Patents

Literature

75results about How to "Achieve wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

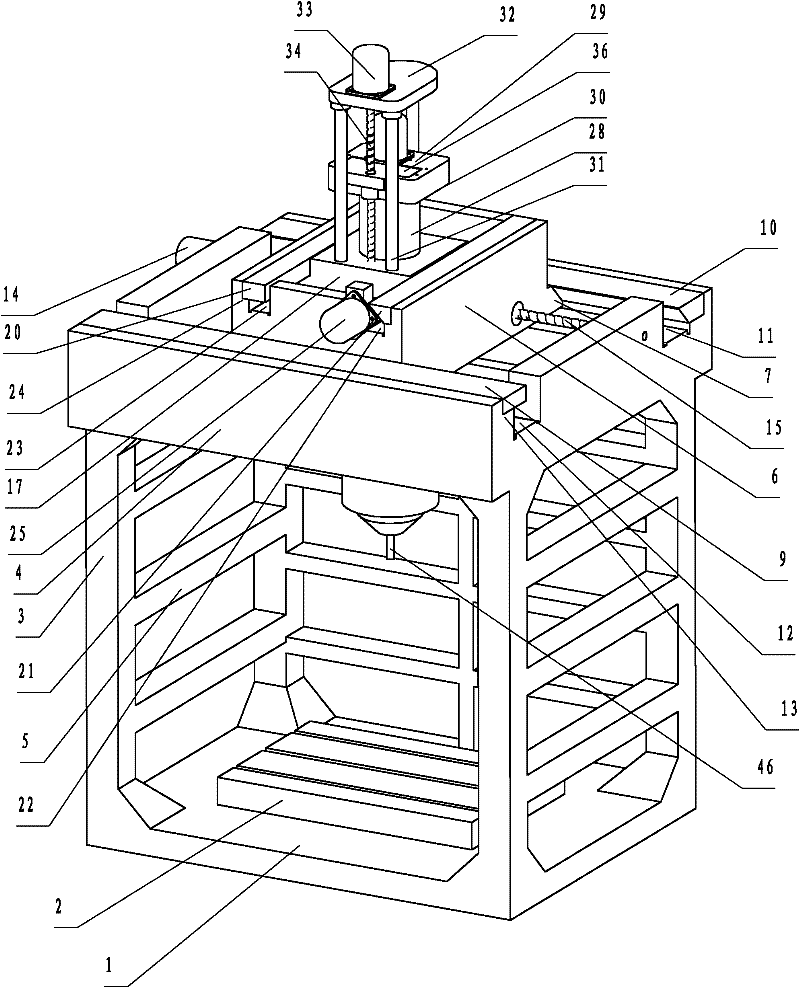

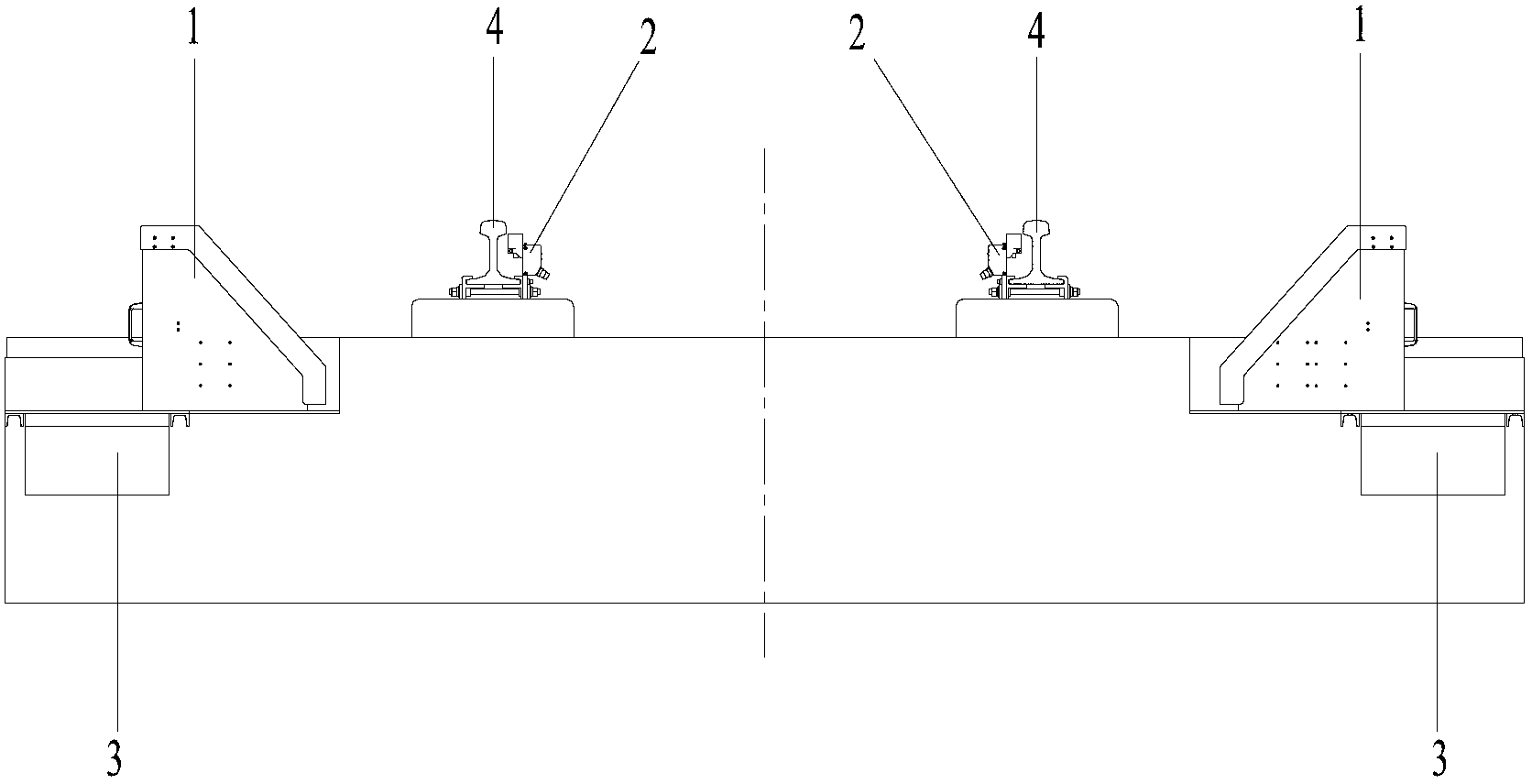

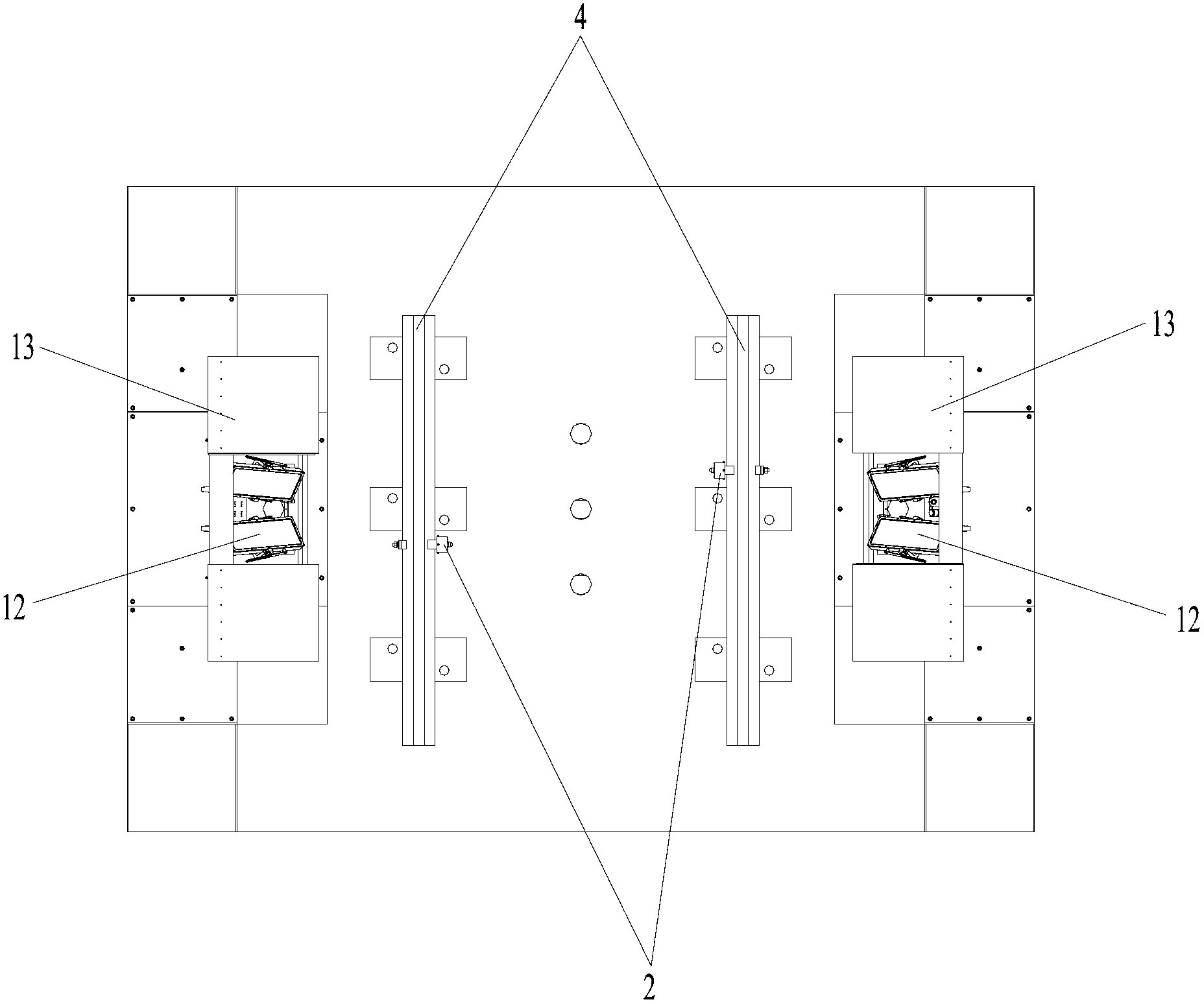

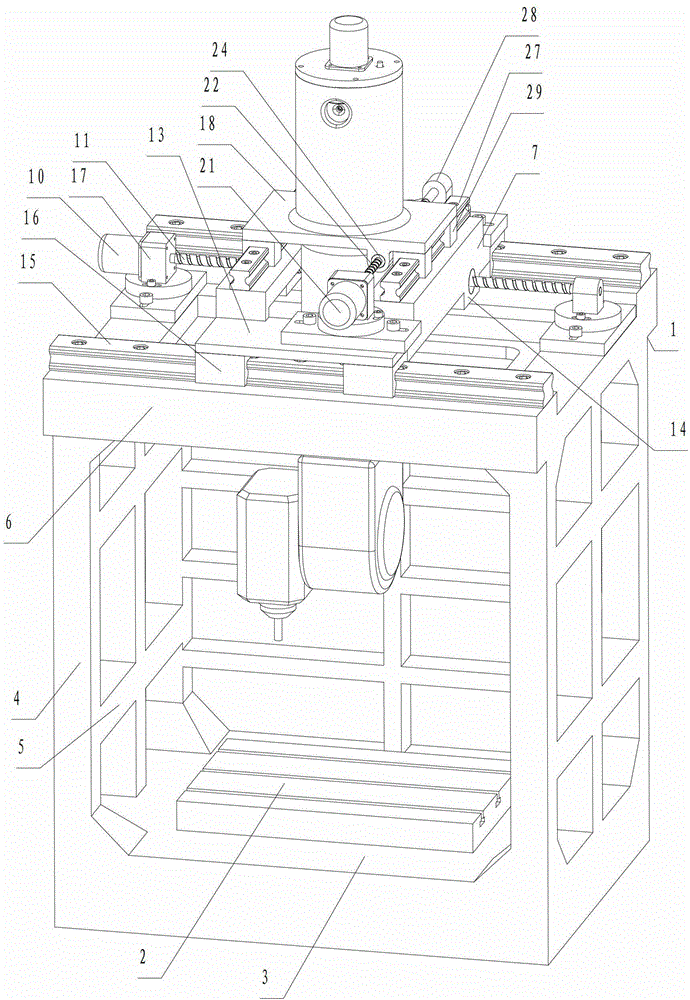

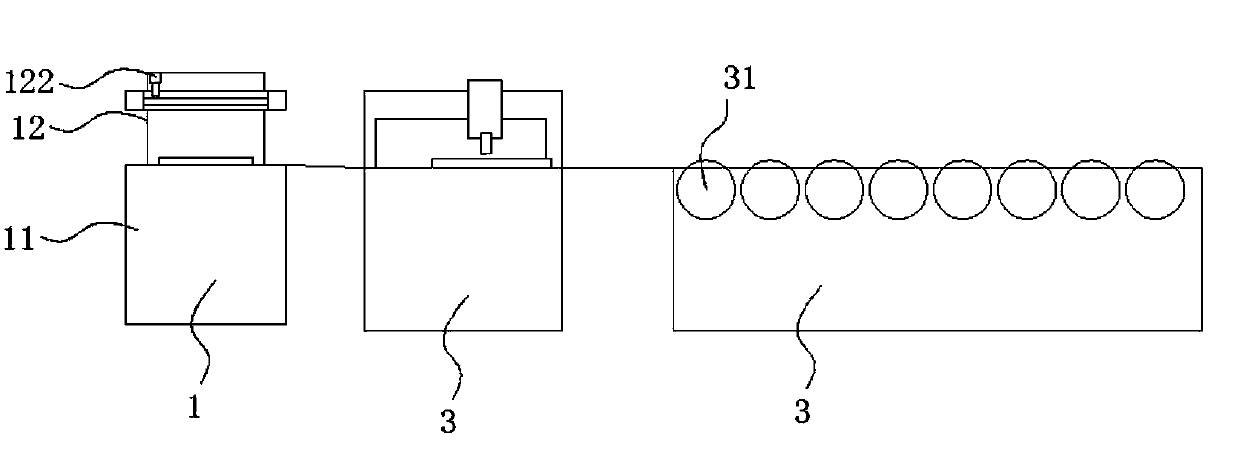

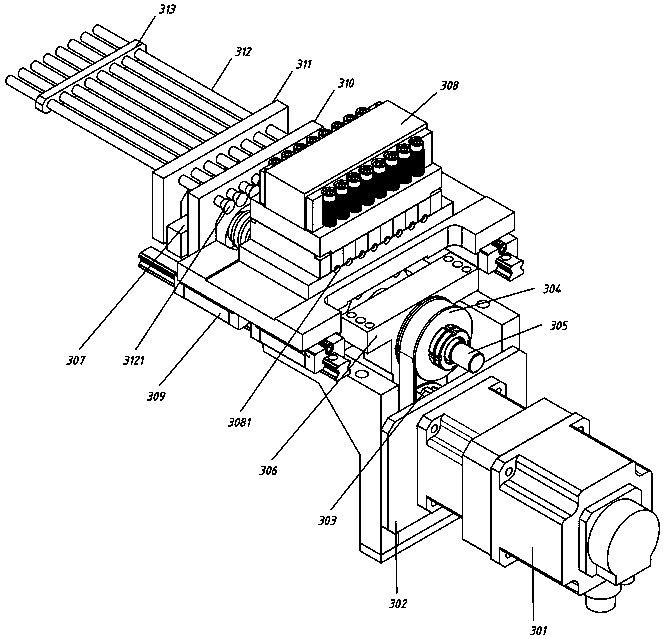

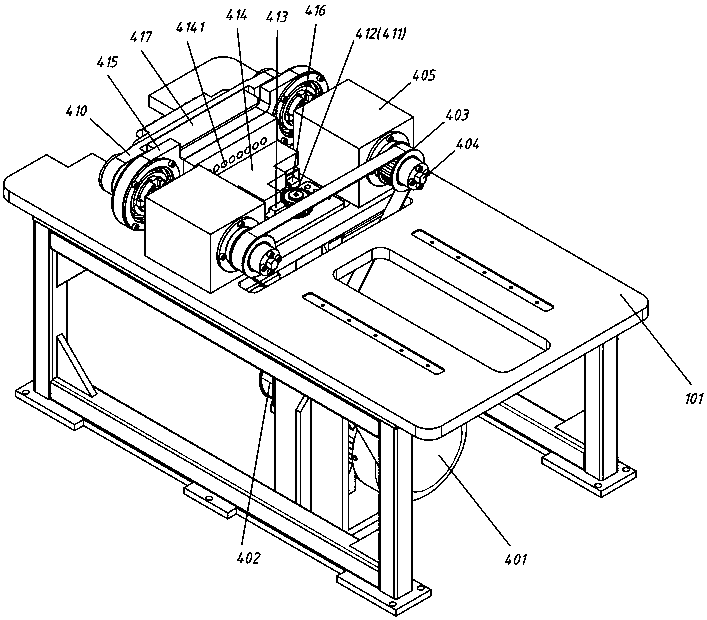

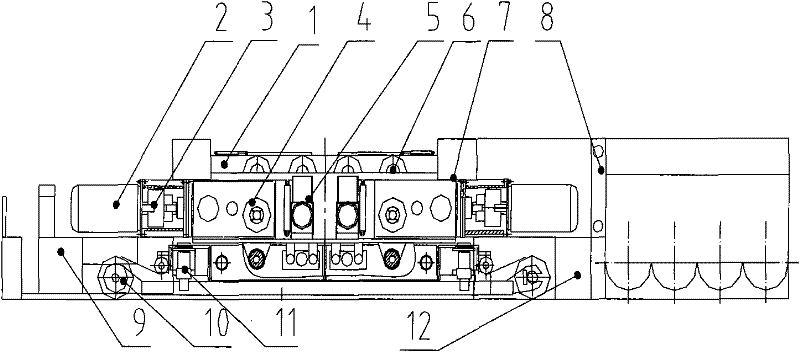

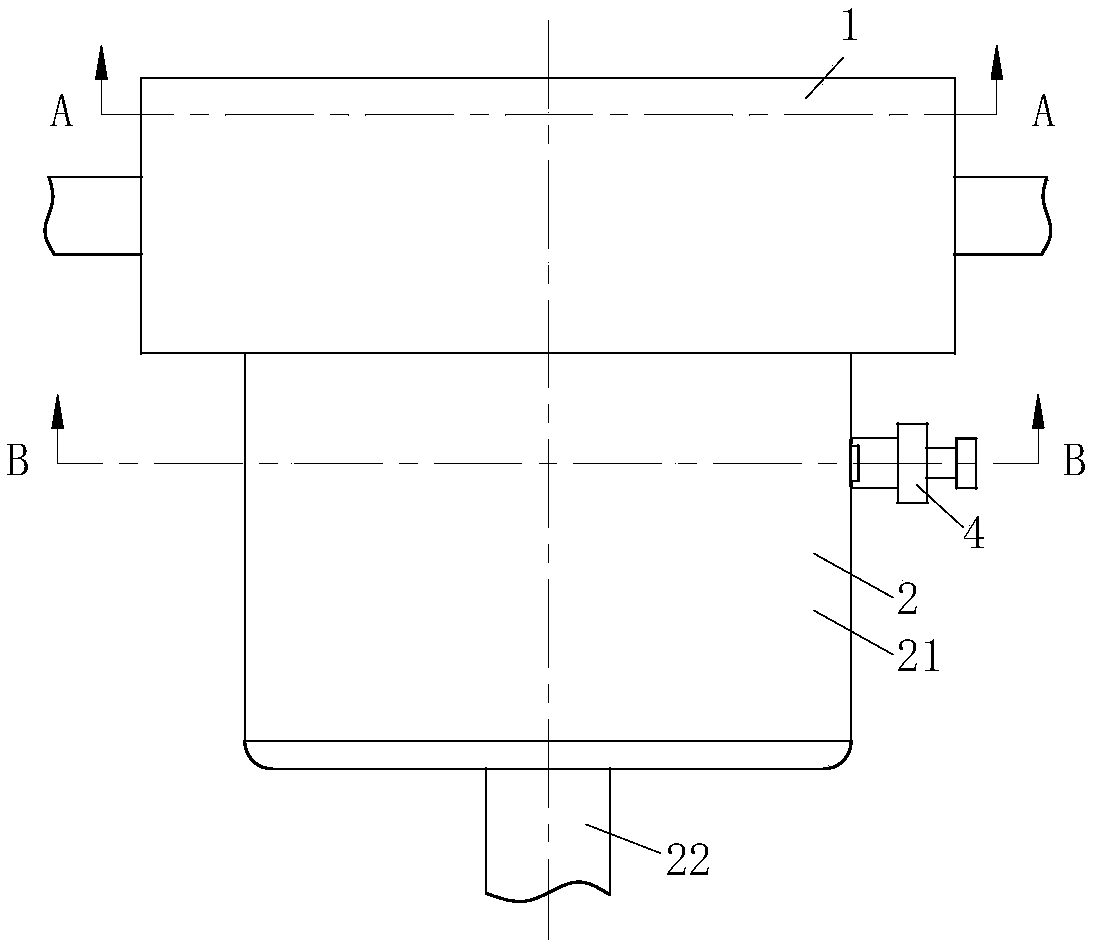

Numerical control equipment, machining process, numerical control production line and automatic article storage system

InactiveCN102528567AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersProduction lineNumerical control

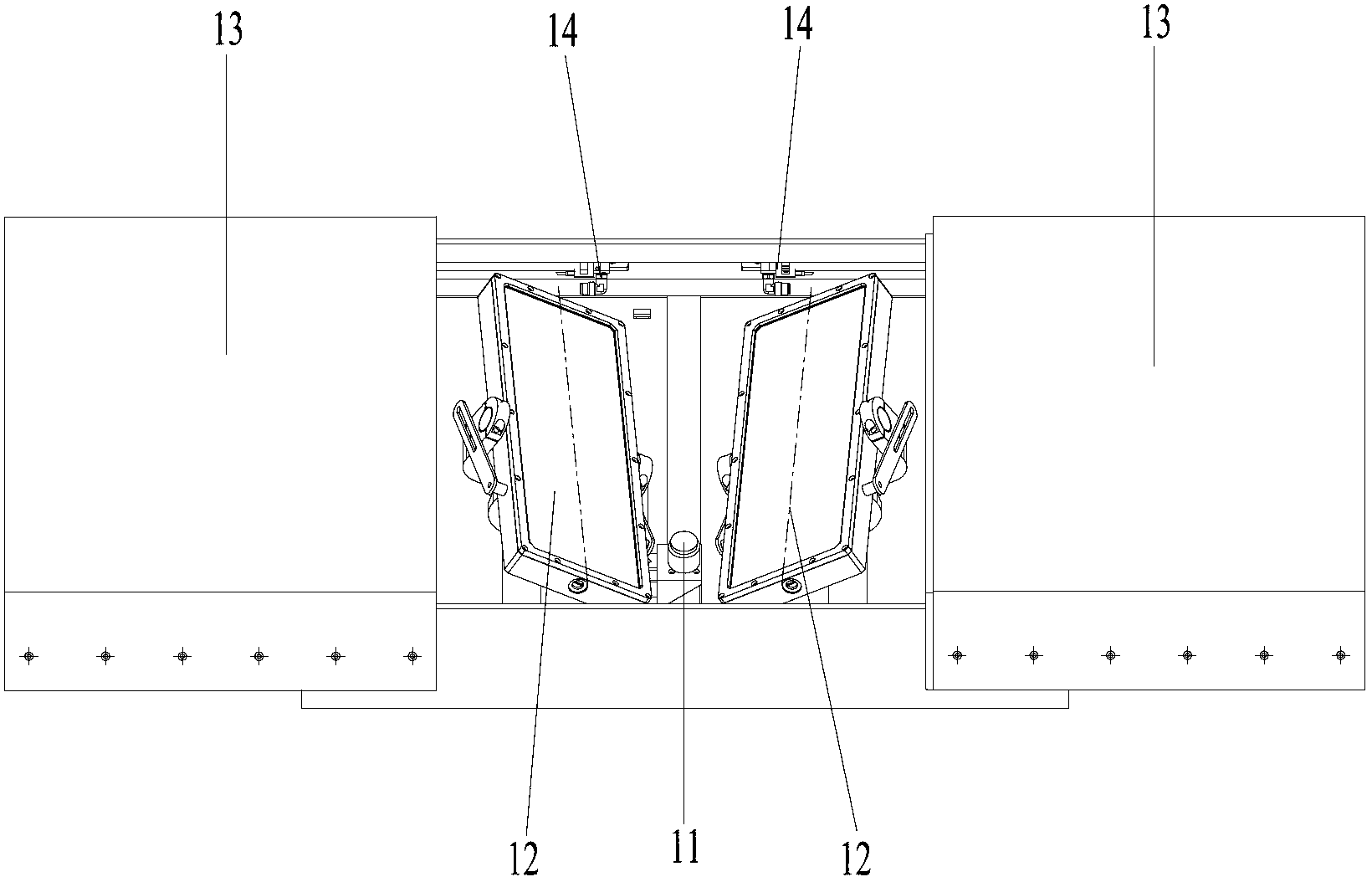

Numerical control equipment comprises a main frame, a workpiece clamping device, an X-directional sliding seat, a first driving device, Y-directional sliding seat, a second driving device and a Z-directional guide device. The main support frame is of a closed-loop structure with a vertical opening; an X-directional front guide rail and an X-directional rear guide rail which are matched with each other are arranged between the main support frame and the X-directional sliding seat; the first driving device drives the X-directional sliding seat to move back and forth and comprises an X-directional lead screw positioned between the X-directional front guide rail and the X-directional rear guide rail; the second driving device drives the Y-directional sliding seat to move back and forth; the Z-directional guide device is mounted on the Y-directional sliding seat and comprises a Z-directional guide rod capable of vertically moving, and a third driving device for driving the Z-directional guide rod to vertically move; and a main machining head is arranged at the lower end of the Z-directional guide rod. The numerical control equipment has the advantages of fine stability, accuracy in positioning and smoothness in movement, and iron scraps falling after machining a workpiece basically cannot enter the guide rail above the machining head without special protection.

