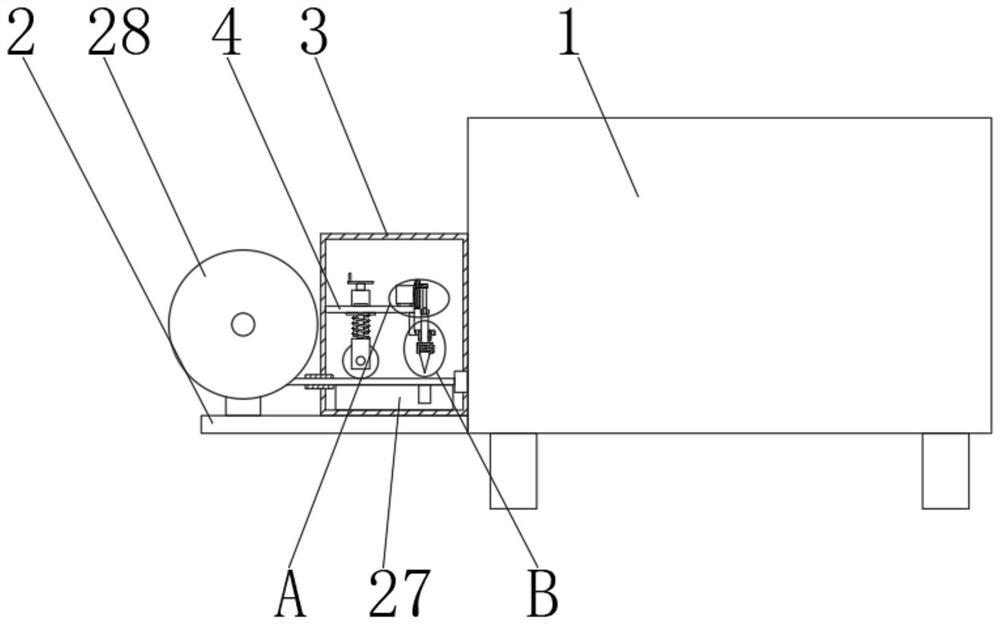

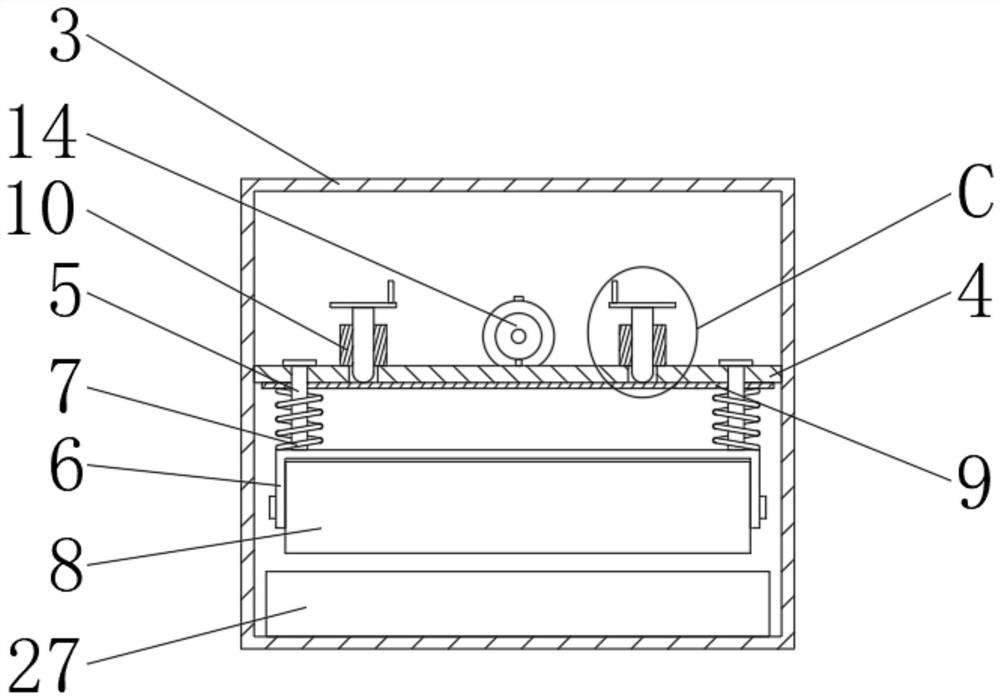

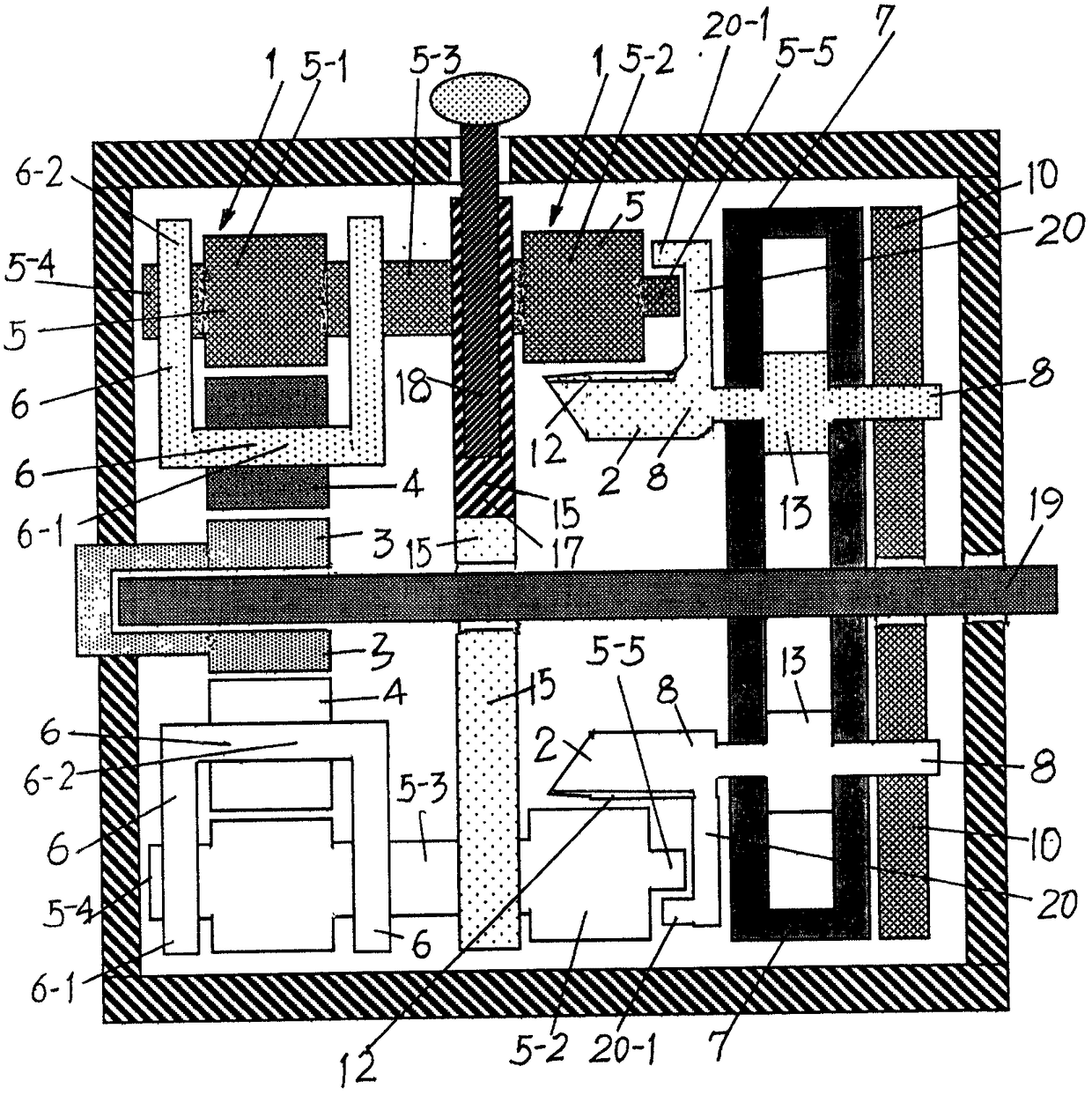

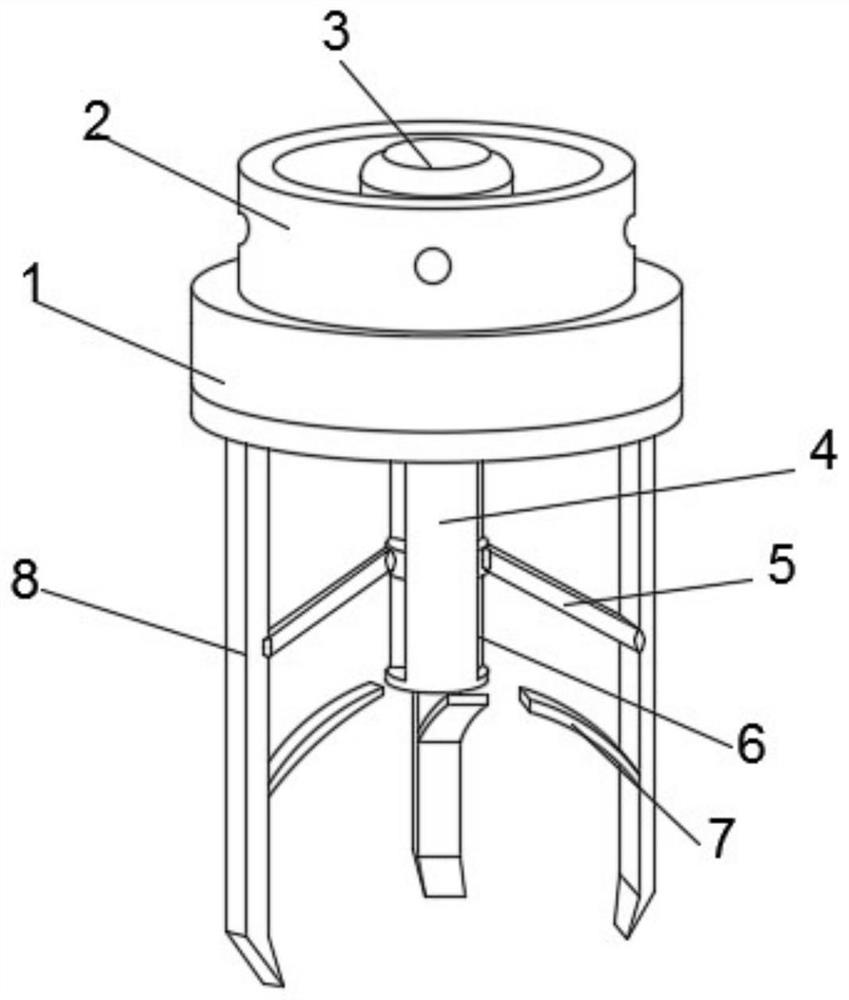

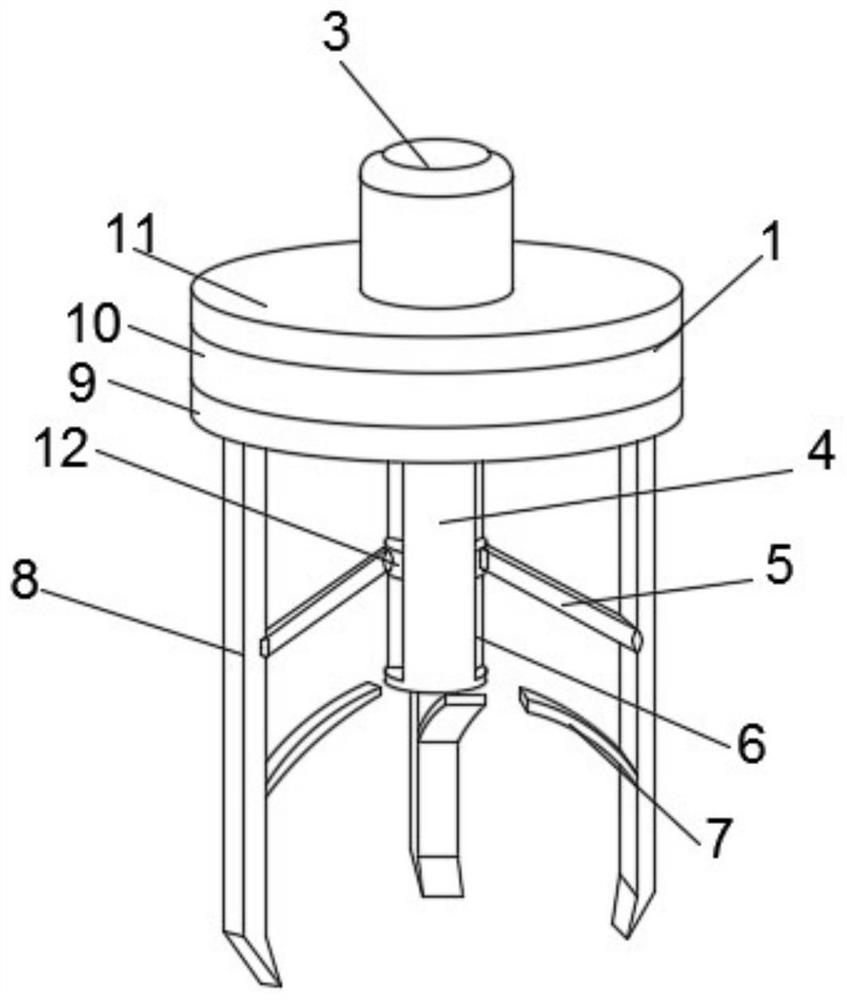

Pharmaceutical stirrer

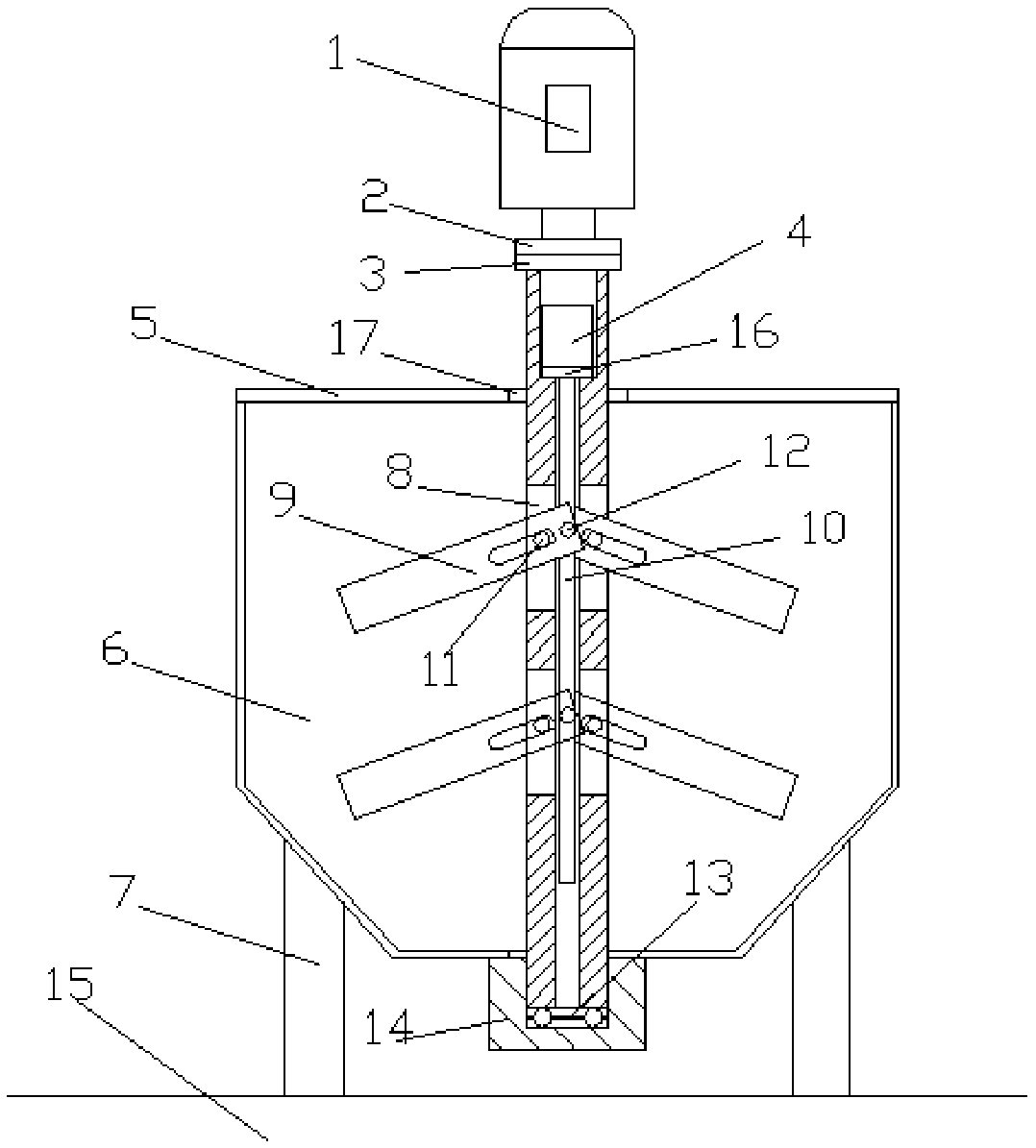

InactiveCN109012323AChange angleChange radiusRotary stirring mixersTransportation and packagingPulp and paper industryLiquid surfaces

The invention discloses a pharmaceutical stirrer. The stirrer comprises a stirring device and a cylinder, the stirring device comprises a motor, a stirring shaft and stirring blades, a shaft hole is arranged in the middle of the stirring shaft, limiting grooves are arranged in two sides of the stirring shaft, a first pinhole is arranged in every limiting groove, a telescopic shaft is arranged in the shaft hole in a clearance manner, the upper end of the telescopic shaft is connected with a telescopic cylinder, the telescopic cylinder is fixed in a cylinder mounting cavity, second pinholes arearranged in the telescopic shaft, and every stirring blade is provided with a U-shaped groove and a through hole. When the stirrer works, the telescopic cylinder drives the telescopic shaft to telescope, the stirring blades with the end parts hinged to the telescopic shaft are pulled together in the movement process of the telescopic shaft in order to realize the change of the angles and the radiuses of the stirring blades, and the rotating motion of the stirring blades is combined to realize the stirring of a plurality of liquid surfaces, so the stirring efficiency is greatly improved.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

