Sewing machine with adjustable needle bar stroke

A needle bar stroke and sewing machine technology, which is applied in the direction of sewing machine components, sewing machine needle seats, sewing machine control devices, etc., can solve the problems of limited application range and inability to adjust, and achieve the goals of saving consumption, reducing friction and wear, and ensuring adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

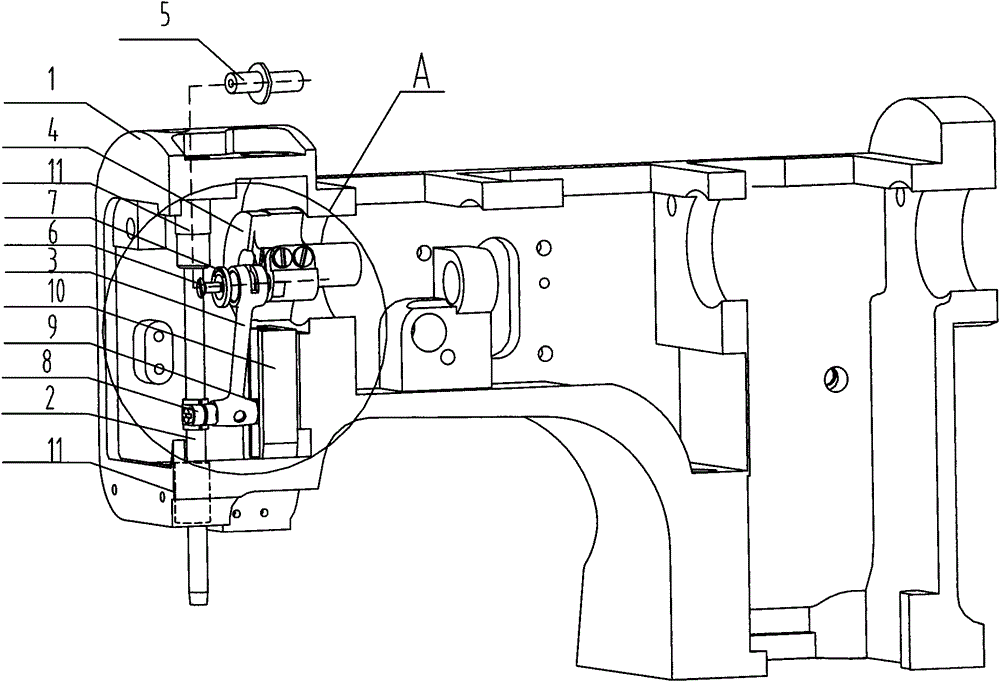

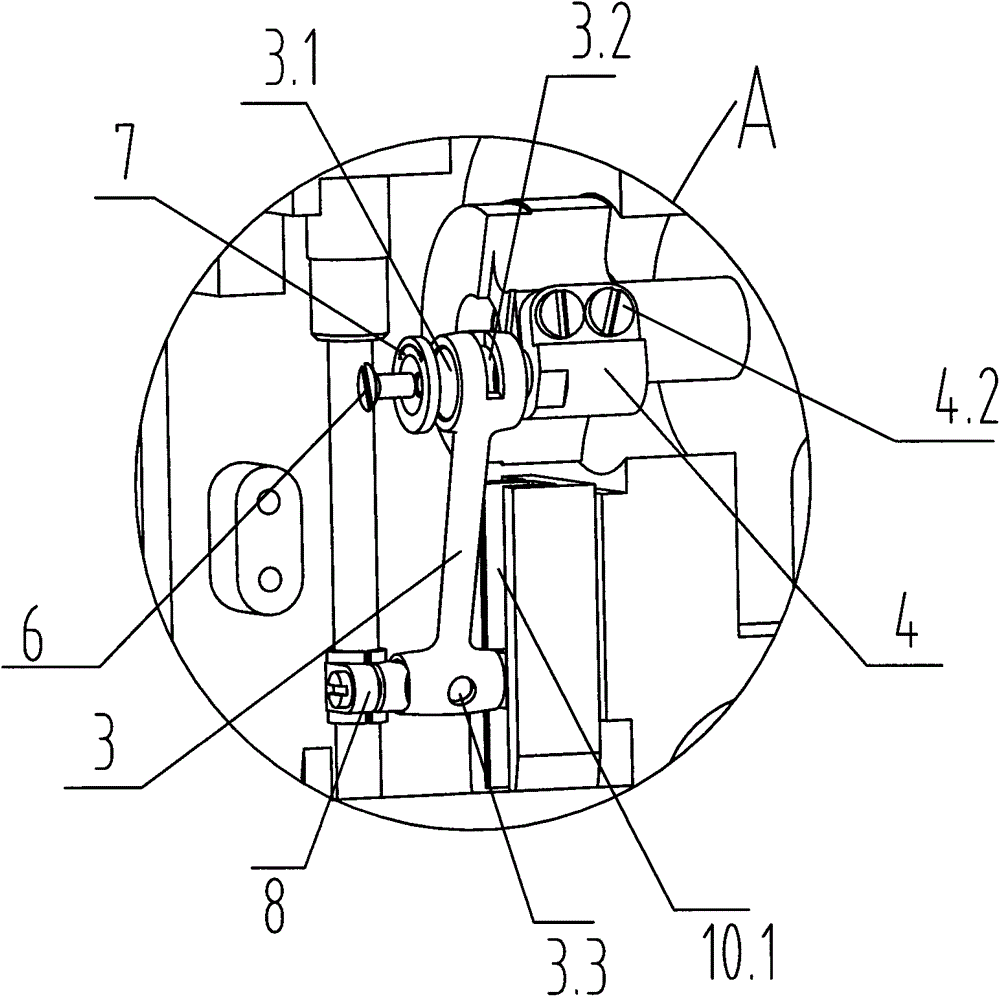

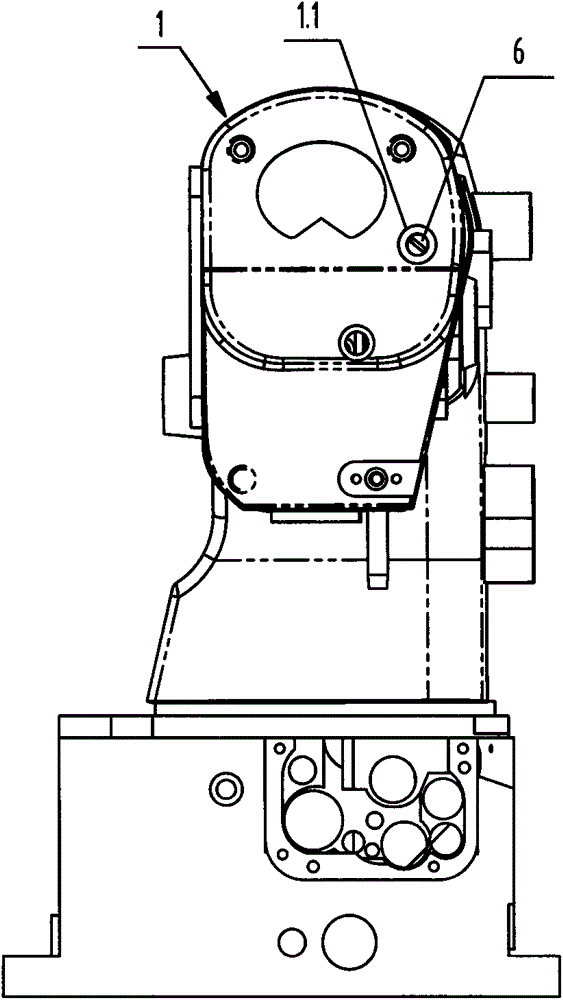

[0031] refer to Figure 1 to Figure 11 The embodiment of the sewing machine with adjustable needle bar stroke of the present invention will be further described.

[0032] The needle bar stroke in the sewing machine is the displacement between the pointer bar rising to the highest point and falling to the lowest point in the vertical direction, while the needle bar on the existing sewing machine rises to the highest point and falls to the lowest point in the vertical direction These two points cannot be changed, that is to say, the stroke of the needle bar is fixed and cannot be adjusted. In the actual use of the sewing machine, the thickness of the sewing cloth changes again, so a sewing machine with only one needle bar stroke cannot adapt, so the present invention designs a sewing machine that can adjust the needle bar stroke voluntarily as required. A sewing machine with an adjustable needle bar stroke, comprising a needle bar 2, a connecting rod 3, a crank 4, a main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com