Owner:杨东佐

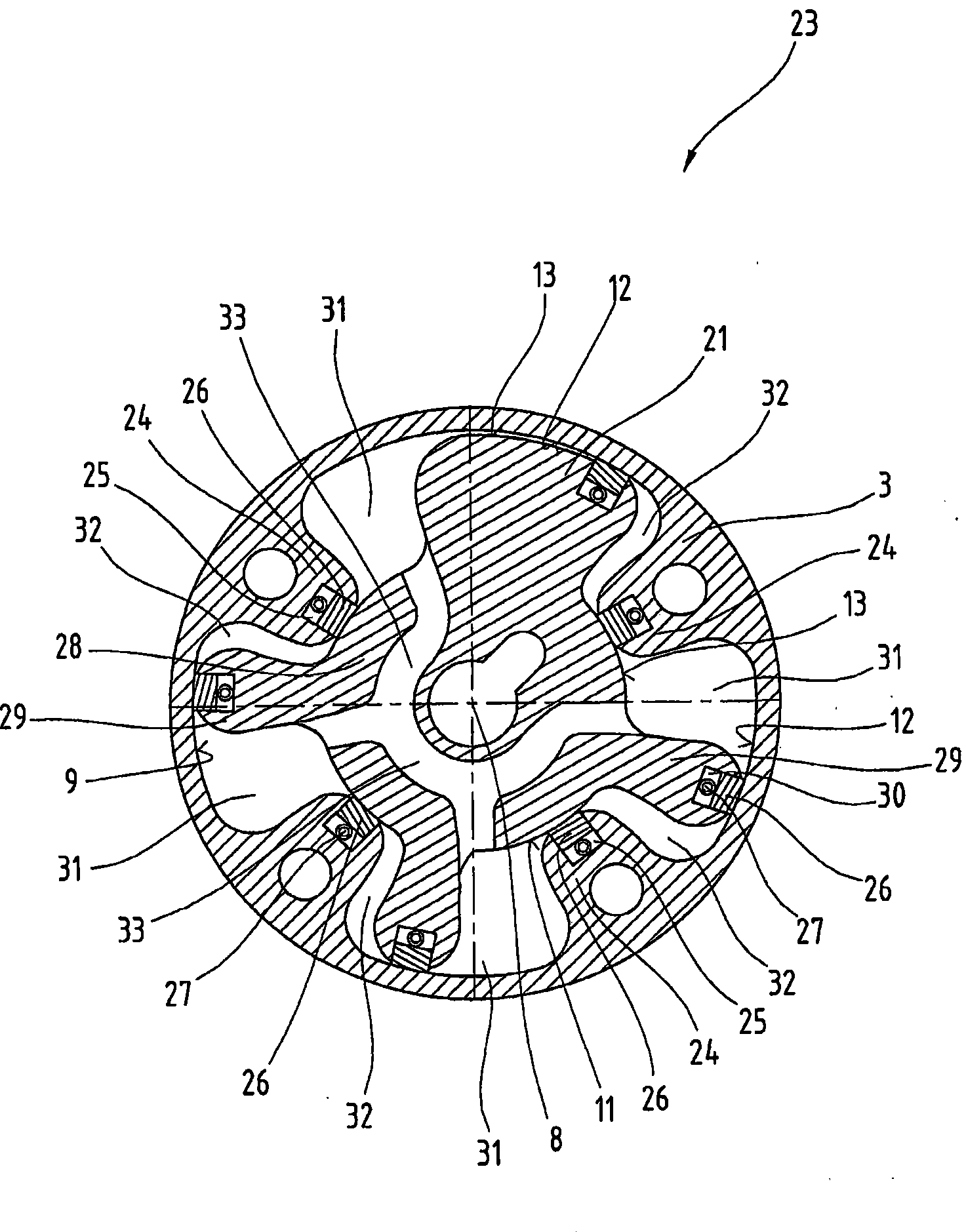

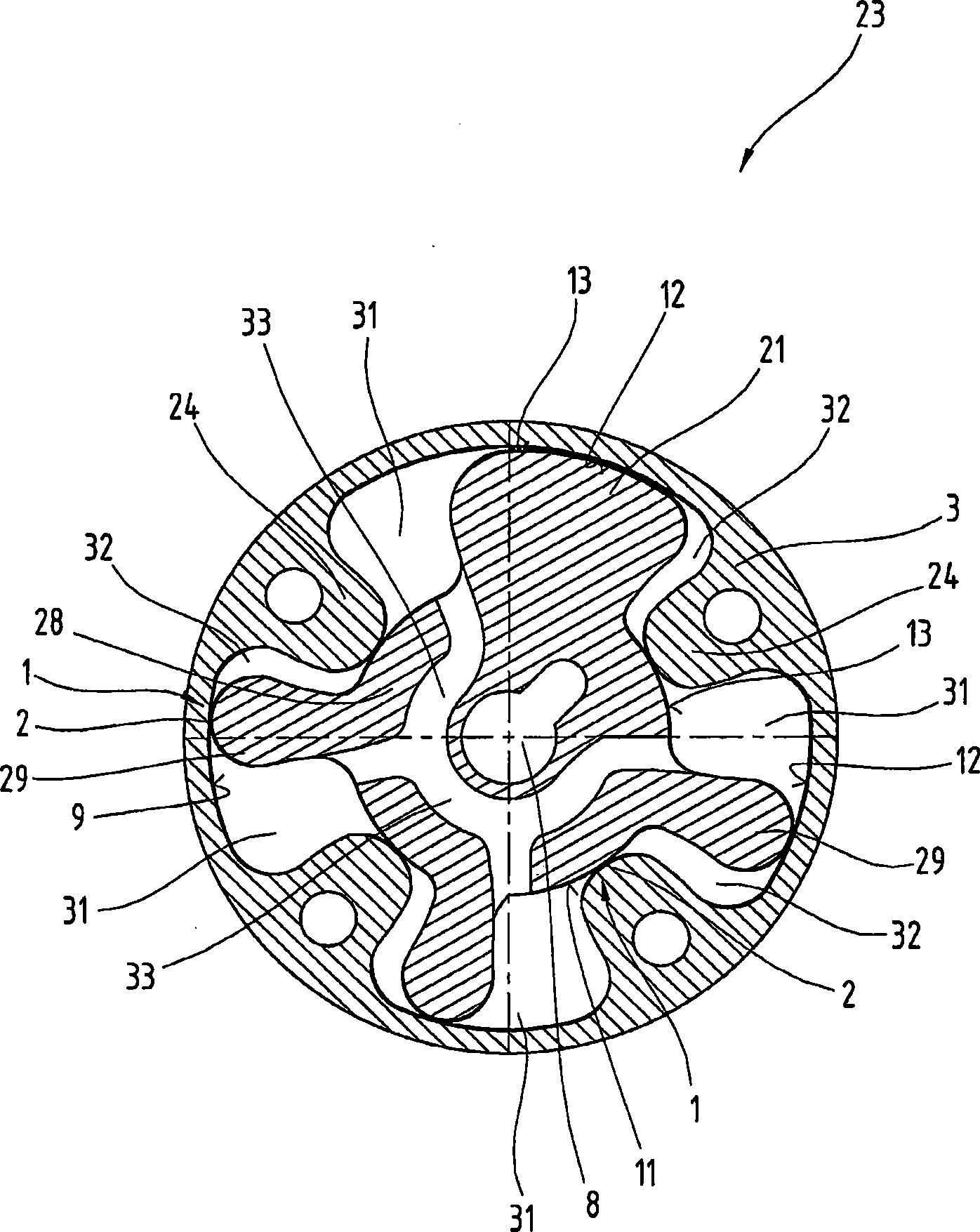

Component, especially a preform, comprising a coating

The invention relates to a component comprising at least one structural element (3), especially a moulded part (4), which consists of a powder or a powder mixture containing metallic and optionally non-metallic components, and is produced by pressing said powder or the powder mixture and then sintering. At least one surface section (12) of the structural element (3), which is used to co-operate with another surface section (13) of another component (14, 22) during the application of a pressurised force acting between the two surface sections (12, 13), is coated with a lubricating lacquer (2). The invention further relates to a method for producing one such structural element (3, 14, 22) coated with the sliding lacquer (2).

Owner:MIBA SINTER AUSTRIA

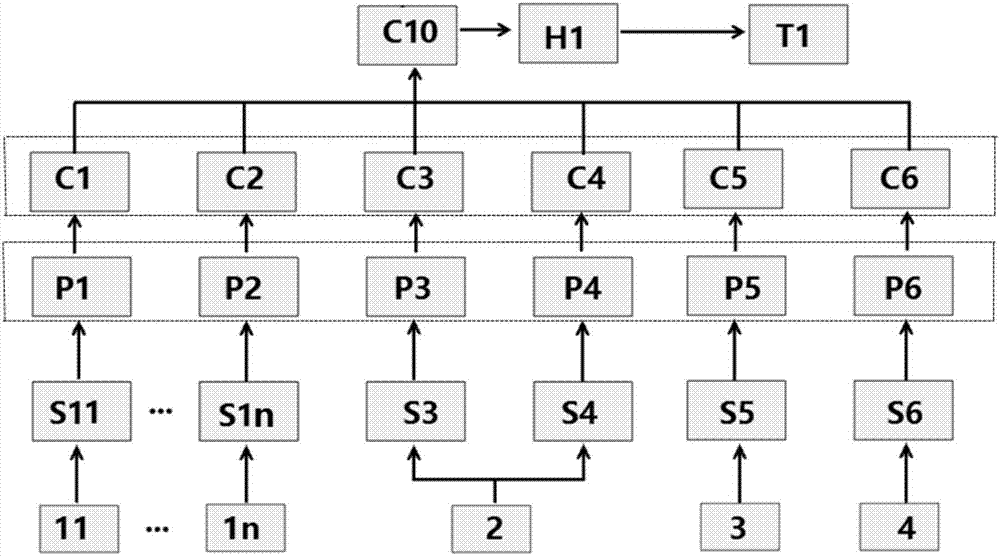

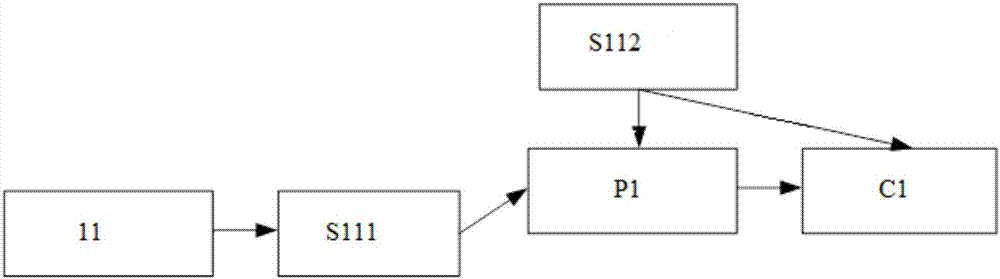

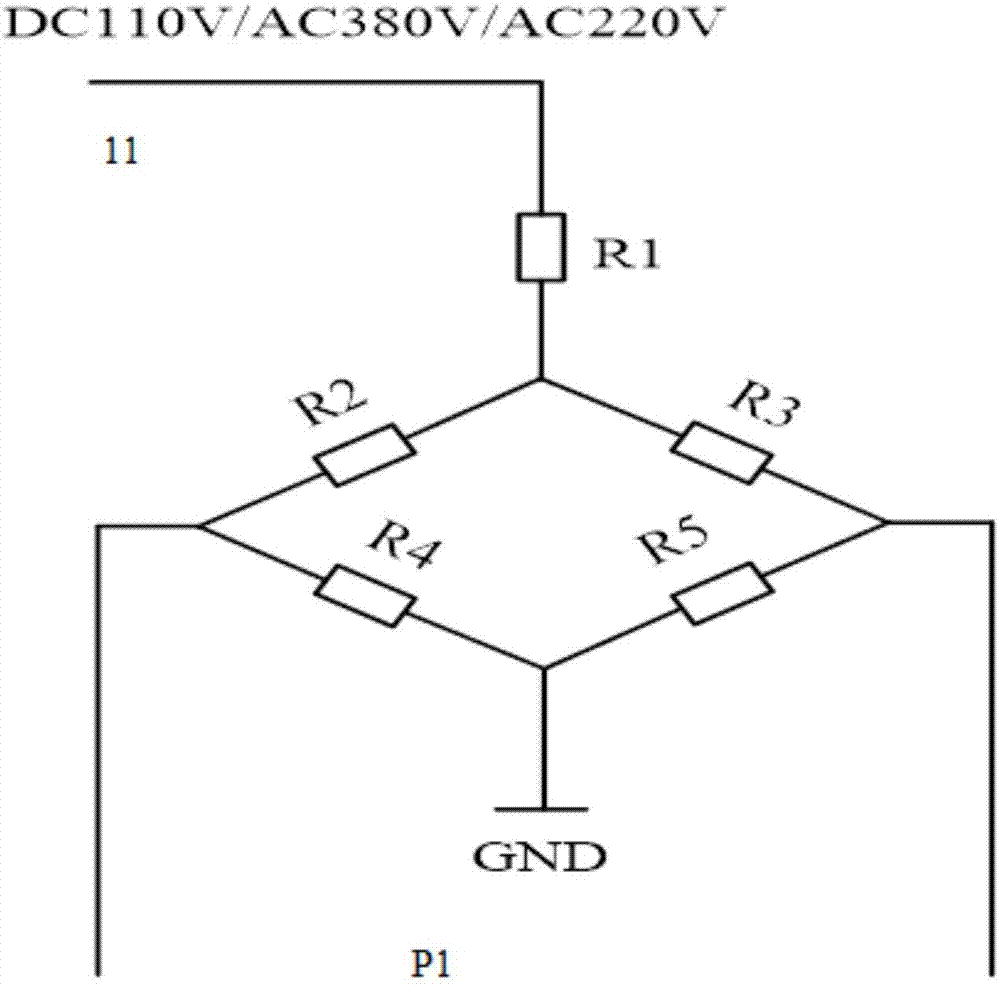

Conveyer belt operation monitoring system and method

ActiveCN107082253ARealize fault trend predictionRealize abnormal alarmControl devices for conveyorsMicrocontrollerMicrocomputer

The invention relates to a conveyer belt operation monitoring system and method. The conveyer belt operation monitoring system comprises a data processing module, a voltage converting and detecting module, a vibration sensor, a temperature sensor, a displacement sensor, a wireless communication module and an upper computer, wherein the voltage converting and detecting module is used for monitoring a pull switch; a single-chip microcomputer is used for reading a voltage outputted by a voltage converting circuit, performing A / D conversion, performing packing and performing encapsulating; the wireless communication module is used for sending the packed and encapsulated voltage data to the upper computer; the vibration sensor is used for acquiring vibrating data of a gear box; the temperature sensor is used for acquiring temperature data of the gear box; and the displacement sensor is used for acquiring the axial displacement offset of a conveyer belt roller. Through the adoption of the conveyer belt operation monitoring system and method disclosed by the invention, the comprehensive real-time accurate monitoring of the operation state of the conveyer belt system can be realized, so that the problems that a conveyer belt pull switch are difficult to detect and position in a flash manner are solved, and the functions of prejudging failure trend of the gear box, warning abnormal situations, warning the situation that shaft scurrying is generated on a driving roller are realized.