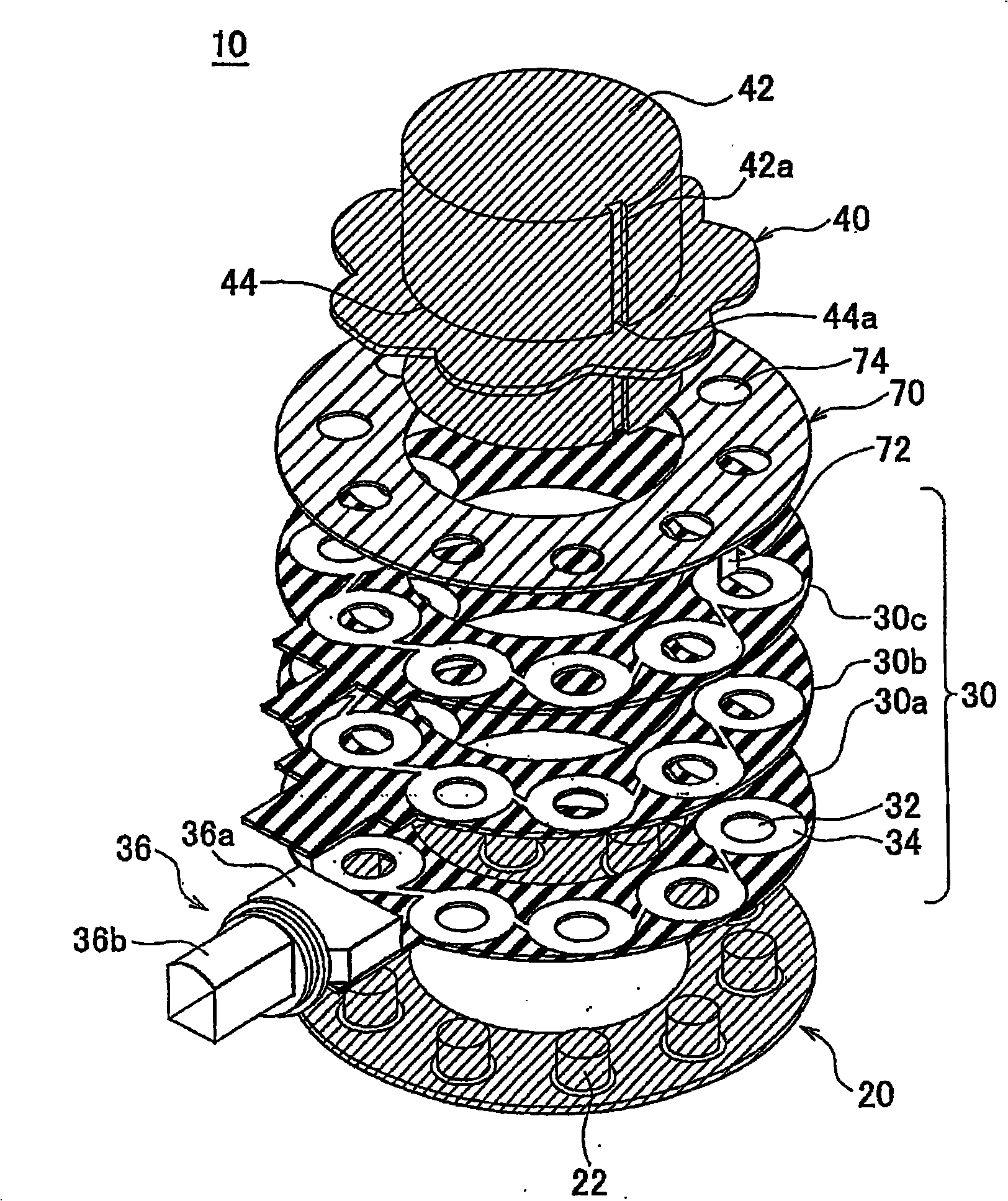

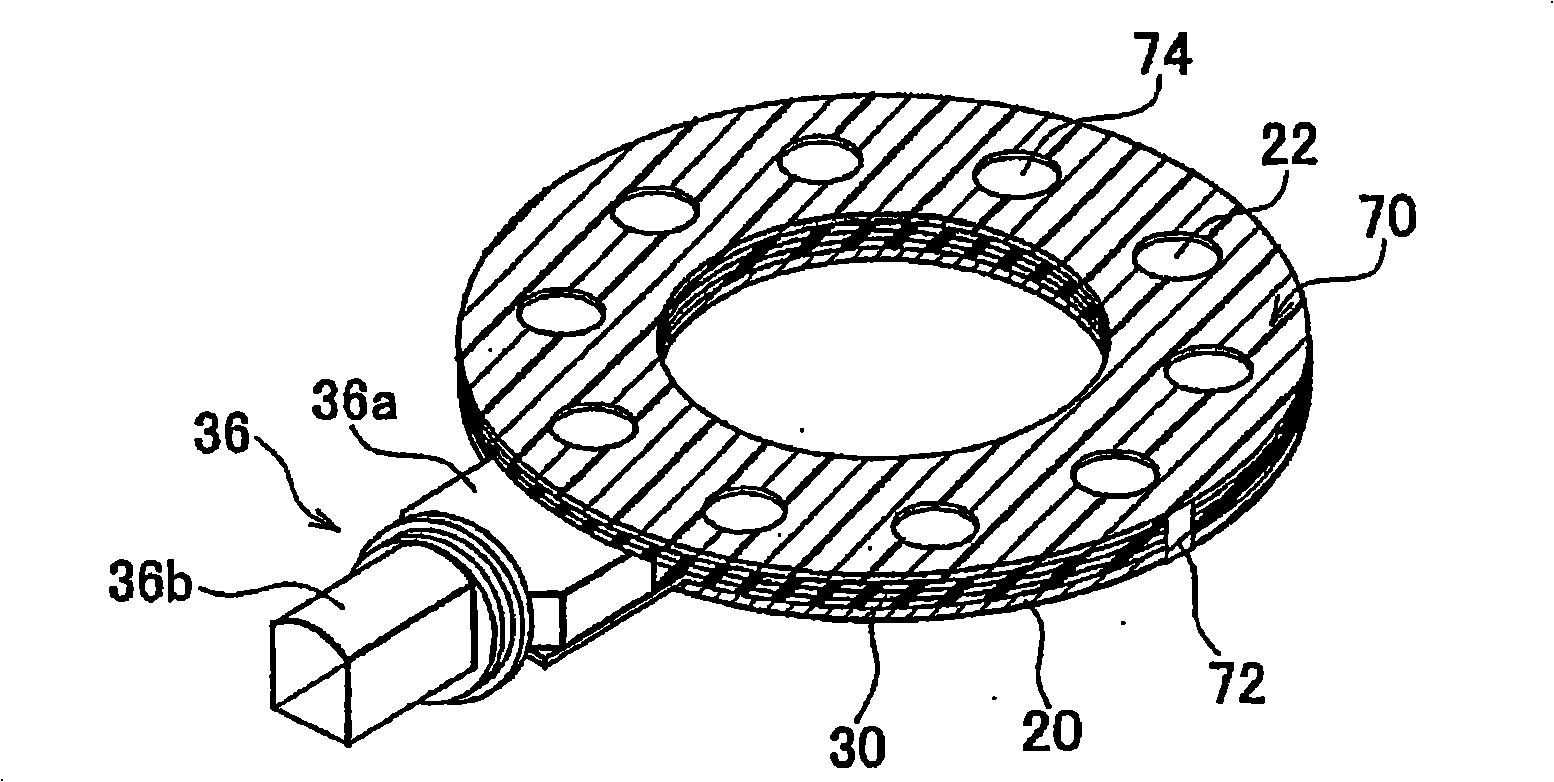

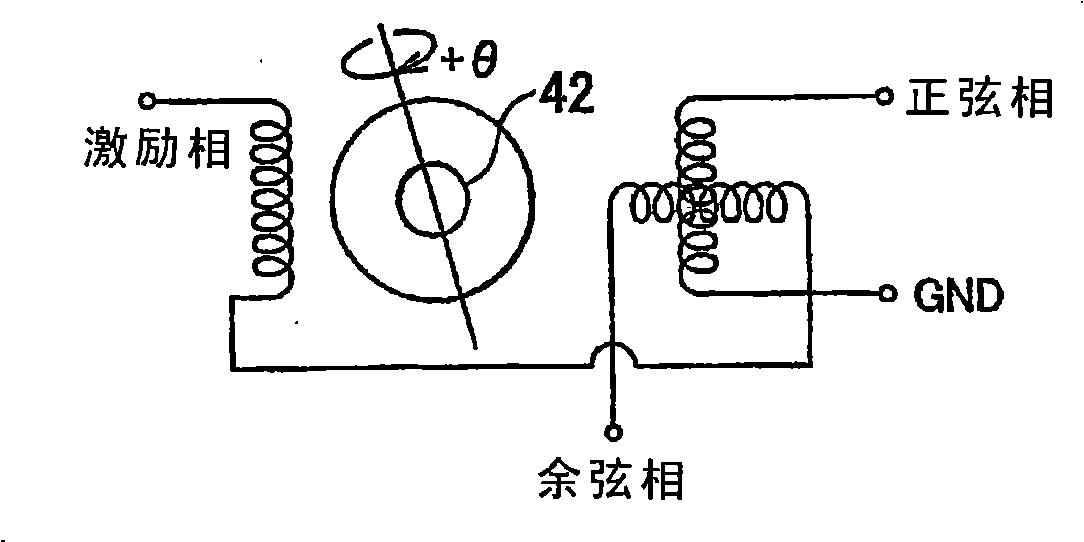

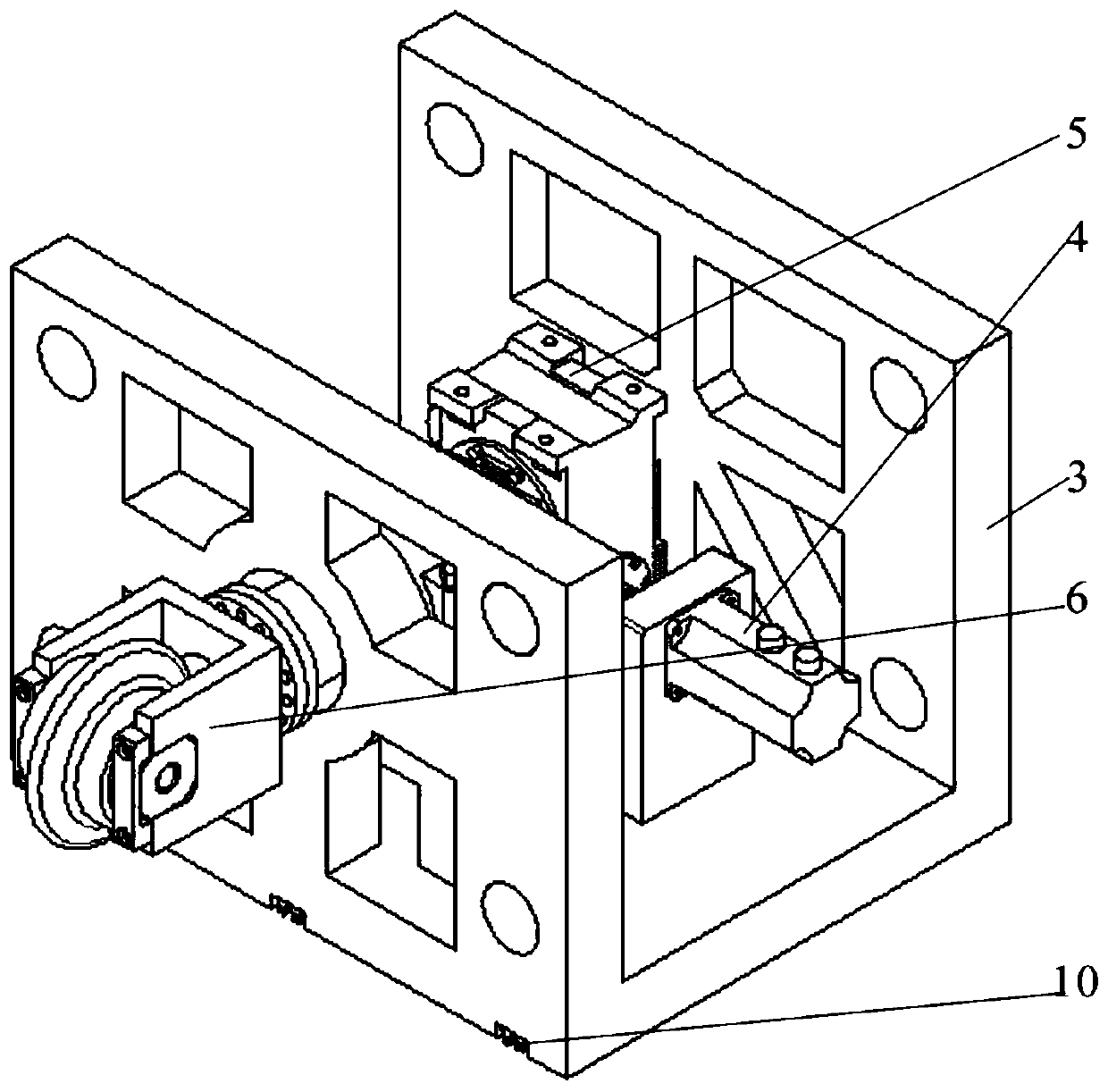

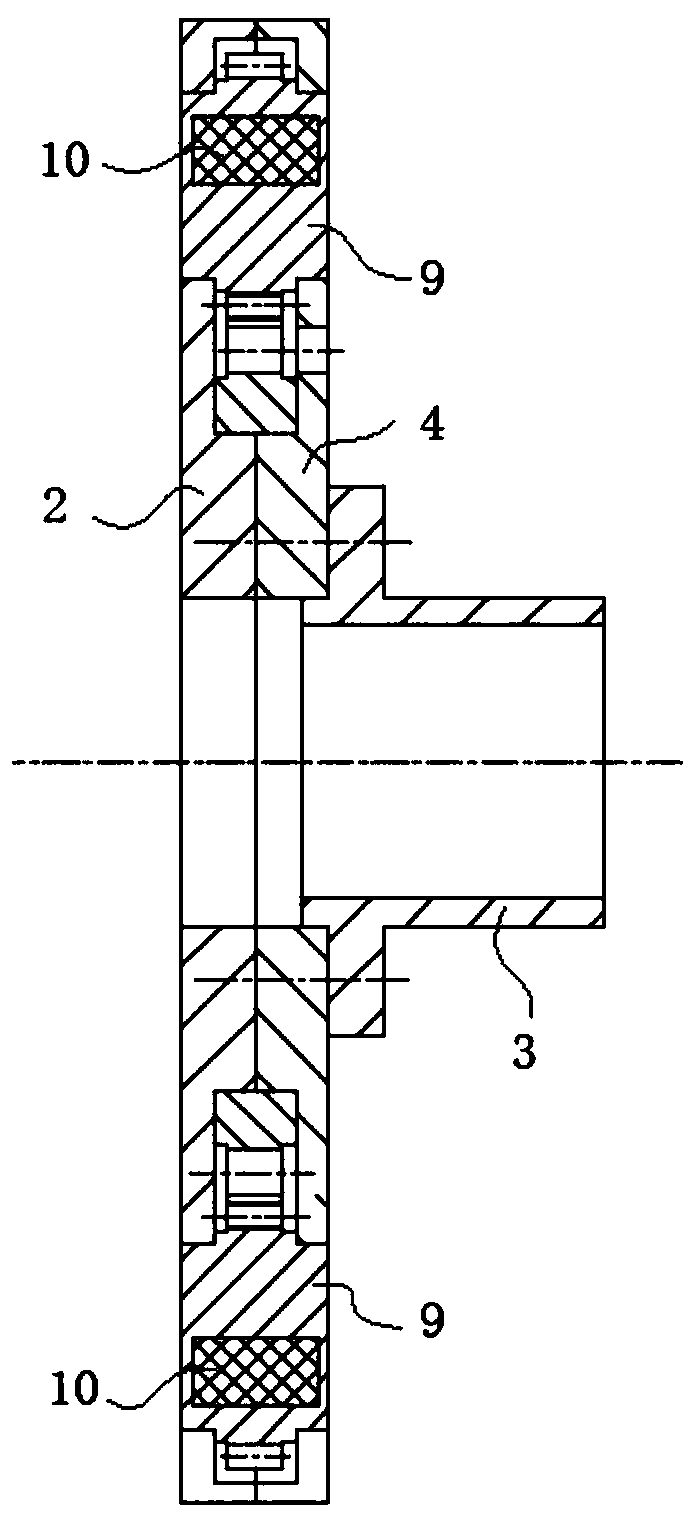

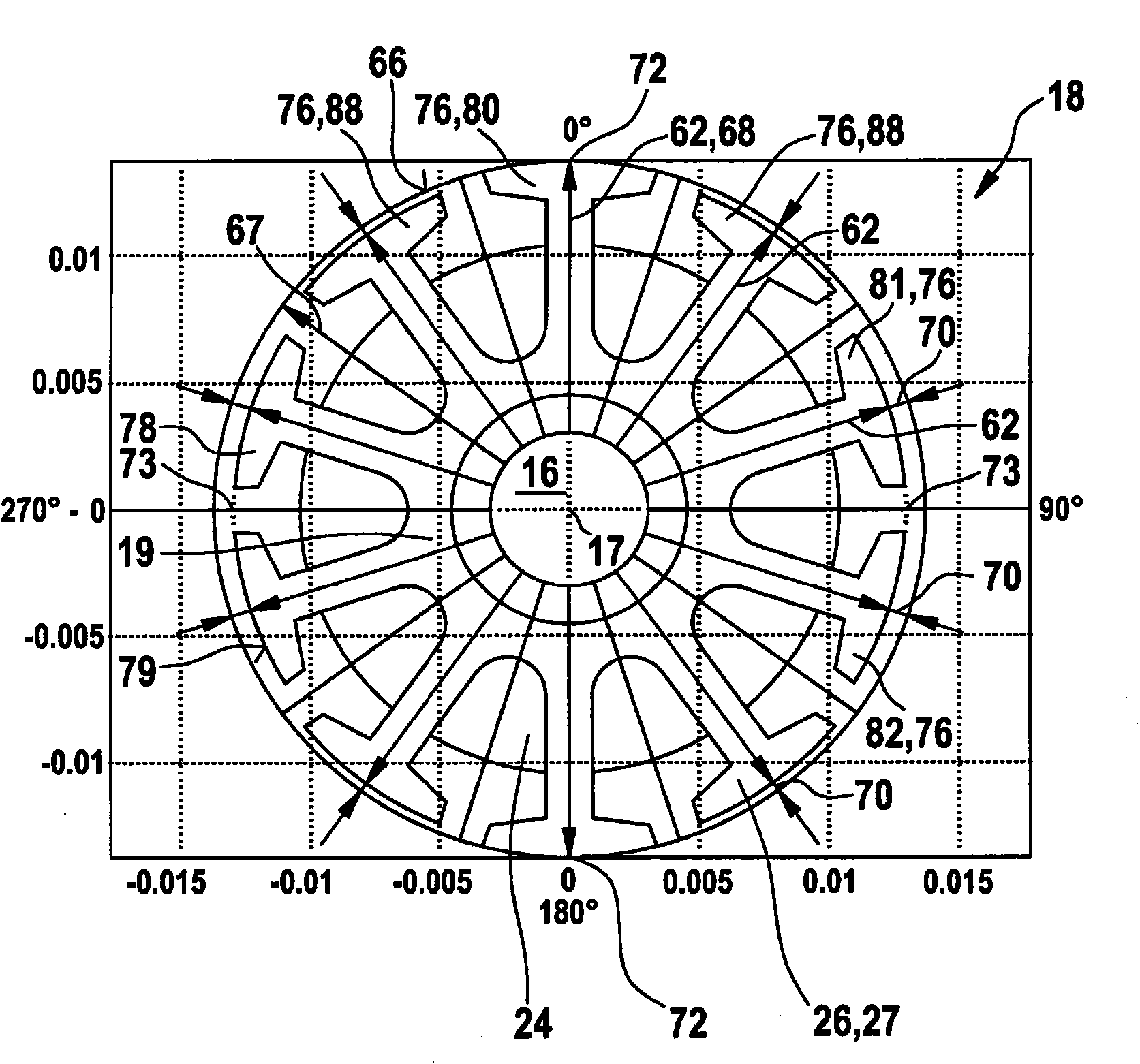

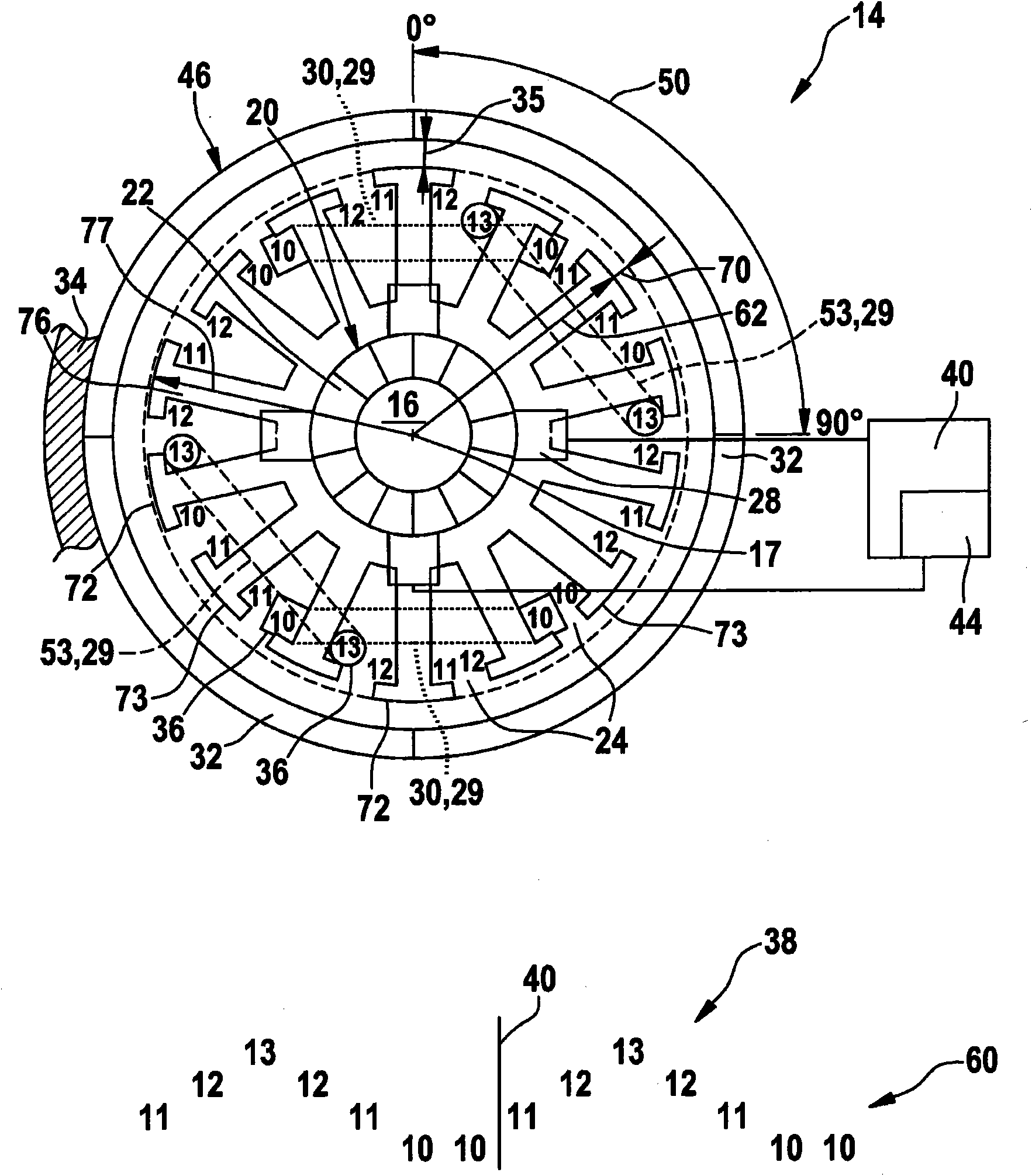

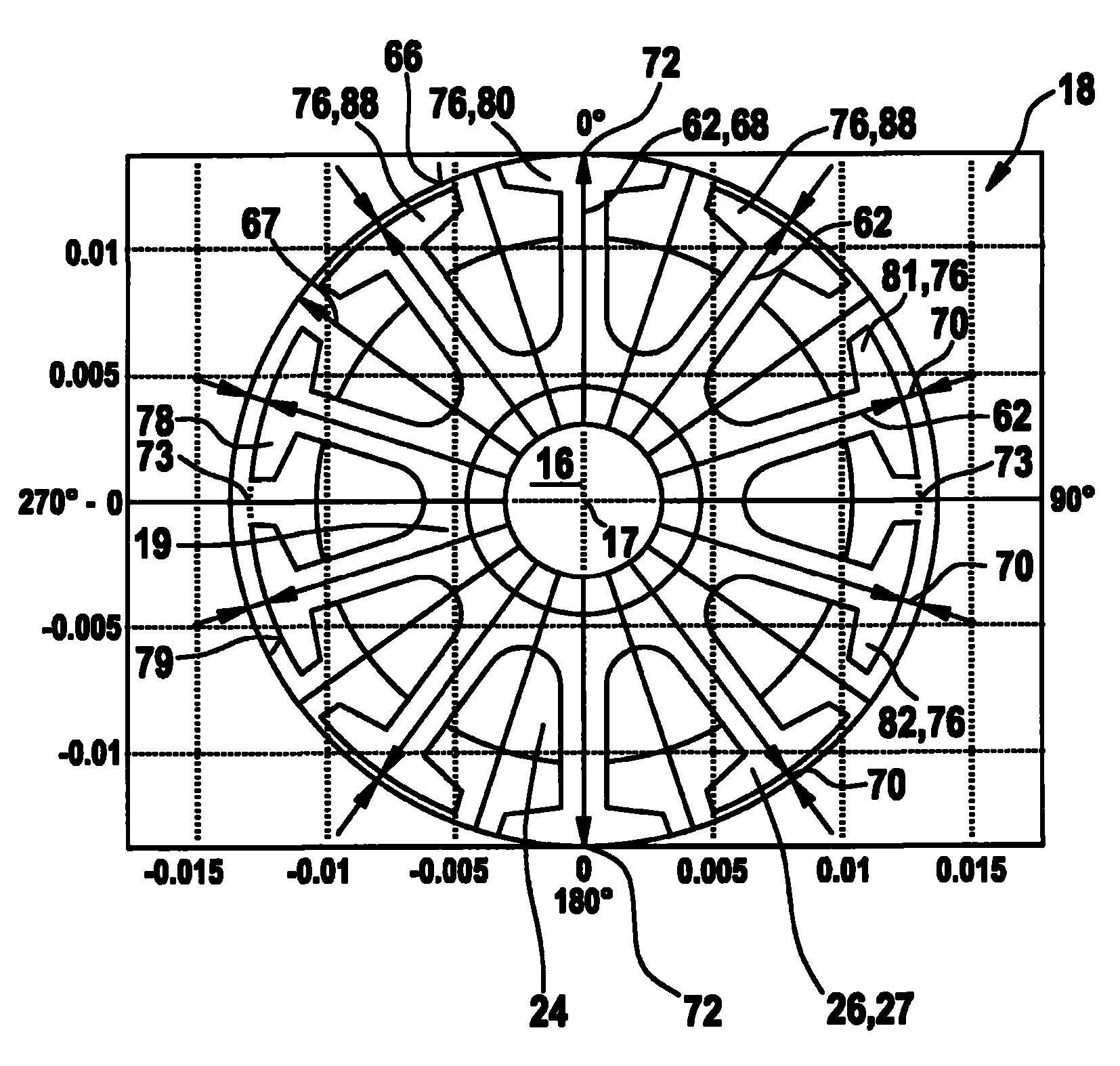

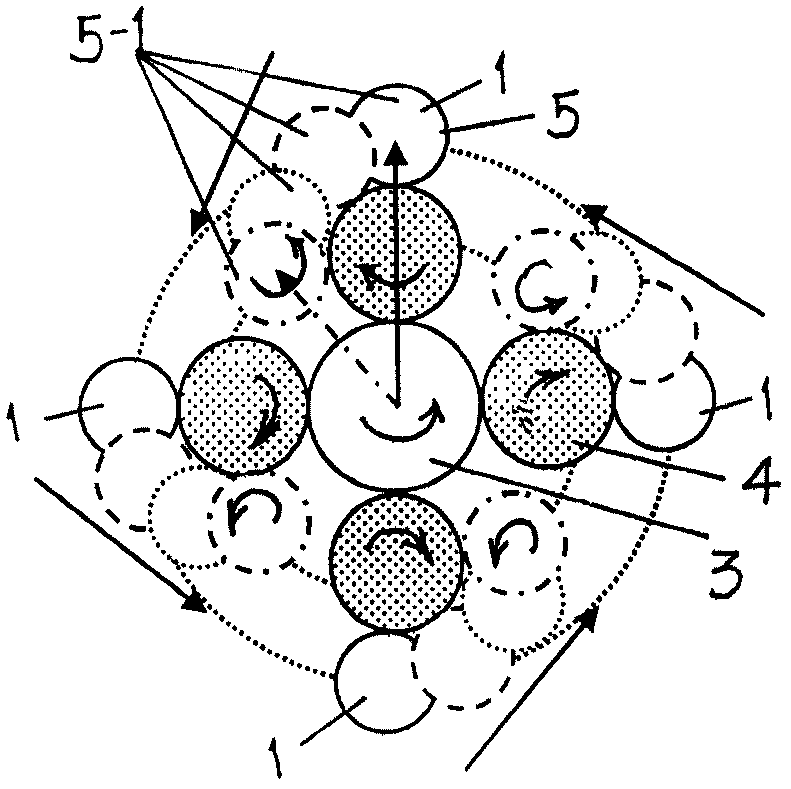

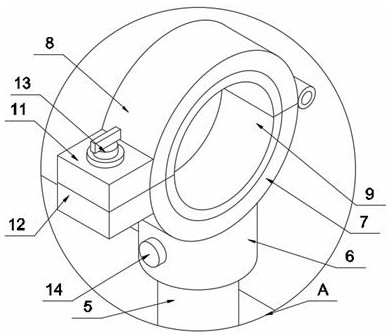

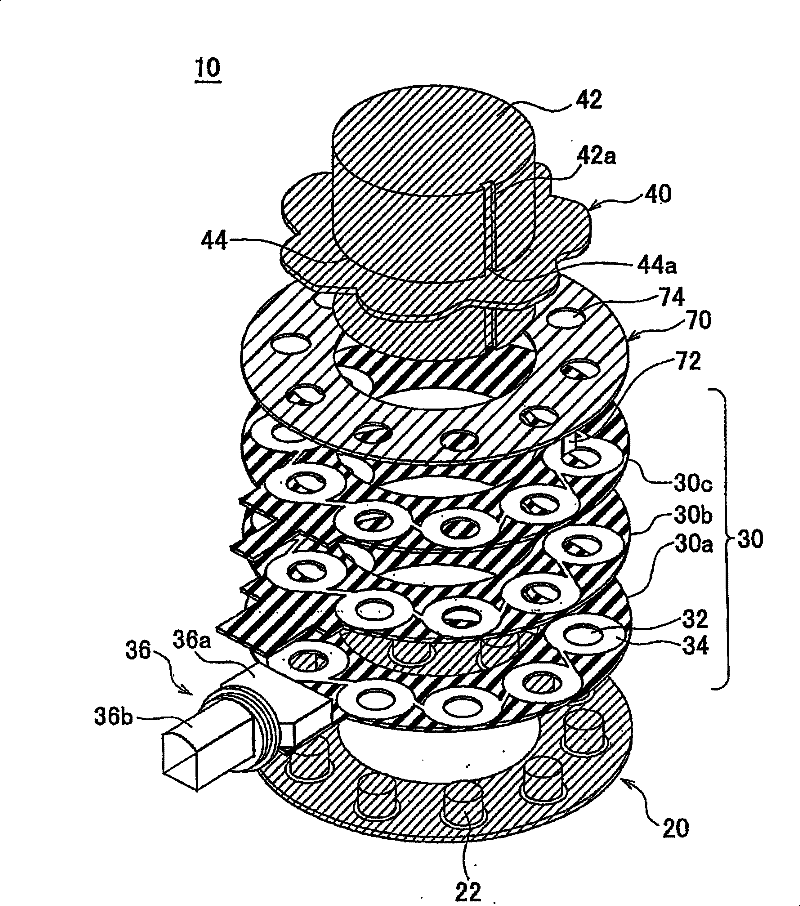

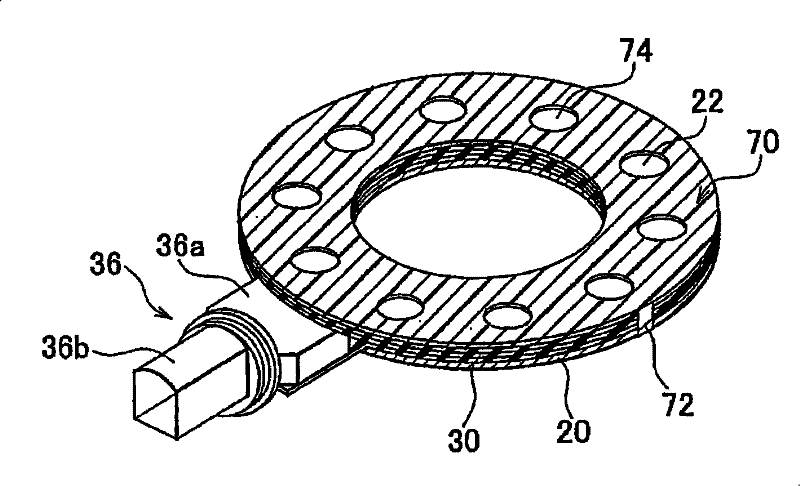

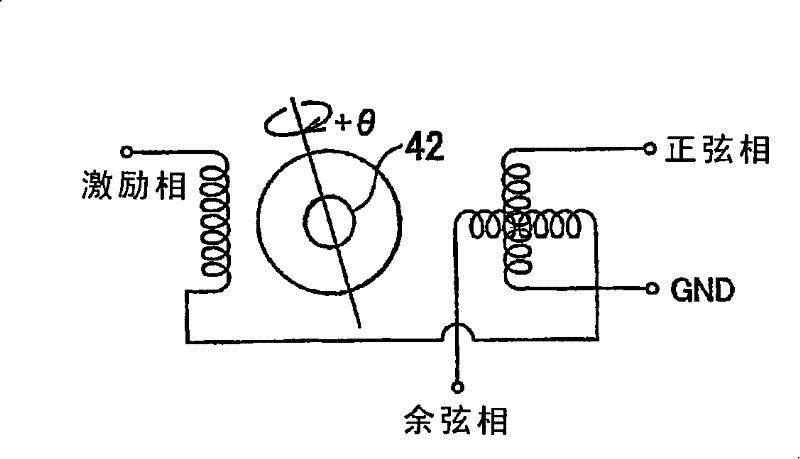

Magnetic resolver

ActiveCN101346873AMaximize the range of variationChange radiusDynamo-electric machinesConverting sensor output electrically/magneticallyEngineeringMechanical engineering

A magnetic resolver includes: a plurality of columnar cores disposed on an annular plate; a coil portion disposed around each of the columnar cores; and an annular rotor having a sinusoidal profile that rotates in a plane parallel to the top faces of the columnar cores around a rotation axis that passes through the center of the annular plate. The coil portion may be formed of a patterned coil formed on an annular substrate that has a plurality of through holes made therein through which the plurality of cores are passed, the patterned coil being formed around the through hole.

