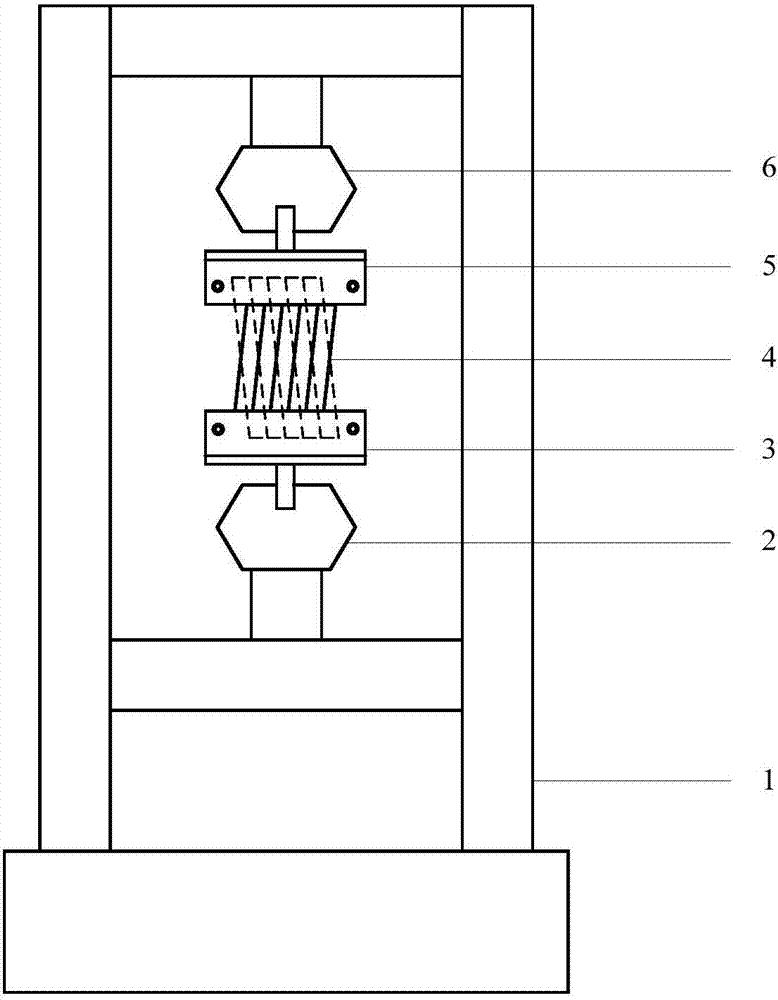

Test method and device for simulating interlayer wearing of flexible standpipe armors

A flexible riser and test device technology, applied in the direction of measuring device, strength characteristics, test wear resistance, etc., can solve the problems of inability to evaluate the protection effect of wear-resistant layer, inability to simulate practical applications, etc., and achieve intuitive test results and reasonable design. , The effect of the simple test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Testing the Interlaminar Abrasion Resistance of Steel Tensile Armor Layer of Unbonded Flexible Riser

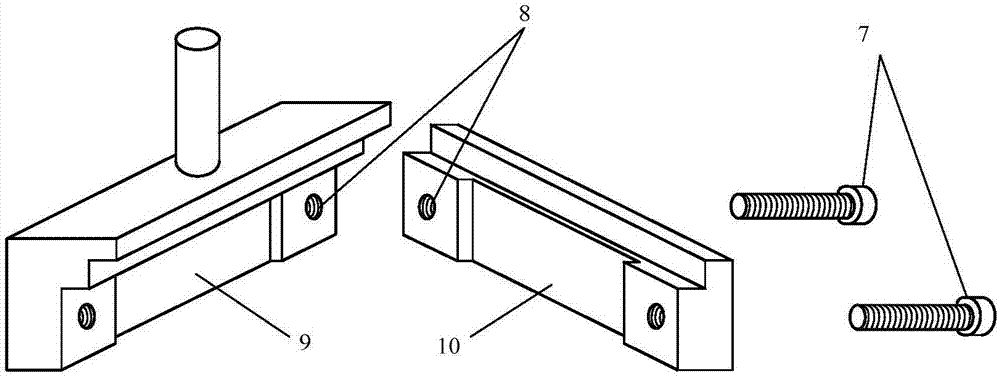

[0042] 1) Sample preparation: use the steel armor wire to prepare 10 straight splines with a length of 10 cm (the cross-section of the sample is the original shape of the steel armor wire, which is a rectangle in this example) as test samples;

