Patents

Literature

30results about How to "High displacement sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Numerical control equipment

InactiveCN102699768AGuaranteed shape and position accuracyAchieve rigid fixationFeeding apparatusLarge fixed membersNumerical controlEngineering

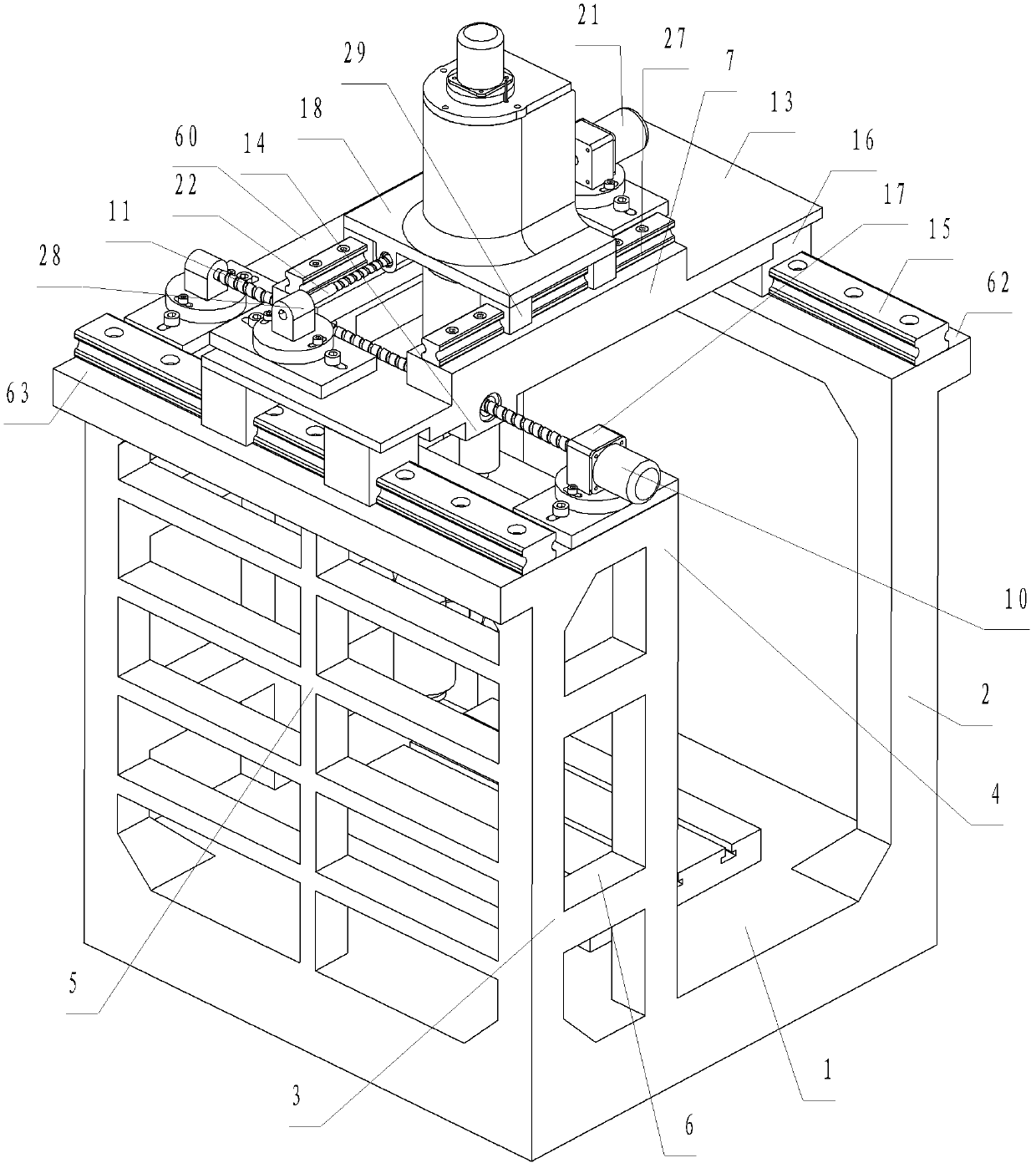

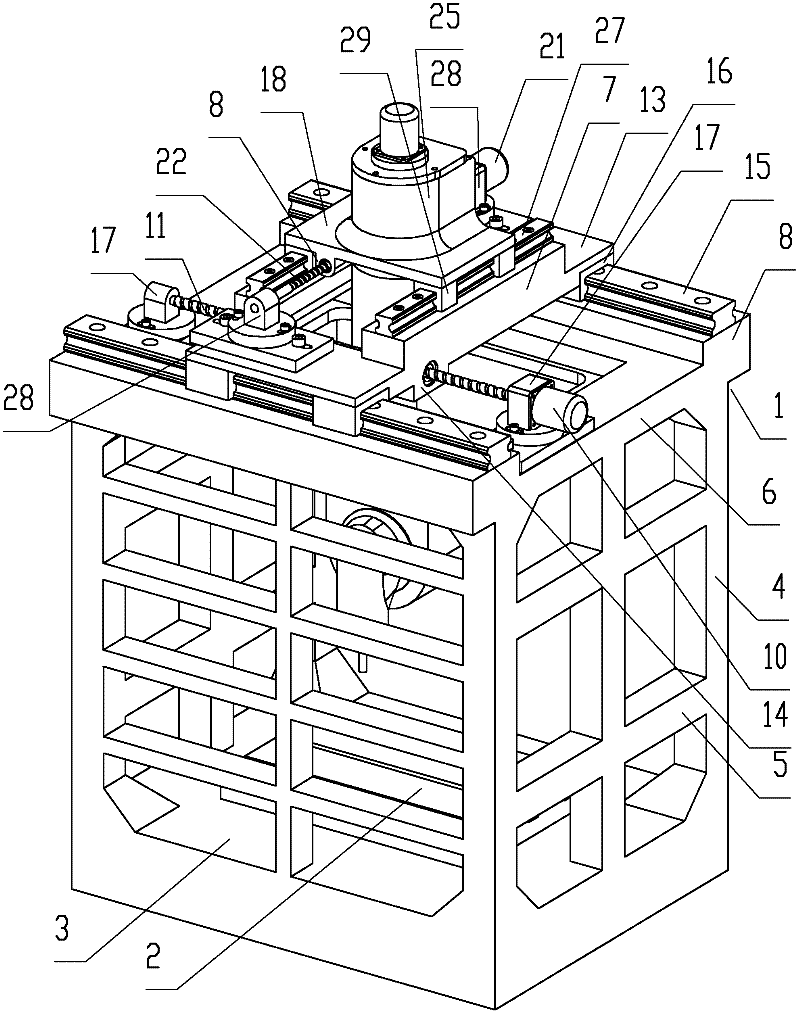

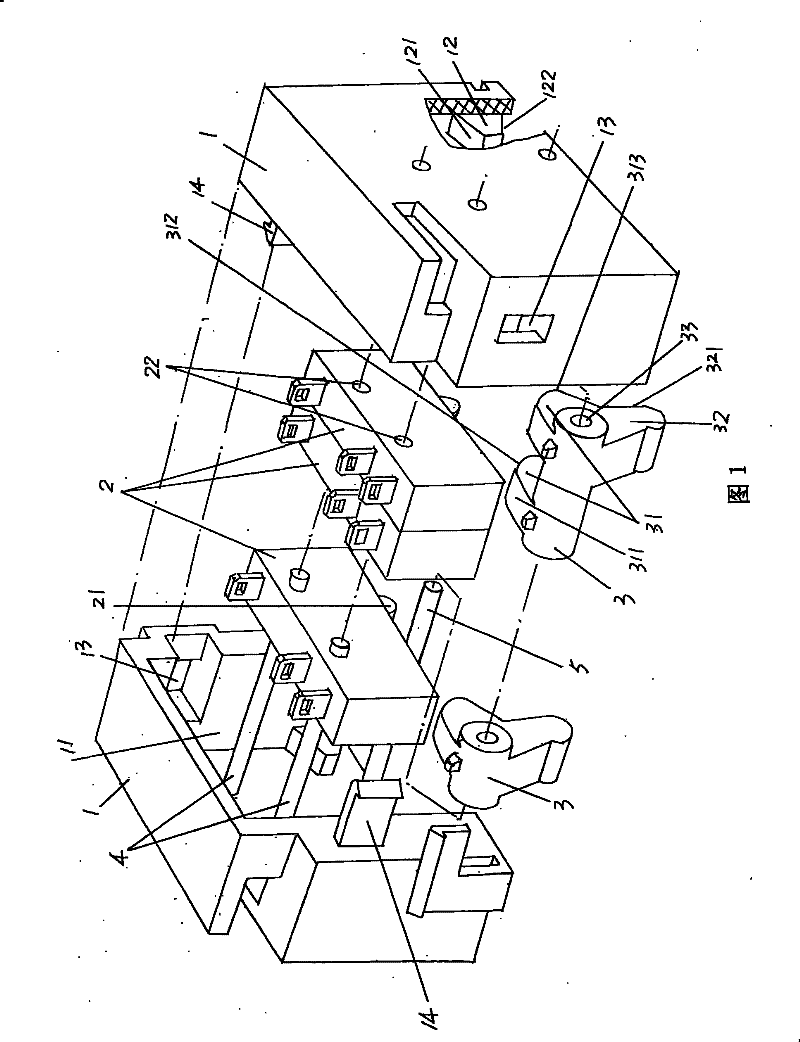

Numerical control equipment comprises a main frame and a workpiece clamping device. The main frame consists of a base, a first main support portion and a second main support portion, and the first main support portion and the second main support portion are arranged on two opposite sides of the base and are mounted with the base. The numerical control equipment is characterized in that the first main support portion and the second main support portion consist of separate first sides on the middle upper portions, a first driving device and a first driving device mounting portion, the first driving device drives an X-direction sliding seat to reciprocate, the first driving device mounting portion is connected with the first main support portion or the second support portion and is placed between an X-direction front guide rail and an X-direction rear guide rail, and the first driving device consists of an X-direction lead screw or a group of X-direction linear motors which drives the X-direction sliding seat to reciprocate and is parallel to the X-direction front guide rail and the X-direction rear guide rail. The X-direction lead screw penetrates through the X-direction sliding seat, and two ends of the X-direction lead screw are protruded out of a worktable and mounted on the first driving device mounting portion; or two ends of a stator of each X-direction linear motor are protruded out of the worktable and are fixed to the first driving device mounting portion. The numerical control equipment has the advantage that a workpiece is convenient to hoist.

Owner:杨东佐

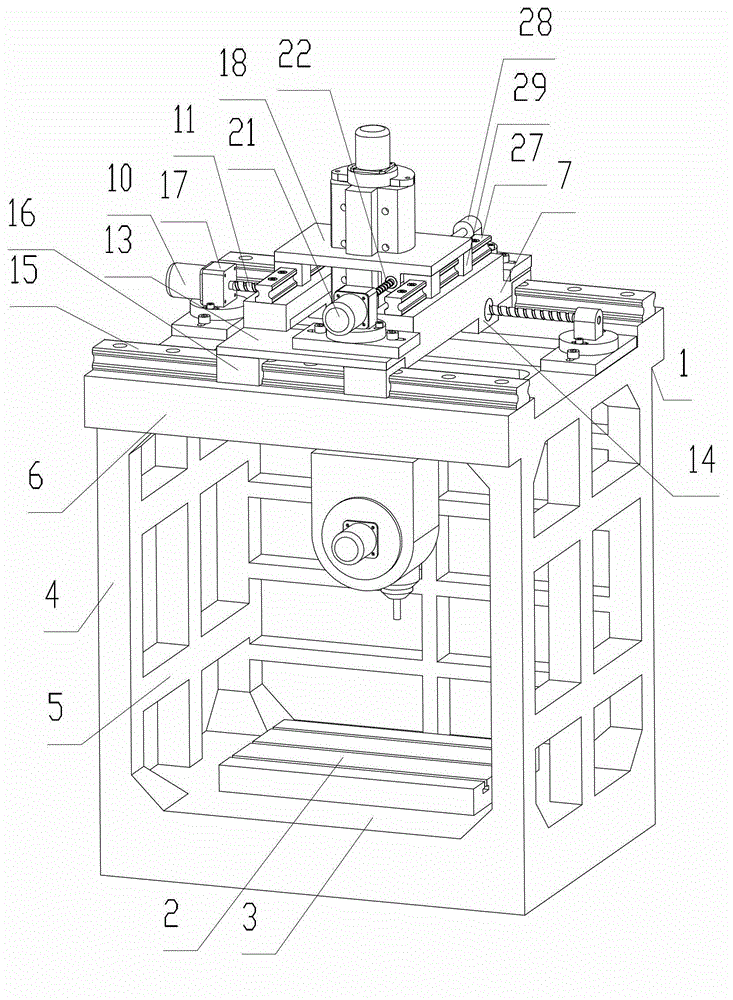

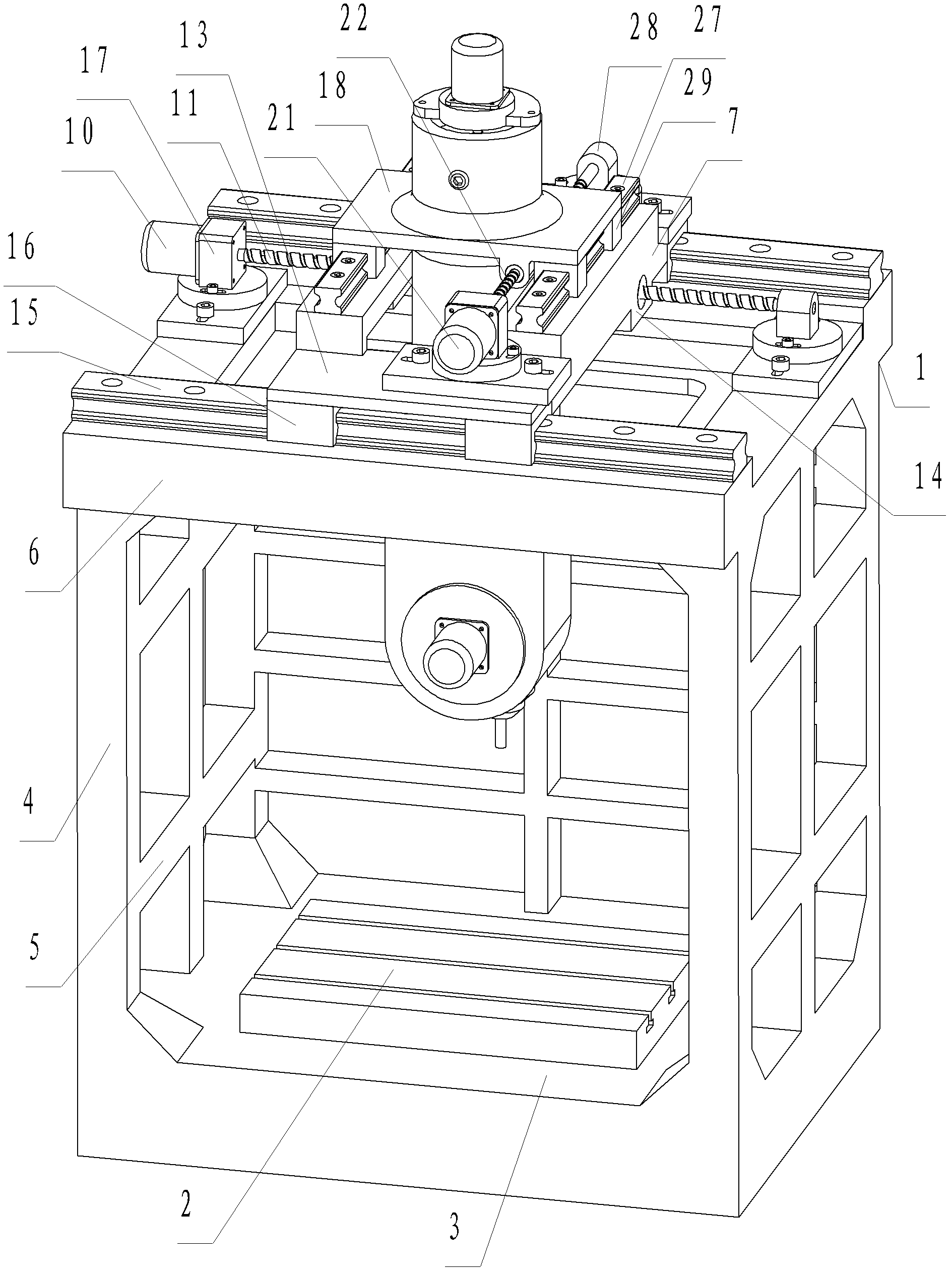

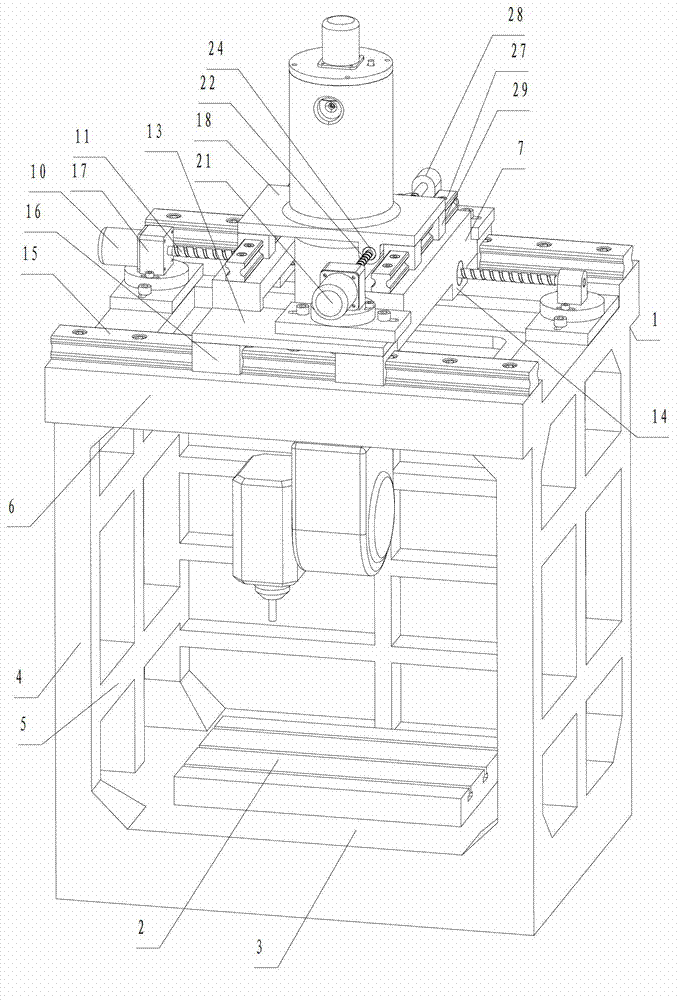

Numerical control equipment, machining process, numerical control production line and automatic article storage system

InactiveCN102528567AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersProduction lineNumerical control

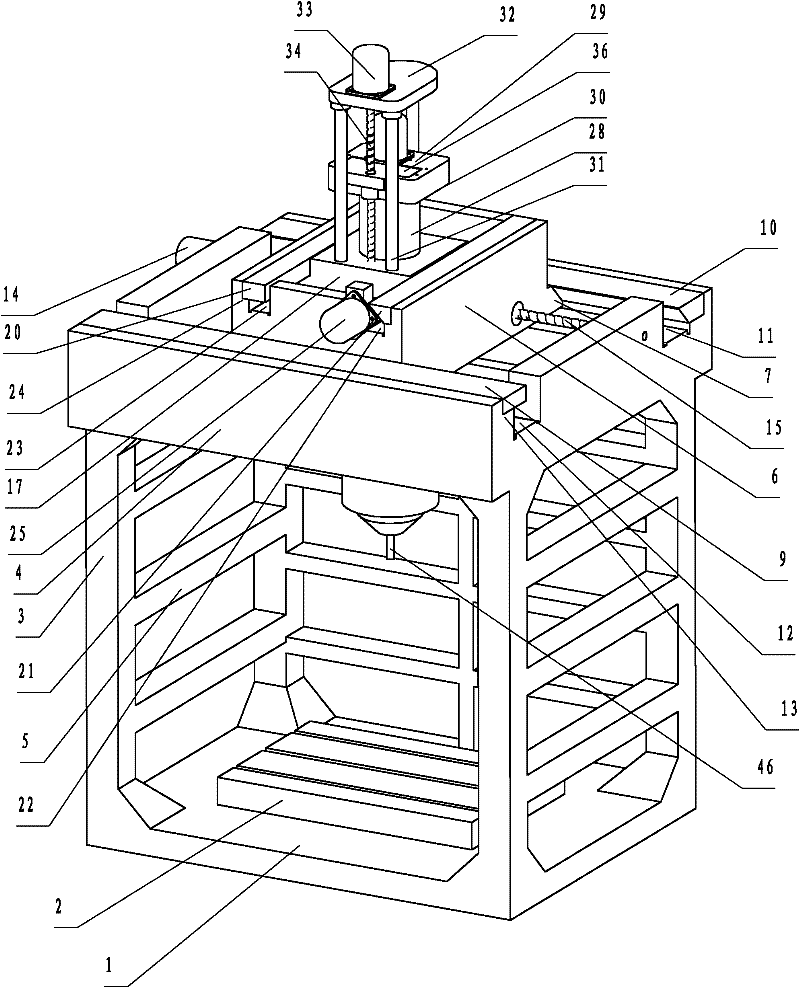

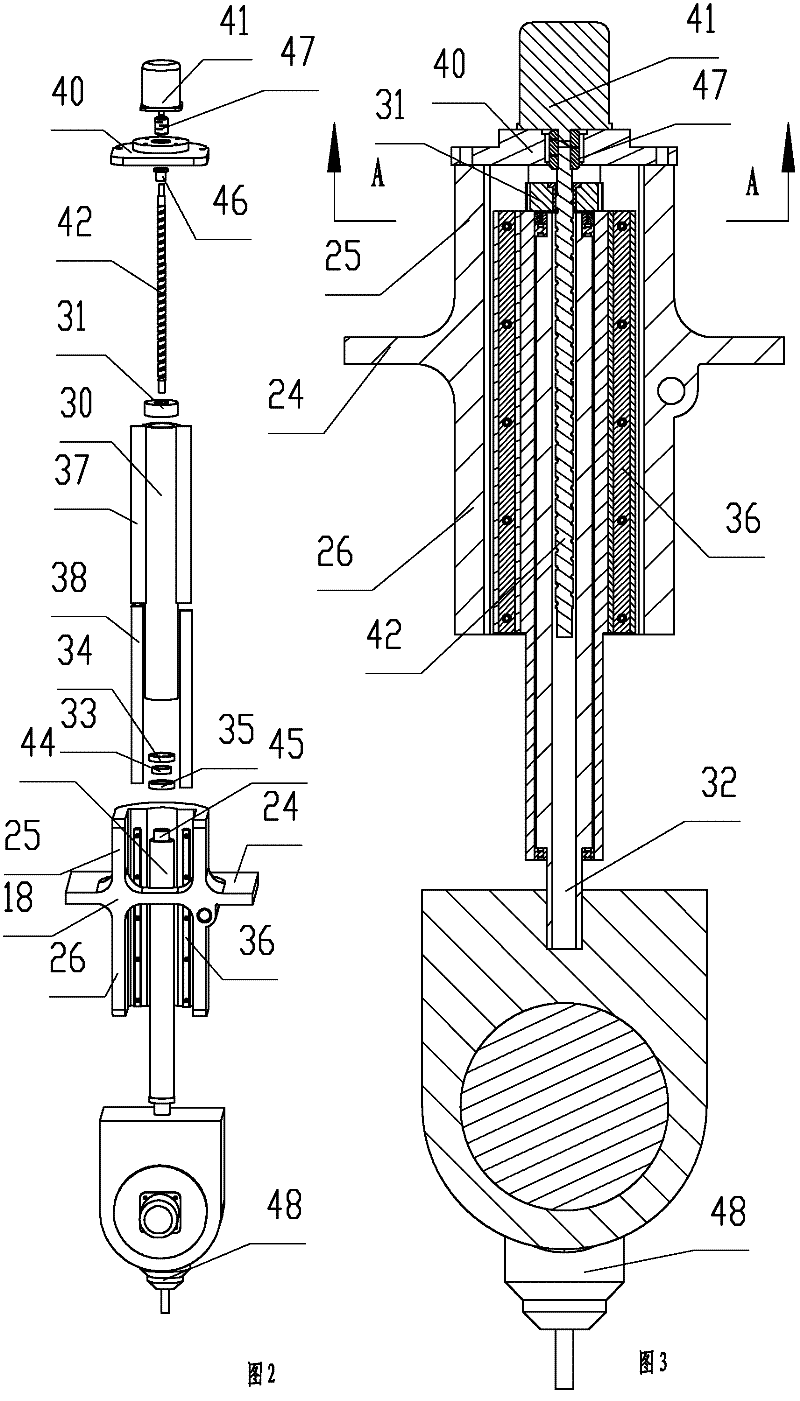

Numerical control equipment comprises a main frame, a workpiece clamping device, an X-directional sliding seat, a first driving device, Y-directional sliding seat, a second driving device and a Z-directional guide device. The main support frame is of a closed-loop structure with a vertical opening; an X-directional front guide rail and an X-directional rear guide rail which are matched with each other are arranged between the main support frame and the X-directional sliding seat; the first driving device drives the X-directional sliding seat to move back and forth and comprises an X-directional lead screw positioned between the X-directional front guide rail and the X-directional rear guide rail; the second driving device drives the Y-directional sliding seat to move back and forth; the Z-directional guide device is mounted on the Y-directional sliding seat and comprises a Z-directional guide rod capable of vertically moving, and a third driving device for driving the Z-directional guide rod to vertically move; and a main machining head is arranged at the lower end of the Z-directional guide rod. The numerical control equipment has the advantages of fine stability, accuracy in positioning and smoothness in movement, and iron scraps falling after machining a workpiece basically cannot enter the guide rail above the machining head without special protection.