Owner:TOYOTA JIDOSHA KK +1

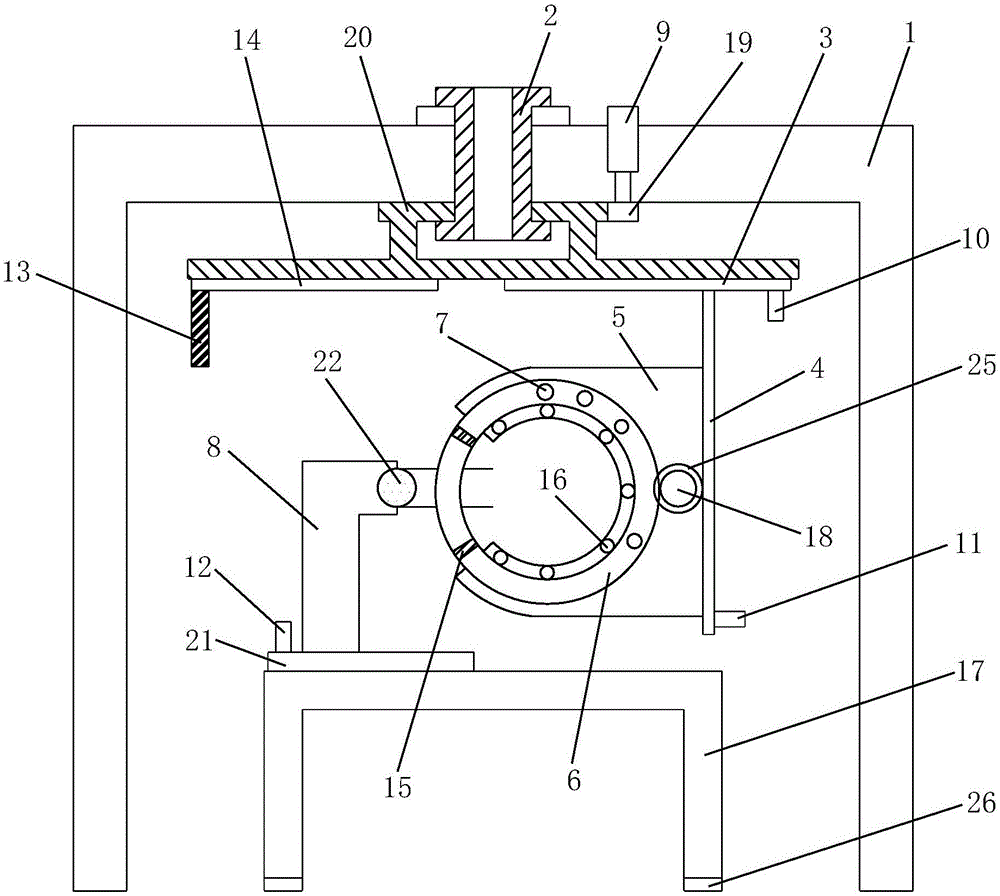

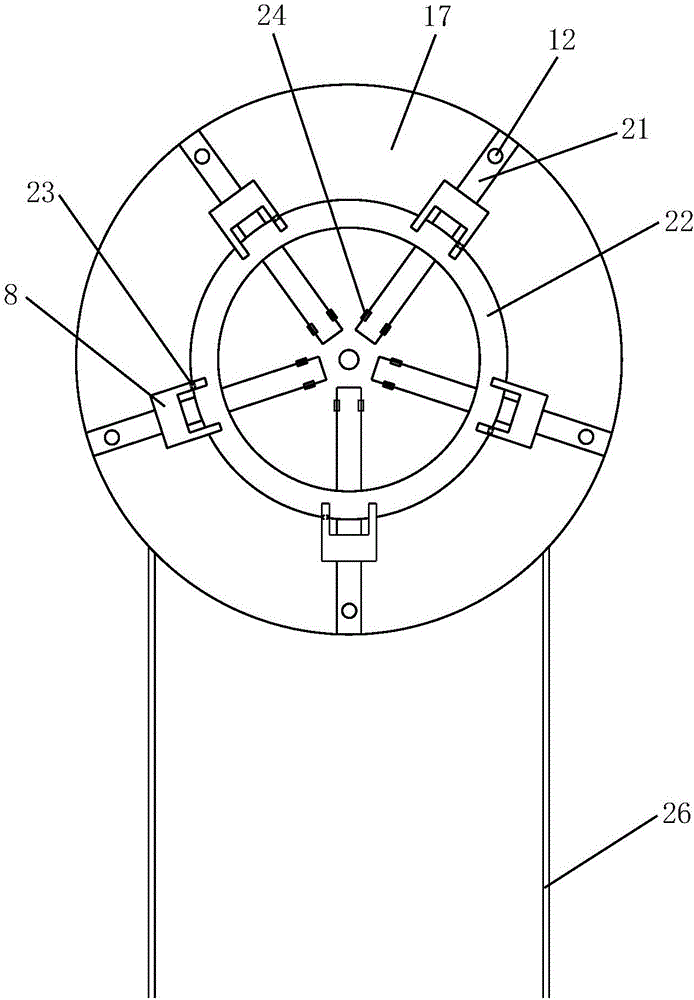

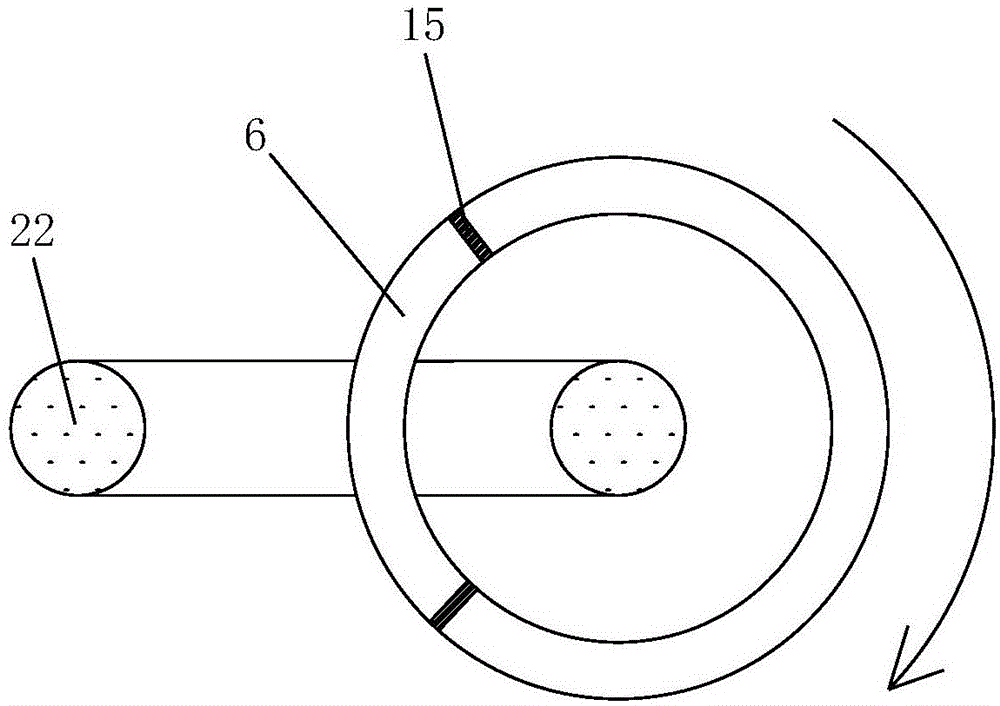

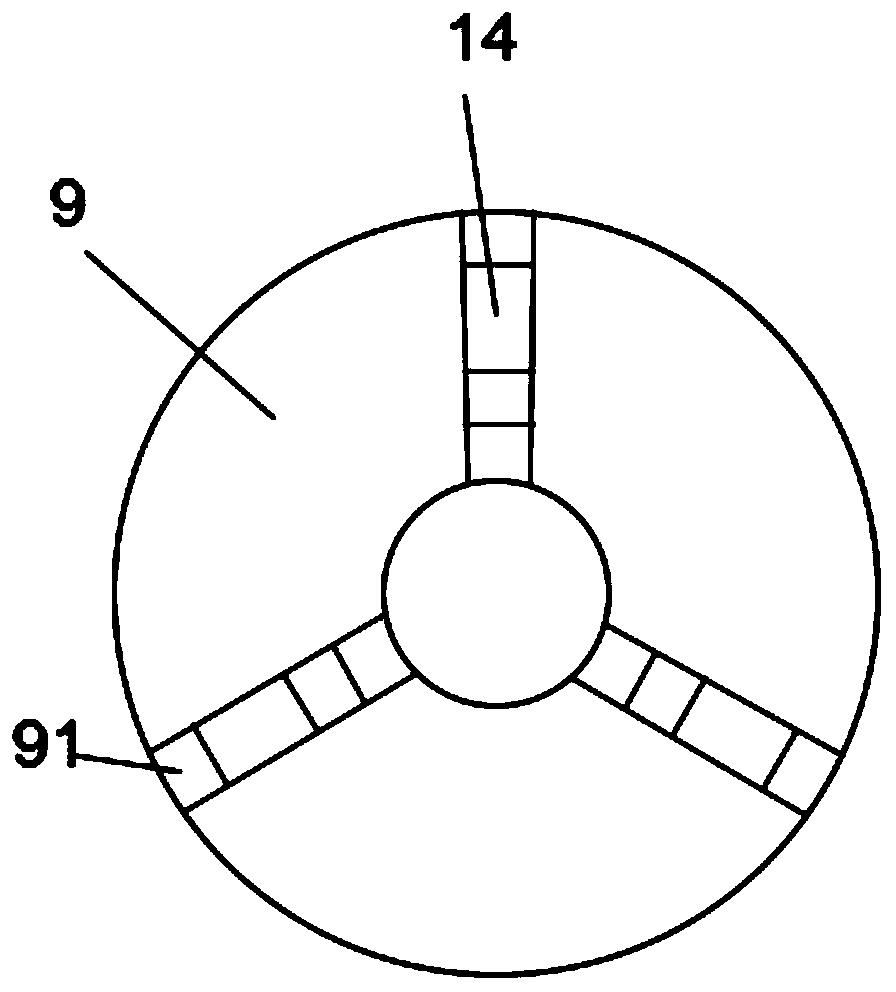

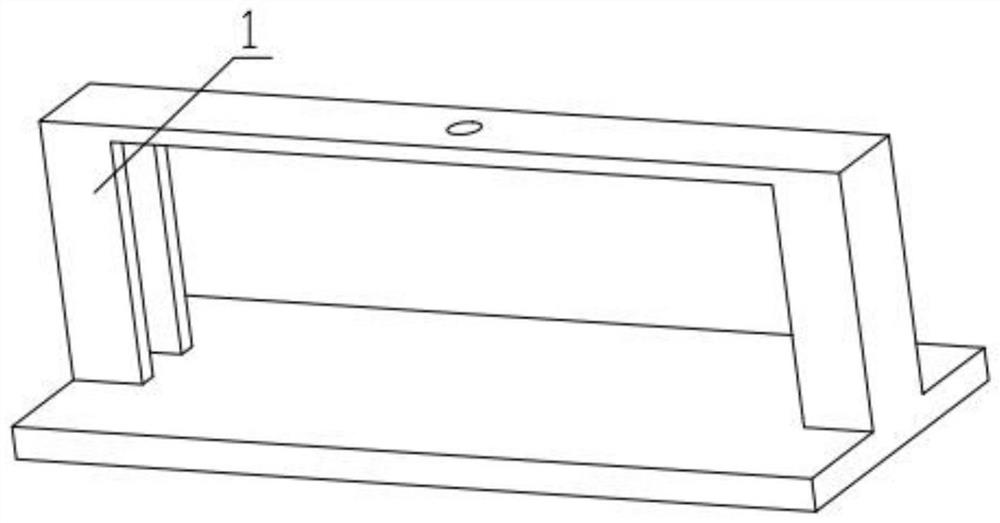

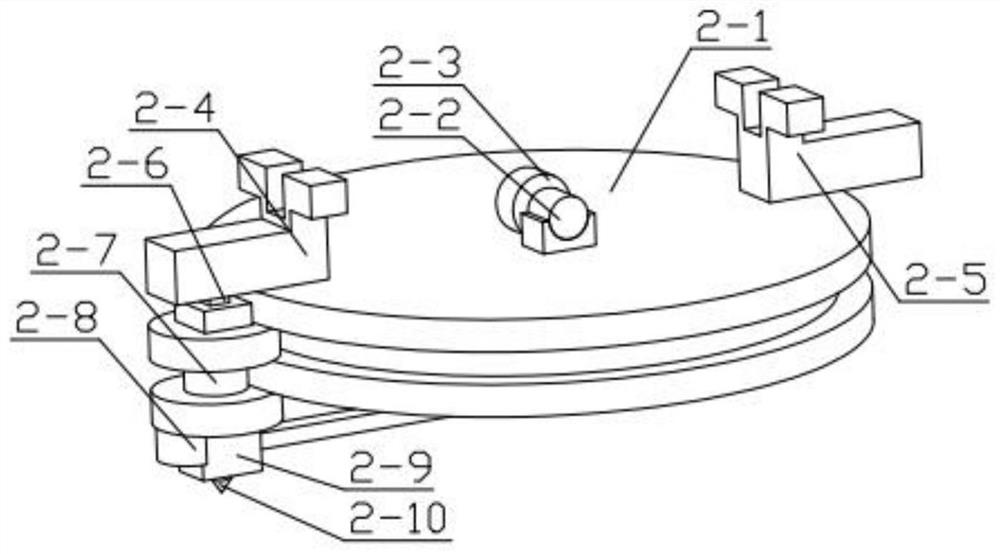

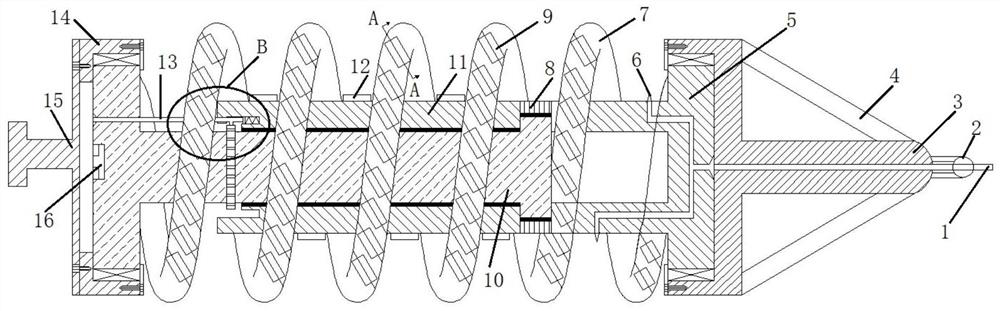

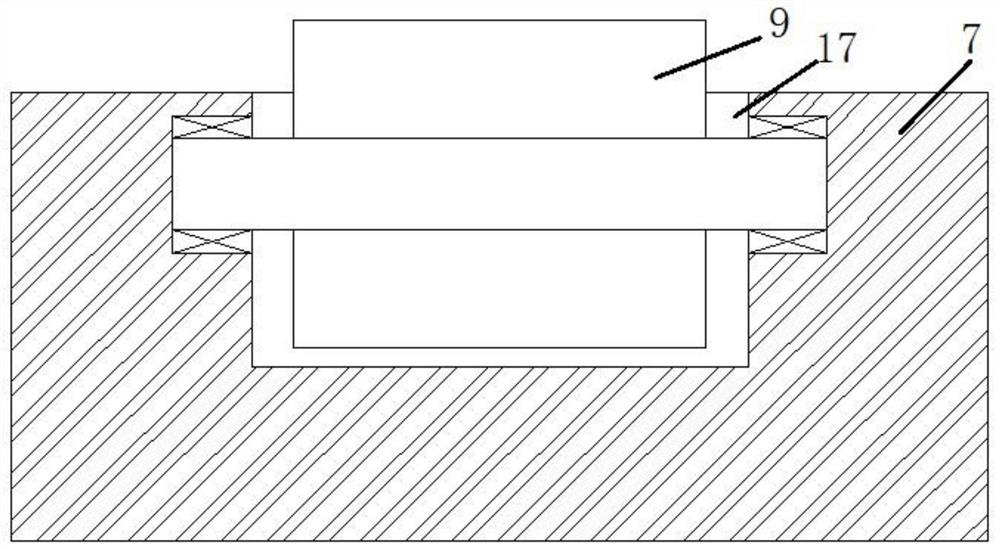

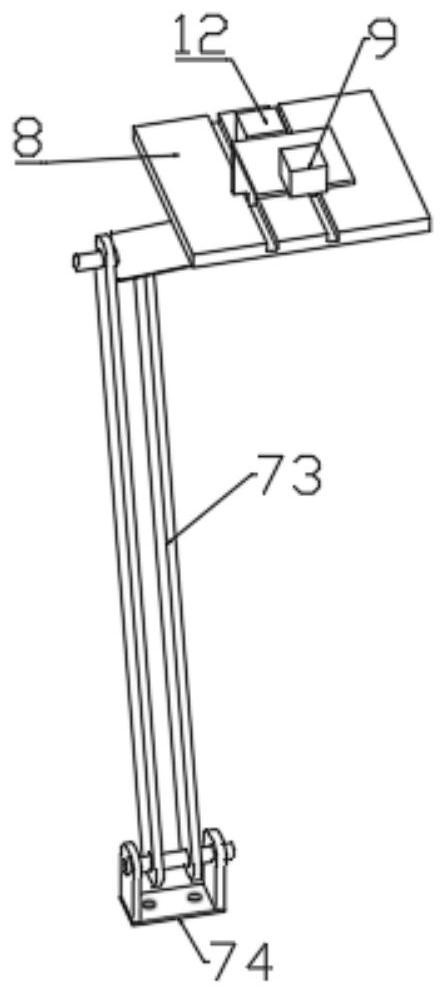

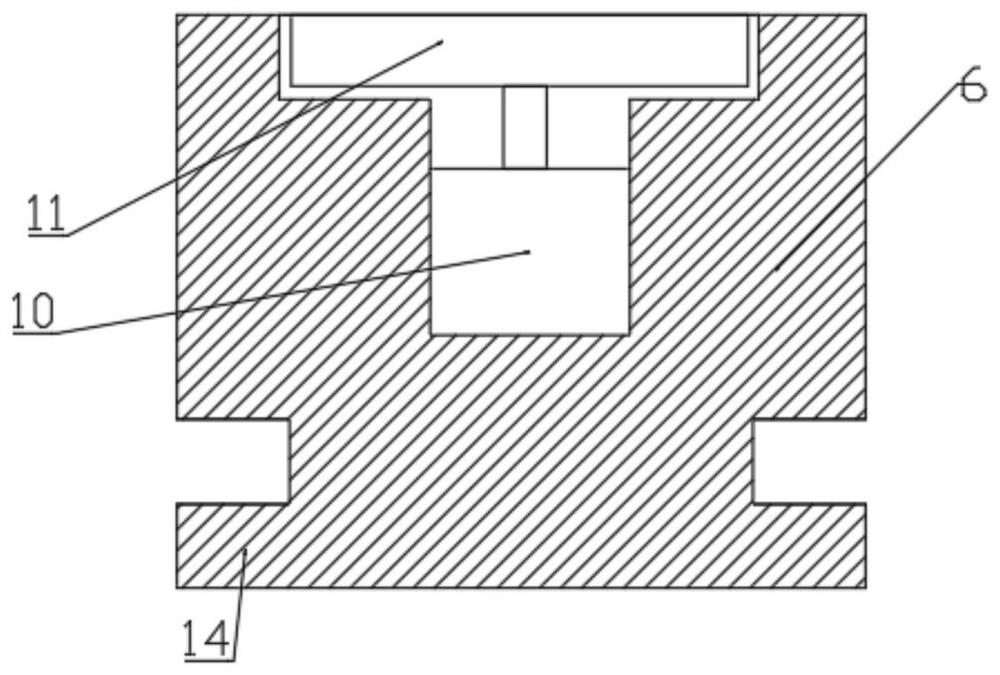

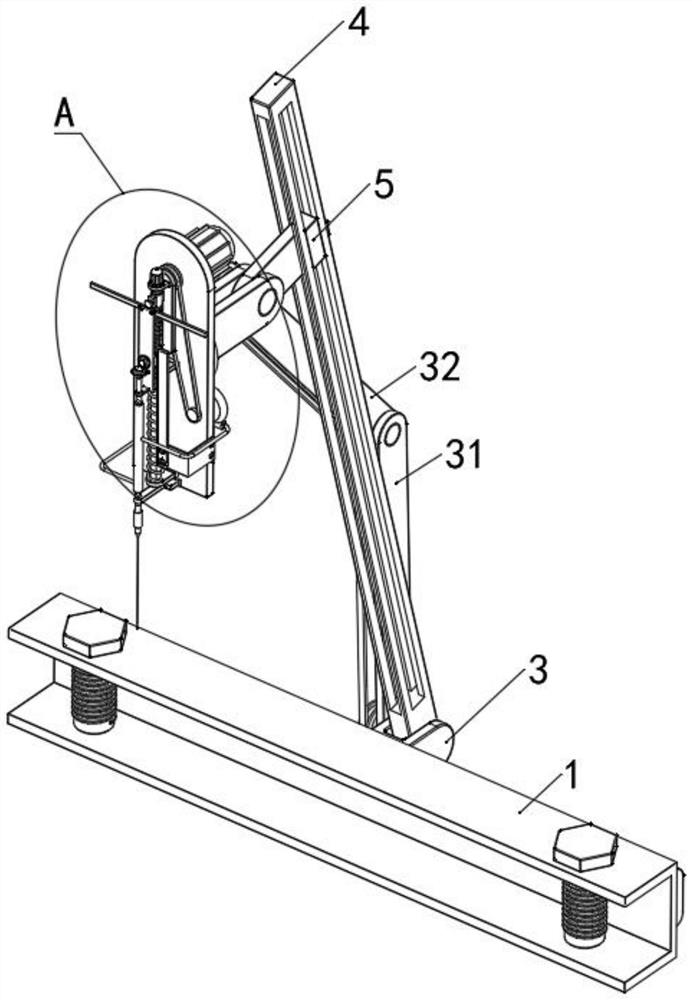

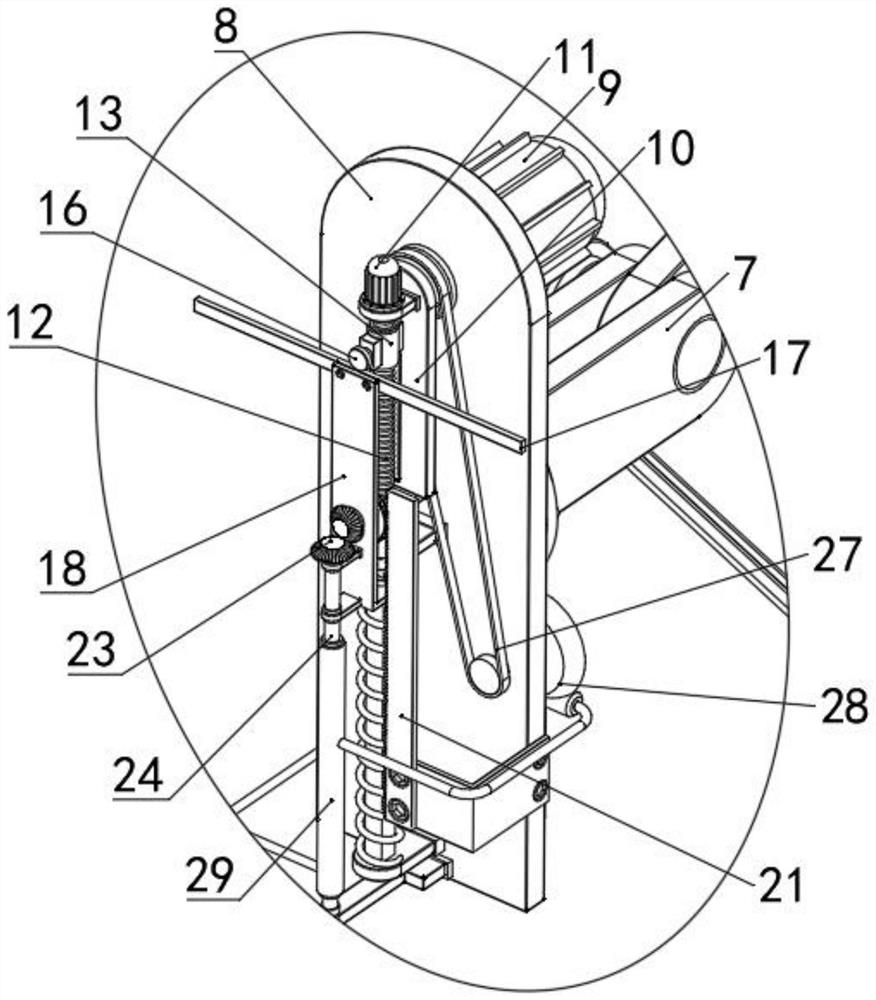

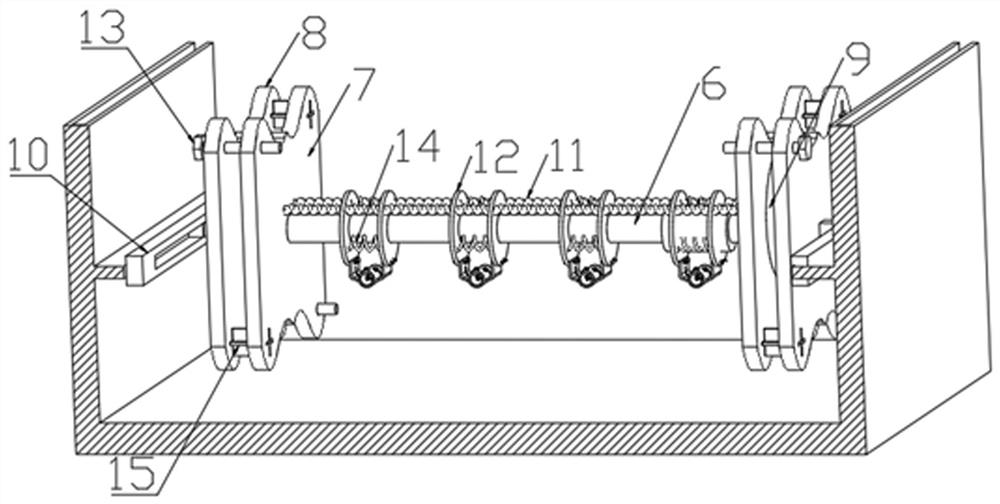

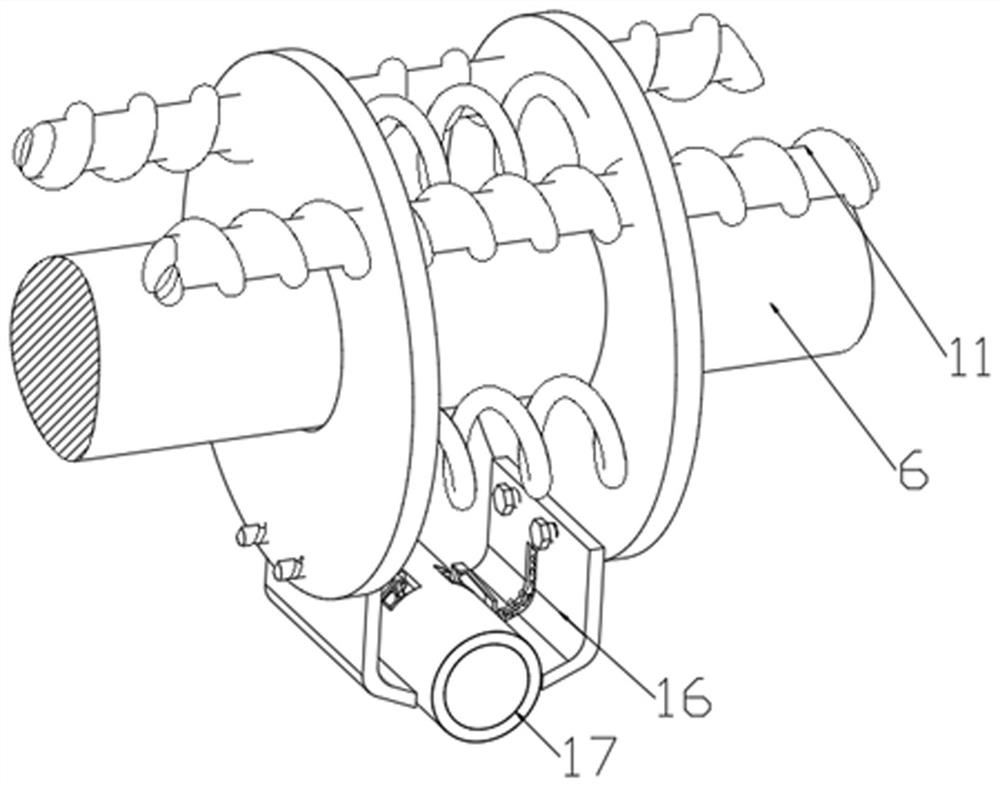

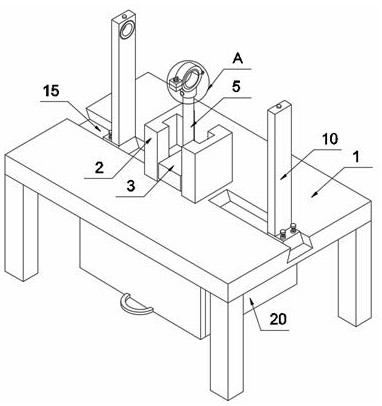

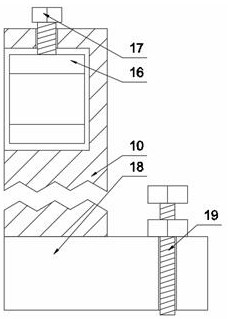

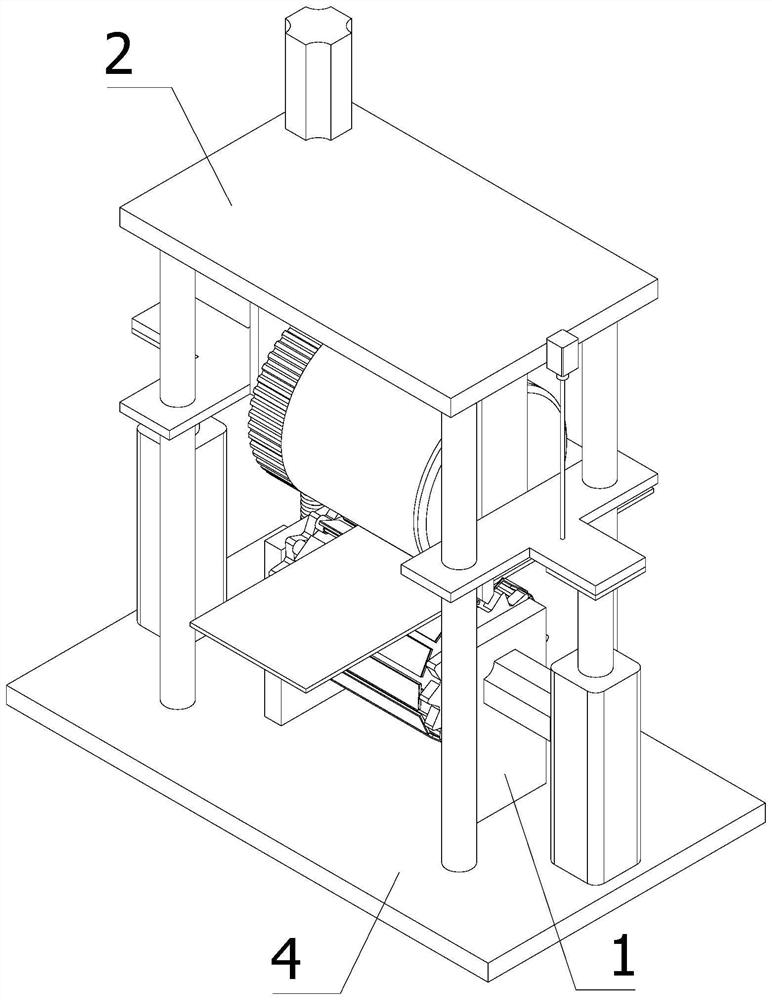

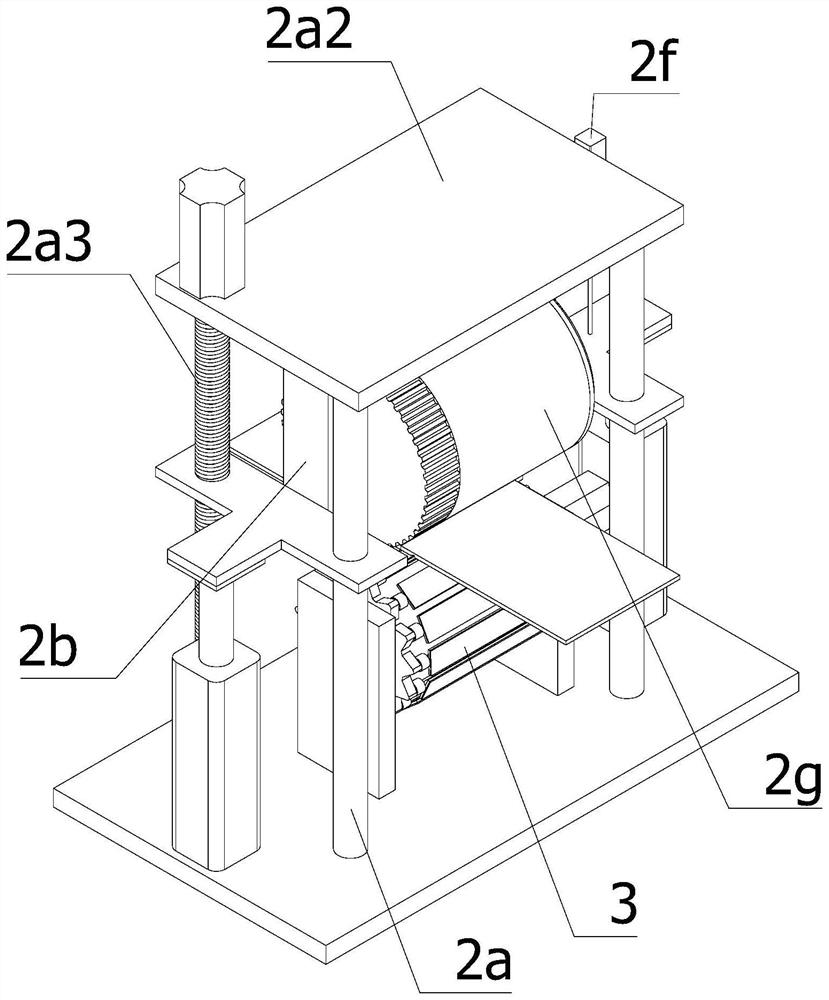

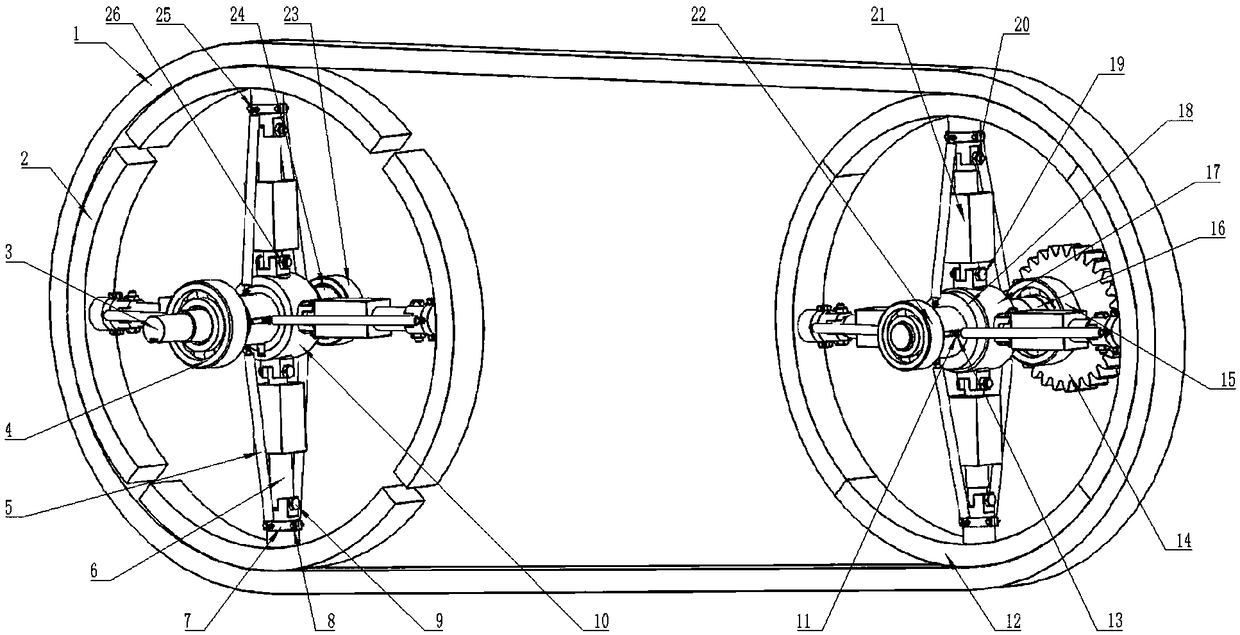

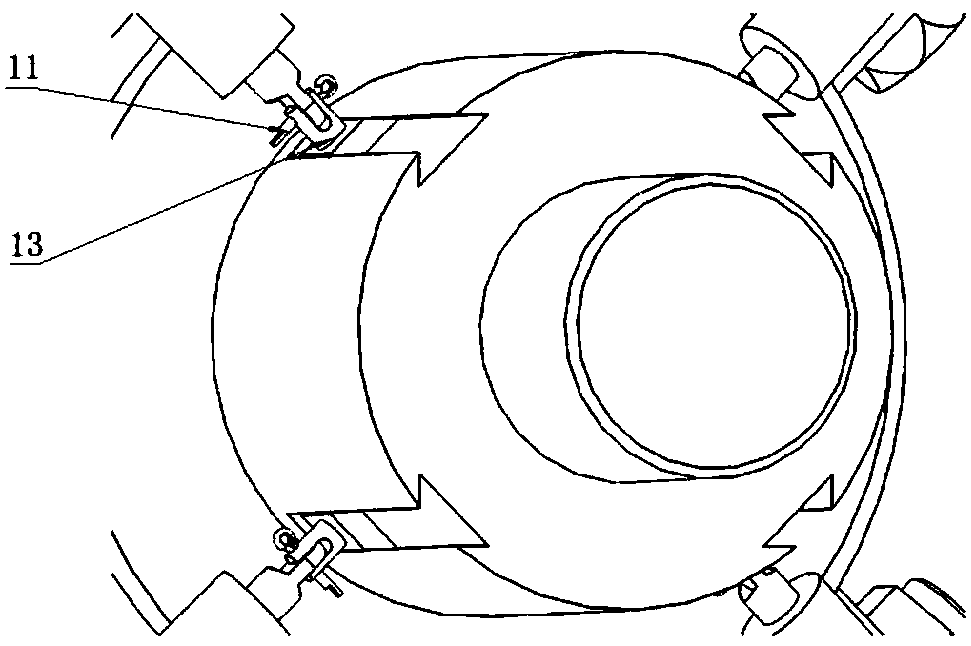

Gantry type annular container winding machine

The invention discloses a gantry type annular container winding machine. The gantry type annular container winding machine comprises a gantry bracket, a base and a wire nozzle bracket, wherein the base is arranged in the gantry bracket, the wire nozzle bracket is arranged above the base, a plurality of core mold clamping devices for fixing an annular core mold are mounted on the base, a wire nozzle bracket rotating device for driving the wire nozzle bracket to rotate around the periphery of the outer side of the annular core mold is mounted on the top of the gantry bracket, the wire nozzle bracket is mounted in the bottom of the wire nozzle bracket rotating device, an annular wire nozzle is mounted on the wire nozzle bracket, a driving mechanism for driving the annular wire nozzle to rotate around the periphery of the cross section of the annular core mold, and yarn guiding wheels are mounted on the annular