Owner:QINHUANGDAO PORT

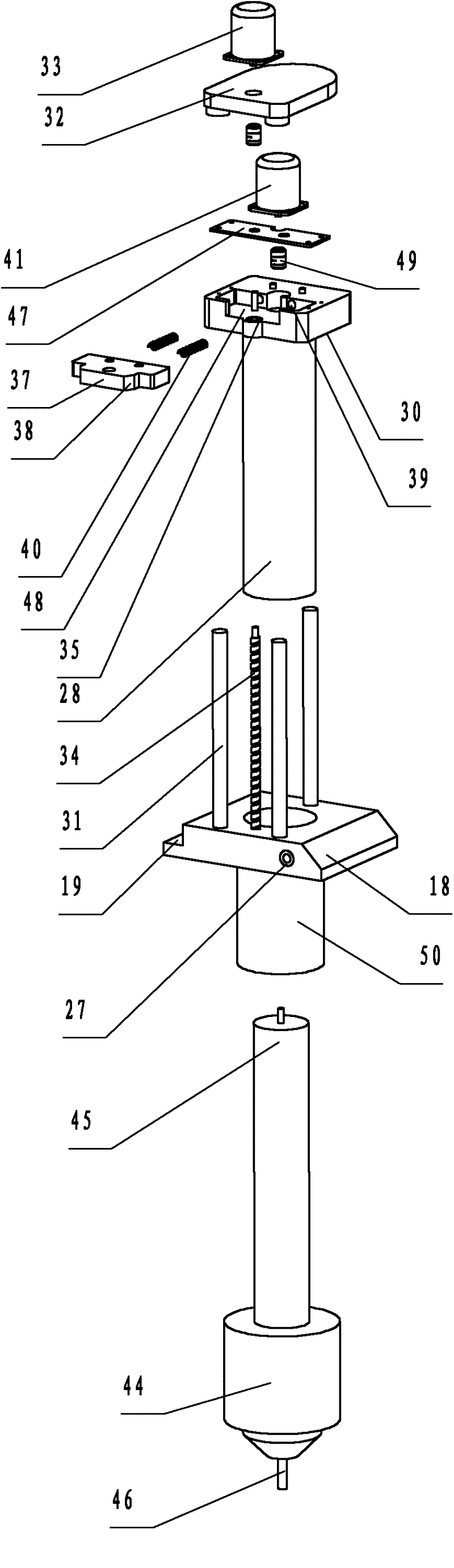

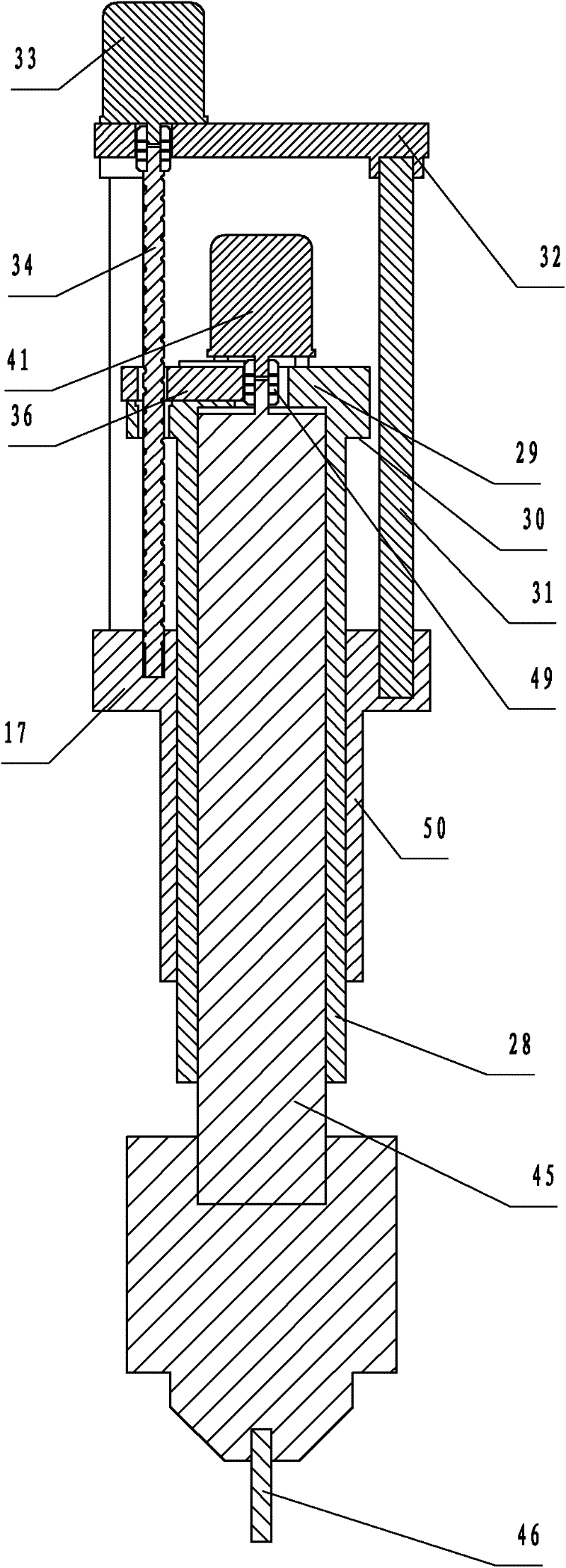

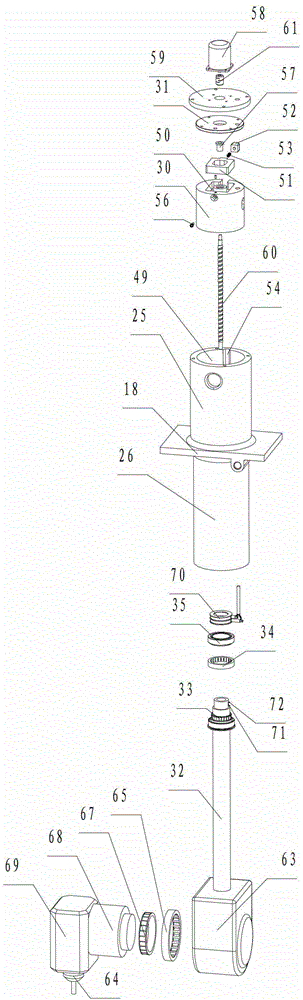

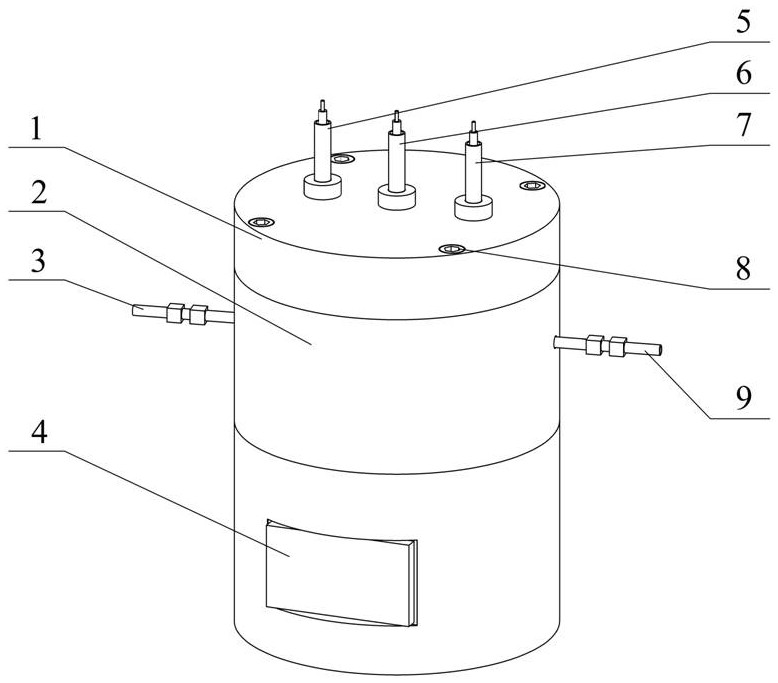

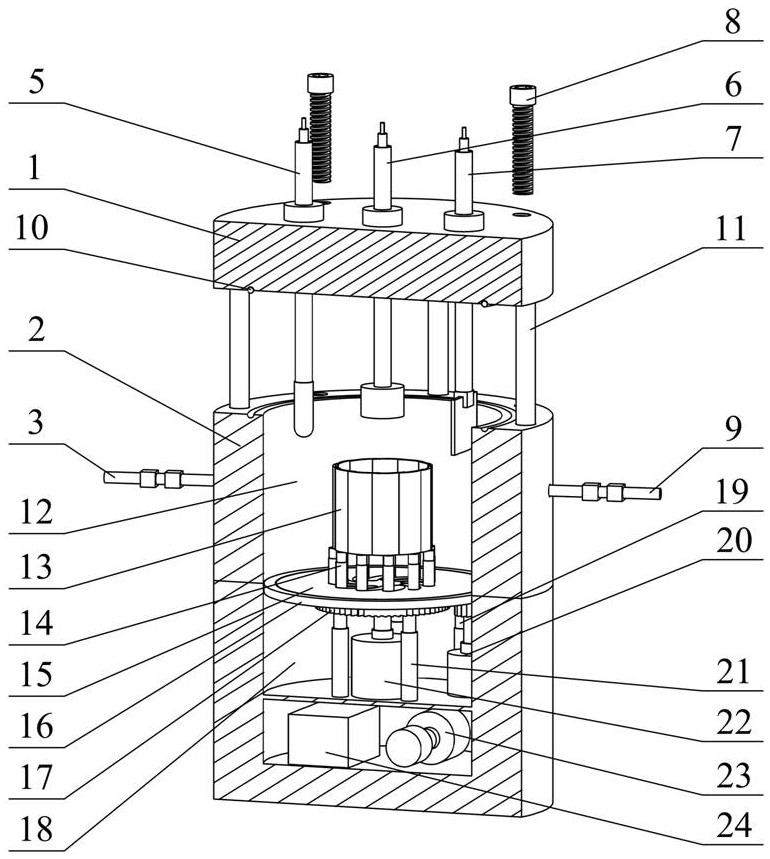

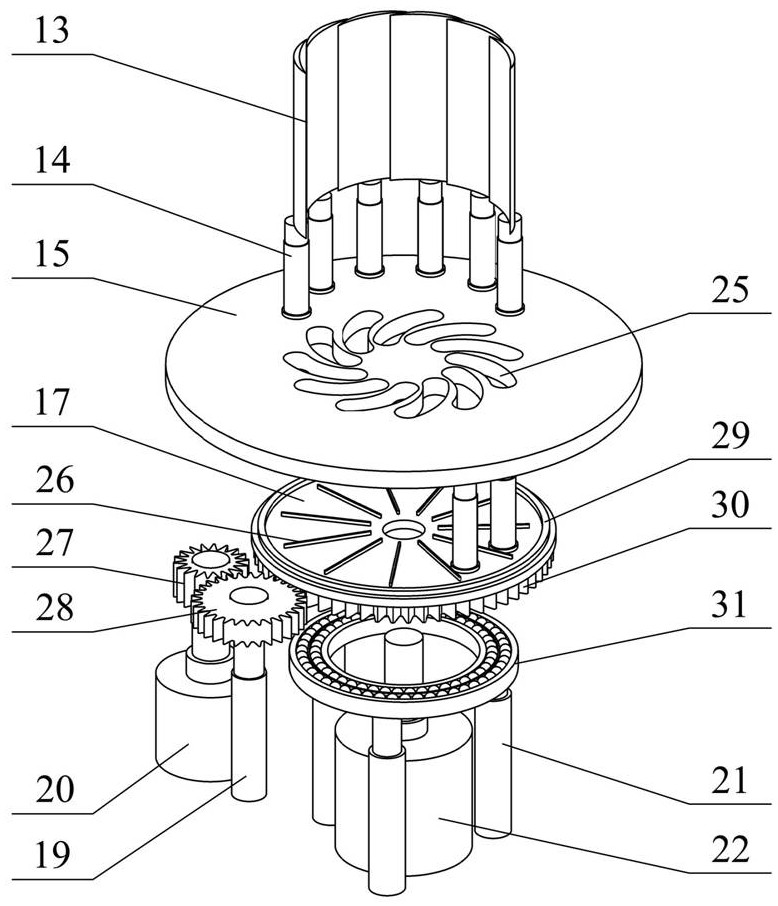

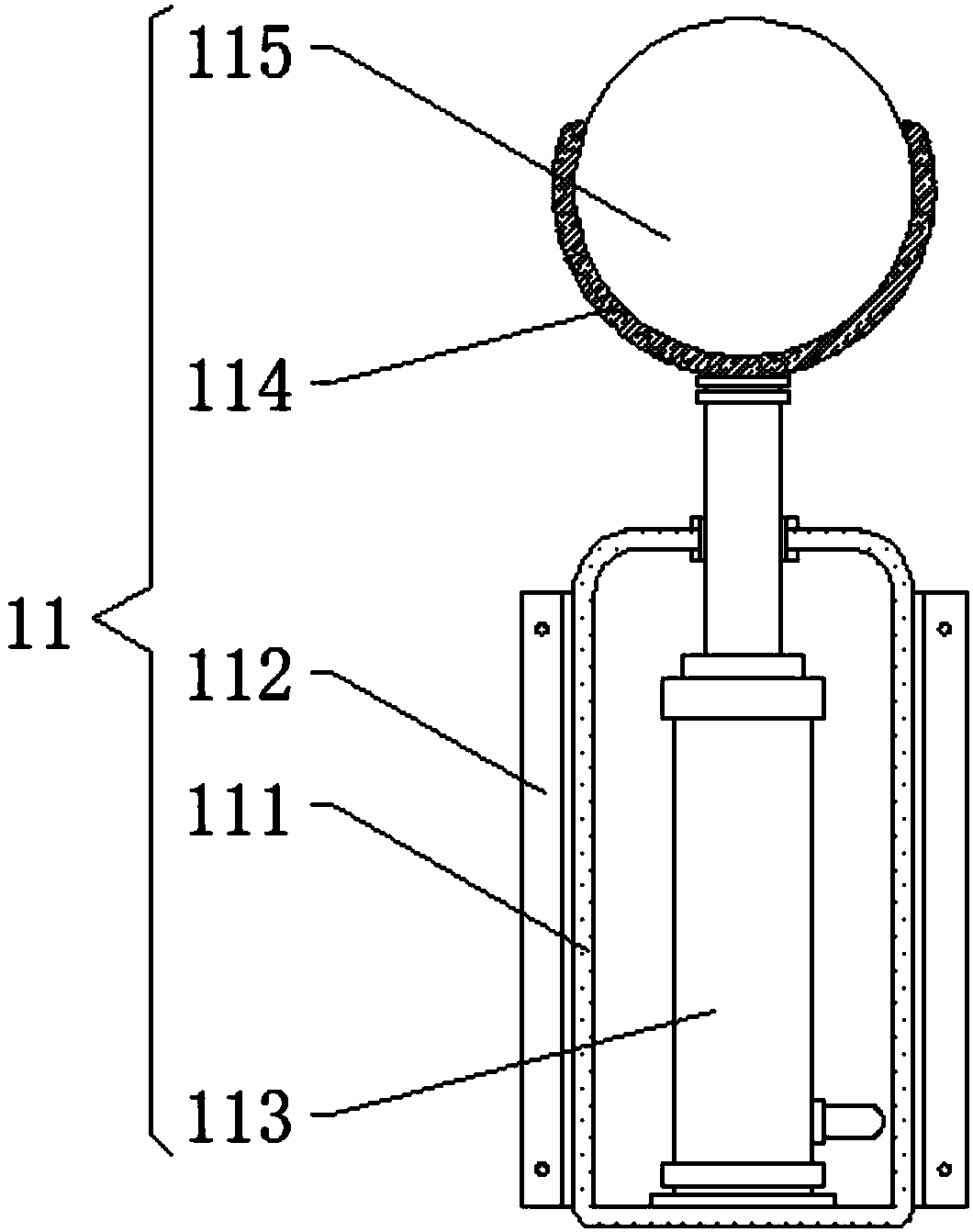

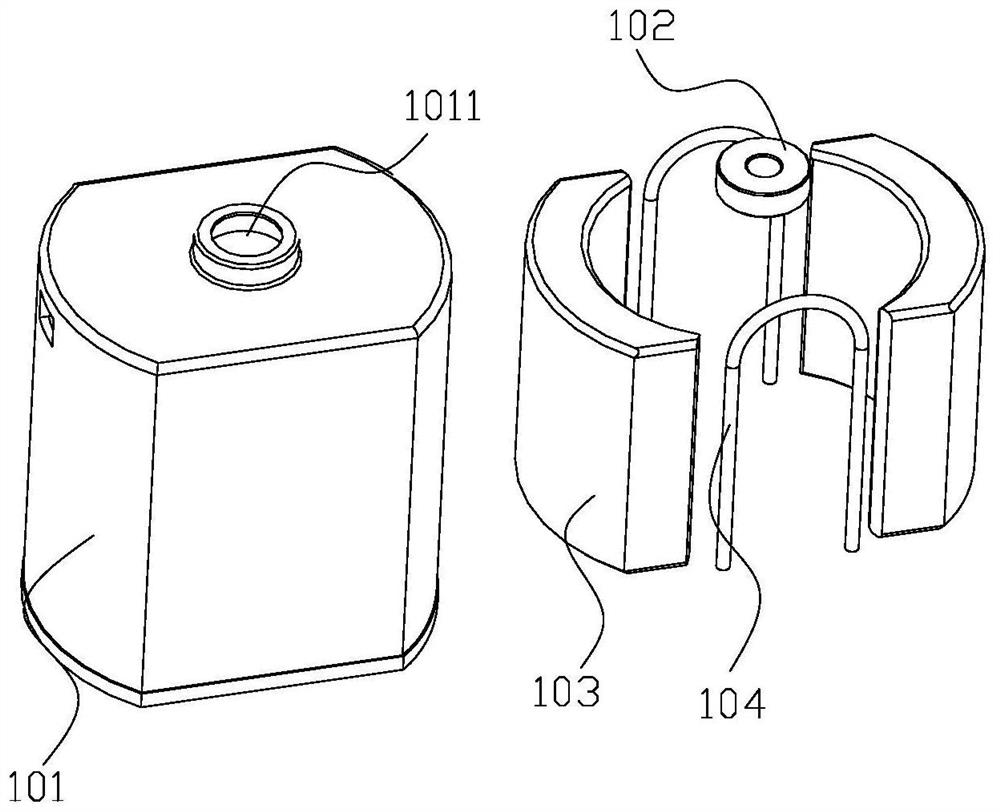

Semi-automatic bottle opener for laboratory microminiature reagent bottle

InactiveCN110171793ASimple structureEasy to openTight-fitting lid removalThreaded caps removalEngineeringHigh pressure

The invention relates to a semi-automatic bottle opener for a laboratory microminiature reagent bottle. The semi-automatic bottle opener for the laboratory microminiature reagent bottle comprises a case; a pedestal for placing a reagent bottle is arranged in the case; the pedestal adopts a hollow structure with an opening upper end; the case is provided with a bottle plug clamping mechanism corresponding the part above the pedestal; the bottle plug clamping mechanism comprises a bottle cap clamp holder, a rubber air bag and a high-pressure gas cylinder; the bottle cap clamp holder adopts a hollow annular structure; the bottle cap clamp holder is rotatably connected with the case through a bearing; the rubber air bag is annular; the rubber air bag is arranged on the inner circle side surface of the bottle cap clamp holder; the rubber air bag is connected with the high-pressure gas cylinder through a gas guide pipe; an electromagnetic valve is arranged on the gas guide pipe; a motor is arranged in the case; and an output shaft of the motor is in transmission connection with the bottle cap clamp holder through a transmission mechanism. The semi-automatic bottle opener for the laboratory microminiature reagent bottle can clamp and open the microminiature reagent bottle conveniently, can reduce damage to the reagent bottle and can reduce the labor amount of personnel.

Owner:HENAN UNIVERSITY

Self-lubricating silicone rubber and preparation method thereof

InactiveCN107815124AImprove physical performanceDoes not affect basic performanceOther chemical processesPolymer scienceSilica gel

The invention provides a self-lubricating silicone rubber which is characterized by being prepared from all the following ingredients in parts by weight: 100 parts of methyl vinyl silicone rubber, 20to 50 parts of fumed silica, 1 to 5 parts of hydroxyl silicone oil, 0.1 to 1 part of fluorine mold release agent, 10 to 20 parts of methyl phenyl silicone oil and 2 to 10 parts of magnesium oxide. According to the self-lubricating silicone rubber and a preparation method thereof, raw rubber matching is improved to improve physical performance of the silicone rubber, non-reactive silicone oil is added to reduce surface friction after silica gel vulcanization, the defined amount of MgO is added to improve reverse resistance of silica gel products, and the special fluorine mold release agent ingredient is added to improve demoulding performance and roller banding performance; thus, basic performance of the silicone rubber is not affected, surface friction of the silica gel is reduced, productabrasion is reduced, a dynamic sealing effect of the silica gel is achieved, and service life of products is prolonged.

Owner:东莞新东方科技有限公司

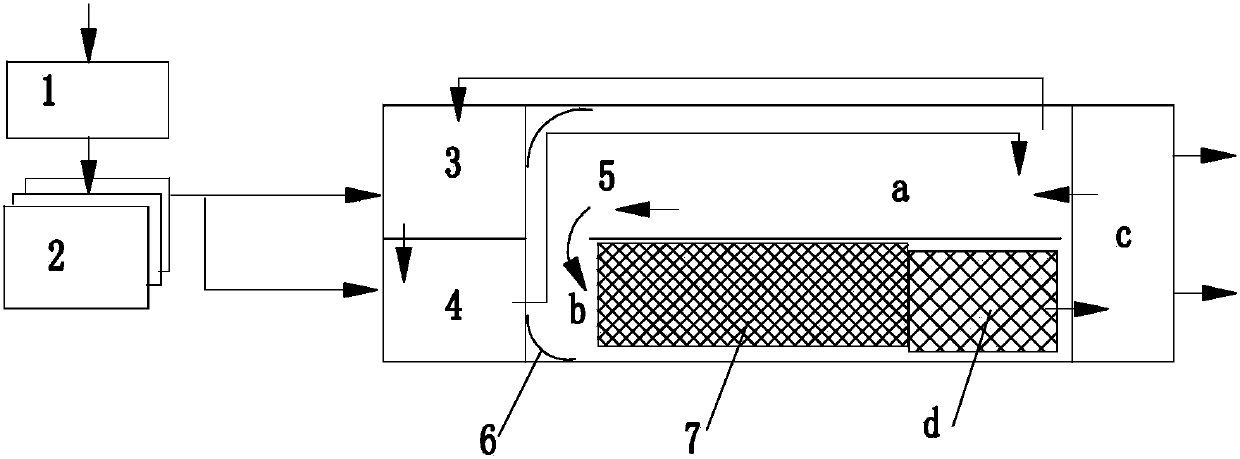

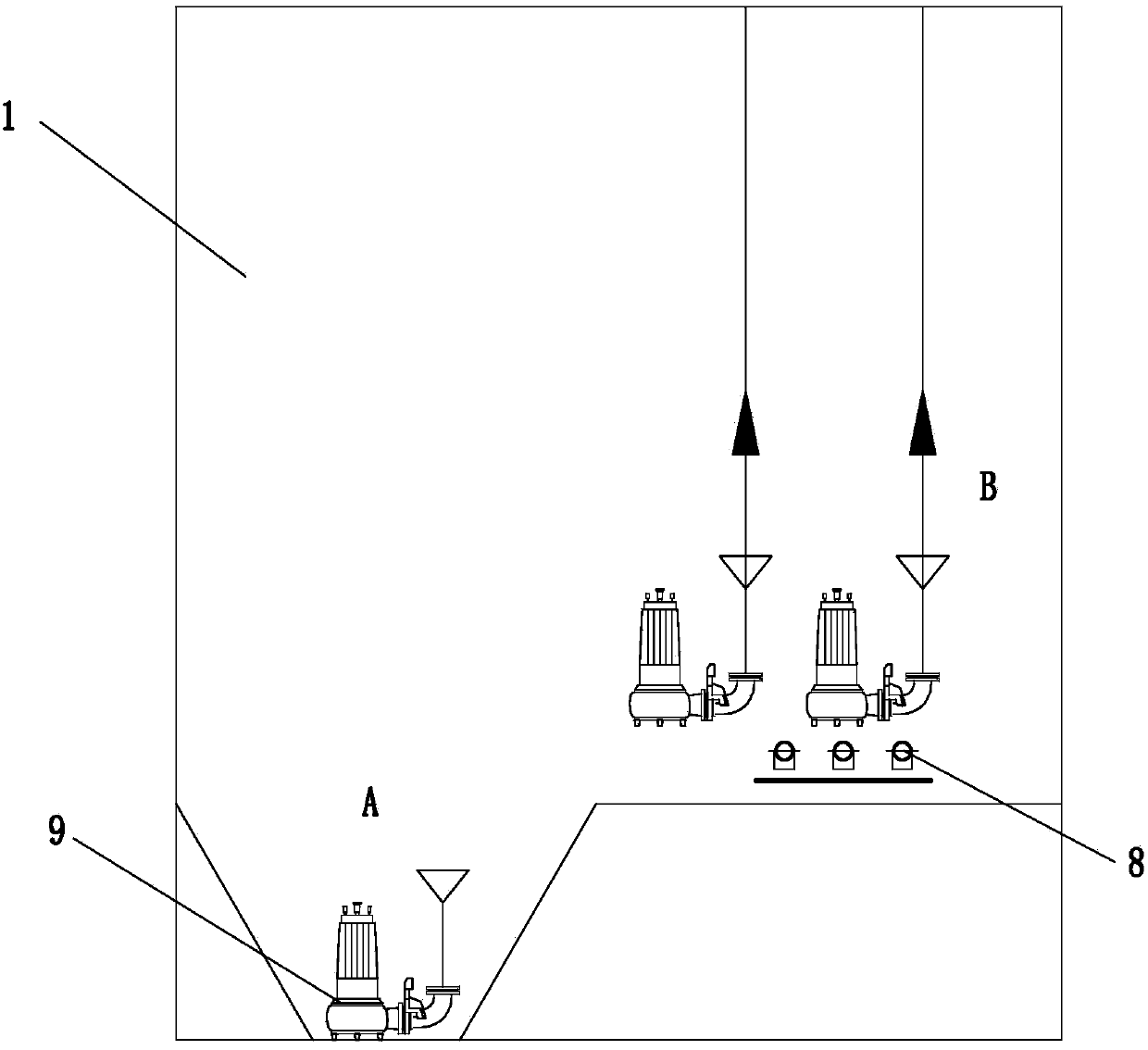

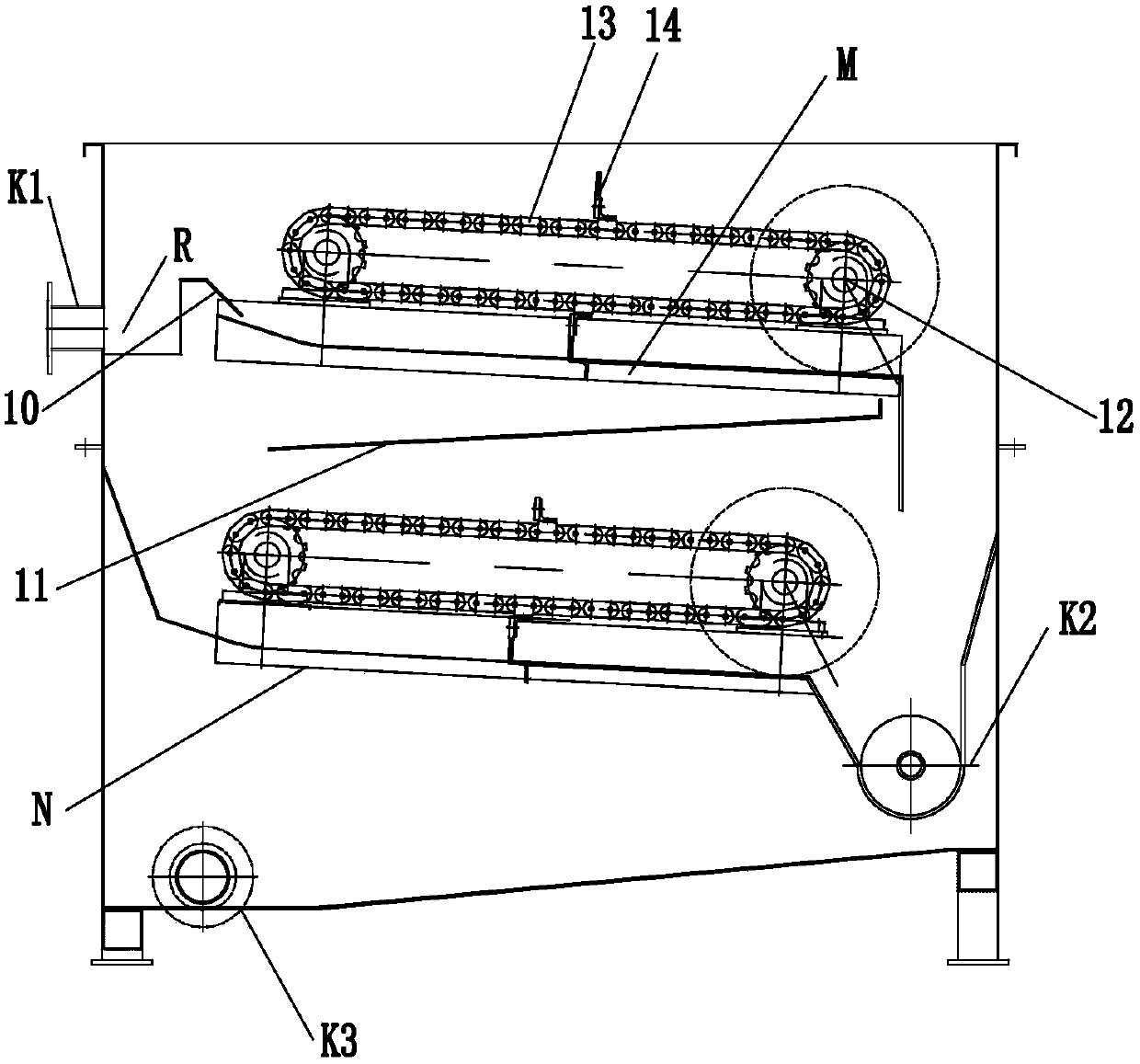

Integrated short-process efficient denitrification and phosphorus removal sewage treatment system and process

ActiveCN104003586AReduce wearExtend your lifeEnergy based wastewater treatmentMultistage water/sewage treatmentOxidation ditchWater treatment system

The invention relates to an integrated short-process efficient denitrification and phosphorus removal sewage treatment system and process. The integrated short-process efficient denitrification and phosphorus removal sewage treatment system comprises a water inlet regulation pond with a sand setting function, a three-dimensional combined flat plate type grating, a hypoxic preconditioning pond, an anaerobic pond, a single-channel oxidation ditch, a cage type filler system and an MBR system, wherein the cage type filler system and the MBR system are arranged in the oxidation ditch, and the MBR system has the functions of a secondary sedimentation tank. The water inlet regulation pond is connected with the three-dimensional combined flat plate type grating. The three-dimensional combined flat plate type grating is connected with the hypoxic preconditioning pond and the anaerobic pond. The hypoxic preconditioning pond is communicated with the anaerobic pond. The anaerobic pond is connected with the single-channel oxidation ditch. The MBR system with the functions of the secondary sedimentation tank is communicated with the bottom of an aeration zone and the bottom of a non-aeration zone of the single-channel oxidation ditch. The three-dimensional combined flat plate type grating can complete the filtering function of a thin grating and the filtering function of an ultra-thin grating through once hydraulic lifting; the cage type filler system, the MBR system with the functions of the secondary sedimentation tank, and the like are arranged in the single-channel oxidation ditch, the requirement for unceasing running is fully considered when faults happen to a filtering film assembly, and therefore it is ensured that water outlet is stable and reaches the standard.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST +1

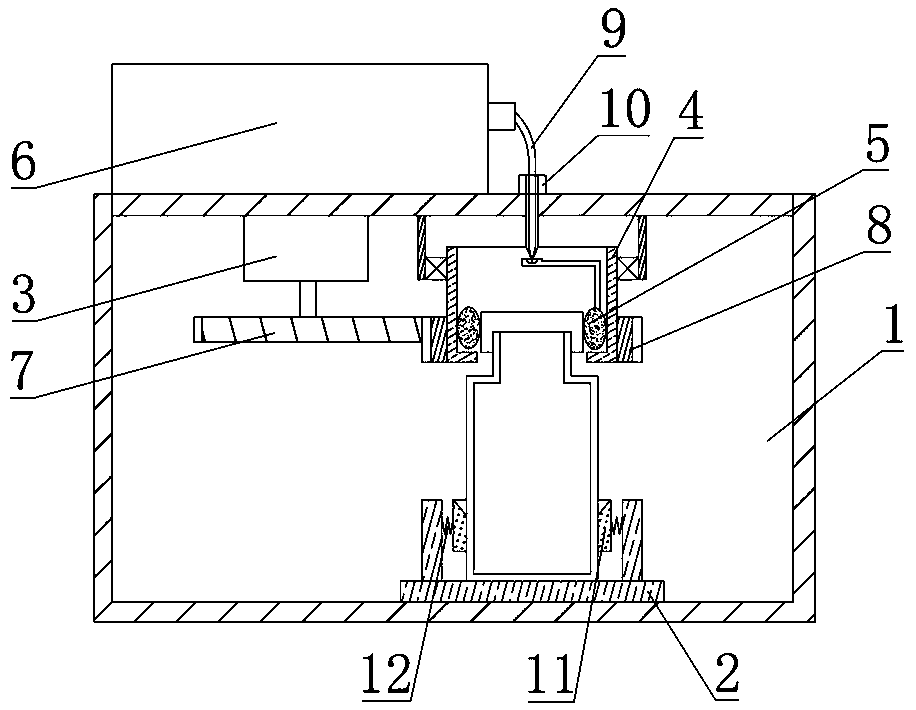

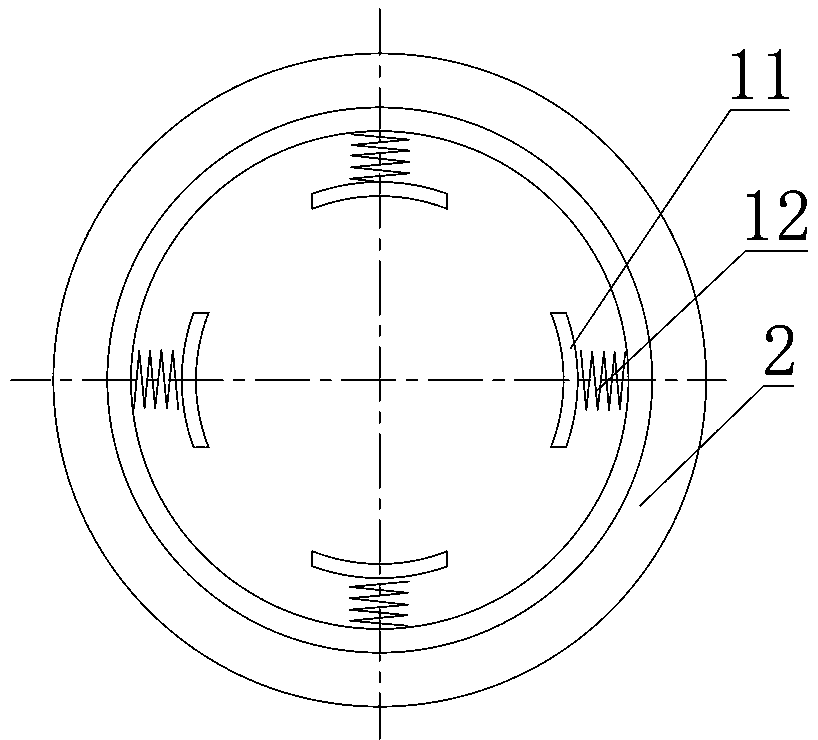

Brake shoe abrasion detection device based on image processing technology

ActiveCN102937413AAchieve wearAutomatic wear detectionUsing optical meansImaging processingElectric power system

The invention discloses a brake shoe abrasion detection device based on an image processing technology. Installing carriers are connected with data collecting boxes. Each data collecting box comprises a collecting box casing with a switch cover, a light supplementing system, a camera system and an electric control system, wherein the switch cover is closed and opened on the collecting box casing through a telescopic component, and the light supplementing system, the camera system and the telescopic component are respectively connected with the electric control system. The light supplementing systems are located on two sides of the camera systems, the data collecting boxes are installed on two sides of a track through the installing carriers, the top surfaces of the data collecting boxes are flushed with the top surface of the track, and trigger switches are installed on the inner side of the track and connected with the electric control systems. Compared with the prior art, according to the brake shoe abrasion detection device based on the image processing technology, the image processing technology is adopted to perform on-line non-contact type detection on train brake shoes, shutdown is not needed in the detection process, images of each train brake shoe are accurately collected, the brake shoe abrasion value is obtained by analysis process of captured images, and detection precision is high.

