Transmission for achieving stepless speed changing in electro-mechanical actuation mode

A technology of infinitely variable speed and electromechanical actuation, which is applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of reduced transmission friction, low reliability, and low working life, and increase the frictional contact area , Improve the speed accuracy, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

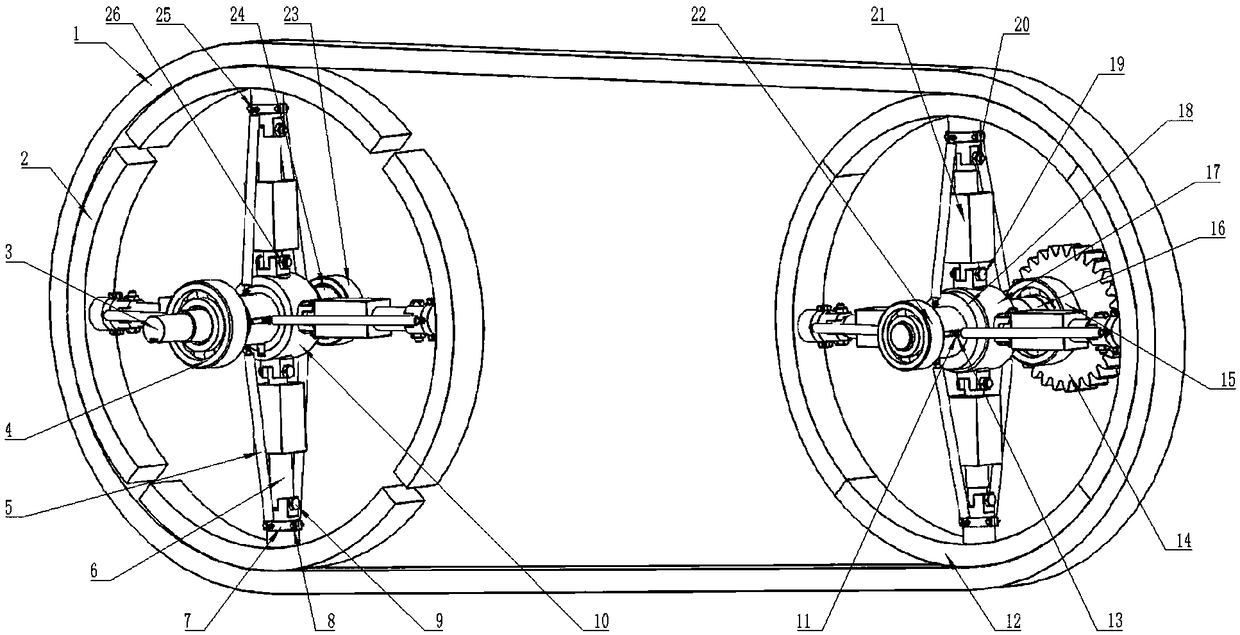

[0021] refer to figure 1 and figure 2 , a transmission mechanism used as an actuator to realize stepless speed change in this embodiment, including three parts: an input shaft assembly, a belt, and an output shaft assembly;

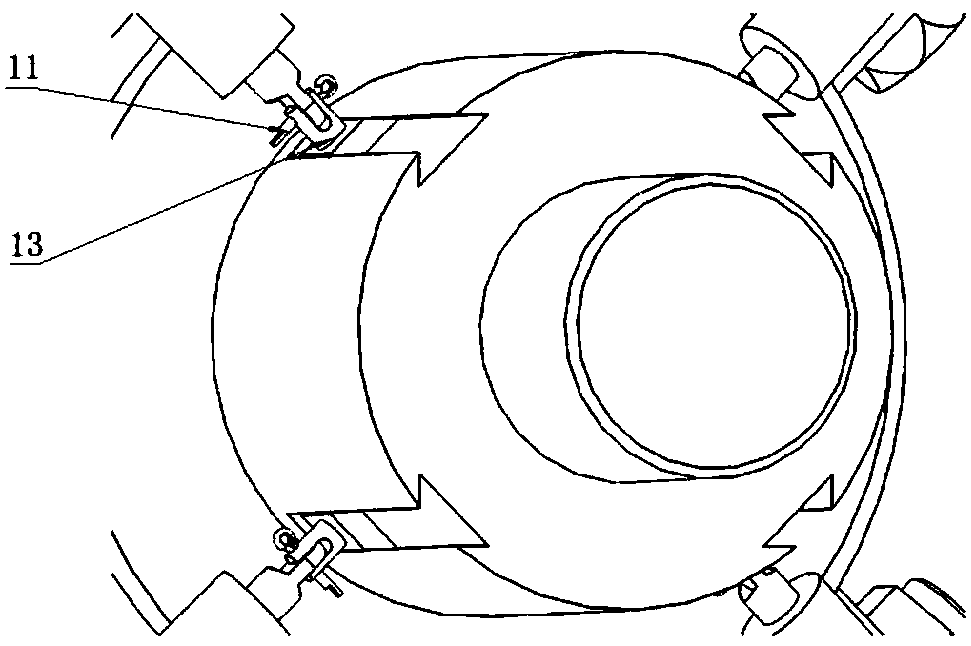

[0022] The input shaft assembly includes an input shaft 3, a driving pulley 2, a first driving shaft bearing 4, a second driving shaft bearing 23, a support rod 5, an actuator 6 at the driving wheel, a tightening ring 7, a screw 8, Hex screw 9, collar 10 at the input shaft, cotter pin 11, slider 13, hex screw 19, power interface 24 at the input shaft, cotter pin 25 and nut 26;

[0023] The input shaft 3 is connected with the motor through a key, and the power source is input into the whole speed reducer. The input shaft 3 is connected with the collar 10 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com