wire nozzle. According to the gantry type annular container winding machine disclosed by the invention, the annular core mold is immobilized by virtue of the core mold clamping devices, the annular wire nozzle rotates around the periphery of the outer side of the annular core mold and around the periphery of the cross section of the annular core mold, and a fiber is wound on the surface of the core mold by rotational synthesis, so that the problem of inaccurate locating and yarn grinding caused by a friction drive mode of the annular core mold is solved.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

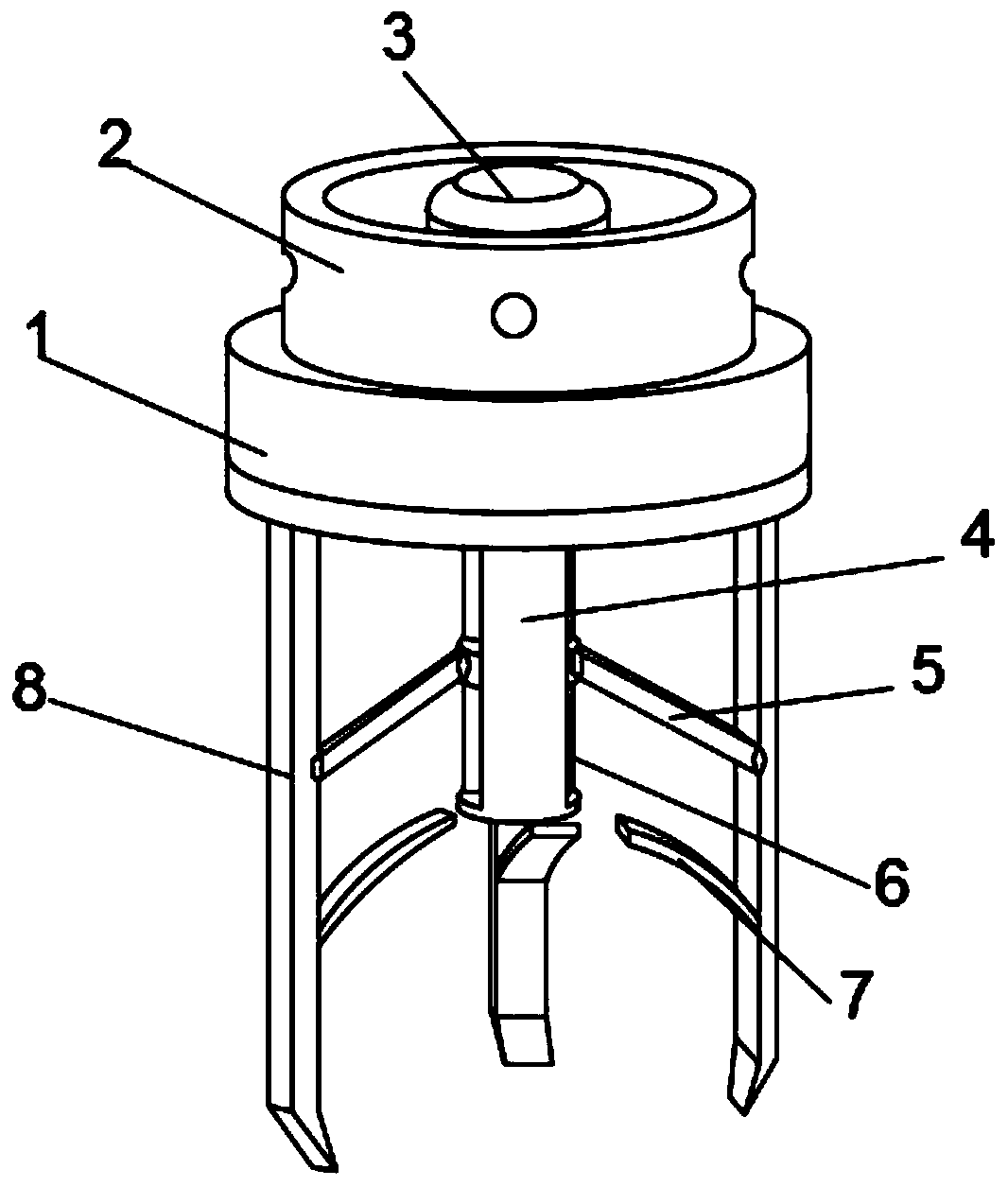

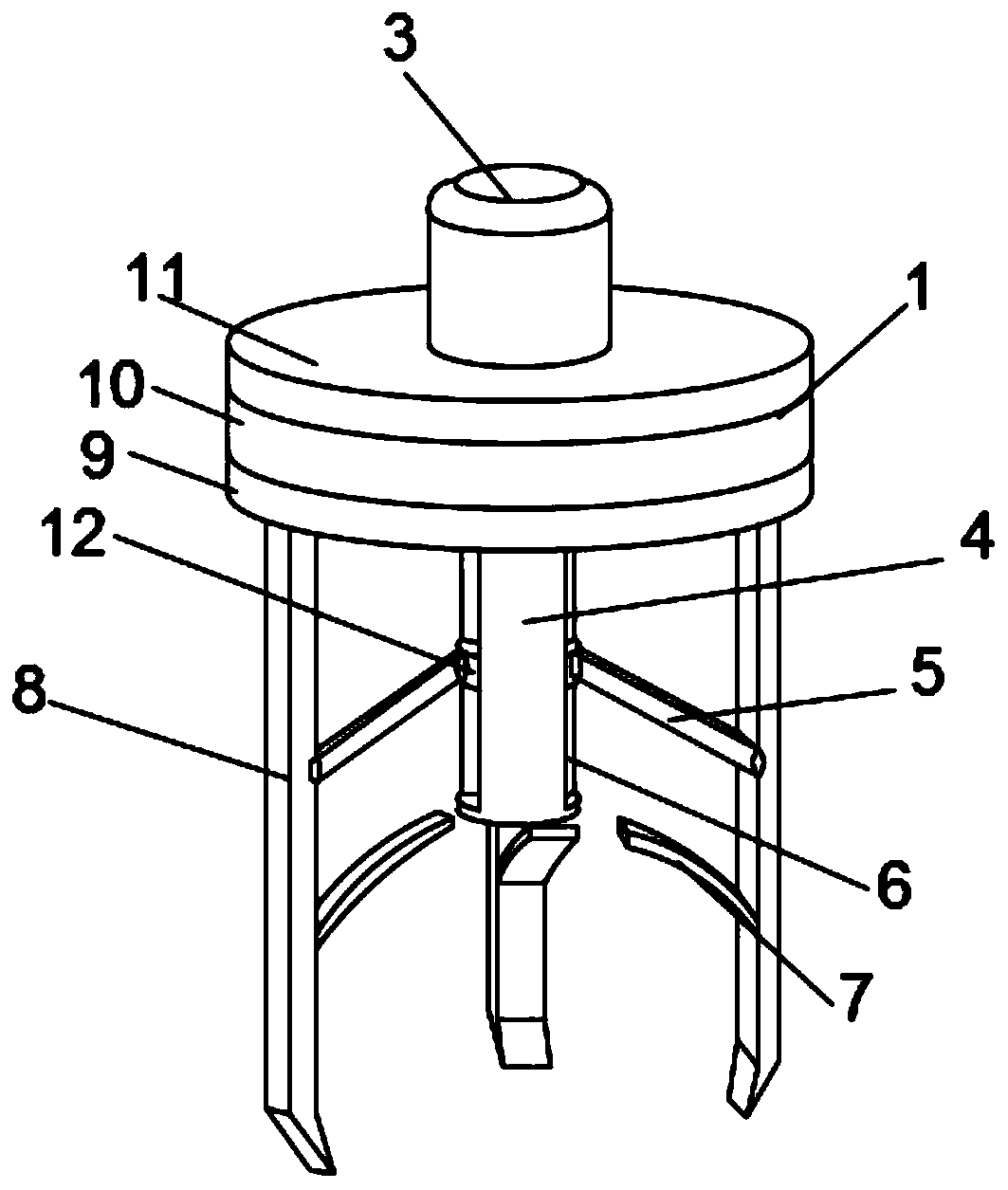

Star base

InactiveCN101810405AAdjust radiusAvoid the problem of arbitrary slidingFeetLocking mechanismArchitectural engineering

The invention discloses a star base, which consists of a base and a castor. The base is formed by connecting a central disk and five extension arms radiated from the central disk; any one of the extension arms is provided with a groove along the length direction thereof; a support post is embedded in any one of grooves; any one of support posts is provided with more than two through holes along the length direction thereof; the bottom surface of any one of the grooves is provided with more than two screw holes along the length direction thereof, and a bolt is arranged in at least one screw hole and at least passes through one through hole; the castor is arranged at the outer end of the support post, and is provided with a locking device; the relative positions of the extension arms and the support post can be adjusted so as to change the radius of the star base and reduce cost; and the locking mechanism is arranged in the castor so as to avoid the problem that a vacant seat slides freely.