Owner:SOUTHWEST JIAOTONG UNIV

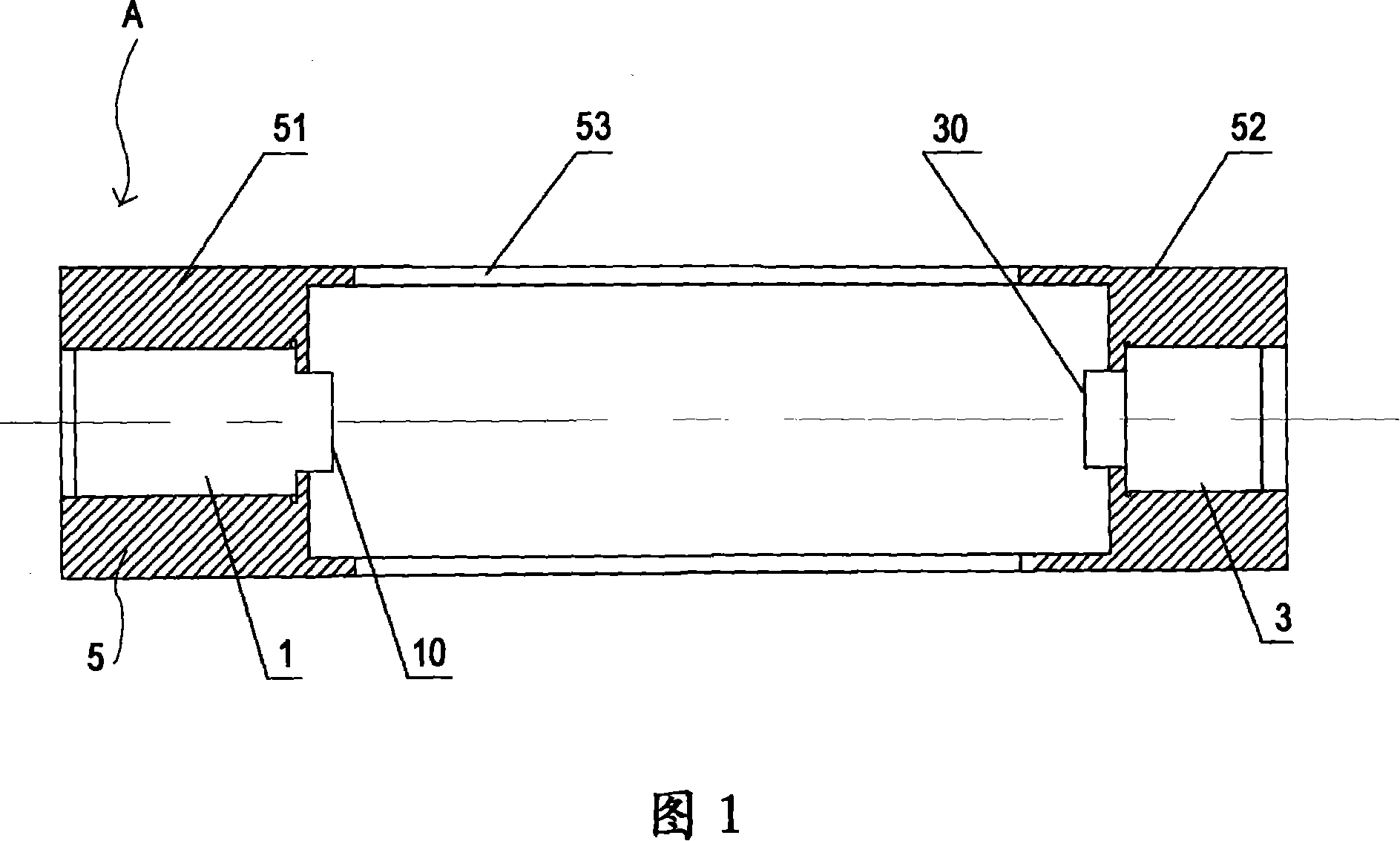

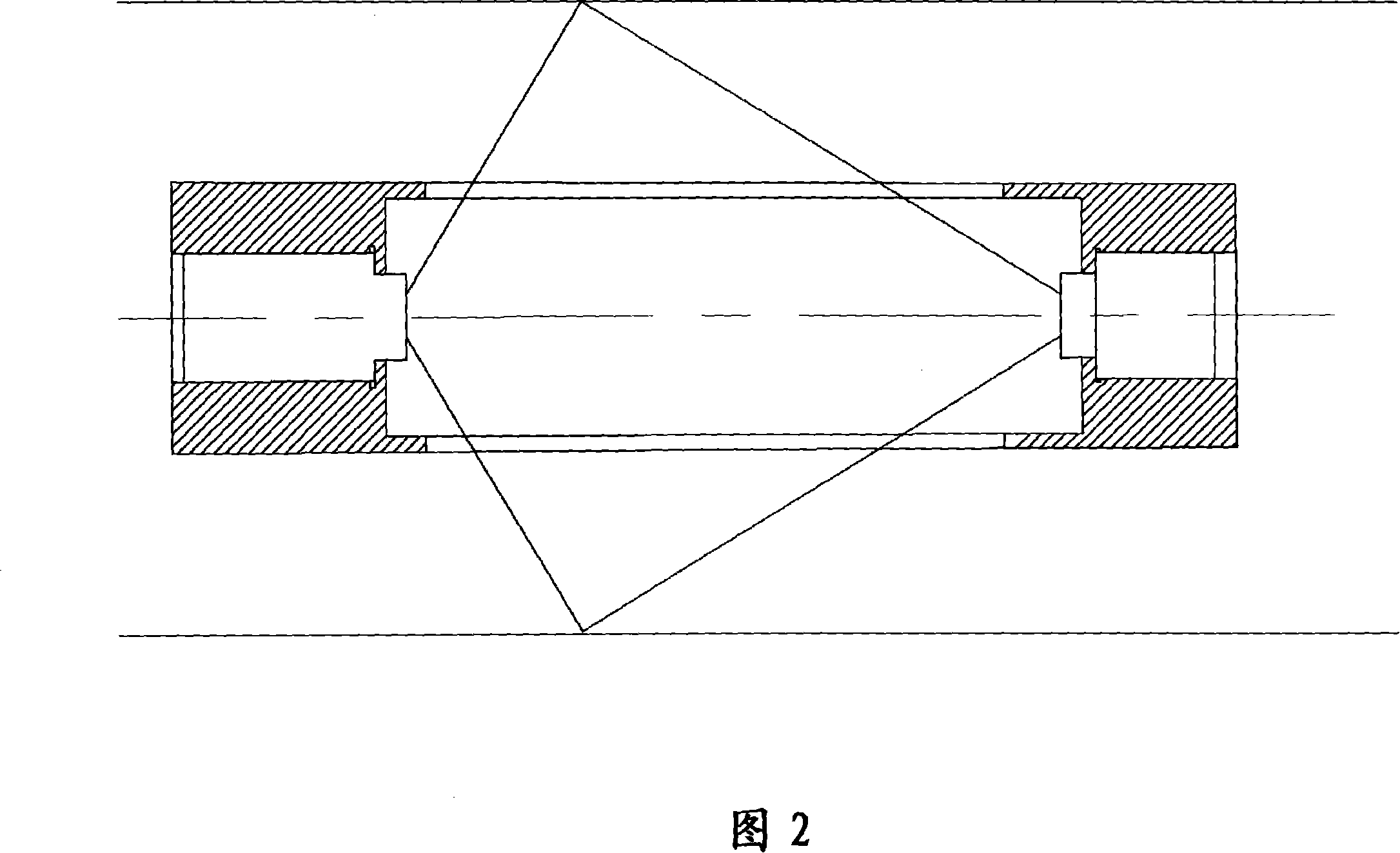

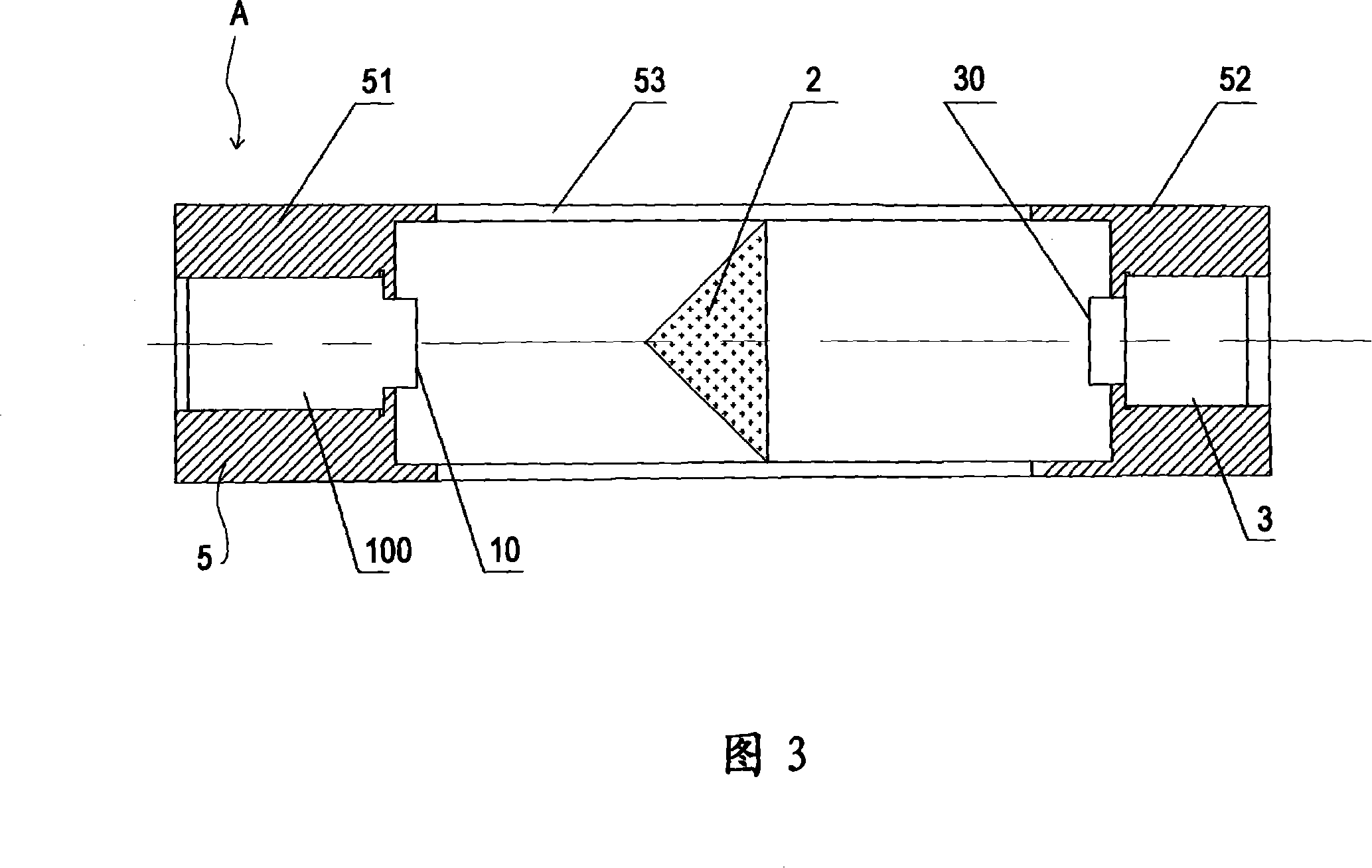

Optical measuring method for hole cubage

InactiveCN101109621AAvoid scratchesAdjust the sampling frequencyUsing optical meansElectric machineryOptoelectronics

The invention provides an optic measuring method for the volume of a hole, which comprises the following procedures: a. placing a laser source into the hole to be measured and turning on the laser; b. making a light pickup that is arranged opposite to the laser light to pick up the light reflected from the hole wall; c. driving the laser light and the light pickup to move along the axial direction of the hole in even speed; d. picking up in repeated way the light reflected by the hole wall, obtaining all data before the to-be-measured end of the hole, processing all data and getting the hole volume. In this way, the measurement with high accuracy of the volume of the hole can be achieved in a contactless way.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