Owner:杨东佐

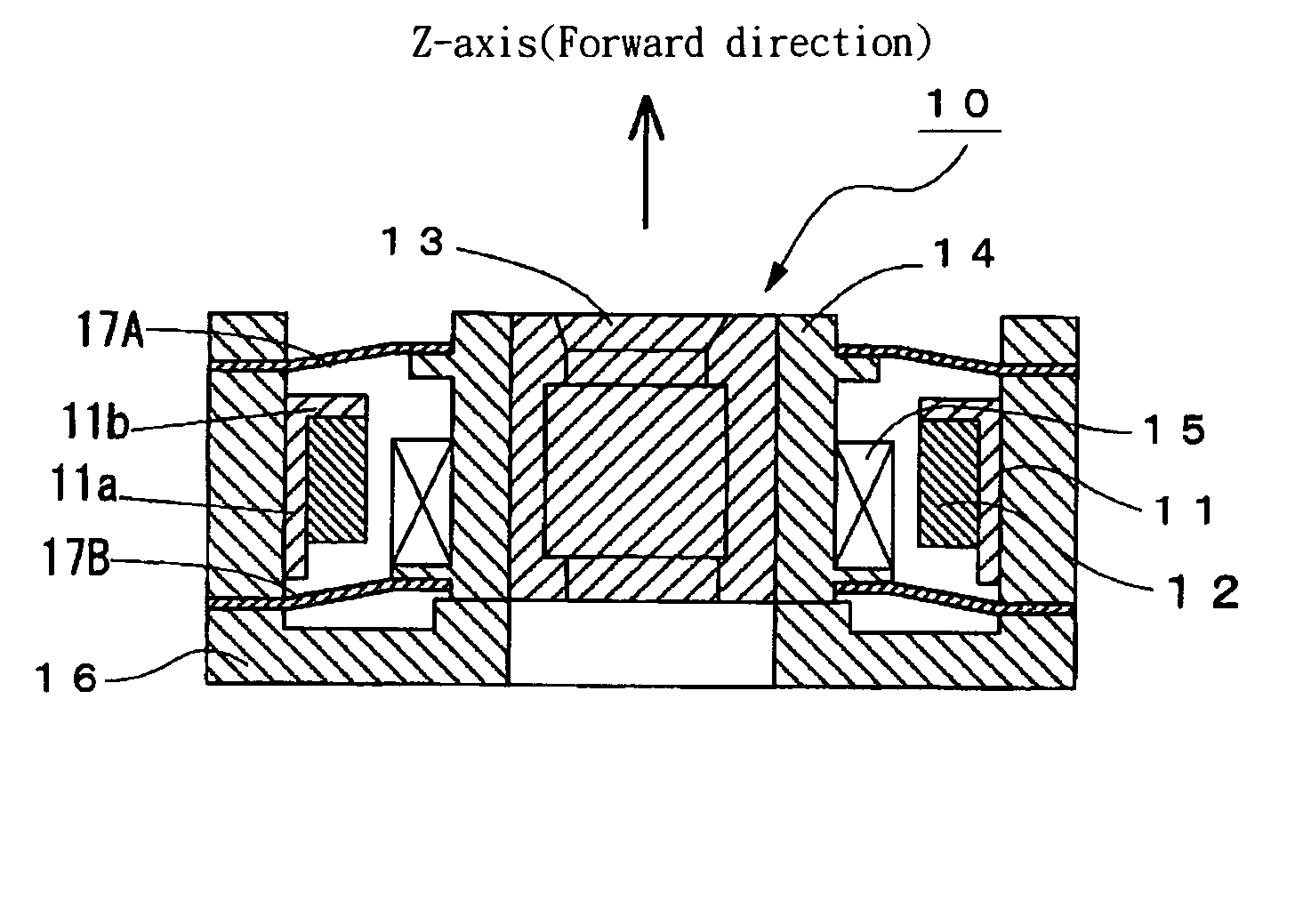

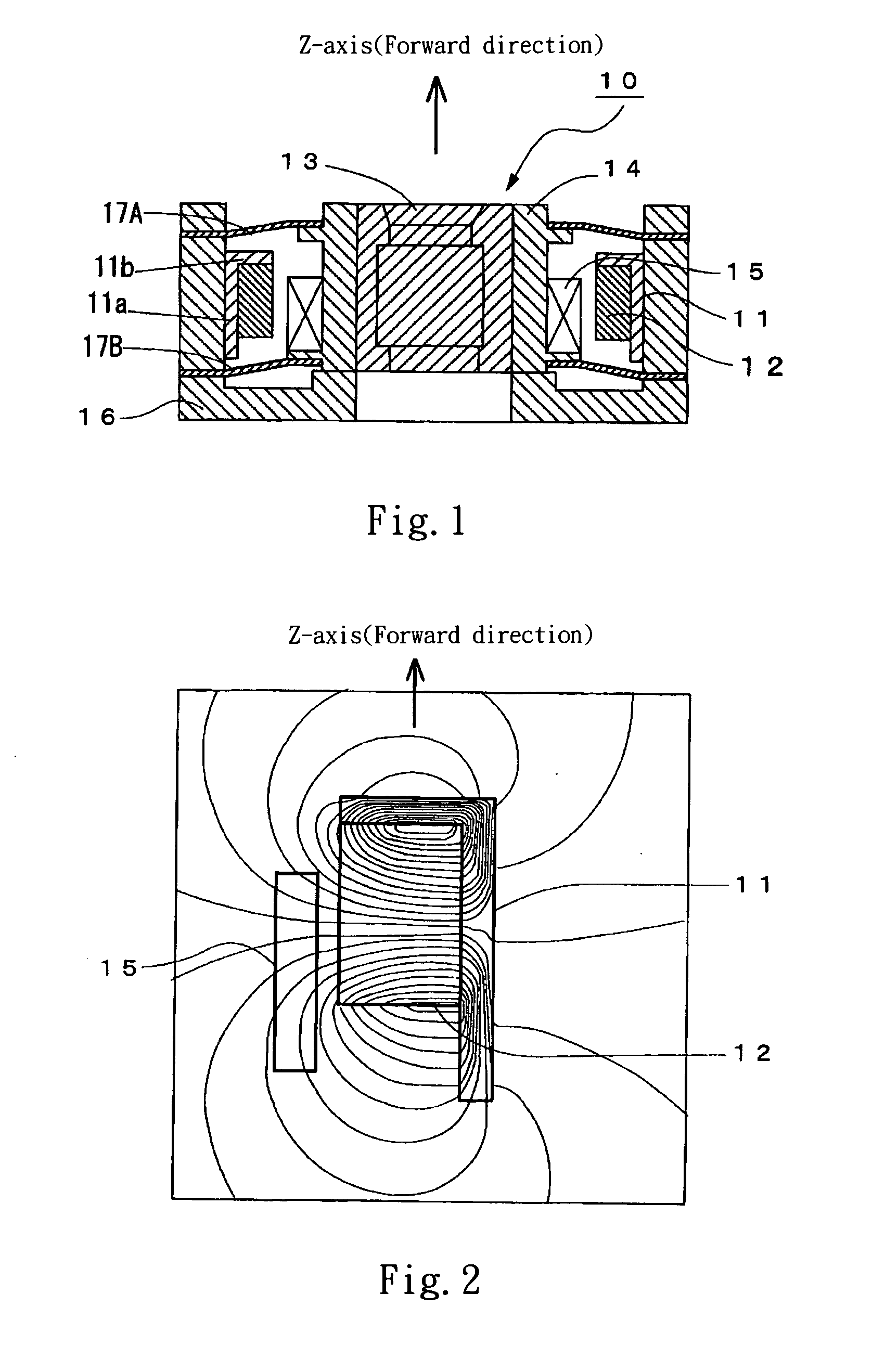

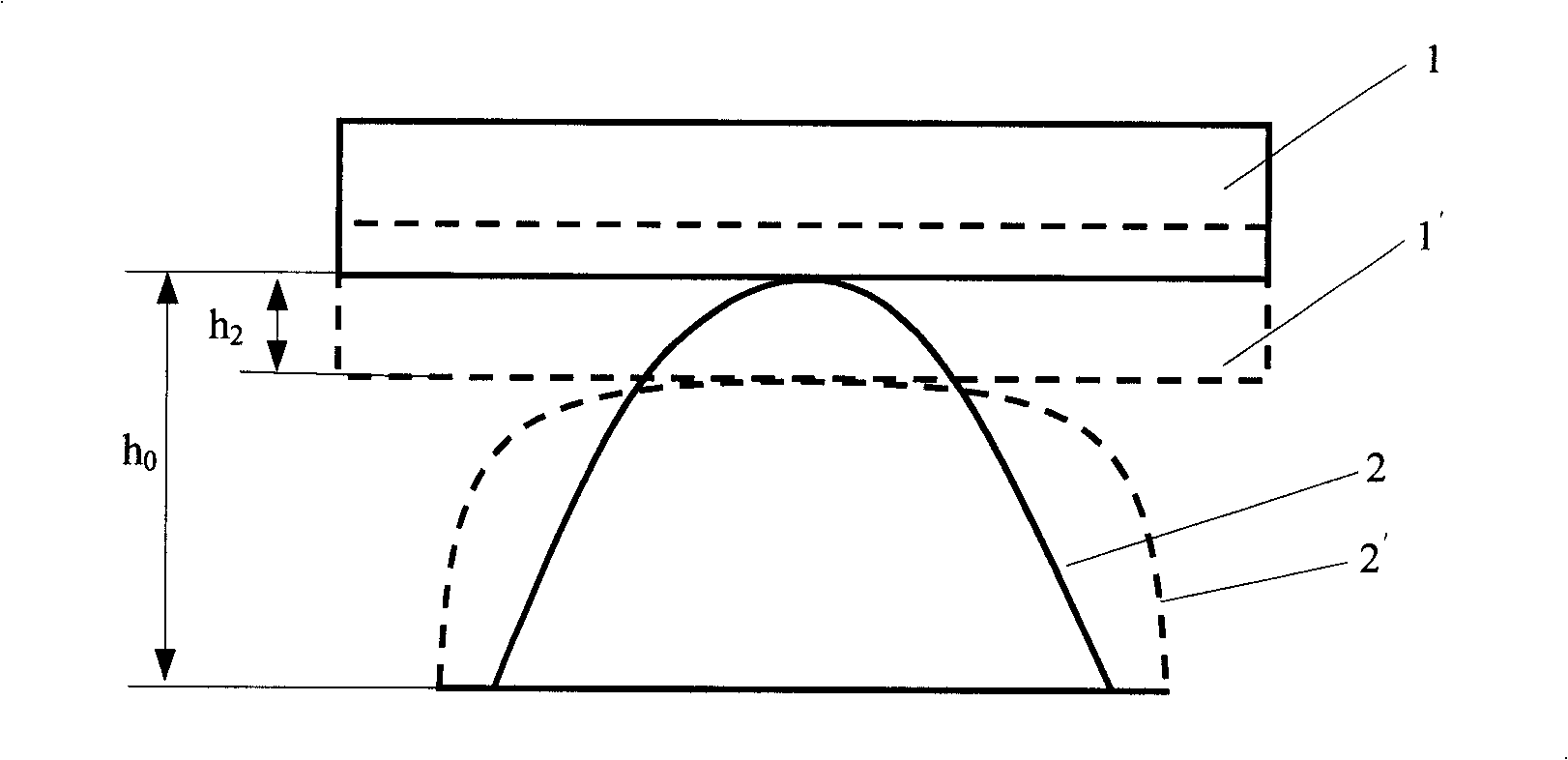

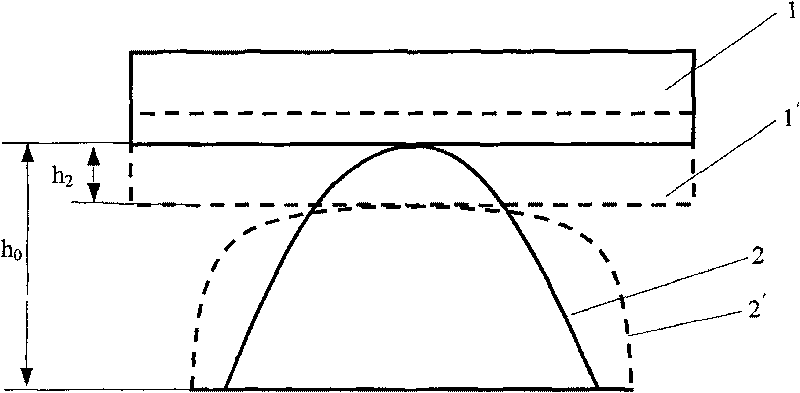

Lens driving device

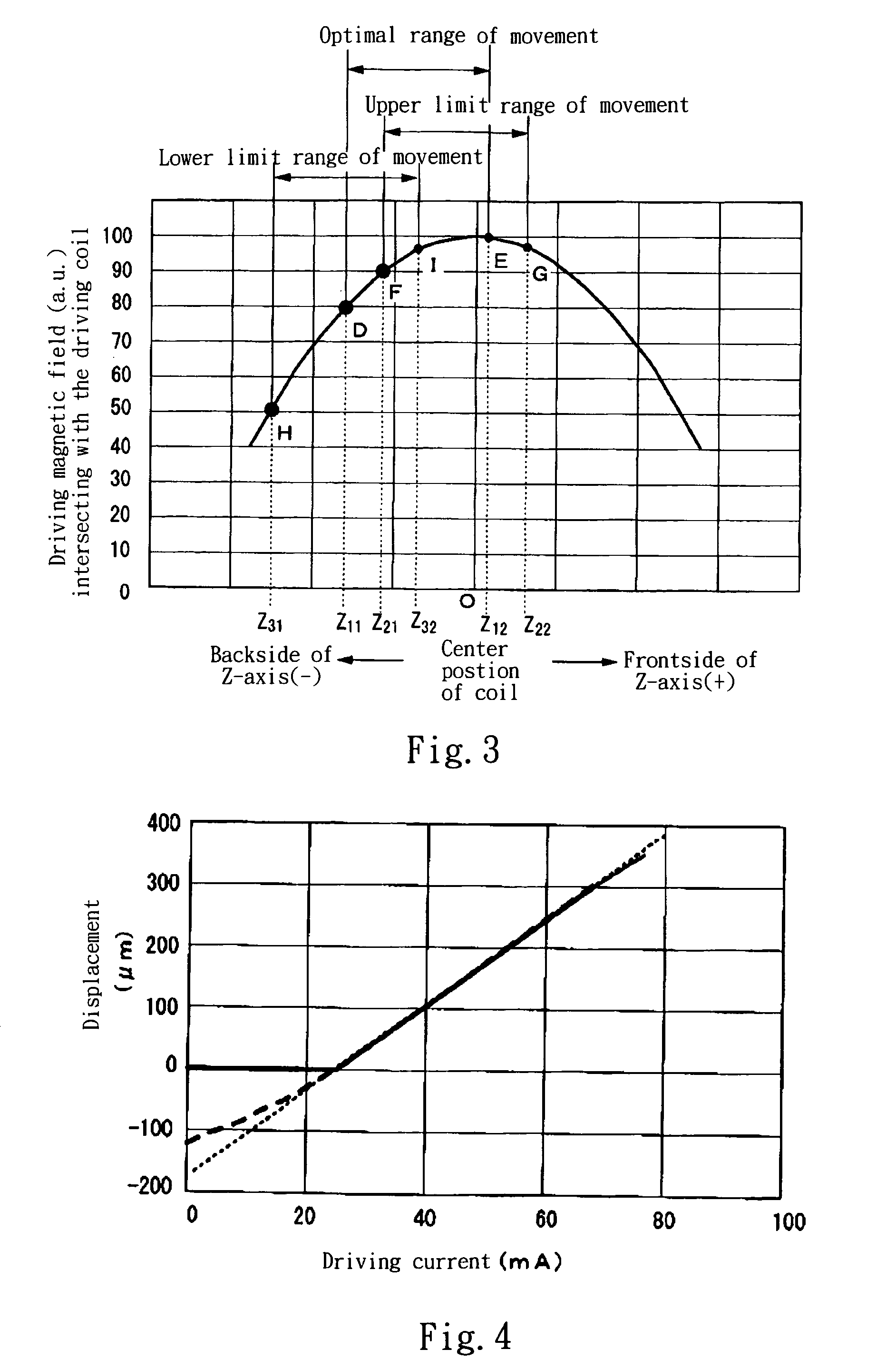

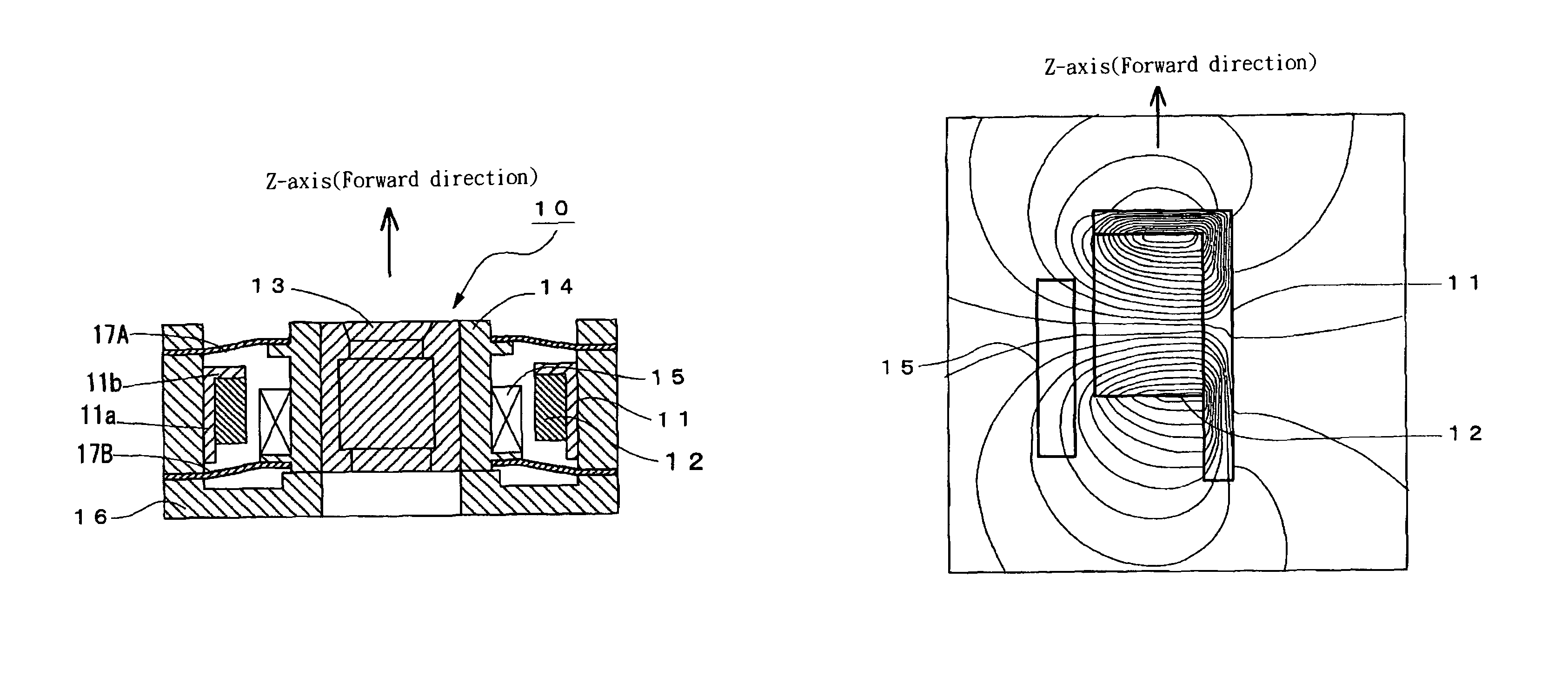

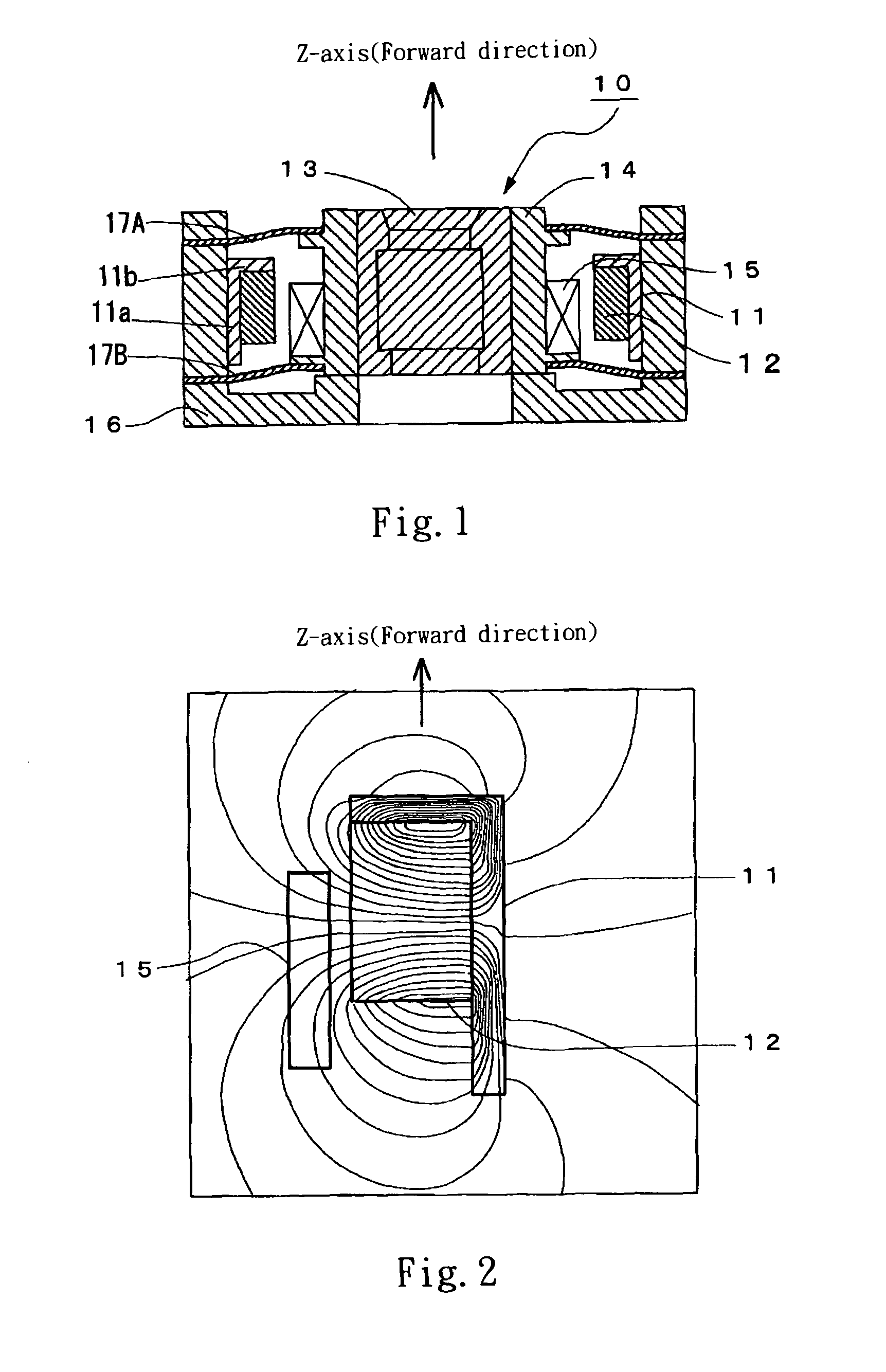

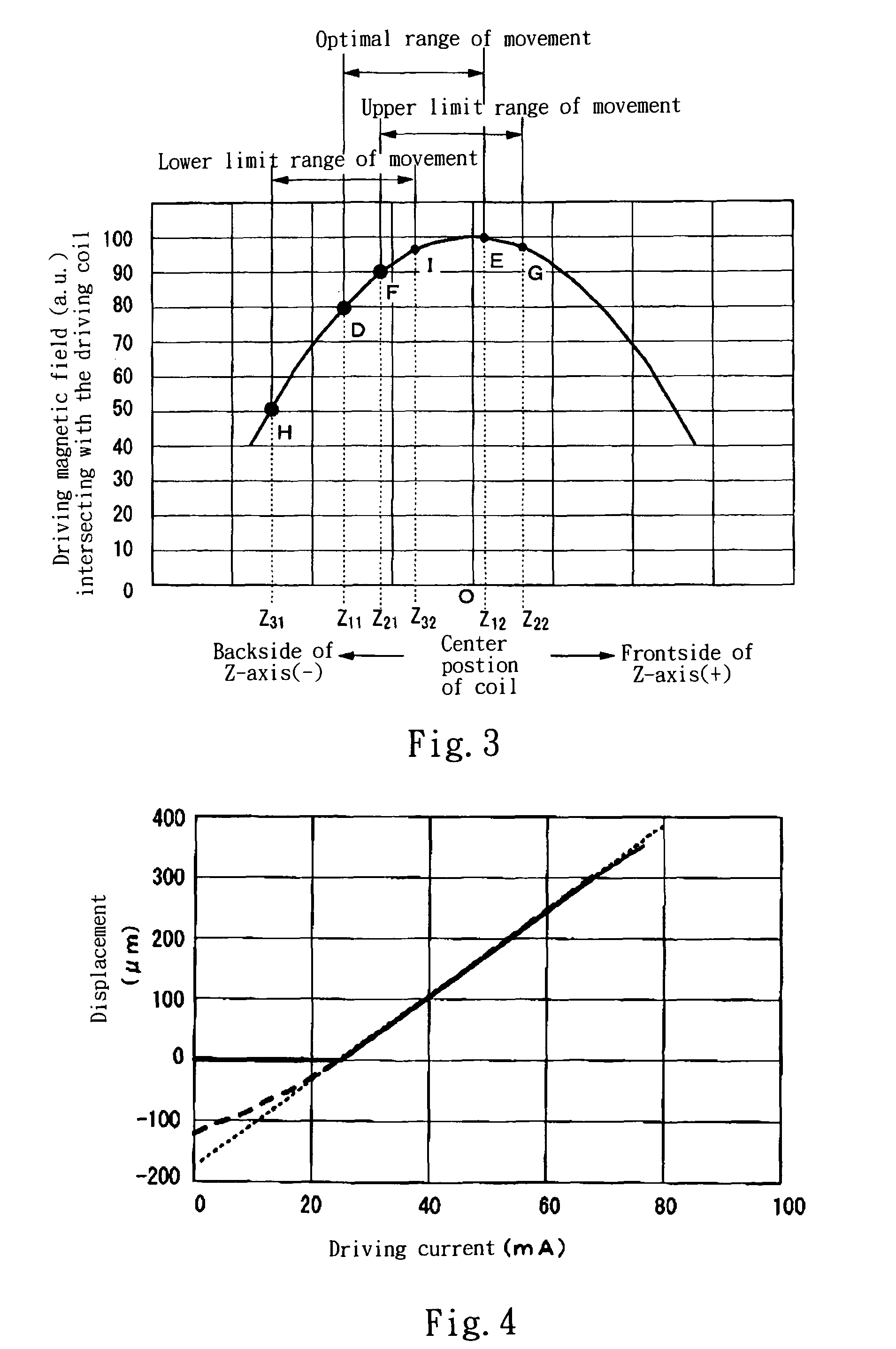

ActiveUS20100232042A1Improve linearityHigh displacement sensitivityMountingsPropulsion systemsDriving currentCamera lens

In the present invention, a lens driving device has appropriate offset for miniaturization, excellent linearity of driving current versus displacement, and good displacement sensitivity. A casing holding a yoke with at least one permanent magnet mounted on an inner circumference thereof is connected with a lens holder having a driving coil installed on an outer sidewall thereof between an upper spring member and a lower spring member. When the driving coil is not powered, the lens holder props against the casing at a side opposite to an imaged object. When the lens holder props against the casing, the position of the driving coil along Z axis causing a magnitude of driving magnetic field intersecting with the driving coil is 50%˜90% of a maximum value of the driving magnetic field intersecting with the driving coil while the lens holder moves toward the imaged object.

