A test bench for simulating tool behavior at various positions on the cutter head

A technology for simulating a knife and a test bench, which is used in measuring devices, testing wear resistance, testing machinability, etc., to achieve the effect of reducing floor space, accurate test data, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

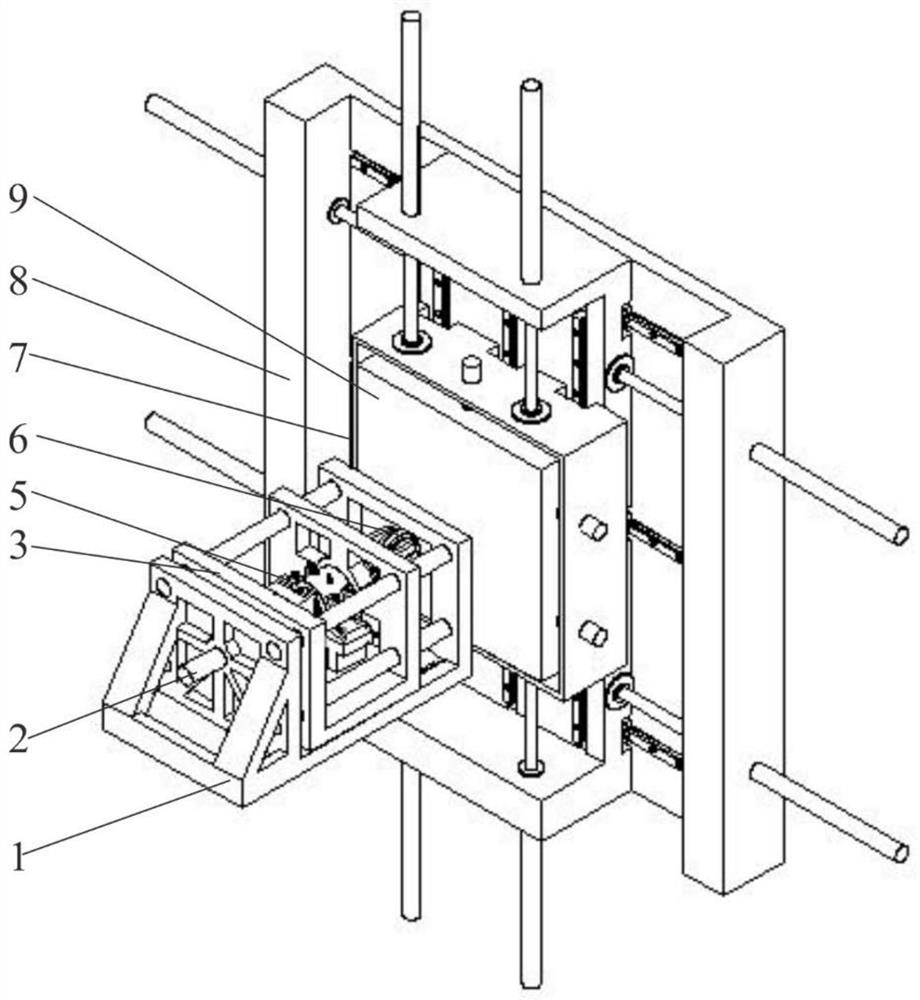

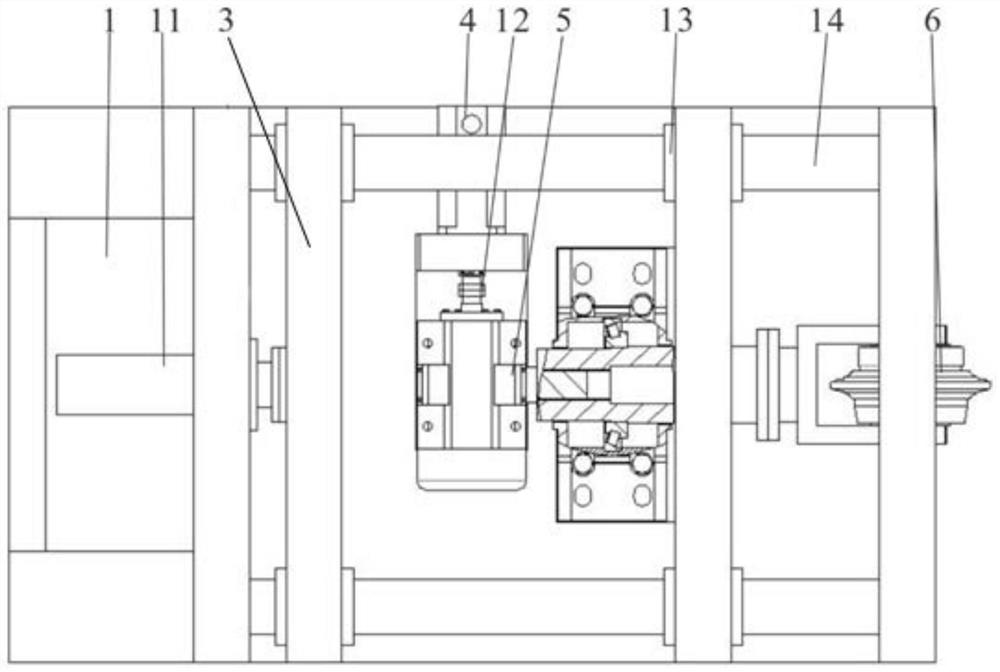

[0055] A simulation test of each station position of the tool cutter behavior, including horizontal and vertical base 8 of the base 1, a hydraulic propulsion system is provided with a transverse base 12, the hydraulic propulsion system 2 is connected to the tool griffe 6 system, provided with a rock box 8 on the longitudinal mobile system base 7, 9 is provided with a tank system on the rock of the rock tank 7 mobile system. Rock mobile tank system 7 to promote rock tank system 9 according to a set path, the tool according to a set path on the rock breaking rock sample. In this embodiment, the base 1 laterally arranged horizontally, vertically rock tank 7 is provided a mobile system, separate rock tank 7 is fixed to the mobile system on the foundation, the center and the center griffe tool system 6 coincides rock sample surface 904 perpendicular to the feeding direction of the tool system 6 griffe.