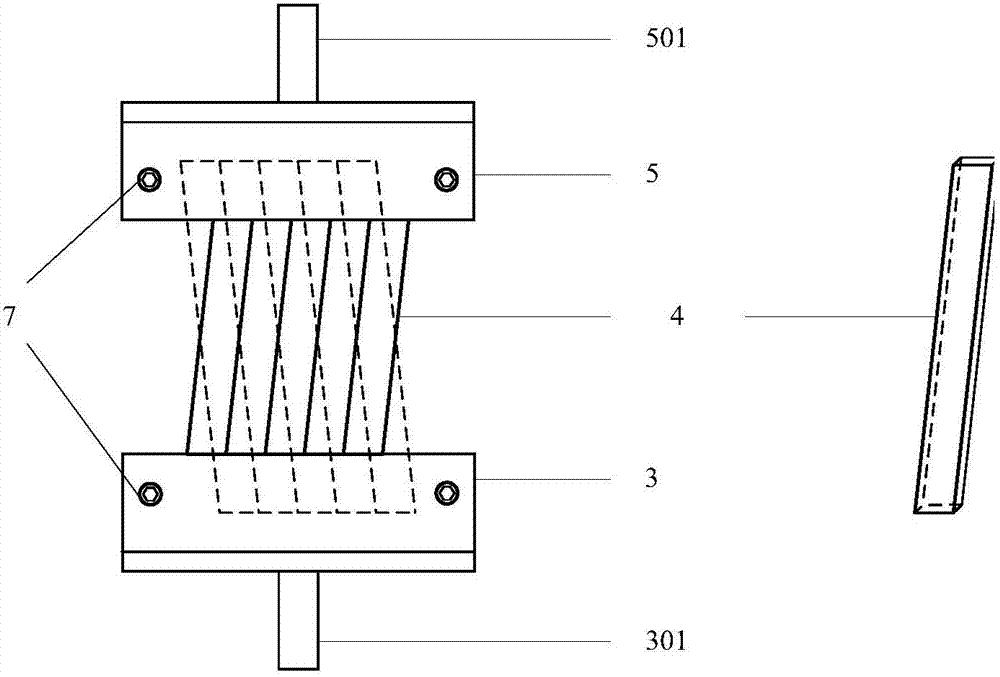

[0043] 2) Sample assembly: Divide the samples into 2 groups, 5 in each group. The ends of each group of samples are closely arranged and even, the two groups of samples cross and overlap, the axial cross angle is 50° (equal to the interlayer winding angle of the steel armor wire in the flexible riser), and the ends of the two groups of samples are placed on the sample In the sample groove of the fixture, and the test fixture is tightly fixed by fastening bolts. It is required that the clamping handles of the two sets of sample fixtures are axially coincident, and the laying direction of each set of samples is at the sa...

Embodiment 2

[0049] Example 2: Test the interlaminar wear resistance of the tensile armor layer of the non-bonded flexible pipe carbon fiber reinforced composite material

[0050] 1) Sample preparation: use the same material and process as the carbon fiber composite armor wire to make 10 straight splines with a length of 15 cm (the cross-section of the sample is equal to the original shape of the armor wire) as test samples;

[0051] 2) Sample assembly: Divide the samples into 2 groups, 5 in each group. Each group of samples is closely arranged and the ends are even. The two groups of samples cross and overlap. The axial cross angle is 60° (equal to the interlayer winding angle of the armor wire in the flexible riser). The ends of the two groups of samples are placed in the sample fixture. Add an appropriate amount of epoxy adhesive in the sample groove, and fix the test fixture tightly by fastening bolts. It is required that the clamping handles of the two sets of sample fixtures overlap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com