Owner:SHANGHAI AVARTE FURNITURE

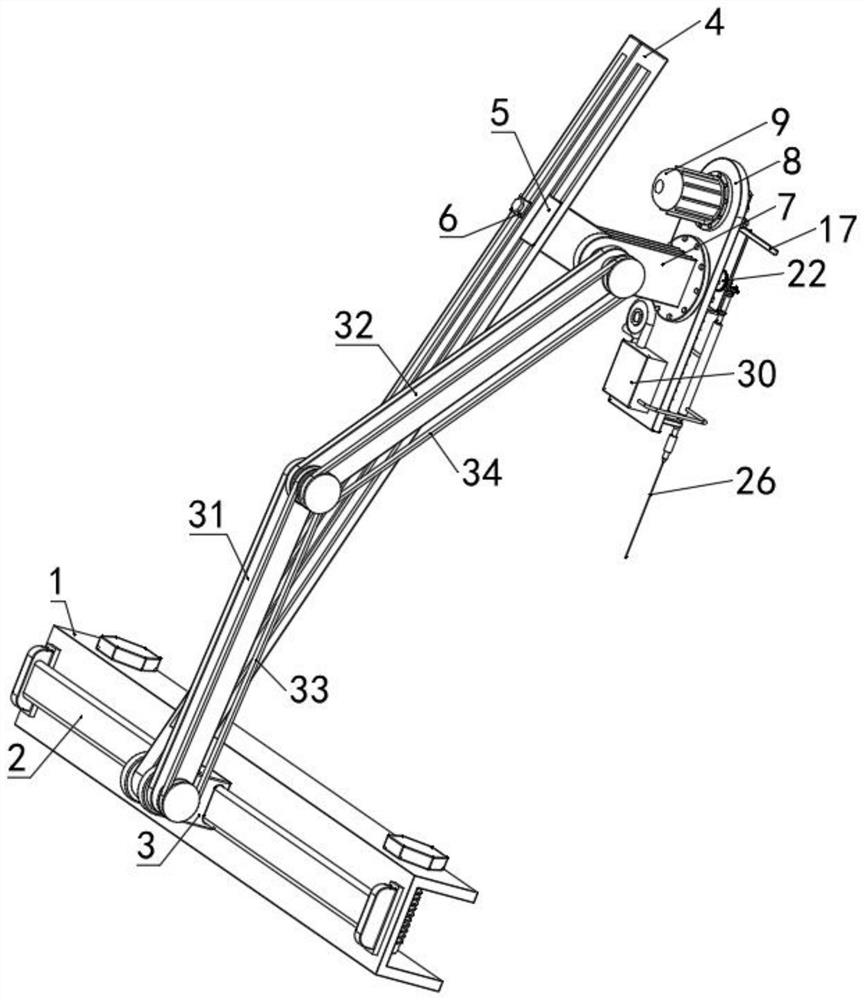

Robot mechanical hand clamping structure

Owner:NANJING YUSHENG ROBOT CO LTD

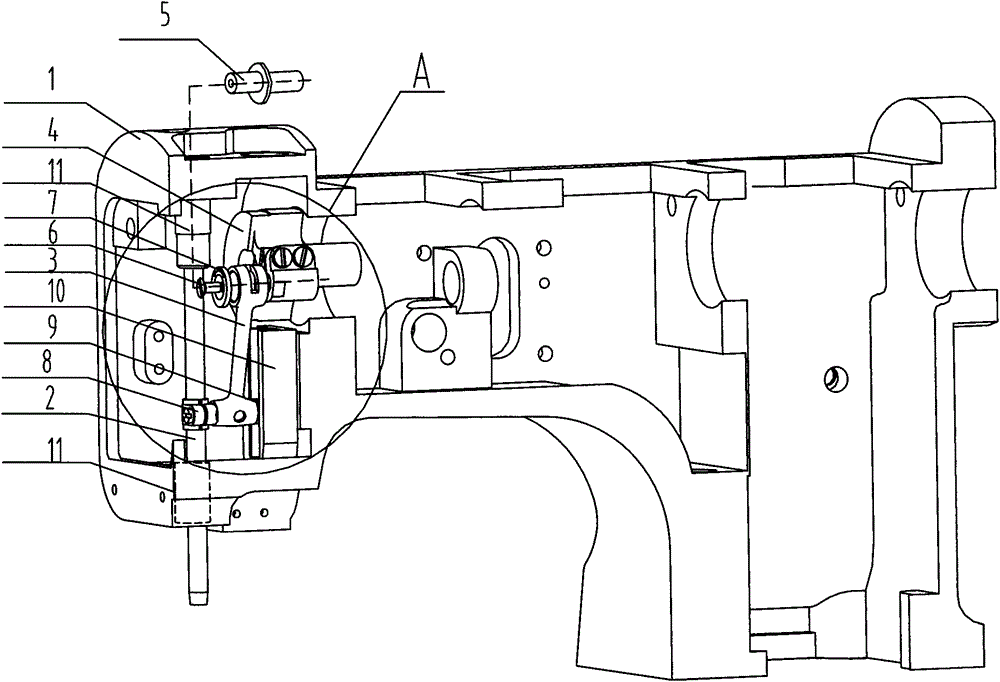

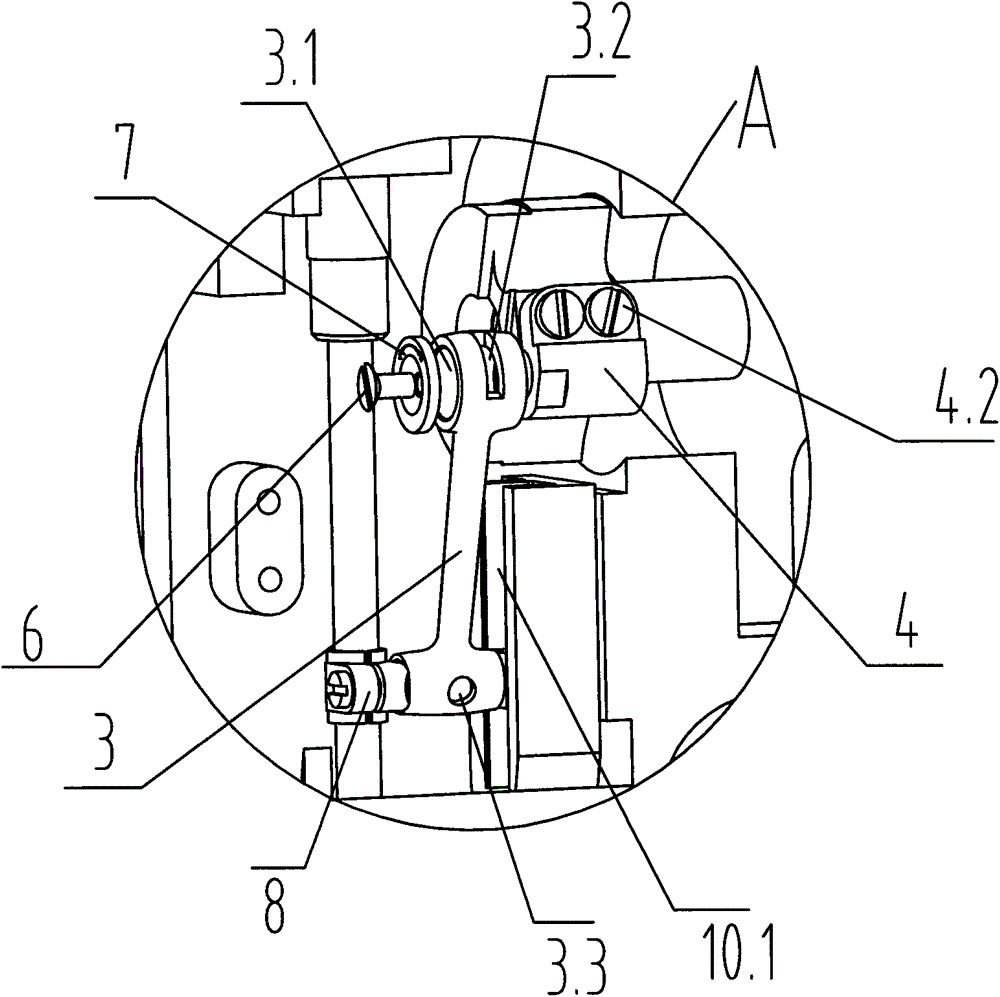

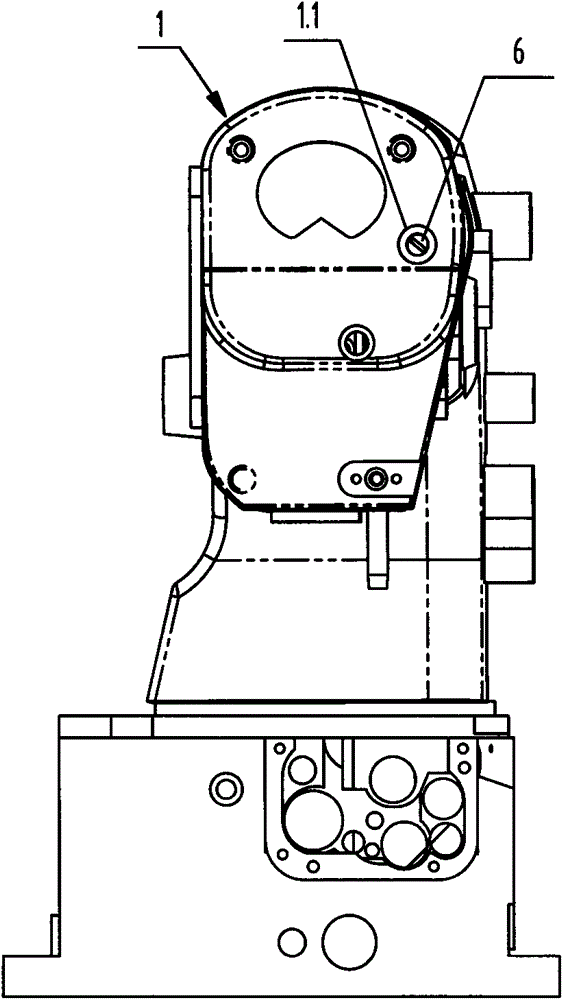

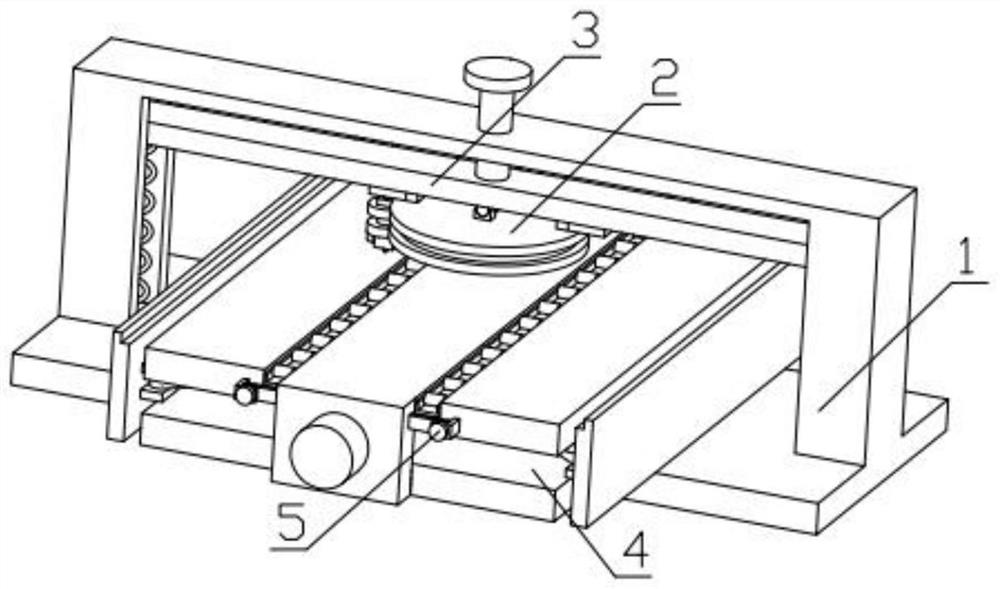

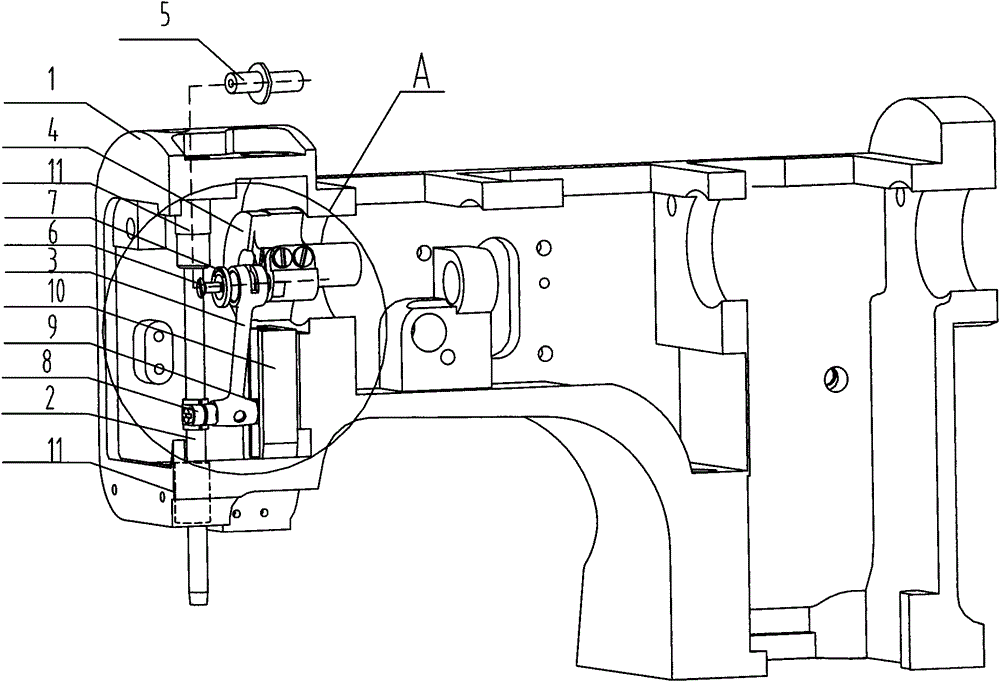

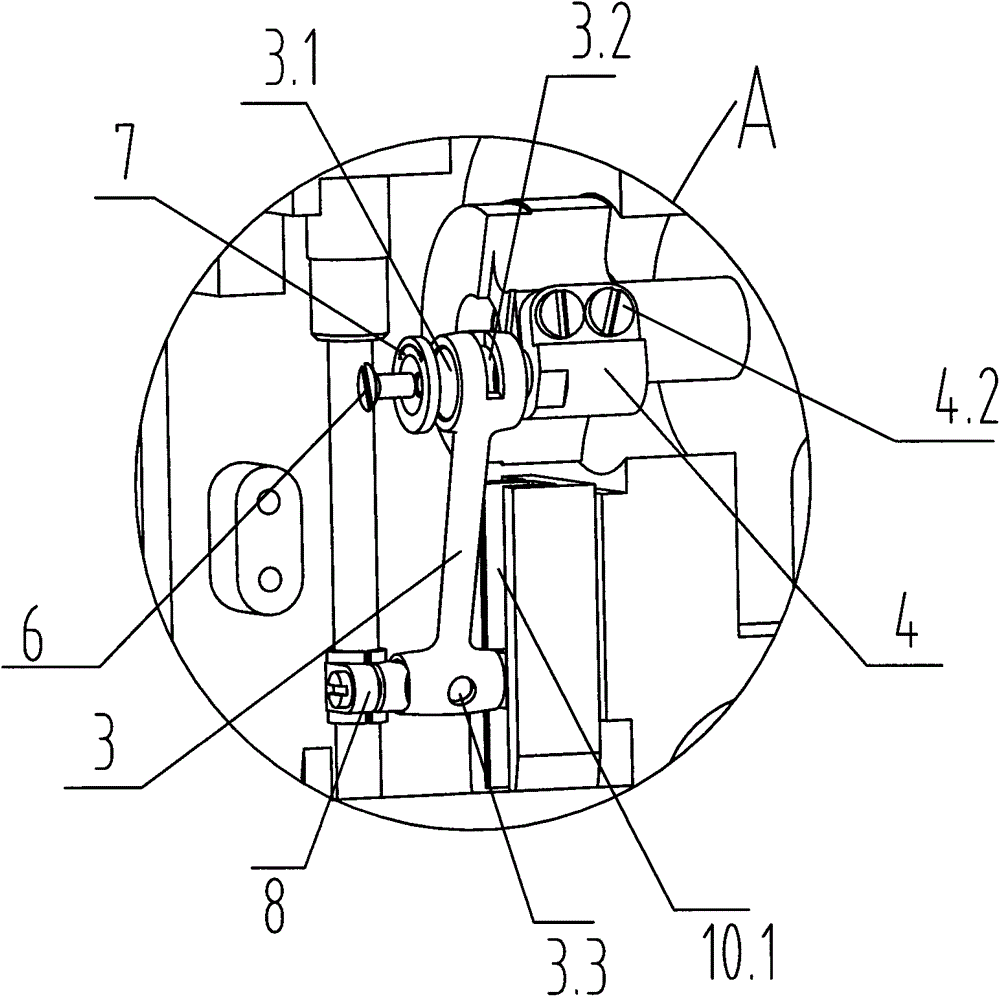

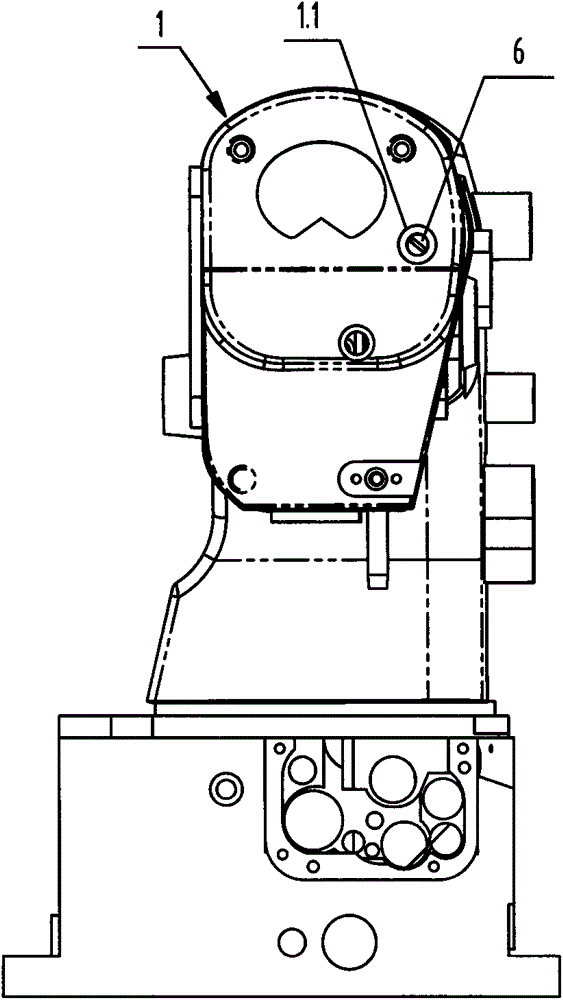

Sewing machine with adjustable needle bar stroke

ActiveCN104131422AChange radiusRealize stroke adjustmentLubrication/cooling devicesSewing-machine control devicesElectric machinerySewing machine

The invention discloses a sewing machine with an adjustable needle bar stroke, and belongs to the technical field of sewing machines. The sewing machine comprises a needle bar, a connection bar, a crank, a main shaft and a motor and further comprises an eccentric link pin. The upper end of the connection bar is connected with the crank through the eccentric link pin, the upper end of the connection bar is provided with an axial through hole, a first shaft is matched in the axial through hole in the connection bar in a rotating mode, the outer end of the first shaft is connected with an adjusting screw in a threaded mode in the axial direction and is cushioned with a limiting gasket for preventing the upper end of the connection bar from axial movement, and a left cover of a machine head at the position where the adjusting screw stretches outwards in the axial direction is provided with a screw hole for a screw driver to be inserted so as to screw the adjusting strew conveniently. The sewing machine with the adjustable needle bar stroke has the advantages of being adjustable in the needle bar stroke, simplifying the adjusting mode, saving oil and the like.