Owner:MICRO WIN TECH +2

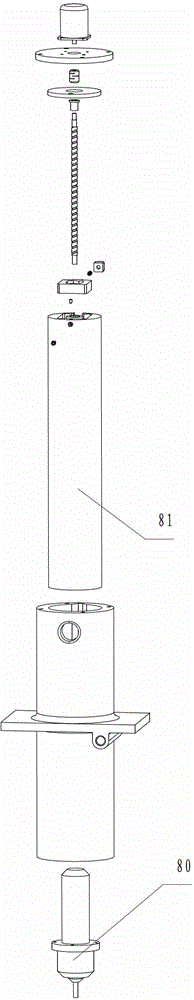

Numerical control equipment

InactiveCN102528568AGuaranteed shape and position accuracyImprove carrying capacityFeeding apparatusLarge fixed membersNumerical controlEngineering

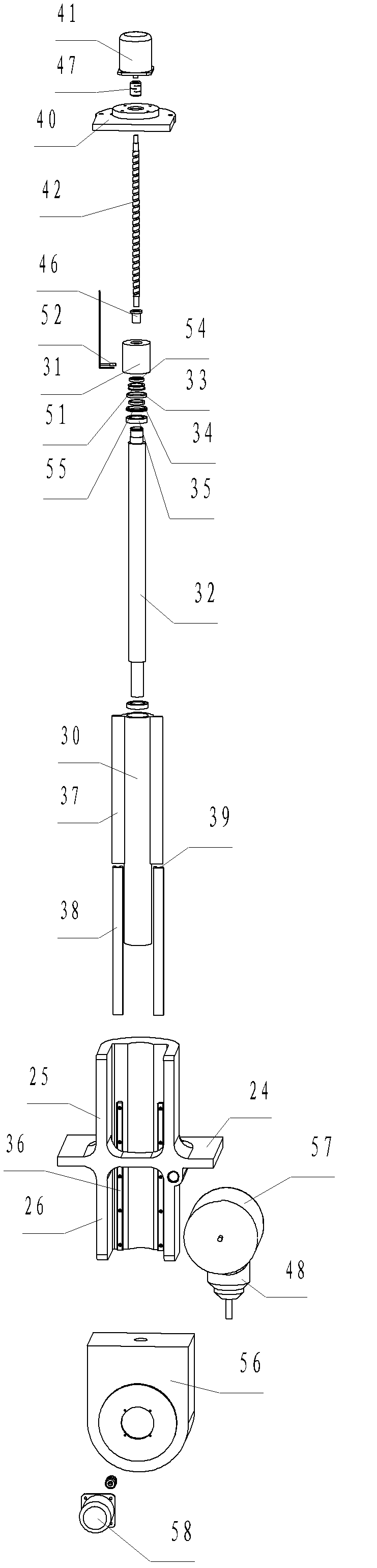

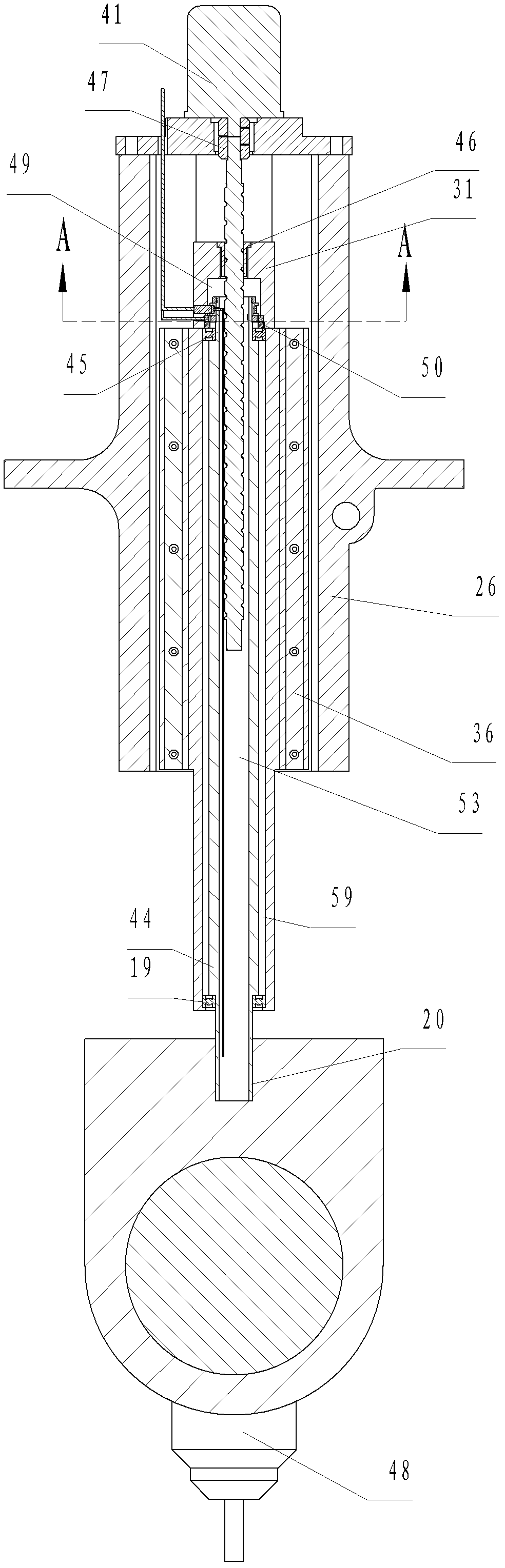

Numerical control equipment comprises a Z-directional guide device, a sliding seat, a sliding seat fixing device, a sliding seat driving device, a workpiece clamping device, a main machining head and an electric control device. The Z-directional guide device is mounted on the sliding seat comprising a sliding seat bottom plate and a U-shaped part arranged on the sliding seat bottom plate; the Z-directional guide device comprises a Z-directional guide rod and a Z-directional guide rod driving device; two first Z-directional linear guide rails are fixedly arranged on a Y-directional sliding seat while second Z-directional linear guide rails are arranged on the Z-directional guide rod; the Z-directional guide rod can only be vertically and movably mounted together with the Y-directional sliding seat; and a main machining head is arranged below the Z-directional guide rod. By means of matching the first Z-directional linear guide rails with the second Z-directional linear guide rails to realize Z-directional guide, guide effects are fine, and the Z-directional guide rod no longer needs a rotation stop structure. When the first Z-directional linear guide rails and the second Z-directional linear guide rails are abraded, only the first Z-directional linear guide rails and the second Z-directional linear guide rails need to be replaced, while the Z-directional guide rod is not needed to be replaced.

Owner:杨东佐

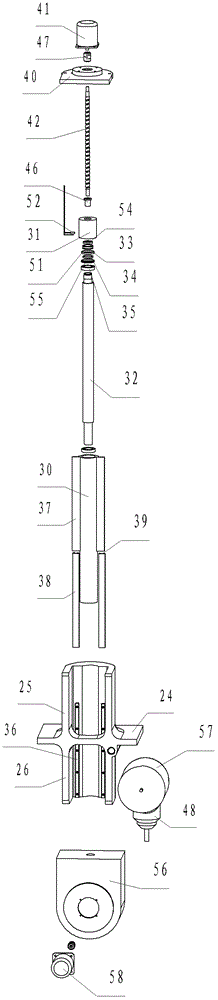

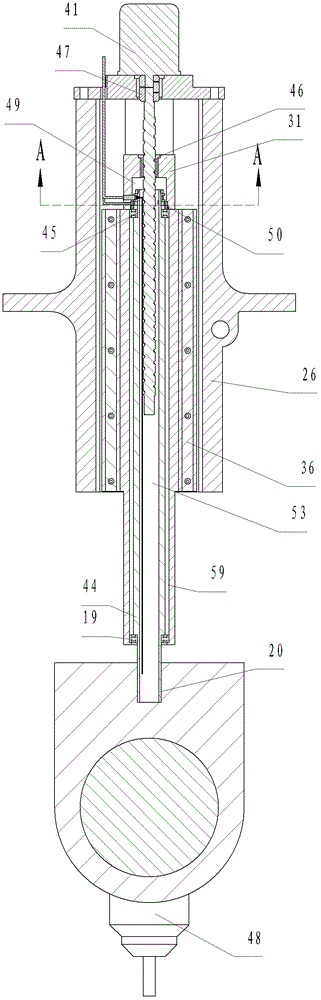

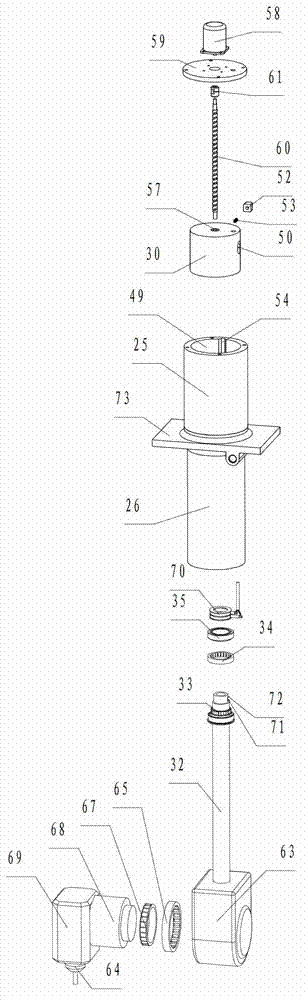

Gas/ solid two-phase composite gyration basic method and device

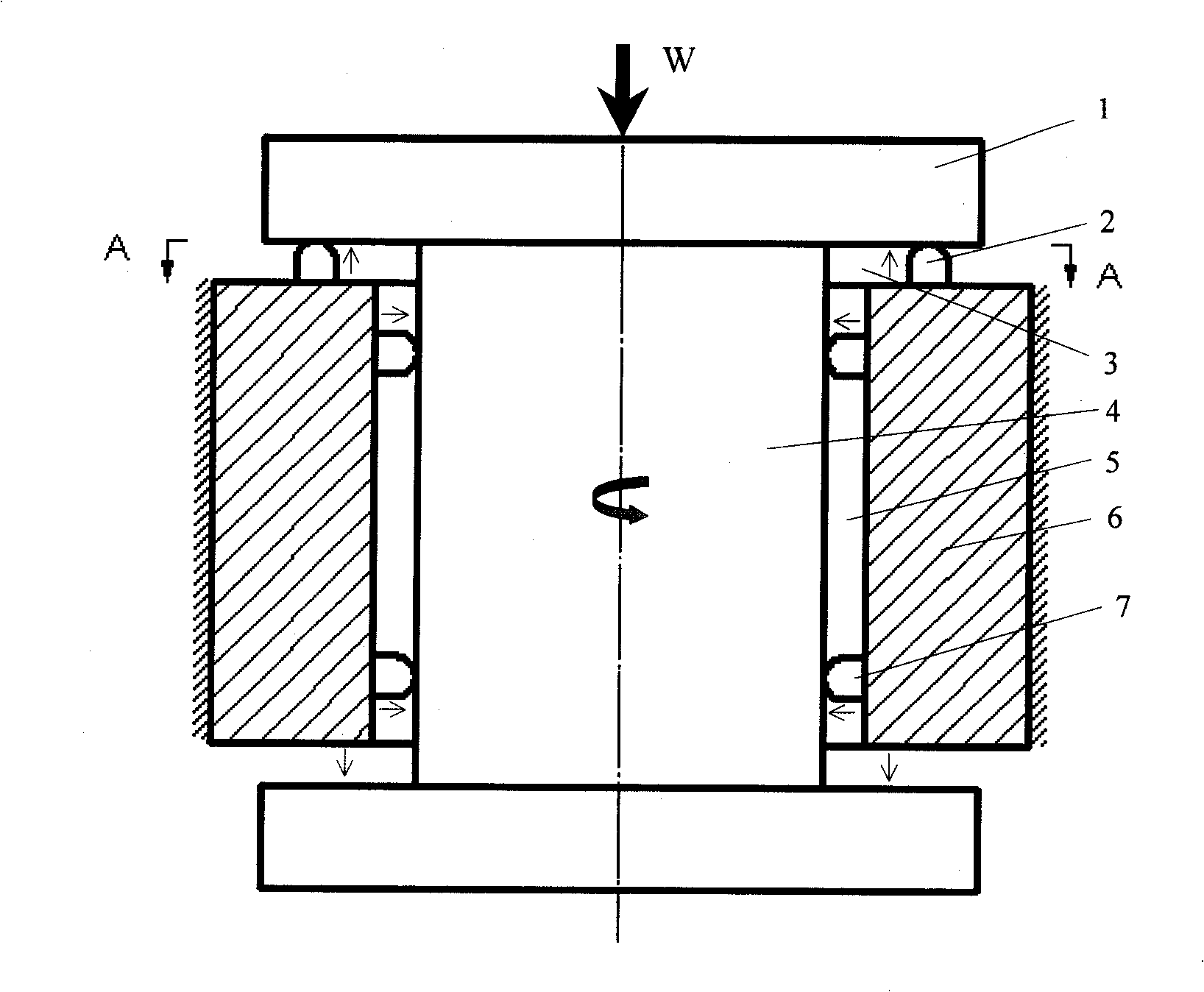

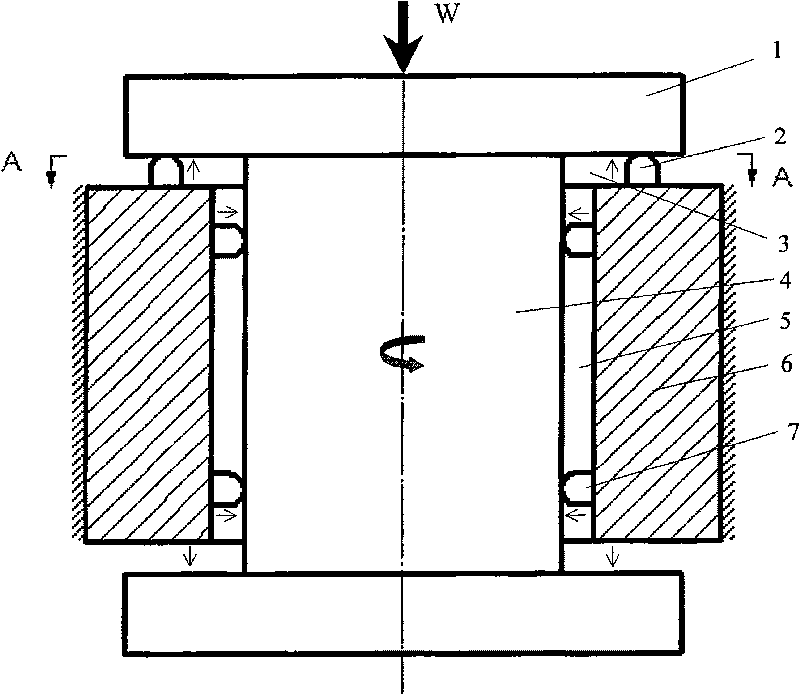

InactiveCN101338790AOvercome the shortcomings of not being able to take care of these features at the same timeImprove carrying capacityBearingsGas lubricationGas phase

The present invention relates to a gas phase / solid phase composite gyration benchmarking method and a device, which belong to the technical field of precision gyration benchmarking. The method compositely uses the gas lubricating and error averaging technology and the solid supporting and damping technology, the method applies axial solid support in the axial anti-thrust gaseous film of a gas-floated shafting to form a composite supporting mode with the primary solid support and the subsidiary gas support or the primary gas support and the subsidiary solid support or the gas support and the solid support which are the equivalent in order to notably enhance the axial rigidity and bearing capacity of the gas-floated shafting. Applying radial solid support in the radial gaseous film of the gas-floated shafting, the method utilizes the slight elastic deformation of elastic elements to dissipate the medium / high-frequency micro-vibration energy of a mainshaft and the stored deformation energy and static friction characteristic of the elastic elements to enhance positioning damp in order to increase positioning precision. In the device, the solid elastic elements are respectively assembled in the axial anti-thrust gaseous film and the radial gaseous film. The method can establish a gyration benchmark which also takes high precision, high rigidity, high support, low vibration and high displacement sensitivity into consideration.

Owner:HARBIN INST OF TECH

Numerical control equipment

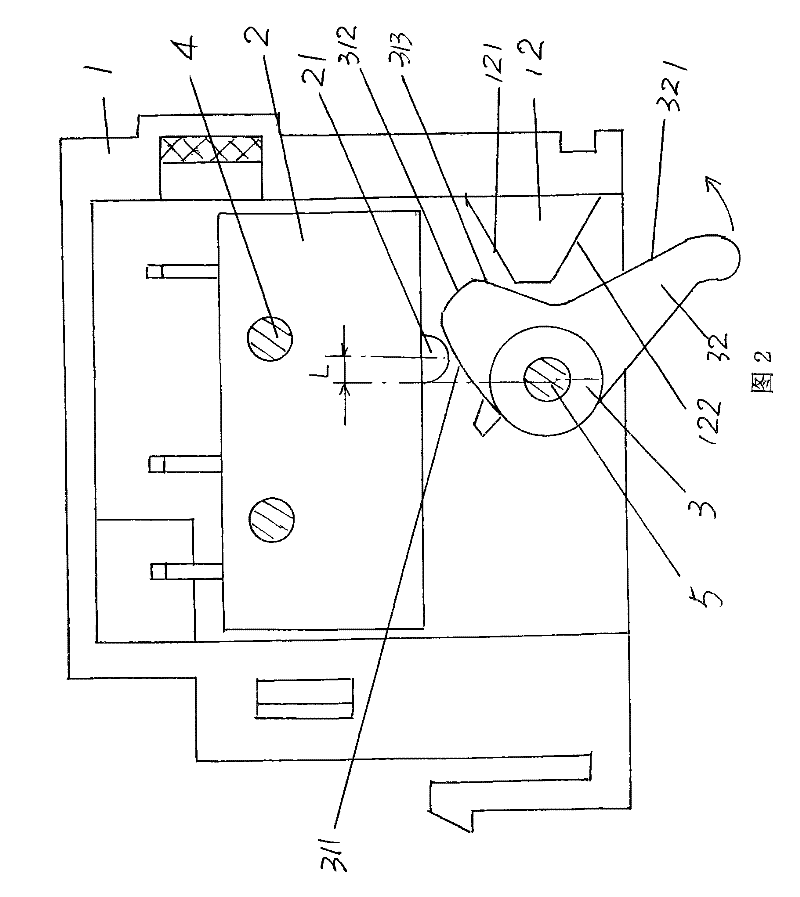

InactiveCN102941512AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersNumerical controlClosed loop

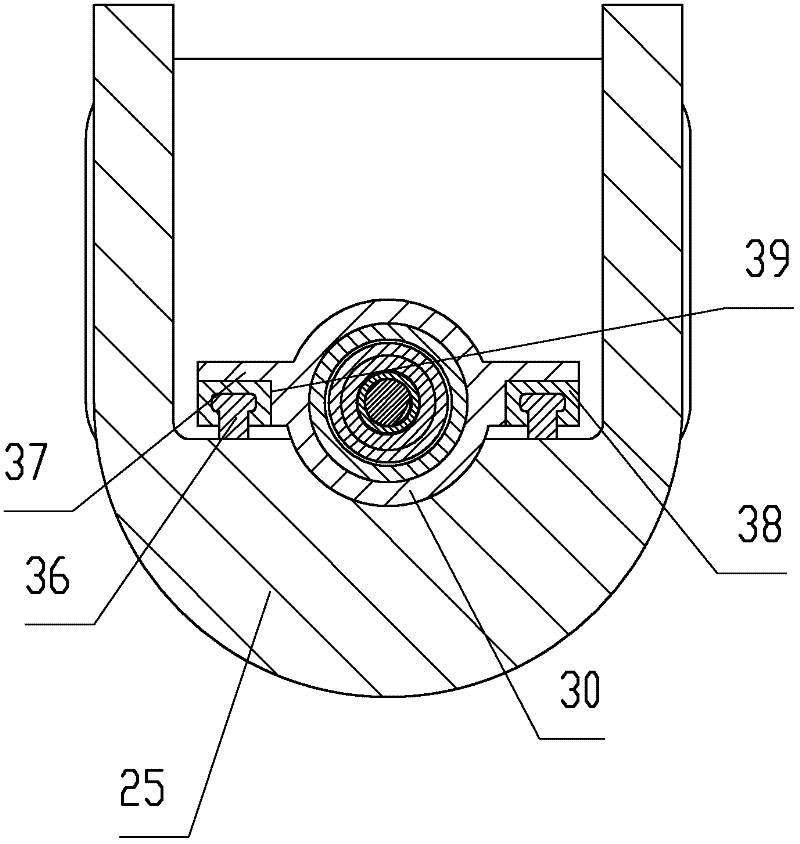

The invention provides numerical control equipment, wherein a main supporting frame is in a closed loop structure of which the opening faces the vertical direction; an X forward guide rail and an X backward guide rail which are matched with each other are arranged between the main supporting frame and an X-direction sliding seat; a Z-direction guide rod is a round guide rod; the Z-direction guide rod only can be installed together with a Y-direction sliding seat in an up-and-down movement way; a rotation stopping structure for preventing the Z-direction guide rod from rotating along the horizontal direction of the axis of the guide rod is also arranged; the rotation stopping structure comprises a third rotation stopping block, a fourth rotation stopping block, a third spring and a limit mechanism; an accommodation groove is formed in the top part of the Z-direction guide rod; the limit mechanism limits the third rotation stopping block and the fourth rotation stopping block to move in the setting range of the accommodation groove; a rotation stopping groove is formed in a guide hole matched with the Z-direction guide rod; the third spring is installed between the third rotation stopping block and the fourth rotation stopping block; and the third rotation stopping block protrudes from the outer periphery of the Z-direction guide rod and is matched with the rotation stopping groove. The numerical control equipment has the advantages that when a main processing head moves up and down, the stability is good and the imbalance torsion is not easy to generate.

Owner:杨东佐

Numerical control equipment

InactiveCN102909611AGood orientationGuaranteed shape and position accuracyFeeding apparatusLarge fixed membersNumerical controlOrbit

Numerical control equipment comprises a Z-direction guiding device, a sliding seat mounted with the Z-direction guiding device, a sliding seat fixing device, a sliding seat driving device, a workpiece clamping device and a main processing head, further comprises a Z-direction linear guiding rail accommodating hole which penetrates a Y-direction sliding seat and a convex part of the sliding seat, wherein the sliding seat comprises a sliding seat baseplate and a convex part; the convex part protrudes out of the sliding seat baseplate; a first fixing plane is arranged on the outer side surface of the convex part; the Z-direction guiding device comprises a Z-direction guiding rod and a Z-direction guiding rail driving device; one side surface of the Z-direction linear guiding rail accommodating hole is a second fixing plane parallel to the first fixing plane; two first Z-direction linear guiding rail orbits are fixed on the second fixing plane; second Z-direction linear guiding rail orbits are arranged on the Z-direction guiding rod; and the main processing head is arranged under the Z-direction guiding rod. The numerical control equipment has the advantages that the guiding effect is good; a rotating prevention structure is required to be designed additionally; and when the first Z-direction linear guiding rail orbits and the second Z-direction linear guiding rail orbits are abraded, all that is needed is to replace the first Z-direction linear guiding rail orbits and the second Z-direction linear guiding rail orbits.

