Device for pressing a gear rack against a pinion

A pinion and rack technology, applied in the direction of belts/chains/gears, hoisting devices, components with teeth, etc., can solve the problem of the steering wheel being stuck by the pressing device and troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

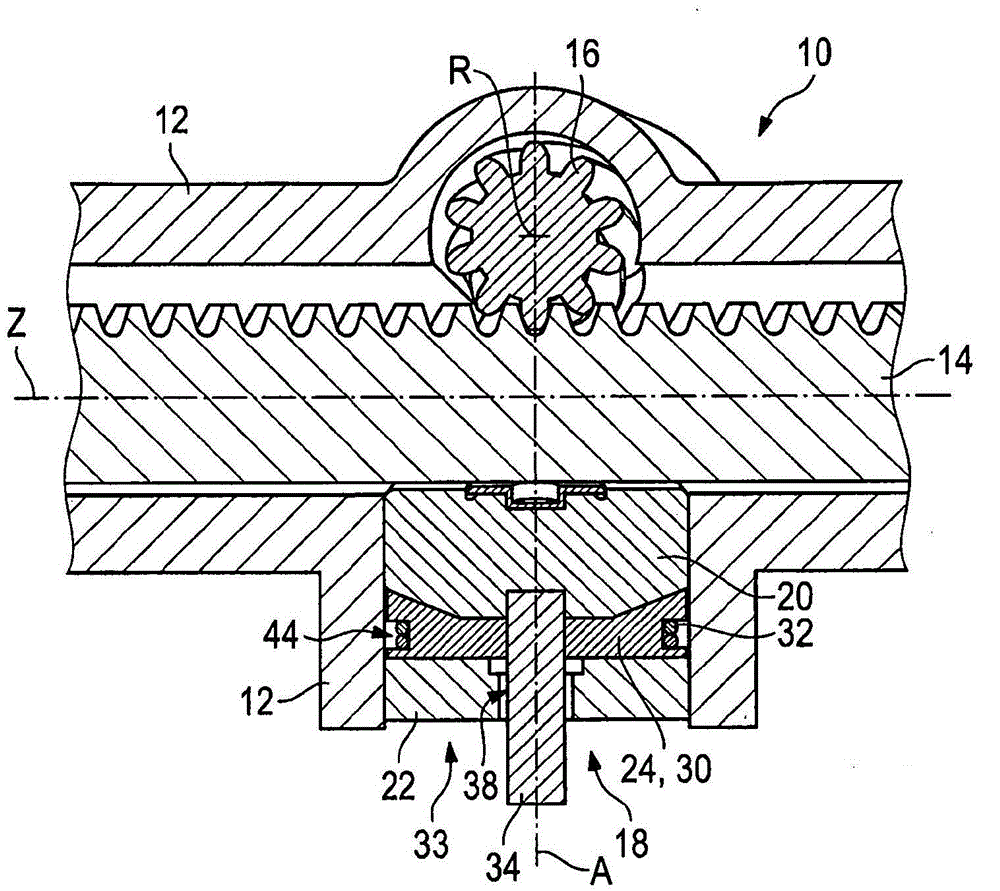

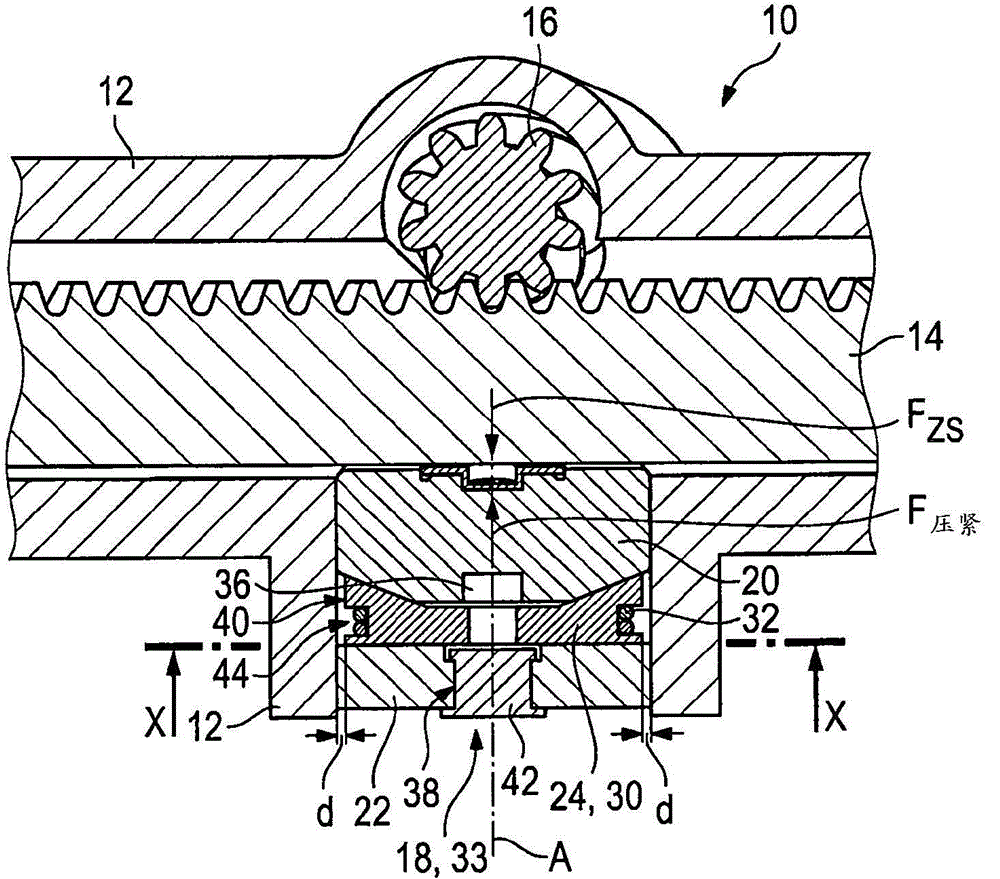

[0030] figure 1 and 2 Shown is a part of a rack-type steering mechanism 10 for a motor vehicle, which has a housing 12, a toothed rack 14 mounted longitudinally displaceably in the housing 12, a The pinion 16 in and a pressing device 18 load the rack 14 to the pinion 16 . Here, the hold-down device 18 according to figure 1 shown in assembled state and according to figure 2 Shown in use.