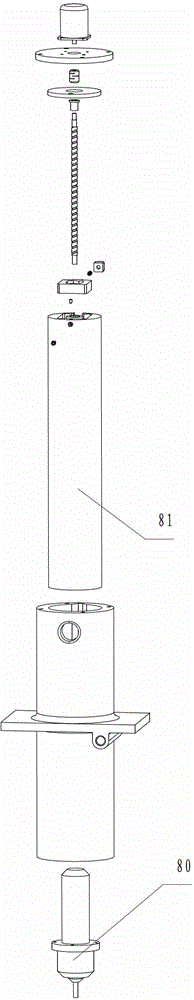

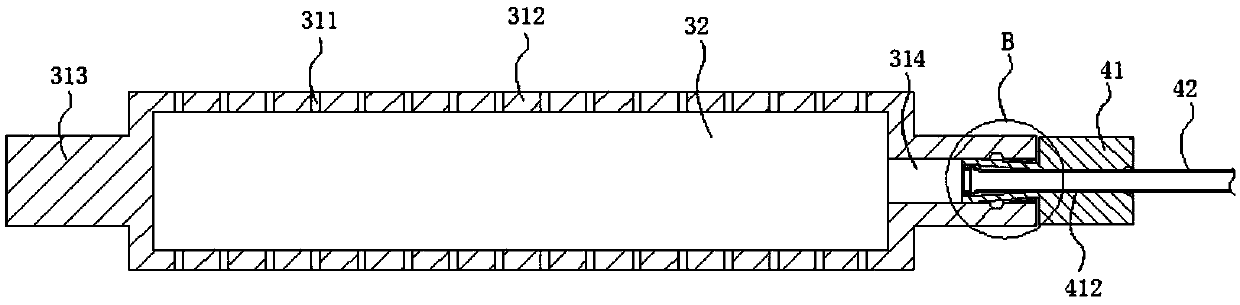

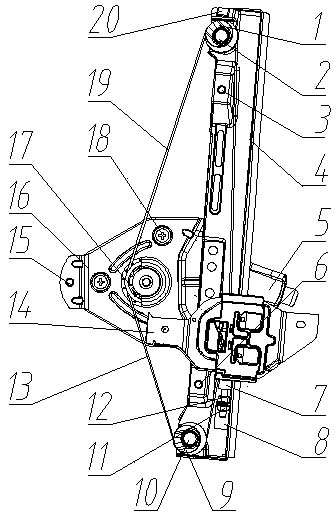

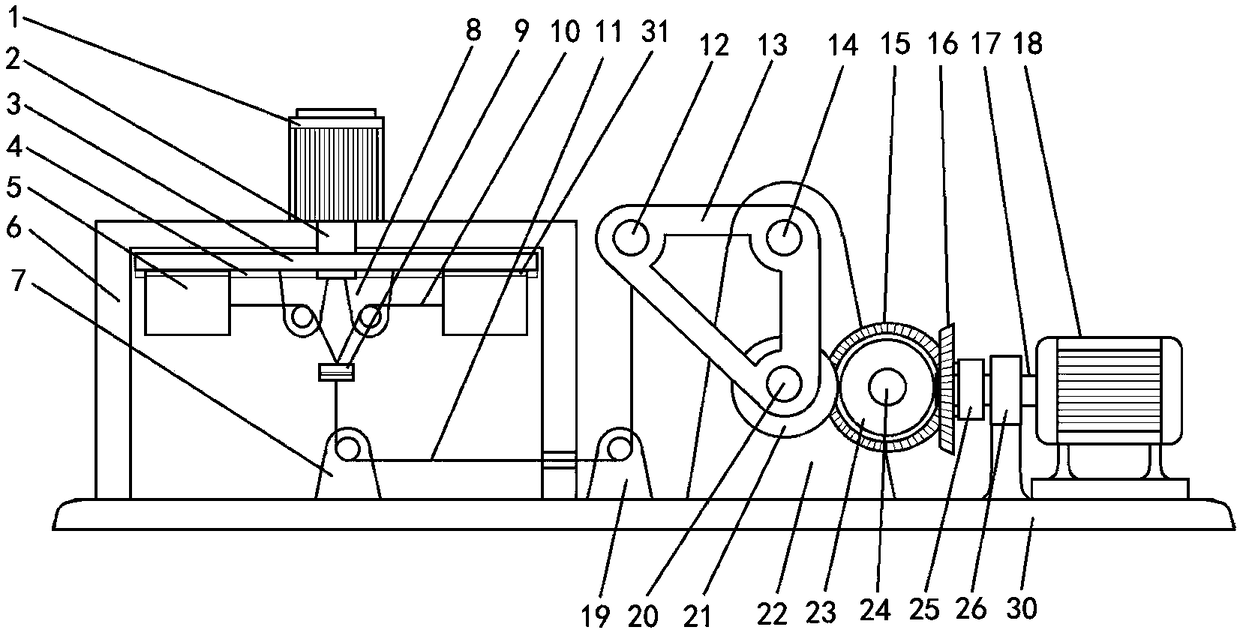

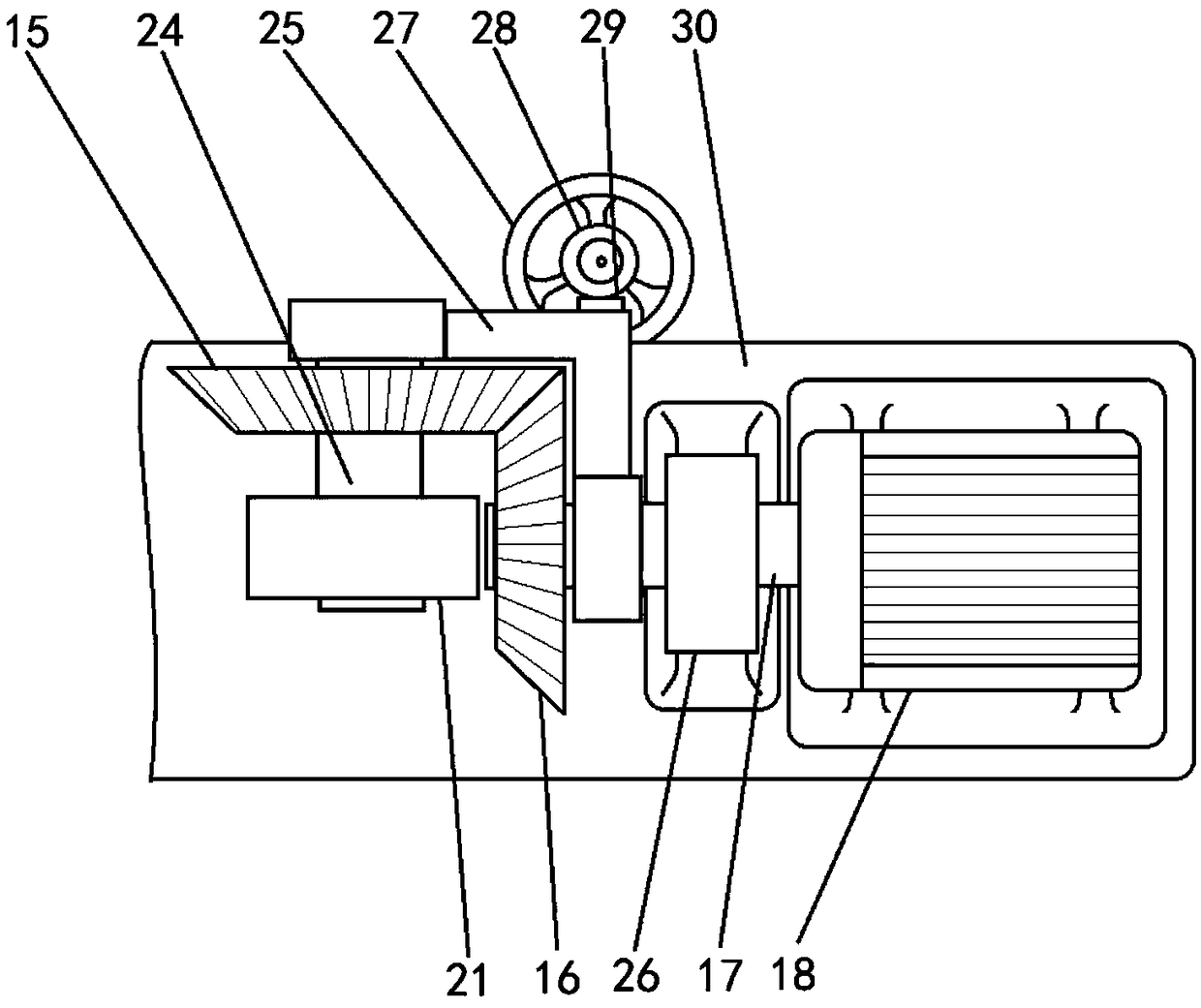

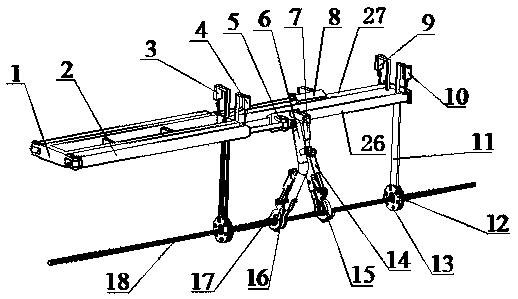

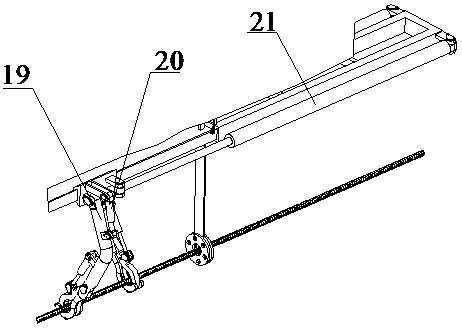

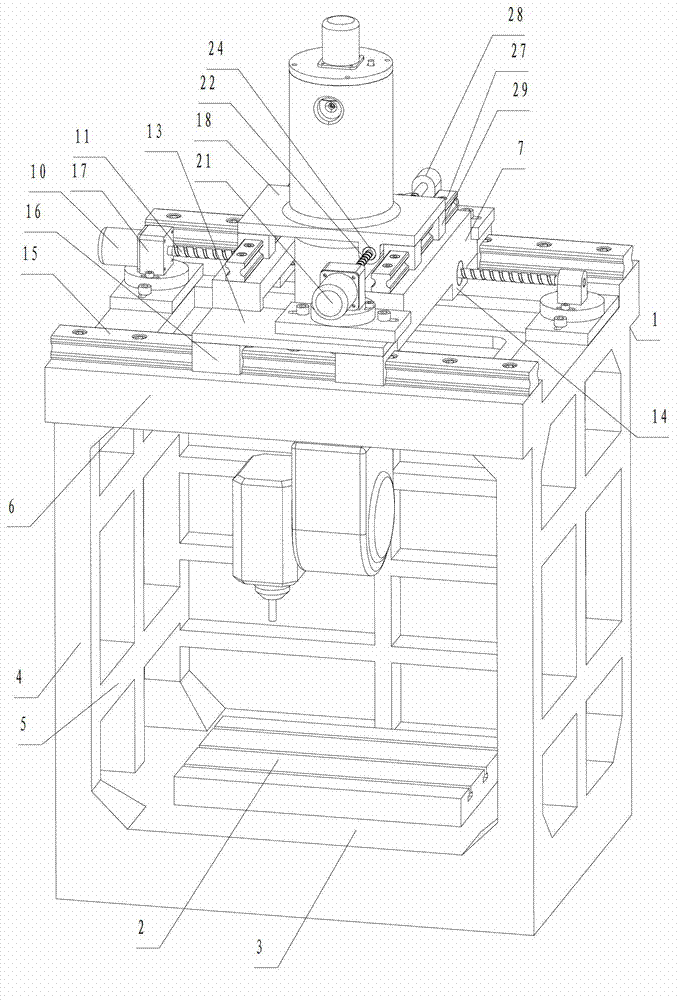

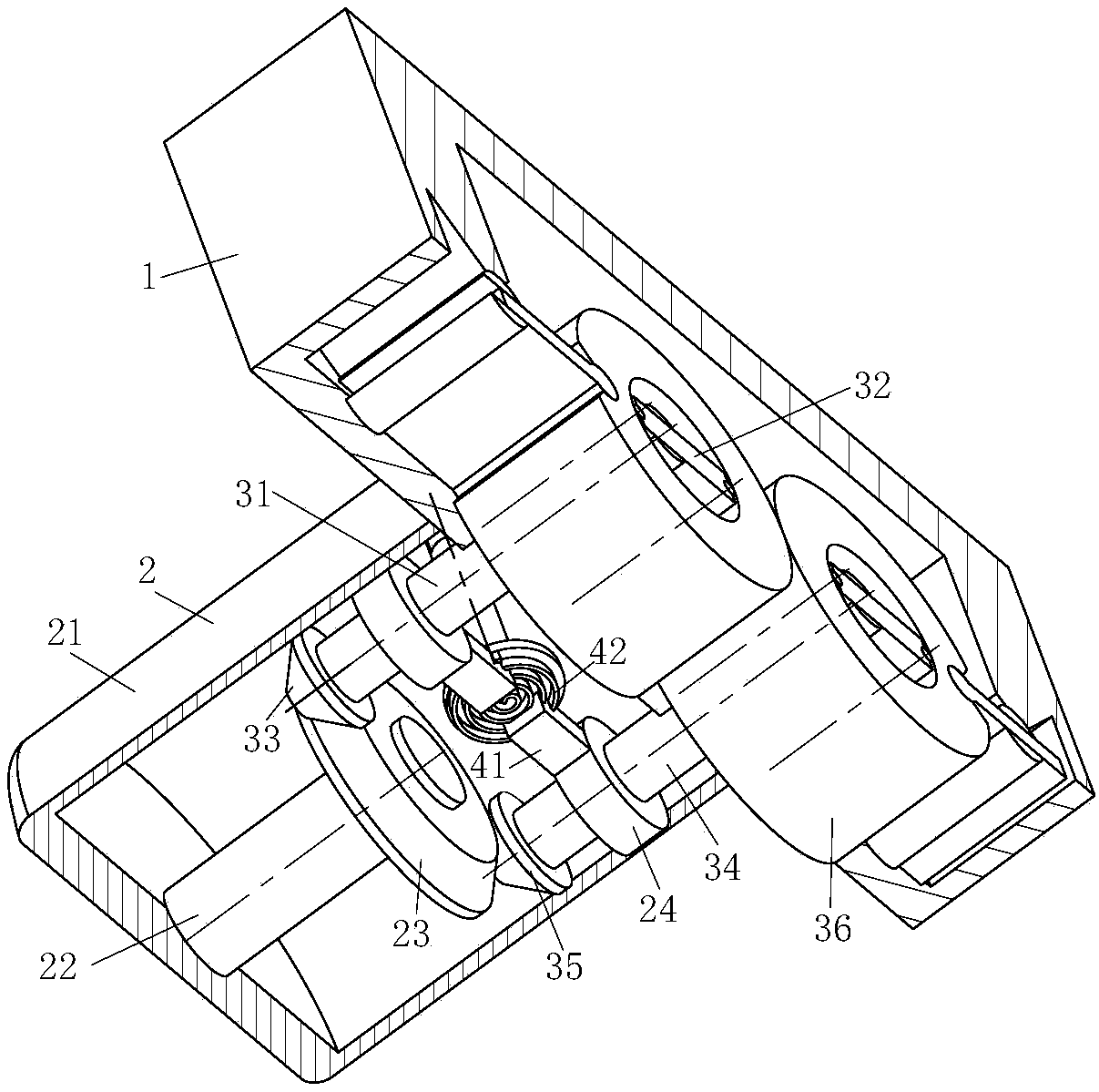

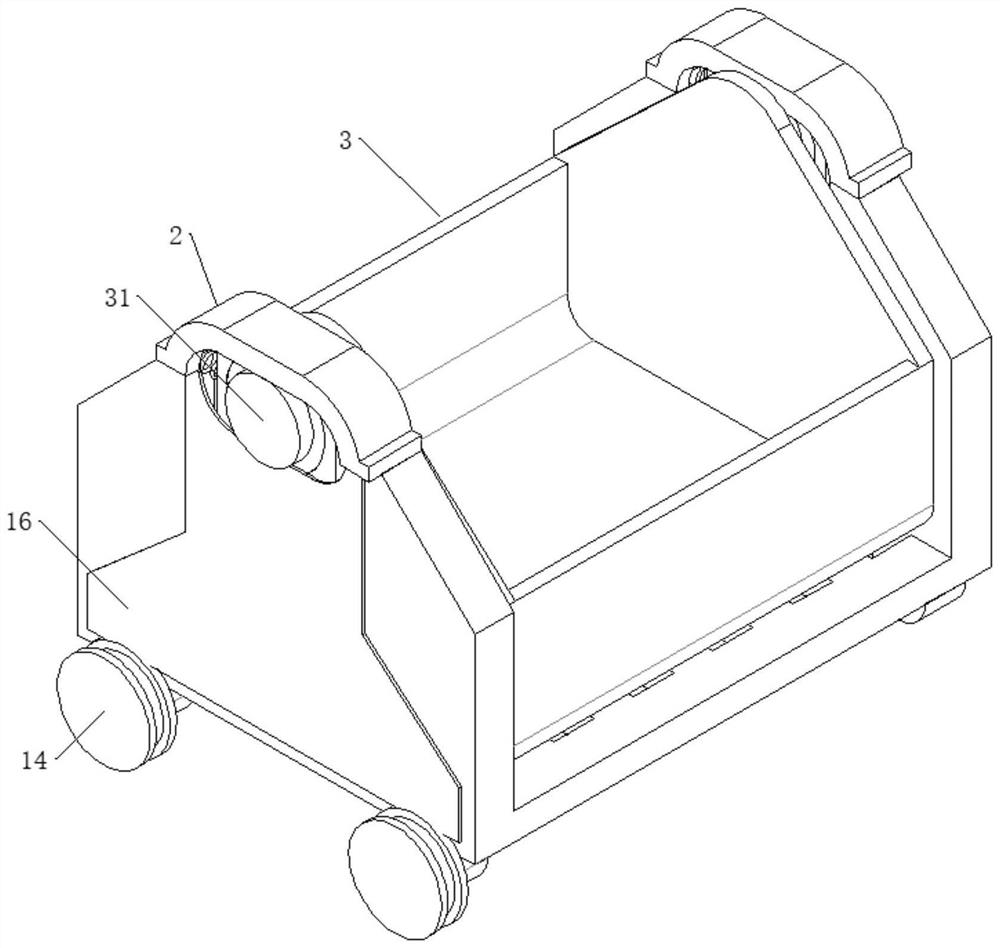

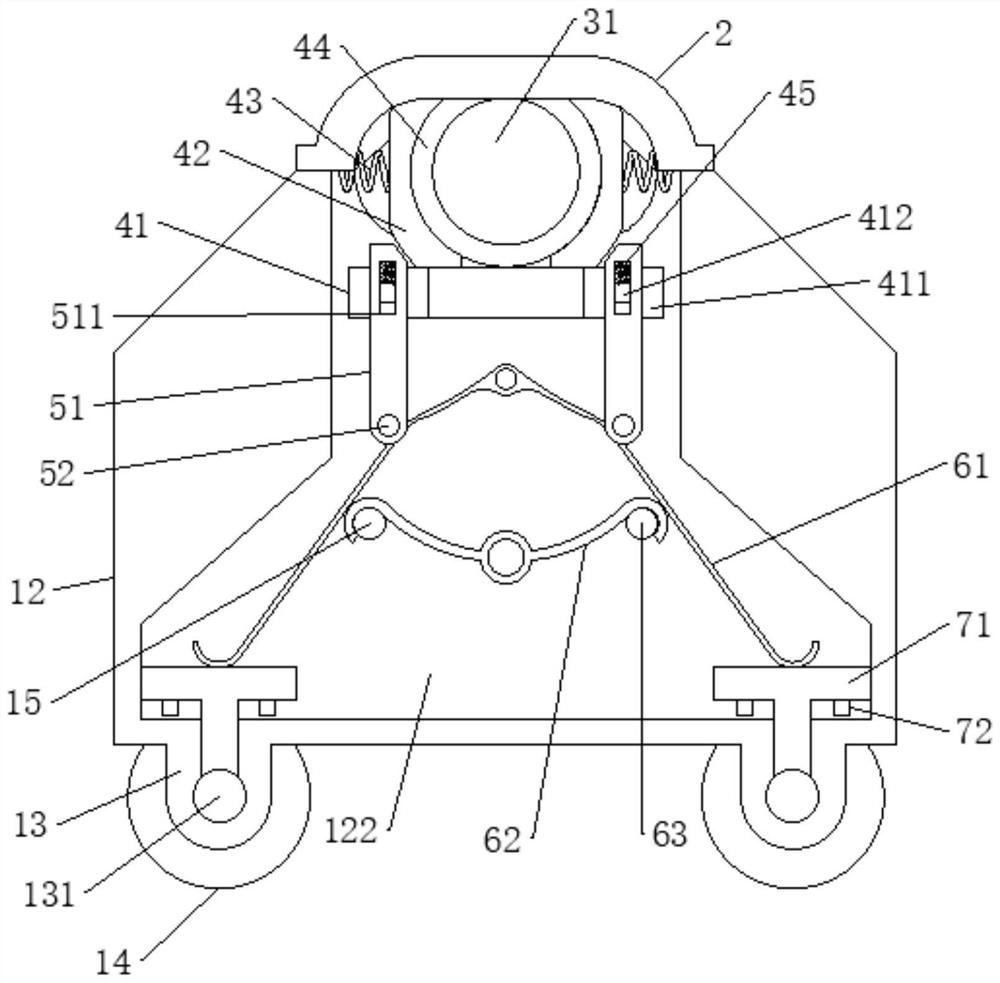

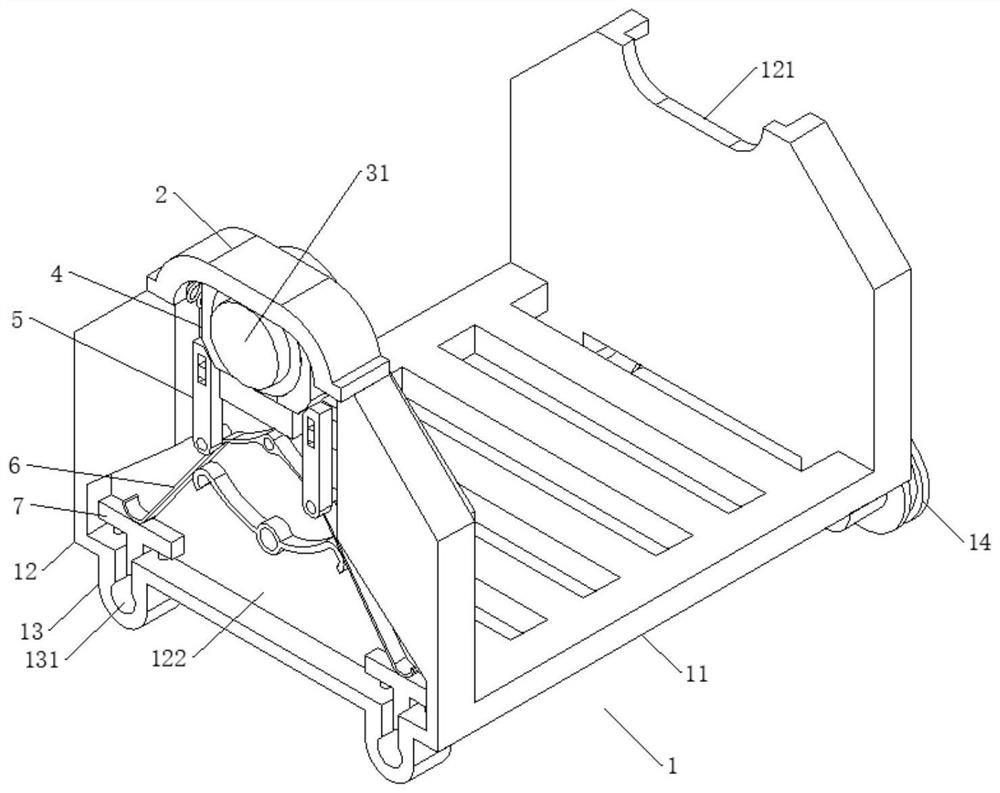

Numerical control equipment

InactiveCN102941512AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersNumerical controlClosed loop

The invention provides numerical control equipment, wherein a main supporting frame is in a closed loop structure of which the opening faces the vertical direction; an X forward guide rail and an X backward guide rail which are matched with each other are arranged between the main supporting frame and an X-direction sliding seat; a Z-direction guide rod is a round guide rod; the Z-direction guide rod only can be installed together with a Y-direction sliding seat in an up-and-down movement way; a rotation stopping structure for preventing the Z-direction guide rod from rotating along the horizontal direction of the axis of the guide rod is also arranged; the rotation stopping structure comprises a third rotation stopping block, a fourth rotation stopping block, a third spring and a limit mechanism; an accommodation groove is formed in the top part of the Z-direction guide rod; the limit mechanism limits the third rotation stopping block and the fourth rotation stopping block to move in the setting range of the accommodation groove; a rotation stopping groove is formed in a guide hole matched with the Z-direction guide rod; the third spring is installed between the third rotation stopping block and the fourth rotation stopping block; and the third rotation stopping block protrudes from the outer periphery of the Z-direction guide rod and is matched with the rotation stopping groove. The numerical control equipment has the advantages that when a main processing head moves up and down, the stability is good and the imbalance torsion is not easy to generate.

Owner:杨东佐

System for manufacturing LED lamp

InactiveCN107726078AAvoid direct contactReduce wearElectric circuit arrangementsPretreated surfacesEngineeringHeat losses

The invention discloses a system for manufacturing LED lamps, which includes a pasting mechanism, a lamp assembly mechanism and a drying mechanism; the lamp assembly mechanism includes a bracket, a workbench arranged on the bracket, and can move left and right along the bracket The moving arm and the punch arranged on the moving arm; the drying mechanism includes a plurality of rotatable drying parts, a driving part for driving the drying parts to rotate, and an air guide set in the drying parts. A channel and an air supply component for supplying air to the air guide channel; a number of drying holes communicated with the air guide channel are distributed at intervals on the outer surface of the drying member. In the present invention, the hot air is directly in contact with the LED patch lamp after being sprayed. Compared with the traditional drying method, the drying speed is increased by at least 60%, and the drying efficiency is high; and the hot air is directly contacted with the LED patch after the air is discharged Lamp contact, heat energy loss is small, effectively reduce energy consumption, and realize energy saving and environmental protection.

Owner:潘明安

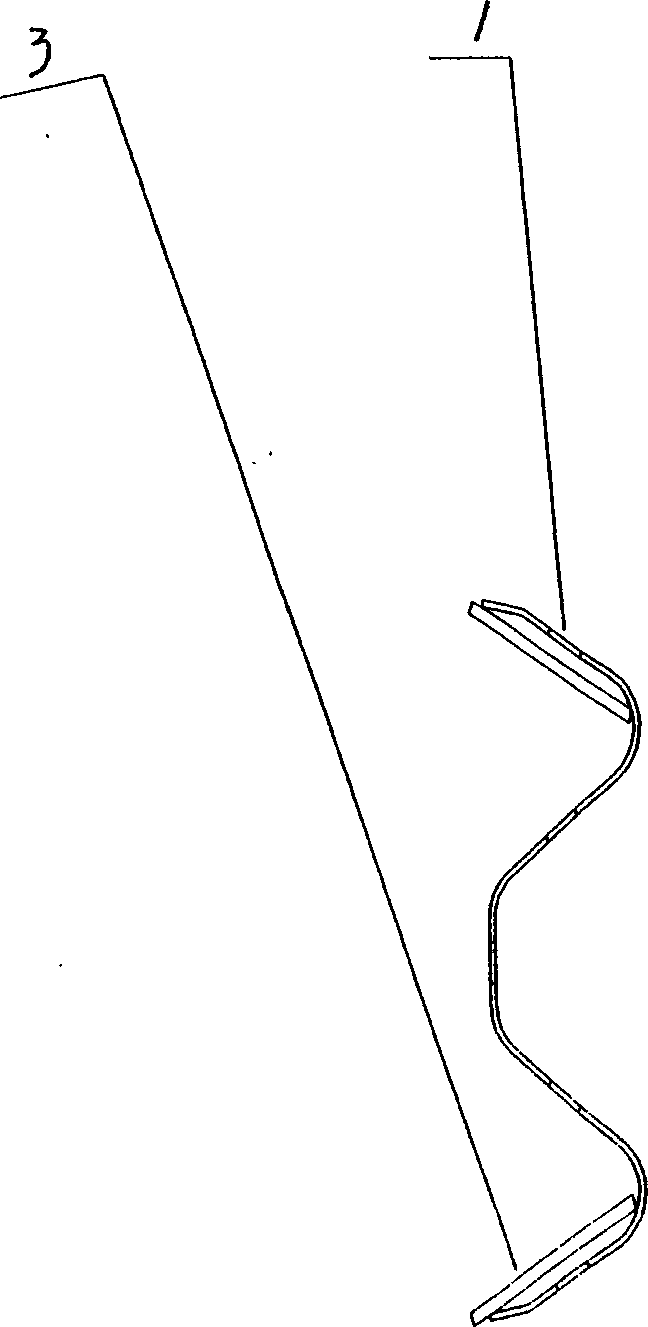

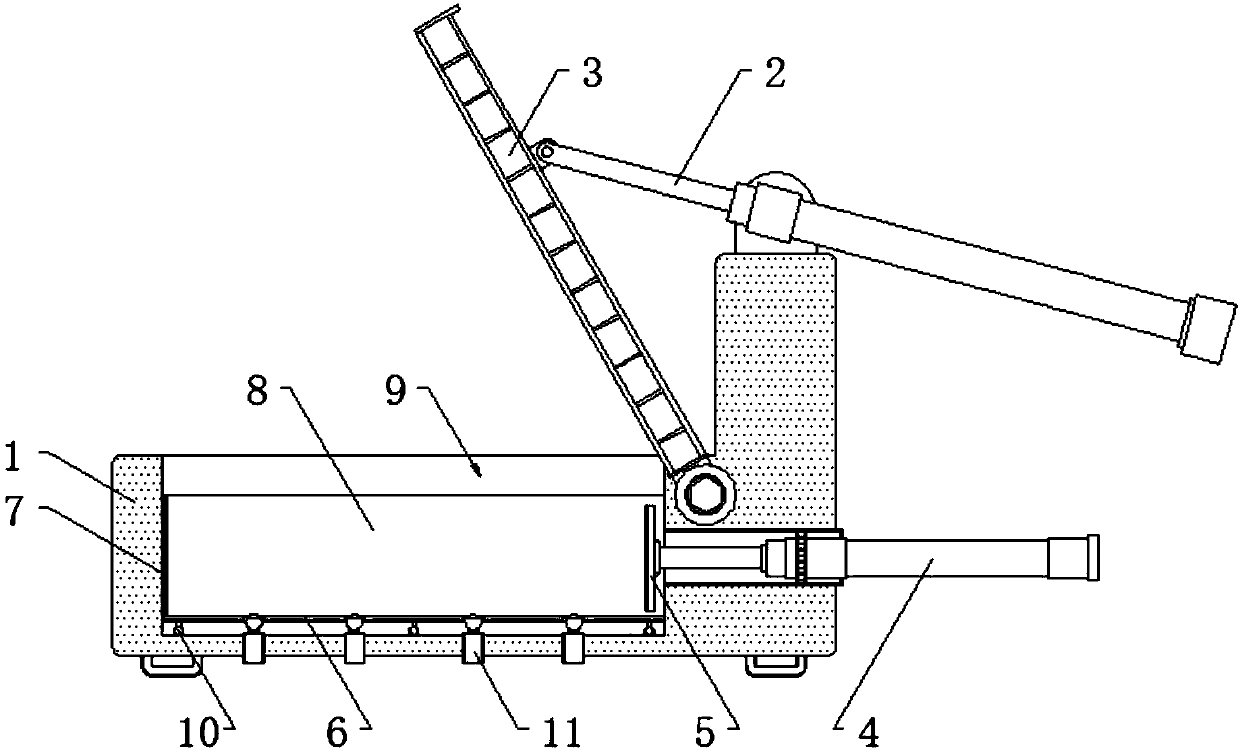

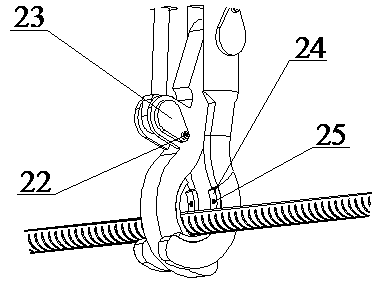

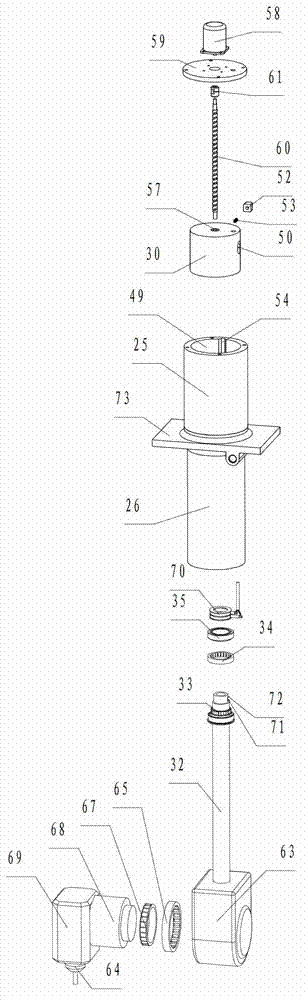

Pipe bending and ring sleeving integrated machine for pipe fitting

PendingCN109317972ARealize zero rowAchieve wearOther manufacturing equipments/toolsTube shearing machinesPipe fittingEngineering

A pipe bending and ring sleeving integrated machine for a pipe fitting comprises a pipe cutting part, a bending part, a discharging part and a ring sleeving mechanism which are sequentially arranged,wherein the pipe cutting part is used for cutting the pipe fitting into pipes with specified length; the cut pipes are fed into the bending part for bending; the pipes are bent into U shapes and thenare discharged to the ring sleeving mechanism for sleeving with rings through the discharging part. With the adoption of the machine, the U-shaped pipe bending and ring sleeving processes can be finished by one machine, so that the carrying ring is reduced, the production efficiency is high, and the occupied area is small; a mode of rotatably cutting without scraps through an inner cutting tool iscarried out, so that cutting scraps cannot be produced; a bent U-shaped elbow workpiece can be directly degreased without being washed, thus zero emission of washing liquid is realized, and the environmental protection is realized; and moreover, the workpiece is uniformly stressed during being cut, and an inclined notch is avoided; a following part is additionally arranged during bending, so thatthe abrasion of the outer sidewall of a metal pipe fitting is decreased, and the quality of the bent metal pipe fitting can be effectively improved.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

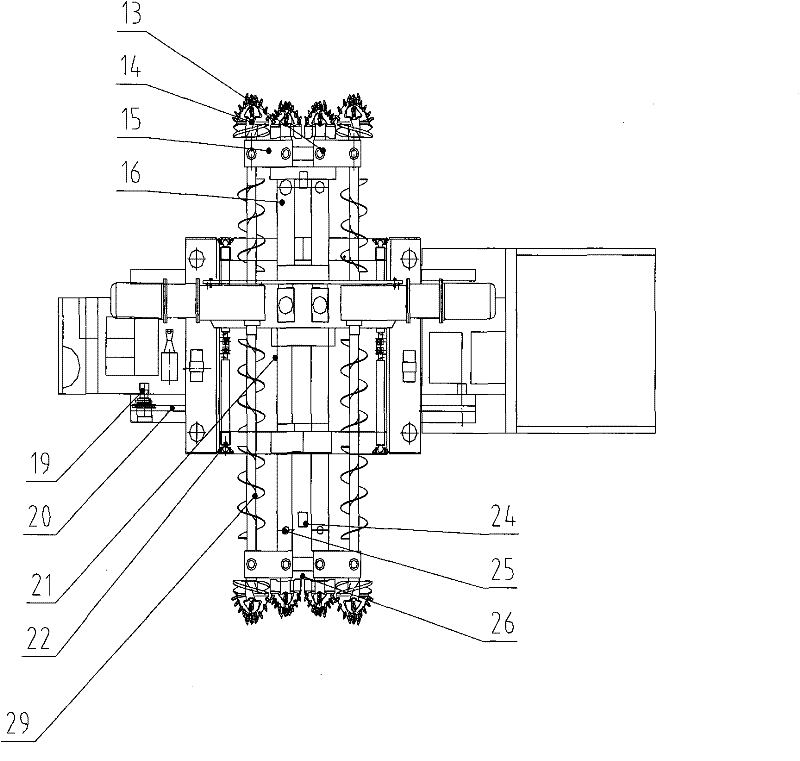

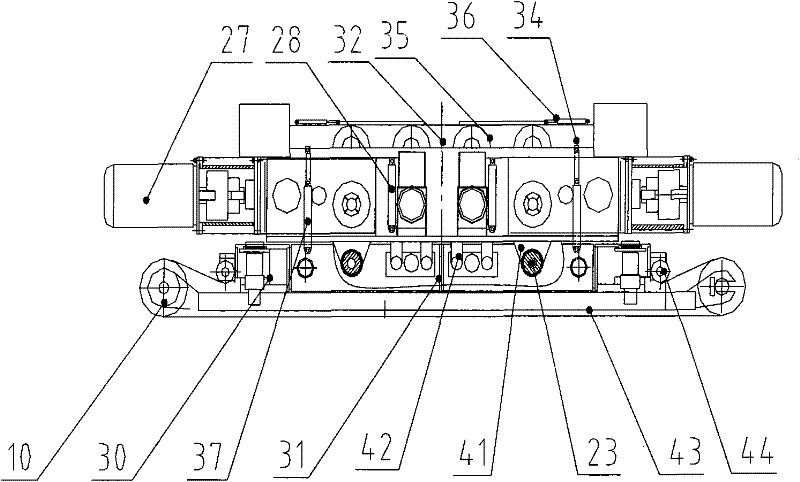

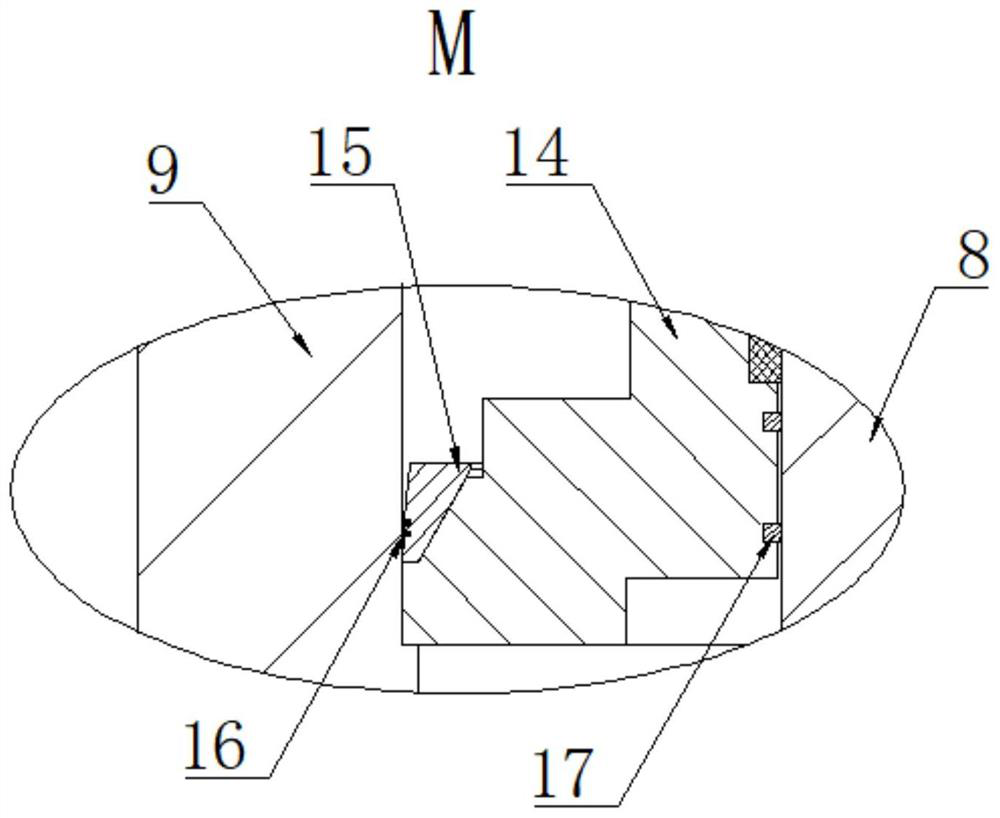

Coal drilling machine

InactiveCN101705820BAchieve separationSolve the docking problemSlitting machinesElectric controlSafe operation

The invention discloses a mining coal machine, in particular a coal drilling machine suitable for mining a thin coal seam, which comprises a main frame, an electric control system (12), a hydraulic system (9), a drilling tool and an auxiliary system (8), wherein one or two sides of the main frame are provided with a four-shaft linkage drilling tool; the drilling tool consists of a drilling rod (29), an air pipe (16), a front transmission gear box (15) with four output shafts and a drilling bit (14); power is transmitted to the drilling bit (14) through the drilling rod (29) and the front transmission gear box (15); and the air pipe (16) is communicated to the drilling bit (14) end. The invention also discloses a coal drilling machine of which the two sides of the main frame are provided with drilling tools. When used for thin and ultrathin coal seam mining, the coal drilling machine realizes an unmanned working face mining mode with convenient and safe operation, and solves the problems that the mining method of conventional equipment cannot mine or can mine but has low efficiency, high cost, bad reliability and poor safety, which is ideal equipment for safe and efficient mining of the thin and ultrathin coal seam.