Owner:杨东佐

Numerical control equipment

InactiveCN102554712APrevent rotationSimple structureFeeding apparatusLarge fixed membersNumerical controlEngineering

Owner:杨东佐

Numerical control equipment

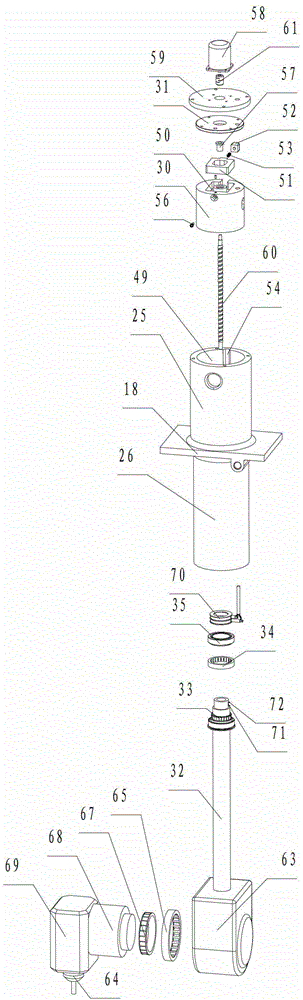

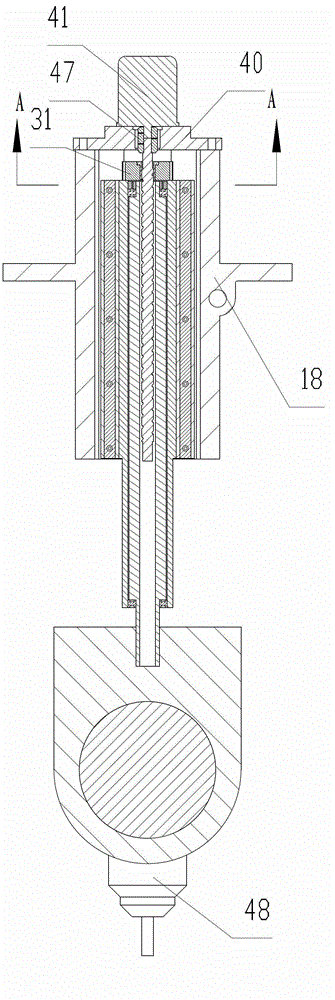

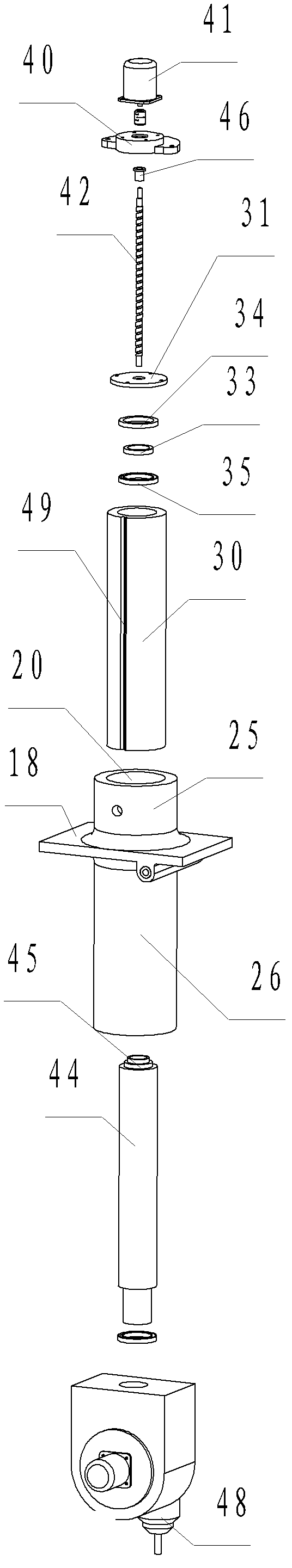

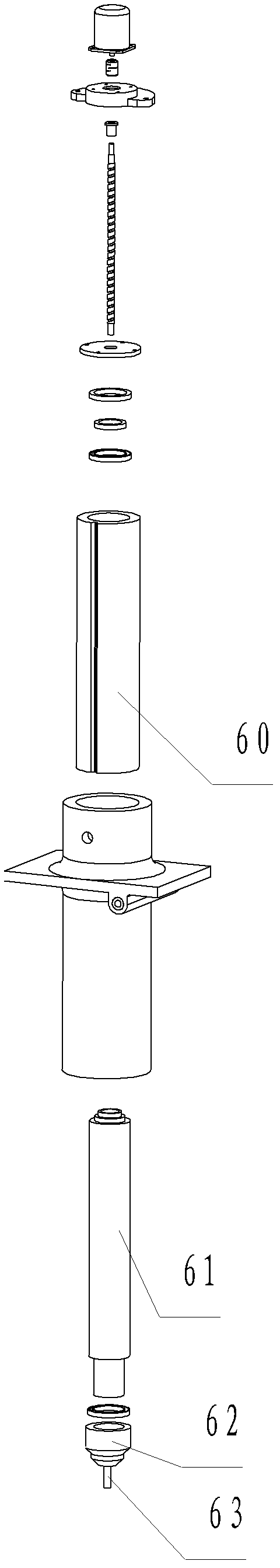

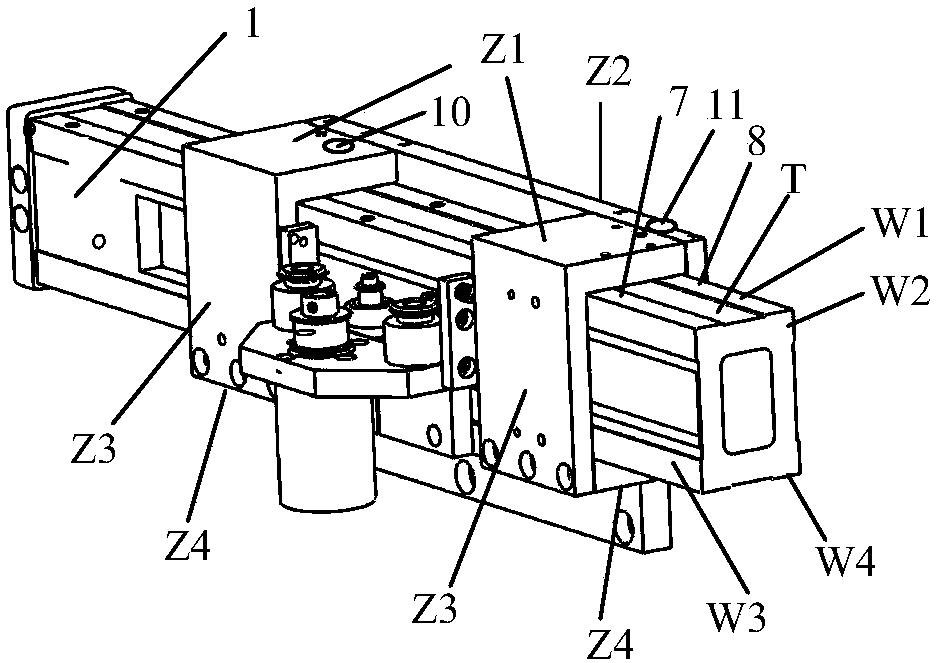

ActiveCN102717306AHigh displacement sensitivityLow driving powerFeeding apparatusLarge fixed membersNumerical controlElectric machine

Numerical control equipment comprises a spindle device, a slide seat, a slide seat driving device, a workpiece clamping device and a main processing head, wherein Z-direction guide rod is mounted together with the slide seat only in a up-and-down moving manner; a rotating shaft is arranged in the Z-direction guide rod and can only rotate relative to the Z-direction guide rod; a Z-direction screw rod nut is fixed with the Z-direction guide rod; a conducting ring is arranged on the circumference of the rotating shaft; an electric wire accommodating hole or electric wire accommodating groove communicated with the conducting ring is formed in the rotating shaft; an electric wire is accommodated in the electric wire accommodating hole or electric wire accommodating groove; a swinging seat is formed integrally or fixed at the lower end of the rotating shaft; one end of the electric wire is electrically connected with the conducting ring; the other end of the electric wire is electrically connected with a main processing head driving motor and a swing shaft driving device which are mounted on the rotating shaft; the conducting ring is in triboelectric connection with an electric brush electrically connected an external power supply; and the electric brush is fixed with the Z-direction guide rod. The numerical control equipment has the advantages that the rotating shaft can rotate continuously by 360 degrees, and the electric wire connected with a main shaft motor and a rotating shaft driving device is prevented from being twisted off.

Owner:广东省仁丰五金电器有限公司

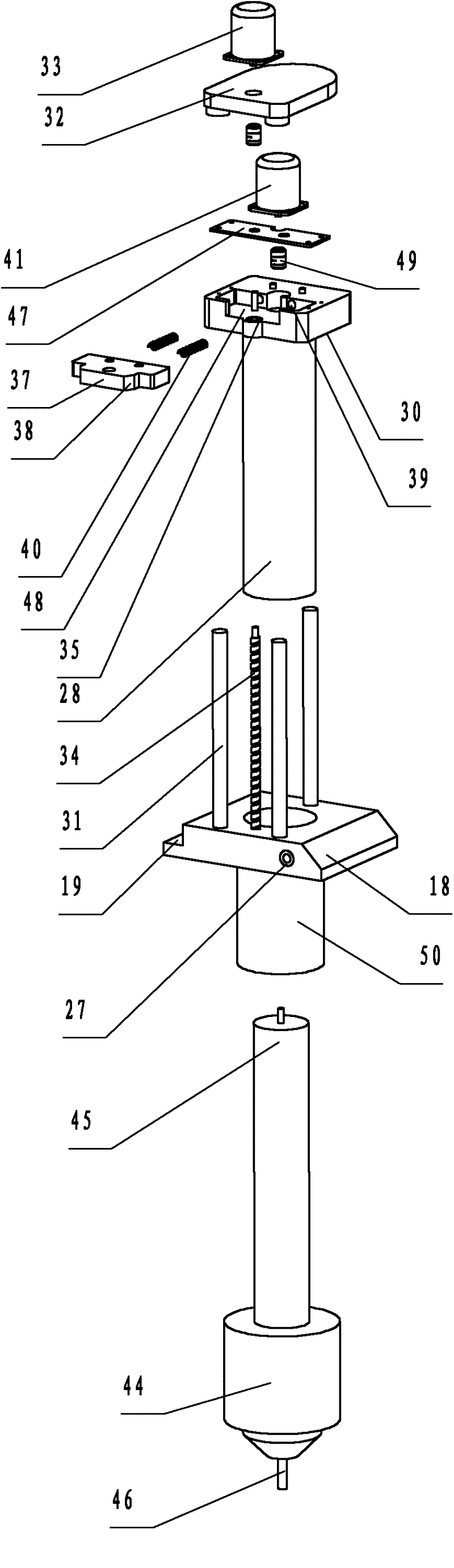

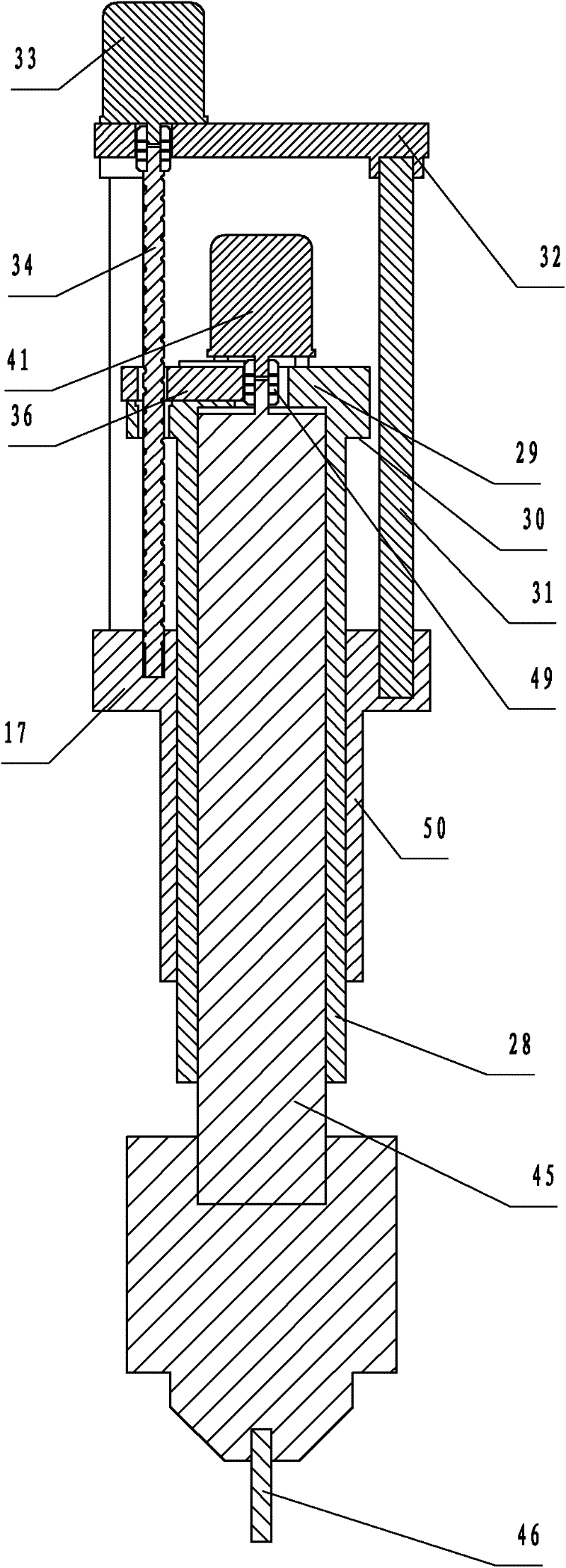

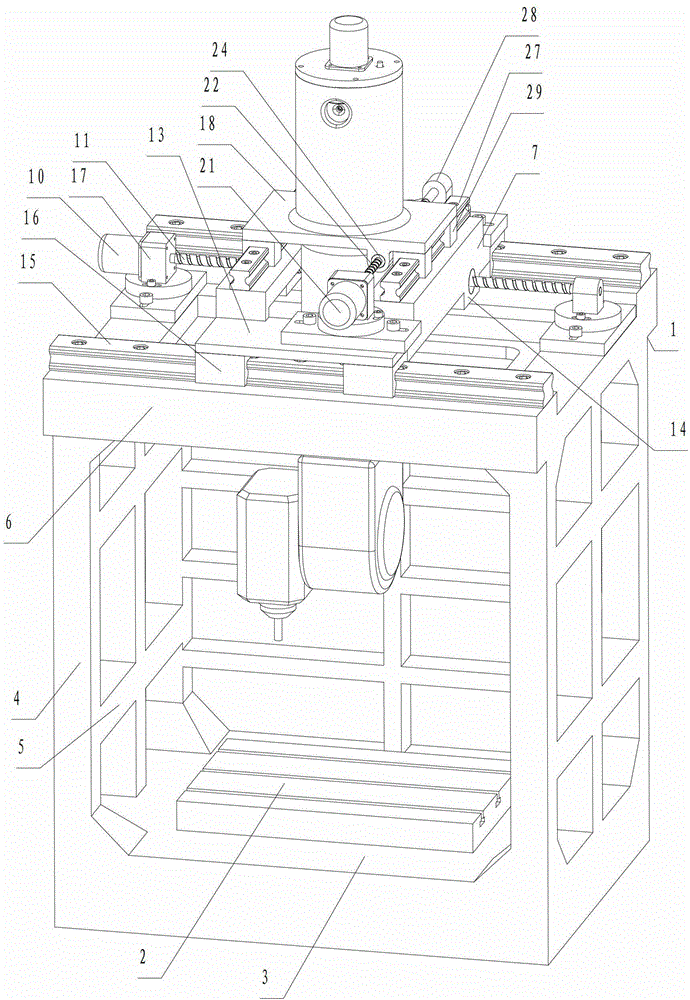

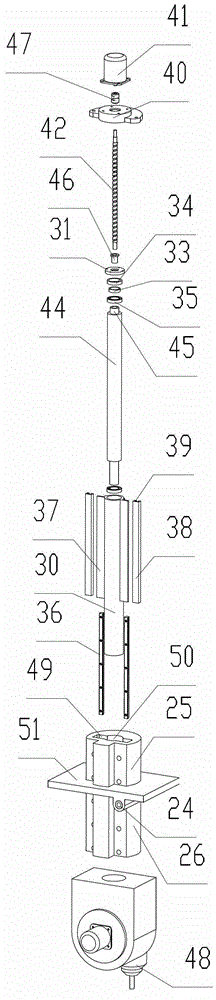

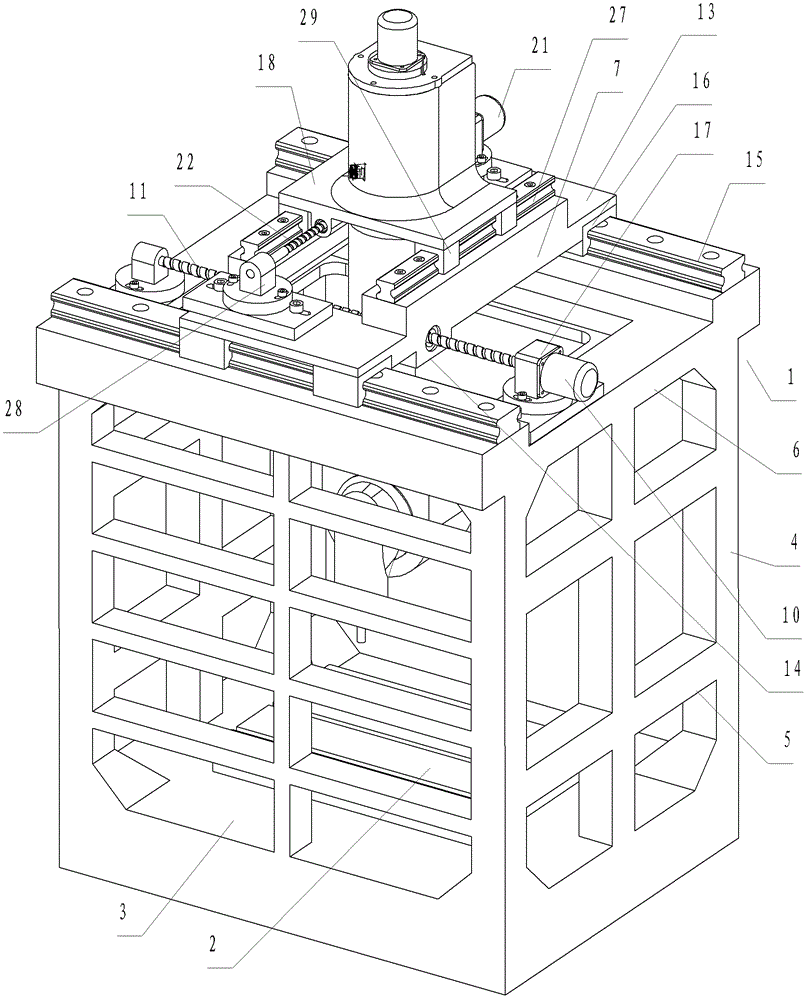

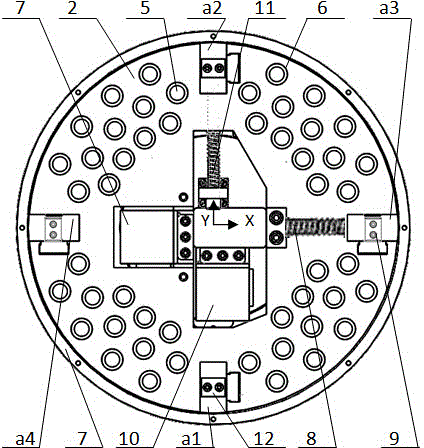

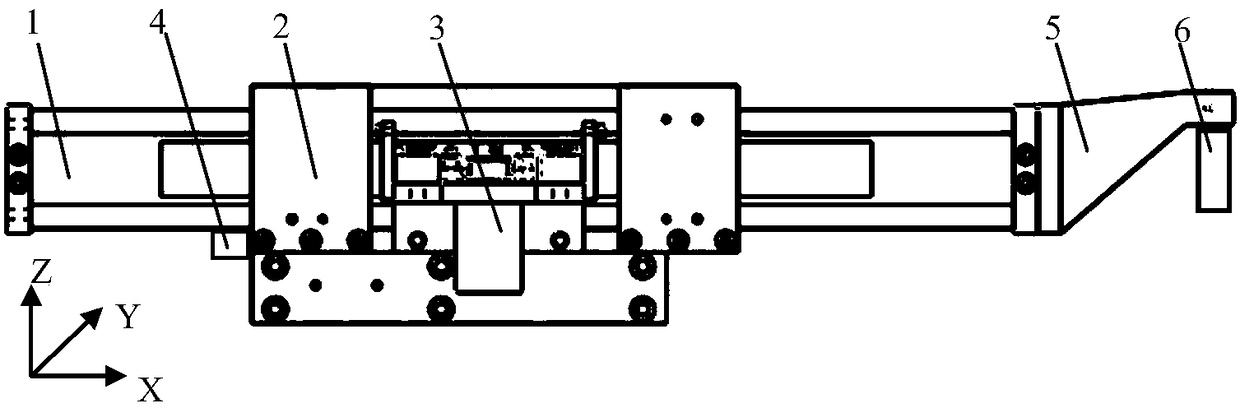

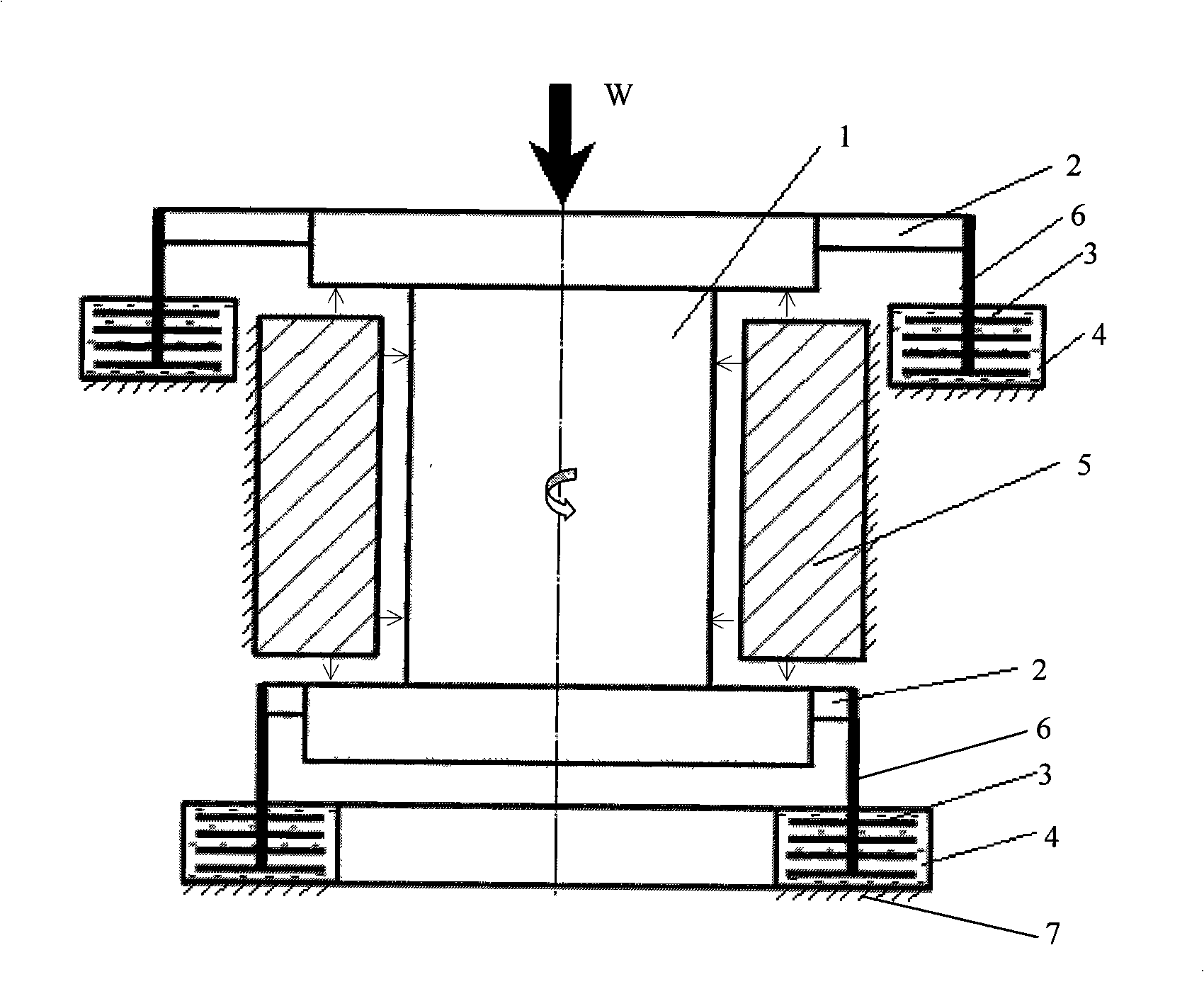

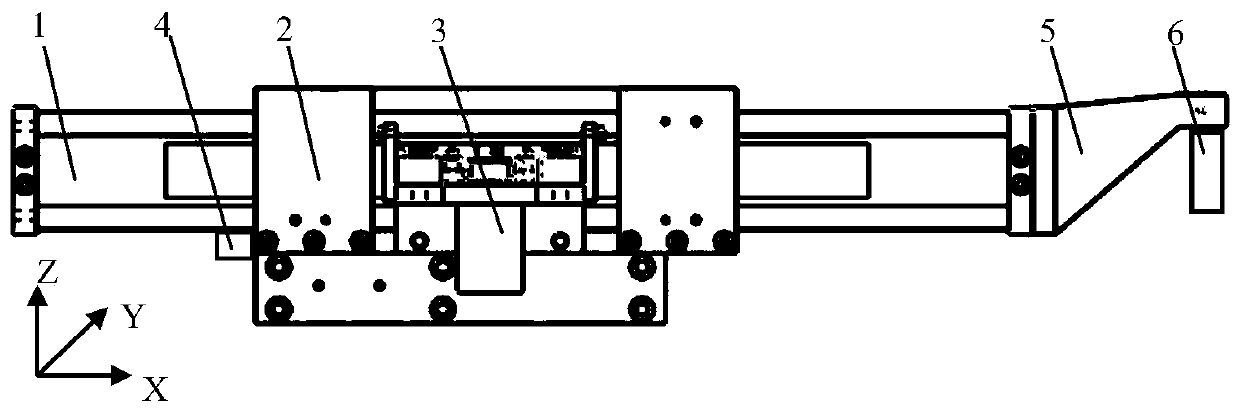

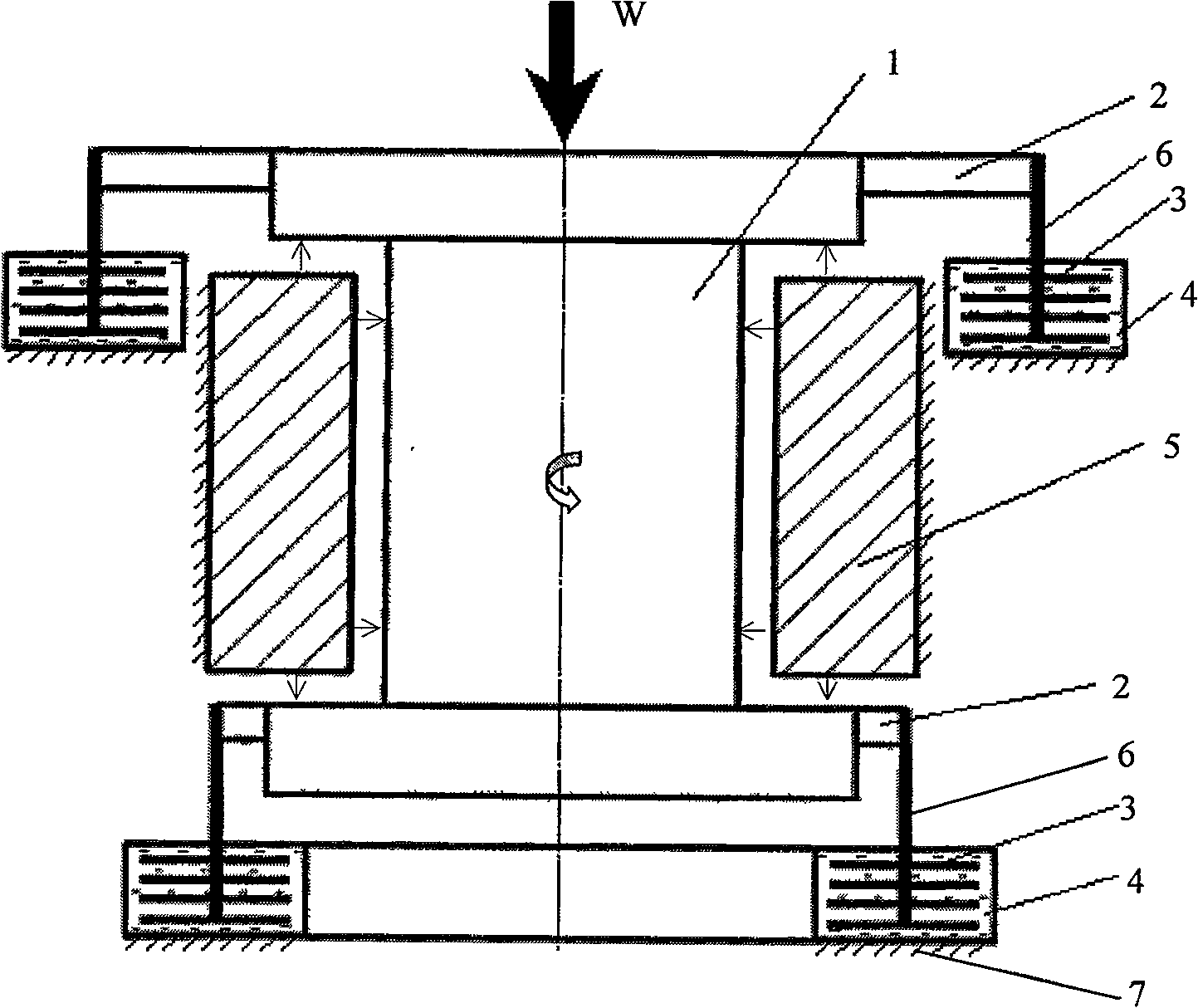

Integrative aligning method and device for aero-engine assembly and measurement based on dense ball rolling supporting