Owner:JACK SEWING MASCH CO LTD

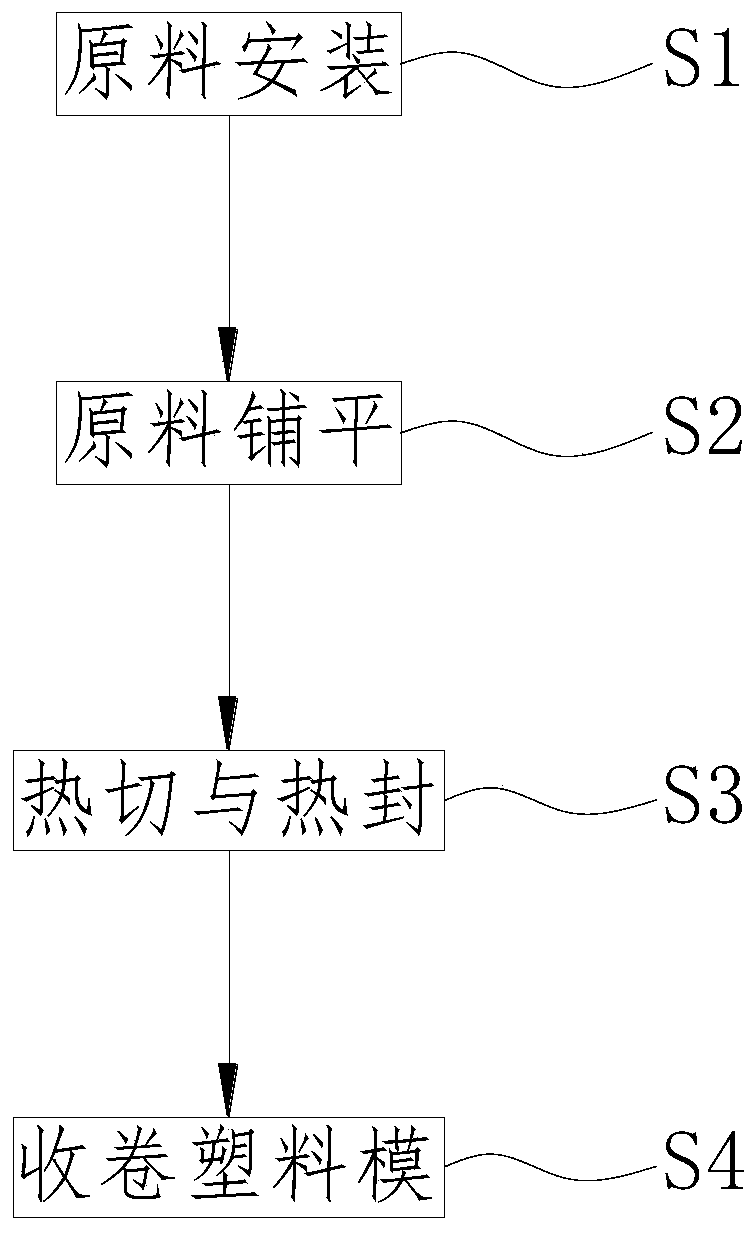

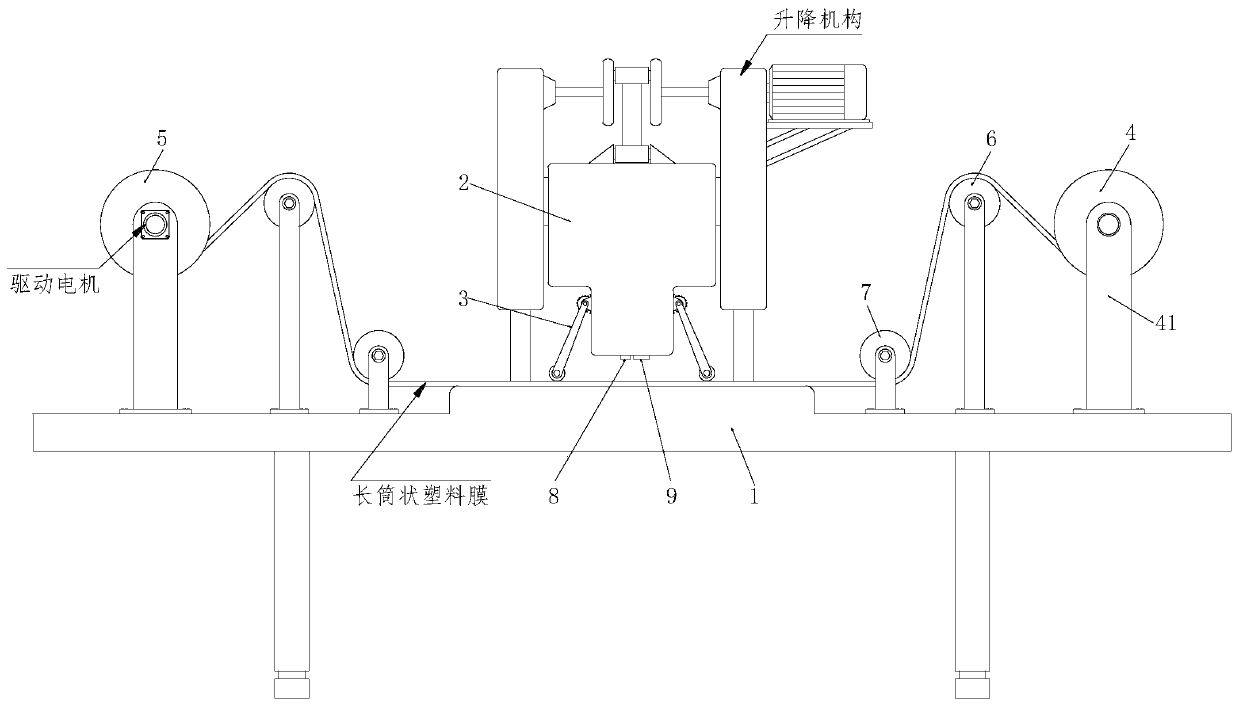

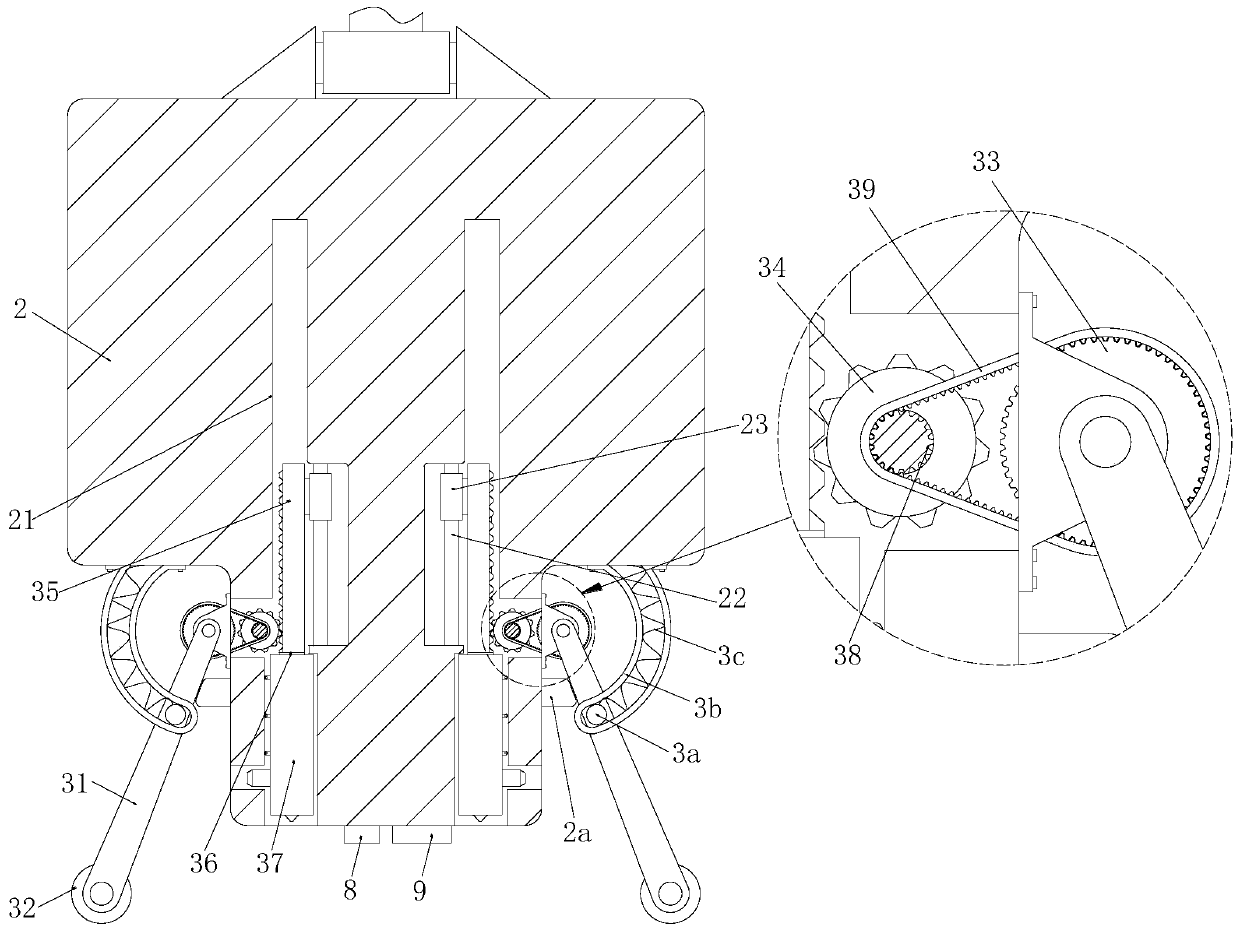

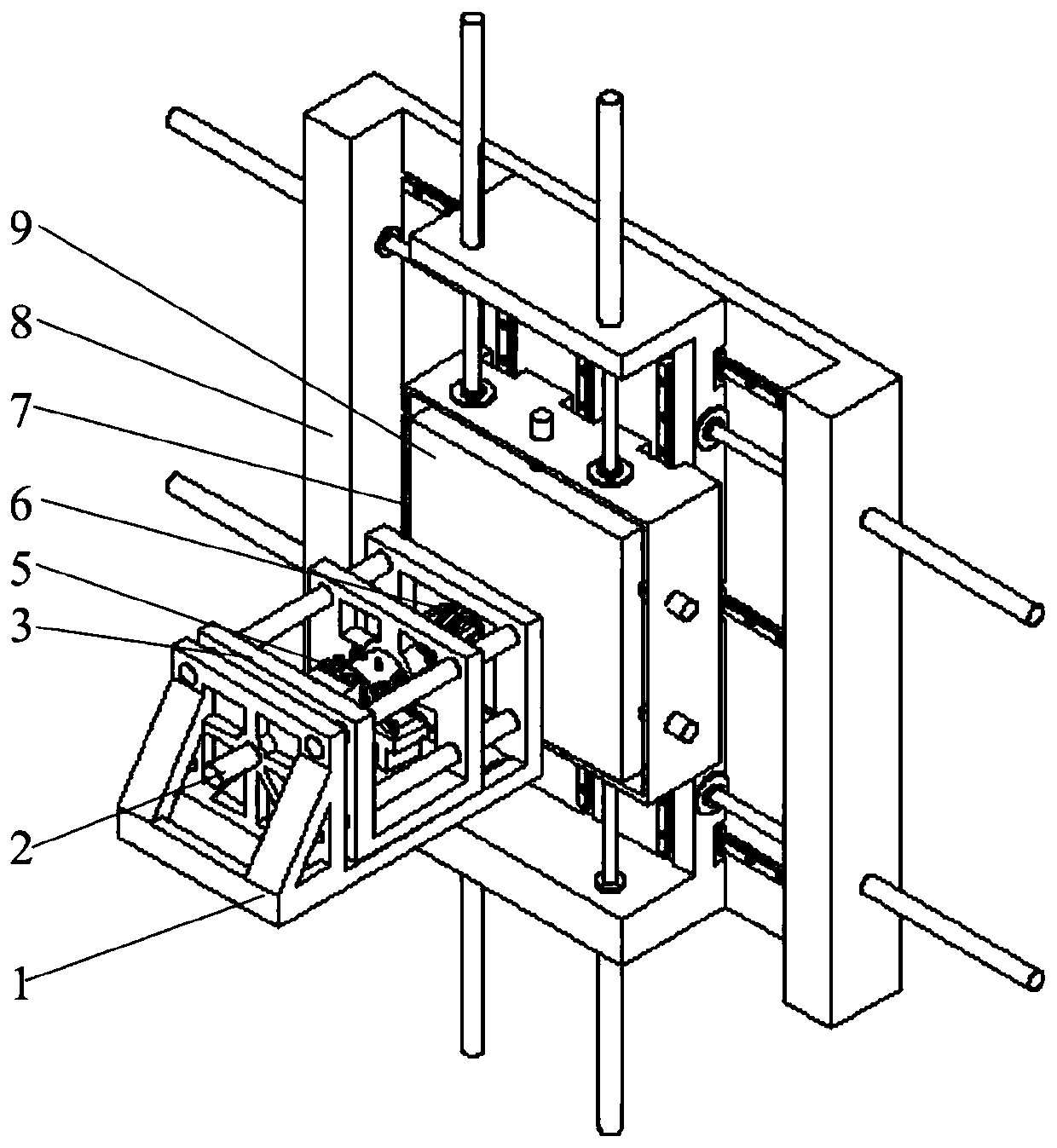

Plastic bag forming manufacturing method

InactiveCN111590963AGuarantee processing qualityChange radiusBag making operationsPaper-makingStructural engineeringPlastic bag

The invention relates to a plastic bag forming manufacturing method which comprises a placing platform, a movable block, a paving mechanisms, a placing mechanism, a winding mechanism, a first positioning roll shaft, a second positioning roll shaft, a hot cutting end and a heat-seal end; a movable block is arranged right above the placing platform; the top of the movable block is connected with a lifting mechanism; the paving mechanisms are symmetrically mounted on the two side walls of the bottom of the movable block; the hot cutting end is arranged on the lower end face of the movable block;the heat-seal end is arranged on the lower end face of the movable block and on the right side of the hot cutting end; the first positioning roll shaft and the second positioning roll shaft are symmetrically mounted on the left and right sides of the movable block and on the upper end face of the placing platform; the winding mechanism is mounted at the left end of the top of the placing platformthrough a bolt; the placing mechanism is mounted at the right end of the top of the placing platform through a bolt; the placing mechanism and the winding mechanism are components with the same structure; and a mounting groove is formed in the movable block. The plastic bag forming manufacturing method has the characteristics of being high in processing quality and practicality.

Owner:合肥新胜塑料科技有限公司

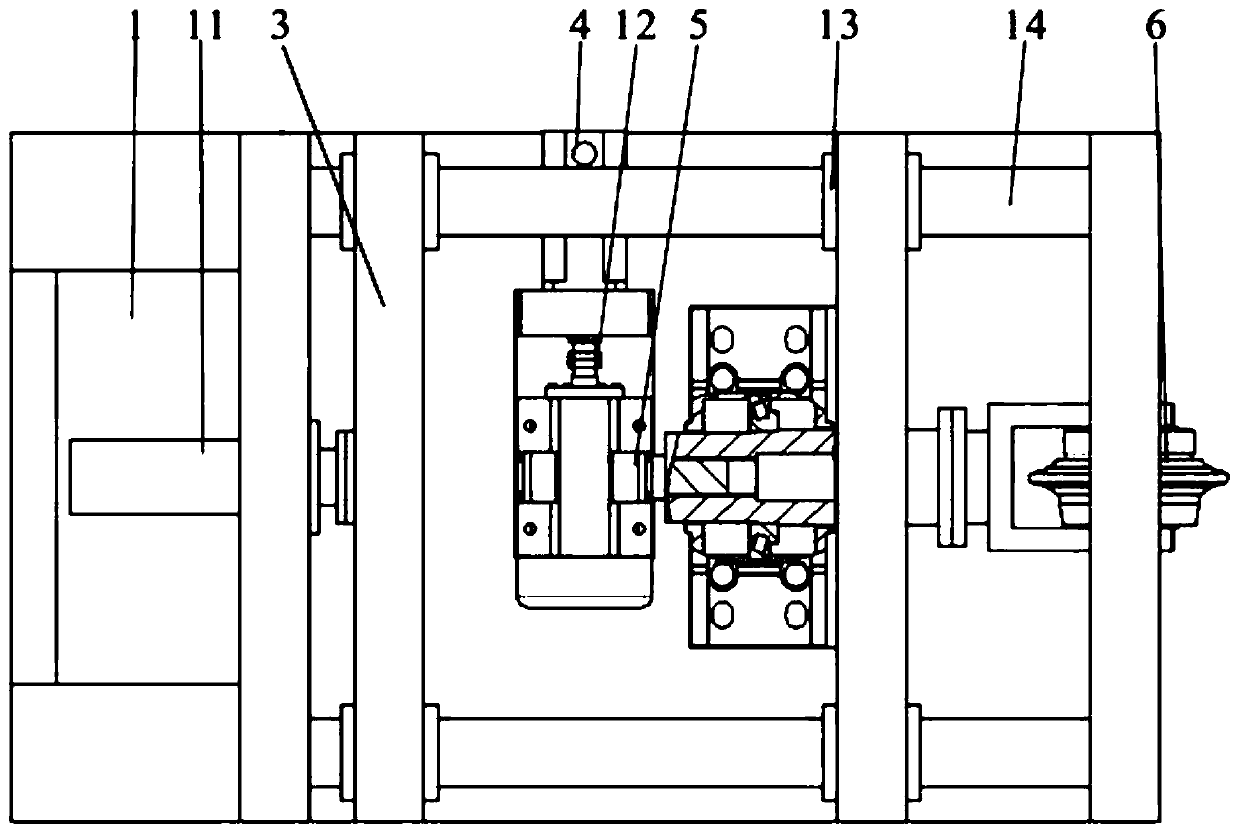

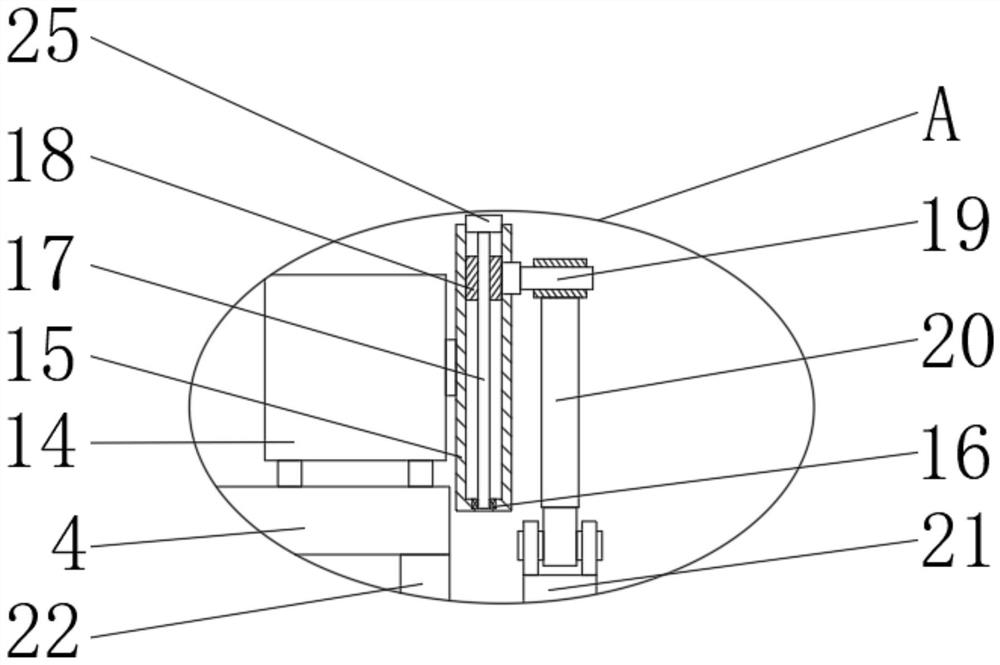

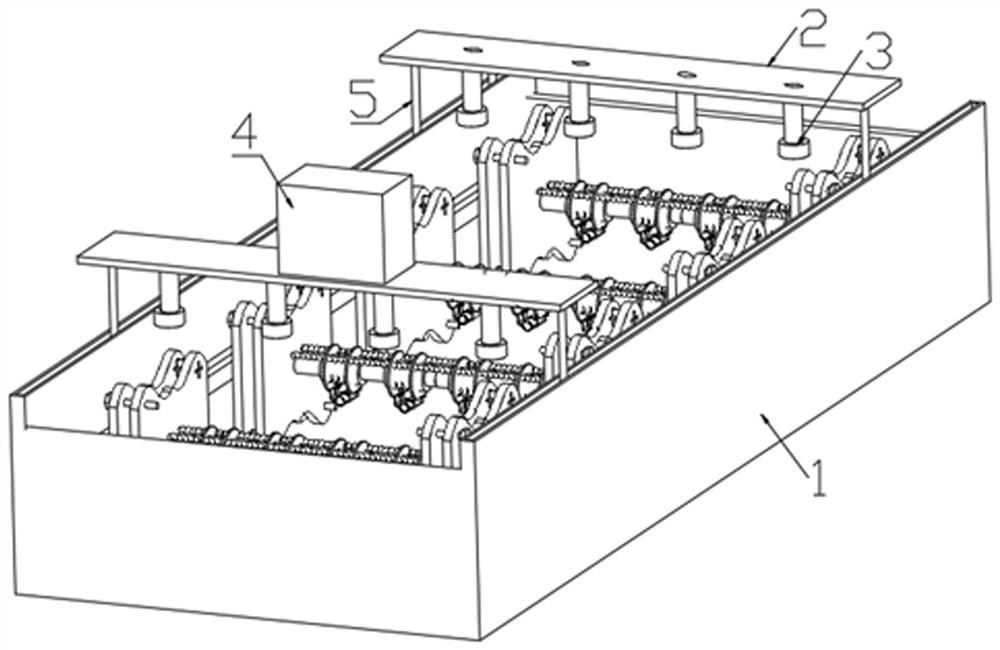

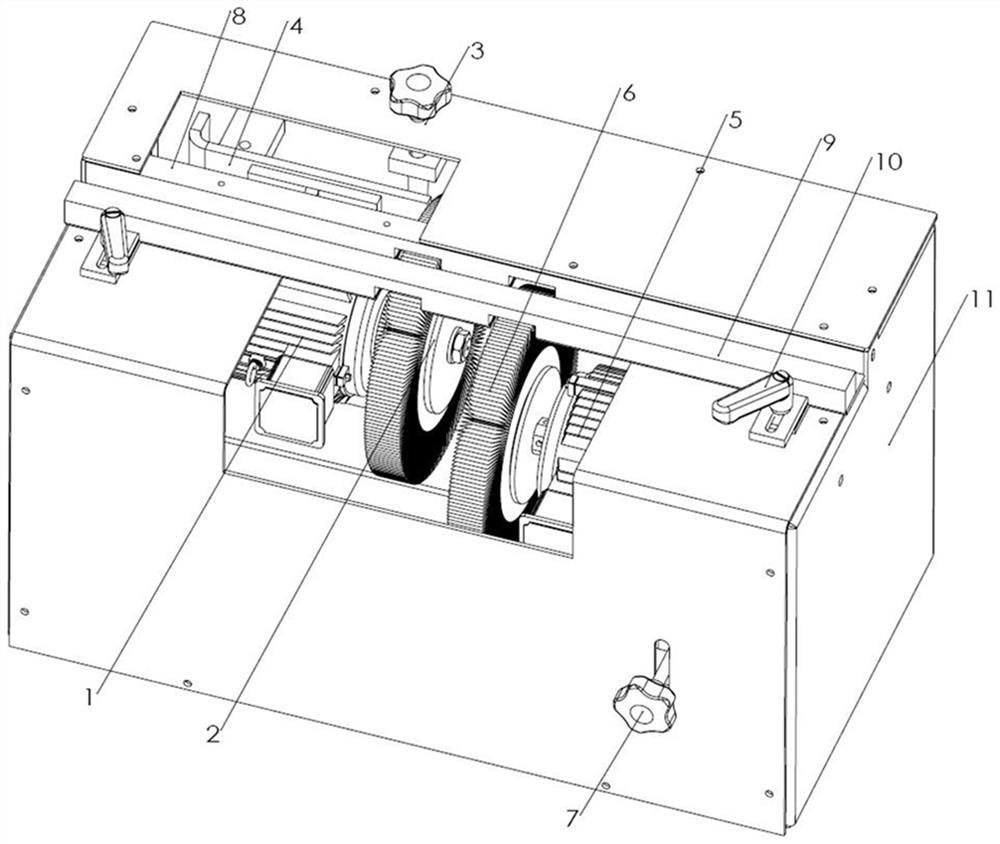

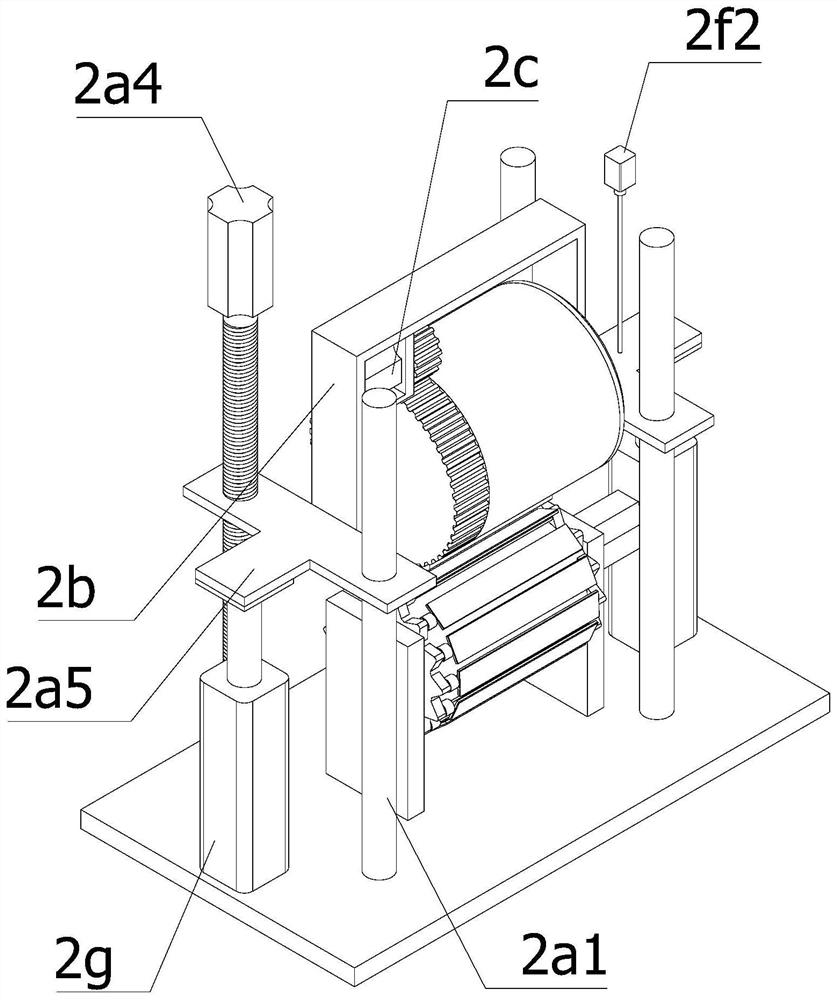

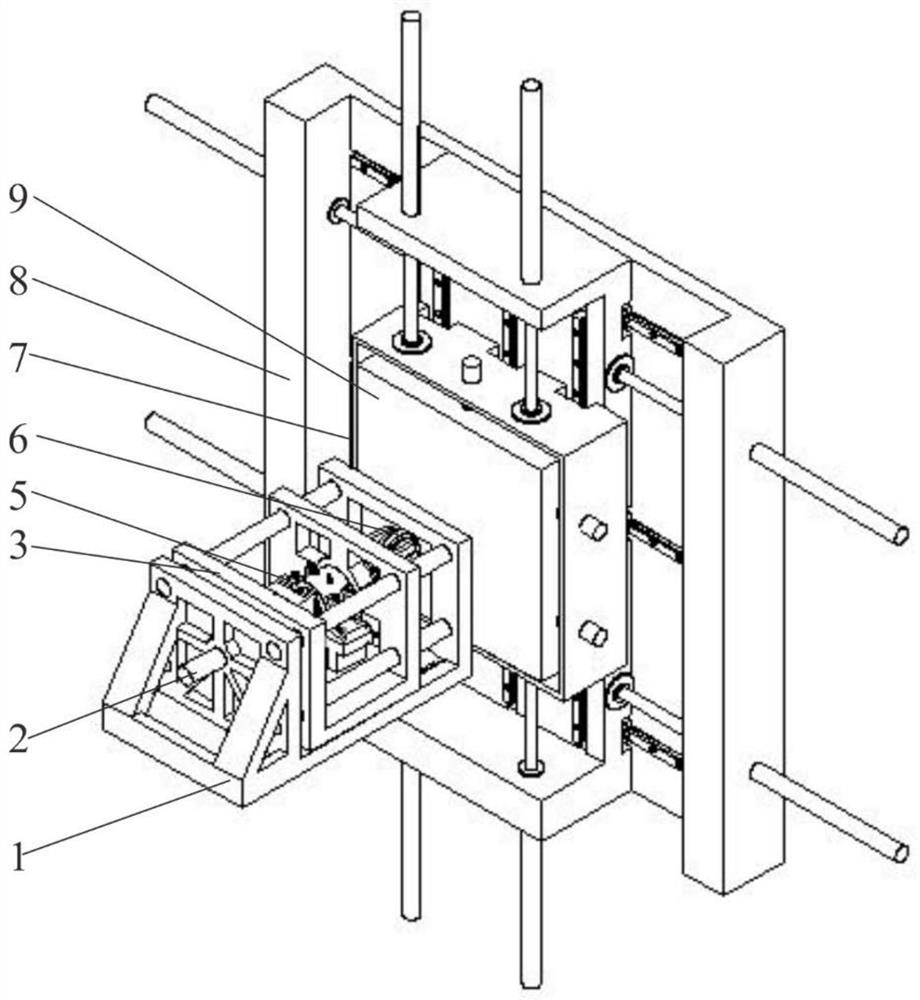

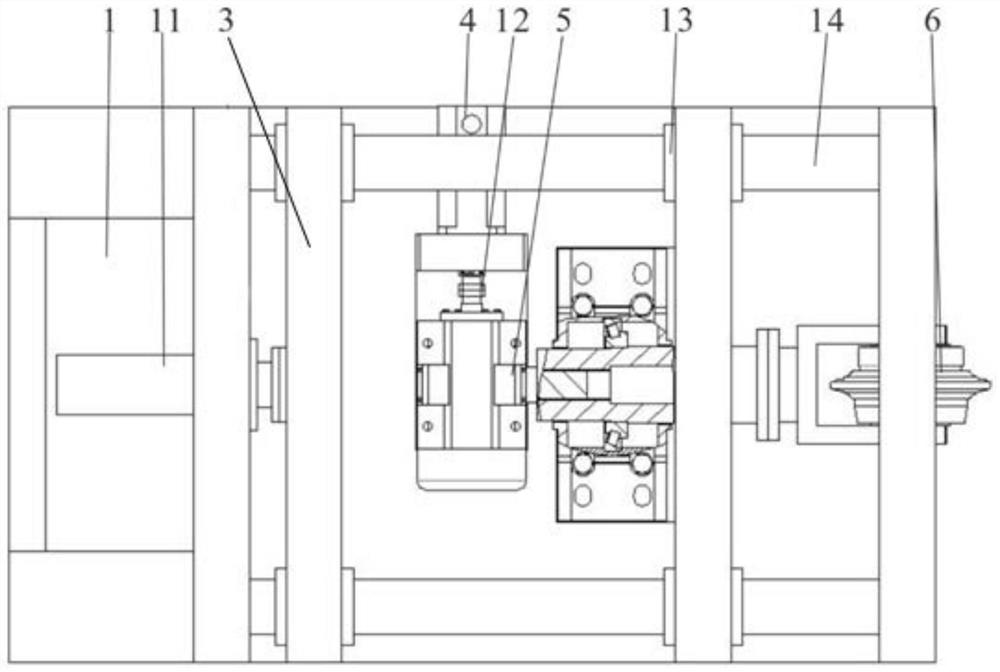

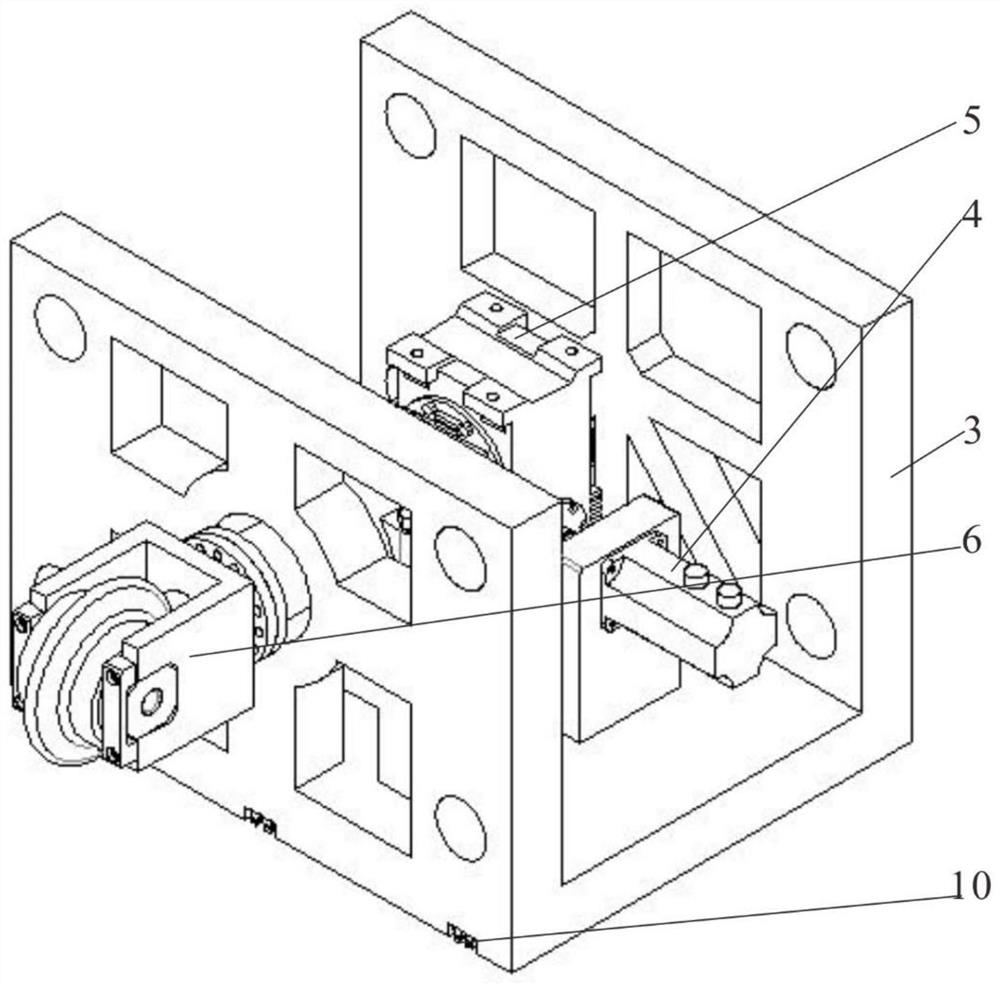

Test bed capable of simulating cutter behaviors at various positions of cutter head

ActiveCN111157388AChange radiusSmall footprintInvestigating abrasion/wear resistanceInvestigating machinabilityTunnel boring machineEngineering

The invention belongs to the technical field of shield tunnel boring machine cutter behavior simulation test beds, particularly relates to a test bed capable of simulating cutter behaviors at variouspositions of a cutter head, and solves the problem that a linear cutting test bed in the prior art cannot simulate working conditions of cutters with various mounting radiuses during tunneling. The technical scheme of the invention is as follows: the test bed comprises a transverse base and a longitudinal base; a hydraulic propelling system is arranged on the transverse base, the hydraulic propelling system is connected with a tool box and tool system, a rock box moving system is arranged on the longitudinal base, a rock box system is arranged on the rock box moving system, and the rock box system corresponds to the tool box and tool system in position. According to the invention, a rock sample is driven to move in a vertical plane to fit circles or arcs with different radiuses, so that the rock breaking working conditions of cutters with different mounting radiuses are simulated, and the test bed is suitable for simulating the working conditions of cutters at all positions on a cutterhead of a shield tunnel boring machine.