Owner:济南隆恒矿山机械有限公司

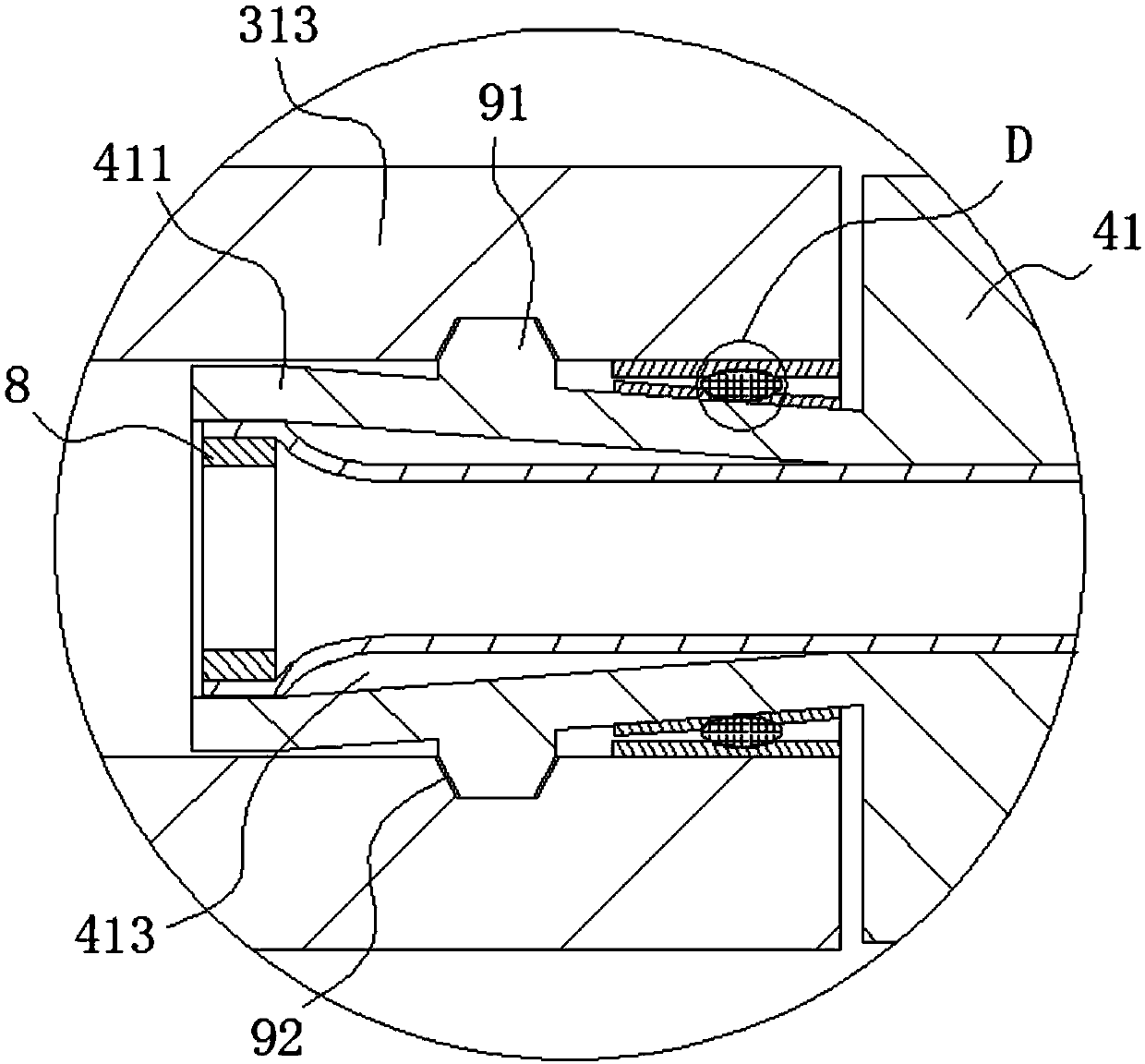

Electrochemical testing device for metal passivation film growth and decline dynamic process

ActiveCN112147021AAchieving a pressure-resistant sealReal-time electrochemical testingWeather/light/corrosion resistanceSurface reaction electrolytic coatingBall bearingRotation - action

The invention provides an electrochemical testing device for a metal passivation film growth and decline dynamic process, and belongs to the field of material performance detection. According to the electrochemical testing device, through reducing and rotating mutually-overlapped abrasive sheet groups, clamping of a sample and the abrasion of a passivation film on the surface of the sample are realized, so that the test is not limited by the original size of the sample and the size change in the abrasion process within a certain range; through the design of a supporting disc with a ball bearing structure, locking and integrated rotating actions of the relative positions between abrasive sheets are achieved at the same time; the rotating abrasion frequency and duration are controlled, so that one or more abrasion tests are realized; through an internally-arranged electrochemical three-electrode system, in-situ and real-time electrochemical testing of the passivation film growth and decline dynamic process is realized; and the electrochemical testing device is simple in principle and easy and convenient to operate, and compared with an existing scratching electrode technology, the effective test area of the sample is increased, and the dynamic electrochemical behaviors of metal passivation film abrasion and self-healing in the high-pressure and caustic corrosion environment or under the frequent abrasion working condition are reflected more accurately.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

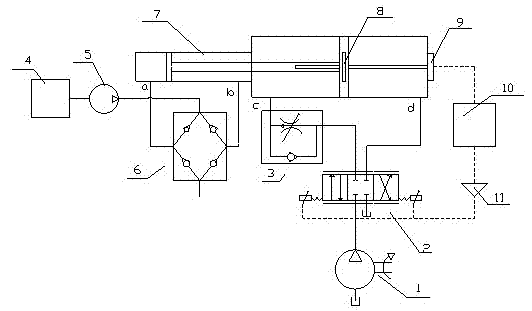

Automatic low-penetration lubricating grease delivery system

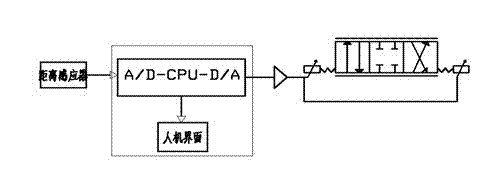

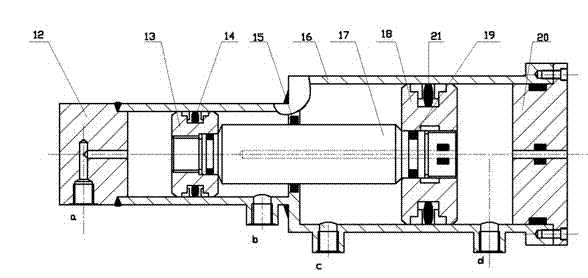

InactiveCN103047528AReduce conveying resistanceFulfillment requirementsEngine lubricationHydraulic cylinderHydraulic pump

An automatic low-penetration lubricating grease delivery system comprises a hydraulic pump station, a lubricating grease handler, a grease pump and a composite hydraulic cylinder. An output end of the hydraulic pump station is connected with a three-position four-way electro-hydraulic proportional reversing valve, an access of the three-position four-way electro-hydraulic proportional reversing valve is connected with a hydraulic cavity access on the right side of the composite hydraulic cylinder through a pipeline, a grease pump outlet connected with the lubricating grease handler is connected with a one-way valve bridge through a pipeline, and two side outlets of the one-way valve bridge are respectively connected with a lubricating grease cavity access on the left side of the composite hydraulic cylinder. An electromagnetic ring is arranged on a piston of the composite hydraulic cylinder, signals are transmitted to a distance sensor at the front end of the composite hydraulic cylinder through a measuring rod penetrating the electromagnetic ring, and an output interface of the distance sensor is connected with an electro-hydraulic controller controlling the three-position four-way electro-hydraulic proportional reversing valve. By arranging the lubricating grease handler, low-penetration lubricating grease is stored and heated, delivery resistance of the system is reduced, and automatic delivery of low-penetration lubricating grease is realized. Good lubricating performance of equipment is guaranteed, and labor intensity is reduced.

Owner:CHINA UNIV OF MINING & TECH

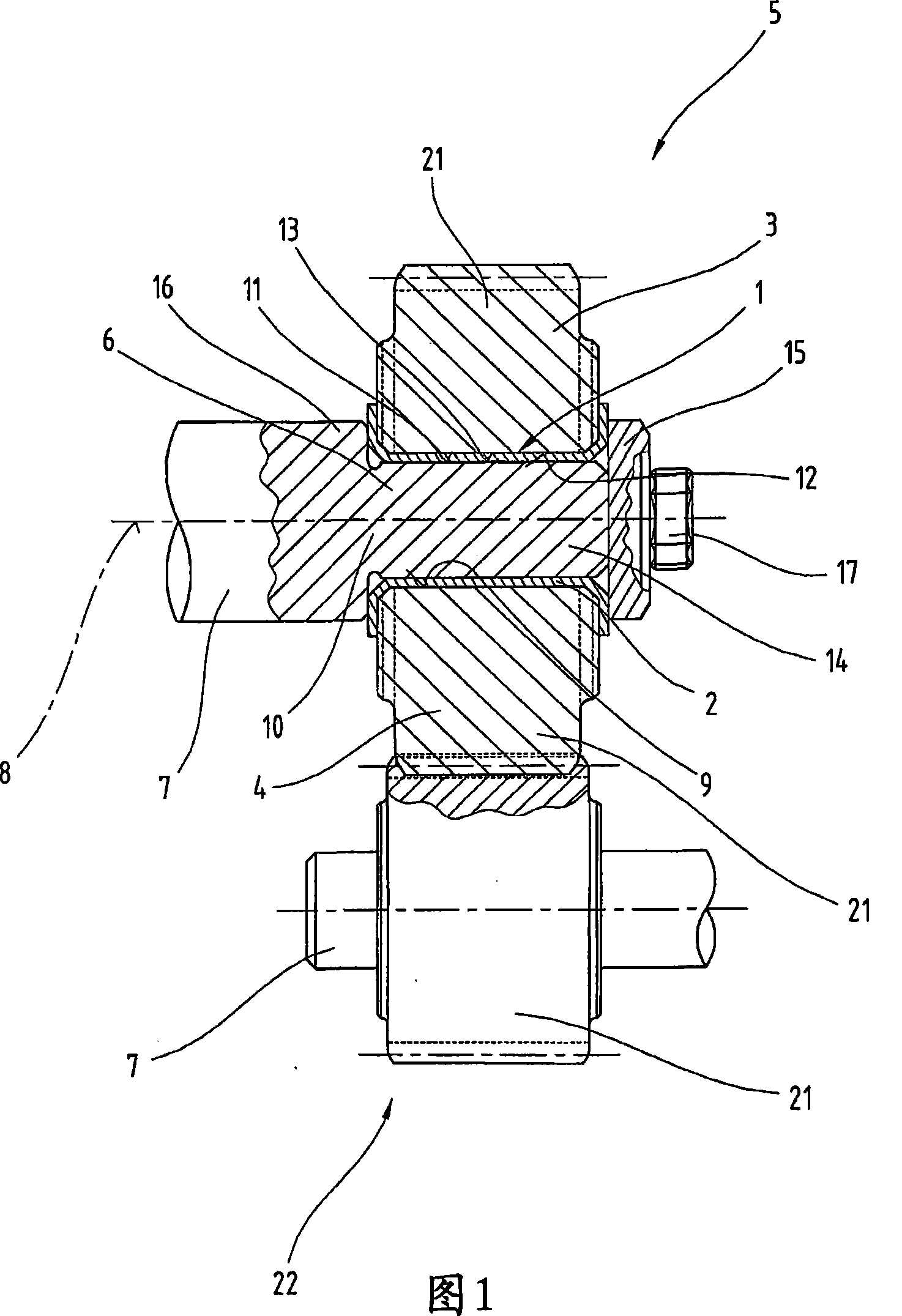

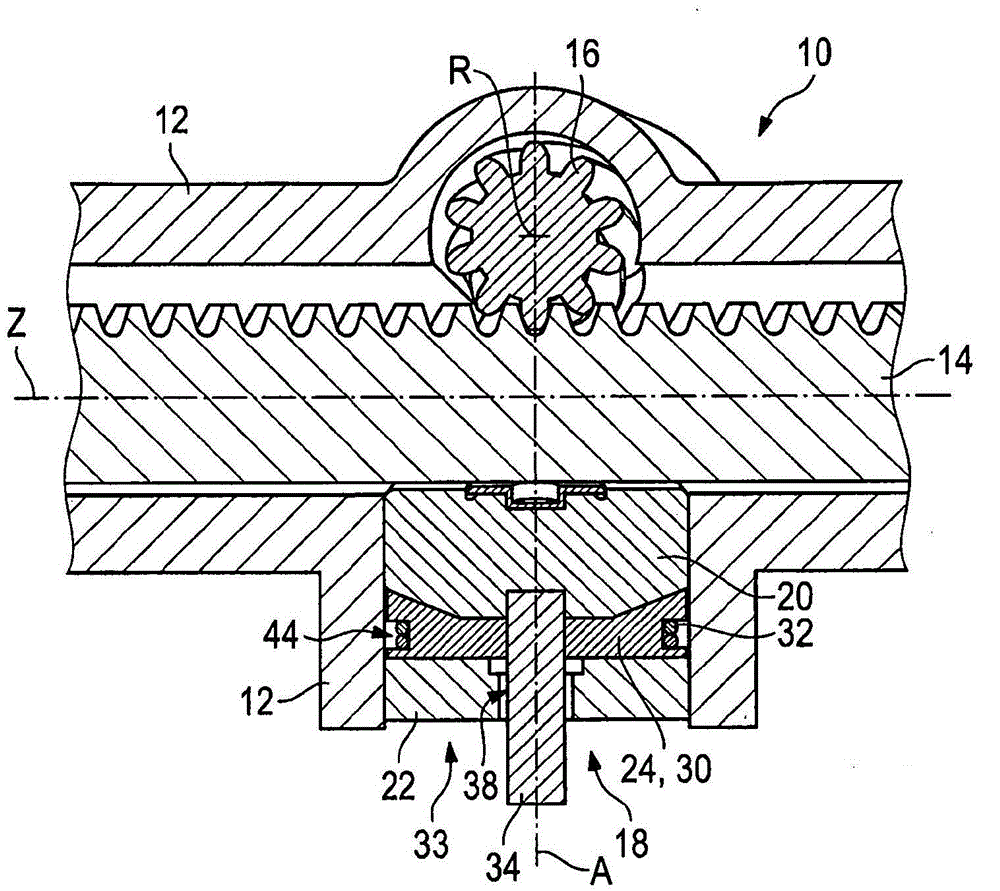

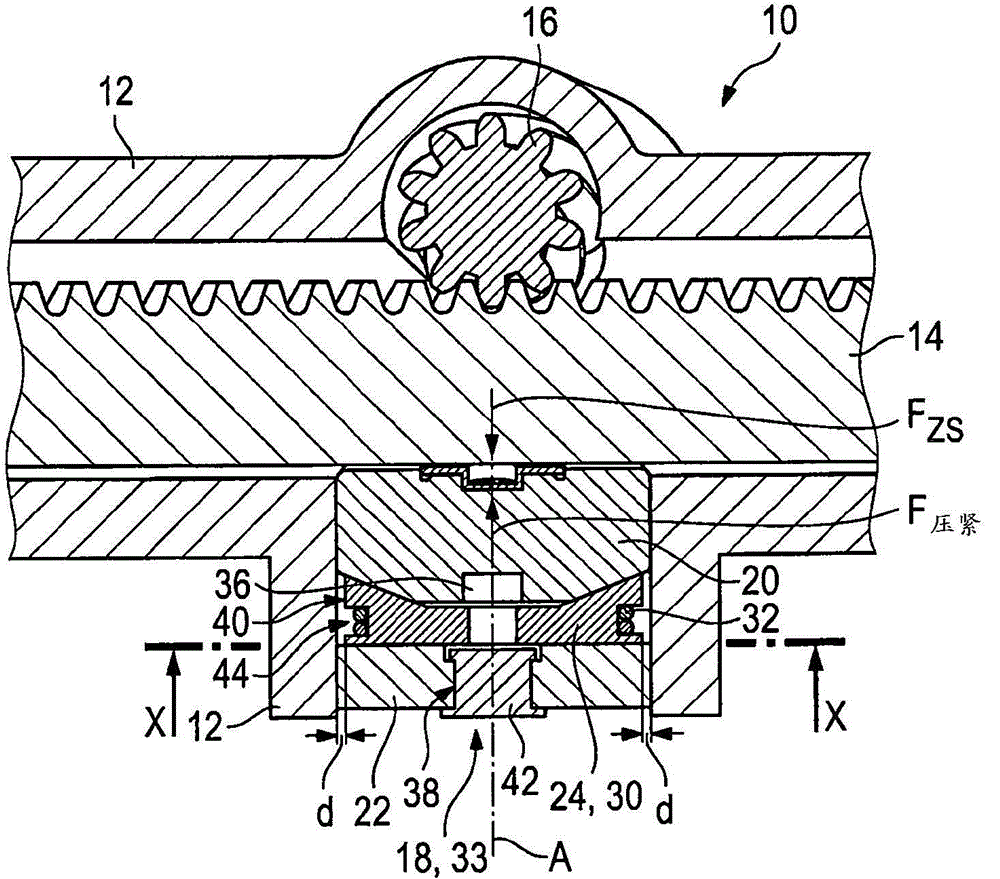

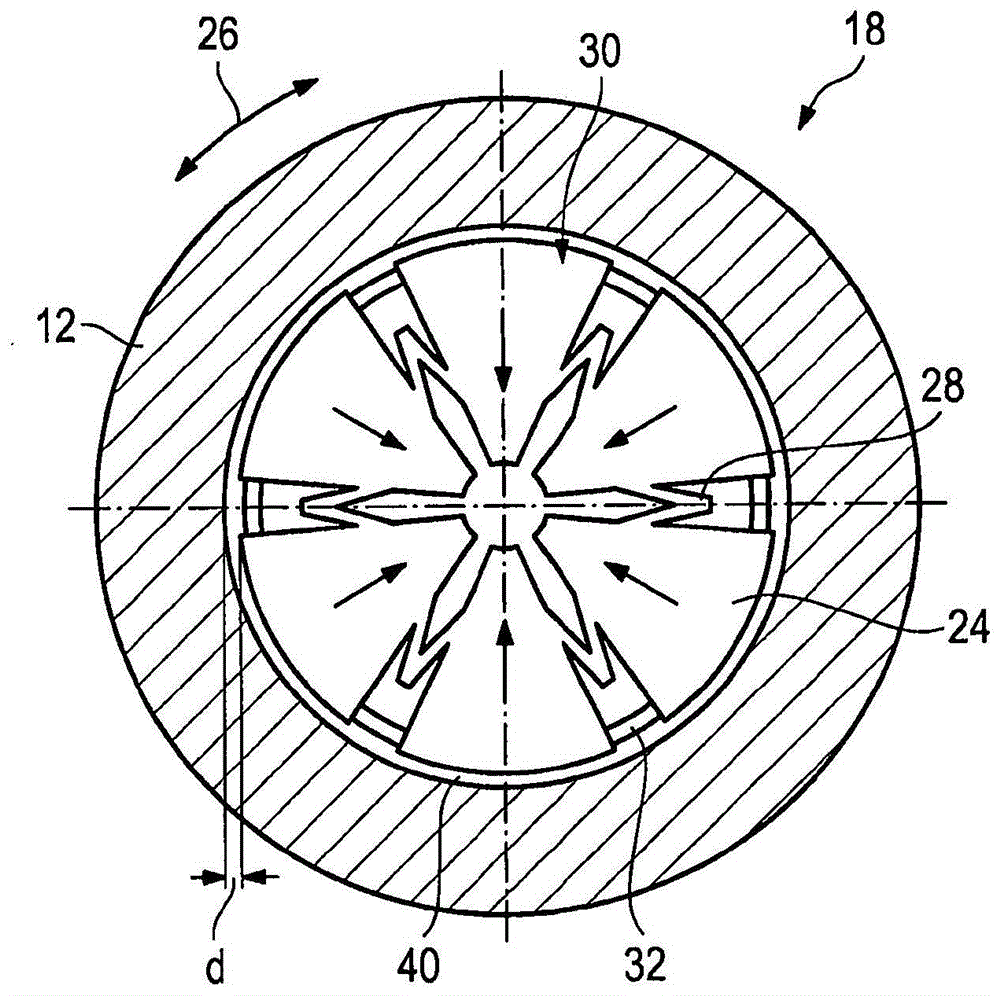

Device for pressing a gear rack against a pinion

Owner:TRW AUTOMOTIVE GMBH

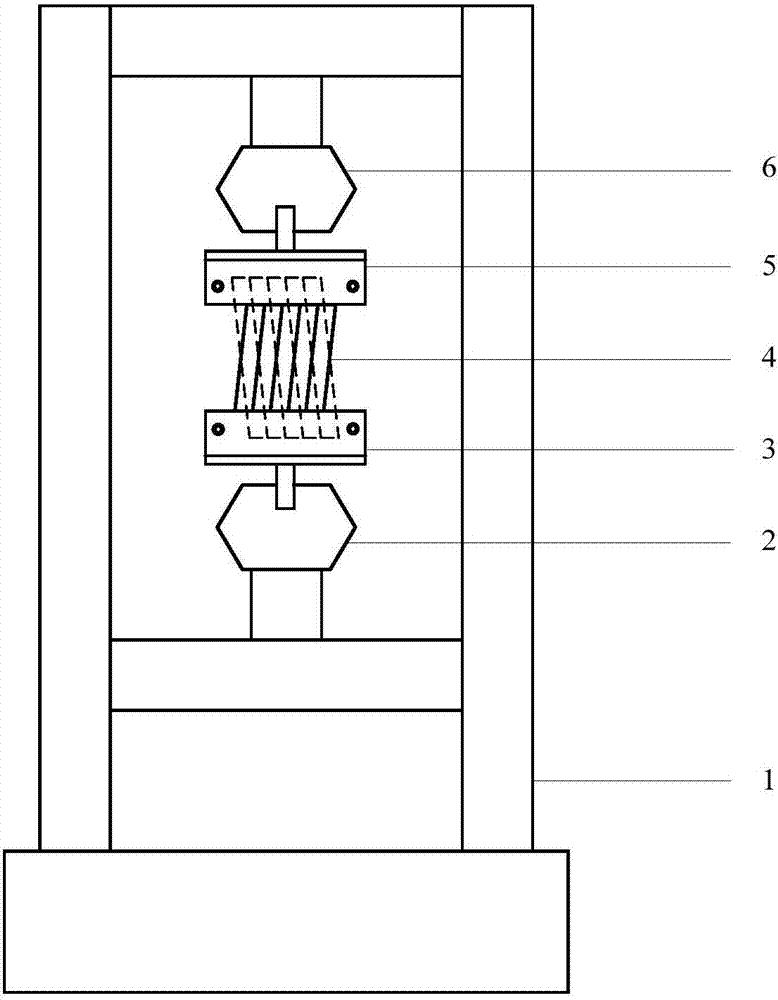

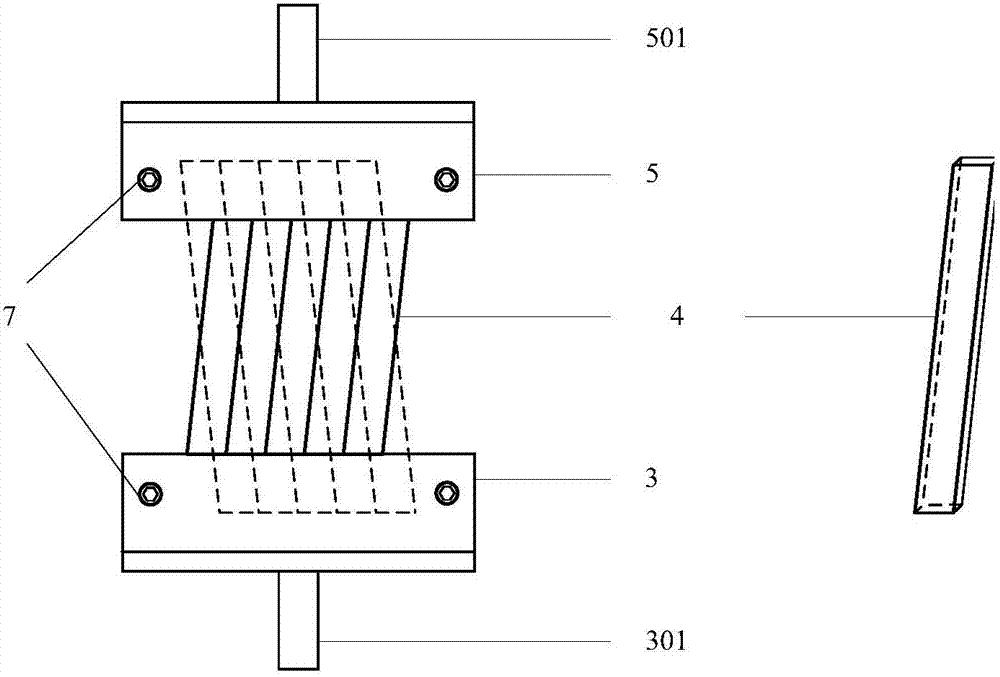

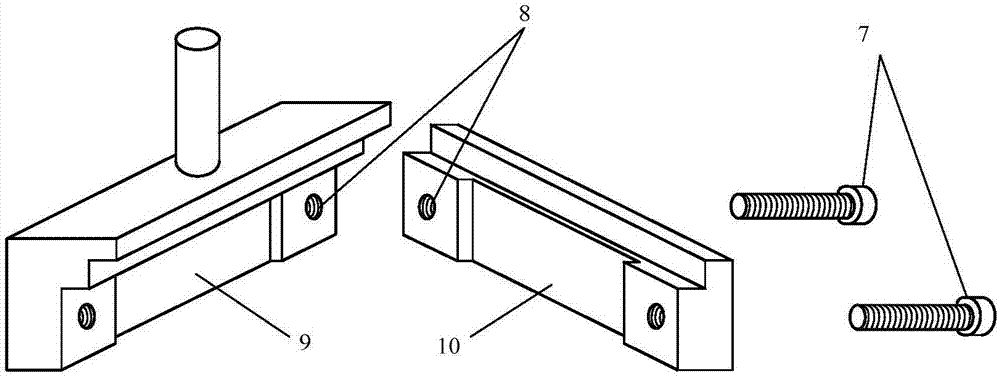

Test method and device for simulating interlayer wearing of flexible standpipe armors

InactiveCN106855482AReasonable designIntuitive test resultsInvestigating abrasion/wear resistanceAssay UnitEngineering

The invention relates to a test method and device for simulating the interlayer wearing of flexible standpipe armors. The test device comprises a universal testing machine, a lower testing machine clamp, a lower sample clamp, an upper sample clamp and an upper testing machine clamp. The test method comprises the following steps: 1, sample preparation; 2, sample assembling; 3, sample installation; 4, device preparation; 5, test starting; 6, test ending; and 7, obtaining of a test result. The universal testing machine applies alternate tensile load to the sample clamps, samples are axially elongated and retracted to realize wearing between samples in the same layer and between interlayer samples, the samples are dismounted after test, and the wearing condition is judged by observing damages and detecting the mass loss of the samples per unit length.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

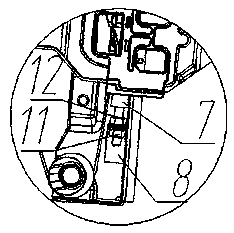

Window regulator with adjustable buffering block

The invention discloses a window regulator with an adjustable buffering block. A motor support of a motor is connected with an installing plate, a reel is installed on one side of the installing platethrough a reel rotating shaft, a guide rail support is arranged on one side of the motor support, a regulator upper fixing screw is arranged on the upper portion of the guide rail support, a regulator lower fixing screw is arranged on the lower portion of the guide rail support, a guide rail is arranged on the guide rail support, an upper guiding wheel is installed on one side of the upper end ofthe guide rail support, a lower guiding wheel is installed on one side of the lower end of the guide rail support, a sliding block is arranged on the guide rail on the guide rail support, a bottom dead center fixing support is arranged on one side of the lower guiding wheel, the bottom end of the adjustable buffering block is inserted into a fixing rack of the bottom dead center fixing support and fixed through a locking nut and an adjusting nut, the sliding block moves to the lower portion and then presses the adjustable buffering block, and an upper steel wire rope and a lower steel wire rope are wound around the reel separately and penetrate through the upper guiding wheel and the lower guiding wheel respectively to be connected with the sliding block. The problem is solved that a buffering block is easily abraded; the adjustable buffering block can effectively compensate for the abrasion of the buffering block.