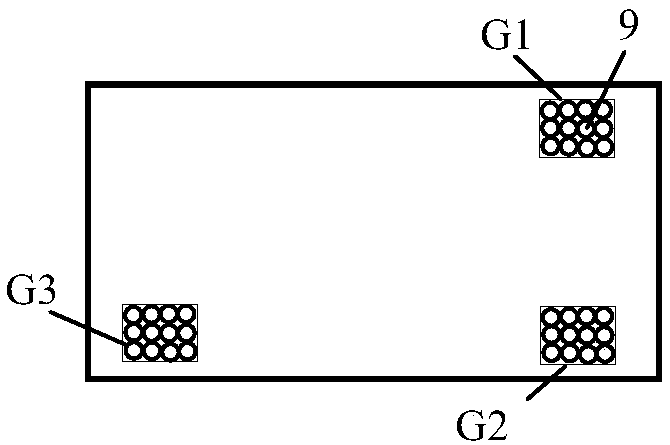

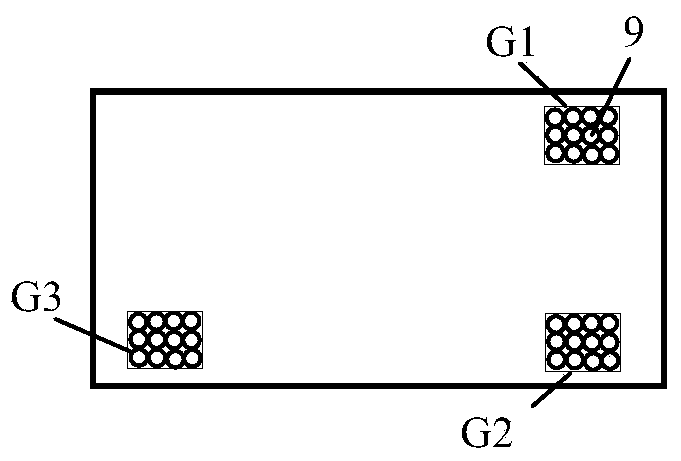

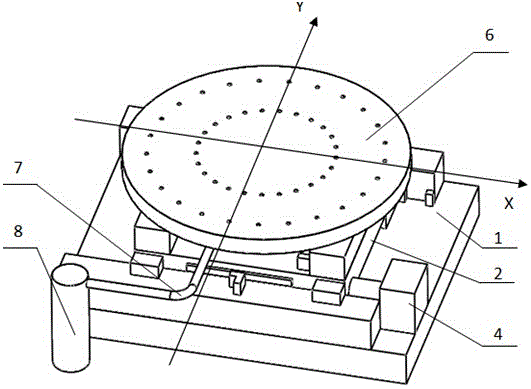

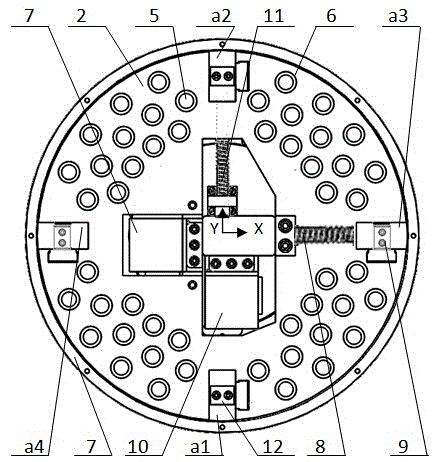

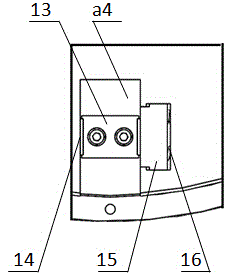

ActiveCN104400414AHigh displacement sensitivityHigh precisionMetal working apparatusAviationRolling resistance

The invention provides an integrative aligning method for aero-engine assembly and measurement based on dense ball rolling supporting and an integrative aligning device for the aero-engine assembly and measurement based on the dense ball rolling supporting. The method is characterized by being realized through the combined motion of a round bottom disc, an interlayer and a motion table; the interlayer is arranged between the motion table and the round bottom disc; small holes are fully distributed in the interlayer; ball type rolling bodies are respectively embedded into the small holes; when the motion table moves along an X direction, the round bottom disc and the interlayer are kept static, the rolling friction is implemented between the round bottom disc and the motion table, and an X-direction guiding system is matched with guiding grooves in the interlayer to play a role in guiding; when the motion table moves along a Y direction, the round bottom disc is kept static, the interlayer and the motion table synchronously move, the rolling friction is implemented between the round bottom disc and the interlayer, and a Y-direction guiding system is matched with guiding grooves in the interlayer to play a role in guiding. According to the aligning method and the aligning device, a two-dimensional motion adjusting device combining high precision, high stability and great load is established.

Owner:HARBIN INST OF TECH

Numerical control equipment

InactiveCN102962730AImprove carrying capacityImprove rigidityFeeding apparatusMetal working apparatusNumerical controlClosed loop

The invention relates to numerical control equipment. A main support frame is in a closed loop structure, and the opening of the structure faces towards the vertical direction; an X-direction front guide rail and an X-direction back guide rail which are mutually matched are arranged between the main support frame and an X-direction sliding seat; a Z-direction guide rod is a round guide rod, and the Z-direction guide rod only can be installed together with a Y-direction sliding seat in an up-and-down movement way; the numerical control equipment is further provided with a rotation stopping structure which is used for preventing the Z-direction guide rod from rotating along the horizontal direction of the axial line of the guide rod; the rotation stopping structure comprises a third rotation stopping block and a third spring; a blind hole is formed in the side surface of the Z-direction guide rod; a rotation stopping groove which is matched with the third rotation stopping block is formed in a guide hole which is matched with the Z-direction guide rod; the third spring is installed between the bottom surface of the blind hole and the third rotation stopping block; and one side of the third rotation stopping block, which is far from the spring, is protruded out of the periphery of the Z-direction guide rod and matched with the rotation stopping groove. The numerical control equipment has the advantages of good stability and difficulty in generating unbalanced torque when a main processing head is moved up and down.

Owner:杨东佐

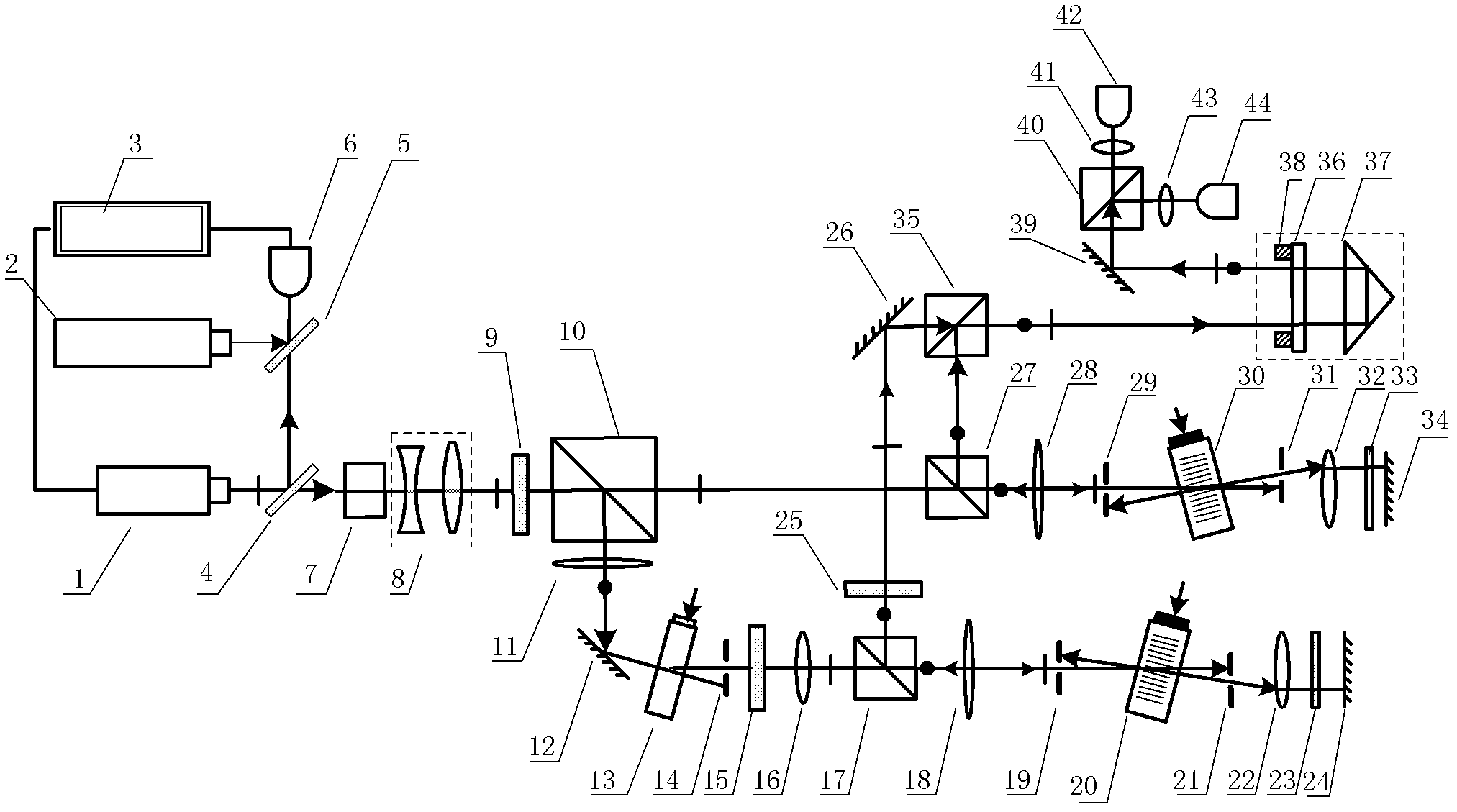

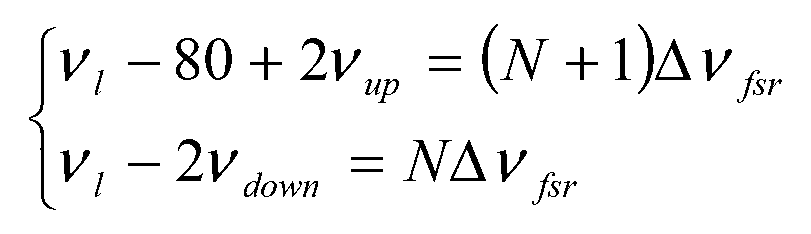

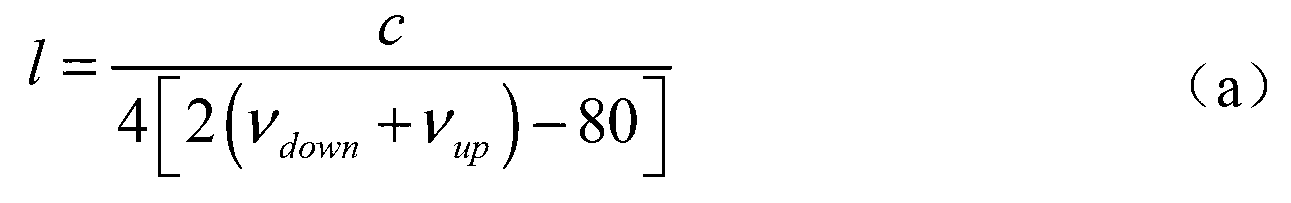

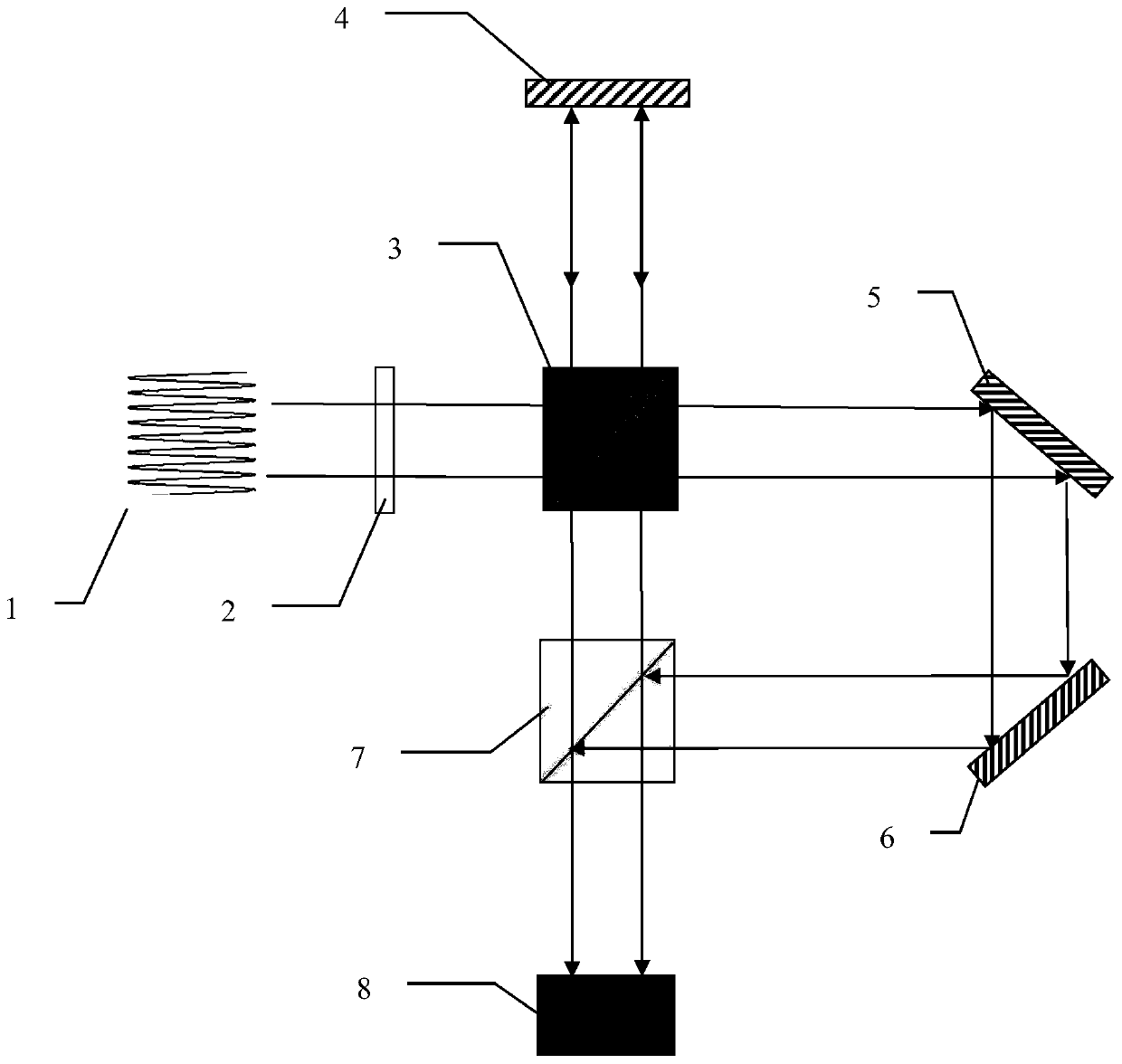

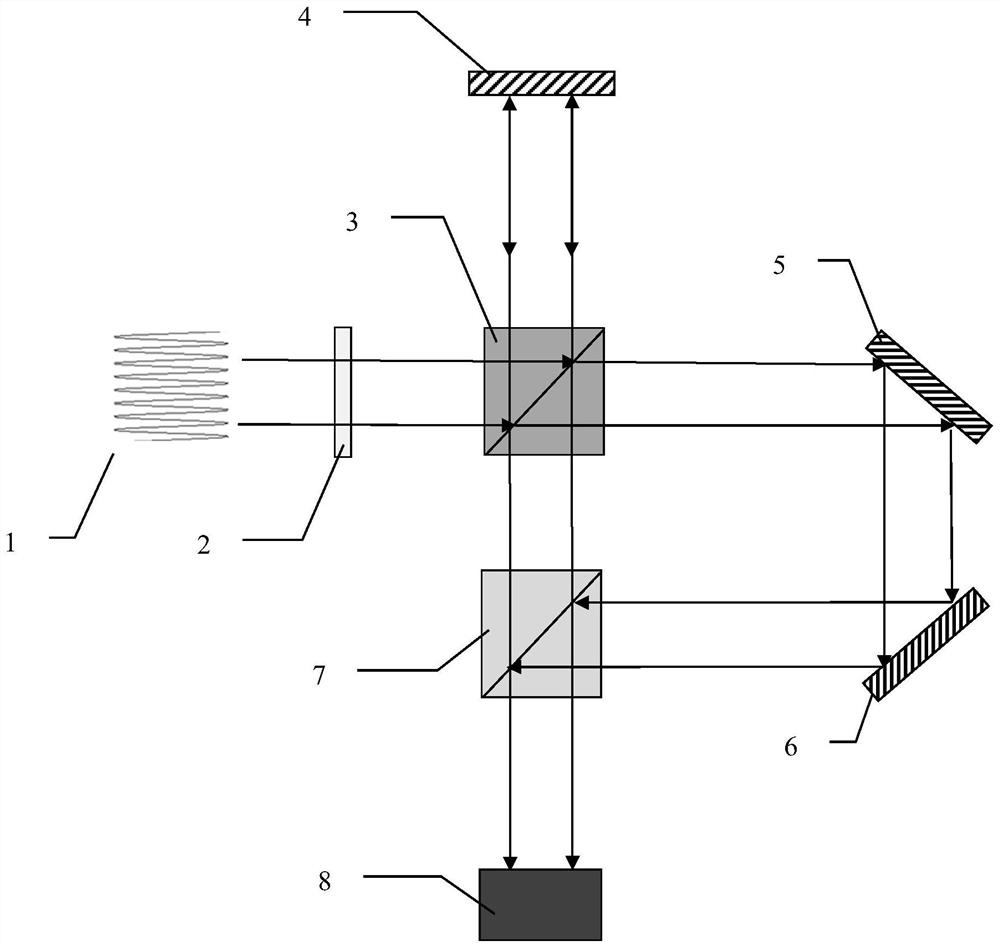

Folding-fabry-perot-cavity-based cavity length measurement method and device

InactiveCN102288103BImprove frequency stabilityHigh displacement sensitivityUsing optical meansLevel measurementAcousto-optics

The invention discloses a folding-fabry-perot-cavity-based absolute distance measurement method and a device, and belongs to the field of laser interference precise measurement. The method comprises the following steps of: dividing incident intrinsic light into two beams of orthogonal polarized light; performing up frequency shifting and down frequency shifting on the two beams of orthogonal polarized light respectively by an acousto-optic variable frequency shifter respectively to form orthogonal polarized light beams with frequency difference; making the orthogonal polarized light beams enter a folding fabry-perot cavity; and performing resonance on the orthogonal polarized light beams with the frequency difference and an adjacent resonance order of the folding fabry-perot cavity respectively, wherein the frequency difference of the adjacent resonance order is a free spectrum range corresponding to the cavity length of the folding fabry-perot cavity and thus, measuring the absolute distance of the cavity length of the fabry-perot cavity according to the free spectrum range. The device for implementing the method can realize nanometer level measurement precision and magnitude measurement range of dozens of millimeters, and is suitable for nonlinear error calibration of nanometer and sub nanometer precision in the magnitude measurement range of dozens of millimeters and a nanometer displacement measurement system with high precision and a wide range.

Owner:TSINGHUA UNIV

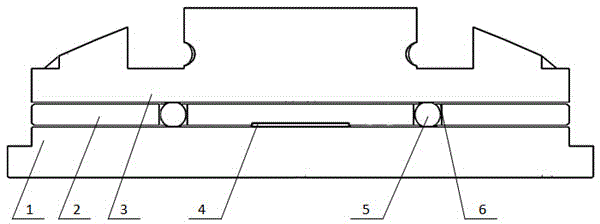

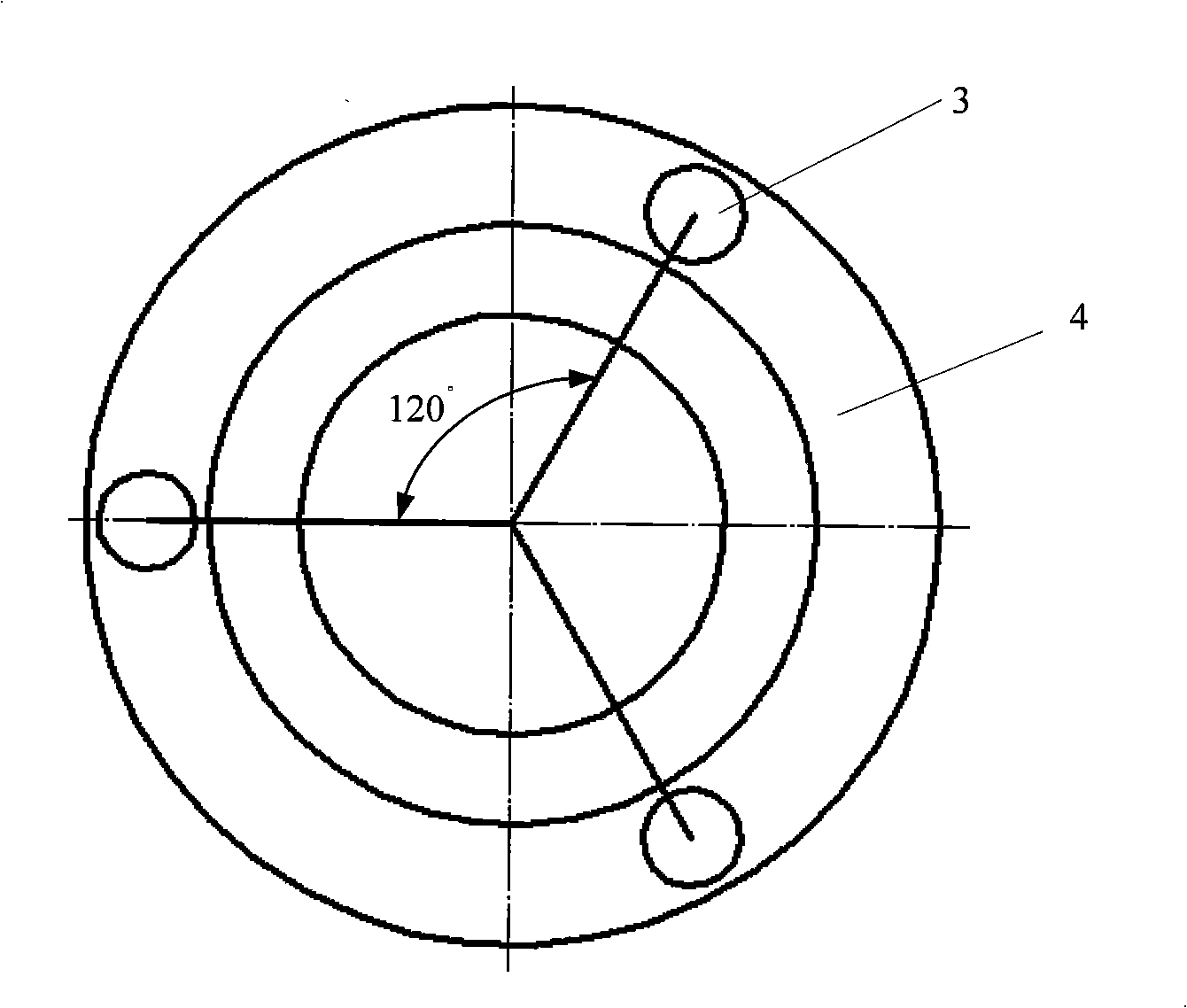

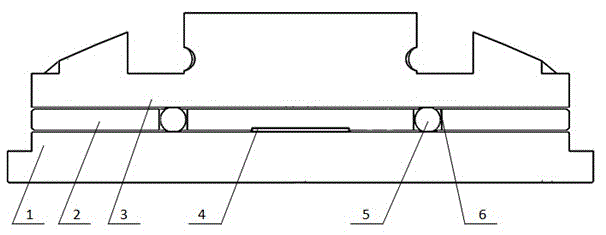

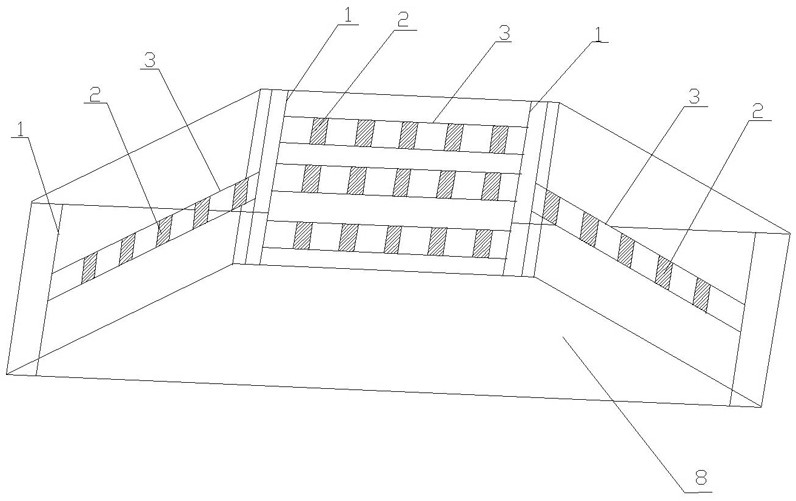

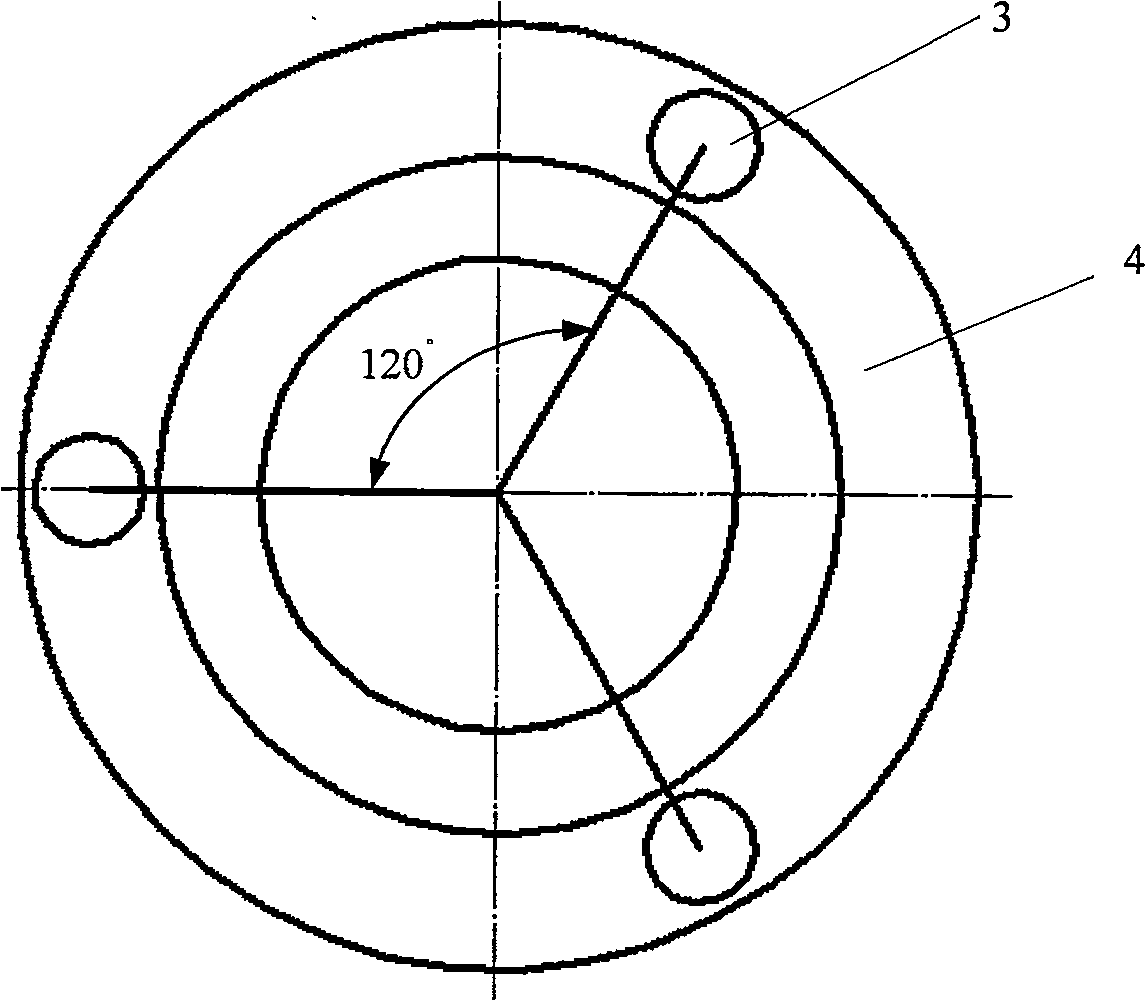

Precision instrument guide rail system based on circular rolling element array arrangement and cambered surface clamping and positioning

ActiveCN108167329AAvoid Motion Steering ErrorsCompact structureLinear bearingsMeasurement apparatus componentsScrew threadMechanical engineering

The invention discloses a precision instrument guide rail system based on circular rolling element array arrangement and cambered surface clamping and positioning and belongs to the technical field ofprecision instruments and machines. A guide rail component is provided with four working faces, the middle area of each working face is of a groove structure, and each working face is symmetrically provided with two coplanar boss working belts of equal height. A guide rail rack component is composed of four supporting guide plates, and each supporting guide plate is provided with a rolling element set which comprises three rolling unit arrays distributed in a triangle mode. Each rolling unit array is formed by densely distributing a plurality of rolling elements. A sensor clamping and lockingcomponent comprises a clamping matrix, a clamping moving body and a clamping feeding mechanism; the clamping matrix is provided with a long-strip-shaped arc hole, a threaded hole and an arc groove; and the clamping moving body moves in the long-strip-shaped arc hole under the action of the clamping feeding mechanism so that a sensor can be locked or released. The precision instrument guide rail system integrates the characteristics of high precision, high rigidity and the clamping and locking features.