[0056] The rock mobile tank system 7 comprises a set of transverse rails 703 and l...

Embodiment 2

[0077]The present embodiment is substantially same as one embodiment aspect, except that: the angle with the seat 602, to install the tool belt angle, to simulate a knife edge or knife over excavation.

[0078] This embodiment confining pressures used to simulate different diameter cutter knife edge to overcut or condition, the same procedure as in Example particular test of a test procedure.

Embodiment 3

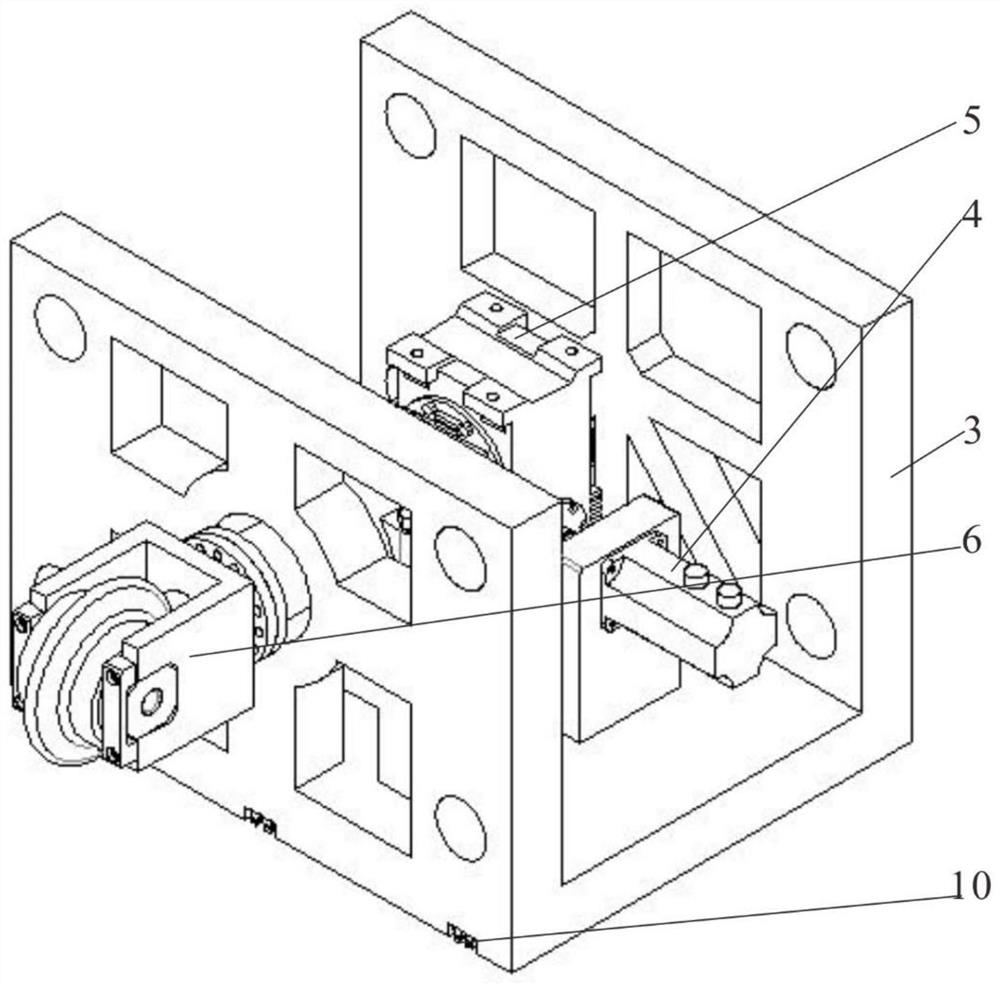

[0080] Substantially the same as one embodiment of the present embodiment aspect, except that: the griffe tool system comprising 6 to total three force sensors 606, connected by three and the plurality knife mounting plate 605 to the force sensor 606, the said multi-tool mounting plate 605 is connected to several three force sensors 601, the three-force sensor 601 is connected to the seat 602, the seat 602 has a bead 603 is bolted, a seat 603 is provided between the bead 602 and there are 604 knives.

[0081] In this embodiment, the multi-blade attachment slot defines a T-shaped upper plate 605, the three force sensor 601 with the T-slot slidably connected and fixed, the pitch of the blade according to the needs of the experiment by T-bolts stepless adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com