Owner:周启城

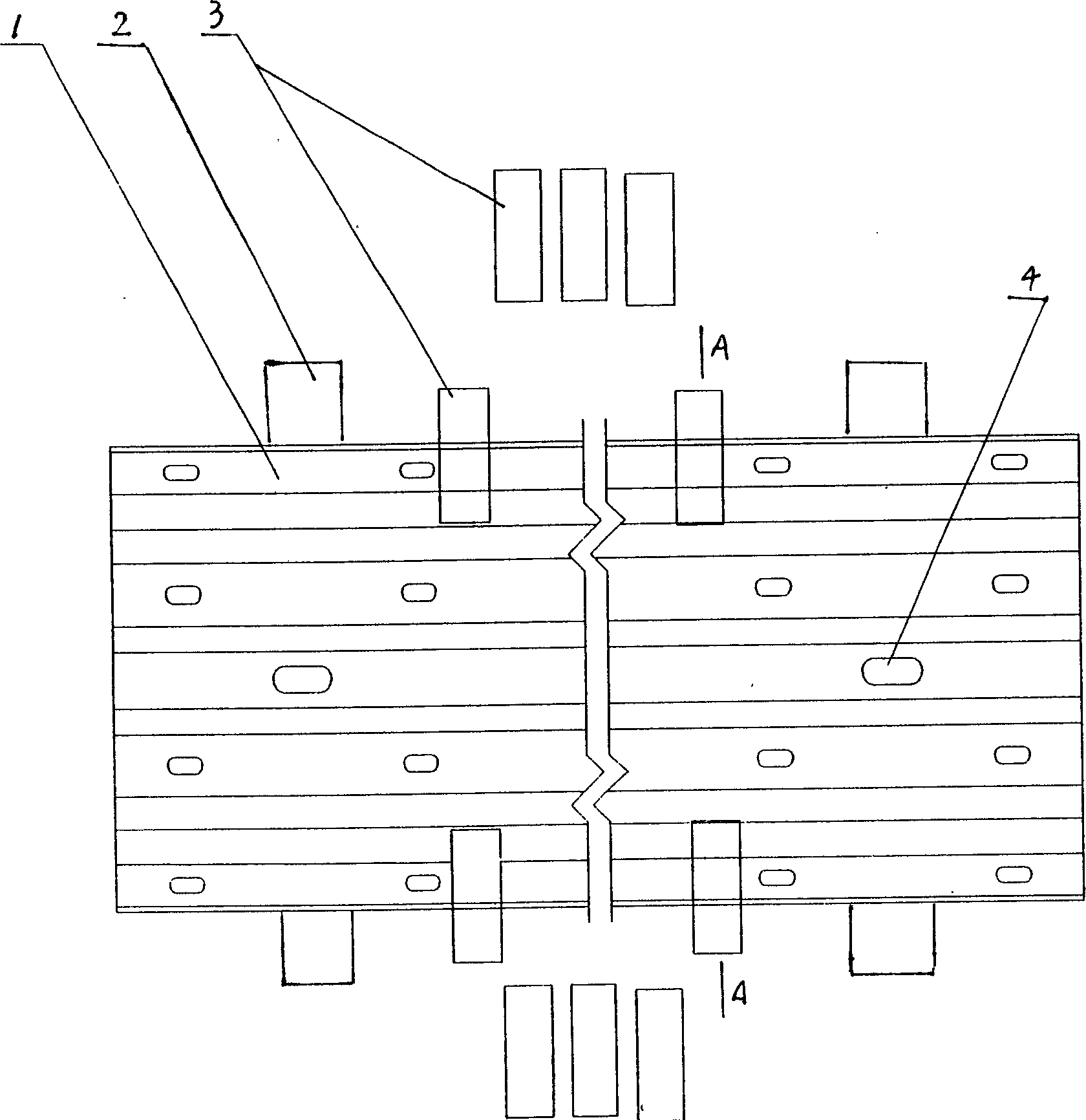

Packaging method for wave shape bridge plate of super highway after coating

InactiveCN1861481AIncrease contact areaRelieve pressureBuilding material packagingWave shapeStructural engineering

Owner:徐州兰德交通科技有限公司

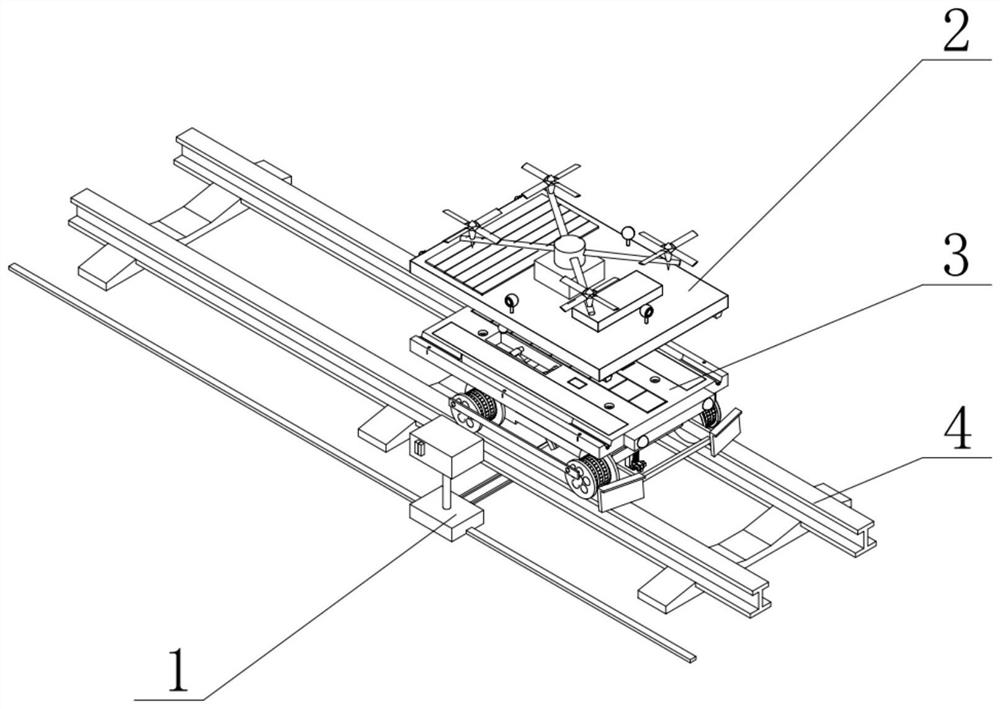

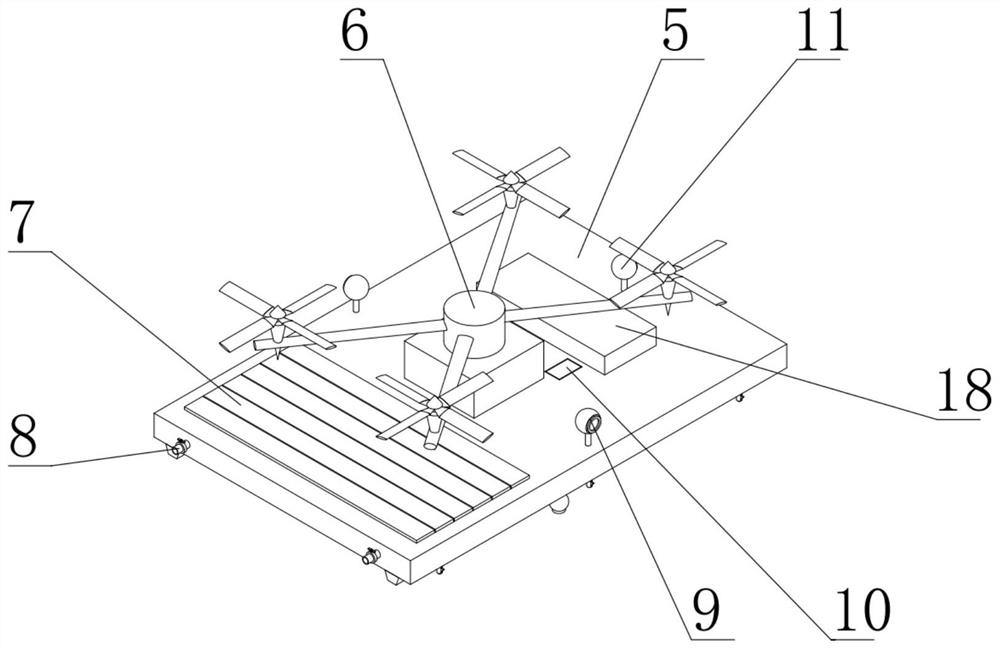

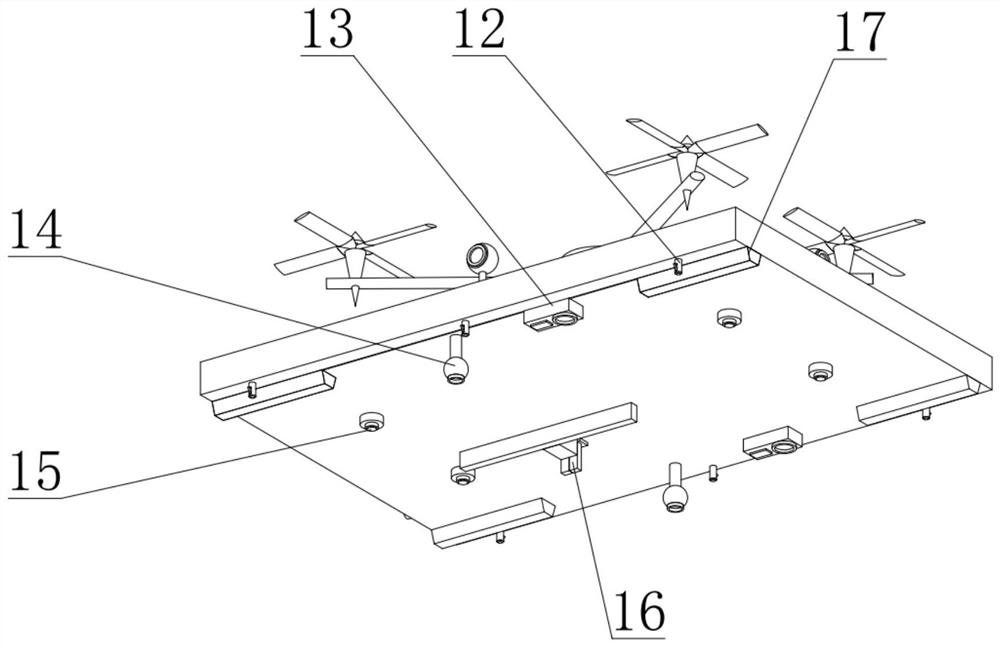

Intelligent monitoring and fault diagnosis instrument for rail

InactiveCN114179565AAchieve wearSolve wear and tearRail-engaging wheelsRailway inspection trolleysControl engineeringEnergy exchange

The invention discloses an intelligent monitoring and fault diagnosis instrument for a rail. The intelligent monitoring and fault diagnosis instrument comprises a station type information energy exchange mechanism, a separated anti-gravity low-consumption detection mechanism, a split type transportation mechanism and a rail mechanism. The invention belongs to the field of rail detection, and particularly relates to an intelligent rail monitoring and fault diagnosis instrument, which creatively applies a flight principle to the diagnosis instrument, realizes the technical effects of stably advancing and detecting on a rail and avoiding a coming and going train, and solves the problems that the diagnosis instrument needs to fixedly advance and detect along the rail and does not need to carry out fault diagnosis on the rail. And the contradictory technical problem is solved. The constant-temperature lossless wheel is provided with the channel with different calibers at the two ends, airflow passes through the interior of the wheel by utilizing different air pressures on the two sides when the wheel rotates, so that the technical effect of cooling the wheel is achieved, and the lossless contact belt is wound on the wheel to reduce the contact area between the wheel and a track; the technical effect of low loss of the rail is achieved.

Owner:樊晟姣

Novel rubber abrasion testing machine capable of inputting road spectrum parameters

ActiveCN108181194AAchieve wearPlastic recyclingInvestigating abrasion/wear resistancePositive pressureEngineering

The invention discloses a novel rubber abrasion testing machine capable of inputting road spectrum parameters. An abrasion positive pressure is controlled by smartly controlling a centrifugal force, and a new structure is used, so that a deflection angle can be more accurately and conveniently added in a rubber abrasion test; and a road spectrum concept is provided, and a method of controlling thecentrifugal force is utilized for realizing addition of the road spectrum parameters, so that the novel rubber abrasion testing machine can more extensively simulate tire rubber abrasion conditions under various road conditions, and more accurate rubber abrasion testing equipment is provided for the field of rubber abrasion.

Owner:QINGDAO UNIV OF SCI & TECH

Wear-resisting metal hydraulic baling press

PendingCN107825747AEasy to assemble and disassembleEasy to movePressesMaterials scienceBolt connection

The invention discloses a wear-resisting metal hydraulic baling press which comprises a machine body and a turnover cover. A connecting lug which is fixedly welded to the middle of the upper surface of a turnover cover body is connected with the tail end of an inner rod of a turnover cover hydraulic pillar through a pin. The middle part of a turnover cover hydraulic pillar body is installed in aninstallation site on the upper portion of one side of the machine body through a rotating shaft. A material box is arranged at the side, far away from the turnover cover, of the inside of the machinebody. The tail end of an inner rod of a longitudinal hydraulic pillar body is connected with a pushing plate through a set bolt. A bottom wear-resisting plate is installed at the bottom of the material box. A side wear-resisting plate is vertically installed at the side, far away from the pushing plate, of the inside of the material box. Long wear-resisting plates are installed at the two sides, far away from the pushing plate and the side wear-resisting plate, of the inside of the material box. Sliders are installed in installation sites arranged at the bottom of the machine body. According to the wear-resisting metal hydraulic baling press, rolling balls on the upper portions of the sliders make contact with the bottom of a material so that the material can be moved smoothly, and internal abrasion of the device is reduced.

Owner:张旋

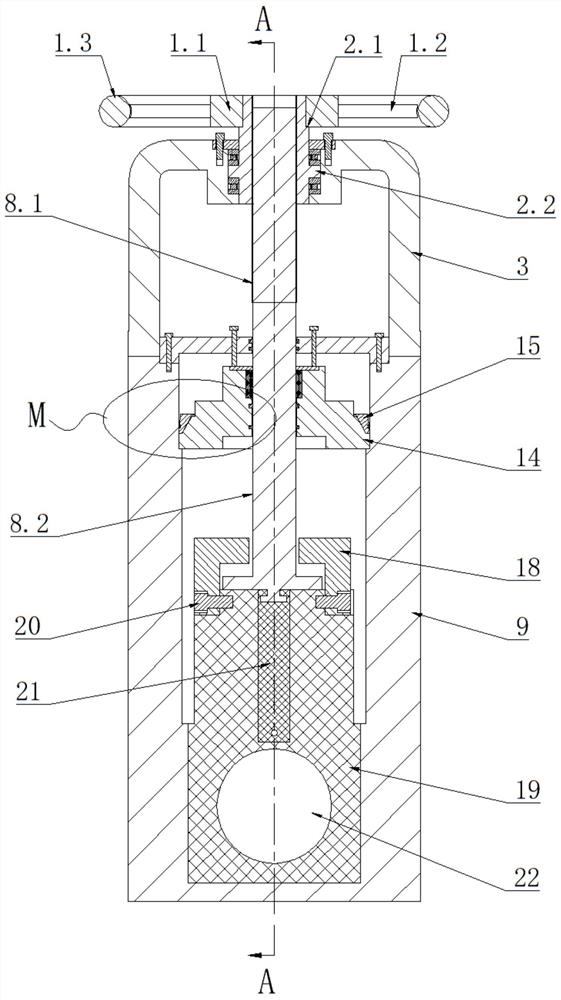

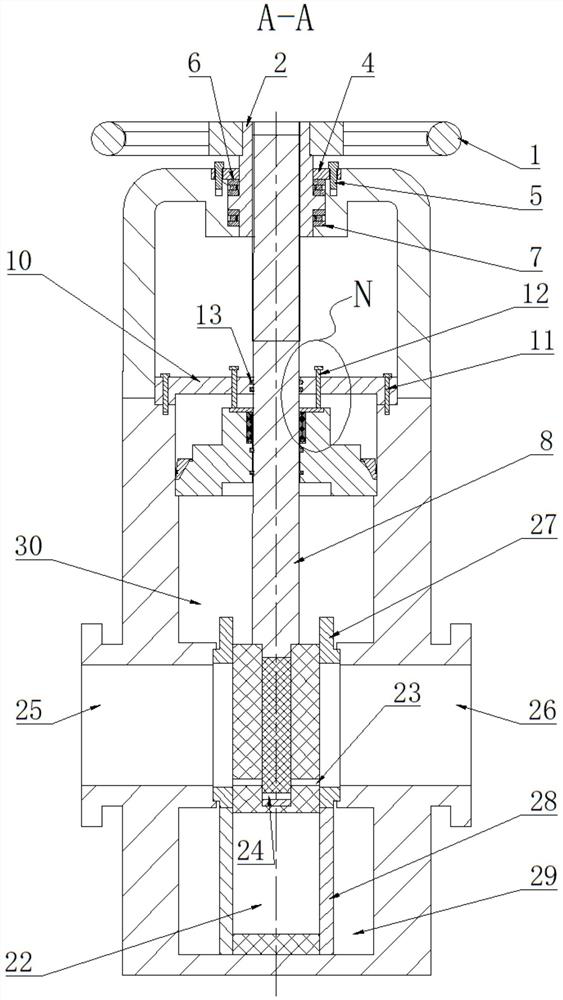

A fully automatic tunnel bolt installation equipment

ActiveCN106869976BEnable continuous installationAvoid deformationProgramme-controlled manipulatorAnchoring boltsMechanical assistanceMachine

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Concrete sealing and curing agent used for low-temperature refrigeration house

The invention discloses a concrete sealing and curing agent used for a low-temperature refrigeration house, which is prepared from the following raw materials in parts by weight through a heating reaction for 2 h in a reaction kettle: 20-40 parts of silicon dioxide, 3-15 parts of lithium, 3-15 parts of titanium and 40-60 parts of water. The concrete sealing and curing agent is an environment-friendly colorless, odorless, non-toxic and non-combustible high-tech aqueous chemical compacting agent and has the advantages of strong permeability, good sealing and curing effects, high cost performance and the like. The concrete sealing and curing agent is super hard and resistant to wear, the ground is not easy to wear but the polishing effect is realized, and the longer the ground is used, the appearance effect is better. The floor on which the concrete sealing and curing agent is used has the advantages of sealing, seepage prevention, mould prevention, high temperature resistance, weathering prevention and dust prevention, is very easy to clean and becomes more beautiful and has permanent and attractive gloss just like marble when the floor is used longer and longer. The floor has beautiful appearance and long service, and worry-free life is realized through one time investment.

Owner:TIANJIN BOHAI LITUO TECH

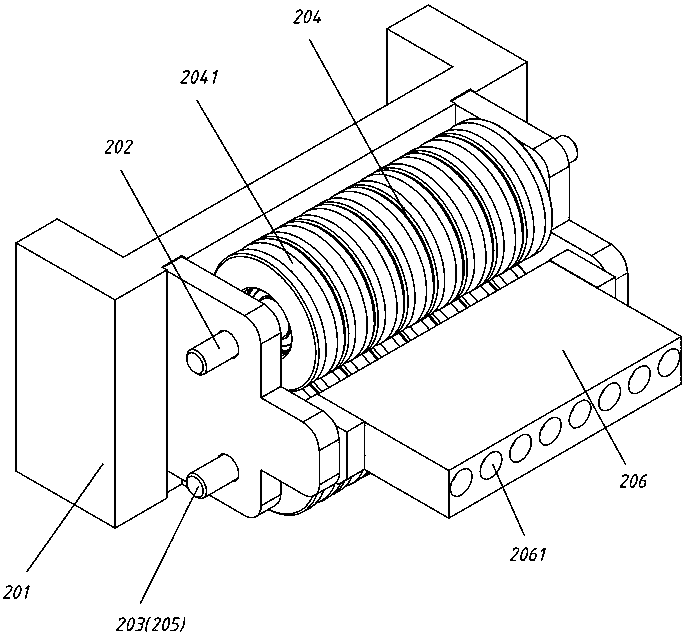

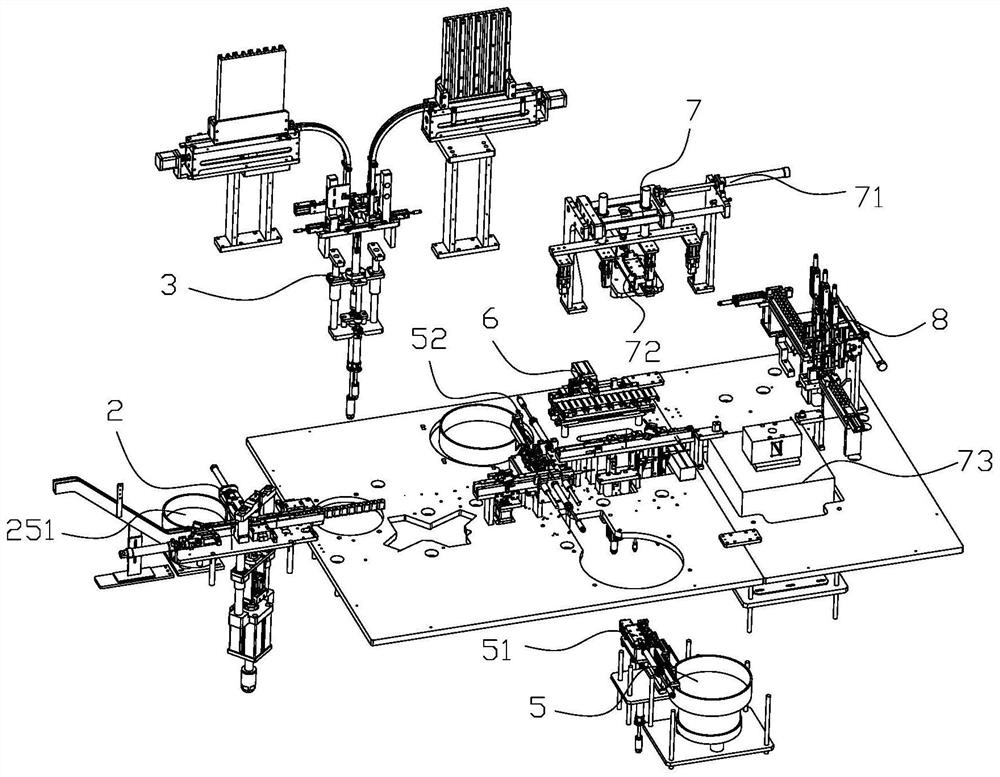

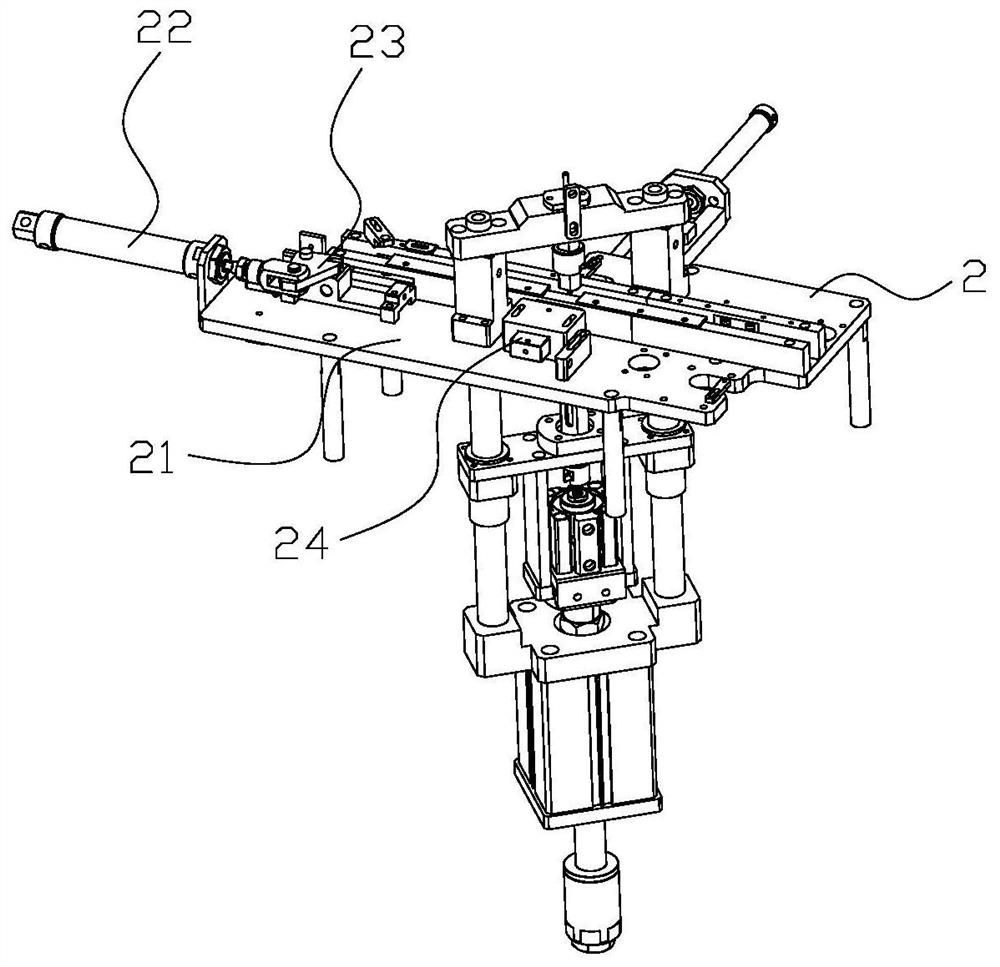

Magnetizing device and magnetizing method for servo motor production

InactiveCN111696751AImprove magnetization efficiency and magnetization qualityImprove assembly efficiencyMagnetic bodiesTransfer mechanismProcess engineering

The invention relates to the technical field of servo motor production, and particularly relates to a magnetizing device and a magnetizing method for servo motor production. The device comprises a magnetizing transfer mechanism, a magnetizing push-in mechanism and a magnetizing mechanism, wherein the magnetizing transfer mechanism is located above the magnetizing push-in mechanism; the magnetizingtransfer mechanism is used for transferring the assembled assembly to the magnetizing push-in mechanism; the magnetizing push-in mechanism is located on the rear side of the magnetizing mechanism andused for pushing the assembled assembly into the magnetizing mechanism, and the magnetizing mechanism is used for magnetizing the assembled assembly. The invention has the advantages that the magnetizing efficiency and the magnetizing quality are improved, and the assembly efficiency of the whole servo motor is improved.