Owner:HARBIN INST OF TECH

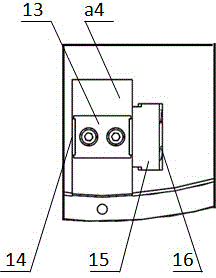

Auxiliary switch for circuit breaker

ActiveCN101436493BProtection lifeGood action reliabilityProtective switch operating/release mechanismsLow voltageDc circuit breaker

The invention provides a circuit breaker auxiliary switch, which belongs to the technical field of low-voltage electrical appliance accessories. The auxiliary switch comprises a pair of mutually matched shells, a microswitch arranged in a shell cavity of the shells and a transmission part which is also arranged in the shell cavity of the shells. A first contact arm which is used for actuating a contact pin of the microswitch and a second contact arm which protrudes out of the shells and is used for actuating an operating mechanism of the circuit breaker are formed on the transmission part. The auxiliary switch is characterized in that a first working surface and a second working surface which are used for continuously touching the contact pin of the microswitch are formed on the first contact arm, wherein the first working surface is formed on the upper end face of the first contact arm, and the second working surface is formed on the top end face of the first contact arm. The auxiliary switch has the advantages that the auxiliary switch is favorable for protecting the life span of the microswitch, and can improve the action reliability and safety of the microswitch, so that the reliability of the auxiliary switch can be guaranteed; and the switch is concise in structure and easy to assemble.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

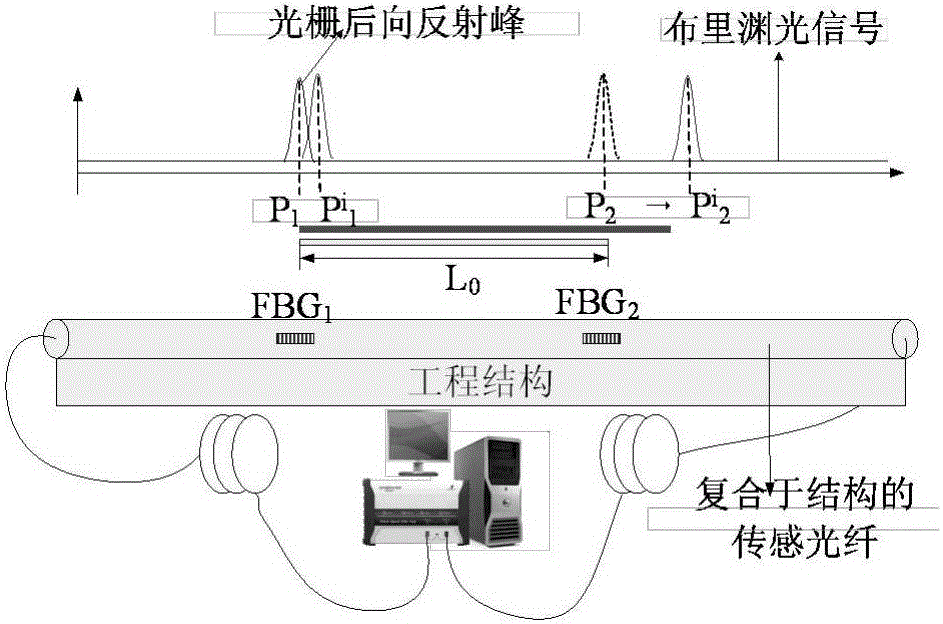

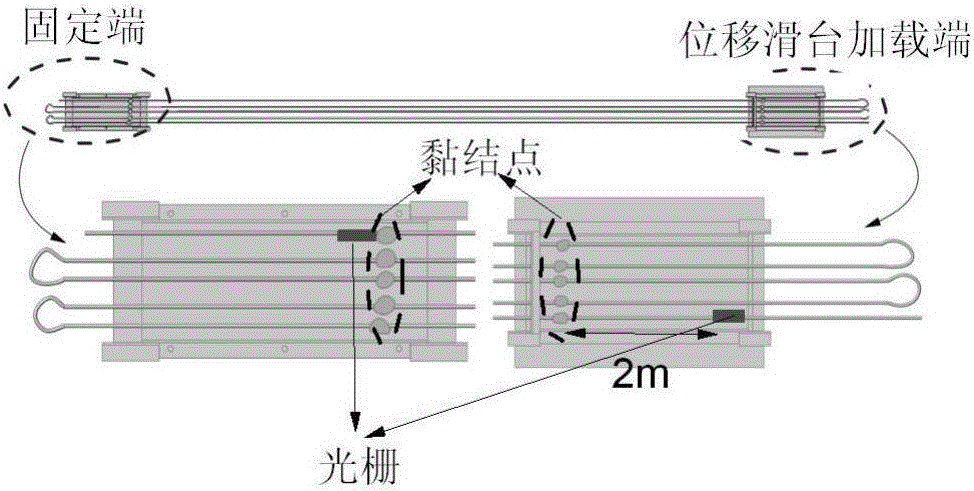

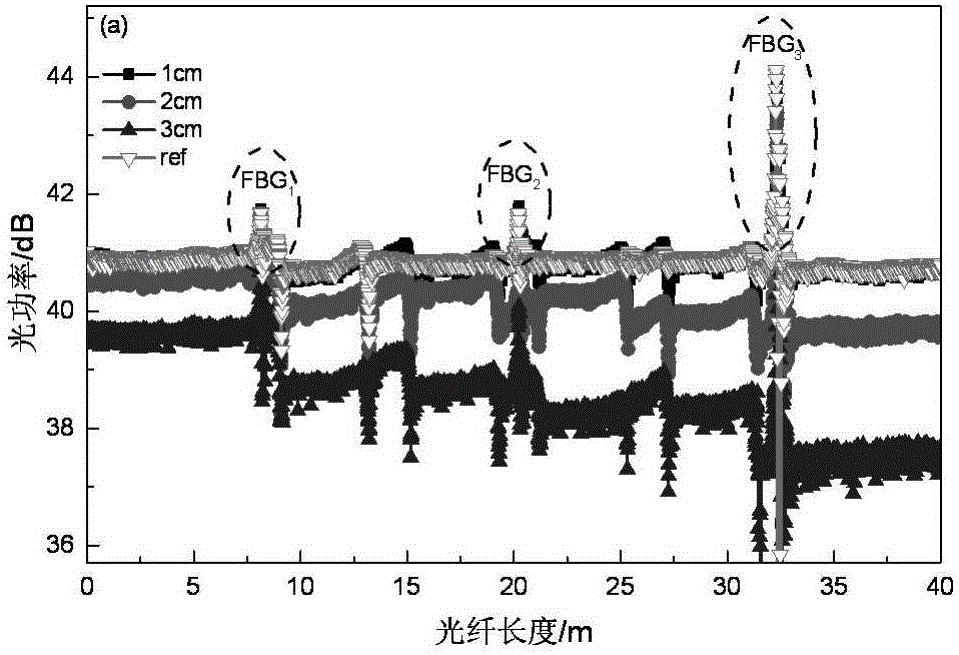

Full distributed fiber displacement sensor based on fiber grating positioning

InactiveCN106091938AFlexible Design of Displacement SensitivityHigh displacement sensitivityUsing optical meansFiberGrating

The invention relates to the technical field of fiber sensing, and especially relates to a full distributed fiber displacement sensor based on fiber grating positioning, for solving the technical problem of designing a full distributed fiber displacement sensor which has a large measurement range, does not require integration for displacement data, is simple in structure and is easily applied to a deep geotechnical engineering structure. The full distributed fiber displacement sensor comprises a full distributed sensing fiber, the full distributed sensing fiber is connected in series with more than two fiber gratings, the fiber gratings are taken as position indicators, and the position of one of the fiber gratings is fixed.

Owner:SHIJIAZHUANG TIEDAO UNIV

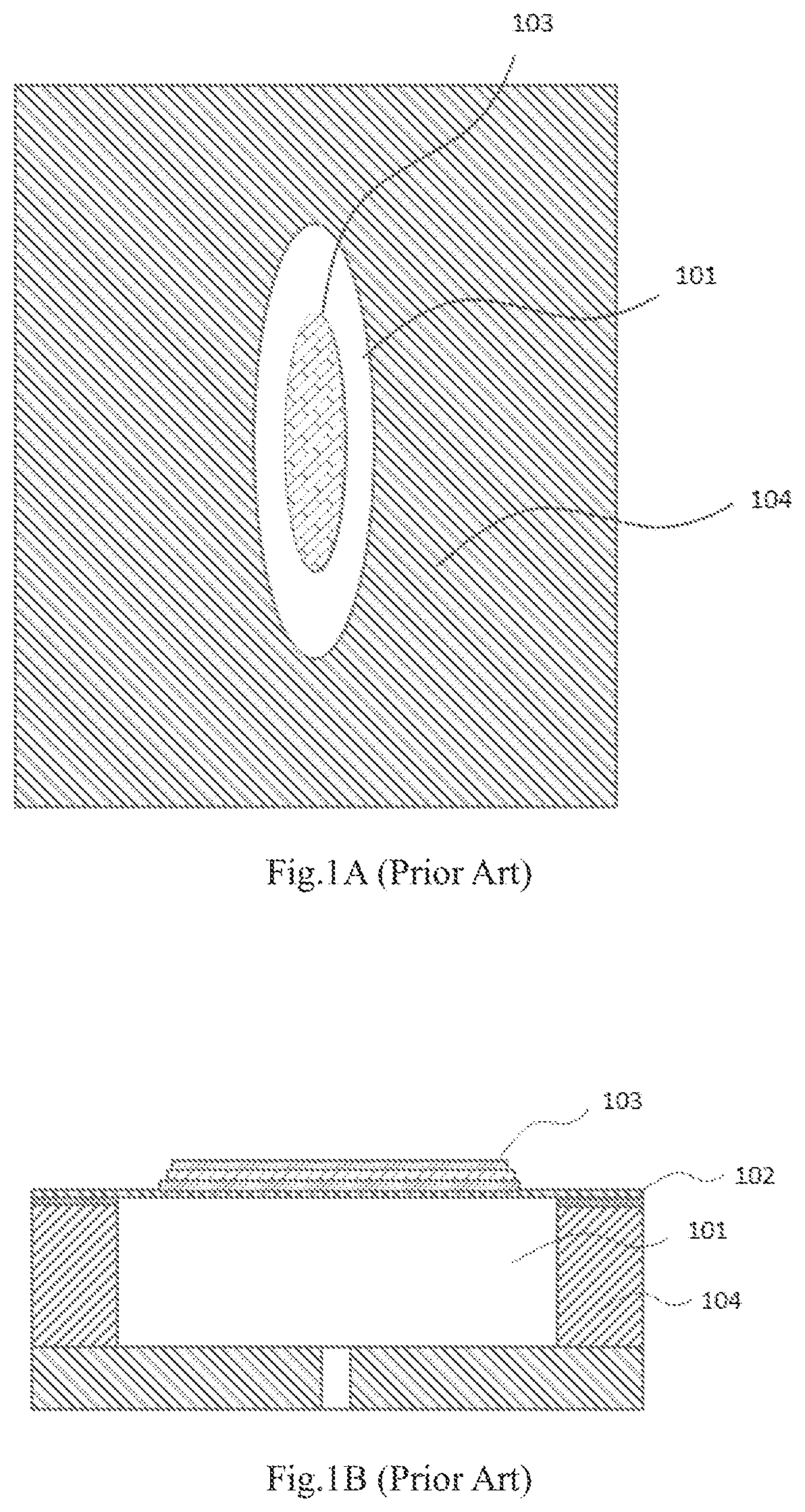

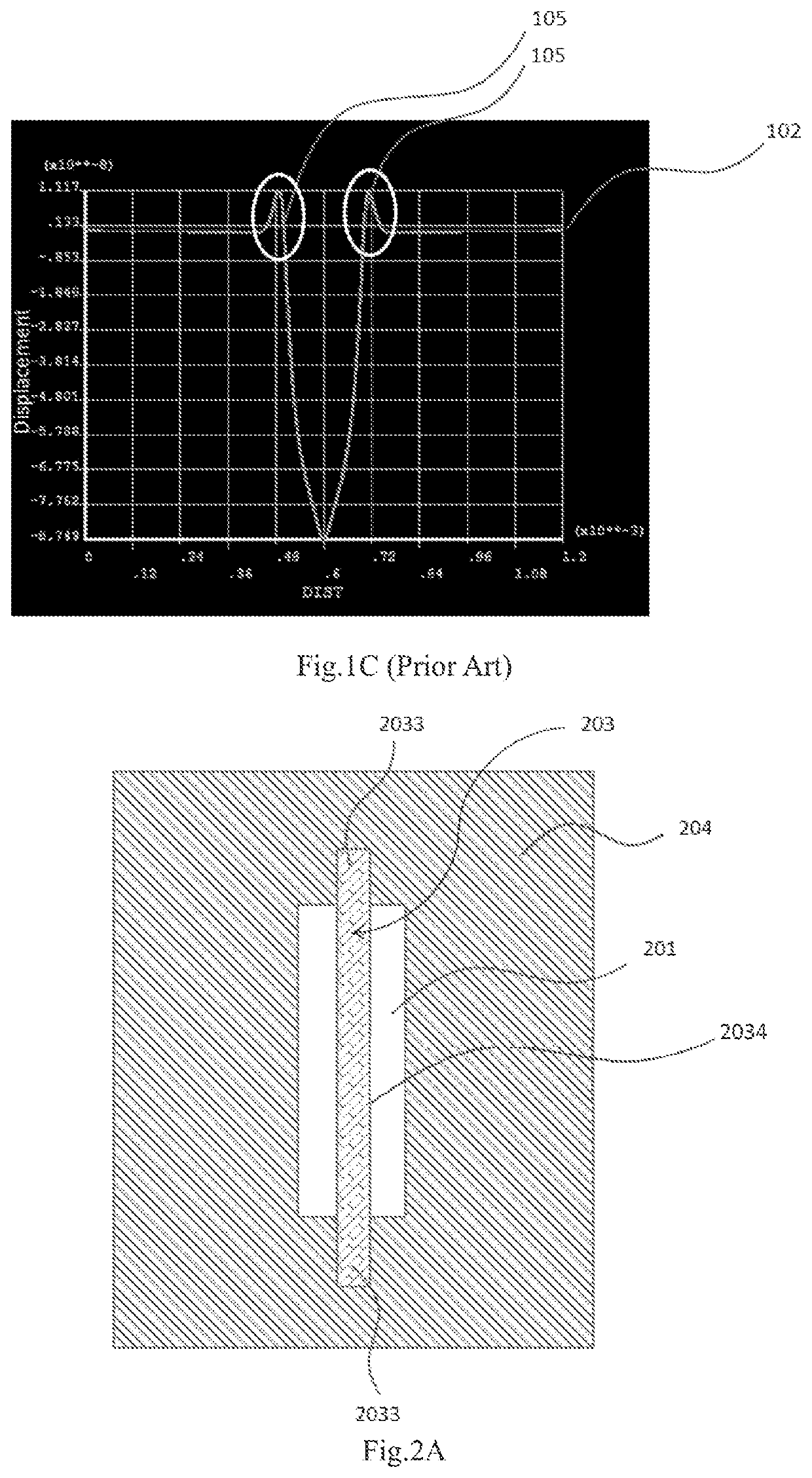

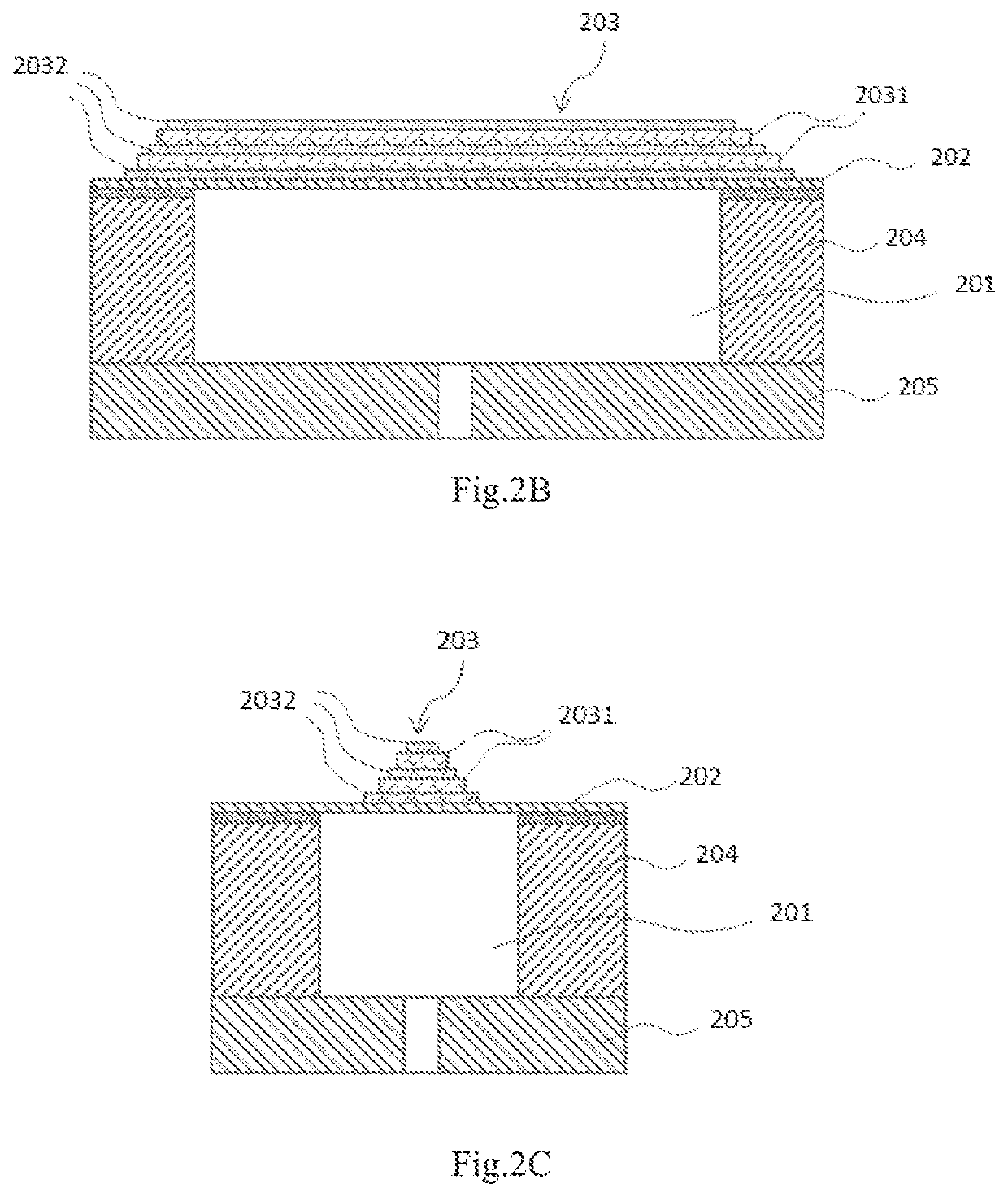

Lens driving device

ActiveUS7944636B2Improve linearityHigh displacement sensitivityMountingsPropulsion systemsDriving currentPower flow

In the present invention, a lens driving device has appropriate offset for miniaturization, excellent linearity of driving current versus displacement, and good displacement sensitivity. A casing holding a yoke with at least one permanent magnet mounted on an inner circumference thereof is connected with a lens holder having a driving coil installed on an outer sidewall thereof between an upper spring member and a lower spring member. When the driving coil is not powered, the lens holder props against the casing at a side opposite to an imaged object. When the lens holder props against the casing, the position of the driving coil along Z axis causing a magnitude of driving magnetic field intersecting with the driving coil is 50%˜90% of a maximum value of the driving magnetic field intersecting with the driving coil while the lens holder moves toward the imaged object.

Owner:MICRO WIN TECH +2

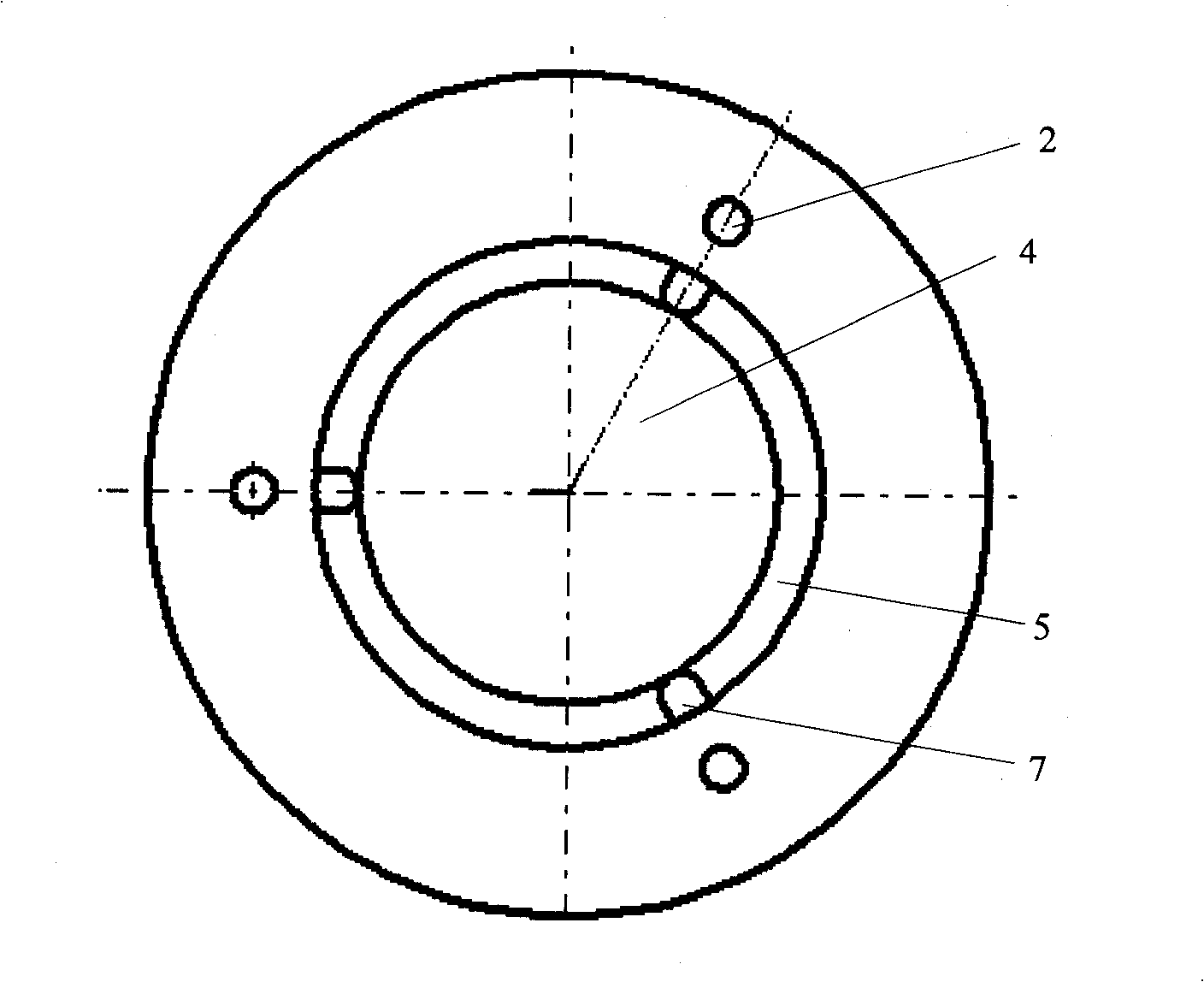

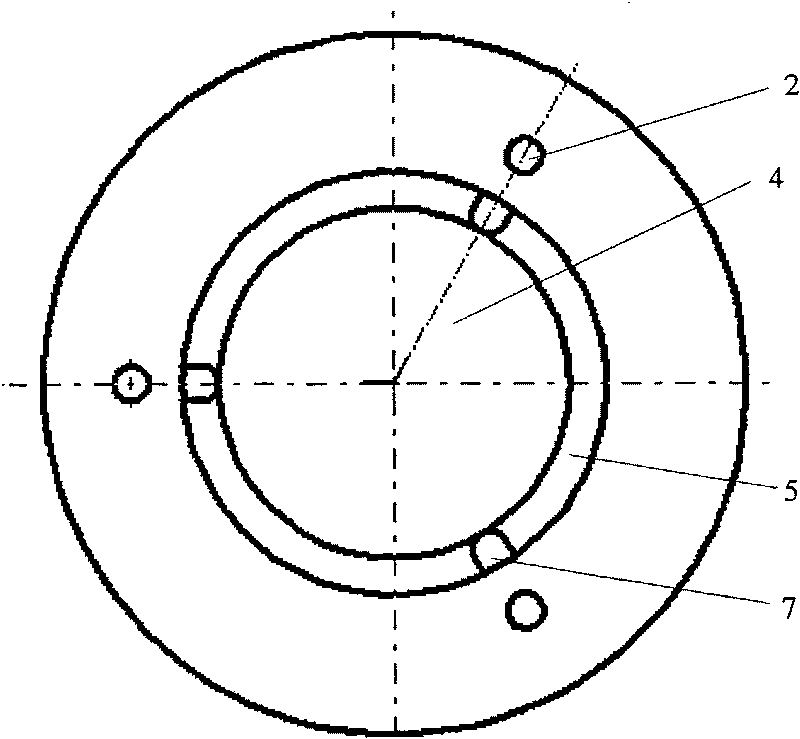

Single (double) wing type gas/ liquid two-phase composite gyration basic method and device

ActiveCN101338791AHigh rotation accuracyHigh displacement sensitivityBearingsViscous liquidGas lubrication

The present invention relates to a single (double) wing type gas phase / liquid phase composite gyration benchmarking method and a device, which belong to the technical field of precision gyration benchmarking. The method compositely uses the gas-lubricated gyration technology and the liquid damping technology, the method utilizes the remarkable advantage of the error-averaging effect of the gas lubricating technology to ensure the gyration precision of a gyration benchmark. At the same time, the method utilizes the notable absorption effect of viscous liquid on the damp or energy of the vibration component of a gyrator to restrict the generation of the medium / high-frequency micro-vibration of the gyrator and improve the motional stability, repetitiveness and positioning reliability of the gyration benchmark. In the device, a liquid-damping system with an appropriate coefficient of viscosity is assembled on the upper end or lower end or both the upper and the lower ends of a gas-floated mainshaft. The method can establish a composite gyration benchmark which also takes high gyration precision, high motional stability, high repetitiveness and high positioning reliability into consideration.