Owner:SOUTHWEST JIAOTONG UNIV

Flexible glass cutting device

InactiveCN111875244AAvoid scratchesReduce work intensityGlass severing apparatusCutting glassEngineering

The invention relates to the related field of glass processing, in particular to a flexible glass cutting device which comprises an installation frame, a cutting mechanism, an extrusion mechanism, a glass fixing mechanism and a convenient pushing mechanism. The cutting mechanism is installed on the extrusion mechanism in a sliding mode, and the extrusion mechanism is fixedly installed on the installation frame. The glass fixing mechanism is fixedly mounted on the installation frame, and the convenient pushing mechanism is fixedly mounted on the glass fixing mechanism. The device has the function of cutting glass with different sizes and thicknesses, has the function of cutting circles with different diameters, has the function of correcting and fixing the position of the glass, and has thefunction of conveniently pushing the glass on an operation table.

Owner:哈尔滨市阿城区胜达建筑材料厂

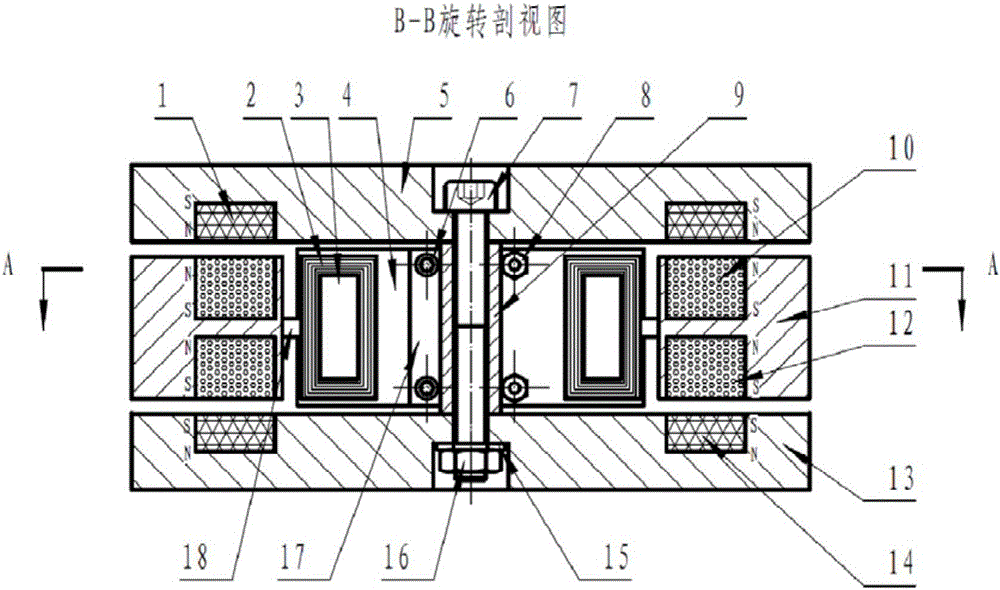

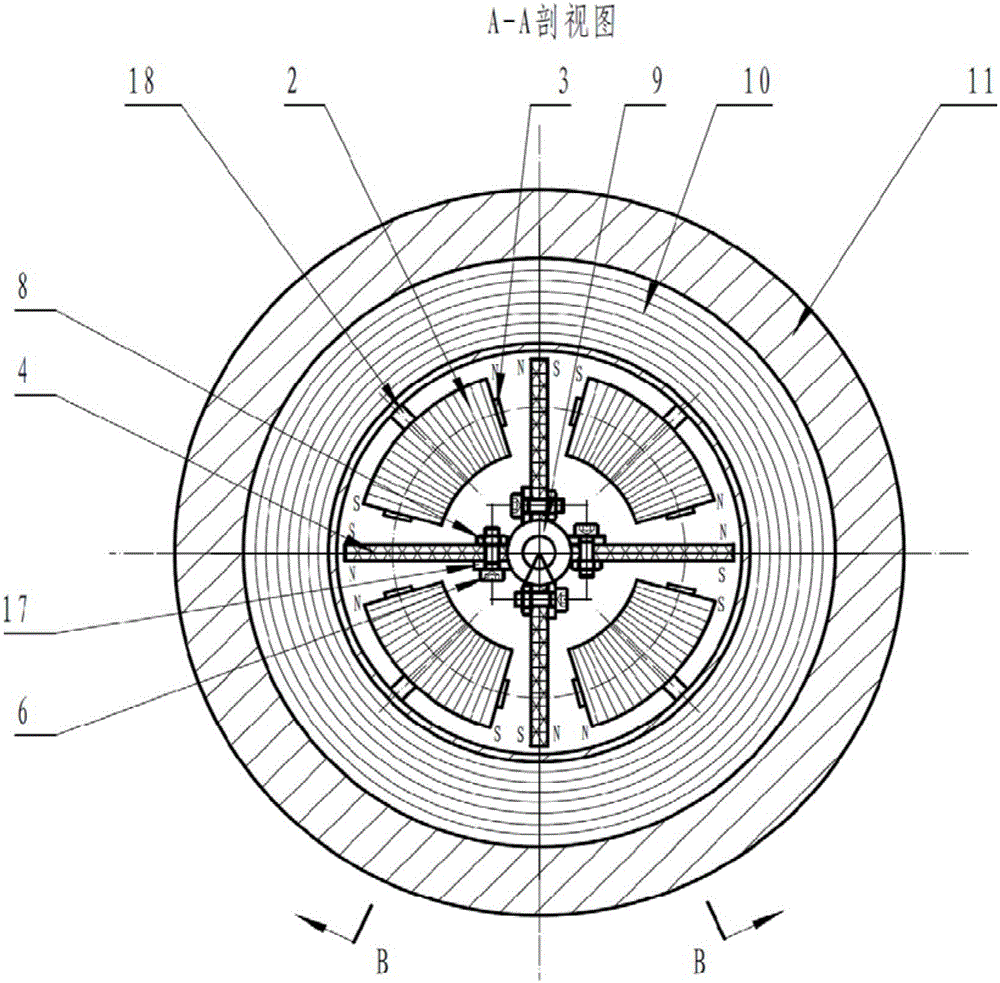

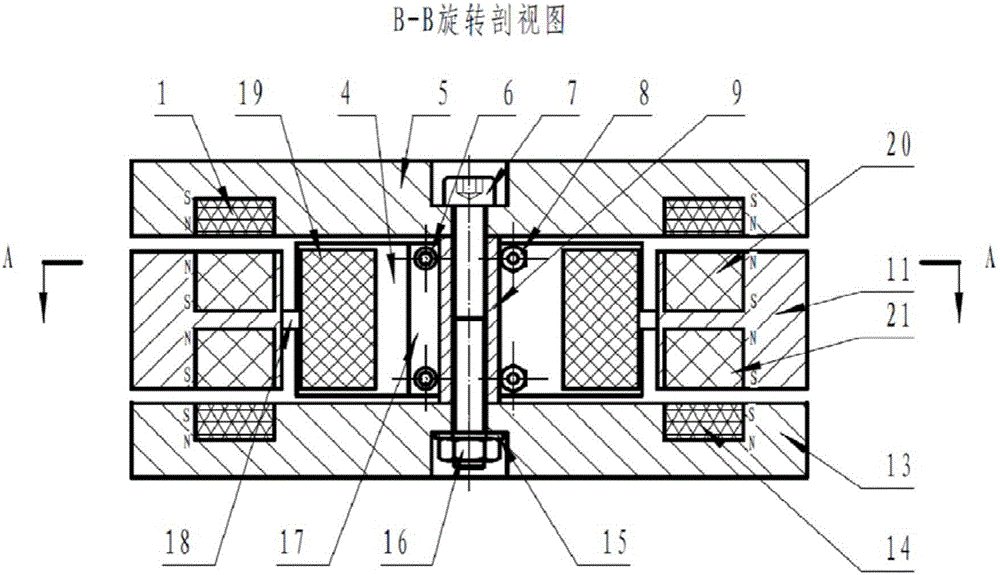

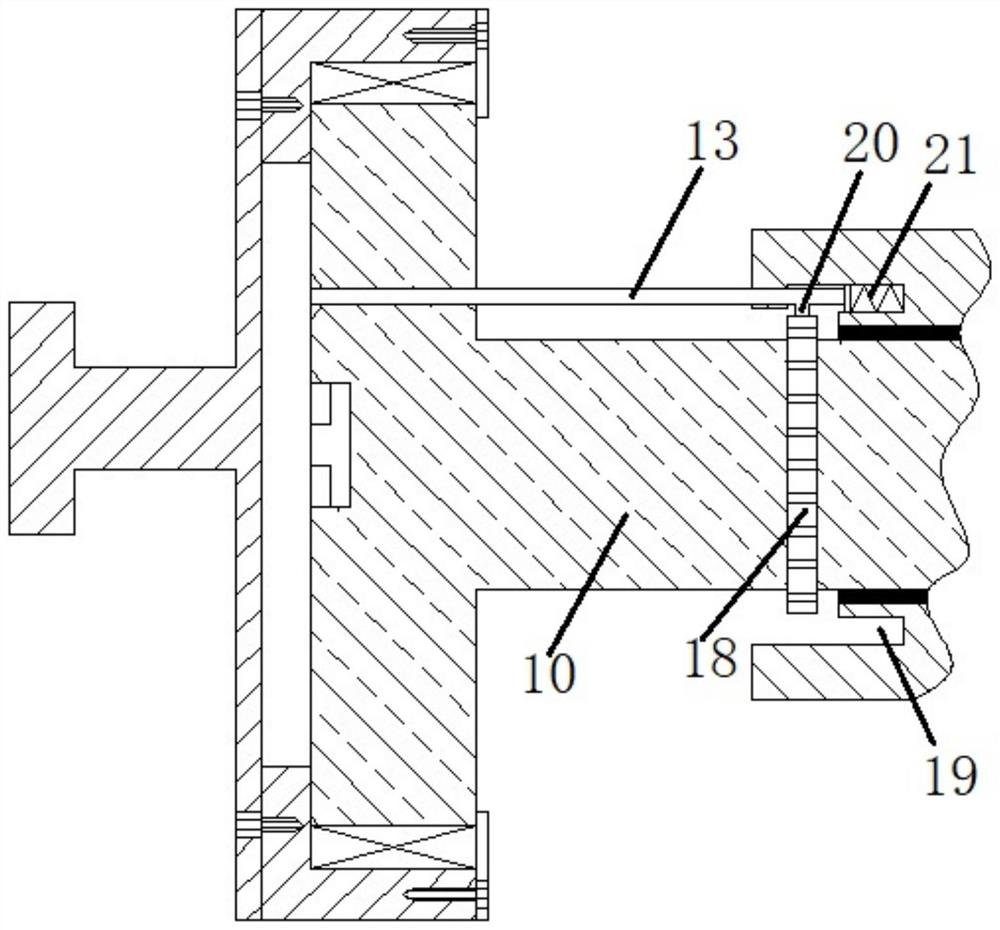

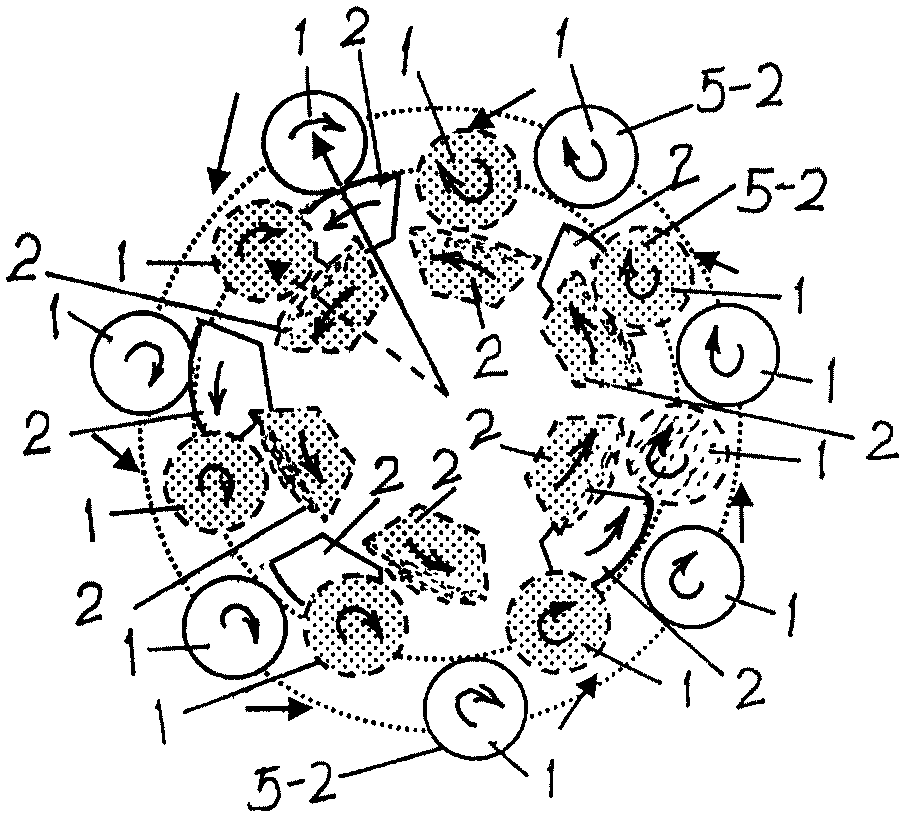

Permanent magnet coupler with variable magnet position and variable speed

PendingCN111313650AEasy to adjustImprove application adaptabilityPermanent-magnet clutches/brakesPermanent magnet rotorElectrical conductor

The invention discloses a permanent magnet coupler with a variable magnet position and a variable speed, and relates to the technical field of permanent magnet eddy current transmission. The permanentmagnet coupler comprises a permanent magnet rotor assembly installed at the load end of a permanent magnet coupler. The permanent magnet rotor assembly is located between a first conductor disc and asecond conductor disc. The permanent magnet rotor assembly comprises a first rotor disc and a second rotor disc which are oppositely and coaxially matched; a coaxial gear ring and a plurality of gearassemblies meshed with the gear ring are installed in the first rotor disc and the second rotor disc. By changing the radial position of the magnet, the action radius of a magnetic field is equivalently changed, so that the transmission torque and the output rotating speed are changed, the adjustment is convenient and fast, the application adaptability is high, and the popularization and application of the variable-speed permanent magnet coupler are facilitated.

Owner:DATANG LINZHOU THERMAL POWER CO LTD

Biological patch cutter for cardiac surgery

The invention discloses a biological patch cutter for cardiac surgery. The cutter comprises a base and a cutting knife cylinder, the base is of a round structure, two lower handles are fixed to the outer side of the base, the two lower handles are symmetrically around about the round of the base, a flange is fixed to the upper surface of each lower handle, and a cutting cavity is formed on the upper surface of the base. In a word, the cutter is reasonable in structural design, convenient to use, and capable of rapidly cutting biological patches in a different-radius manner, the edge of the cutbiological patches is smooth, and practicability is high.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Electrical machine comprising a rotor, and method for operating said electrical machine

InactiveCN101971467AChange radiusCompensate for torque fluctuationsDC commutatorElectric machineEngineering

The invention relates to an electrical machine (12), especially for power-adjusting a mobile part in a motor vehicle, and to a method for operating said machine. The electrical machine according to the invention comprises a stator (34) and a rotor (18) having a radius (62), said radius (62) varying over the circumference of the rotor (18).

Owner:ROBERT BOSCH GMBH

Magnetic force flexible pivot

The invention discloses a magnetic force flexible pivot which comprises two parts including a stator and a rotor. A magnetic force manner is adopted for determining that the rotor has no friction rotation; the stator is provided with a blade type anti-rotation permanent magnet, and magnetic force between the blade type anti-rotation permanent magnet and an anti-rotation magnet of the rotor provides high-repeatability rotation resistance; the stator is provided with a thrust magnet, a thrust bearing manner is formed by the thrust magnet and a thrust permanent magnet of the rotor, and friction-free axial bearing force is provided; and the thrust magnet and the anti-rotation magnet on the stator have three achievement manners including permanent magnet, electromagnetism and compounding, and three manners including the permanent magnet magnetic force flexible pivot, the electromagnetic magnetic force flexible pivot and the compounding magnetic force flexible pivot are formed. The flexible pivot has the beneficial effects that friction is avoided, lubrication is avoided, the action face is large; the high-repeatability rotation resistance is provided, the limitation of the using time number of an existing cross-shaped spring type flexible pivot is eliminated, the extremity of the service life is avoided, the axial bearing force and the rotation resistance are controllable and adjustable, and flexibility and reliability are achieved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

Non-excavation type pipeline repairing integrated device and repairing method

The invention provides a non-excavation type pipeline repairing integrated device and a repairing method, and relates to the technical field of pipeline repairing. The non-excavation type pipeline repairing integrated device comprises a traction part, a supporting part and a connecting part; the supporting part comprises an outer sleeve, an inner rotating shaft and a spiral elastic cage fixed between the outer sleeve and the inner rotating shaft, the outer sleeve sleeves the spiral elastic cage, an inclined wheel is arranged at the outer side of the spiral elastic cage, and the included angle between a rotating shaft of the inclined wheel and the axis direction of the spiral elastic cage is 30-60 degrees; the inner rotating shaft is arranged in the outer sleeve and is rotatably connected with the outer sleeve, and a clamping mechanism for locking the inner rotating shaft is arranged between the inner wall of the outer sleeve and the outer wall of the inner rotating shaft; the inner rotating shaft is rotatably connected with the connecting part; the outer sleeve is rotatably connected with the traction part; and a curing lamp and a nozzle are arranged on the outer sleeve. In order to overcome the defects in the prior art, the device can adapt to various pipeline inner diameter specifications, it is guaranteed that a repairing pipe is completely attached to the inner wall of a to-be-repaired pipeline, and repairing steps are reduced.

Owner:四川兴辉腾集团有限公司

Method for preparing monodisperse cadmium sulfide-silicon dioxide nucleocapsid structure

InactiveCN1258823CChange concentrationAdjust densityFinal product manufactureSemiconductor devicesWater bathsSurface-active agents

The invention discloses an approach to produce monodisperse cadmium sulphide-silicon dioxide nucleocapsid construction. Adopting chemistry water bath sedimentation, it includes nether steps: 1): Use sonic oscillation to make even monodisperse silicon dioxide sphere disperse into solution of deionized water; add sodium citrate as complexing agent, alkylol amine as surface active agent; use ammonia to adjust PH value to 8-13; magnetic stirring in constant temperature of 50-90deg.C; add cadmium chloride and sulfur to react for 1-3 hours; and then get nucleocapsid construction suspending liquid of cadmium sulphide enwrapping silicon dioxide sphere. 2): Use deionized water and absolute ethyl alcohol to clean circularly; remove reaction remnants and drying. The invention has a low cost and simple process. The produced nucleocapsid construction has a averaging diameter without cadmium sulphide grains and heterocoagulation. It can be used as construction primitive to produce three-dimensional photon crystal with unique band gap performance.

Owner:ZHEJIANG UNIV

Semi-automatic N95 mask machine

InactiveCN113249955AConstant pressureAvoid displacementSevering textilesSemi automaticStructural engineering

The invention belongs to the field of mask production, and particularly relates to a semi-automatic N95 mask machine. The semi-automatic N95 mask machine comprises a forming box; a fixing plate is fixedly connected to the outer side of the forming box; a cutting box is fixedly connected to the upper end of the fixing plate; a mounting plate is fixedly connected to the interior of the cutting box; two symmetrically-distributed telescopic rods are slidably connected into the mounting plate; the lower ends of the two telescopic rods are jointly and fixedly connected with a wheel frame; springs are arranged on the outer sides of the telescopic rods; and a pressing roller is rotatably connected into the wheel frame. According to the semi-automatic N95 mask machine, the springs, the pressing roller, an adjusting plate and other structures are additionally arranged in the cutting box, the pressing roller can be pushed through the elastic force of the springs to extrude raw materials in the using process, and therefore the situation that the raw materials are displaced in the raw material cutting process can be avoided; and in addition, the elastic force of the springs can be adjusted through the adjusting plate during long-time use, so that the pressure of the pressing roller is constant.

