Gas lubrication and friction damping composite high rigidity and high stability two-dimensional adjustment table

A technology with frictional damping and high stability, which is applied in the direction of workbench, manufacturing tools, etc., to achieve the effect of improving the positioning accuracy of adjustment, improving displacement sensitivity, and improving positioning stability and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

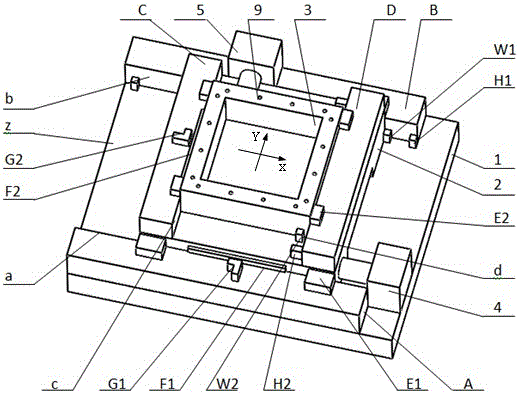

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

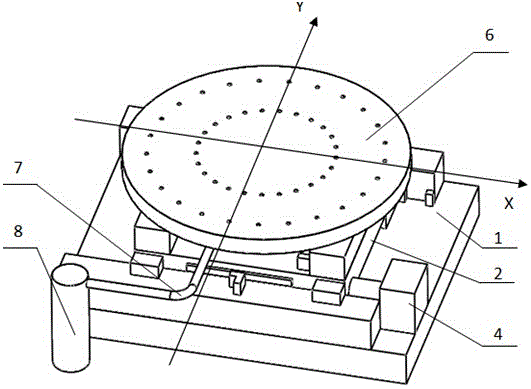

[0040] A gas lubrication and friction damping composite high-rigidity and high-stability two-dimensional adjustment workbench, including a base 1, an X-direction air-floating slide 2, a Y-direction air-floating slide 3, an X-direction drive system 4, a Y-direction drive system 5, Work surface 6, air duct 7 and external air supply system 8.

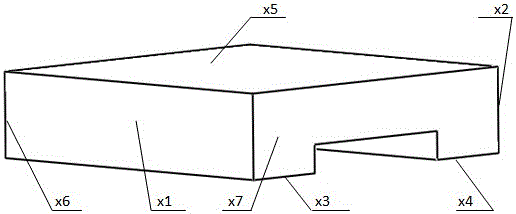

[0041] The X-direction air-floating slide 2 is equipped with an air-floating working surface x1, an air-floating working surface x2, an air-floating working surface x3, an air-floating working surface x4, an air-floating working surface x5, a non-air-floating working surface x6 and a non-air-floating working surface x6. The air flotation working surface x7, in which the air flotation working surface x1 and the air flotation working surface x2 are parallel to each other, the air flotation working surface x5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com