Owner:哈尔滨超精密装备工程技术中心有限公司

Precision instrument guide rail system based on circular rolling element array arrangement and arc surface clamping positioning

ActiveCN108167329BAvoid Motion Steering ErrorsCompact structureLinear bearingsMeasurement apparatus componentsEngineeringMechanical engineering

The invention discloses a precision instrument guide rail system based on circular rolling element array arrangement and cambered surface clamping and positioning and belongs to the technical field ofprecision instruments and machines. A guide rail component is provided with four working faces, the middle area of each working face is of a groove structure, and each working face is symmetrically provided with two coplanar boss working belts of equal height. A guide rail rack component is composed of four supporting guide plates, and each supporting guide plate is provided with a rolling element set which comprises three rolling unit arrays distributed in a triangle mode. Each rolling unit array is formed by densely distributing a plurality of rolling elements. A sensor clamping and lockingcomponent comprises a clamping matrix, a clamping moving body and a clamping feeding mechanism; the clamping matrix is provided with a long-strip-shaped arc hole, a threaded hole and an arc groove; and the clamping moving body moves in the long-strip-shaped arc hole under the action of the clamping feeding mechanism so that a sensor can be locked or released. The precision instrument guide rail system integrates the characteristics of high precision, high rigidity and the clamping and locking features.

Owner:HARBIN INST OF TECH

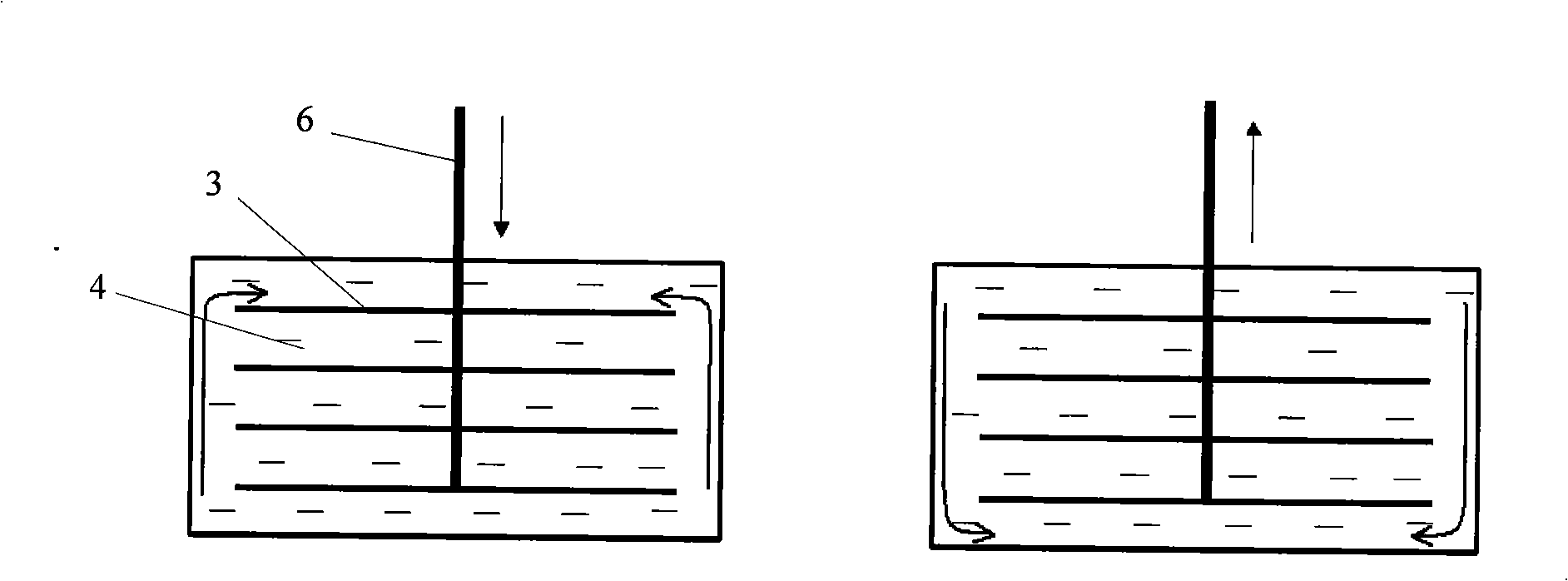

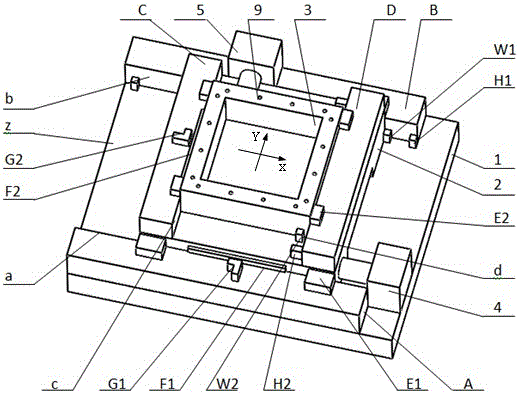

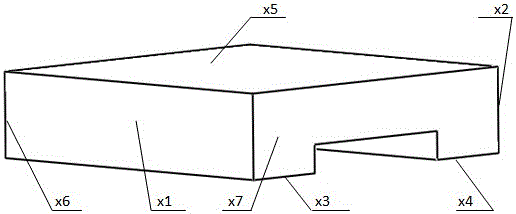

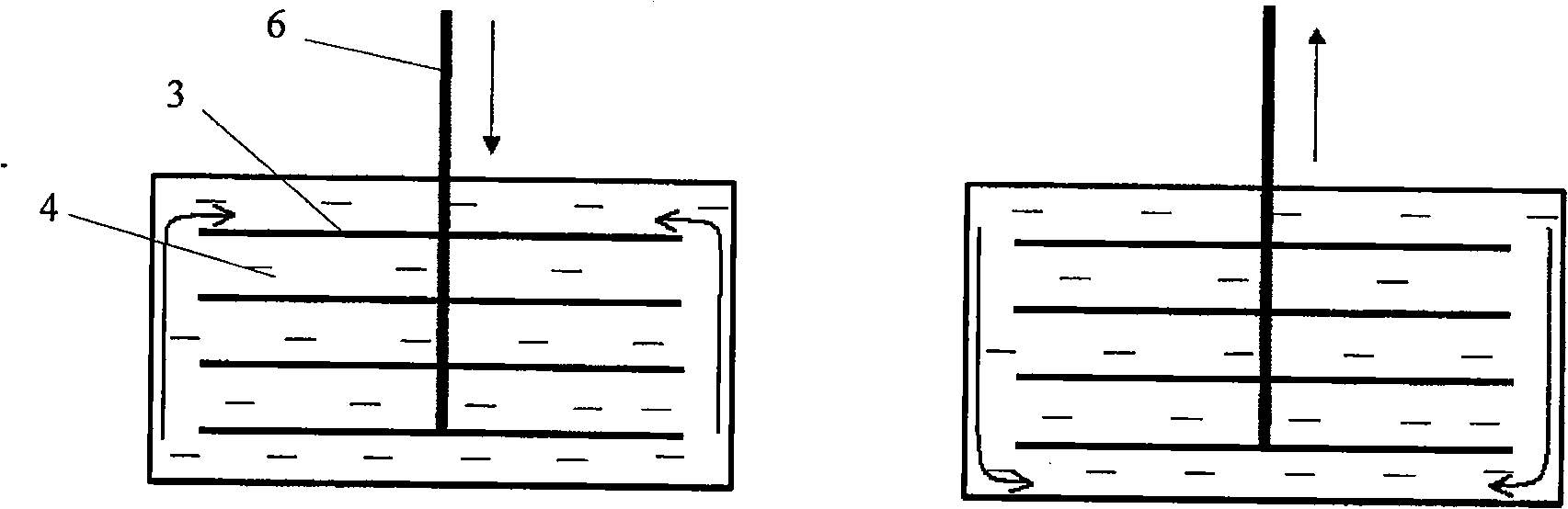

Gas lubrication and friction damping composite high rigidity and high stability two-dimensional adjustment table

ActiveCN104400763BImprove linear motion guidance accuracyHigh displacement sensitivityWork benchesGas lubricationSlide plate

The invention discloses a gas lubrication and friction damping composition type high-rigidity and high-stability two-dimensional adjusting workbench and belongs to the technical field of precise instruments and machines. An X-direction gas floatation sliding plate is configured between a base and a Y-direction gas floatation sliding plate; a supporting gas film is formed between a gas flotation working face x5 on the X-direction gas flotation sliding plate and a gas flotation working face y3 on the Y-direction gas floatation sliding plate to support the Y-direction gas flotation sliding plate; a supporting gas film is formed between a gas flotation working face z on the base and gas flotation working faces x3 and x4 on the X-direction gas floatation sliding plate to support the X-direction gas flotation sliding plate; guide rails A and B parallel to each other are fixedly mounted on the gas flotation working face z of the base; guide rails C and D parallel to each other are fixedly mounted on the X-direction gas flotation sliding plate; a friction damping unit E1 is in contact fit with the guide rail A and the guide rail B; a friction damping unit E2 is in contact fit with the guide rail C and the guide rail D. The invention provides a precise plane two-dimensional adjusting device with high rigidity and high positioning stability.

Owner:HARBIN INST OF TECH

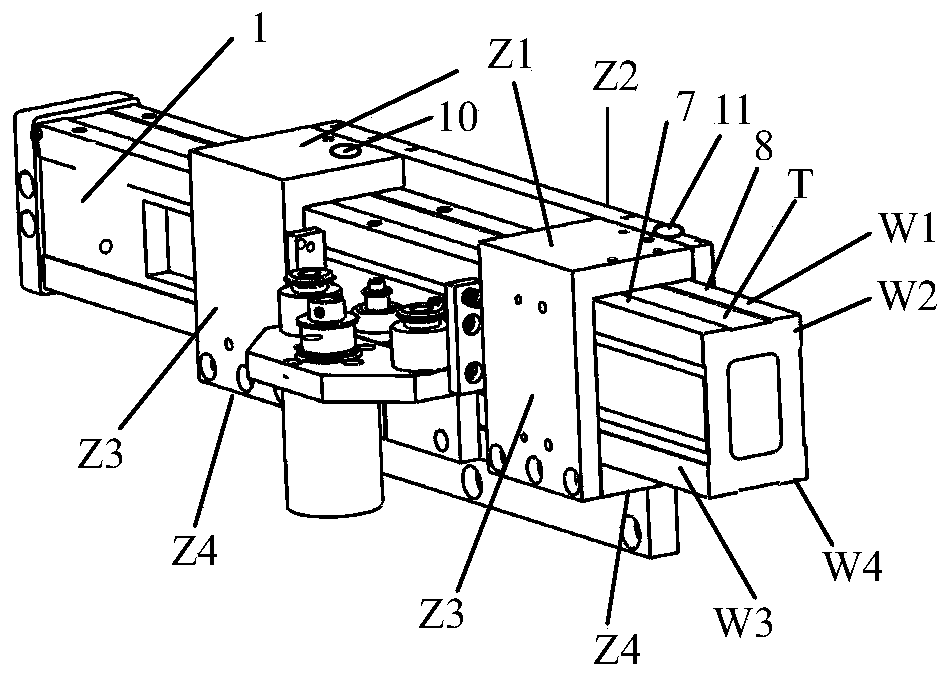

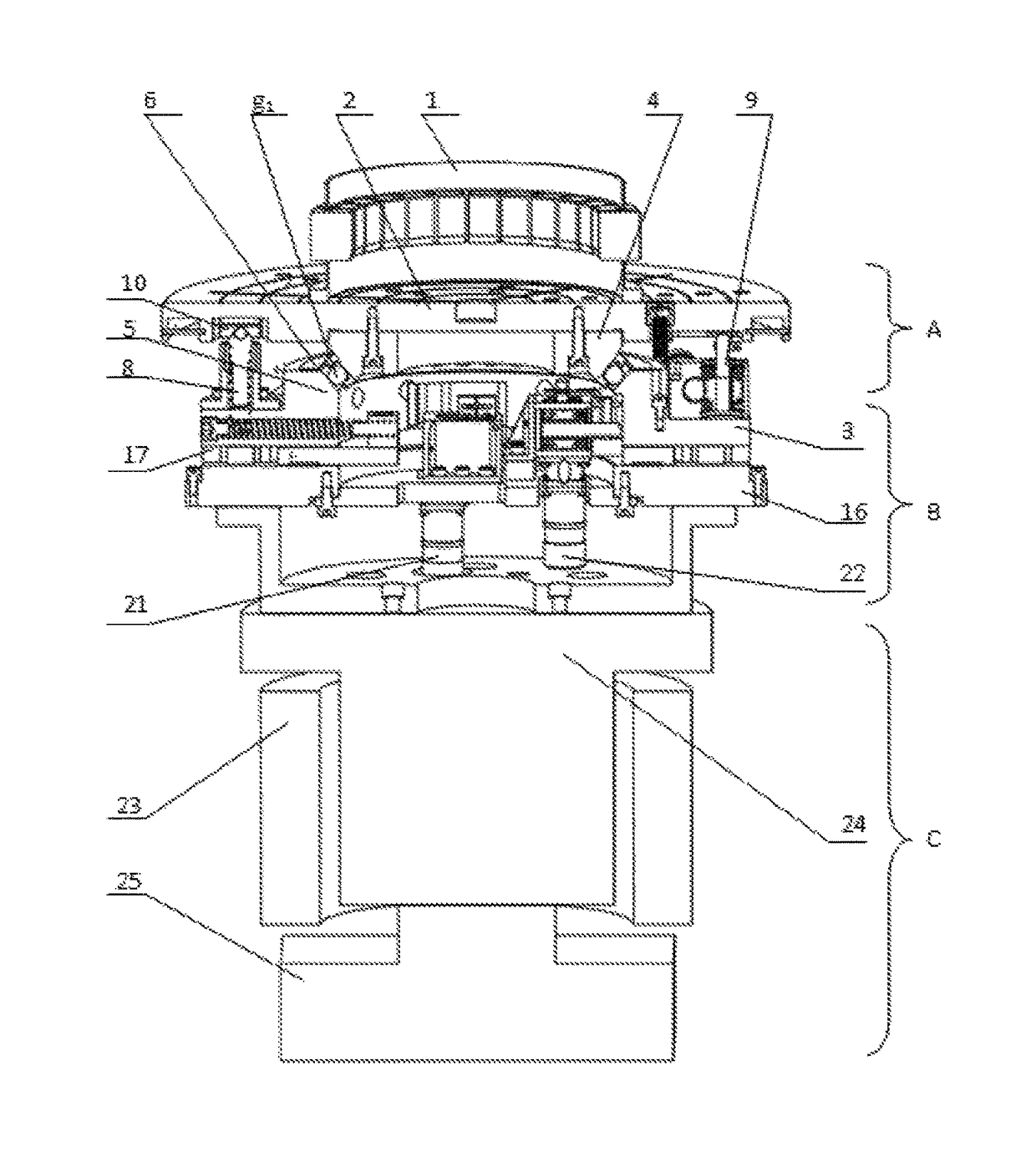

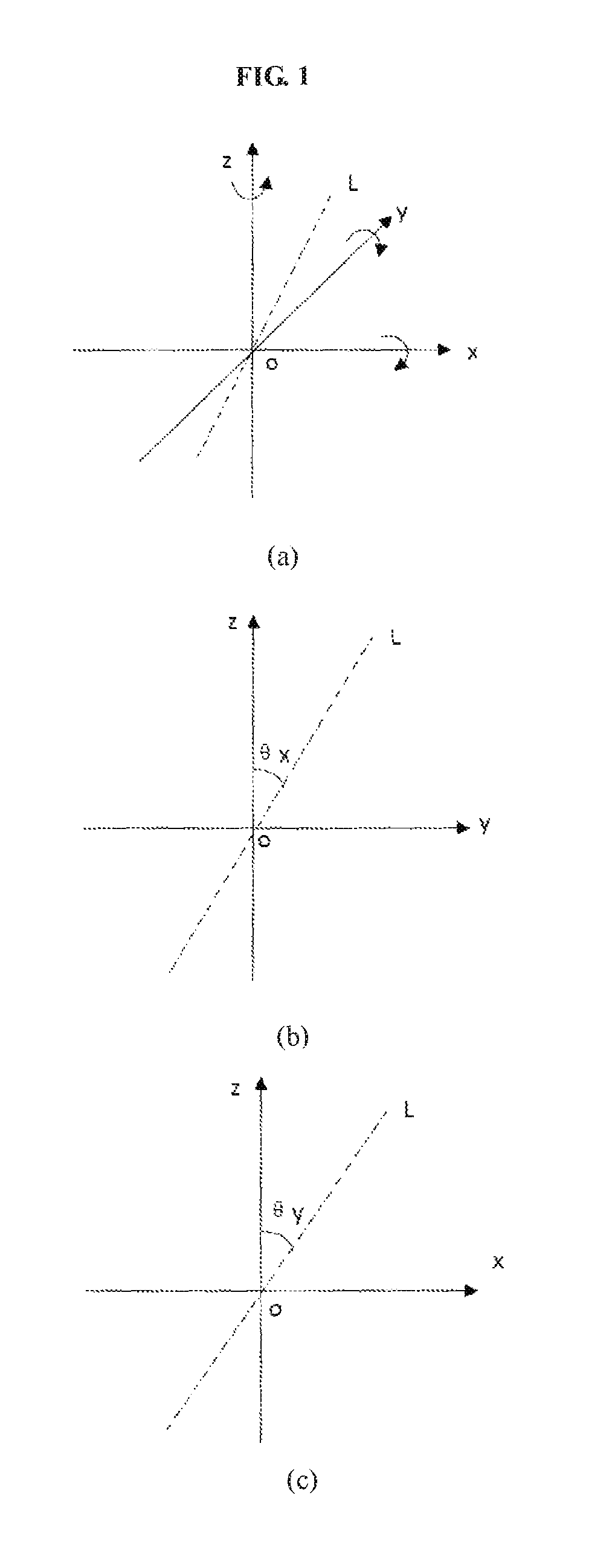

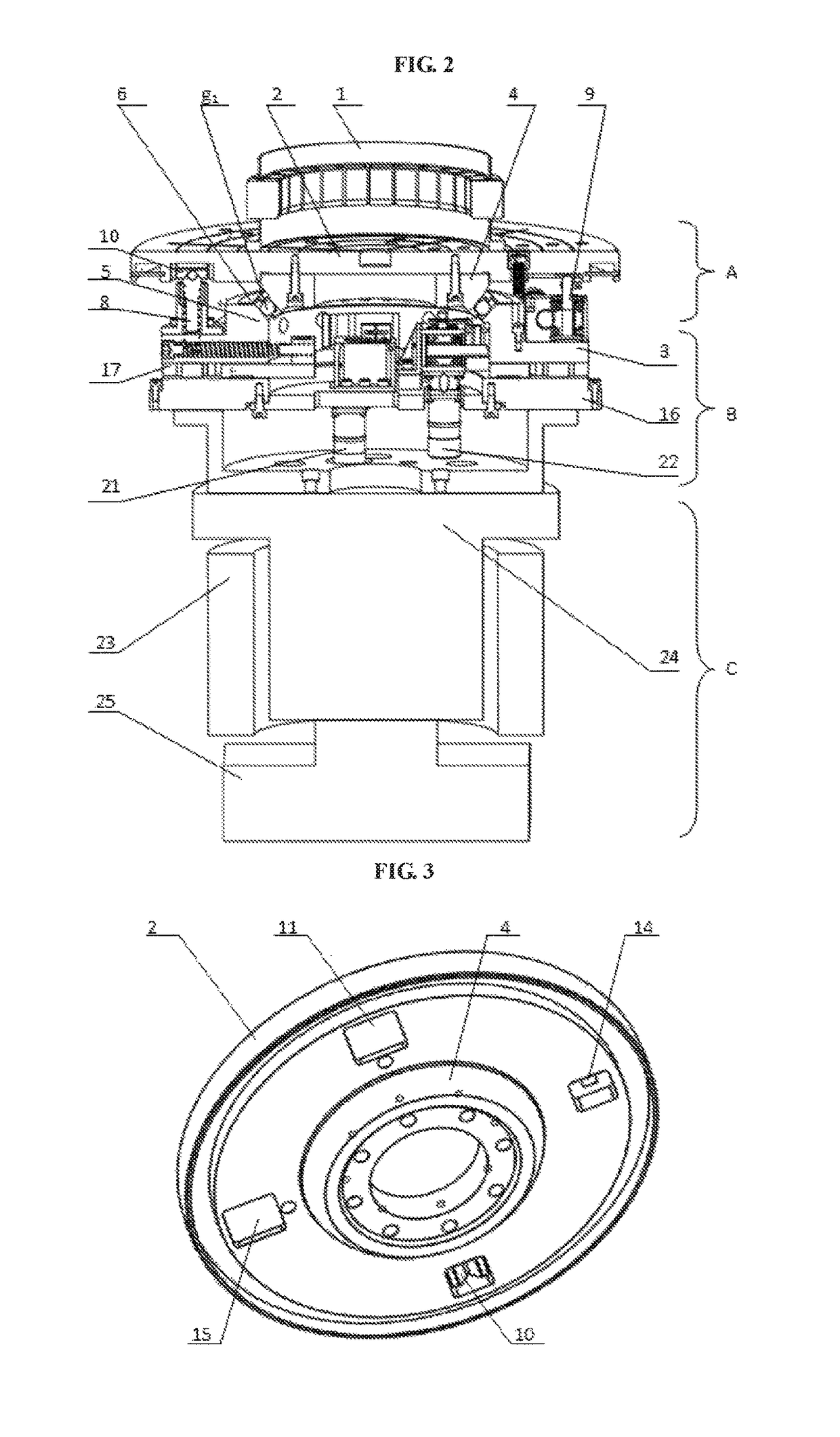

Five-degree-of-freedom adjustment and positioning method and apparatus for assembly/measurement of rotor and stator of aircraft engine

ActiveUS9695707B2Prevent rotationHigh movement precisionEngine manufactureEngine fuctionsHigh stiffnessDegrees of freedom

A five-degree-of-freedom adjustment and positioning method and apparatus for assembly / measurement of rotor and stator of an aircraft engine; said method comprises adjusting a plane motion and a rotation of a tested piece through composite motion comprising five degrees of freedom: a 360° rotatory motion around a Z axis, a plane motion along an X axis and a plane motion along a Y axis, a rotatory motion around the X axis and a rotatory motion around the Y axis; said apparatus comprises: a clamping mechanism, a turning platform component, a translational platform component and a rotational platform component. The present invention designs a five-degree-of-freedom adjustment and positioning method and apparatus having properties of large load bearing, high precision and high stiffness, thus improving assembly efficiency and measurement accuracy of the aircraft engine.

Owner:HARBIN INST OF TECH

Integrated alignment method and device for aero-engine assembly and measurement based on dense bead rolling bearing

ActiveCN104400414BHigh displacement sensitivityHigh precisionMetal working apparatusAviationRolling resistance

The invention provides an integrative aligning method for aero-engine assembly and measurement based on dense ball rolling supporting and an integrative aligning device for the aero-engine assembly and measurement based on the dense ball rolling supporting. The method is characterized by being realized through the combined motion of a round bottom disc, an interlayer and a motion table; the interlayer is arranged between the motion table and the round bottom disc; small holes are fully distributed in the interlayer; ball type rolling bodies are respectively embedded into the small holes; when the motion table moves along an X direction, the round bottom disc and the interlayer are kept static, the rolling friction is implemented between the round bottom disc and the motion table, and an X-direction guiding system is matched with guiding grooves in the interlayer to play a role in guiding; when the motion table moves along a Y direction, the round bottom disc is kept static, the interlayer and the motion table synchronously move, the rolling friction is implemented between the round bottom disc and the interlayer, and a Y-direction guiding system is matched with guiding grooves in the interlayer to play a role in guiding. According to the aligning method and the aligning device, a two-dimensional motion adjusting device combining high precision, high stability and great load is established.