[0031] The housing 12 of the pressing device 18 is in the present case formed in one piece with the housing 12 of the rack steering 10 . Alternatively, however, the pressing device 18 can also have a separate housing which is attached to the housing of the rack steering 10 .

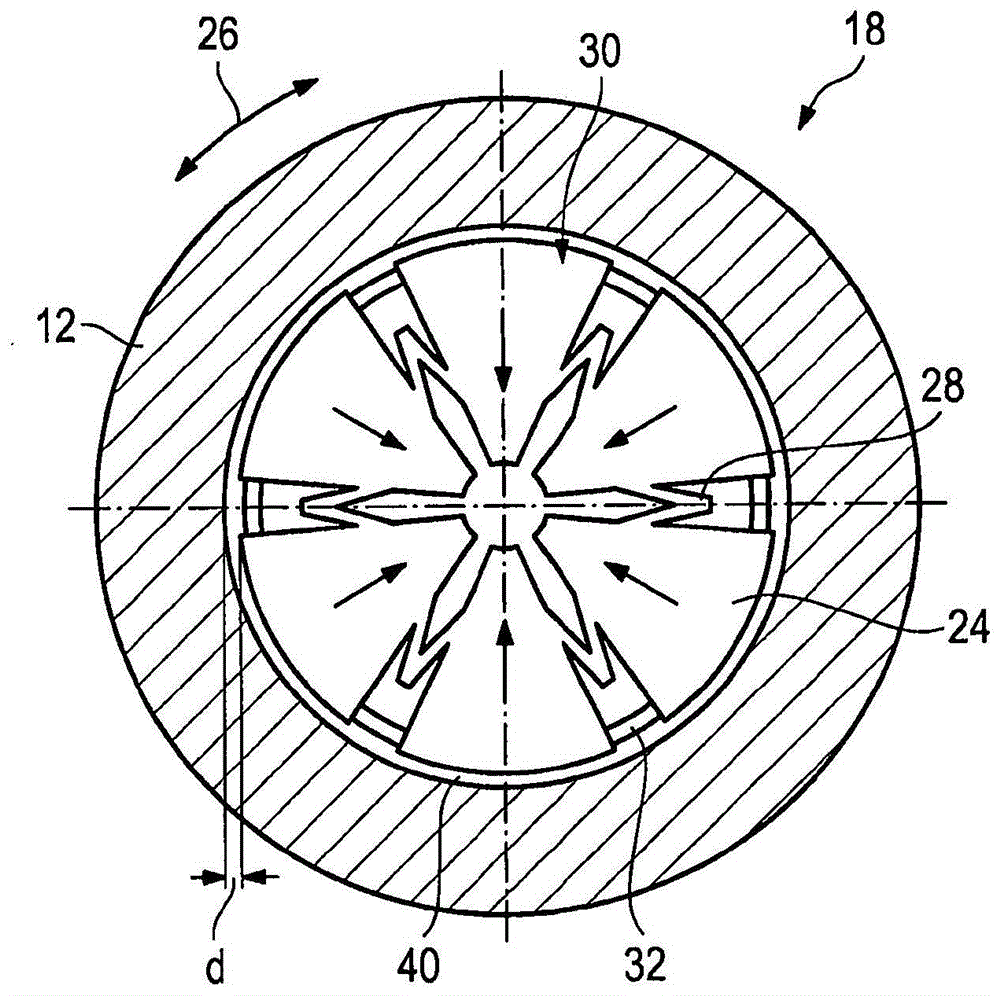

[0032] The device 18 for pressing the rack 14 onto the pinion 16 comprises a housing 12, a pressure element 20 guided movably in the housing 12 along the pressing axis A, a A bearing element 22 on the housing 12 and a plurality of radially loaded wedges 24 , which are respectively supported on the pressure part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com