Packaging method for wave shape bridge plate of super highway after coating

A technology for expressways and packaging methods, applied in packaging, building materials packaging, transportation and packaging, etc., can solve problems such as coating damage, corrosion protection, shedding of steel substrates, increased friction between plates, etc., to achieve coating protection and lighten The effect of pressure and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

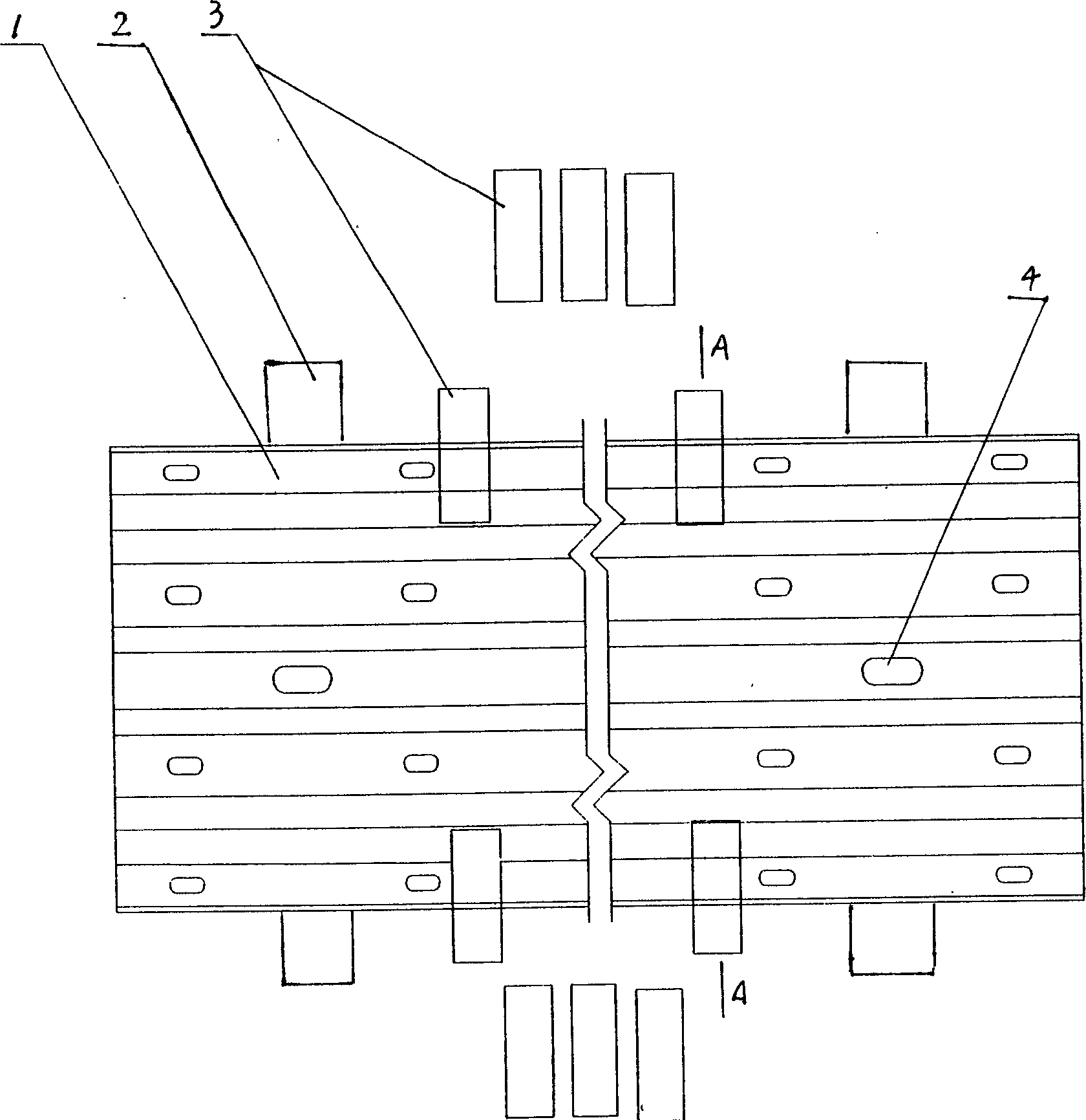