Owner:HARBIN INST OF TECH

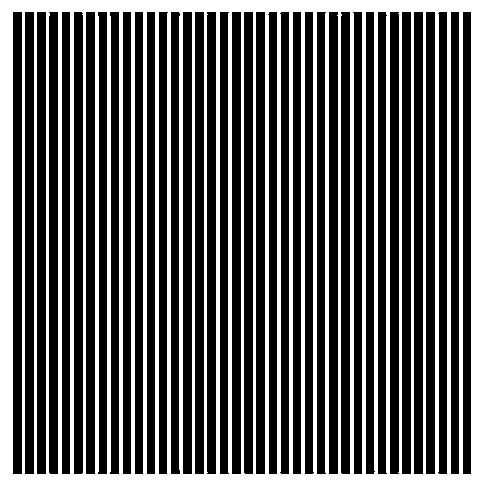

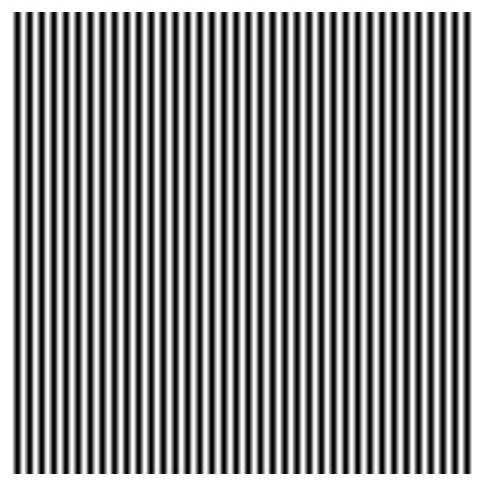

Interference phase shift sensitivity enhancing method based on moire fringes

The invention discloses an interference phase shift sensitivity enhancing method based on moire fringes. The method comprises the steps that an interference fringe light field formed by a spatial modulation type interferometer passes through a polaroid and then enters a common beam splitter prism, reflected light is reflected by a first plane mirror and then returns along an original light path, passes through the common beam splitter prism again and then enters an array detector through a polarization beam splitter prism, and a set of interference fringe distribution is formed; and transmission light is reflected twice in sequence, then enters the polarization beam splitting prism, and enters the array detector after being reflected, so that another group of interference fringe distribution with opposite fringe orientations is formed. A third plane mirror is adjusted, so that an included angle is formed between two groups of interference fringes on the array detector, and moire fringes are formed. When phase shift occurs to the interference fringes, obvious displacement occurs to the moire fringes. The interference phase shift sensitivity enhancing method based on the moire fringes has universality and can effectively improve the measurement sensitivity of a spatial modulation type interference instrument.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

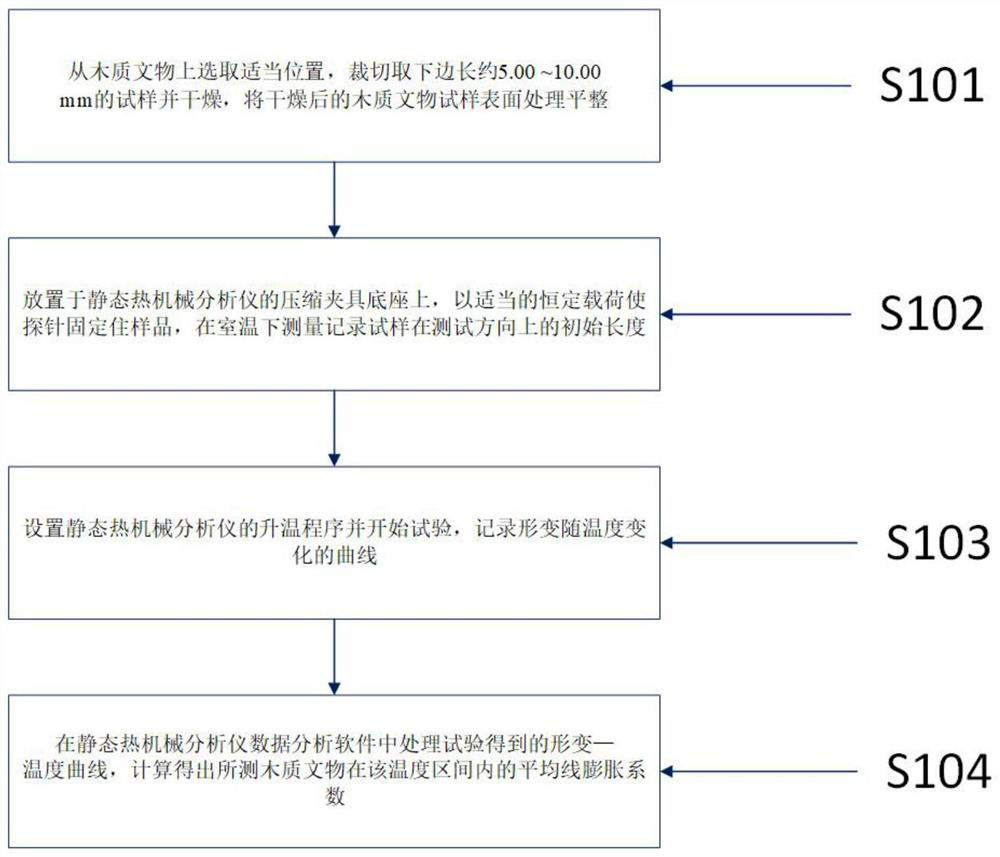

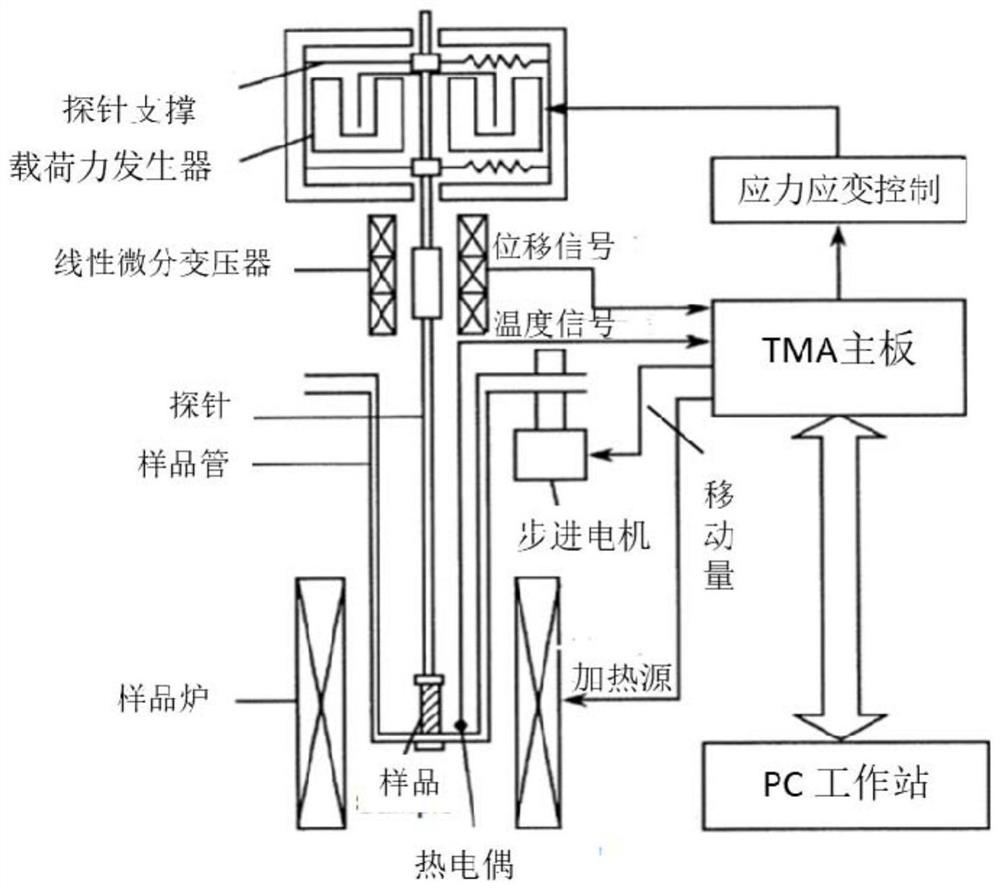

Method and system for testing linear expansion coefficient of wooden cultural relics with static thermomechanical analyzer

ActiveCN113791112BAvoid sizeHigh data efficiencyMaterial thermal coefficient of expansionEngineeringInitial sample

Owner:UNIV OF SCI & TECH BEIJING

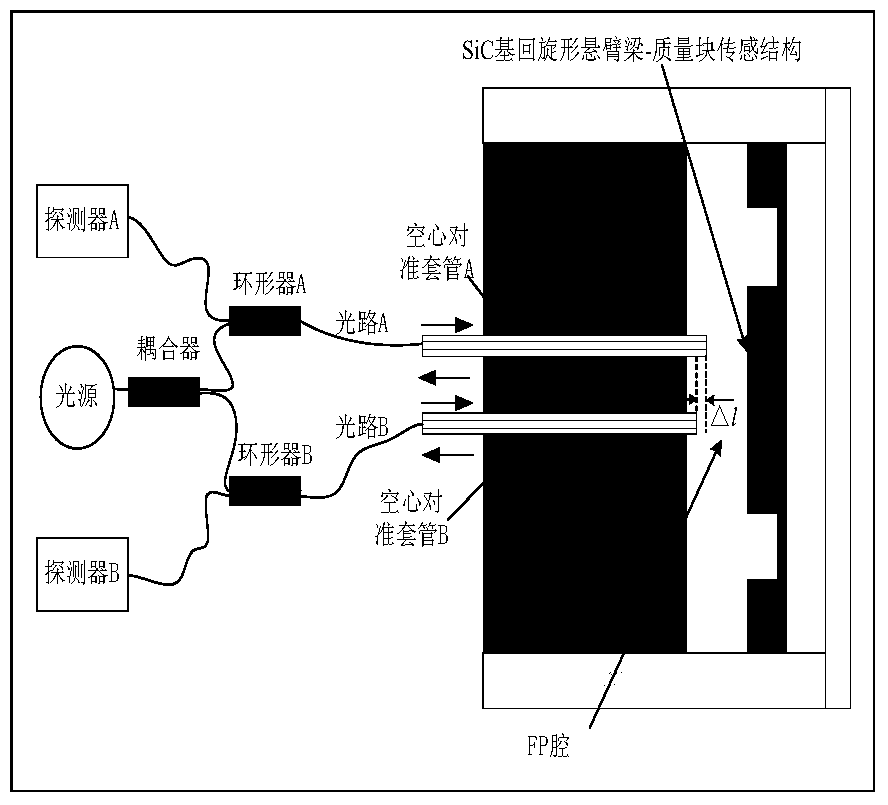

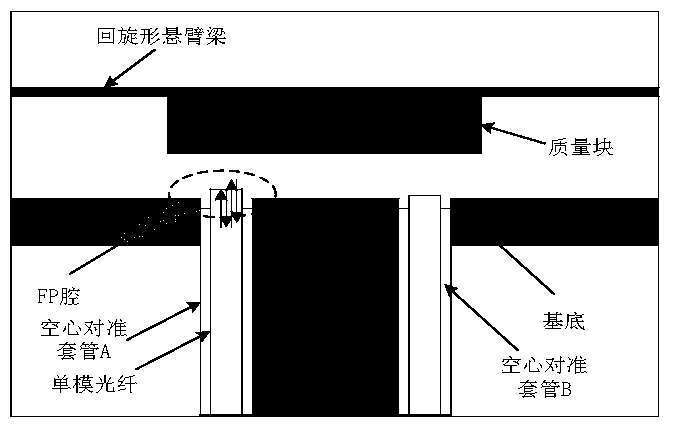

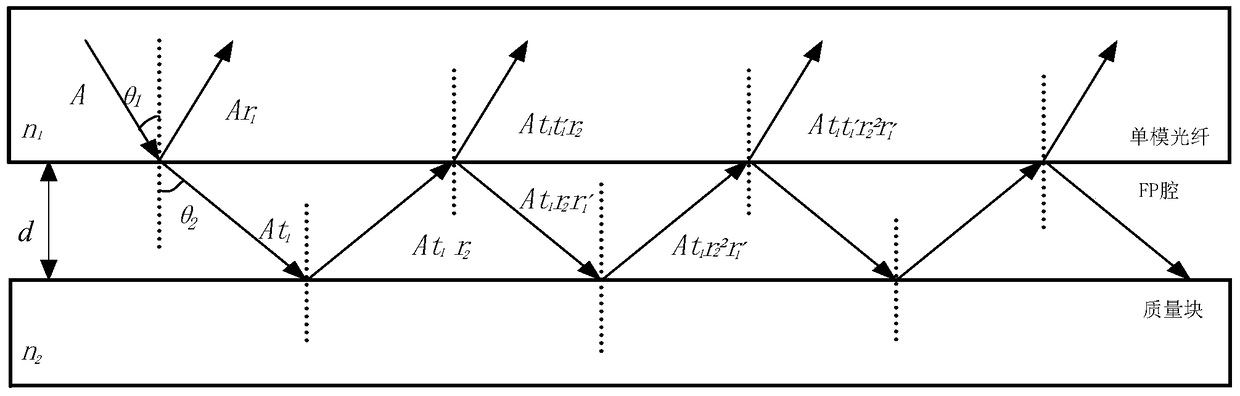

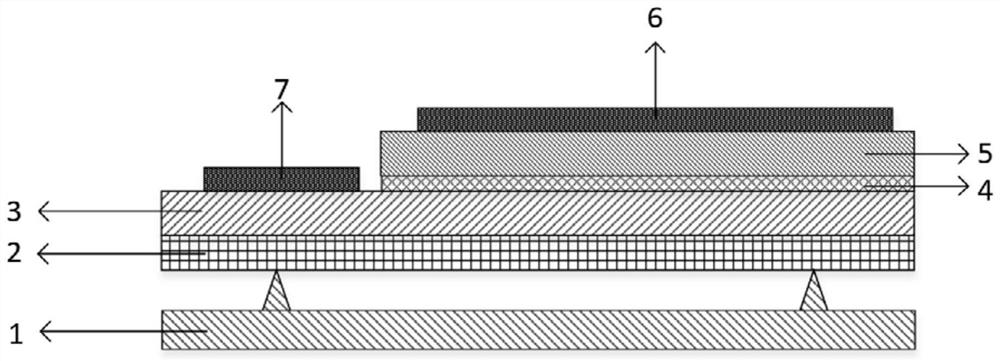

A SIC-based micro-optical high-temperature accelerometer and its design method

ActiveCN105004884BImprove radiation resistanceImprove high temperature stabilityAcceleration measurement using interia forcesManufacturing technologyAccelerometer

The invention discloses a SiC-based micro-optics high-temperature accelerometer and a design method, and belongs to the MOEMS technology field. A malposed double-FP cavity structure is formed through cavity length difference design, a mode of linear region overlapping of two paths of return signals in alternative change is achieved, and the measuring range of the accelerometer is widened. Through a mode of plating of a high-temperature anti-reflection film on a surface of a mass block, noise interference is reduced, and therefore the measuring precision is raised. The micromachining manufacturing technology of the sensing structure of the SiC-based micro-optics high-temperature accelerometer is provided, and the high temperature resistant characteristic of the sensing head of the accelerometer is achieved supplemented by a combined structure of an optical fiber with high temperature resistance and a hollow aligning sleeve and high temperature resistance packaging design. Through design of the SiC-based circle-round cantilever beam-mass block sensing structure, excellent mechanical response characteristics and displacement sensitivity of the sensing head are achieved. Severe environment working capabilities such as high temperature resistance or the like of the accelerometer are raised, and performances at aspects of measurement precision, dynamic measurement scope and miniaturization and the like are excellent.

Owner:安徽华驰动能科技有限公司

Piezoelectric sensor and method for simulating dam slope collapse self-powered monitoring through vibration table by usingpiezoelectric sensor

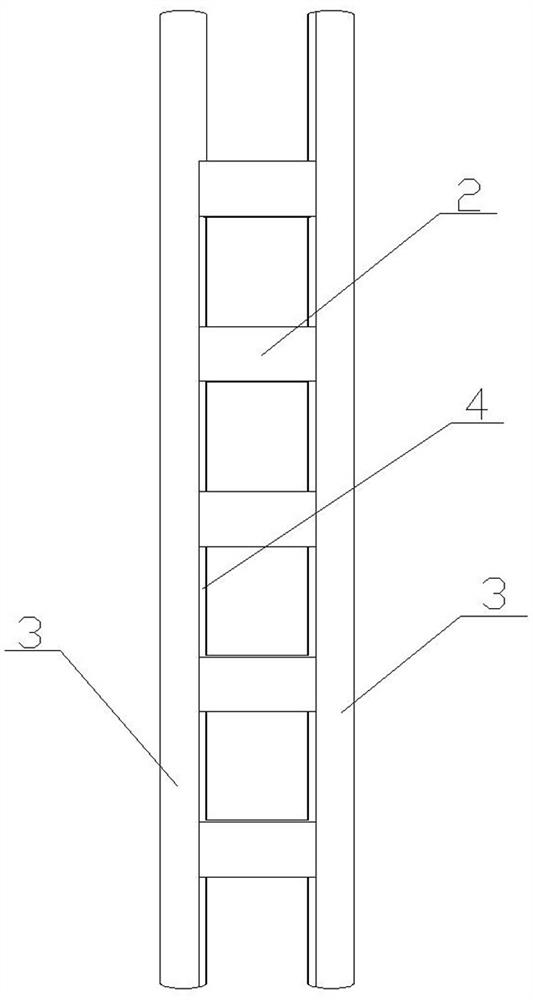

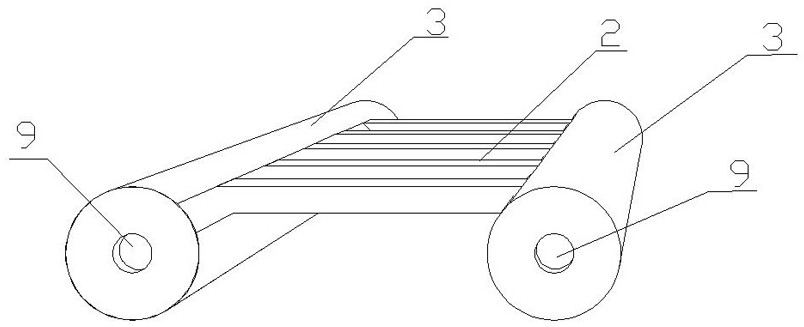

ActiveCN112254908ADisplacement Sensitivity of High Voltage Electric RulerHigh displacement sensitivityBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesMonitoring systemEngineering

The invention discloses a piezoelectric sensor, which comprises a piezoelectric assembly and a fixing steel frame for fixing the piezoelectric assembly, wherein the piezoelectric assembly comprises aplurality of piezoelectric rulers and two steel rails, the two steel rails are oppositely arranged, the piezoelectric rulers are fixed between the two steel rails respectively, the steel rails and thepiezoelectric rulers are combined to form a ladder shape, the outer ends of the steel rails are wrapped with abrasive paper, the upper ends and the lower ends of the steel rails are fixed to the corresponding fixing steel frames respectively, and the piezoelectric assembly is connected with an electric energy storage box and a side slope early warning monitoring system through conducting wires respectively. According to the invention, the pressure sensor is high in precision and high in practicability, the piezoelectric ruler generates electric energy through bending deformation, the electricenergy is provided for a slope early warning monitoring system, self power supply is achieved, and cost is saved.

Owner:WENZHOU UNIVERSITY

A Sensitivity Enhancement Method Based on Moiré Fringe Interferometric Phase Shift

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

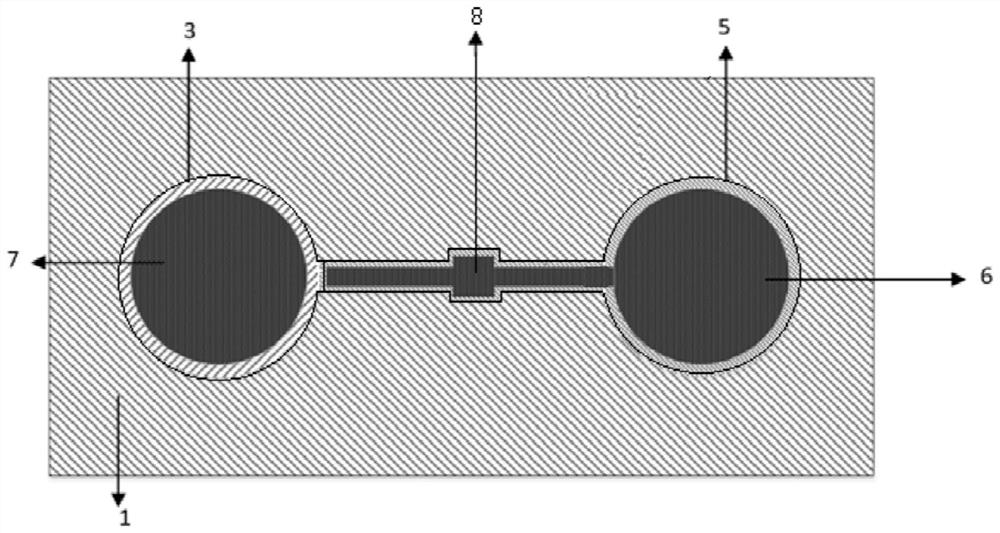

Thin-film piezoelectric actuator

ActiveUS11292255B2Efficiently actuatedEliminate undesired displacementInking apparatusPiezoelectric/electrostrictive devicesPiezoelectric actuatorsThin membrane

A piezoelectric device comprises a pressure chamber forming layer, a vibration plate disposed on and connected with the pressure chamber forming layer to form a pressure chamber, and a piezoelectric element disposed on the vibration plate and used for driving the vibration plate to move and thus changing a volume of the pressure chamber, wherein the piezoelectric element is disposed on the vibration plate in such a manner as to cover a portion of the pressure chamber, the piezoelectric element has two opposite ends respectively extending beyond an edge of the pressure chamber and covering the pressure chamber forming layer. The piezoelectric device of the present invention can efficiently actuate the vibration plate, eliminate undesired displacements of the vibration plate in the opposite direction at the edge of the chamber, and provide higher displacement sensitivity to driving voltage.

Owner:SAE MAGNETICS (HK) LTD

Gas/ solid two-phase composite gyration basic method and device

InactiveCN101338790BOvercome the shortcomings of not being able to take care of these features at the same timeImprove carrying capacityBearingsGas lubricationGas phase

The present invention relates to a gas phase / solid phase composite gyration benchmarking method and a device, which belong to the technical field of precision gyration benchmarking. The method compositely uses the gas lubricating and error averaging technology and the solid supporting and damping technology, the method applies axial solid support in the axial anti-thrust gaseous film of a gas-floated shafting to form a composite supporting mode with the primary solid support and the subsidiary gas support or the primary gas support and the subsidiary solid support or the gas support and the solid support which are the equivalent in order to notably enhance the axial rigidity and bearing capacity of the gas-floated shafting. Applying radial solid support in the radial gaseous film of the gas-floated shafting, the method utilizes the slight elastic deformation of elastic elements to dissipate the medium / high-frequency micro-vibration energy of a mainshaft and the stored deformation energy and static friction characteristic of the elastic elements to enhance positioning damp in order to increase positioning precision. In the device, the solid elastic elements are respectively assembled in the axial anti-thrust gaseous film and the radial gaseous film. The method can establish a gyration benchmark which also takes high precision, high rigidity, high support, low vibration and highdisplacement sensitivity into consideration.

Owner:HARBIN INST OF TECH

Single (double) wing type gas/ liquid two-phase composite gyration basic method and device

ActiveCN100554710CHigh rotation accuracyHigh displacement sensitivityBearingsViscous liquidGas lubrication

The single (double) wing type gas / liquid two-phase composite rotary reference method and device belong to the field of precision rotary reference technology; the method uses gas lubrication rotary technology and liquid damping technology in combination, and takes advantage of the significant error averaging effect of gas lubrication technology to ensure The rotation accuracy of the rotary reference; at the same time, the viscous liquid has a significant damping or energy absorption effect on the vibration component of the rotary body to suppress the generation of medium and high-frequency micro-vibrations of the rotary body, and improve the motion stability, repeatability and positioning of the rotary reference Reliability; the device is equipped with a liquid damping system with an appropriate viscosity coefficient at the upper end, or lower end, or upper and lower ends of the air-floating main shaft; Composite rotary reference for precision and positioning reliability.

Owner:哈尔滨超精密装备工程技术中心有限公司

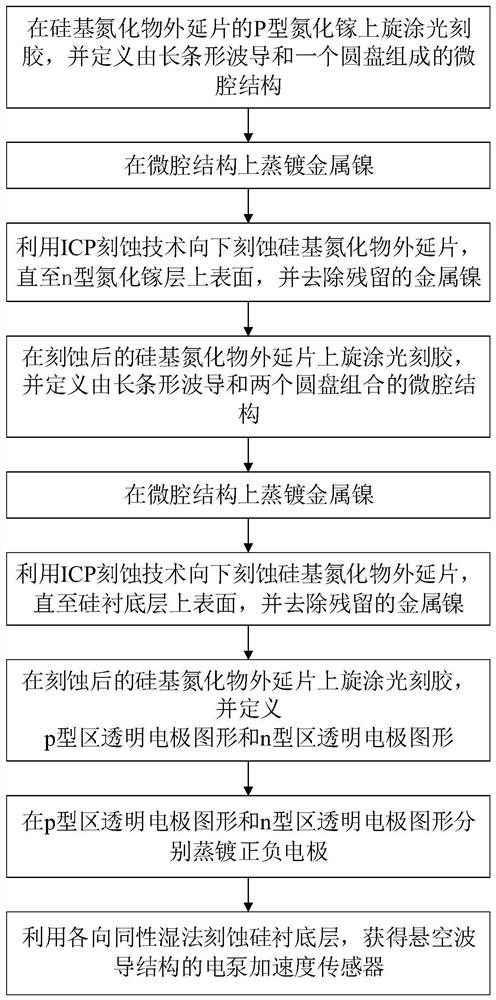

Electric pump acceleration sensor and preparation method thereof

PendingCN113624992AHigh-resolutionProne to deformationDecorative surface effectsAcceleration measurementGallium nitrideWaveguide

The invention discloses an electric pump acceleration sensor and a preparation method thereof, the acceleration sensor comprises a mass block and a suspended waveguide structure, and the mass block is arranged in the middle of the suspended waveguide structure; the suspended waveguide structure comprises a silicon substrate layer, a u-type gallium nitride layer, an n-type gallium nitride layer, a quantum well layer, a p-type gallium nitride layer, a p-type electrode and an n-type electrode which are sequentially arranged from bottom to top, the quantum well layer is arranged on one side of the upper surface of the n-type gallium nitride layer, and the silicon substrate layer supports the two ends below the u-type gallium nitride layer. According to the preparation method, the nitride microcavity with the suspended waveguide structure is prepared on a silicon substrate nitride epitaxial wafer by utilizing photoetching, ICP dry etching and silicon wet etching processes. According to the invention, the light source and the sensing device are focused on the gallium nitride suspended waveguide optical resonant cavity, and the prepared acceleration sensor can be subjected to high-density photoelectric integration and has higher resolution and sensitivity.

Owner:NANJING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com