Owner:河南省邦恩机械制造有限公司

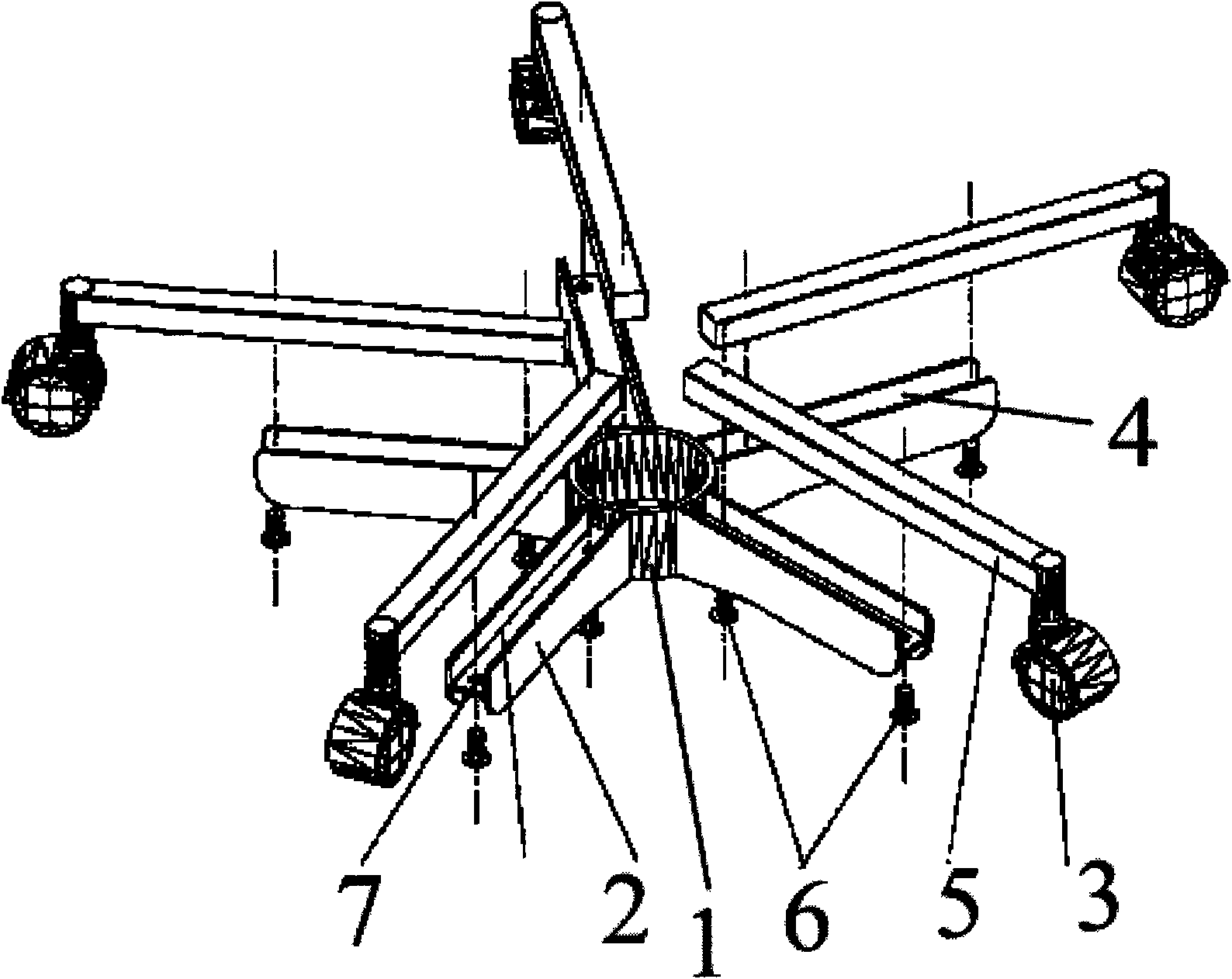

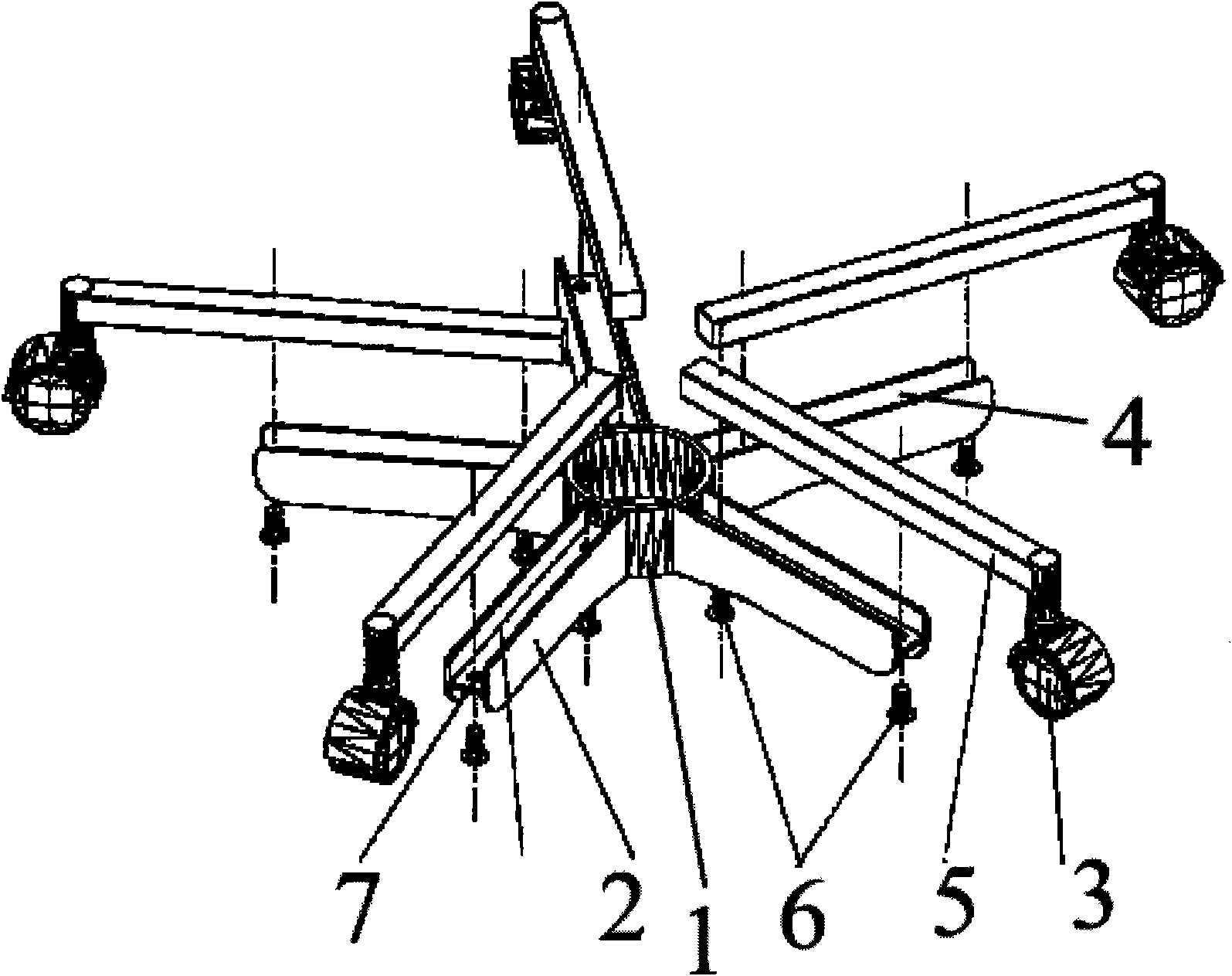

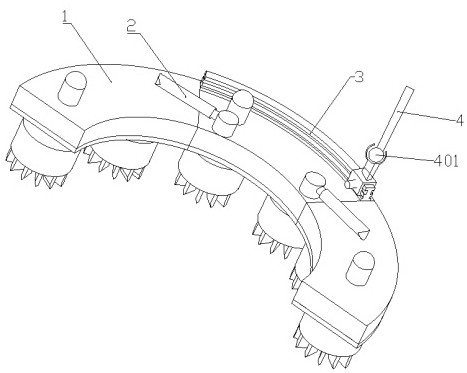

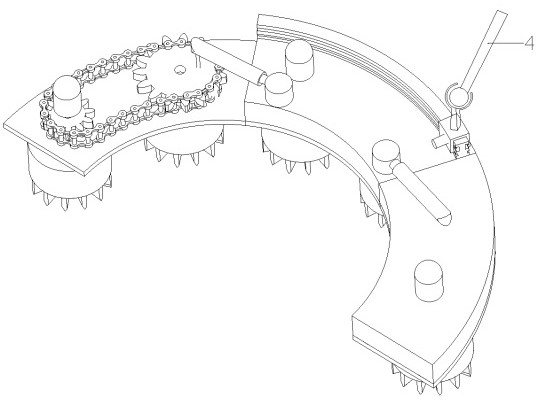

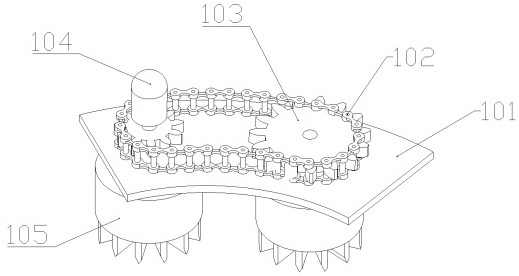

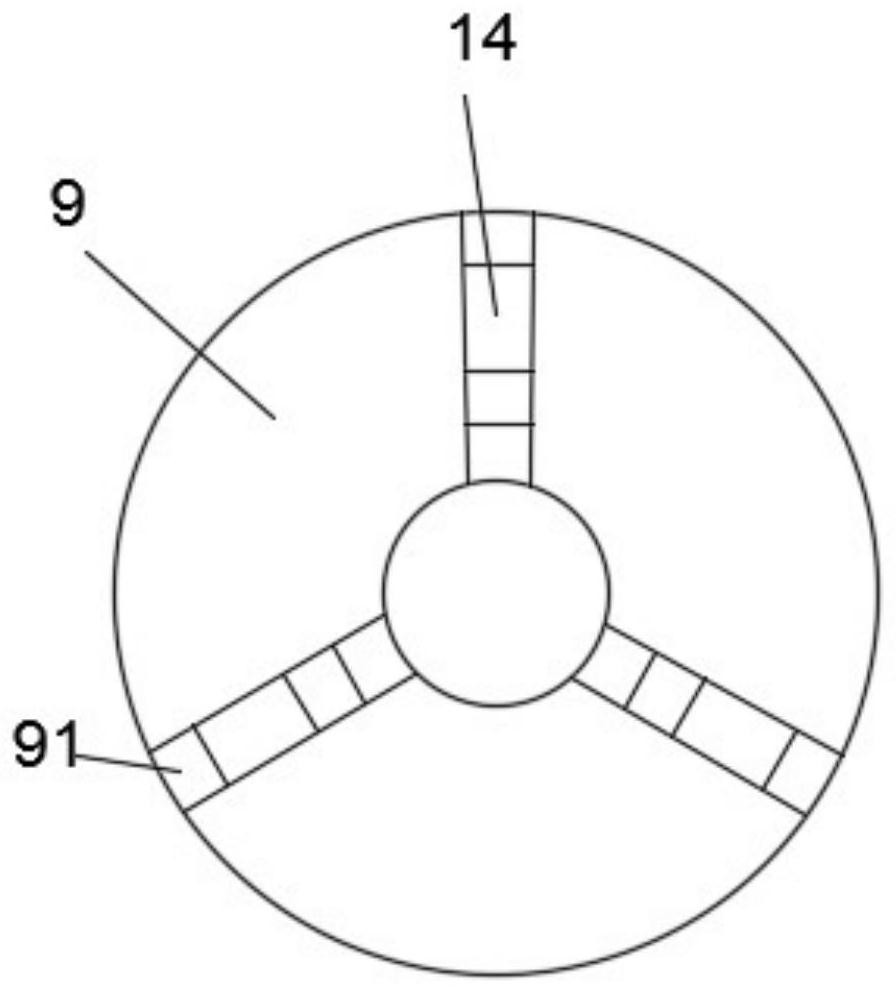

Weeding device suitable for peripheries of roots of trees with different diameters

ActiveCN113016764AAchieve excisionChange radiusWeed killersAgricultural engineeringStructural engineering

The invention discloses a weeding device suitable for peripheries of roots of trees with different diameters. The weeding device comprises at least two groups of weeding devices, rotary telescopic devices and a rotating mechanism. The rotating mechanism is fixedly mounted on one group of weeding devices, and every two groups of weeding devices are movably connected through the rotary telescopic device; and when the weeding device works, the weeding device weeds around trees through the rotating mechanism, when the weeding device encounters the trees with different diameters, the radius of the whole device is changed through rotation and stretching of the rotary telescopic devices, and therefore the peripheries of the roots of the trees with different diameters are weeded. A weeding cutter assembly below the weeding device can adjust the angle of a blade, so that the weeding efficiency is higher, the service life of the blade is prolonged, and the problem that an existing weeding machine cannot adapt to different diameters of trees when weeding around the trees is solved.

Owner:聊城市彩烁农业科技有限公司

Sewing machine with adjustable needle bar stroke

ActiveCN104131422BChange radiusRealize stroke adjustmentLubrication/cooling devicesSewing-machine control devicesElectric machinerySewing machine

The invention discloses a sewing machine with an adjustable needle bar stroke, and belongs to the technical field of sewing machines. The sewing machine comprises a needle bar, a connection bar, a crank, a main shaft and a motor and further comprises an eccentric link pin. The upper end of the connection bar is connected with the crank through the eccentric link pin, the upper end of the connection bar is provided with an axial through hole, a first shaft is matched in the axial through hole in the connection bar in a rotating mode, the outer end of the first shaft is connected with an adjusting screw in a threaded mode in the axial direction and is cushioned with a limiting gasket for preventing the upper end of the connection bar from axial movement, and a left cover of a machine head at the position where the adjusting screw stretches outwards in the axial direction is provided with a screw hole for a screw driver to be inserted so as to screw the adjusting strew conveniently. The sewing machine with the adjustable needle bar stroke has the advantages of being adjustable in the needle bar stroke, simplifying the adjusting mode, saving oil and the like.

Owner:JACK SEWING MASCH CO LTD

Diameter-variable multi-gear combined equivalent gear drive type continuously variable transmission

ActiveCN108105347ARealize stepless transmission transmissionSimple structureToothed gearingsGearing detailsGear driveGear wheel

The invention provides a diameter-variable multi-gear combined equivalent gear drive type continuously variable transmission, and discloses a gear continuously variable transmission. According to thegear continuously variable transmission, a plurality of gears are combined to form an equivalent gear for transmitting rotating mechanical energy, and the transmission is applicable to electric cars.The diameter-variable multi-gear combined equivalent gear drive type continuously variable transmission comprises a driving gear assembly and a driven gear assembly, wherein the last-grade gear, engaged with the driven gear assembly, of the driving gear assembly is the multi-gear-combined type equivalent gear; the primary gear, engaged with the driving gear assembly, of the driven gear assembly isthe multi-gear-column combined type equivalent gear; the two equivalent gears are engaged to transmit the rotating mechanical energy, and synchronous transmission in the engaging state is achieved. The diameter-variable multi-gear combined equivalent gear drive type continuously variable transmission has the advantages that the radius of the plurality of gears [or gear columns] is smoothly changed without any grade and in a balancing manner; the plurality of radius-changed gears [or gear columns] are capable of naturally smoothly changing the rotation transmitting speed without grade and in abalancing manner. Therefore, the rotating power is transmitted through the gears.

Owner:张敏

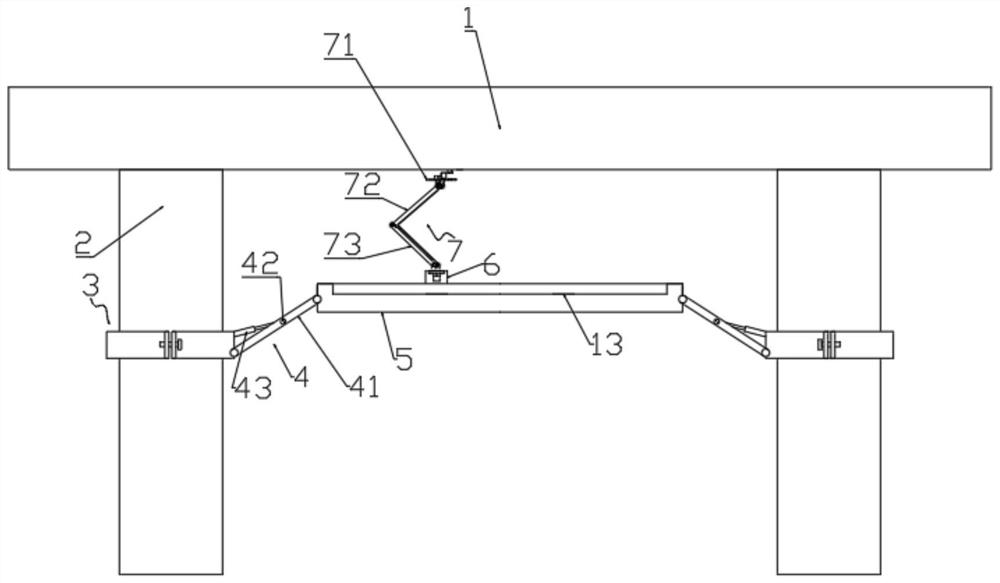

Bridge crack detection device

InactiveCN112853975AAvoid shakingPrevent fallingBridge structural detailsArchitectural engineeringStructural engineering

The invention discloses a bridge crack detection device, and belongs to the technical field of bridge detection, the bridge comprises a main beam and a pier used for supporting the main beam, the crack detection device comprises a pier body connecting part, a platform connecting support, a supporting platform, a sliding block, a connecting rod mechanism, a base and a flaw detection device, the supporting platform is located below the main beam. The two sides of the supporting platform are connected to the two pier body connecting components through the two platform connecting supports respectively, the two pier body connecting components are connected to the two adjacent pier bodies respectively, the sliding block is arranged on the upper surface of the supporting platform and is in sliding fit with the main beam, and the supporting platform can slide in the length direction of the main beam. The flaw detection device is arranged on the base, and the base is connected to the sliding block through a connecting rod mechanism. The bottom of a bridge can be conveniently detected, detection can be conducted in cooperation with manual work, detection is safer, and the detection efficiency is improved.

Owner:温州安荷桥科技有限公司

Depth-adjustable semi-automatic acupuncture instrument

The invention relates to a depth-adjustable semi-automatic acupuncture instrument which is installed on a bed body and comprises a clamping plate connected with the bed body through bolts, the clamping plate is connected with a rotating plate through a sliding assembly, a through groove is formed in the rotating plate, a lifting piece is arranged in the through groove in a sliding mode, and a rubber plate connected with the rotating plate is installed on the lifting piece. A connecting piece is rotationally installed on the lifting piece, a rotating shaft of the connecting piece is connected with the sliding assembly through a horizontal keeping assembly, a vertical plate is arranged on the connecting piece, a motor is fixedly installed on the vertical plate, an output shaft of the motor is rotationally installed on a circumferential piece on the vertical plate and connected with the circumferential piece, and a pulley is arranged on the circumferential piece. The vertical plate is further provided with a transverse rod matched with the pulley, the transverse rod is connected with an elastic assembly installed on the vertical plate, the linkage plate is further rotationally provided with a transmission rod, one end of the transmission rod is provided with a filiform needle, the other end of the transmission rod is connected with the vertical plate through a transmission assembly, and simple and convenient acupuncture nursing is achieved.

Owner:SECOND AFFILIATED HOSPITAL OF XIAN MEDICAL UNIV

Power cable withstand voltage test detection equipment

ActiveCN113064036AEasy to disassembleEasy to installTesting dielectric strengthMeasurement instrument housingPower cableElectric machine

The invention relates to the field of power equipment detection, and in particular relates to power cable withstand voltage test detection equipment which comprises a heat preservation chamber, a thermostatic bath is arranged in the heat preservation chamber, a plurality of fixed insertion rods are arranged on the inner walls of the left side and the right side of the thermostatic bath, a sliding plate is arranged at the other end of each fixed insertion rod, the sliding plate is provided with a sliding groove and a fixing rod which can match the sliding groove and connected with the sliding groove in a front-back sliding mode, the thermostatic bath is connected with a second mounting plate through the fixing rod, two fixing bolts are arranged on the second mounting plate in a threaded mode, the fixing bolts are further connected with a first mounting plate in a threaded mode, the first mounting plate is provided with a plurality of cross-shaped slots which can be in matched insertion connection with cross-shaped clamping rings, and a rotating motor is further mounted between the first mounting plate and the second mounting plate. The detection equipment is simple in structure, and cables with different lengths and radiuses can be tested according to needs.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Full-automatic combination machine for processing crankshaft of engine

InactiveCN112428041AImprove grinding efficiencyChange positionRevolution surface grinding machinesGrinding drivesEngineeringCrankshaft

The invention discloses a full-automatic combination machine for processing a crankshaft of an engine. The full-automatic combination machine comprises a processing table, positioning blocks are symmetrically and fixedly connected to the top of the processing table, a bearing plate is connected between two positioning blocks in a sliding manner, a ball body is rotationally embedded in the bearingplate, a first connecting rod is fixedly connected to the top of one ball body, the top of the outer wall of the first connecting rod is sleeved with a connecting sleeve in a sliding manner, a first arc plate is fixedly connected to the top of the connecting sleeve, a second arc plate is rotationally connected to the top of the first arc plate, polishing plates are fixedly connected to one sides,opposite to each other, of the first arc plate and the second arc plate correspondingly, and supporting columns are arranged on two sides of the top of the processing table. By using the arrangement way of the first arc plate and the second arc plate, a ring can be formed by the first arc plate and the second arc plate, and sleeves the outer wall of the crankshaft, and the crankshaft rotates alongwith the ring when the ring rotates, so that the polishing plates polish the crankshaft, which improves the crankshaft polishing efficiency.

Owner:芜湖肯昌机电有限公司

Plate cutting section deburring device

PendingCN114346809AChange radiusAdjust the deburring effectEdge grinding machinesGrinding carriagesElectric machineryEngineering

A plate cutting section deburring device comprises a left motor, a left disc brush device, a vertical adjusting mechanism, a mounting frame, a right motor, a right disc brush device, a horizontal adjusting mechanism, a baffle mechanism, an adjusting block, a handle and a frame. The vertical adjusting mechanism can adjust the distance between the left disc brush device and the baffle mechanism and the distance between the right disc brush device and the baffle mechanism. The horizontal adjusting mechanism can adjust the distance between the left disc brush device and the right disc brush device. The handle is rotated anticlockwise, the distance between the adjusting block and the baffle mechanism is changed through the kidney-shaped hole in the adjusting block, and therefore the purpose of machining plates with different thicknesses is achieved. A plate needing to be machined is vertically placed between the baffle mechanism and the adjusting block, the plate is moved to penetrate through the position between the left disc brush device and the right disc brush device, and therefore the purposes of deburring of the two sides of the cut section of the plate and rounding of corners are achieved.

Owner:帕玛自动化科技(苏州)有限公司

A gripping structure and gripping method of a robot manipulator

The invention discloses a gripping structure and a gripping method of a robot manipulator, comprising a housing and a mechanical claw mounted on the housing, a motor is fixedly installed on the top of the housing, a chuck, The turntable and the chuck seat, the chuck is slidably mounted with a block that can slide outward, the block is slidably mounted with a slider, the slider is rotatably mounted with a first shaft, and the mechanical claw The top is rotatably installed with the first rotating shaft, a bracket is fixedly installed in the center of the chuck, a sliding disc is slidably installed on the outside of the bracket, and a support bar is installed on the outer side of the sliding disc, and the support bar is far away from the side of the sliding disc. One end is rotated and installed with the inner side of the mechanical claw. The invention facilitates the adjustment of the mechanical claw. At the same time, the opening angle of the mechanical claw can always be in the triangular pyramid structure with a large opening at the top and a small opening at the bottom, making the gripping of workpieces more stable and firm.

Owner:NANJING YUSHENG ROBOT CO LTD

Equidistant cutting equipment for intelligent manufacturing of iron sheets

InactiveCN114700546AAchieve the effect of equidistant cuttingTechnical Requirements for Realizing Any AdjustmentShearing machinesShearing machine accessoriesEngineeringStructural engineering

The invention relates to the technical field of cutting equipment, in particular to equidistant cutting equipment for intelligent manufacturing of iron sheets, which comprises a side plate, an adjusting mechanism, a conveying mechanism, a pressure bearing mechanism and a base. The first guide assembly is fixedly arranged on the base in the height direction of the base. The support is slidably arranged on the first guide assembly in the height direction of the first guide assembly. The first roller is rotatably arranged on the bracket; a driving assembly used for driving the first rolling wheel to rotate is fixedly arranged on the side wall of the support. The distance adjusting assembly is arranged in the first roller; the monitoring assemblies are arranged on the first rolling wheel and the support respectively. By arranging the first guiding assembly, the support, the driving assembly, the distance adjusting assembly, the monitoring assembly and the first rolling wheel, the effect that the distance adjusting assembly can still achieve the equal-distance cutting effect on iron sheets under the condition that the conveying mechanism continuously operates is achieved, and meanwhile the technical requirement that the equal-distance cutting distance can be adjusted at will is met.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Magnetic resolver

ActiveCN101346873BMaximize the range of variationChange radiusDynamo-electric machinesConverting sensor output electrically/magneticallyEngineeringMechanical engineering

A magnetic resolver includes: a plurality of columnar cores disposed on an annular plate; a coil portion disposed around each of the columnar cores; and an annular rotor having a sinusoidal profile that rotates in a plane parallel to the top faces of the columnar cores around a rotation axis that passes through the center of the annular plate. The coil portion may be formed of a patterned coil formed on an annular substrate that has a plurality of through holes made therein through which the plurality of cores are passed, the patterned coil being formed around the through hole.

Owner:TOYOTA JIDOSHA KK +1

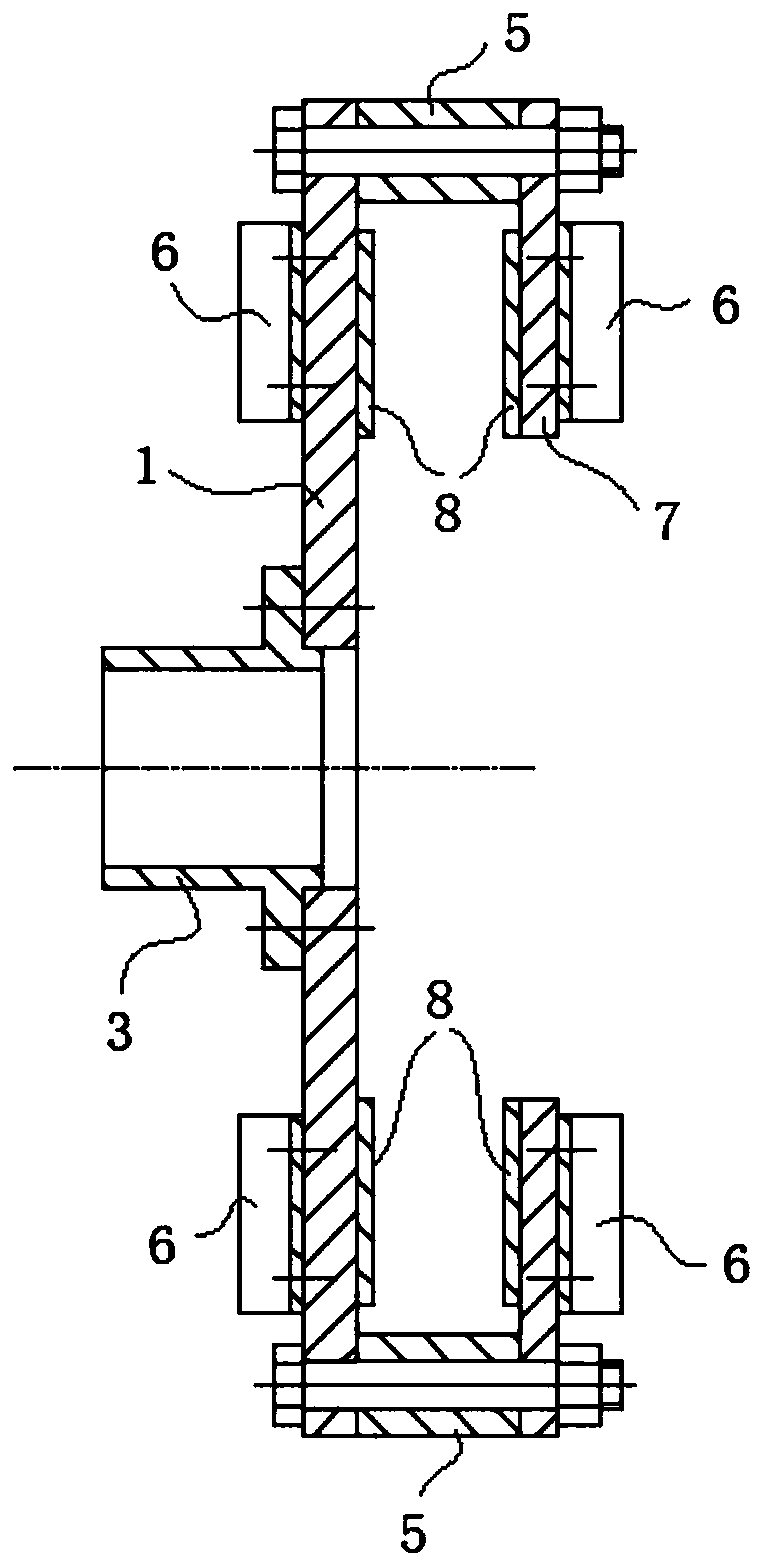

Transmission for achieving stepless speed changing in electro-mechanical actuation mode

The invention relates to a transmission for achieving stepless speed changing in an electro-mechanical actuation mode. The transmission is composed of an input shaft, an output shaft, an actuator, a shaft ring, a belt pulley sheet, a belt and the like. An actuator push rod can stretch out or retract back under action of a feedback signal, and the belt pulley sheet is driven to stretch out or retract back accordingly, so that the diameter of a belt pulley is changed and the transmission ratio of the transmission is further changed. Compared with a transmission applied at the current stage, a method has the advantages that the structure is simple, the belt is less abraded and assembly is simple. A supporting rod assembly is used for supporting the belt pulley sheet and plays a role in fixing. An output signal is input into the actuator, closed-loop control is formed, and thus the transmission precision is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A test bench for simulating tool behavior at various positions on the cutter head

ActiveCN111157388BChange radiusSmall footprintInvestigating abrasion/wear resistanceInvestigating machinabilityVertical planeClassical mechanics

The invention belongs to the technical field of a shield tunnel boring machine cutter behavior simulation test bench, and in particular relates to a test bench capable of simulating the cutter behavior at each position of a cutterhead, which solves the problem that the linear cutting test bench in the prior art cannot simulate various installation radius cutters. The problem of working conditions during excavation. The technical solution of the present invention is: comprising a horizontal base and a vertical base, the horizontal base is provided with a hydraulic propulsion system, the hydraulic propulsion system is connected with a knife box cutter system, and the vertical base is provided with a rock box A moving system, the rock box moving system is provided with a rock box system, and the rock box system corresponds to the position of the tool box cutter system. The invention drives the rock sample to move in the vertical plane, and fits circles or arcs with different radii, thereby simulating the rock-breaking working conditions of cutters with different installation radii. working conditions.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com