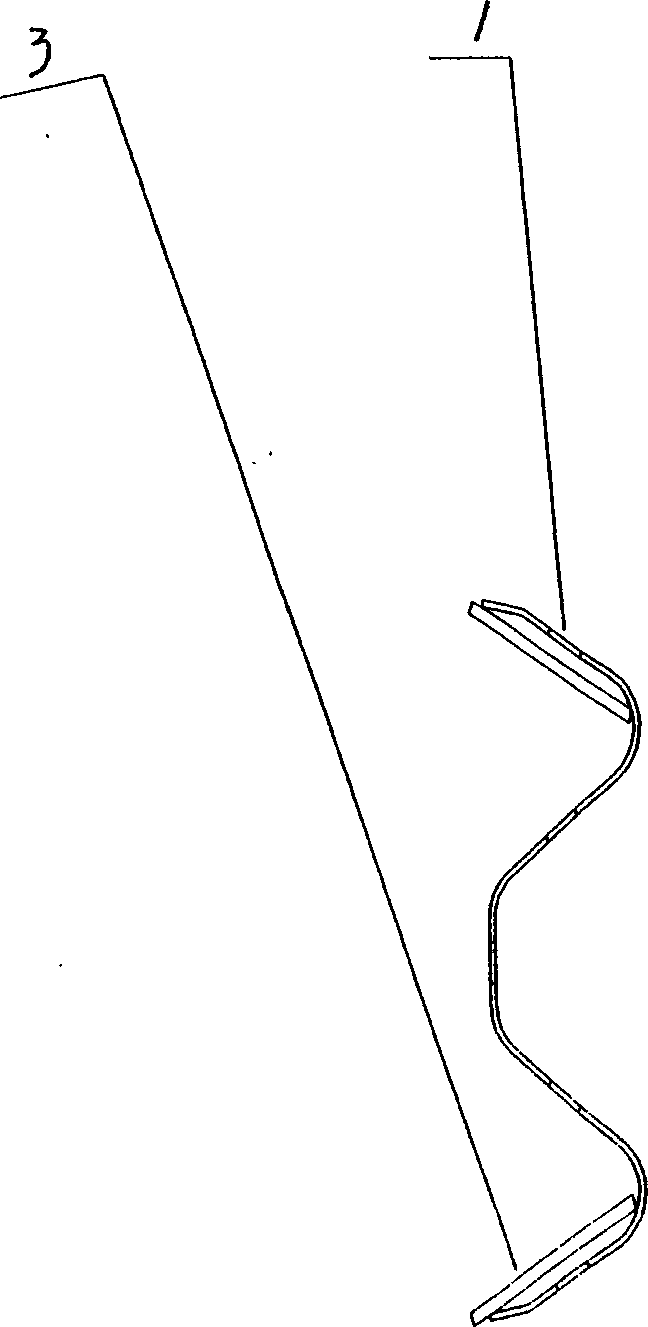

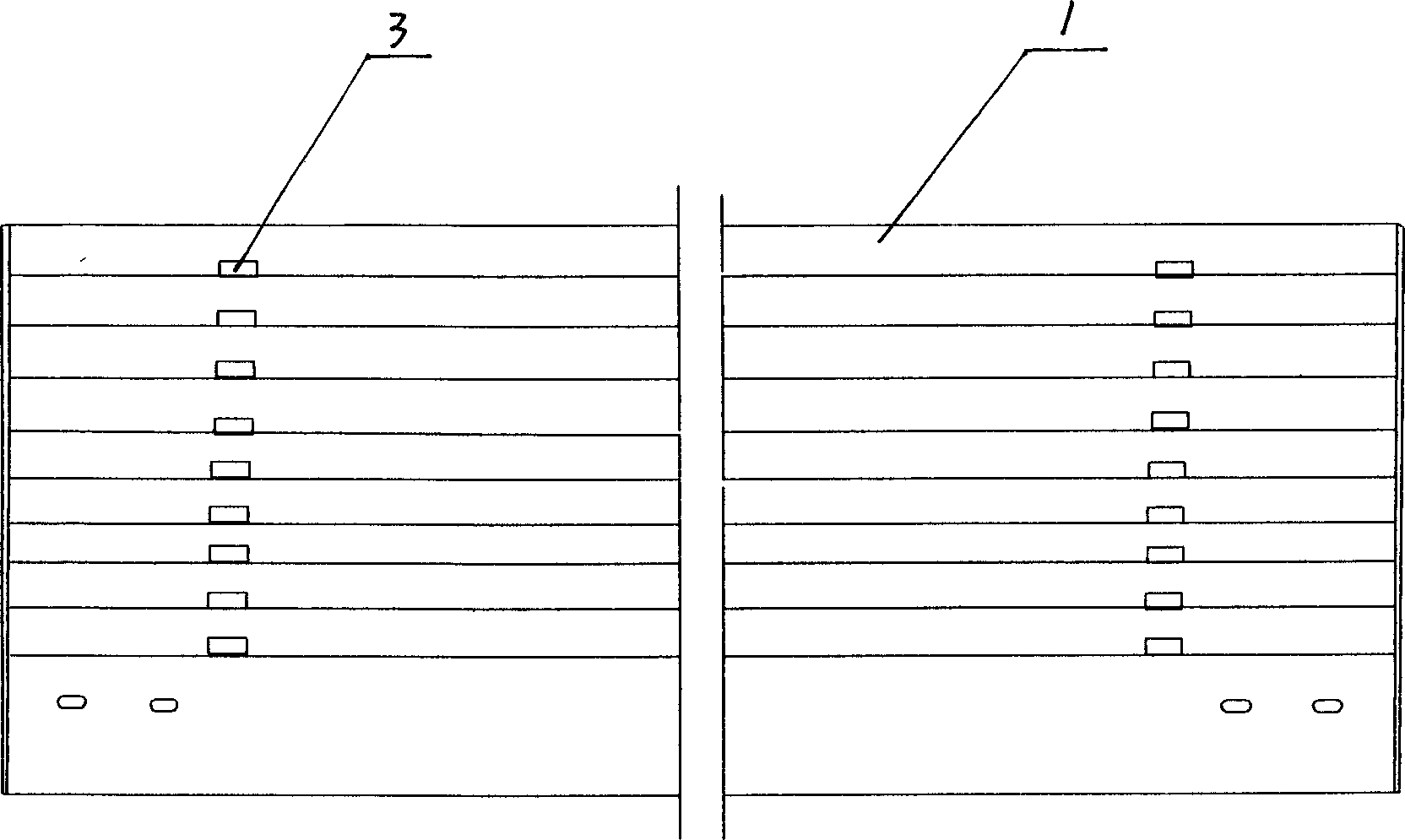

[0022] Such as figure 1 , figure 2 Shown: Put a piece of expressway corrugated beam slab (nine-hole standard slab) that has been painted off the assembly line on the sleeper 2 (it is convenient for transshipment or forklift by wearing a sling, and also avoid direct contact with hard objects on the ground to prevent damage to the coating) , in the groove of its both sides leaning against board respectively puts five long pieces of wood chips 3, the size of long wood chips is long * wide * height (thick) 120mm * 25mm * 7mm, about 900mm mutually intervals. Then stack the second board, place the same number of long pieces of wood at the same position and then put the third board... Such as image 3 As shown, after putting the tenth board, such as Figure 4 , Figure 5 As shown, pass the 8# iron wire 5 (double strand) wrapped with plastic tape through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com