Owner:高鑫斌

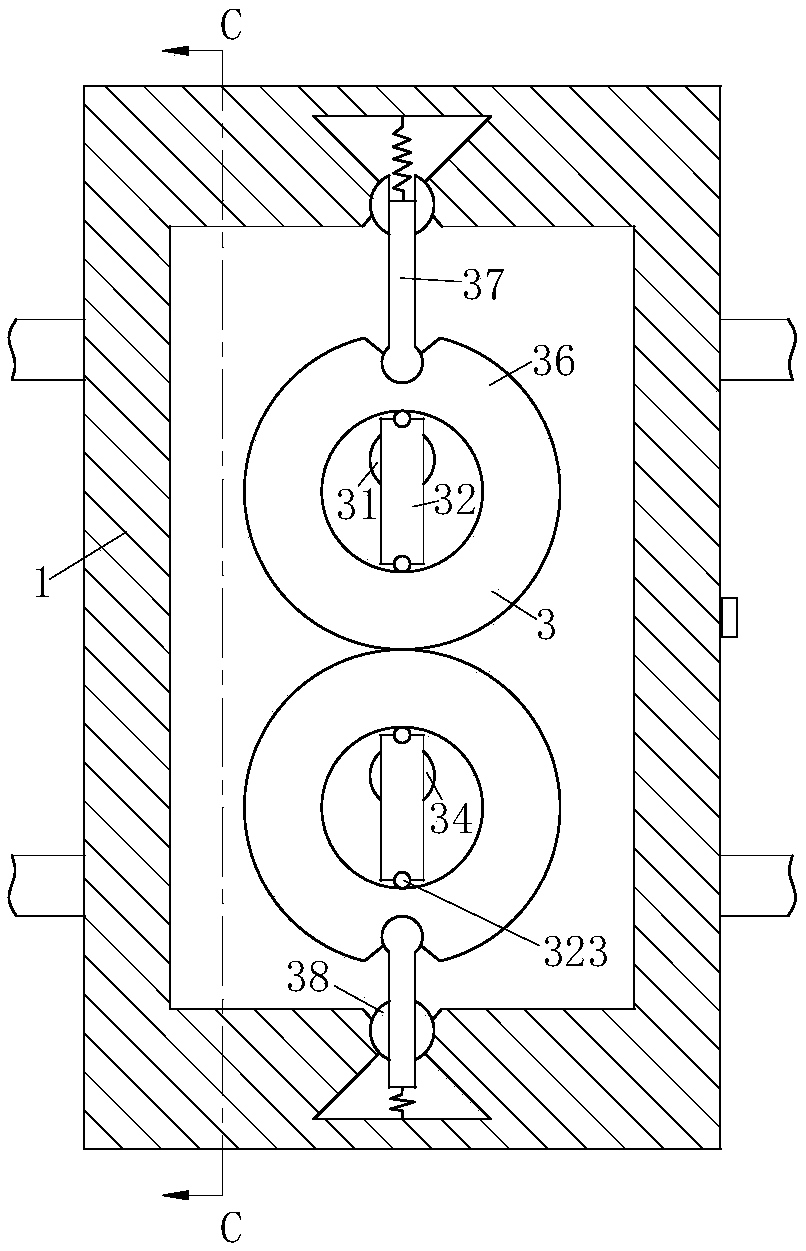

Numerical control equipment

InactiveCN102962730AImprove carrying capacityImprove rigidityFeeding apparatusMetal working apparatusNumerical controlClosed loop

The invention relates to numerical control equipment. A main support frame is in a closed loop structure, and the opening of the structure faces towards the vertical direction; an X-direction front guide rail and an X-direction back guide rail which are mutually matched are arranged between the main support frame and an X-direction sliding seat; a Z-direction guide rod is a round guide rod, and the Z-direction guide rod only can be installed together with a Y-direction sliding seat in an up-and-down movement way; the numerical control equipment is further provided with a rotation stopping structure which is used for preventing the Z-direction guide rod from rotating along the horizontal direction of the axial line of the guide rod; the rotation stopping structure comprises a third rotation stopping block and a third spring; a blind hole is formed in the side surface of the Z-direction guide rod; a rotation stopping groove which is matched with the third rotation stopping block is formed in a guide hole which is matched with the Z-direction guide rod; the third spring is installed between the bottom surface of the blind hole and the third rotation stopping block; and one side of the third rotation stopping block, which is far from the spring, is protruded out of the periphery of the Z-direction guide rod and matched with the rotation stopping groove. The numerical control equipment has the advantages of good stability and difficulty in generating unbalanced torque when a main processing head is moved up and down.

Owner:杨东佐

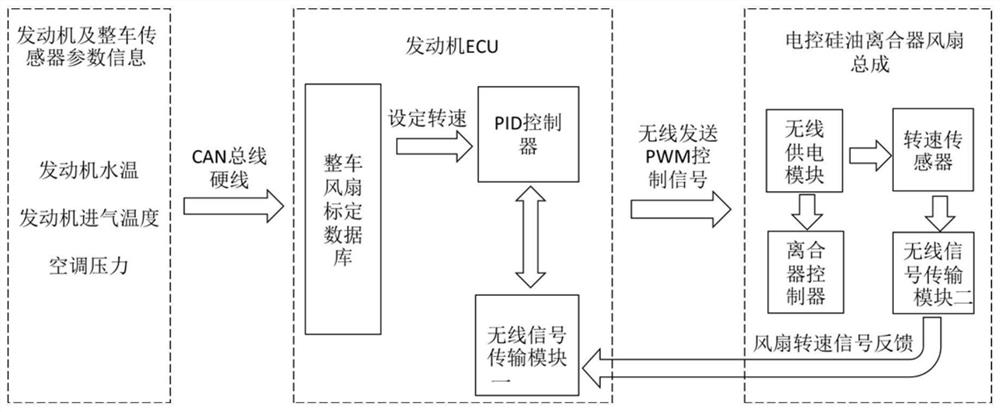

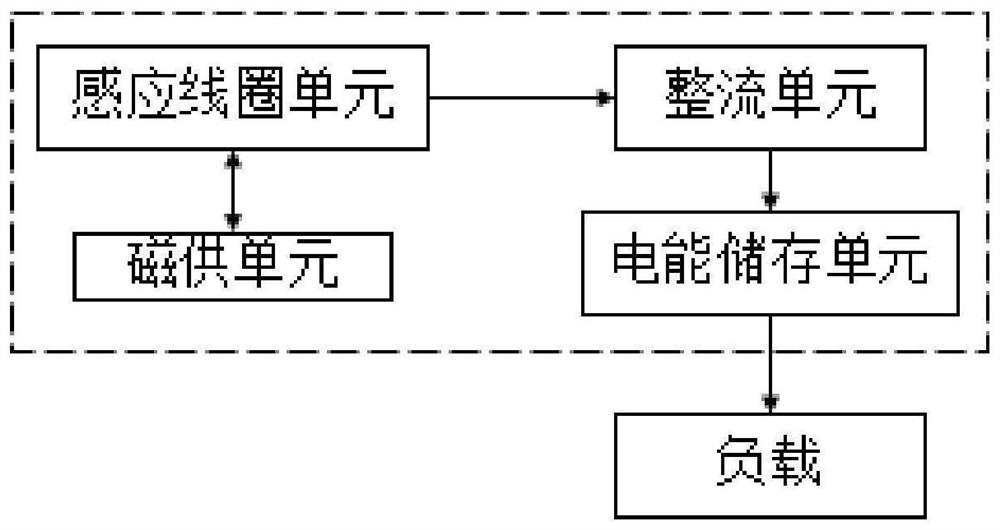

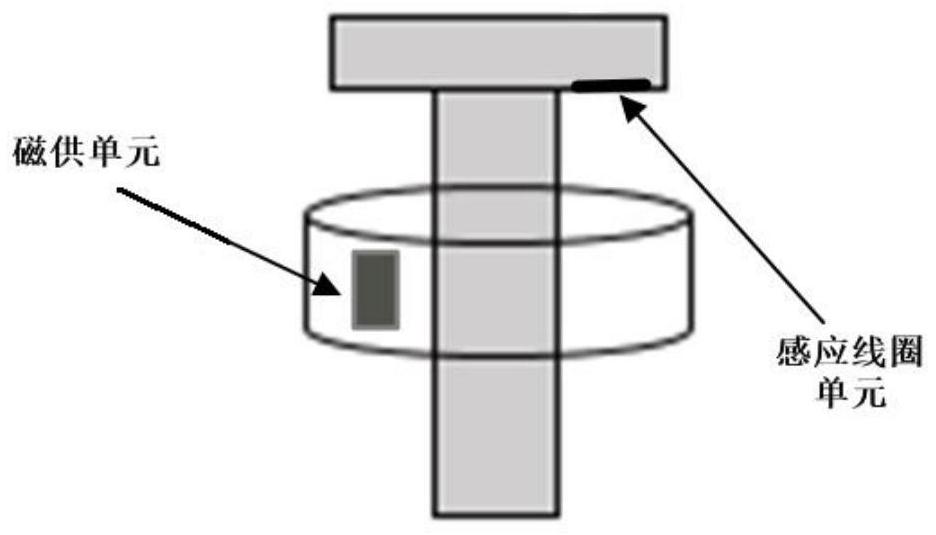

Electric control silicone oil fan control system and method for wireless power supply and signal transmission

InactiveCN113833557AAchieve wearRealize energy reuseCoolant flow controlPump controlWireless controlControl signal

The invention provides an electric control silicone oil fan control system and method for wireless power supply and signal transmission. A wireless power supply device is additionally arranged on an electric control silicone oil fan driving shaft to supply power to a rotating speed sensor and a clutch controller on an electric control silicone oil fan clutch assembly; wireless signal transmission equipment is additionally arranged on the silicone oil fan clutch controller to achieve receiving and sending of rotating speed signals and clutch control signals; the wireless signal transmission equipment is additionally arranged at the ECU end of an engine to achieve receiving and sending of control signals and rotating speed signals, and therefore faults such as wire harness wear and connector water inflow are eradicated; meanwhile, energy recycling of fan shaft accessory work can be achieved, and the power supply load of the whole vehicle is reduced; wireless control is achieved through clutch signals, the clutch out-of-control situation caused by pin short circuit faults is prevented, and the system is more reliable and stable; and assembling is reduced, accessories such as wire harnesses and supports are omitted, and part cost is saved.

Owner:湖南行必达网联科技有限公司

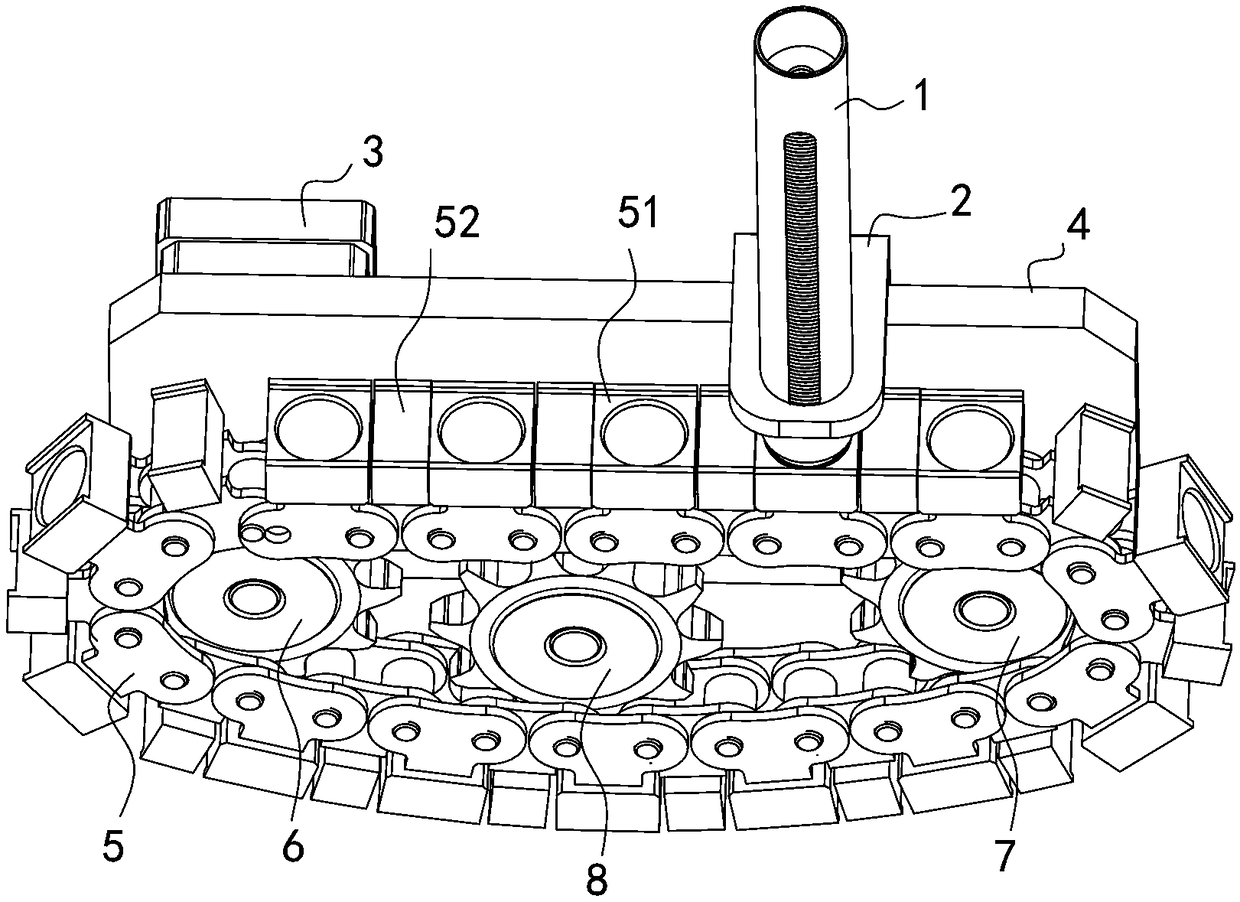

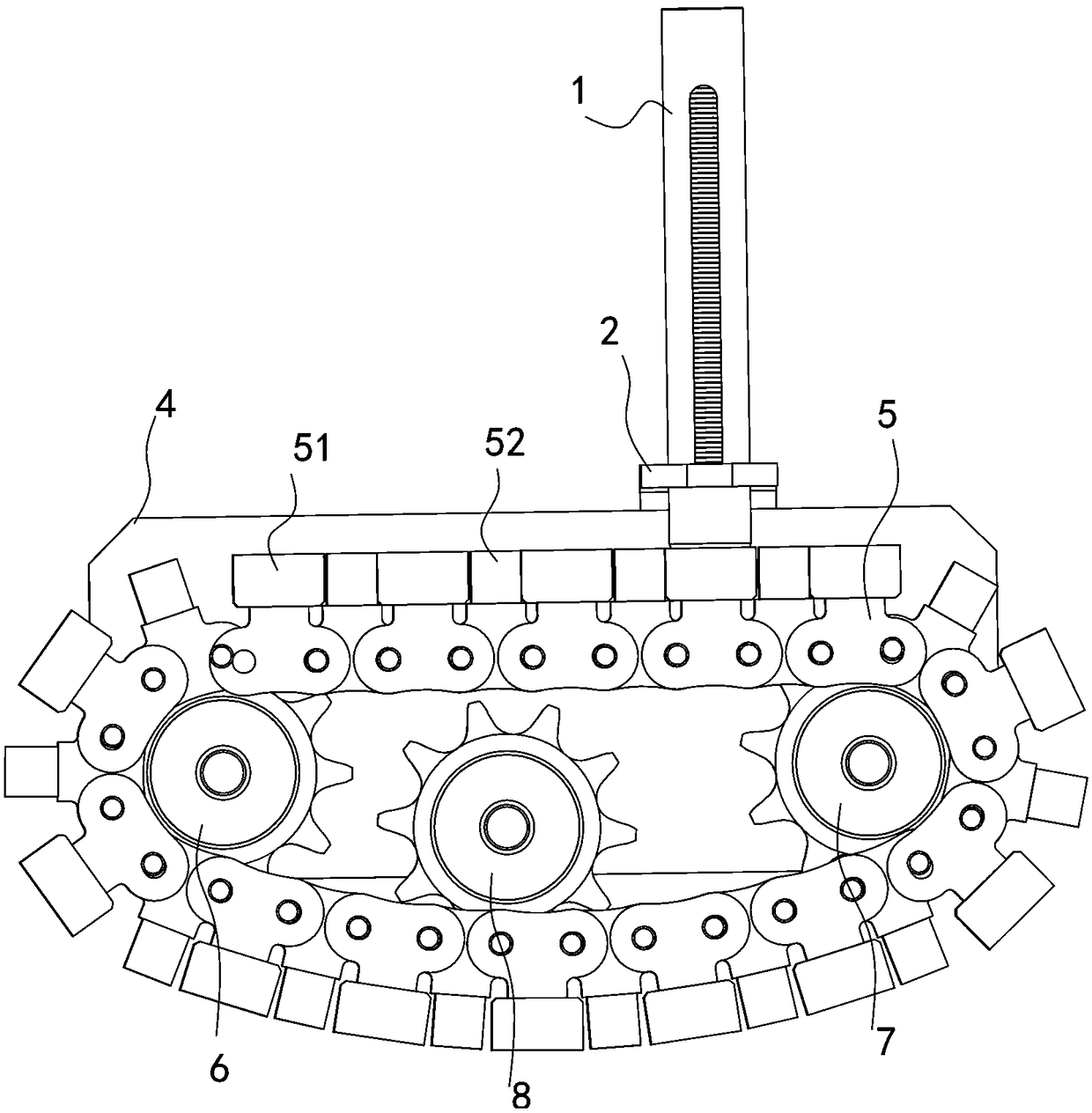

Chain type spacer quantitative feeding and assembling robot

ActiveCN109227073AGuaranteed surface qualityRealize quantitative captureMetal working apparatusSprocketEngineering

The invention discloses a chain type spacer quantitative feeding and assembling robot, which comprises a material barrel, an L-shaped bracket, a servo motor, a fixing plate and a chain, wherein the material barrel is arranged on the bracket; the bracket is arranged on the fixing plate; the servo motor is arranged on the fixing plate; a driving chain wheel is connected with the output end of the servo motor; the fixing plate is connected with a first driven chain wheel; the chain is meshed with the driving chain wheel and the first driven chain wheel; the chain is provided with grabbing blocks;each grabbing block is internally provided with an electromagnet; each grabbing block is provided with a circular groove; the depth of the circular groove is equal to the thickness of the spacer, a partition block is also fixed on the chain, the partition block is positioned between the grabbing blocks, the material barrel is at a certain distance from the upper surface of the grabbing blocks orthe partition block, and the distance is smaller than the thickness of the spacer; according to the invention, the quantitative feeding and assembling of the spacer are combined together, the efficiency is higher, the abrasion caused by friction between the spacer and other objects is reduced, and the stability of the spacer is more durable.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

Ultrahigh-pressure sand control fracturing valve

ActiveCN112377163AAvoid enteringExtended service lifeFluid removalWell/borehole valve arrangementsUltra high pressureStructural engineering

The invention relates to a fracturing valve, in particular to an ultrahigh-pressure sand control fracturing valve, and belongs to the technical field of fracturing. The valve comprises a valve body, avalve rod installed in the valve body and a valve plate connected with the valve rod, and is characterized in that the valve plate is of a combined structure and comprises an opening and closing valve plate and a pressure relief valve plate, and the pressure relief valve plate is installed in a pressure relief valve plate containing cavity formed in the upper portion of the opening and closing valve plate in a sliding mode. The valve rod drives the pressure release valve plate to annularly slide between the valve plate hook and the opening and closing valve plate, when the valve rod slides tothe upper limit position relative to the valve plate hook, the pressure release hole of the pressure release valve plate is coaxial with the pressure release hole of the opening and closing valve plate, the fracturing valve is delayed to open for pilot pressure release, and the valve plate is located between the two valve plate seats. After the fracturing valve conducts pressure relief, the valverod drives the valve plate to move upwards to open the fracturing valve. The fracturing valve has the beneficial effects that the fracturing valve can be suitable for ultrahigh-pressure fracturing working conditions, fracturing sand can be effectively prevented from entering the valve cavity, and internal components of the valve cavity are protected against damage.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Anti-wear maintenance method for air conditioner compressor

InactiveCN108488070AReduce wearIncreased durabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsAir compressionPulp and paper industry

The invention belongs to the technical field of compressors, and particularly relates to an anti-wear maintenance method for an air conditioner compressor. A compression module is arranged in an air cylinder and driven by a driving module, and the working process of air suction, compression and air exhaust is achieved; an adjusting module is arranged between a first eccentric shaft and a second eccentric shaft, after rotors are worn to a certain degree, a rotating disc arranged on the adjusting module rotates to adjust the distance between two adjusting blocks, therefore, the two rotors are attached to each other again, and in-time compensation of wear is achieved; and an anti-loosing unit is arranged in the adjusting module, and the stability of wear compensation operation is improved. According to the anti-wear maintenance method for the air conditioner compressor, rotating rollers do not make contact with the side wall of the air cylinder, therefore, the air cylinder does not need to be replaced, wear of the air cylinder is reduced, the maintaining cost is reduced, and the service life of the compressor is prolonged; by arranging the two rotating rollers, air compression is achieved; and by arranging the adjusting module, wear compensation of the rotating rollers is achieved, and the compressor maintaining and curing efficiency is improved.

Owner:北京海松元汽车部件有限公司

Coal mine conveying vehicle

InactiveCN113120010ATo achieve the effect of deceleration and brakingReduce resistanceSelf-applying brakesMine carsMining engineeringStructural engineering

The invention discloses a coal mine conveying vehicle, and relates to the technical field of coal mine electromechanical equipment. The vehicle comprises a frame, the frame comprises a bottom plate and vertical plates, the vertical plates are arranged at the two opposite side edges of the bottom plate, half-kidney-shaped holes are formed in the tops of the vertical plates, two mounting bases are symmetrically arranged on the bottom faces of the vertical plates, sliding grooves are formed in the mounting bases, and cavities communicating with the half-kidney-shaped holes and the sliding grooves are formed in one side faces of the vertical plates; a hopper is rotationally installed between the two vertical plates, and a shaft body of the hopper is installed in the clamping part in a matched mode and is fixed through a fixing part fixedly installed at the top end of the half-kidney-shaped hole. Rollers are rotationally mounted at the bottoms of the sliding grooves, friction parts making contact with roller shaft bodies are further mounted in the sliding grooves, and the tops of the friction parts make contact with the elastic pieces. The hopper filled with a coal mine pushes the corresponding sliding rods on the transverse rod to slide downwards under the action of gravity, the first V-shaped rod is pushed to rotate, the friction blocks are pushed to be tightly attached to the rotating shafts of the rolling wheels, and the speed reducing and braking effects are achieved.

Owner:姚冬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com