Integrated alignment method and device for aero-engine assembly and measurement based on dense bead rolling bearing

An aero-engine, assembly measurement technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to guarantee the high precision and high resolution of the adjustment device, insufficient rigidity, large space, etc., to avoid motion interference, The effect of reducing the difficulty and cost of manufacturing and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

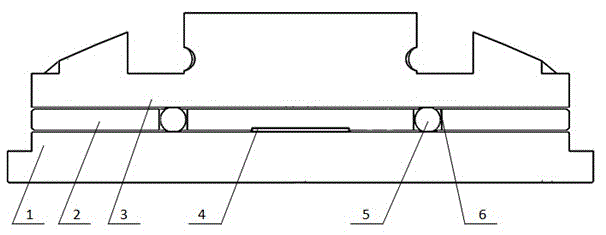

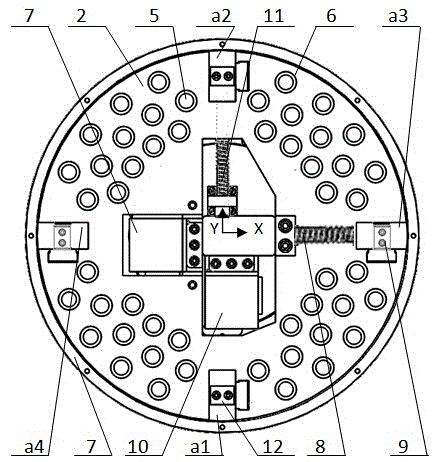

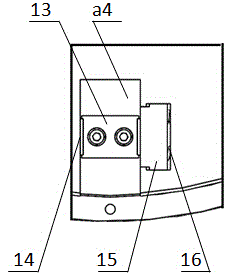

[0032] An integrated centering device for assembly and measurement of aero-engines based on dense bead rolling bearings, the device includes a circular chassis 1, an interlayer 2, a motion table 3, an X-direction driving device 7, an X-direction restoring device 8, and an X-direction guiding system 9 , Y-direction driving device 10, Y-direction return device 11 and Y-direction guide system 12; the interlayer 2 is fixedly connected with a wear-reducing block 4, and the wear-reducing block 4 is in contact with the circular chassis 1; in the interlayer A through hole 6 is arranged on the 2, and a spherical rolling body 5 is embedded in the through hole 6, and the sports table 3 is placed on the interlayer 2 and contacts and cooperates with the spherical rolling body 5.

[0033] The Y-direction drive device 10 and the Y-direction return device 11 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com